Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1039results about How to "Large width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

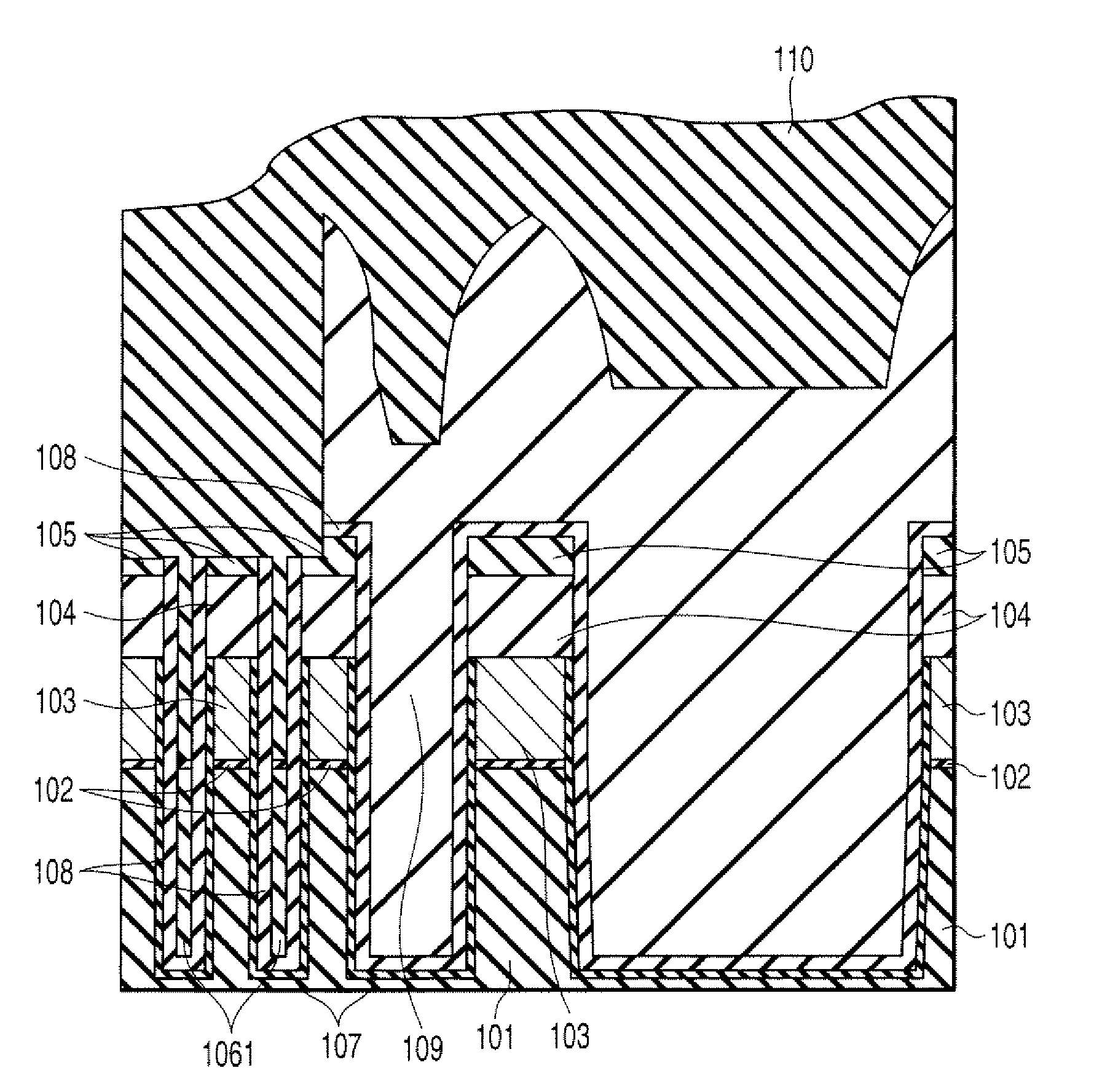

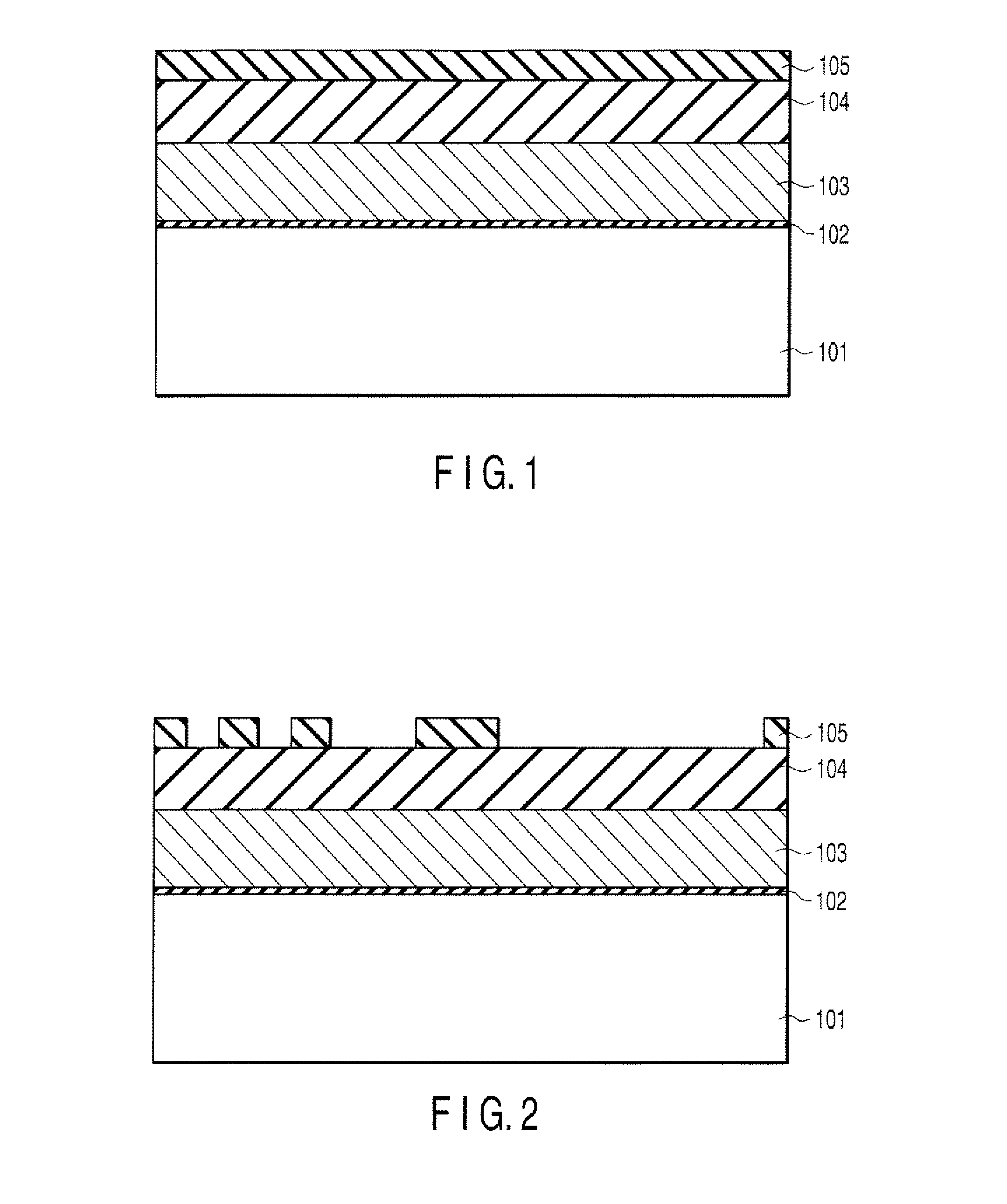

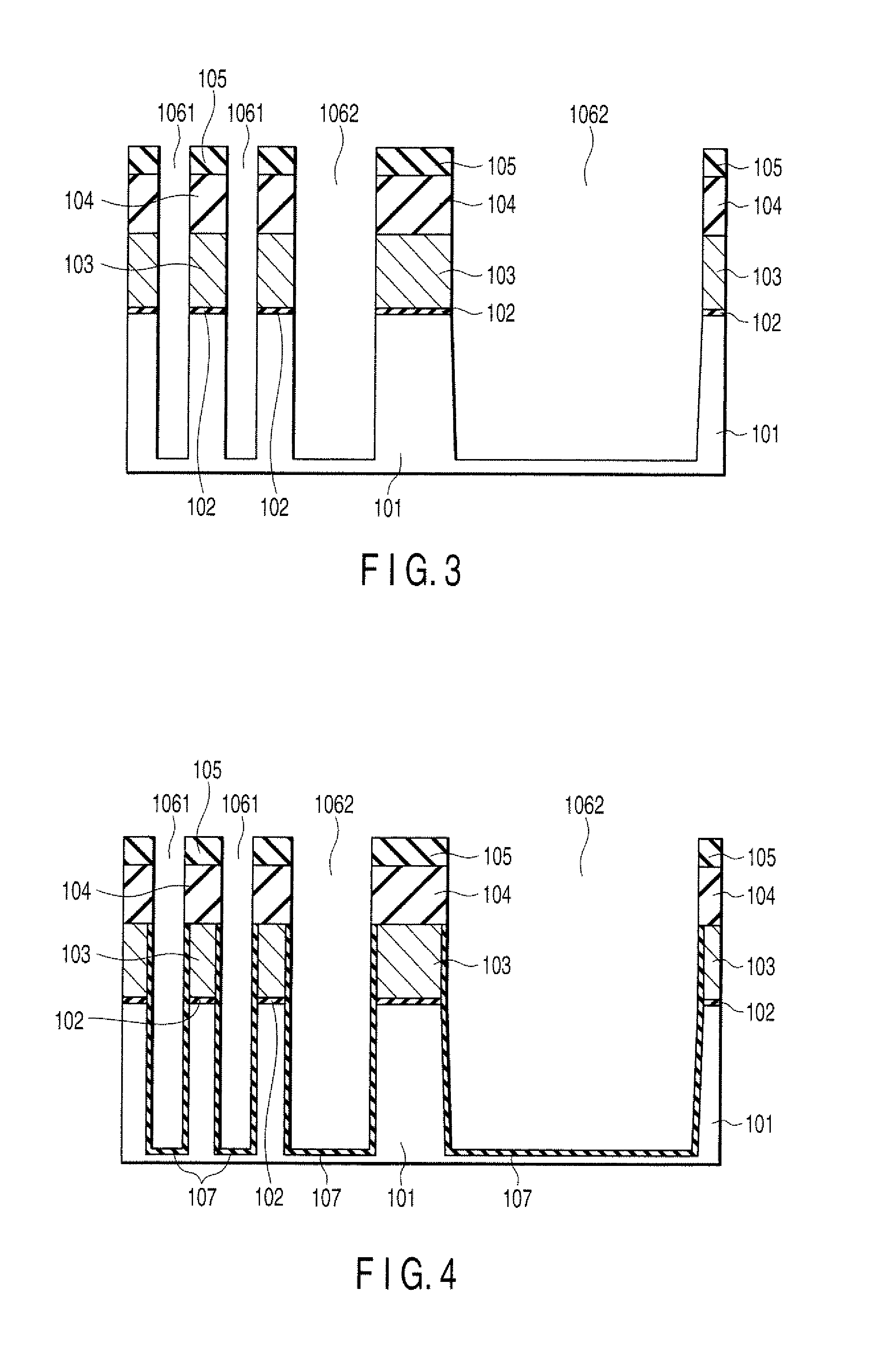

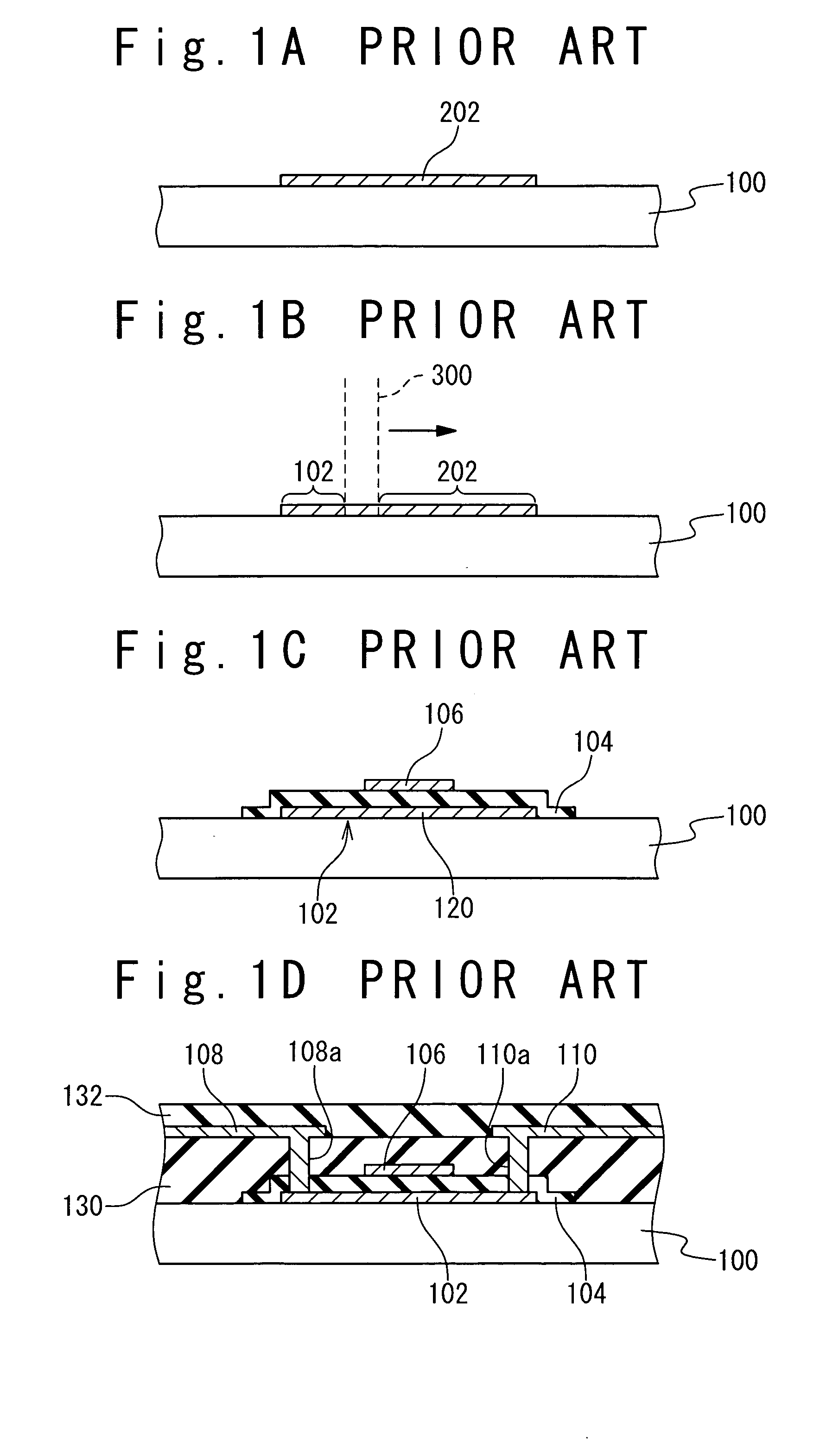

Manufacturing method of semiconductor device using sti technique

InactiveUS20080182381A1Large widthSemiconductor/solid-state device manufacturingHigh densityAnisotropic etching

A first trench and a second trench having width wider than the first trench are simultaneously formed in a main surface area of a semiconductor substrate. The width of an opening portion of the first trench is made narrower by forming a first insulating film on the main surface of the semiconductor substrate and in the first and second trenches. A second insulating film is formed on the first insulating film by use of a high-density plasma-CVD method to form a void in the first trench while covering the opening portion of the first trench, and the second trench is filled with the second insulating film. Then, part of the second insulating film which covers the opening portion is removed by anisotropic etching and the void is filled with an insulating film having fluidity at the film formation time.

