Self-adaption compression ratio variable engine

An engine, self-adaptive technology, applied in engine components, engine control, combustion engine, etc., can solve problems such as low efficiency, small compression ratio, high compression ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

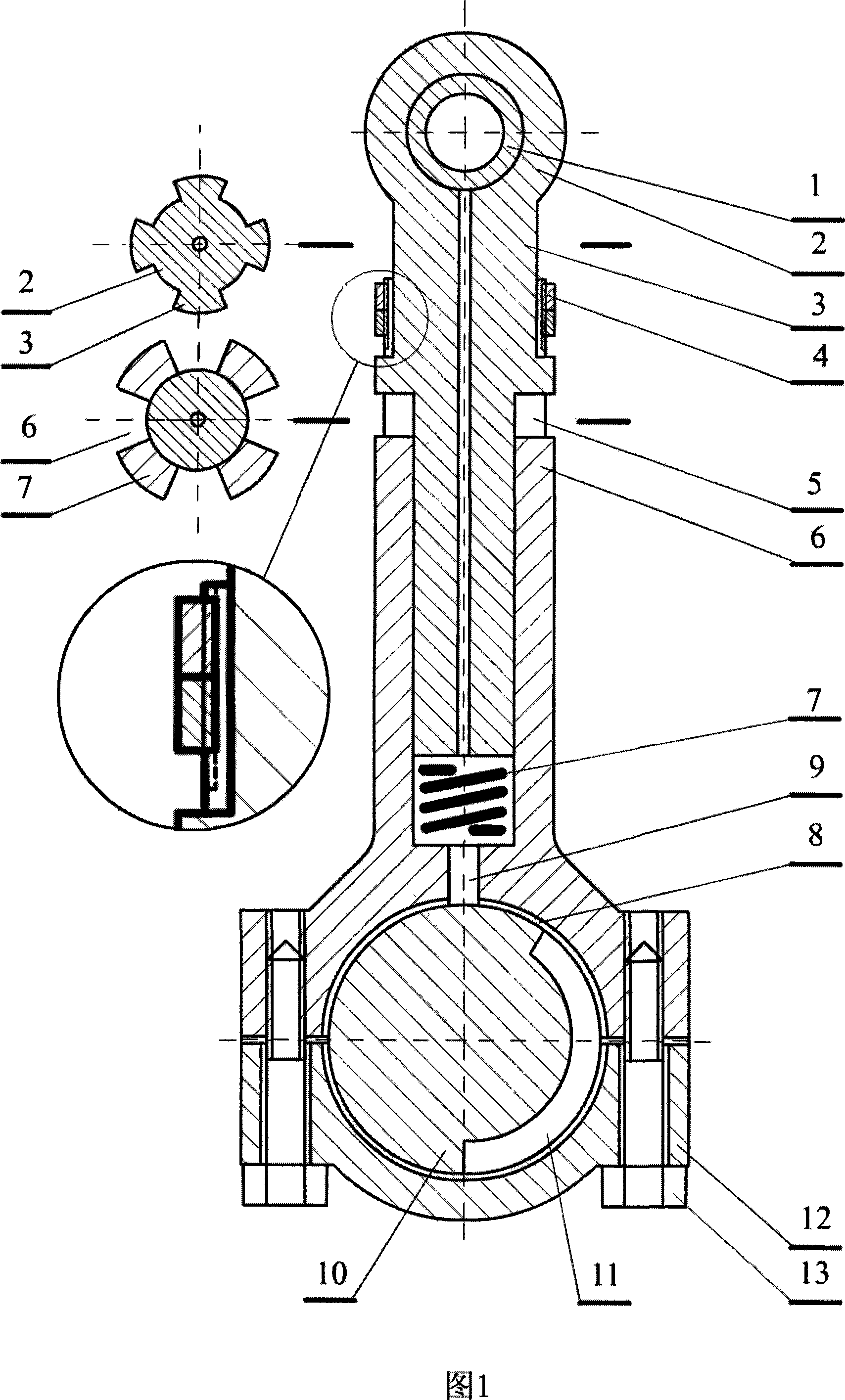

[0045] 1. Draw a picture according to Figure 1 and process the parts of the plunger connecting rod.