Owner:KK TOSHIBA

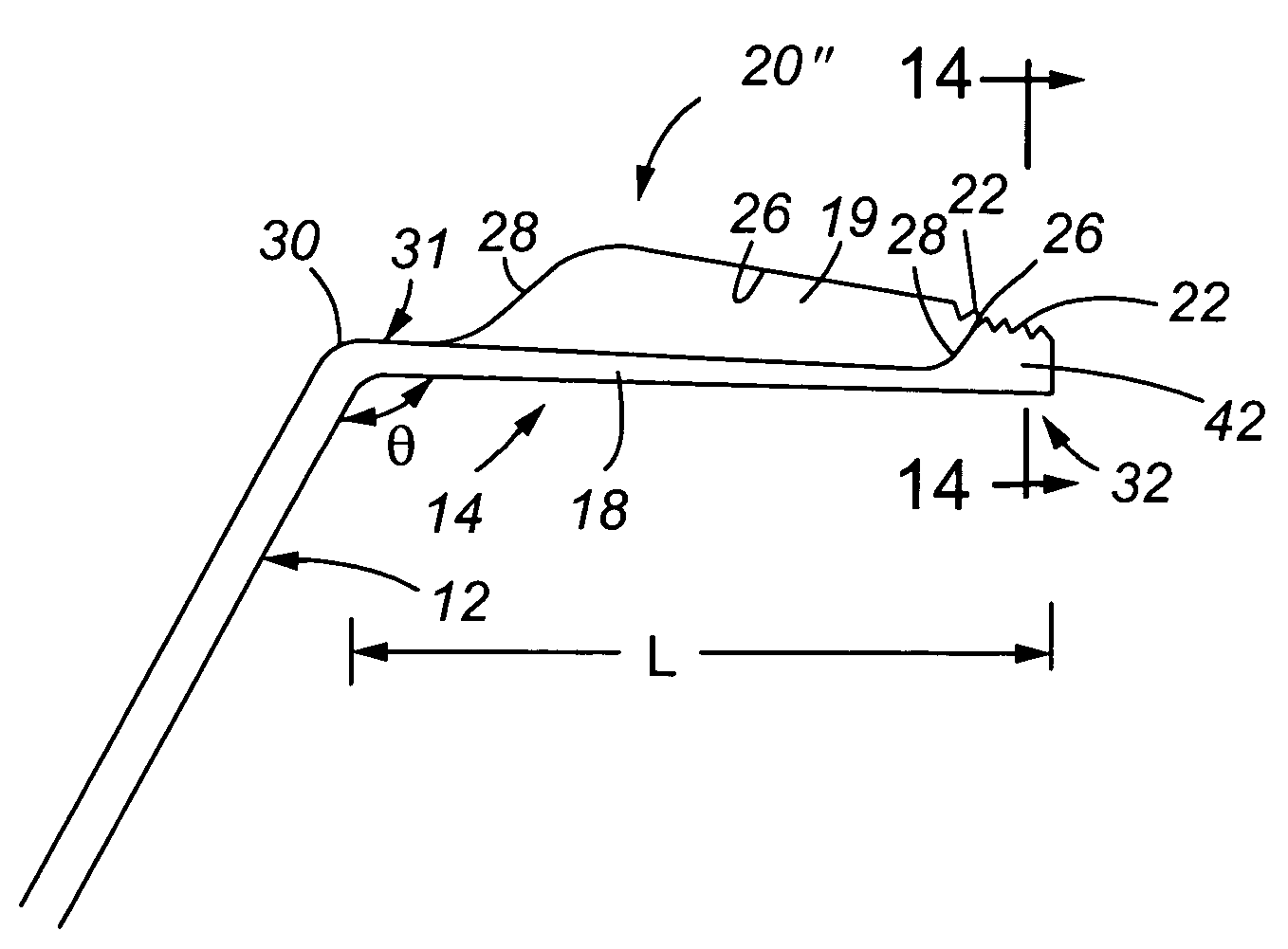

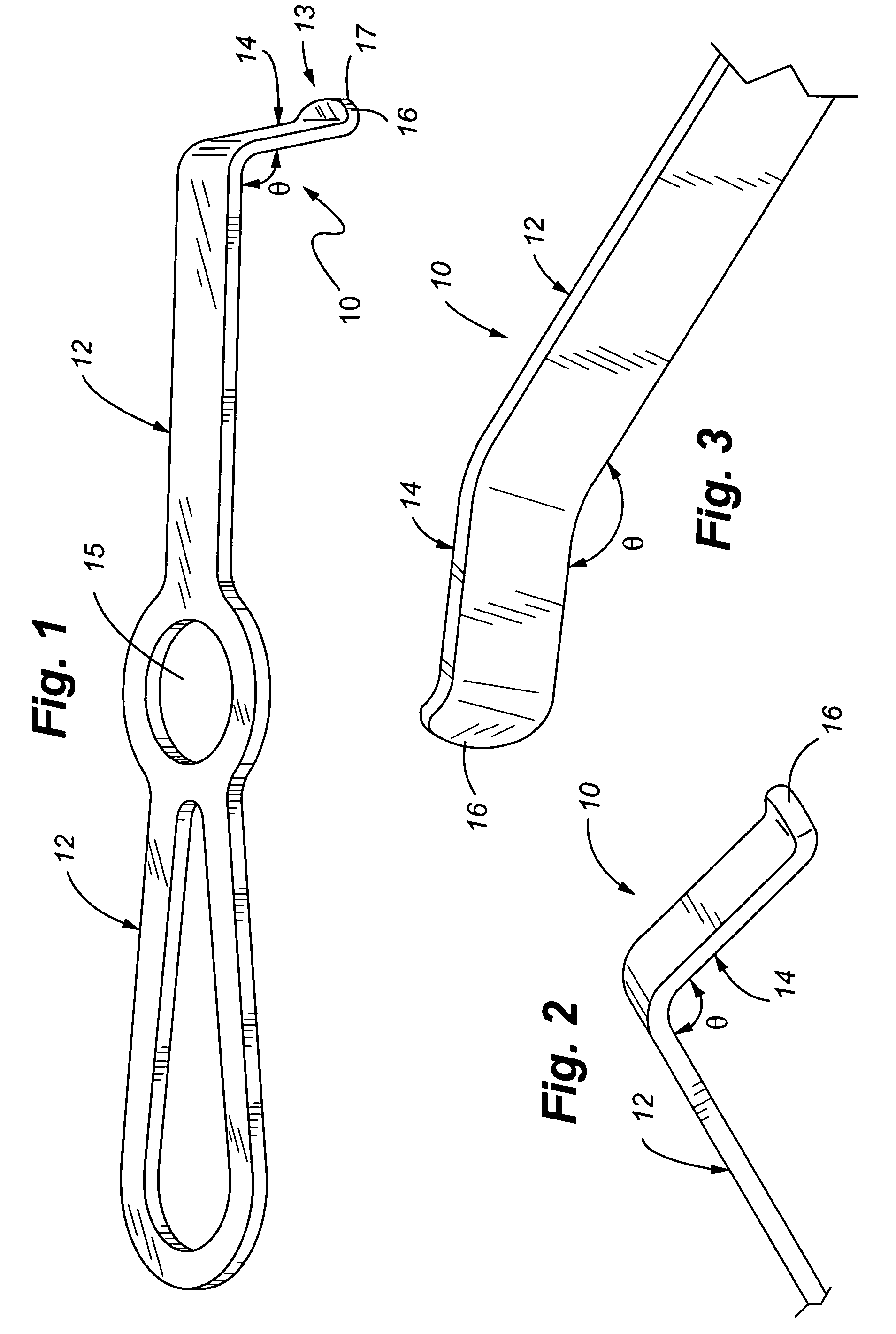

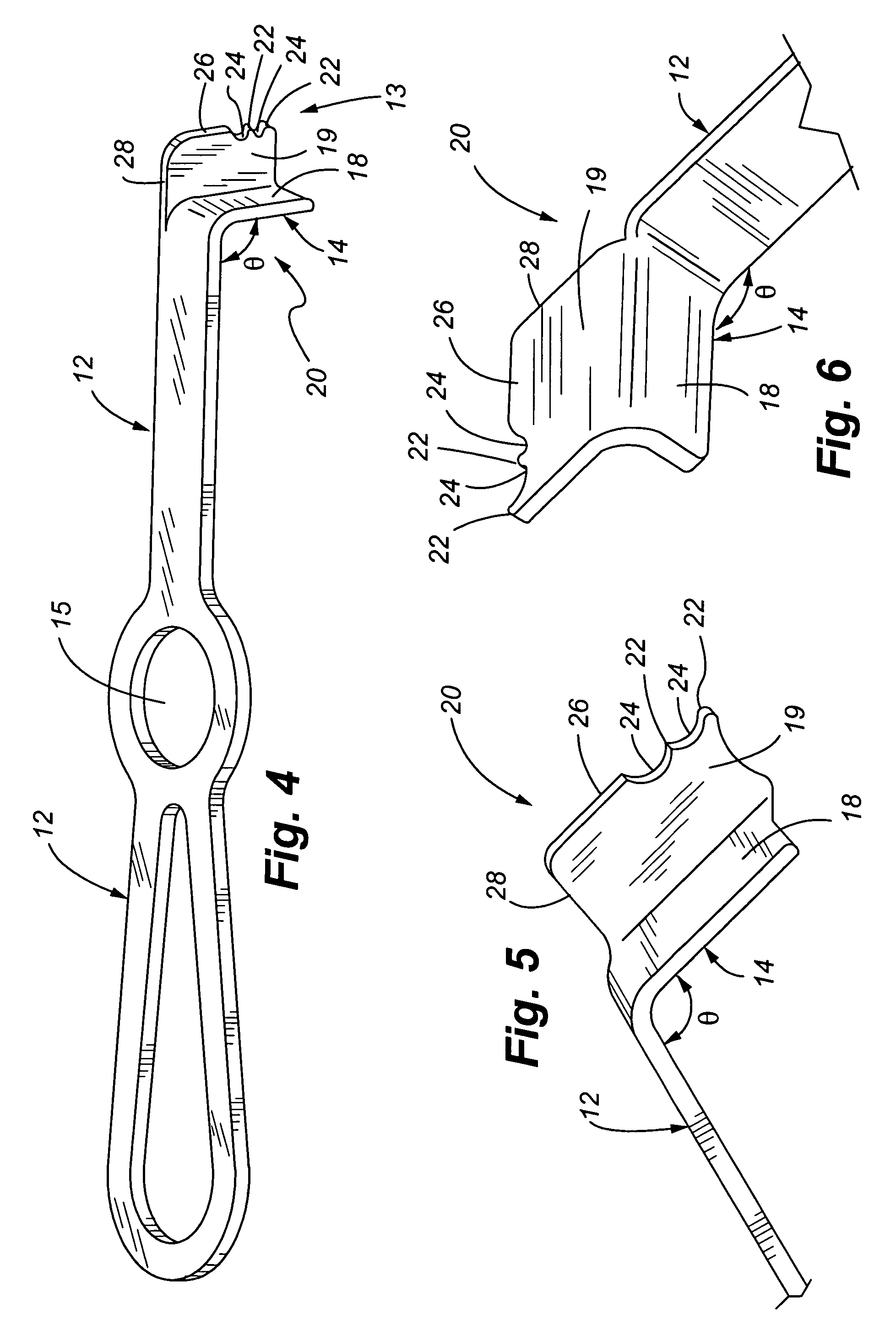

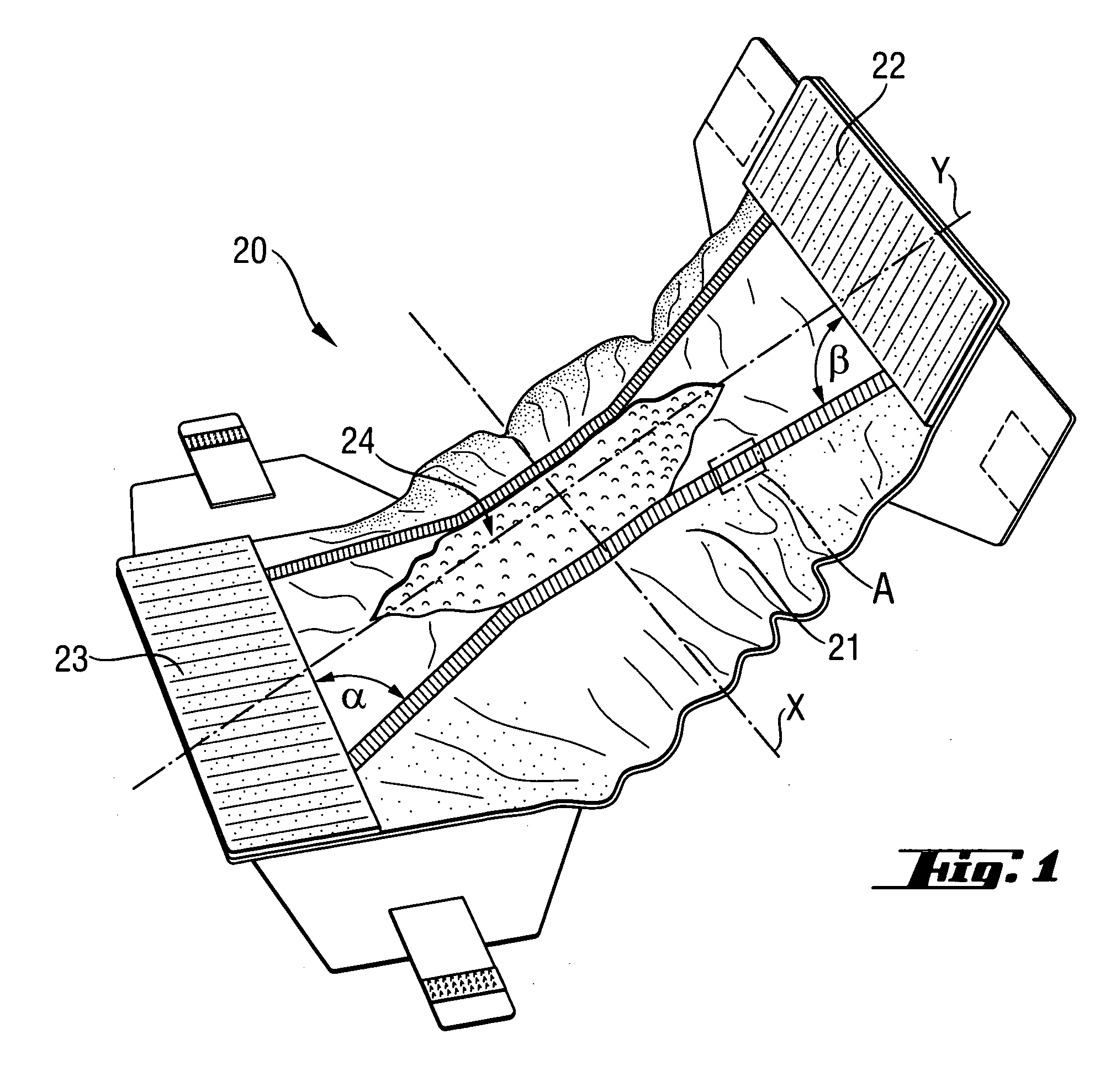

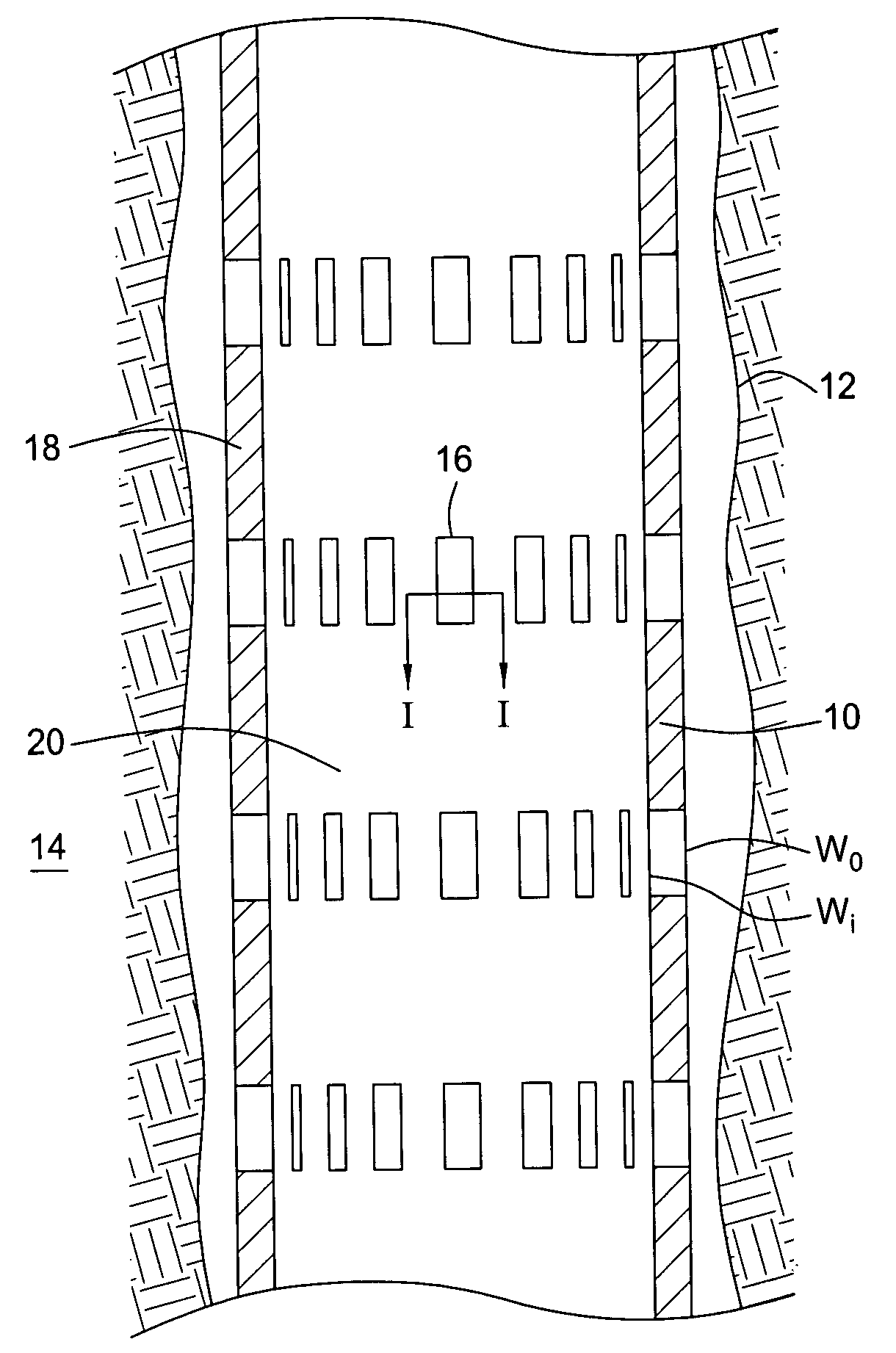

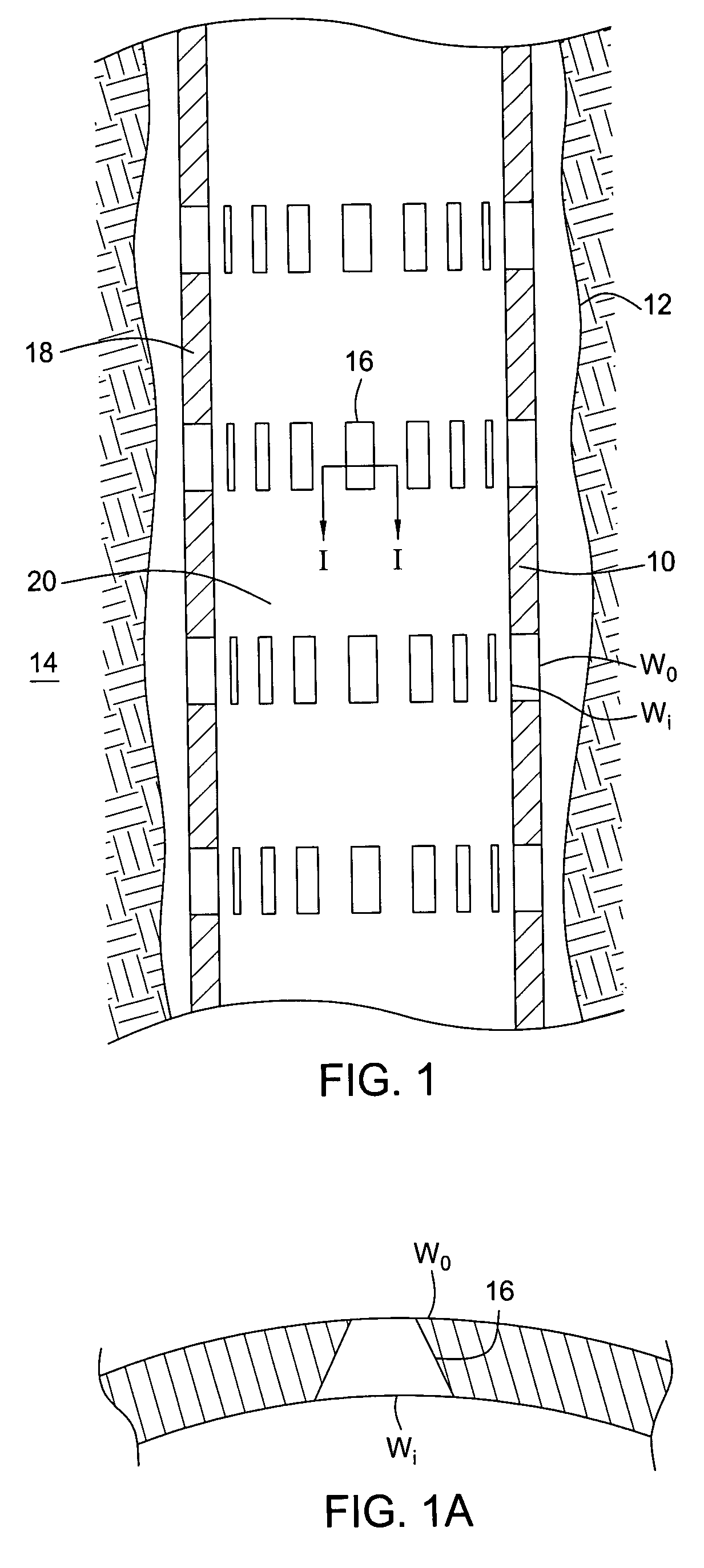

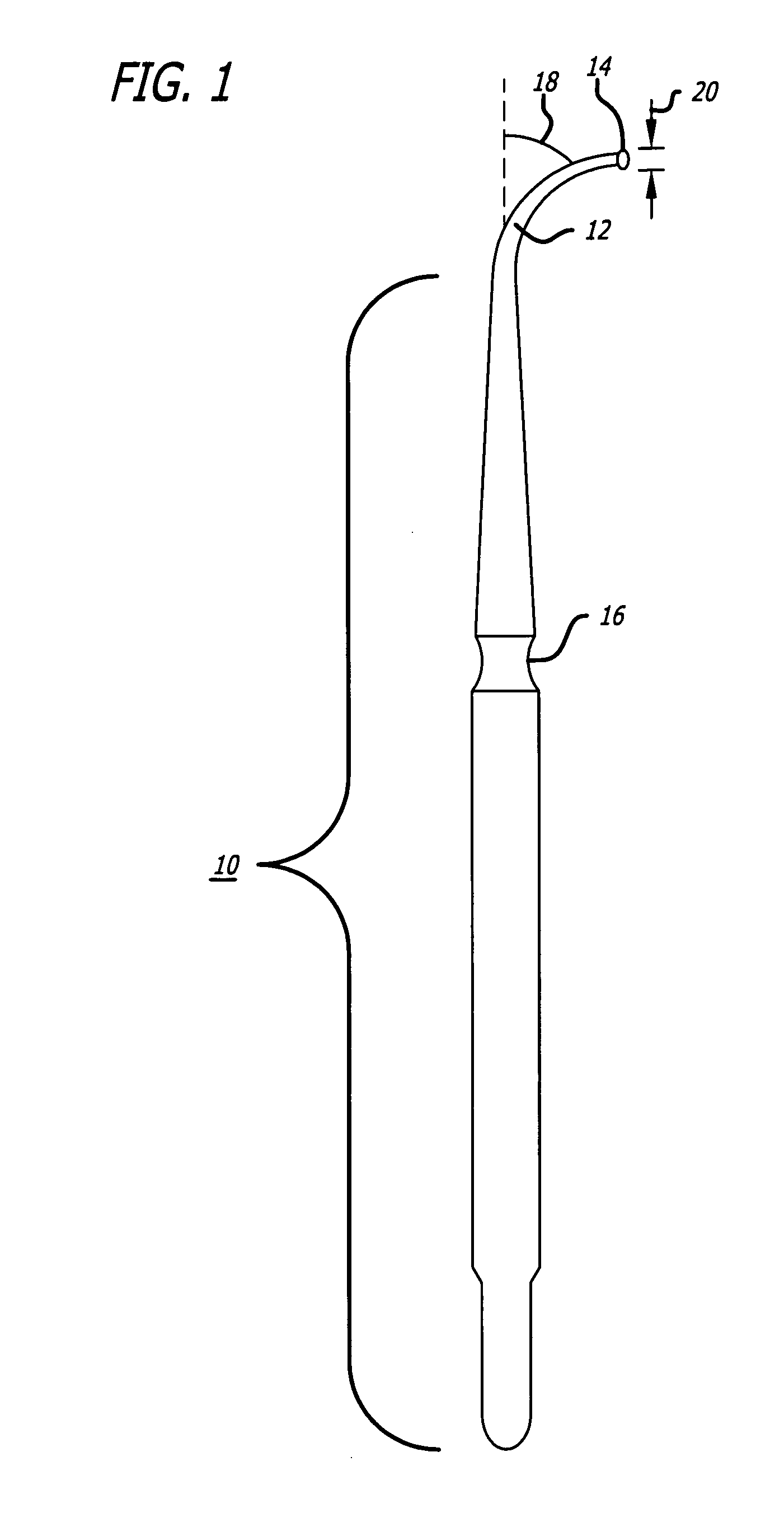

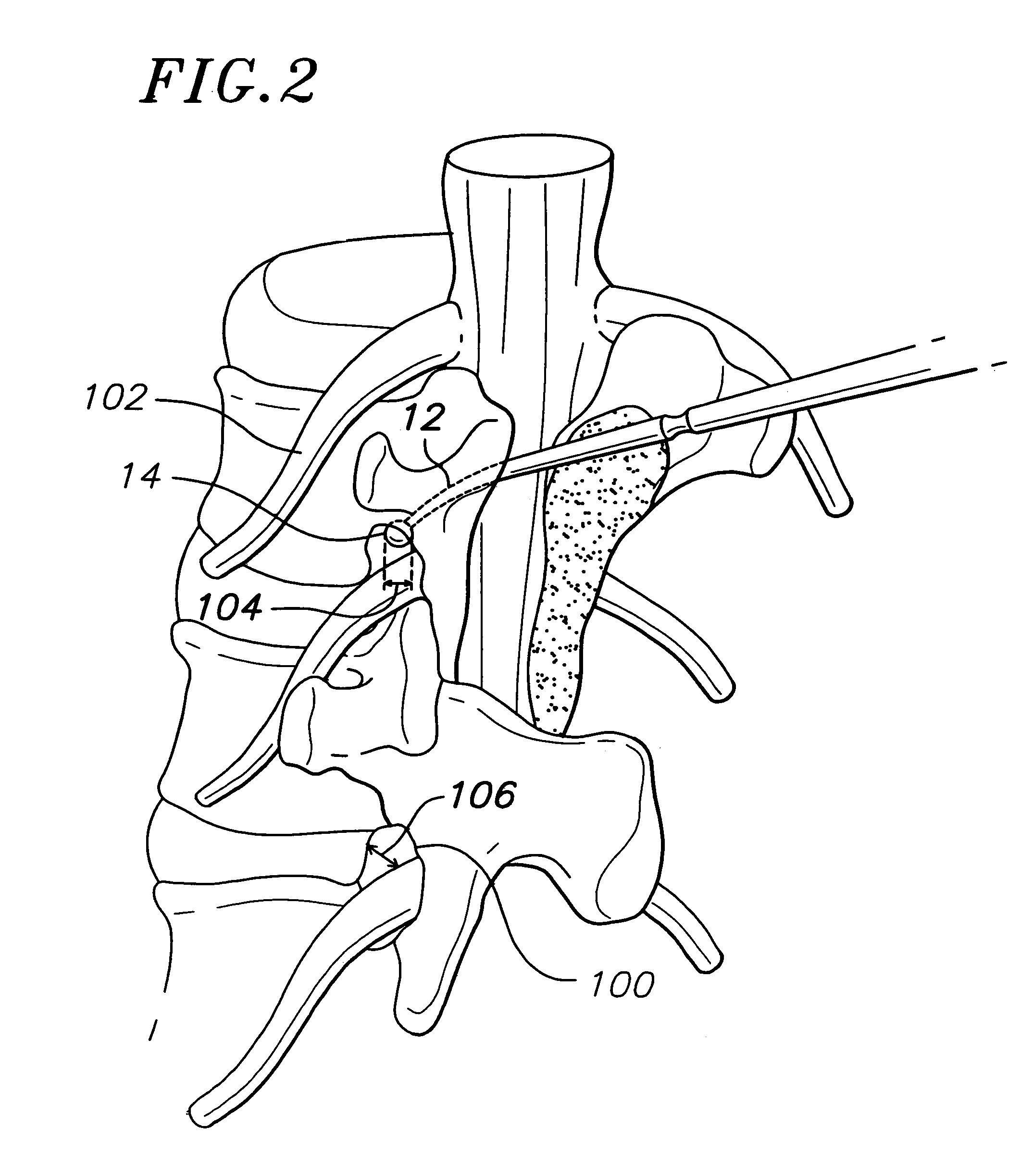

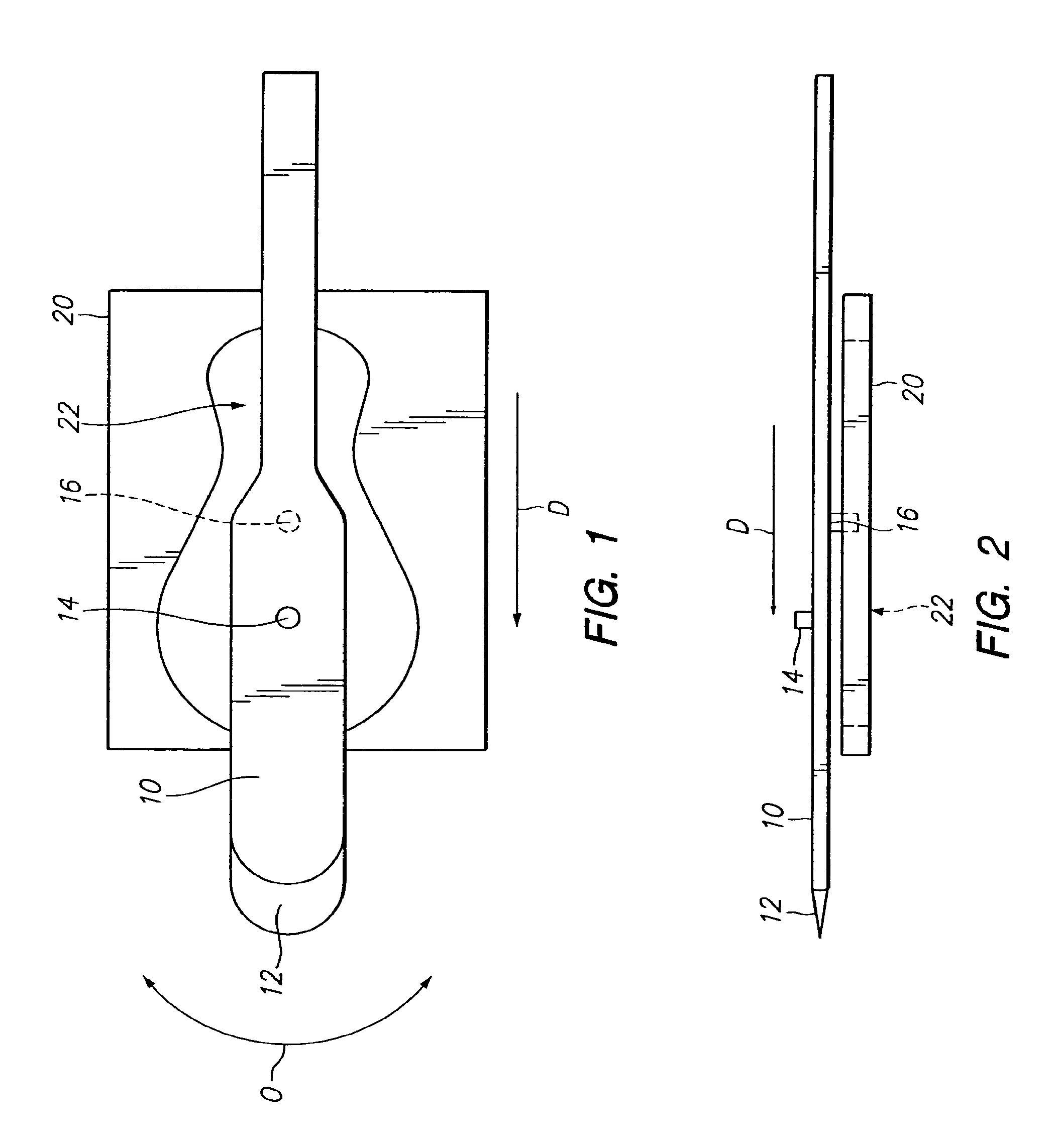

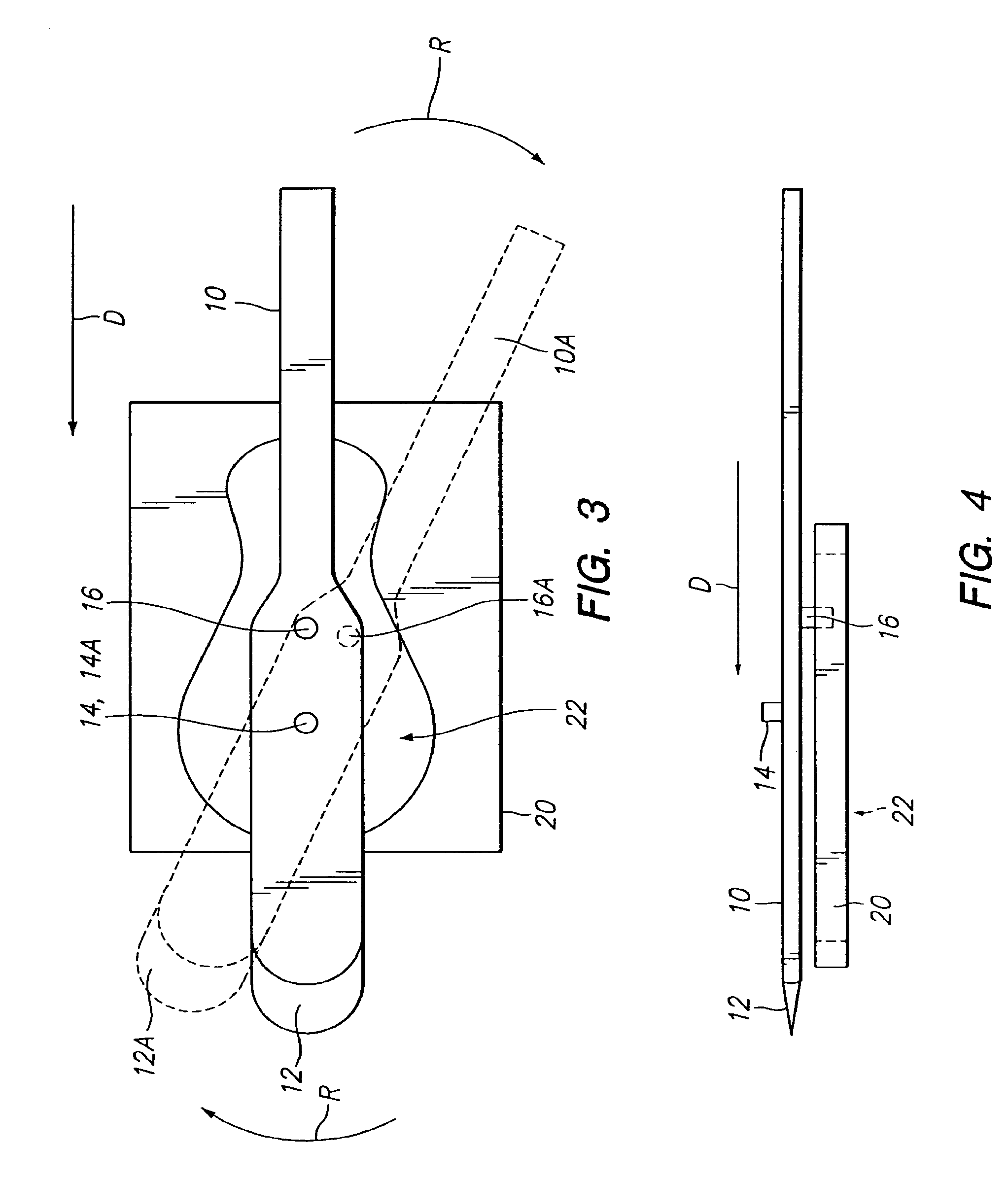

Method and device for microsurgical intermuscular spinal surgery

InactiveUS7166073B2Minimization requirementsMinimizing retractionIncision instrumentsSpinal columnArticular processes

A retractor is provided for performing spinal surgery with a minimal approach, and which spares the lumbar muscles from surgical disruption. A preferred embodiment includes a blade having first and second faces wherein the faces are positioned substantially transverse to one another, and wherein at least one of the faces has a tapered width. Alternatively, both the first and second faces are tapered. Additionally, a third face positioned transverse to the first face and substantially parallel to the third face may be incorporated into the retractor. The second face also preferably includes at least one tooth, and more preferably, a plurality of teeth at its distal end for laterally engaging an articular process of a vertebra of the spine.