[0046] 2. Assemble the connecting rod according to Figure 1, put in the spring 7 first, insert the plunger 2, and then install the circlip or nut 4.

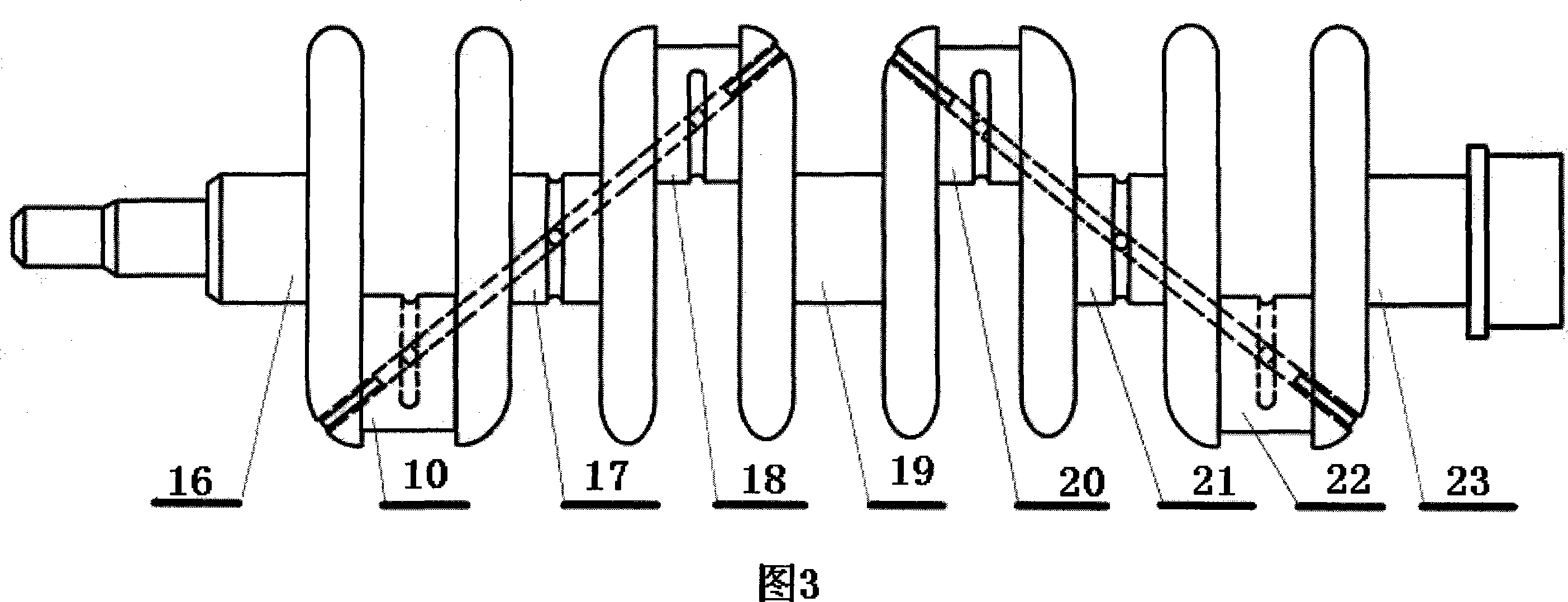

[0047] 3, the crankshaft increases the oil passage, as shown in Figure 3 and 4, the oil passage 25 is obtained by drilling, the two bearing neck annular oil grooves 27 of the lathe machining crankshaft, the four connecting rod neck oil supply grooves 11 of the milling machine processing crankshaft, and drilling Obtain the communication hole 26 from the oil passage 25 to the oil groove 11, drill a hole to obtain the communication hole 28 from the oil passage 25 to the oil groove 27, clean the oil passage and seal the process hole 24.

[0048] 4. Drill the upper half of the sliding bearing.

[0049] 5. Process the cylinder block oil circuit according to Figure 5. Drill the horizontal main oil passage, vertical branch oil passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com