Owner:RITLAND STEPHEN

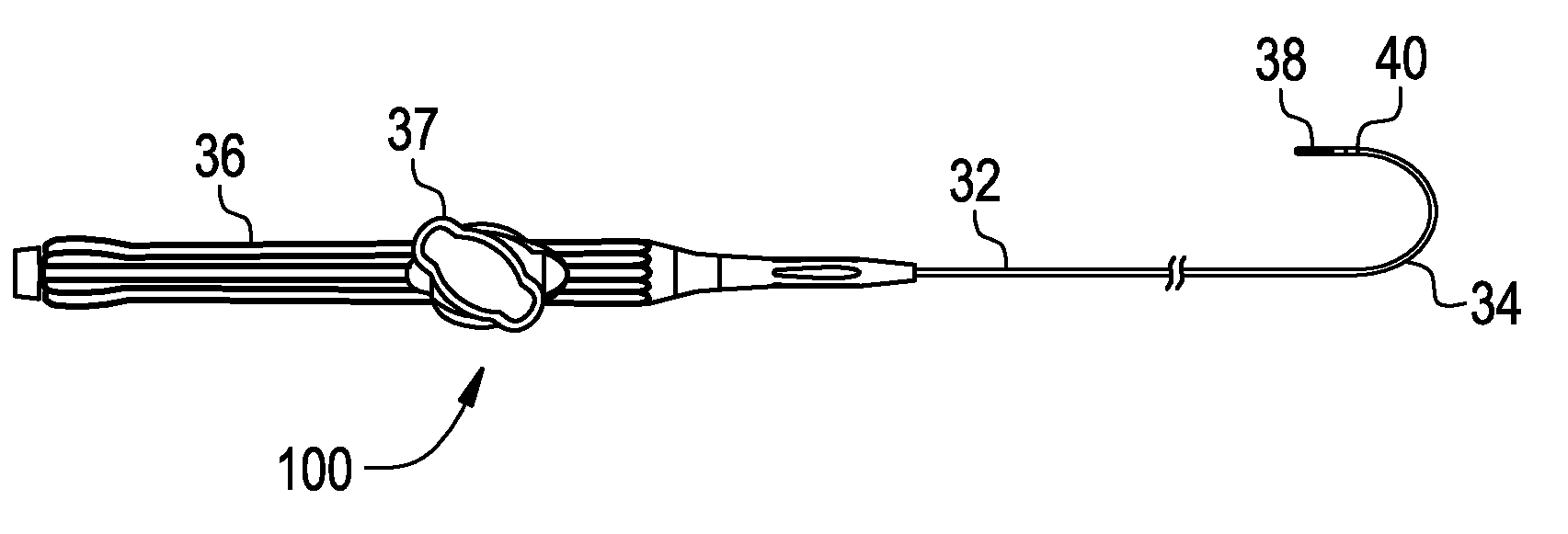

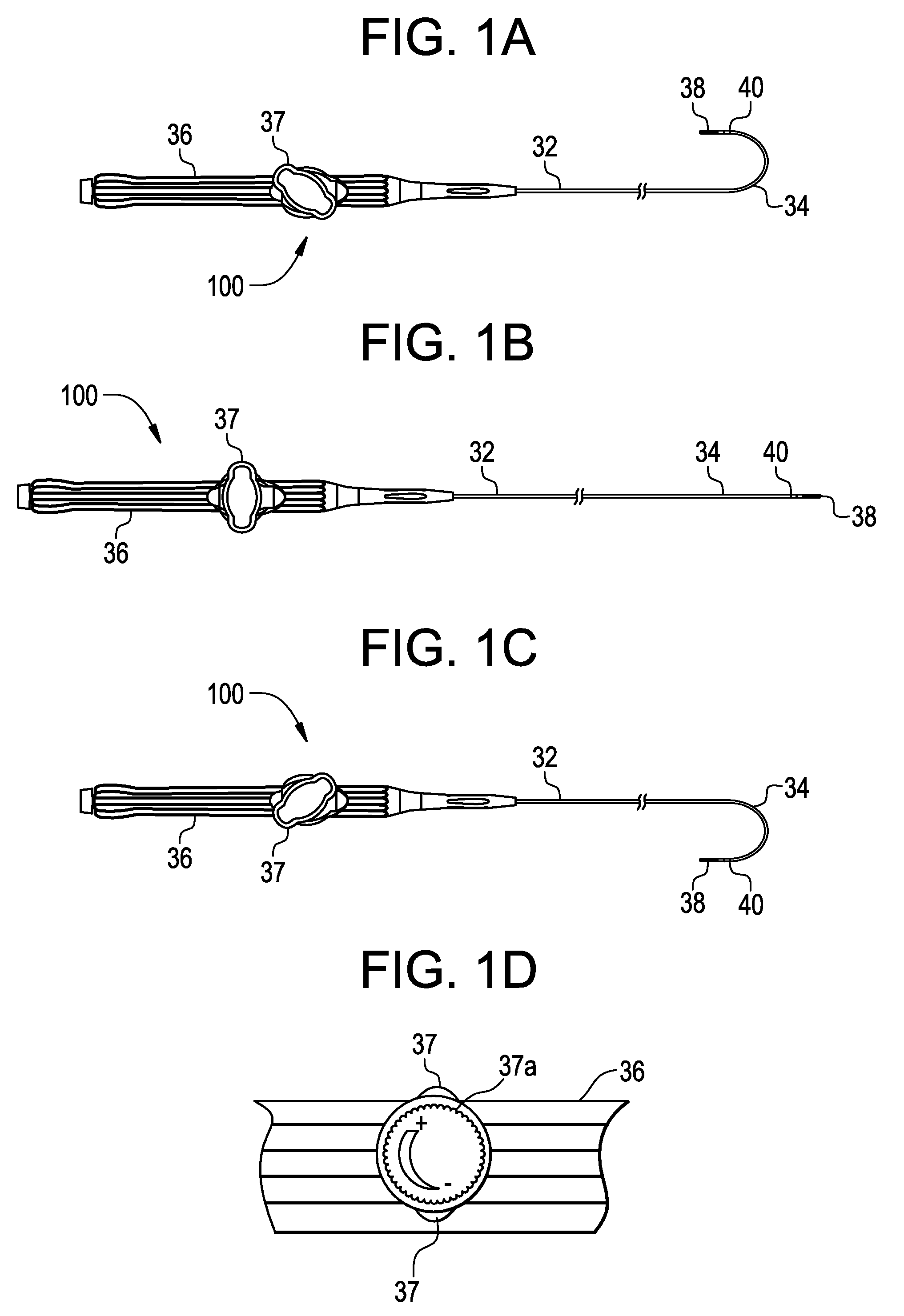

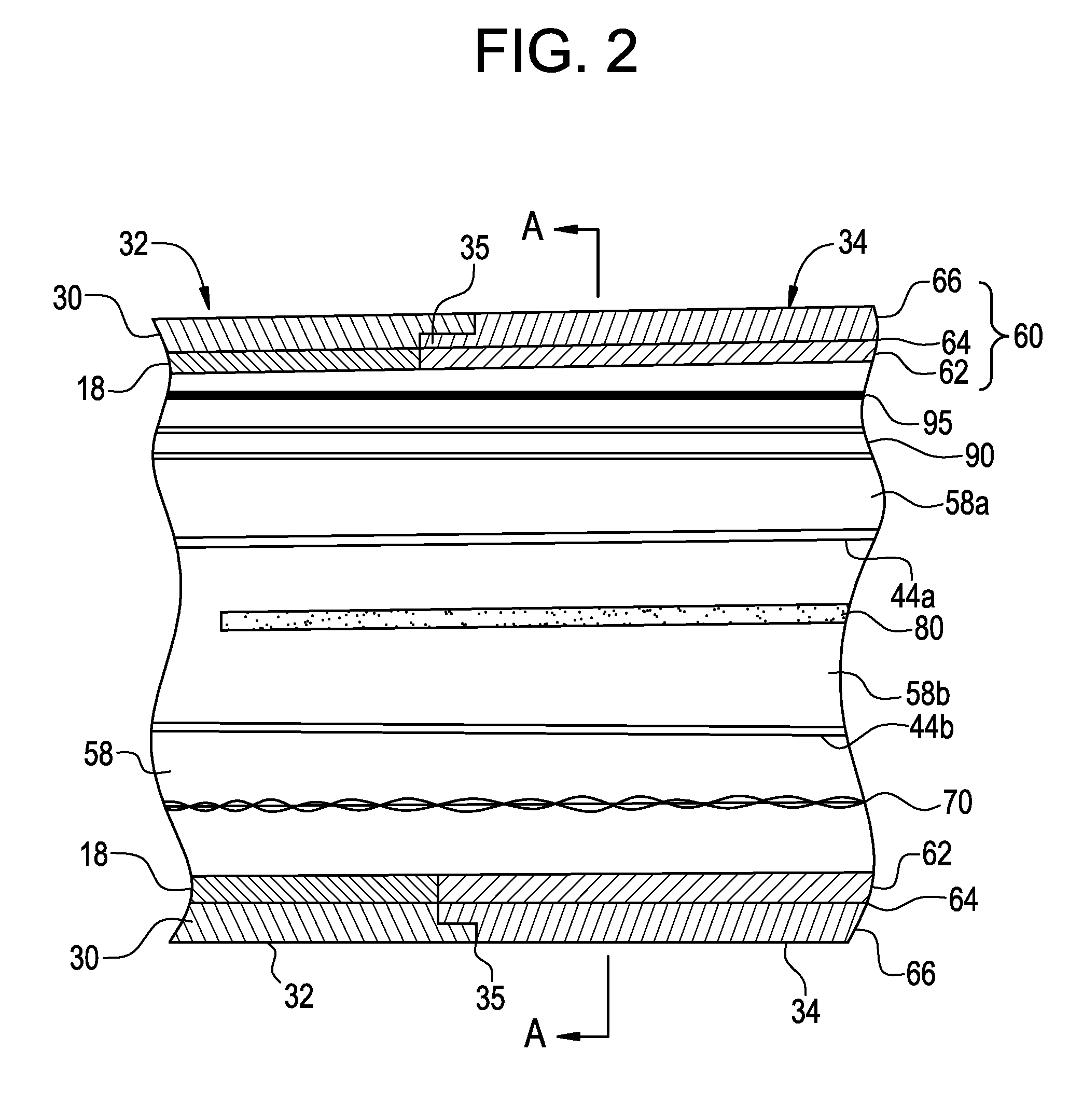

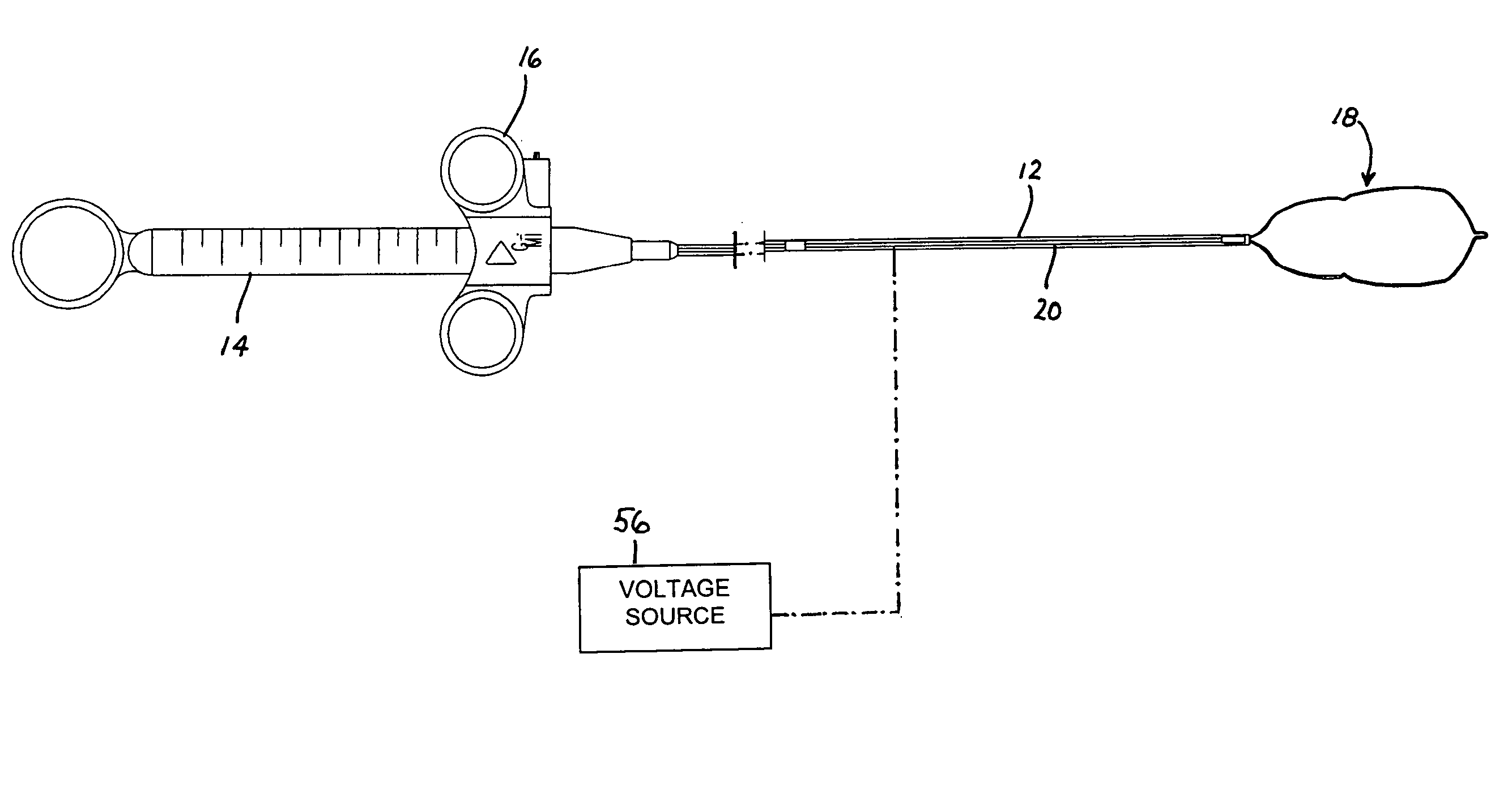

Force-sensing catheter with bonded center strut

ActiveUS20100063478A1Quick assemblyMaximize cross-sectional areaElectrocardiographyStrain gaugeMetallic foilEngineering

A force-sensing catheter for diagnosing or treating the vessels found within a body or body space includes a center strut that is bonded, preferably thermally, along its longitudinal axis with the thermoplastic tubular member within which it is housed. The tubular member preferably has three layers: an inner layer, a braided layer and an outer layer. One or more semiconductor or metallic foil strain gages are affixed to the center strut in order to provide a measure of the bending and torsional forces on the distal tip of the catheter. Temperature compensation is achieved by having a temperature sensor near the strain gages and calibrating the catheter over a range of temperatures.

Owner:BIOSENSE WEBSTER INC

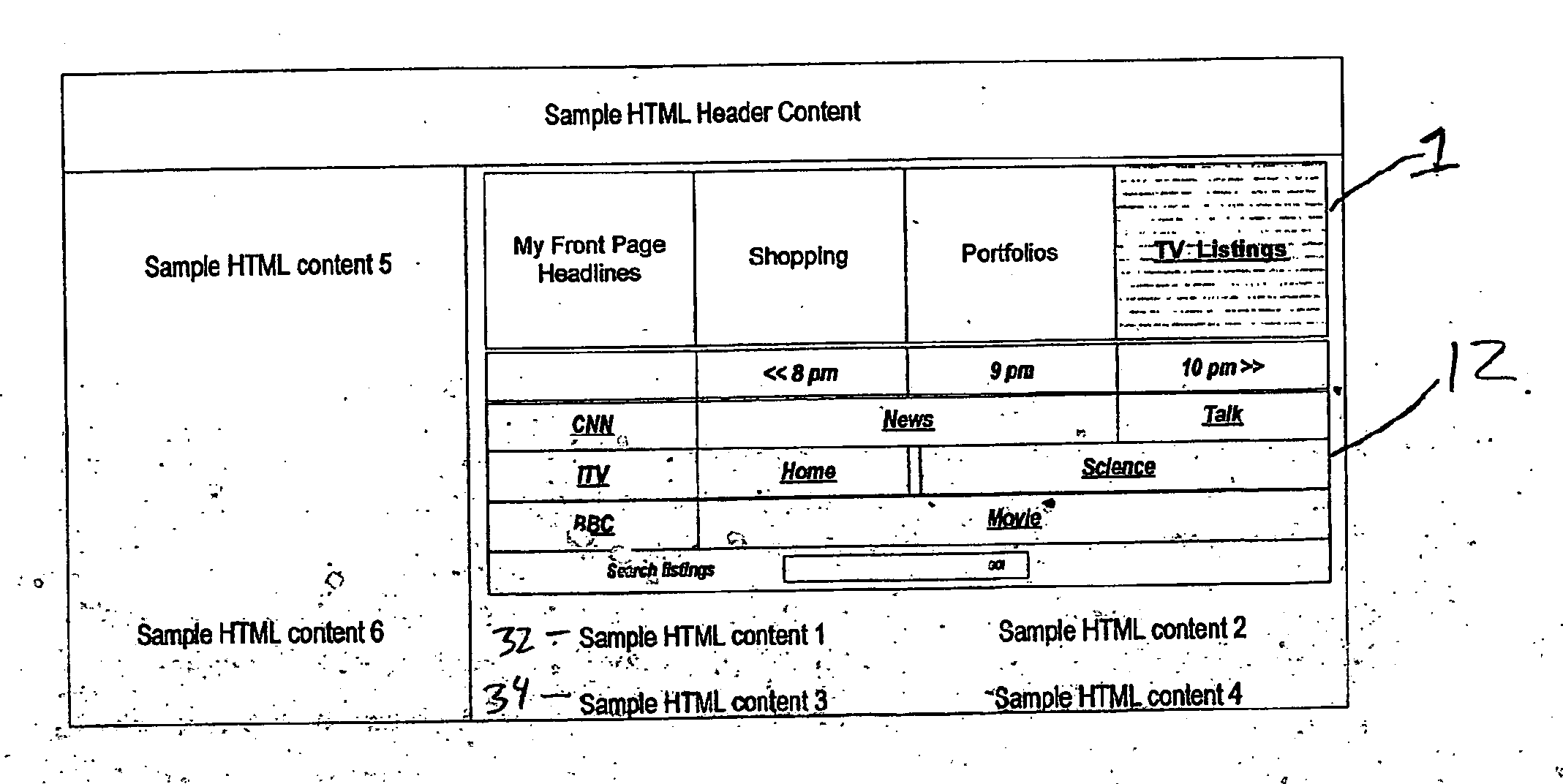

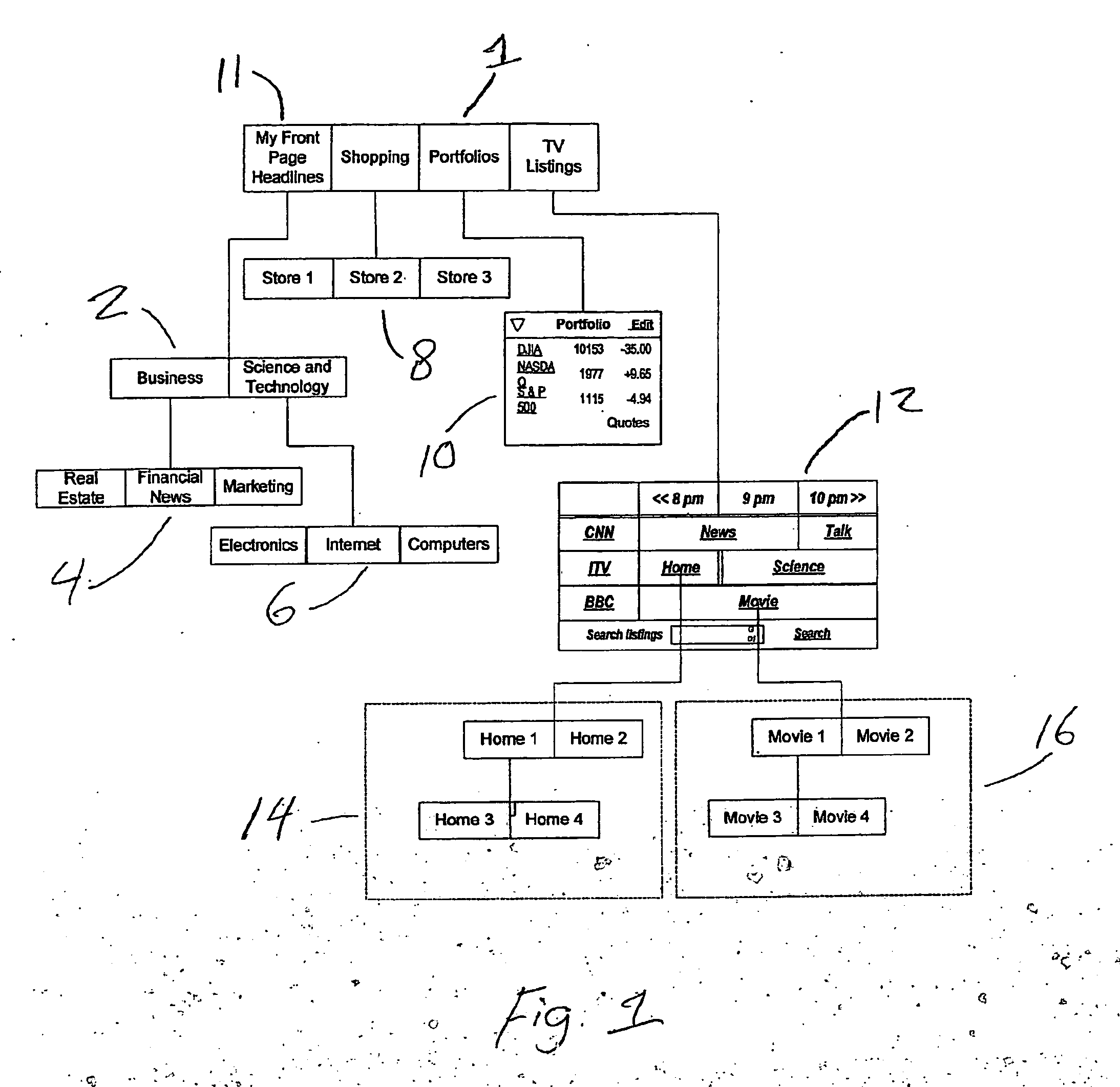

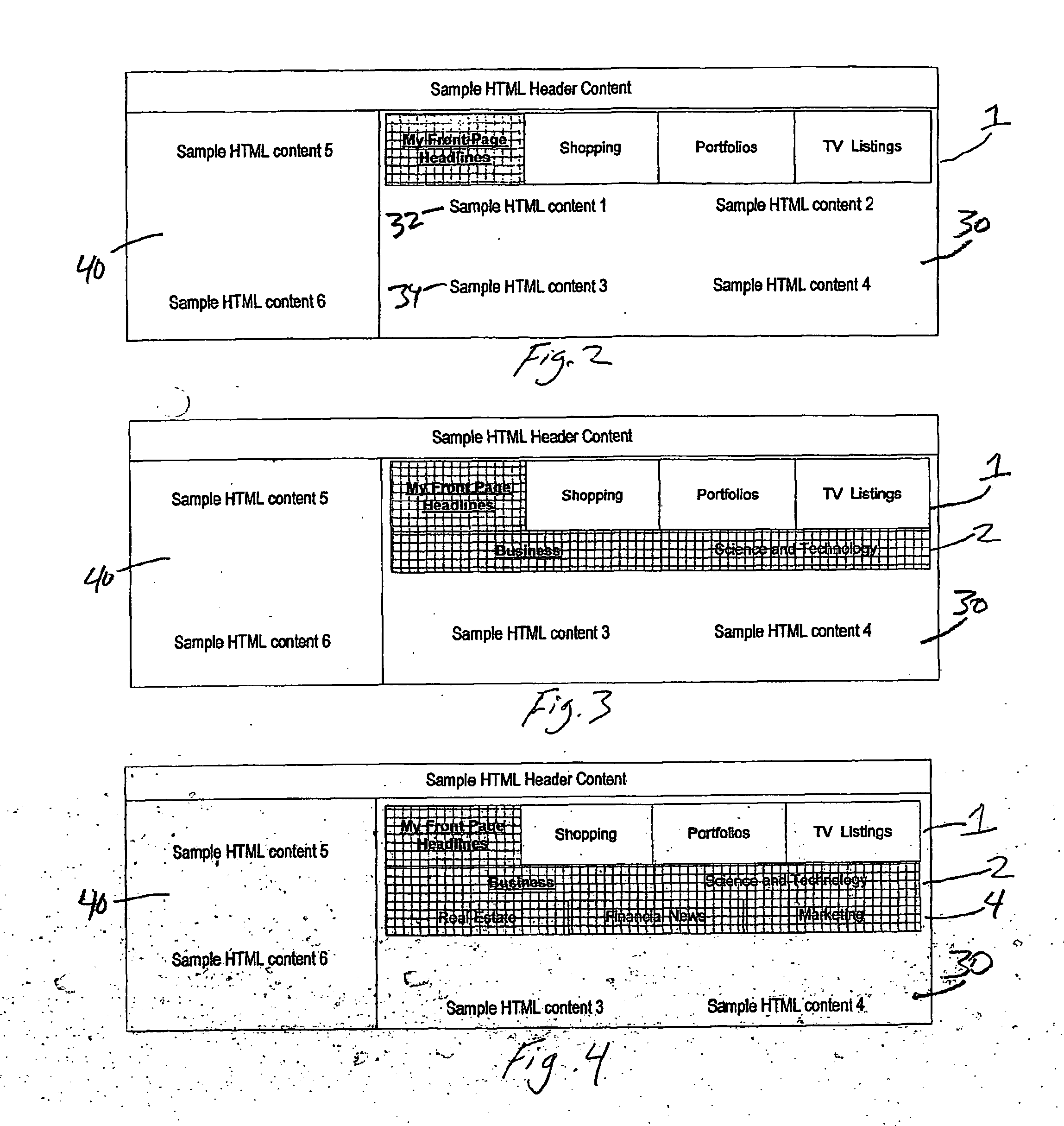

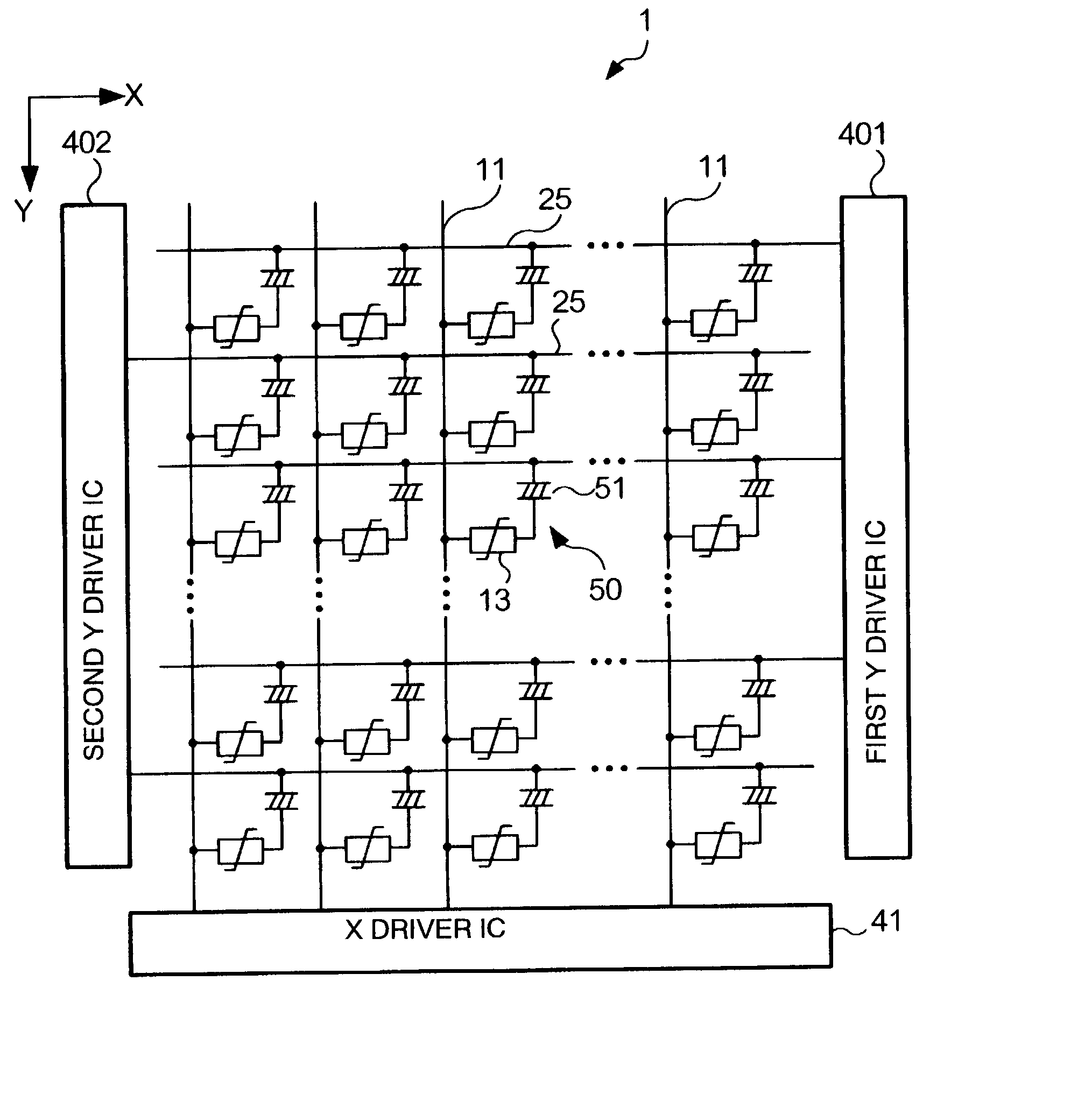

Flexible, dynamic menu-based web-page architecture

InactiveUS20060242557A1Easy to installSmoothly and automatically adjustsDigital data information retrievalDigital computer detailsData elementDatabase

A method of displaying and navigating information using a hierarchical, spring loaded DHTML menu system that adjusts to fit the boundaries of a resizable, container (FIG. 1). A set of standard HTML table row elements, having a hierachical dependency (11), is consistently displayed as a web-page, under reasonable resizing. This is done using a strut row that produces the largest width requirement when the table structure is resizing to occupy a small width. Only the current row elements and the strut element are required in calculating table resizing to ensure that whichever data elements are displayed when a web-page resizing occurs, the browser auto-layout algorithm calculations will result in a resize attributes that enables all other row elements of that menu to be accommodated by the newly determined table width. As the row elements may themselves be table structures, nested menus of information may be displayed and navigated (12).

Owner:NORRIS III FORBES HOLTEN

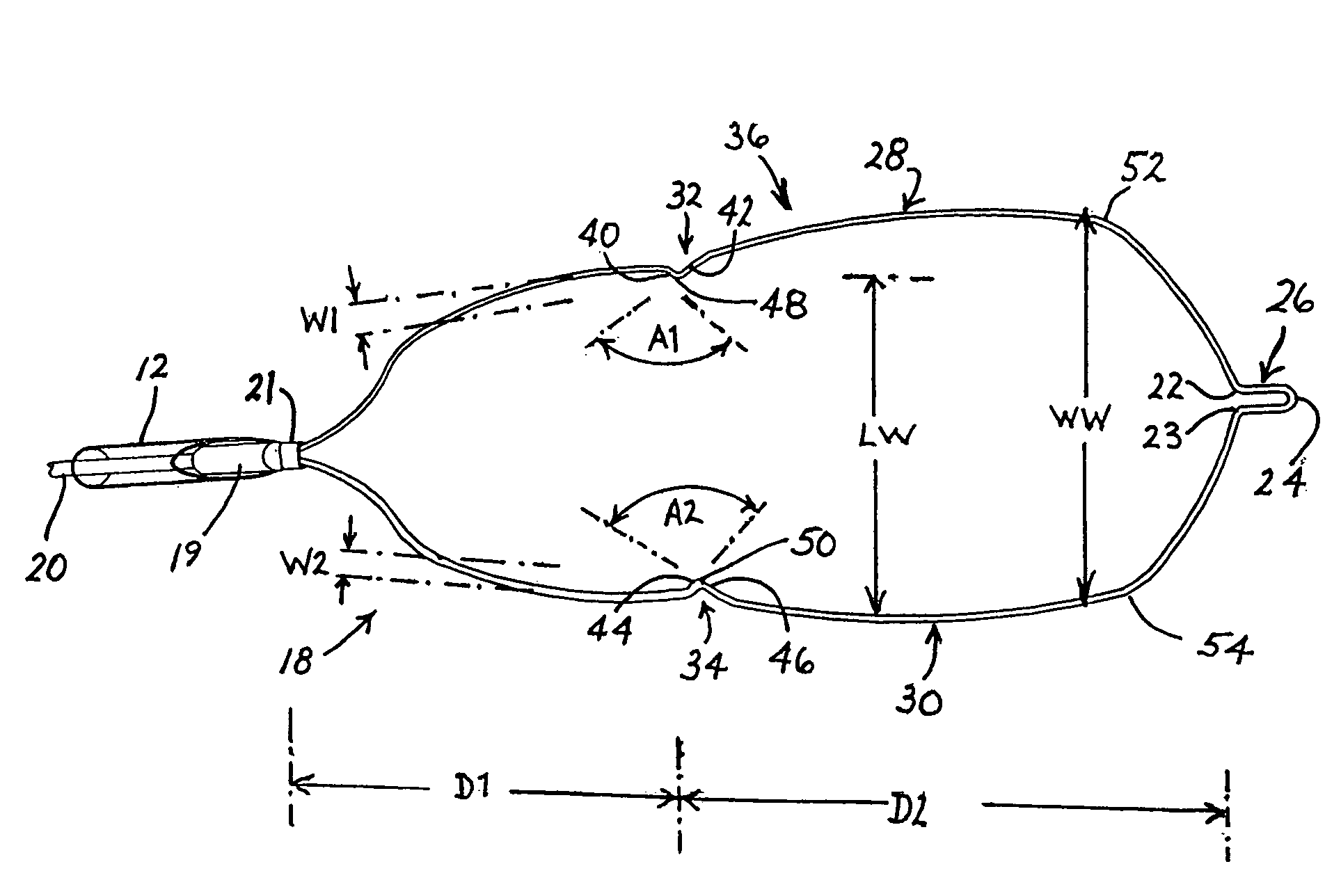

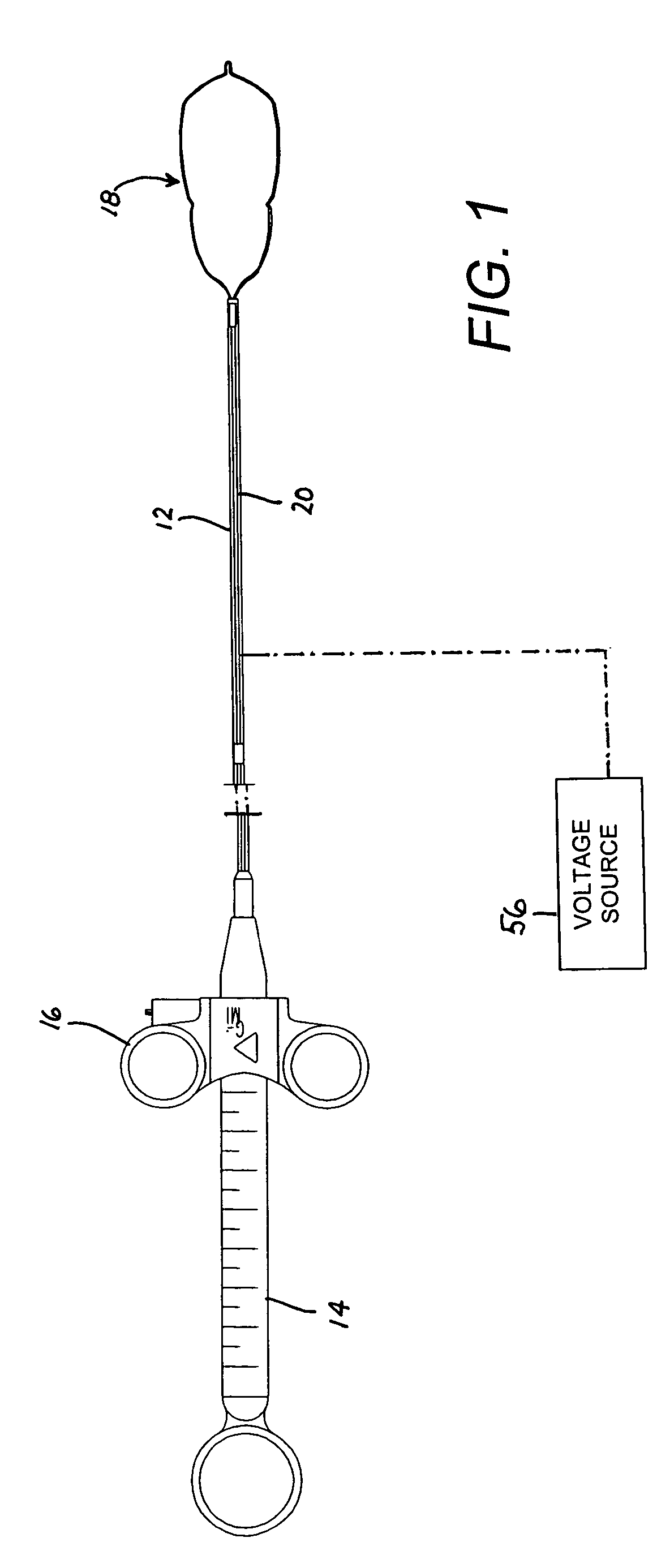

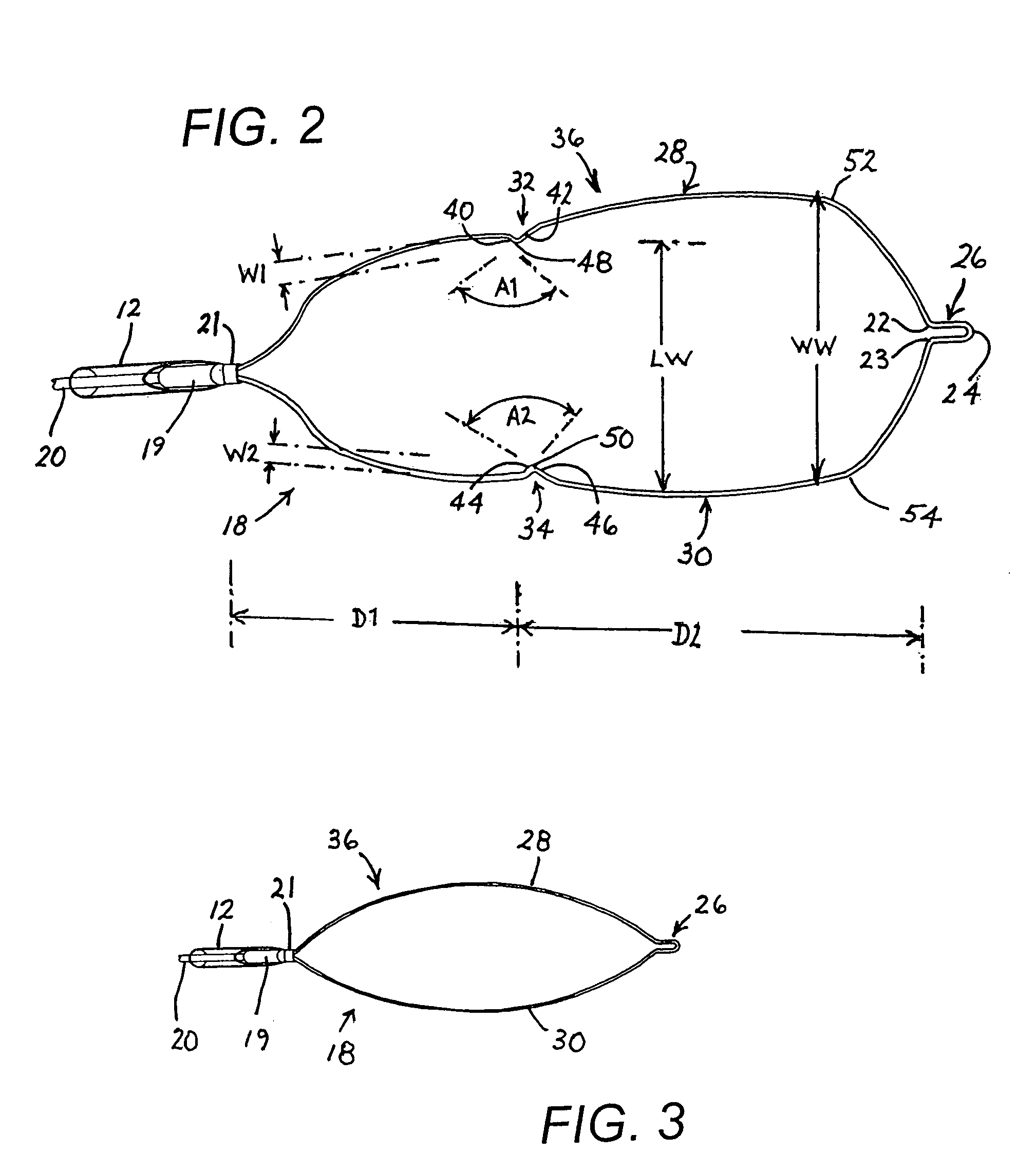

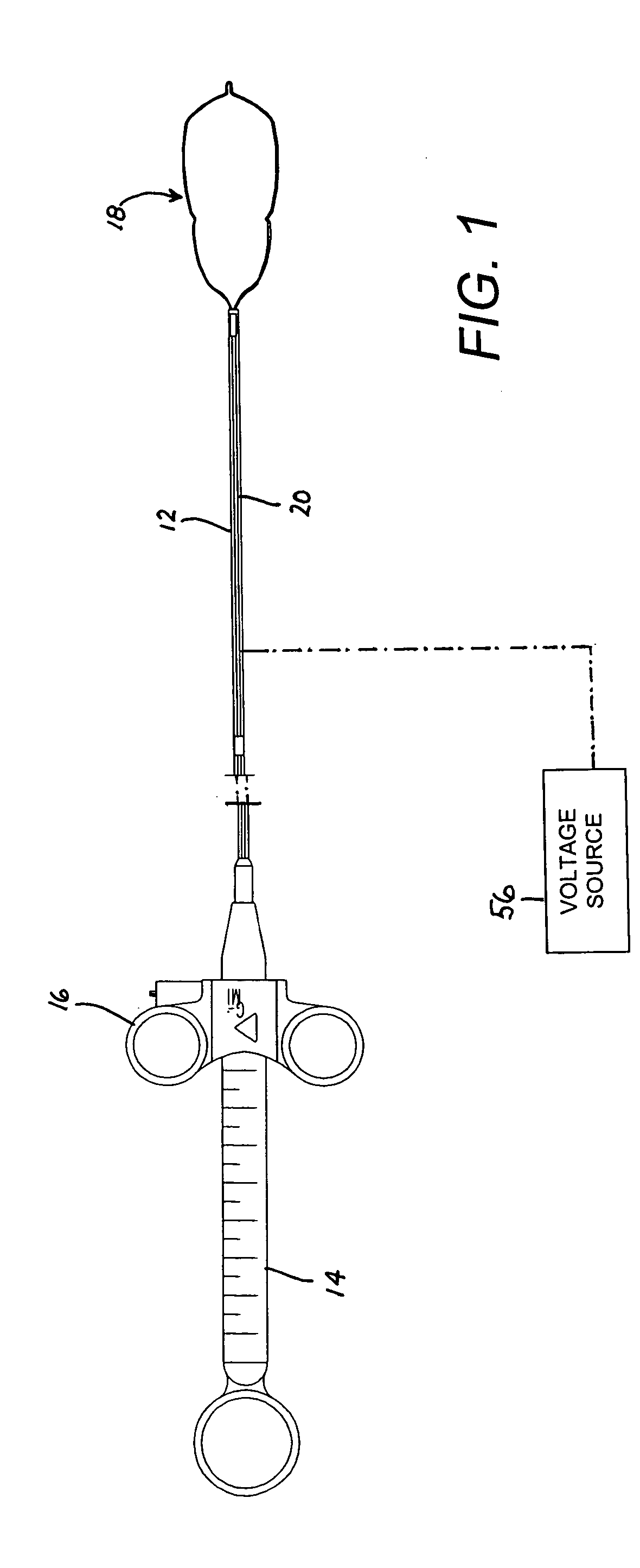

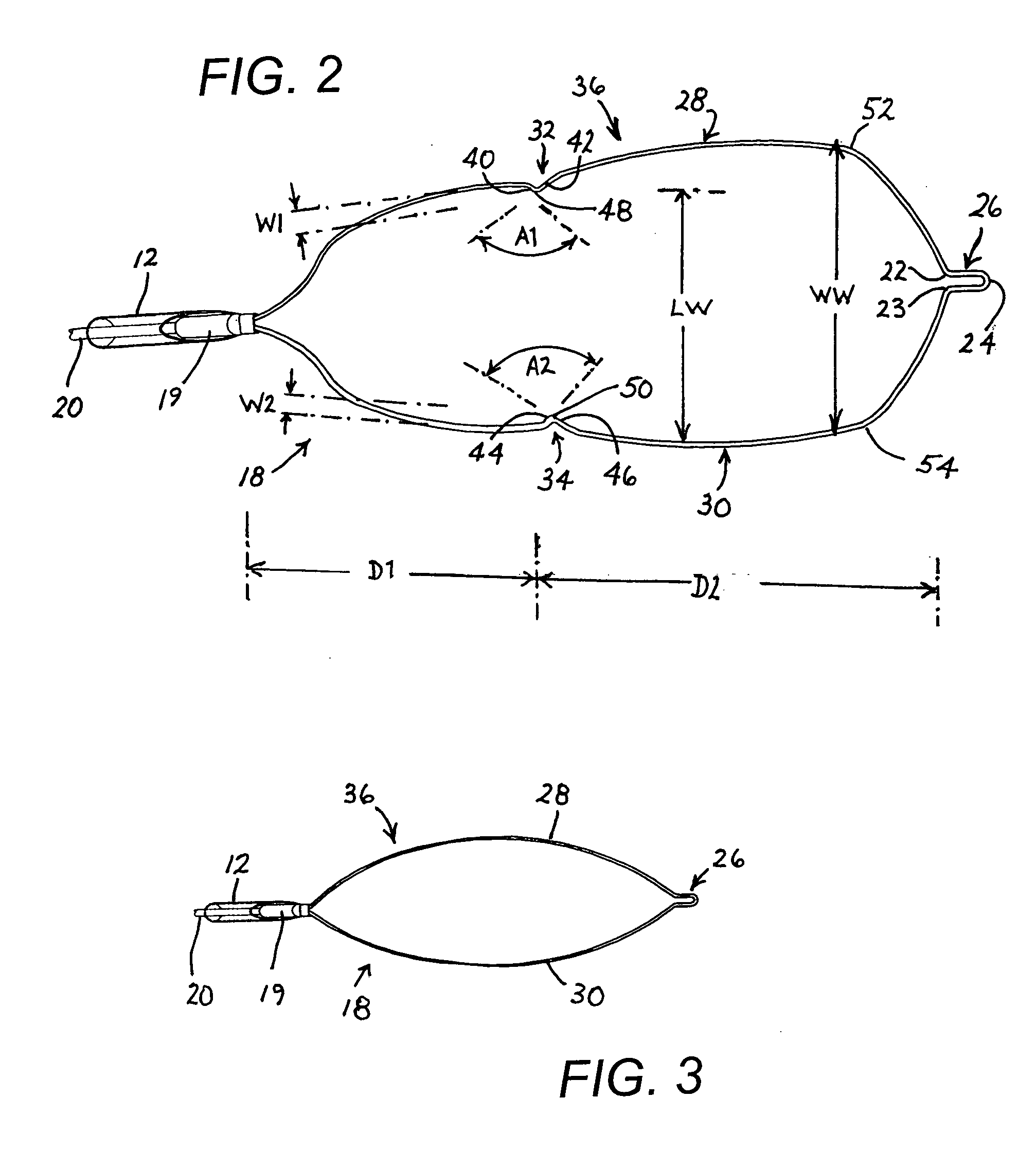

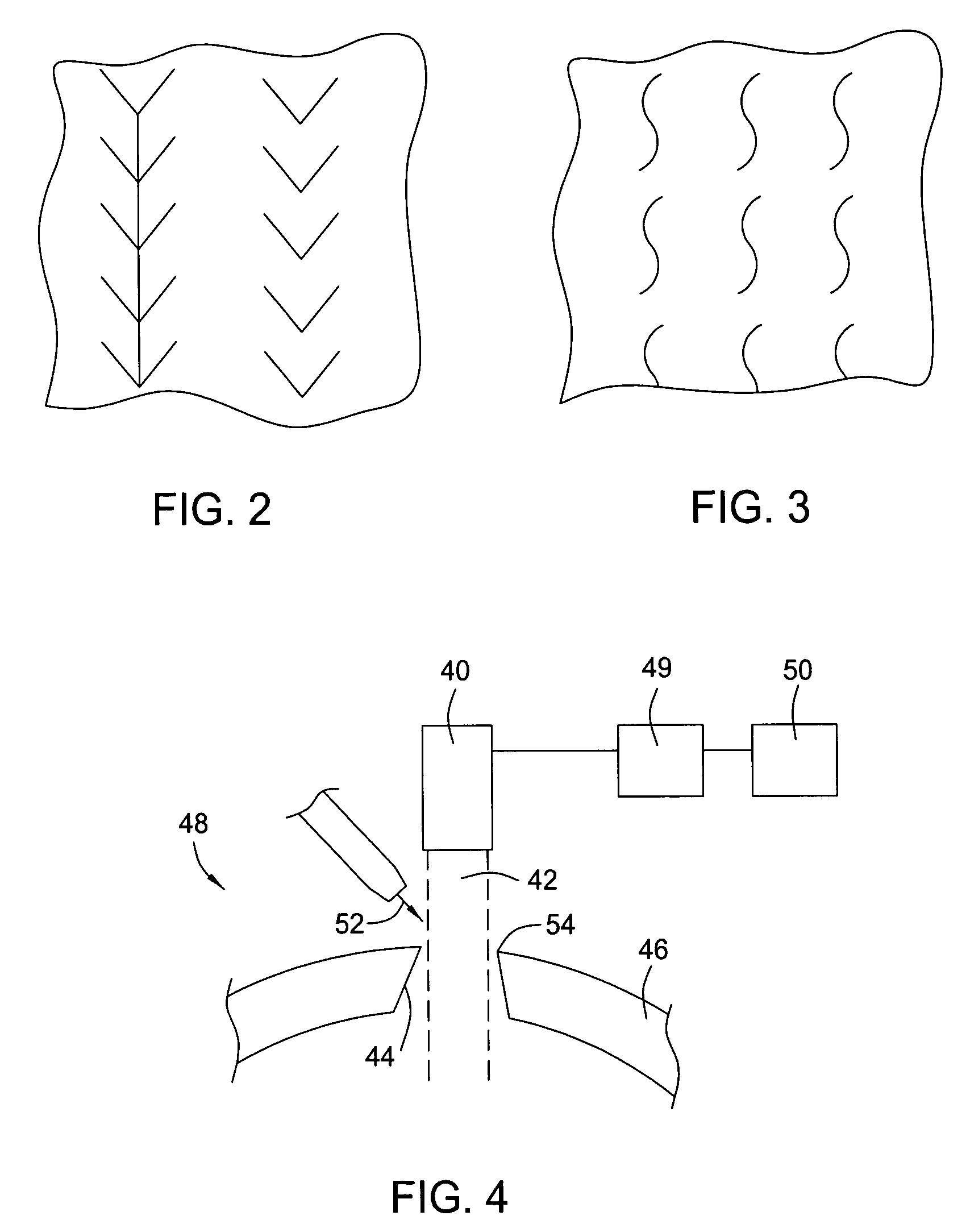

Medical snare loop with indentations for changing effective size of loop and associated method

ActiveUS7270663B2Easy to useSimple and inexpensive to manufactureExcision instrumentsSurgical instruments for heatingEngineeringMouth opening

A medical cauterization snare includes a tubular member such as a catheter, a rod or wire disposed at least partially inside the tubular member, and a resilient loop of a first size attached to a distal end of the rod or wire. The loop includes a nose on a side of the loop opposite the wire. The loop further includes two loop sections each extending between the wire and the nose. The loop sections are each formed with a respective notch or dent for enabling a use of the loop in a second size smaller than the first size. Positioning the loop relative to the tubular member so that the notches or dents are disposed at a mouth opening of the tubular member generates this secondary deployment configuration.

Owner:GRANIT MEDICAL INNOVATION

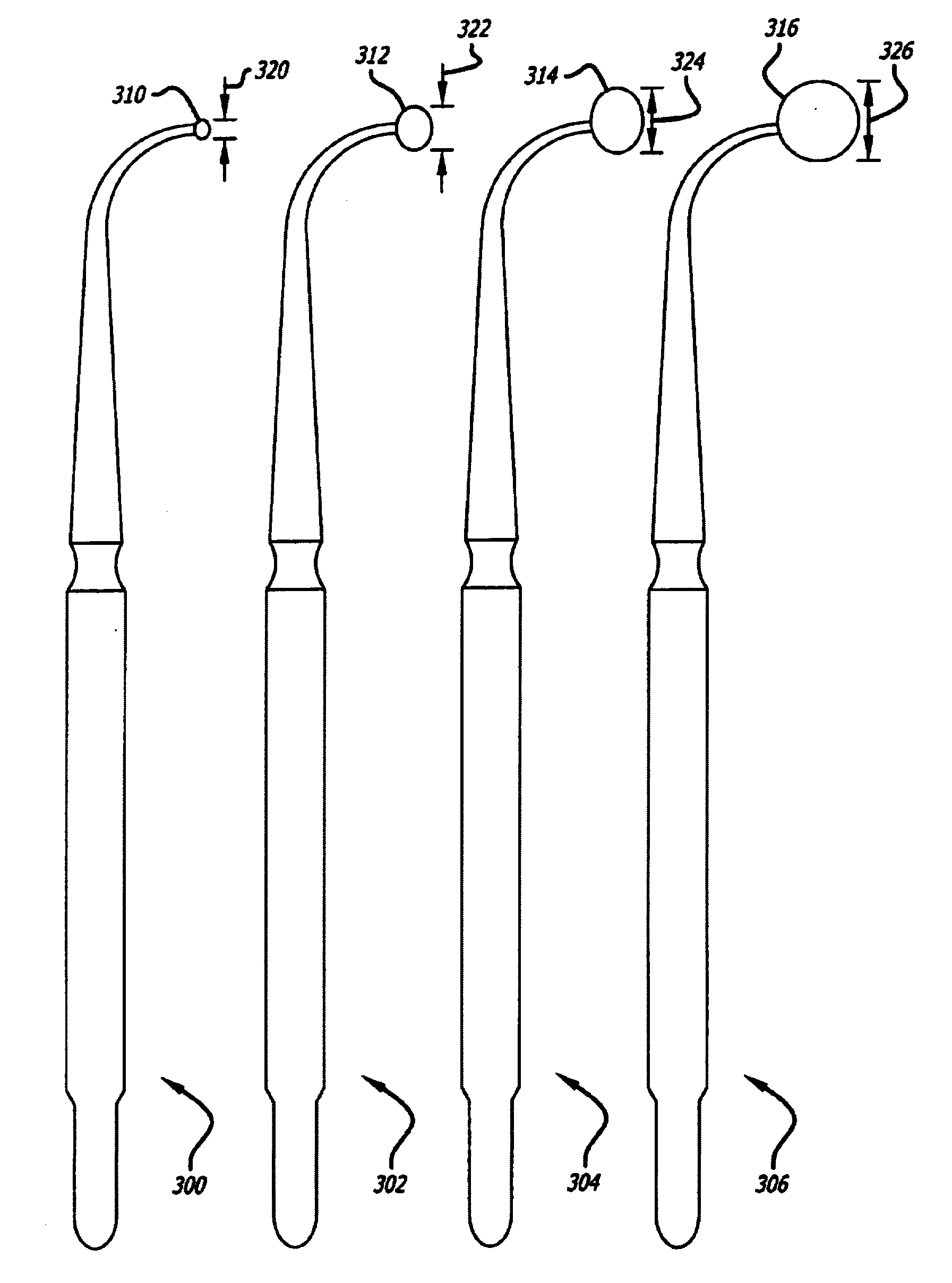

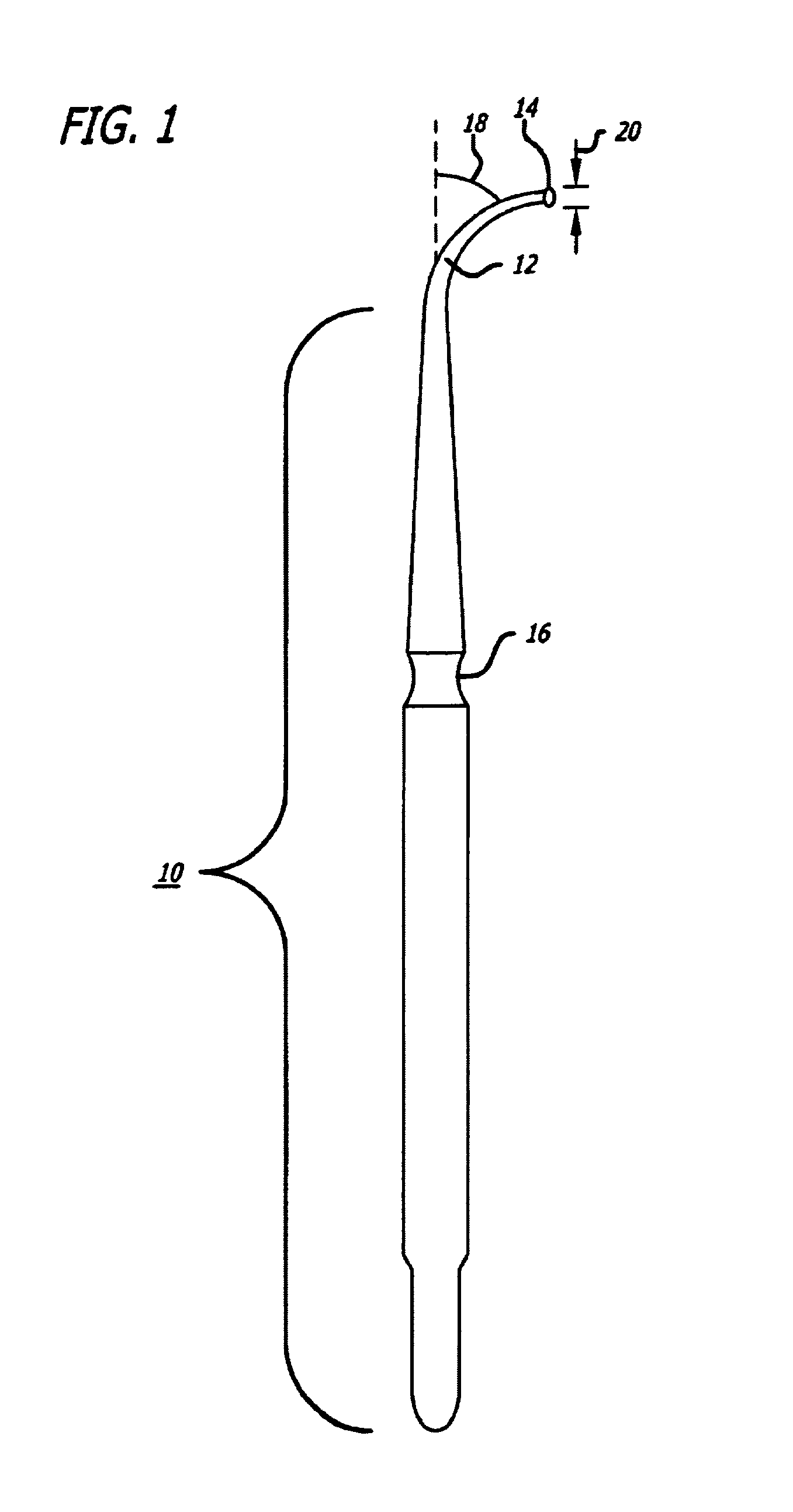

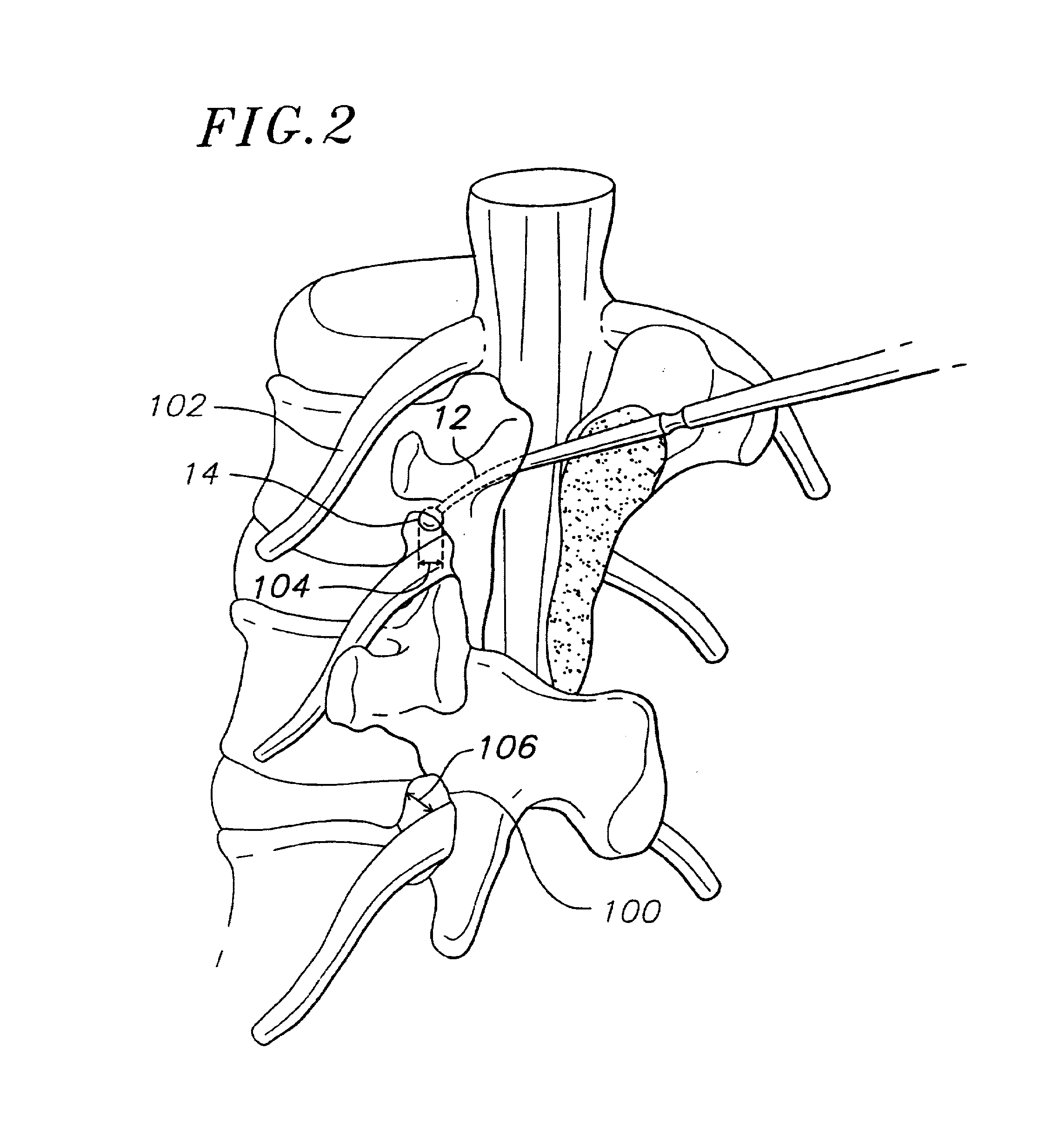

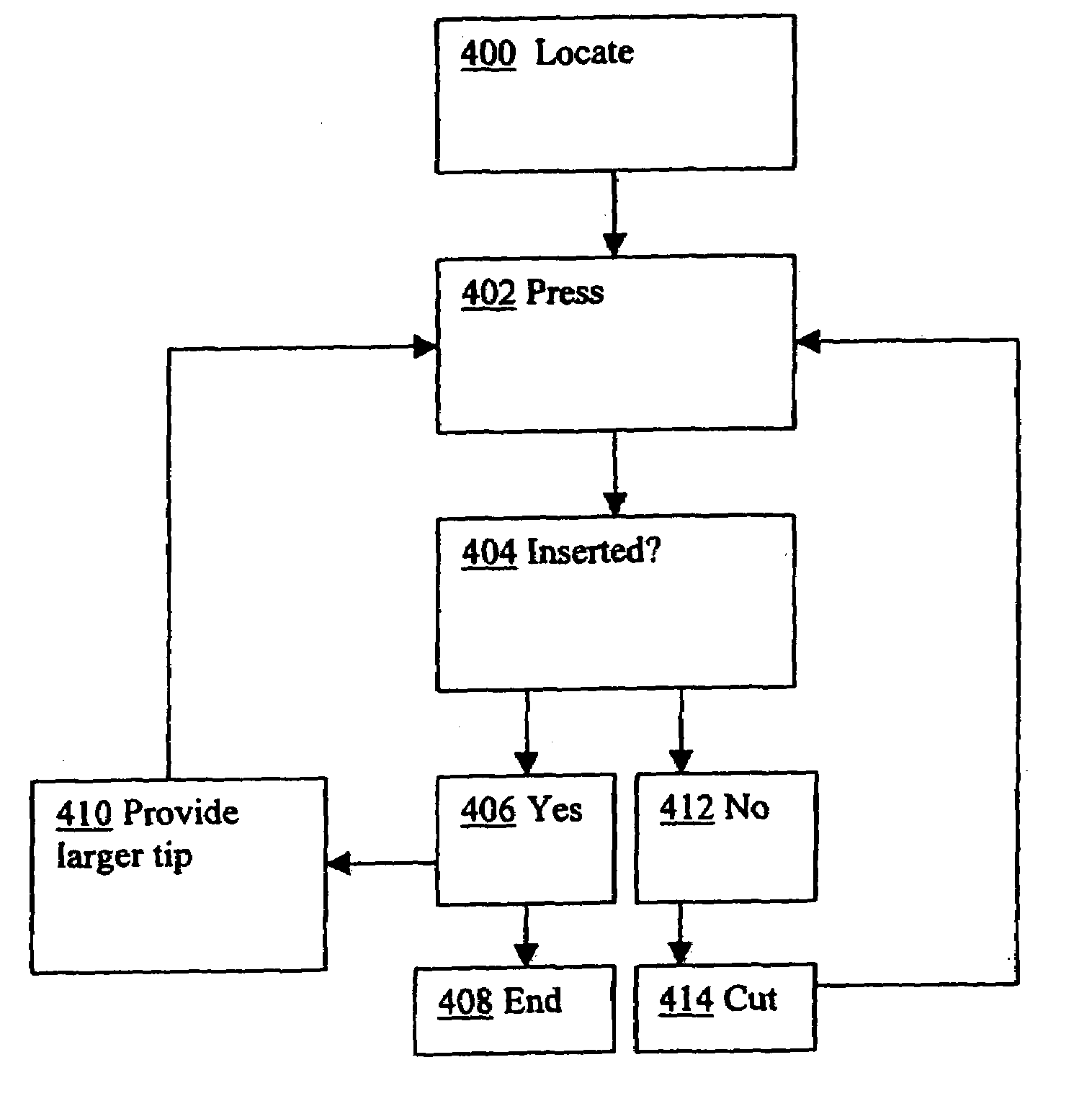

System, method and apparatus for locating, measuring and evaluating the enlargement of a foramen

A system, apparatus, and method for locating, measuring and evaluating the enlargement of a foramen are provided. An instrument has a handle, an angled region, and a tip to be inserted into the foramen. An instrument can be pressed onto the foramen to determine its location and whether the empty space within the foramen is large enough for the maximum width of the tip to be inserted. If the tip cannot insert, the foramen can be cut to enlarge it enough for the tip to insert. A kit of several instruments or a single instrument with tips of different maximum widths are provided for determining the amount of empty space within the foramen through the course of the enlargement.

Owner:AEOLIN

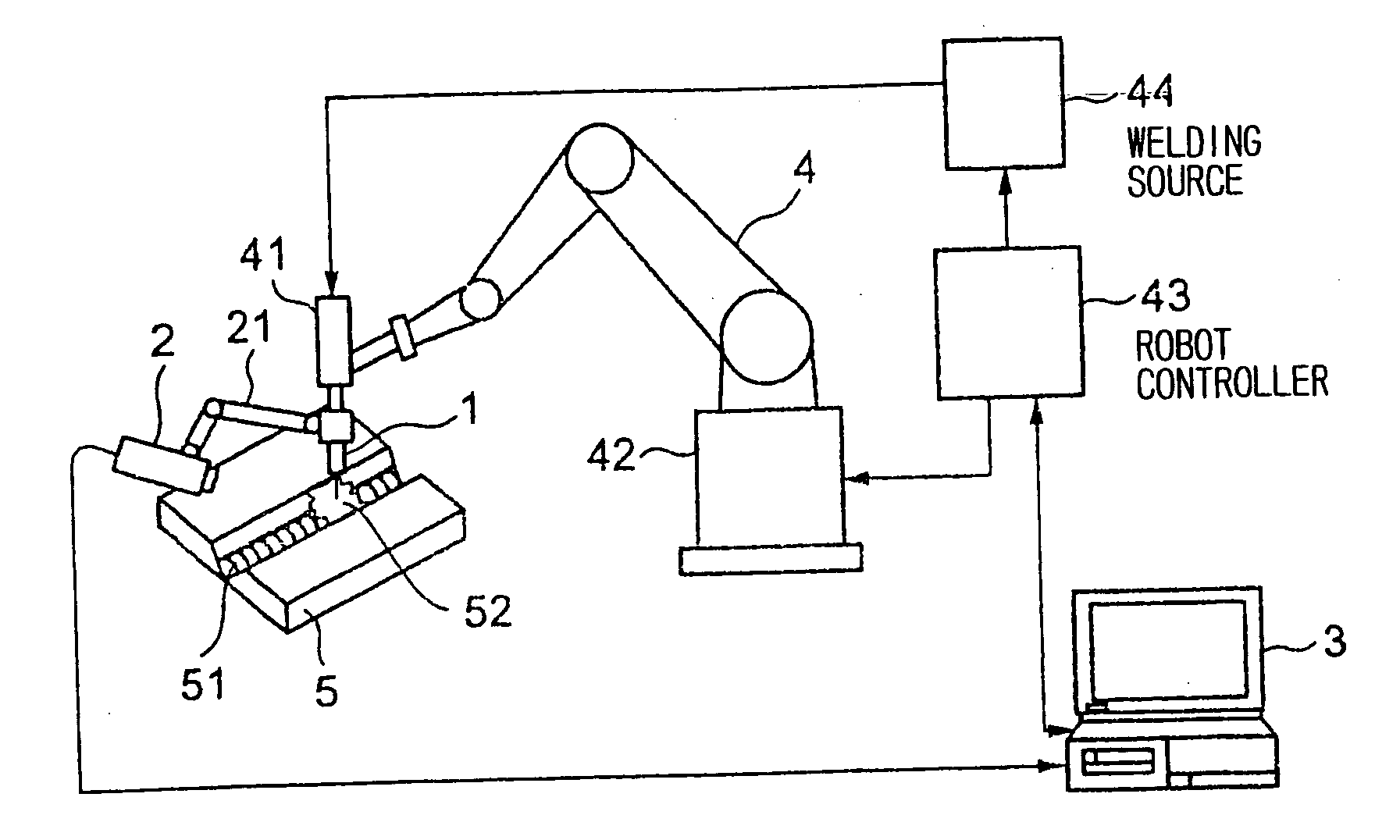

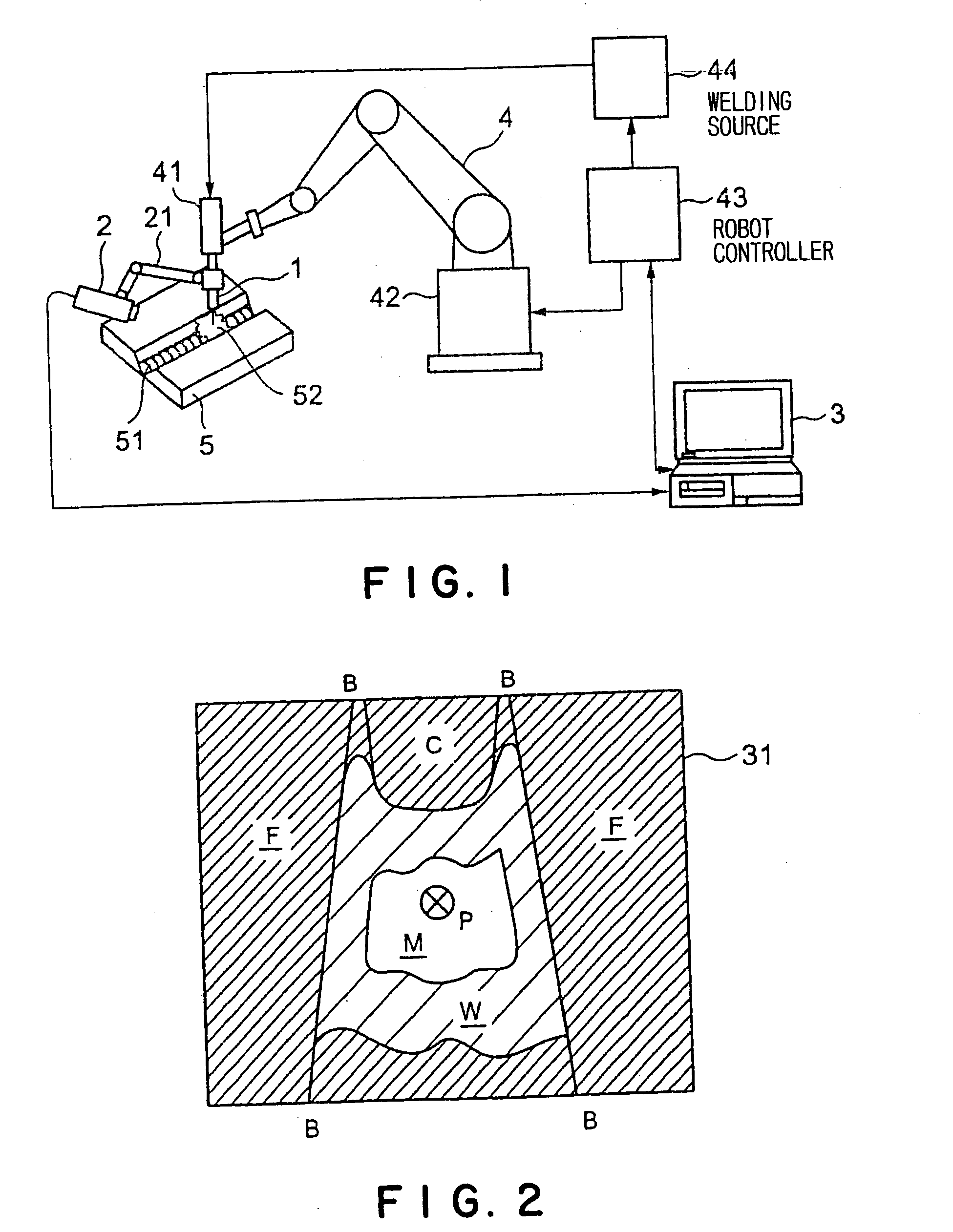

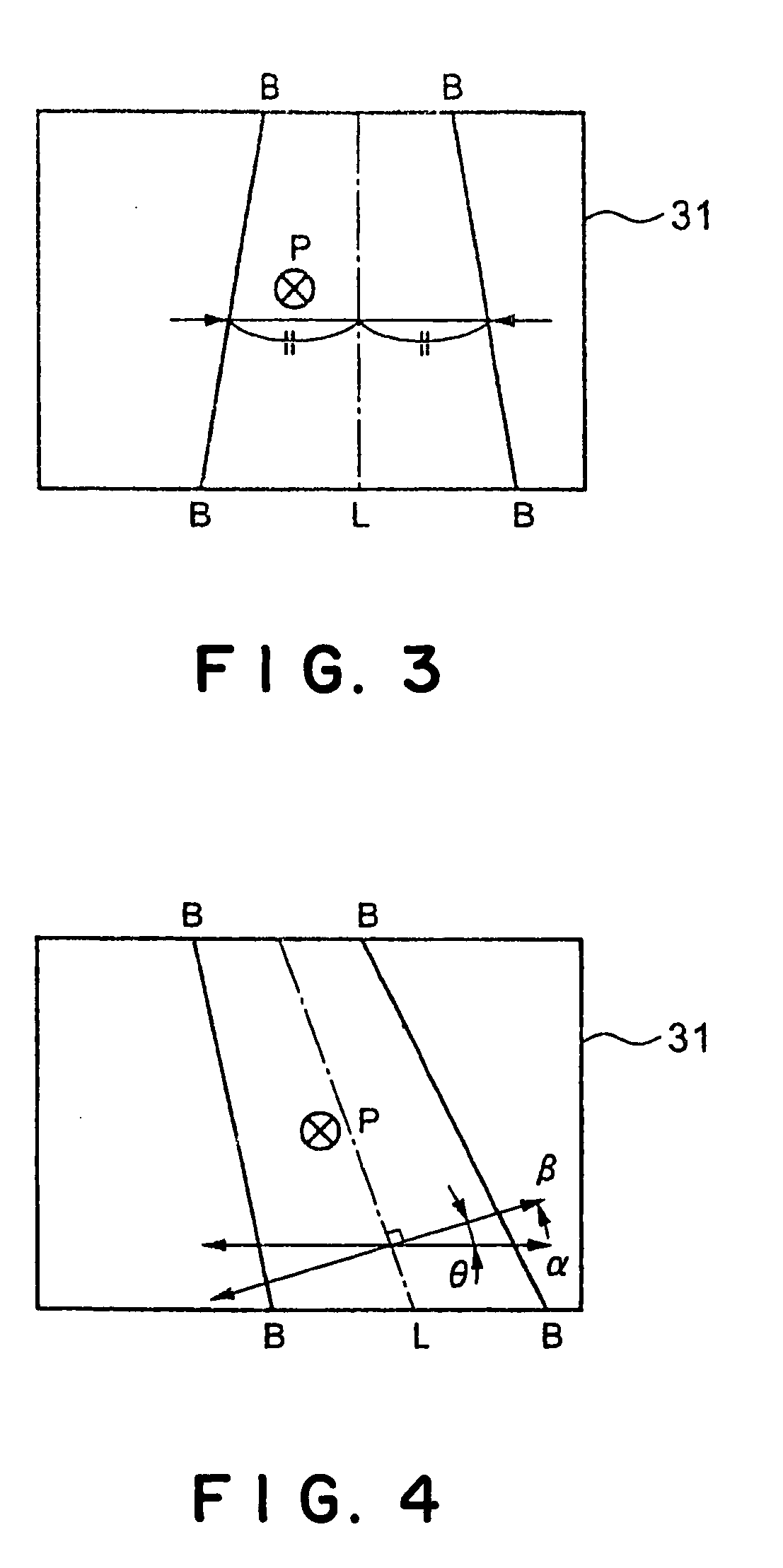

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

Cell sorting device

InactiveUS20110212440A1Large widthWell representedBioreactor/fermenter combinationsBiological substance pretreatmentsAcousticsMicrosystem

An integrated microsystem, comprising: a microchannel, a field generator to create a magnetic field in at least one first portion of the microchannel having a direction substantially collinear with the direction of flow in the portion of the microchannel, the magnetic field also presenting a gradient, wherein the microsystem additionally comprises a detection area in fluid connection with the microchannel,

Owner:CNRS DAE +3

Medical instrument with indented loop and associated method

ActiveUS20050085808A1Easy to useSimple and inexpensive to manufactureExcision instrumentsSurgical instruments for heatingEngineeringMouth opening

A medical cauterization snare includes a tubular member such as a catheter, a rod or wire disposed at least partially inside the tubular member, and a resilient loop of a first size attached to a distal end of the rod or wire. The loop includes a nose on a side of the loop opposite the wire. The loop further includes two loop sections each extending between the wire and the nose. The loop sections are each formed with a respective notch or dent for enabling a use of the loop in a second size smaller than the first size. Positioning the loop relative to the tubular member so that the notches or dents are disposed at a mouth opening of the tubular member generates this secondary deployment configuration.

Owner:GRANIT MEDICAL INNOVATION

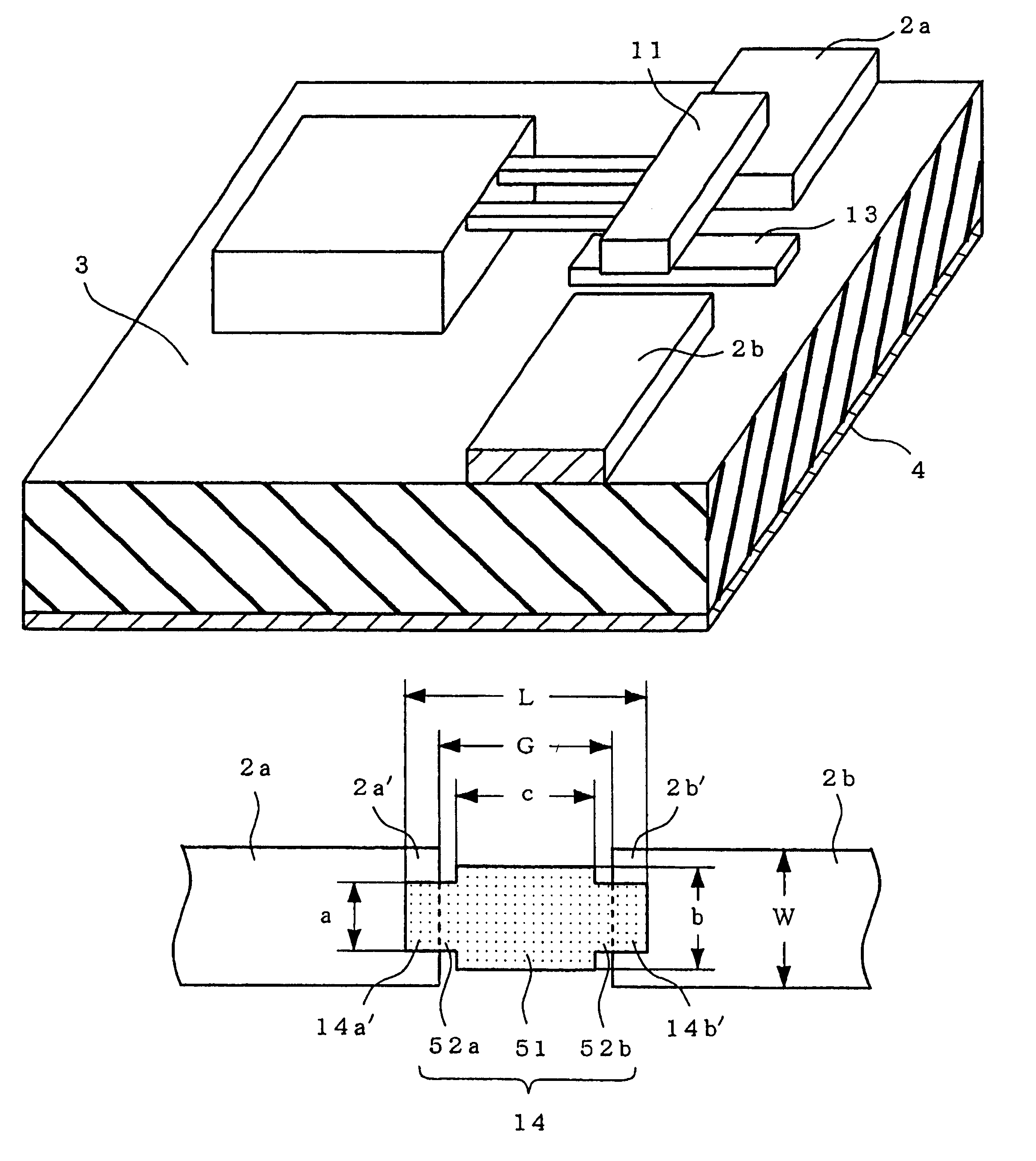

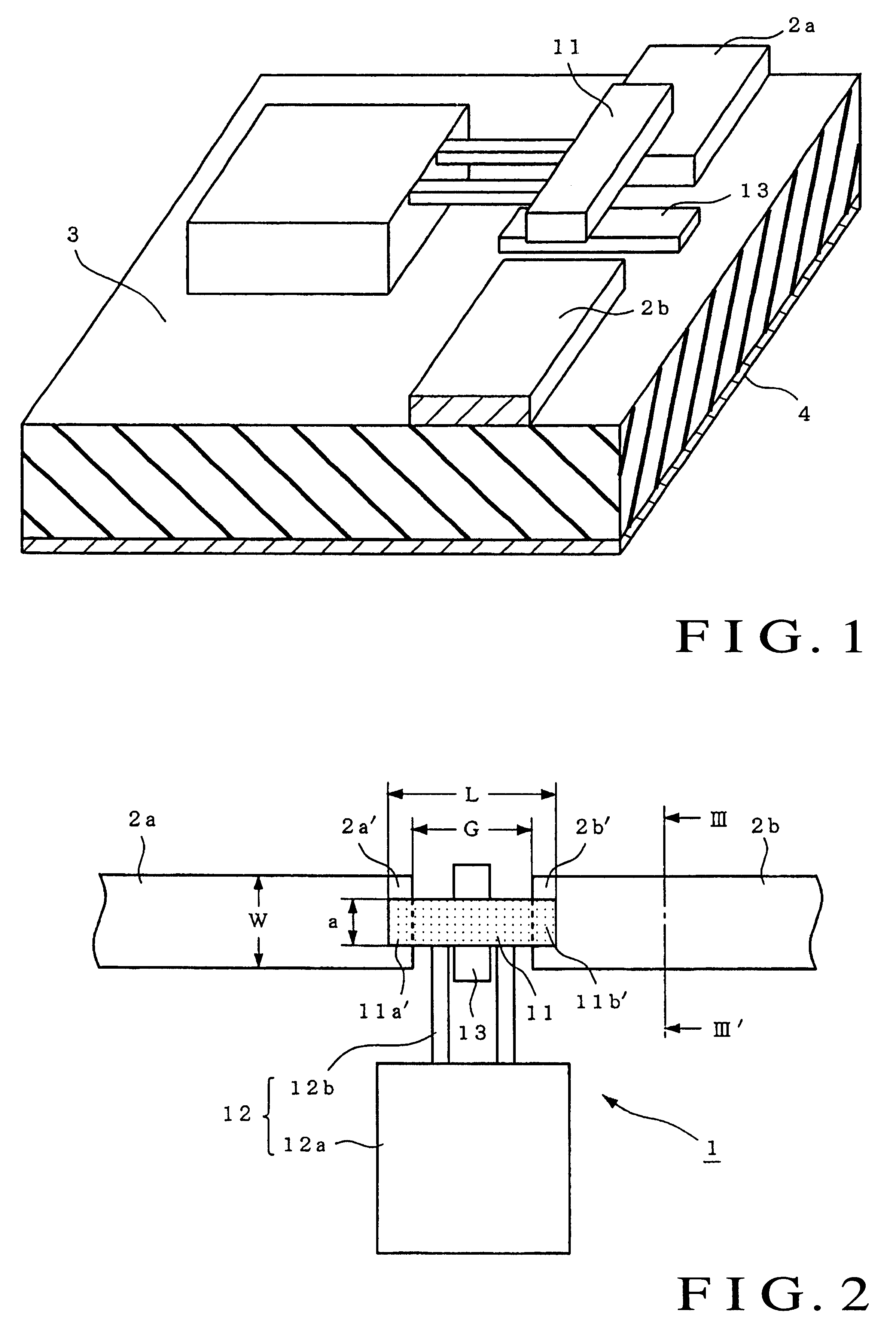

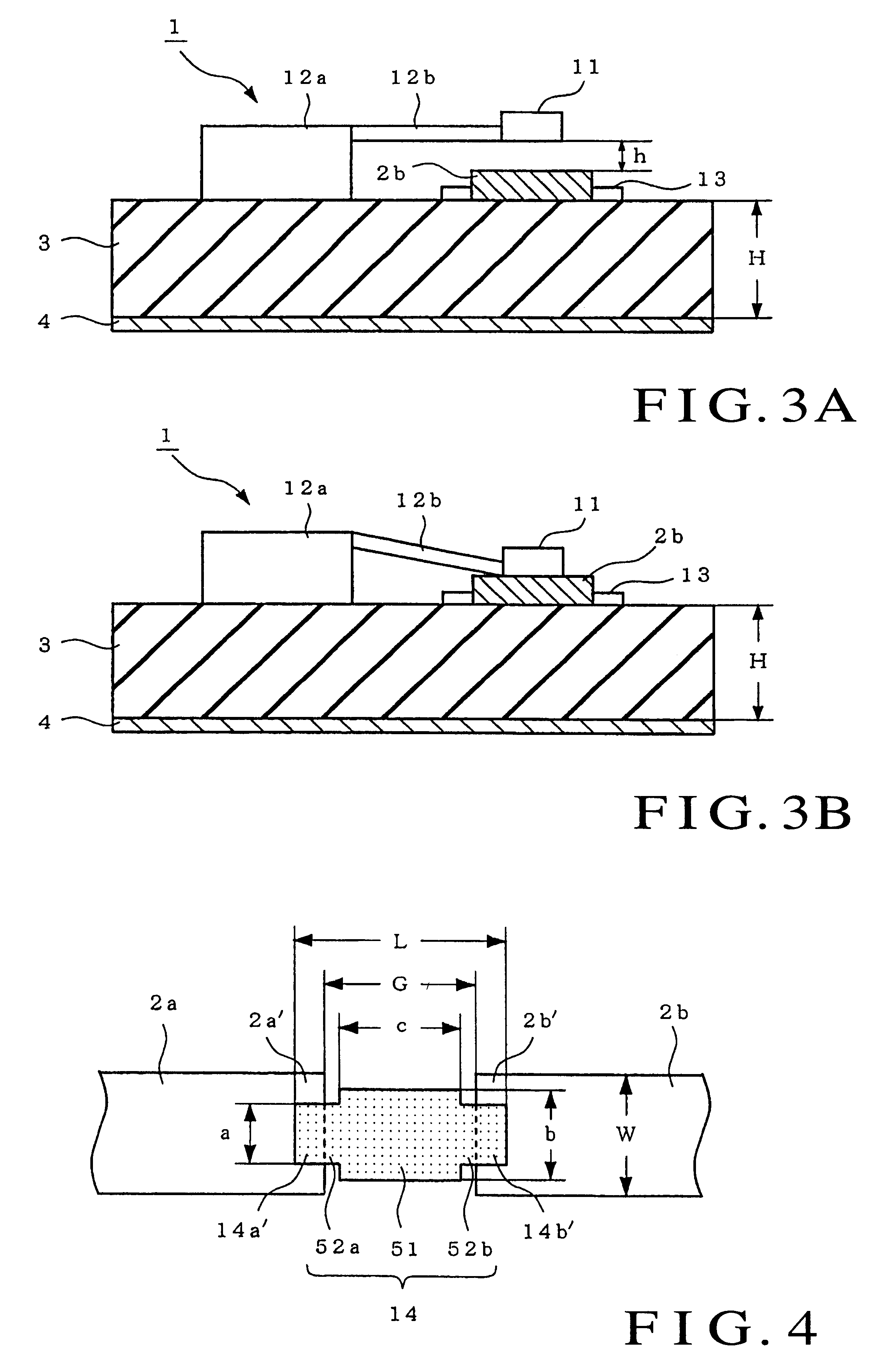

Micromachine MEMS switch

InactiveUS6433657B1Reduce couplingEasy to switchContact surface shape/structureElectrostatic/electro-adhesion relaysEngineeringElectrical and Electronics engineering

A switch includes at least two distributed constant lines (2a, 2b) disposed close to each other, a movable element (11) arranged above the distributed constant lines so as to oppose these distributed constant lines and connecting the distributed constant lines to each other in a high-frequency manner upon contacting the distributed constant lines, and a driving means (13) for displacing the movable element by an electrostatic force to bring the movable element into contact with the distributed constant lines. The movable element has a projection (52a, 52b) formed by notching at least one end of an edge of the movable element which is located on at least one distributed constant line side. In this projection, a width (a) serving as a length in a direction parallel to the widthwise direction of the distributed constant lines is smaller than a width (W) of each of the distributed constant lines.

Owner:NEC CORP

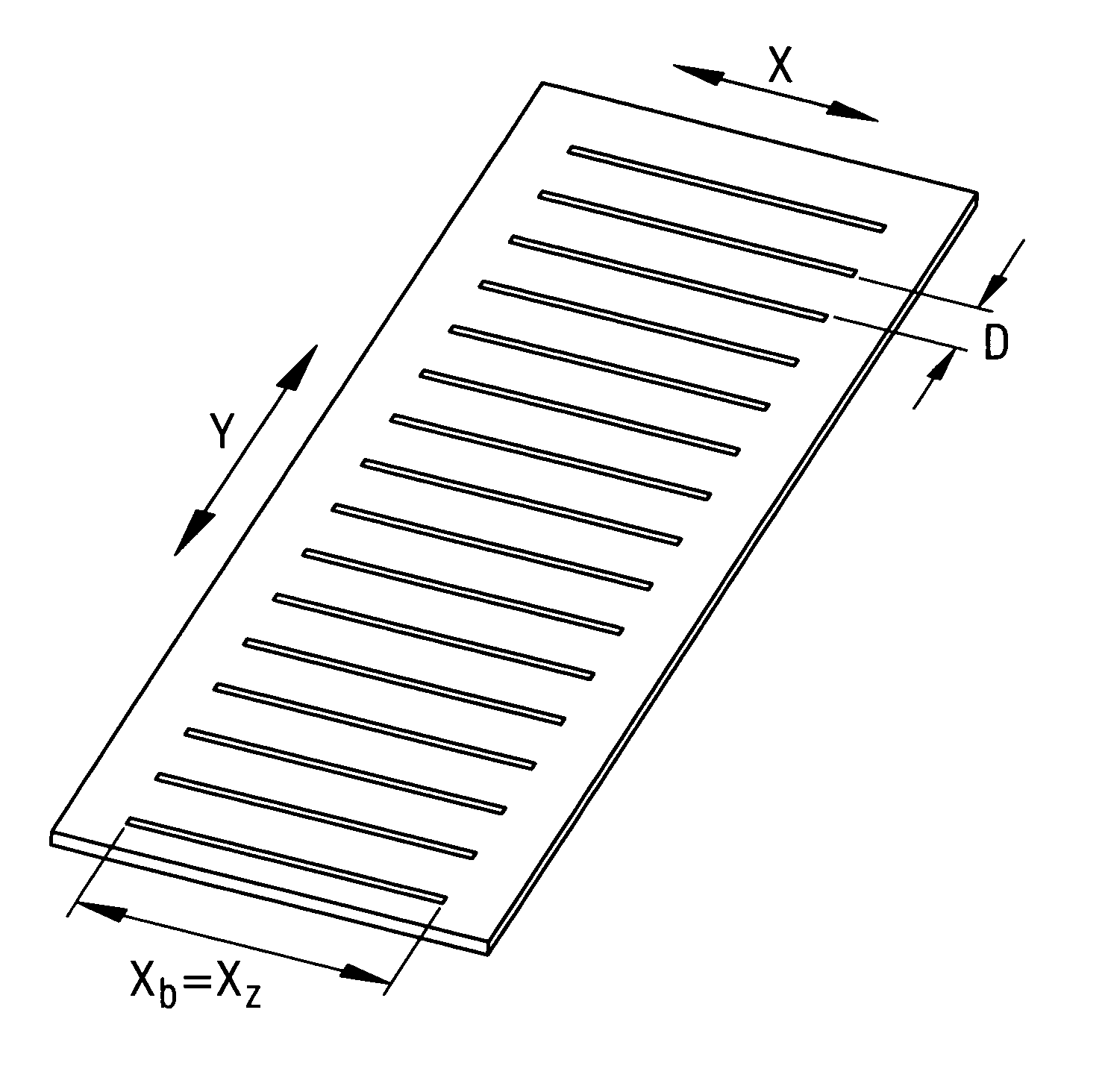

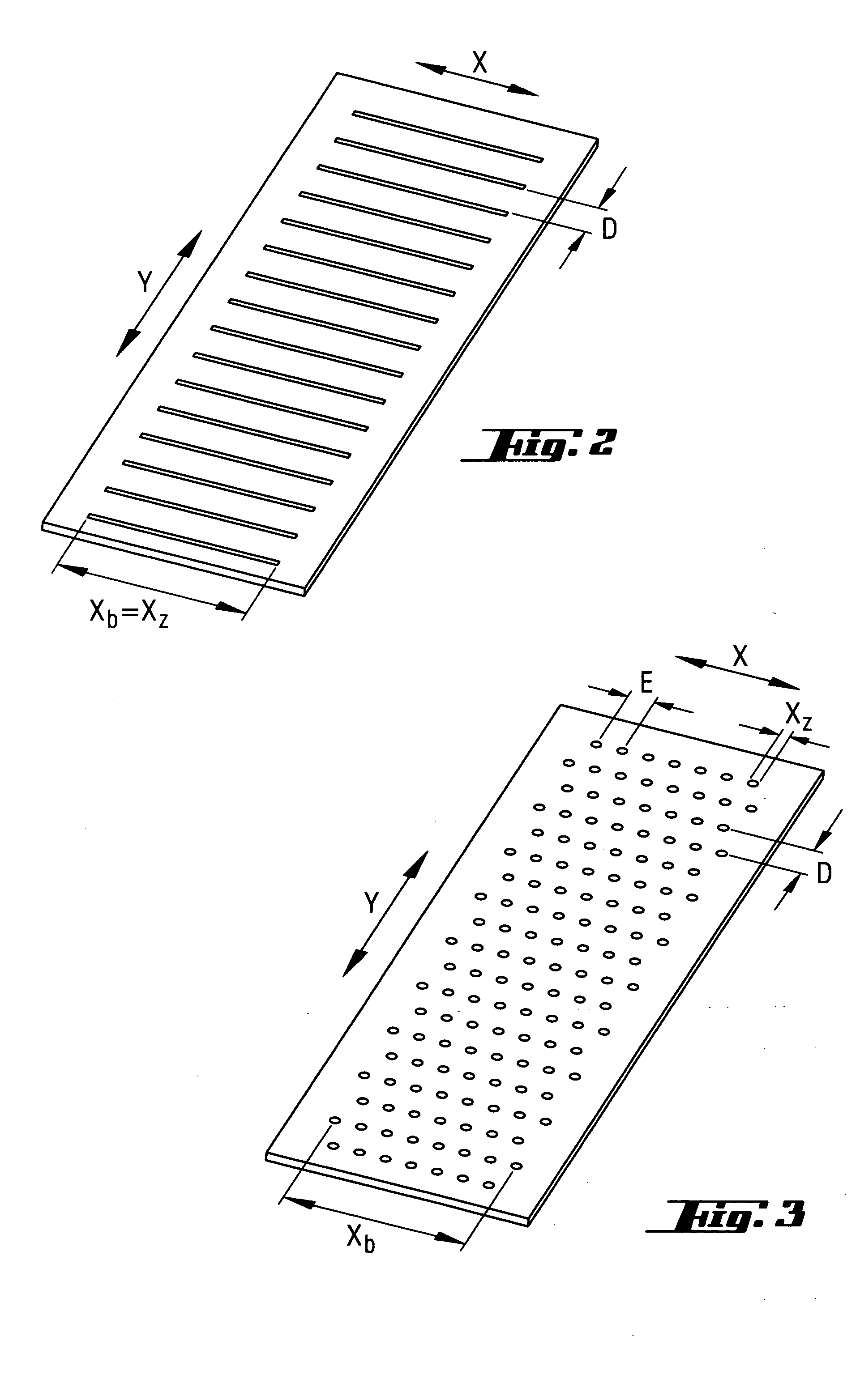

Elasticated materials

This invention relates to an elasticated materials comprising a stiff carrier material that is satisfactorily elasticated with one or more elastic strands with a low load force, due to the use of a specific bonding pattern, with specific bonding areas. The bonding areas are typically separate bonding areas positioned on separate intervals along the length direction of the carrier material, whereby each bonding area comprises one or more separate bonding zones, extending in the width (X) direction. The invention also relates to absorbent articles comprising this elasticated material and processes for making the elasticated material.

Owner:THE PROCTER & GAMBLE COMPANY

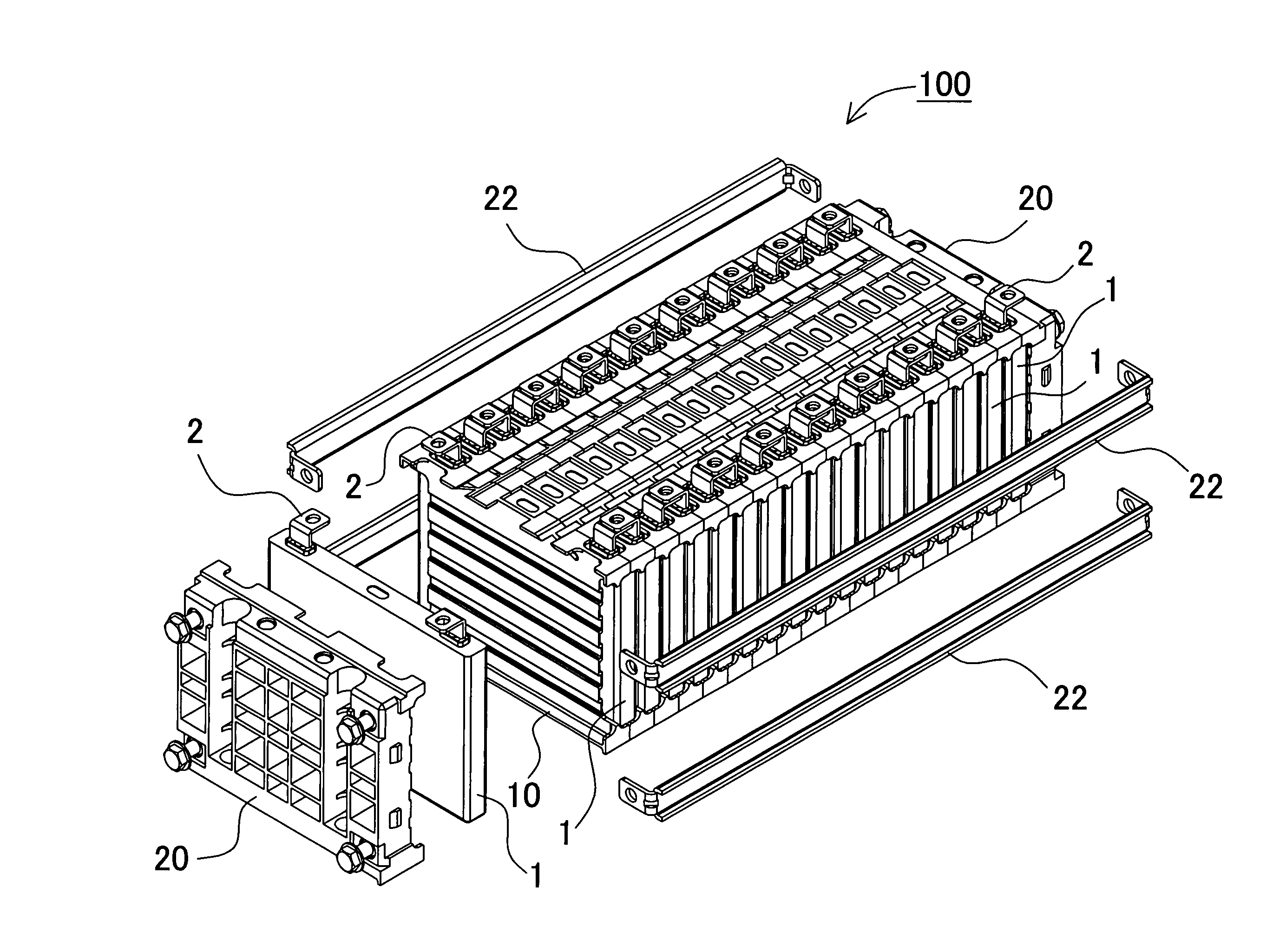

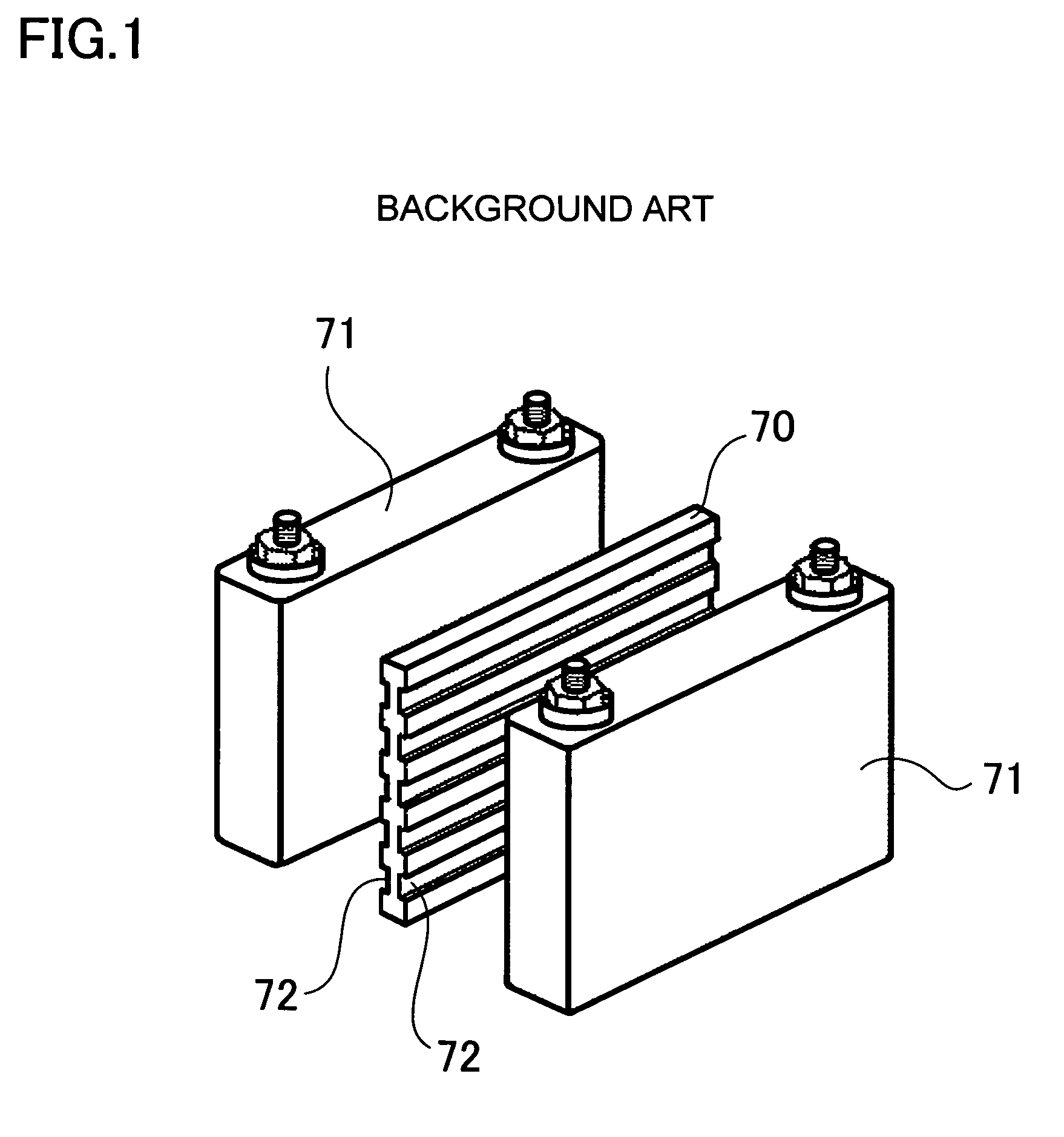

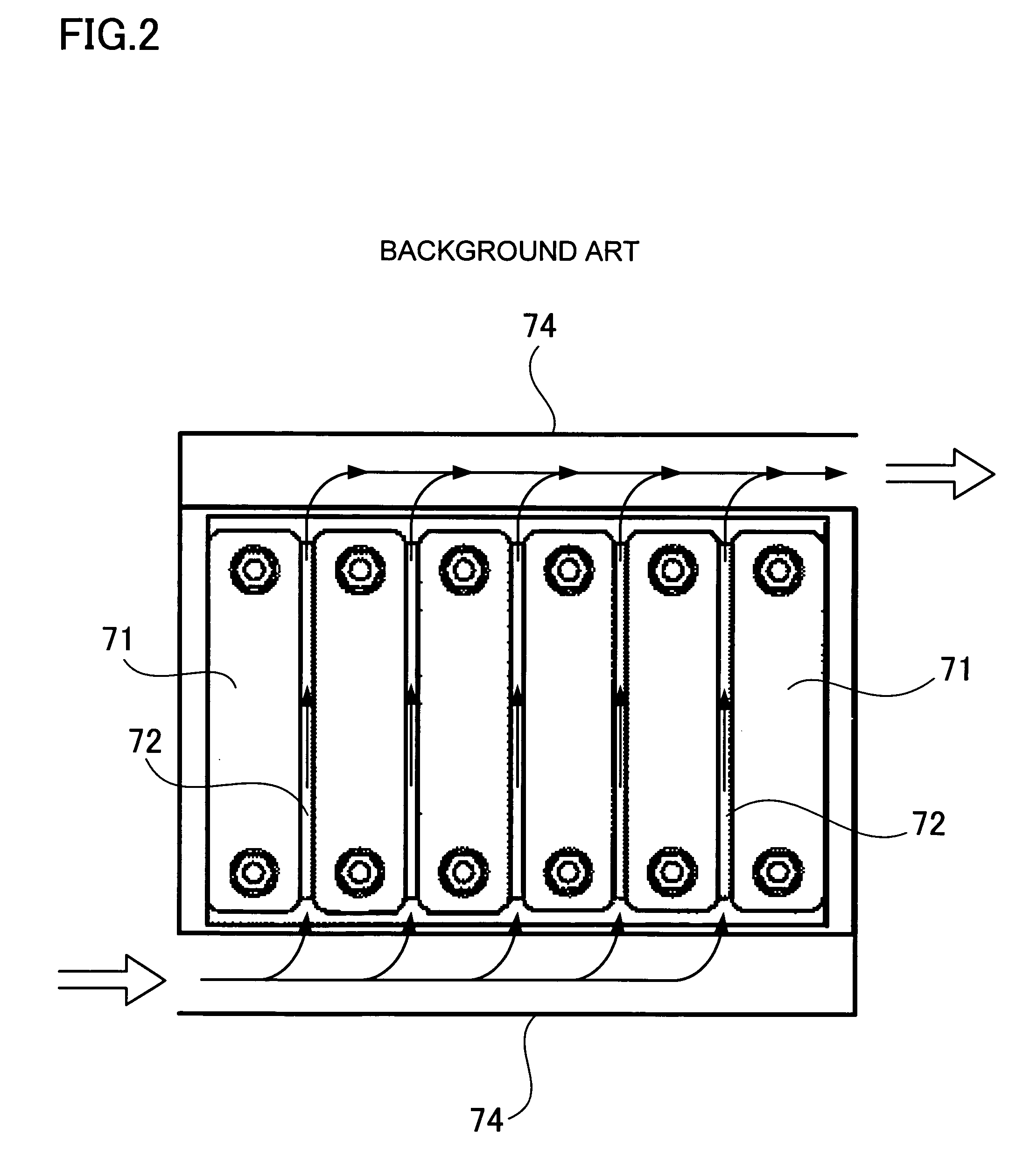

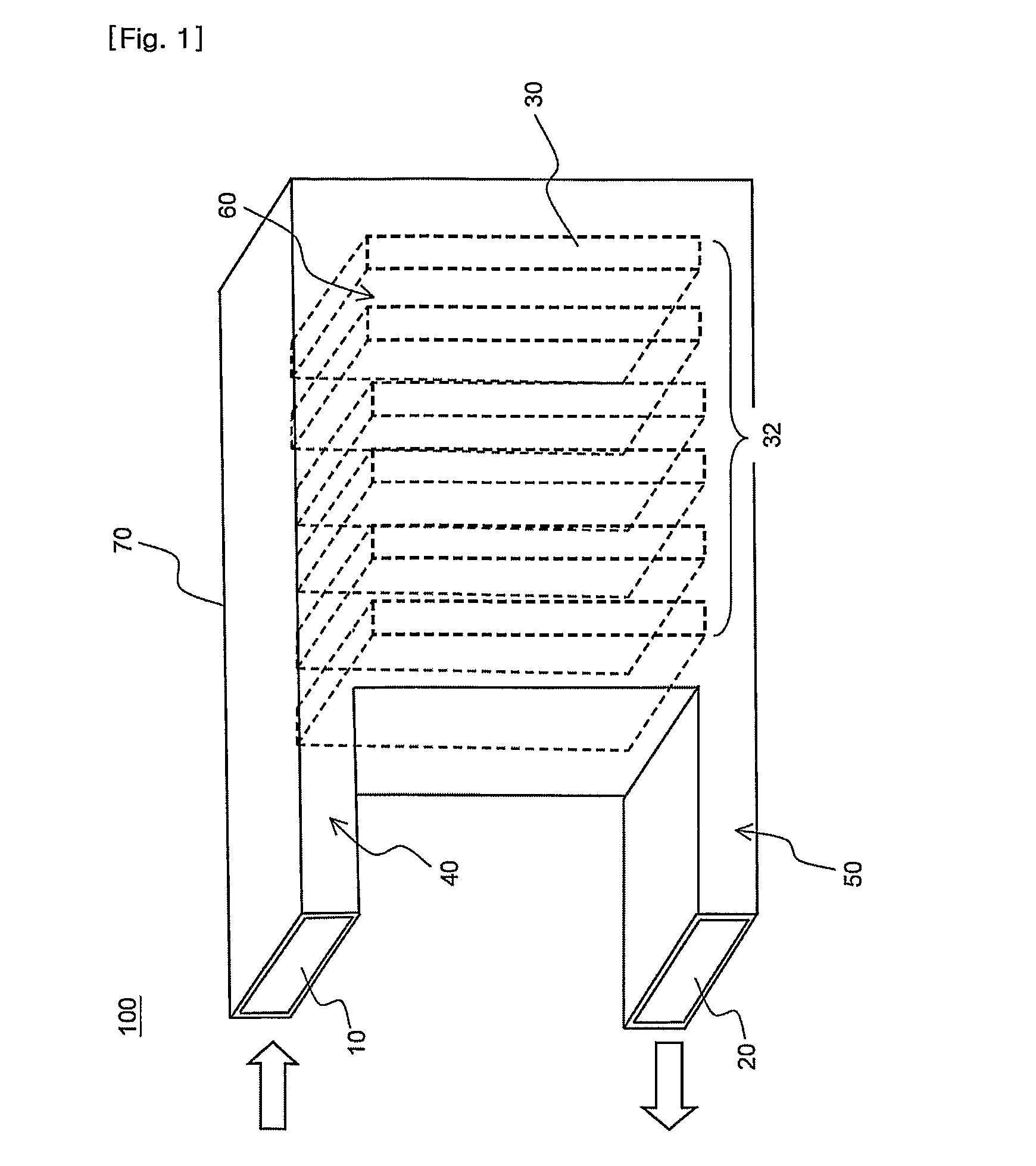

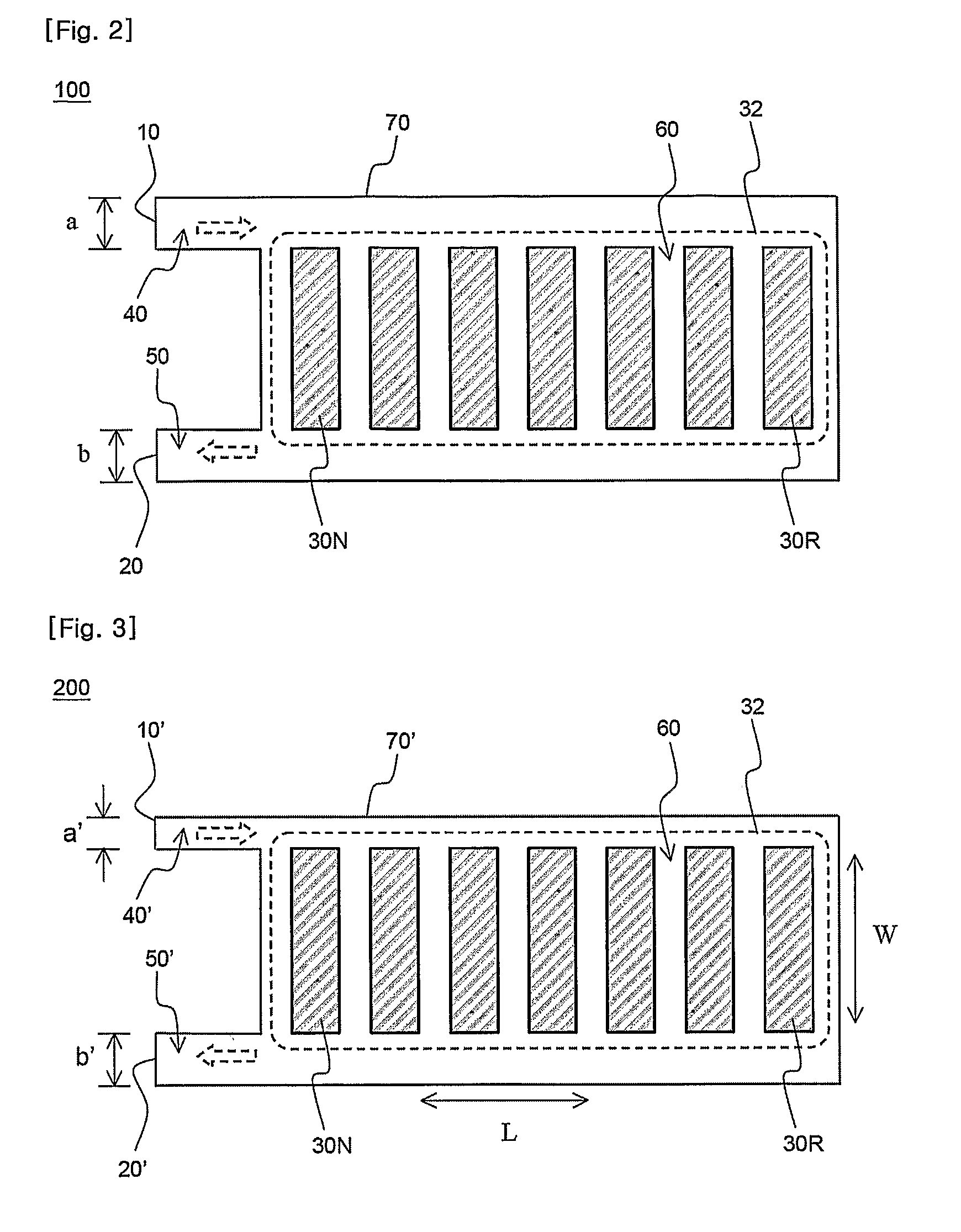

Battery pack and battery pack separator

ActiveUS20090111010A1Reduces cooling gas pressure lossDifference in pressureCell temperature controlCells cooling/heatingEngineeringBattery cell

The battery pack includes plural battery cells 1, and insulating separators 10 disposed between adjacent battery cells 1, where the plurality of battery cells 1 are disposed in a stacked configuration with a prescribed gap between adjacent battery cells 1. A separator 10 has a plural gas channels that enable the flow of cooling gas. The gas channels have cooling gas entranceways and exit ways, which open at the sides of the battery block formed by the stacked battery cells 1. A separator 10 has cut sections formed to position the entranceways and exit ways of the gas channels inward from the sides of the battery block. This allows cooling gas near entranceways and exit ways to be smoothly introduced to, and exhausted from the gas channels, and reduces cooling gas pressure losses in those regions.

Owner:SANYO ELECTRIC CO LTD

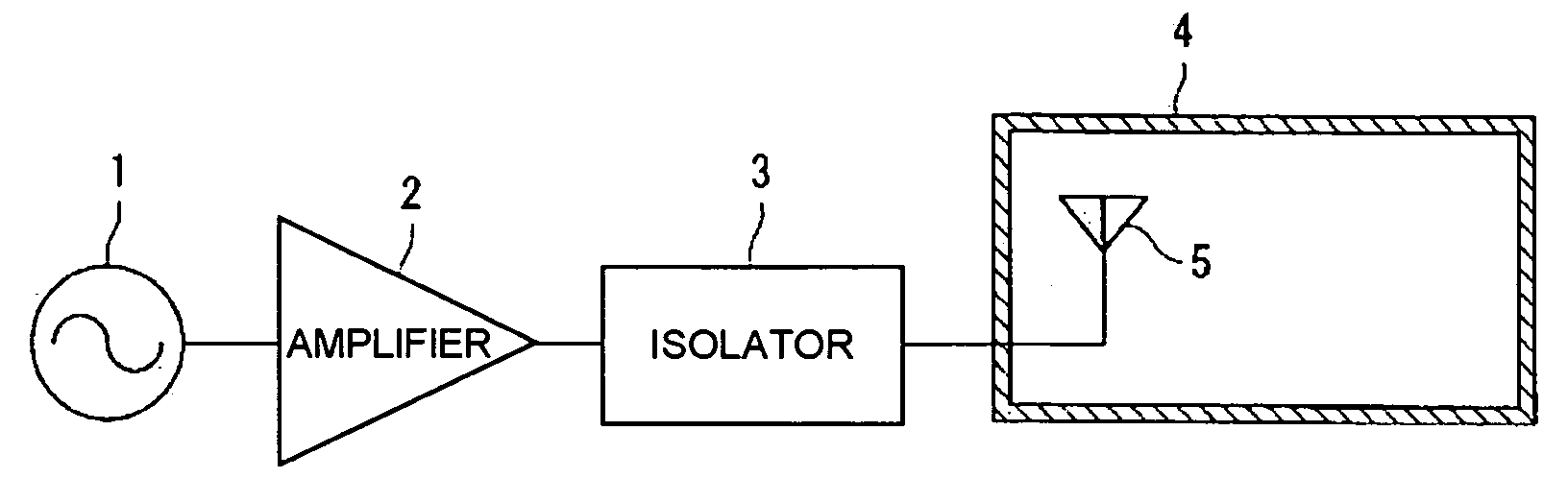

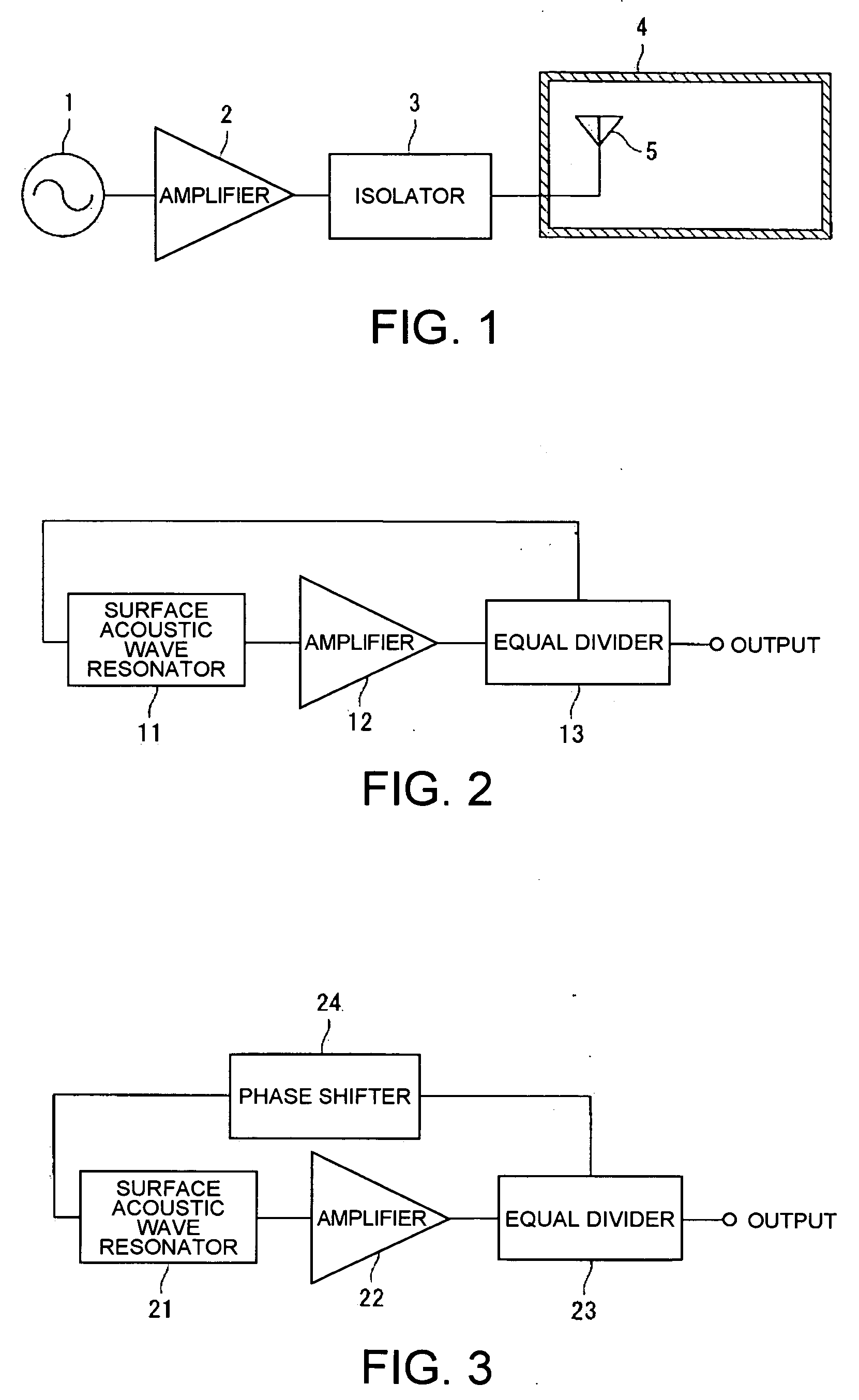

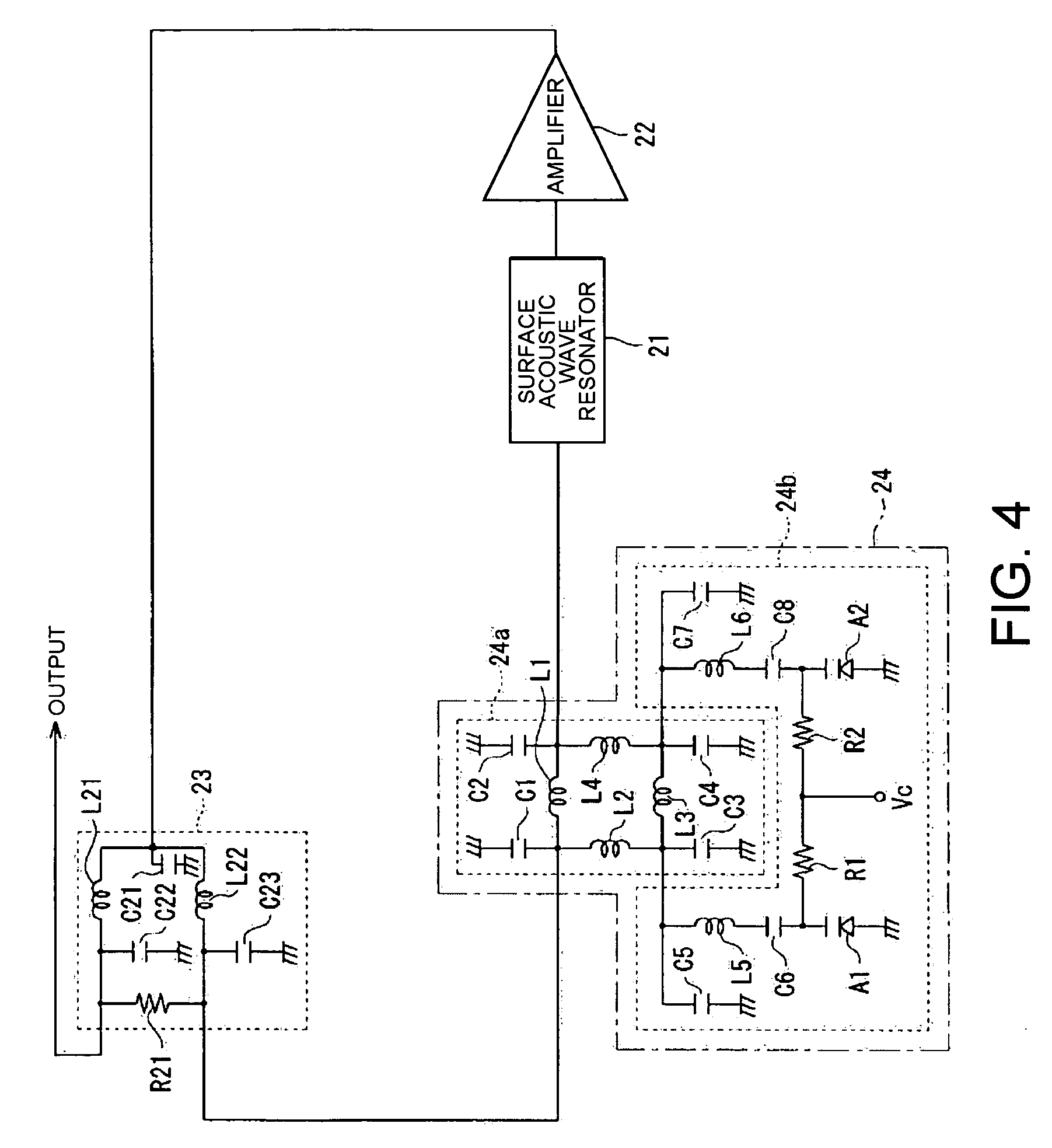

High-frequency heating device, semiconductor manufacturing device, and light source device

InactiveUS20060081624A1Suppression of unwanted emissionReduce adverse effectsMultiple-port networksElectric discharge tubesAudio power amplifierReflected waves

A high-frequency heating device including: a solid-state oscillator that generates a microwave; an amplifier that amplifies the microwave generated by the solid-state oscillator; an isolator that is connected to a stage subsequent to the amplifier and blocks a reflected wave directed from an object exposed with the microwave; an antenna that irradiates the microwave toward the object; and a metal cavity that traps therein the microwave irradiated to the object.

Owner:SEIKO EPSON CORP

Downhole filter

InactiveUS7188687B2Without complexityWithout expenseDrilling rodsConstructionsParticulatesEngineering

A downhole filter comprises a tubular member having a wall defining a plurality of openings. The openings have an outer width less than an inner width. The parts of the opening defining the smaller width are defined by radially outer parts of the openings, such that particulates or sand prevented from passing through the openings will tend to be retained to the outside of the tubular member. A method comprises providing a tubular string having a non-porous tubular portion and a porous tubular portion, and installing the tubular string within a wellbore such that the porous tubular portion is located adjacent a fluid-producing formation within the wellbore. In another embodiment, an apparatus comprises a drill string comprising a non-porous tubular portion and a porous tubular portion, and an earth removal member operatively connected to a lower end of the drill string.

Owner:WEATHERFORD TECH HLDG LLC

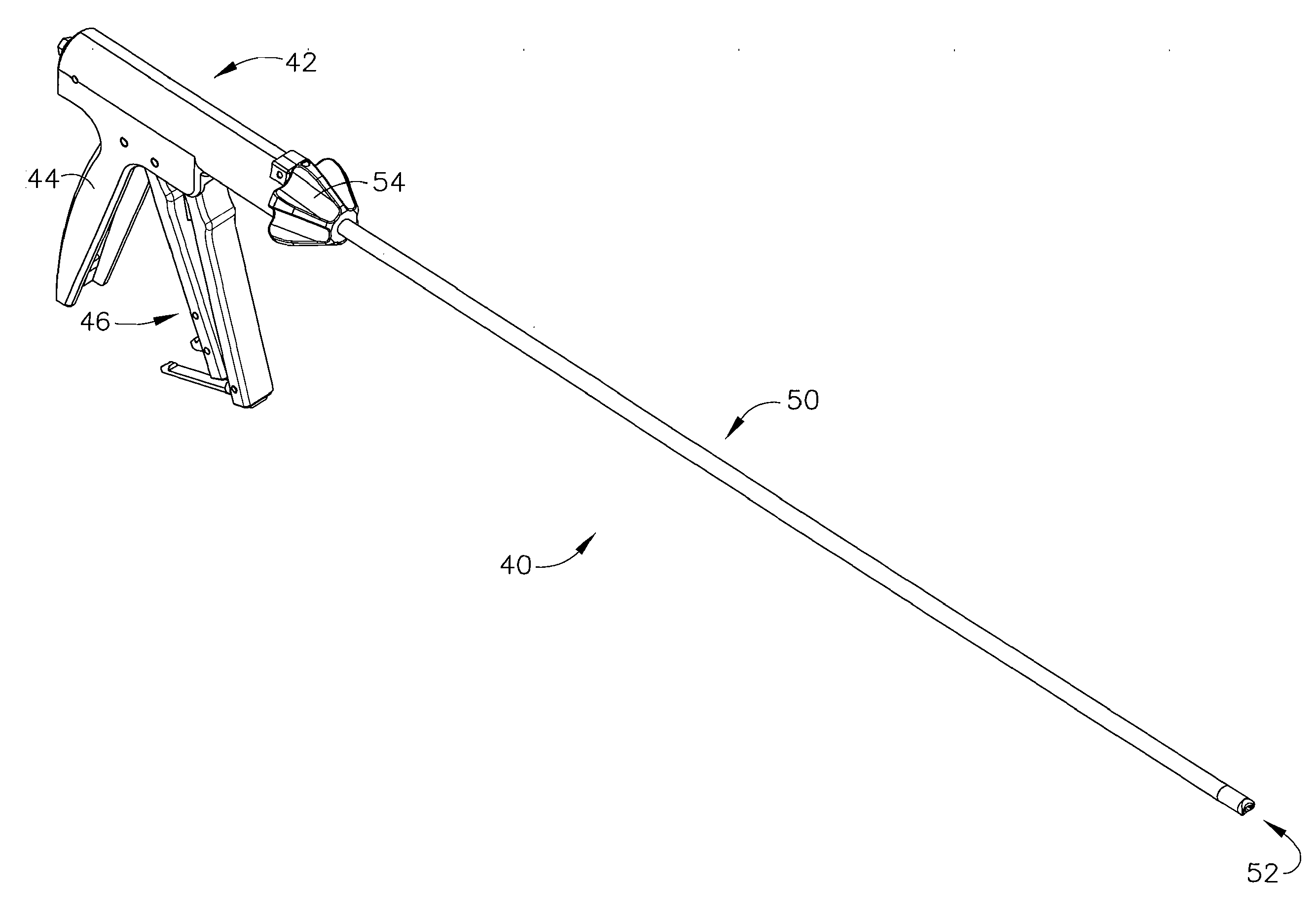

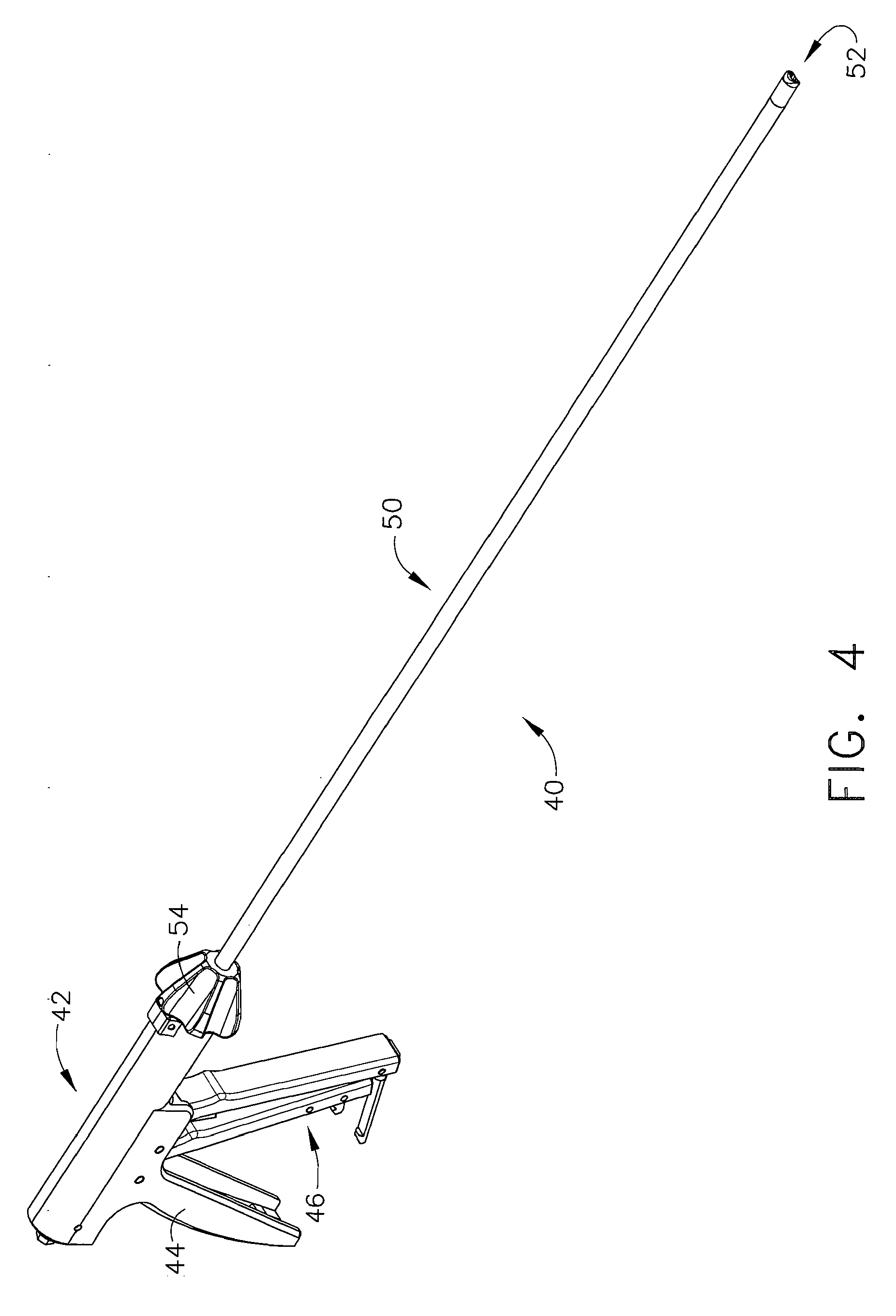

Surgical Stapler For Applying A Large Staple Through A Small Delivery Port And A Method of Using The Stapler To Secure A Tissue Fold

ActiveUS20100191282A1Small shapeHigh strengthSuture equipmentsStapling toolsBiomedical engineeringSurgical Staplers

A method of deploying a surgical fastener into a patient by introducing the fastener into a body of a patient while the fastener is in a first shape having a first loop with a back span and an original size and shape. The method then involves moving end segments of the fastener away from each other substantially along an entire length thereof while keeping the back span in substantially its original size and shape. The method then involves forming the fastener into a second loop having a width greater than a width of the first loop.

Owner:ETHICON ENDO SURGERY INC

Method for locating, measuring, and evaluating the enlargement of a foramen

A method for locating, measuring and evaluating the enlargement of a foramen are provided. An instrument has a handle, an angled region, and a tip to be inserted into the foramen. An instrument can be pressed onto the foramen to determine its location and whether the empty space within the foramen is large enough for the maximum width of the tip to be inserted. If the tip cannot insert, the foramen can be cut to enlarge it enough for the tip to insert. A kit of several instruments or a single instrument with tips of different maximum widths are provided for determining the amount of empty space within the foramen through the course of the enlargement.

Owner:AEOLIN

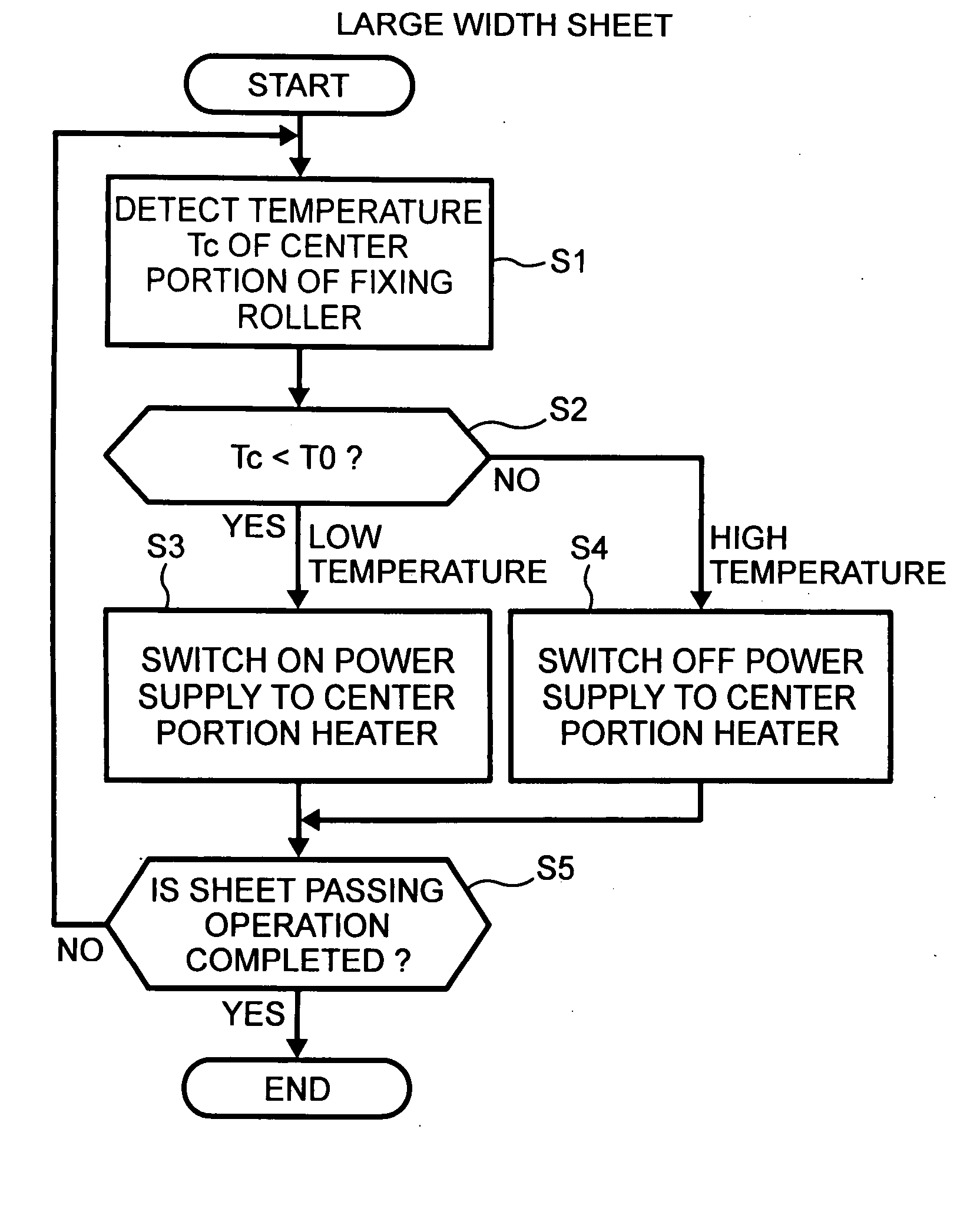

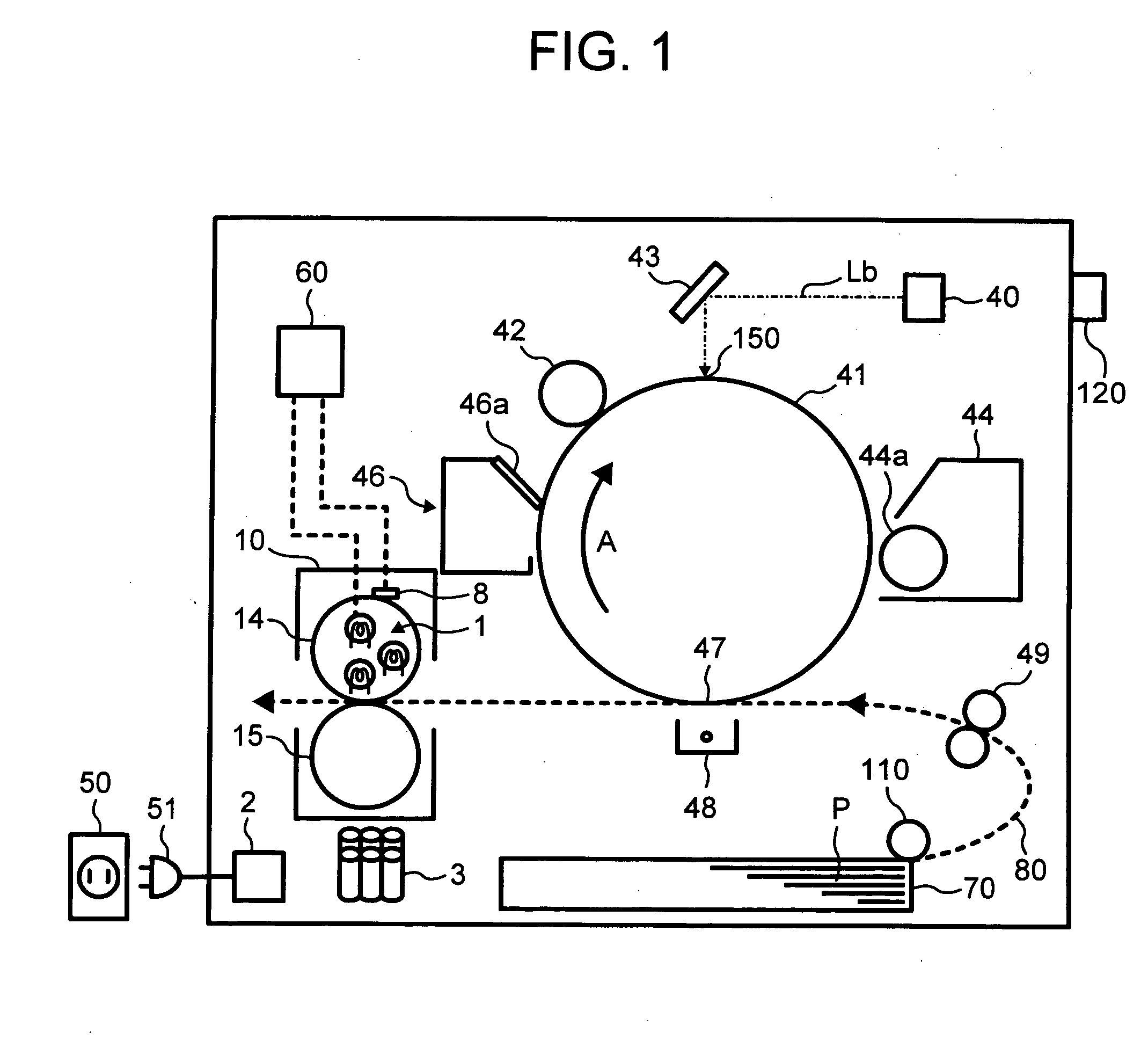

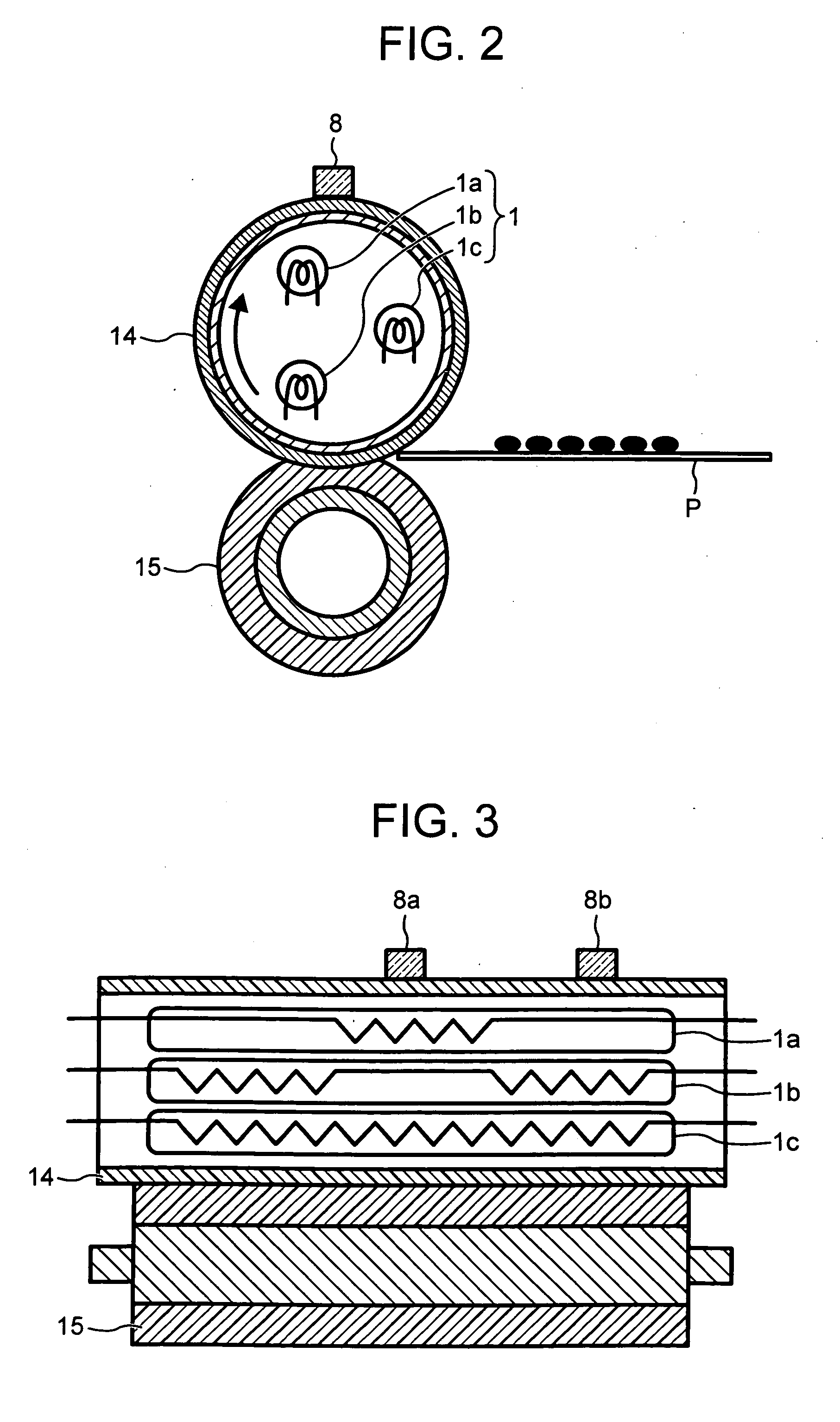

Fixing device, image forming apparatus including the fixing device, and fixing method

ActiveUS20060051120A1Large widthSmall widthElectrographic process apparatusTemperature controlImage formation

A fixing device for fixing an image formed on a recording material includes first and second rotary members having a nip part therebetween, a heating part that heats the first rotary member, a center portion temperature detecting unit that detects a temperature of a center portion of the first rotary member, and an end portion temperature detecting unit that detects a temperature of an end portion of the first rotary member. When recording materials each having a relatively large width consecutively pass through the nip part, a control unit controls a heating amount of a full width heating member based on the temperature detected by the center portion temperature detecting unit, and when recording materials each having a relatively small width consecutively pass through the nip part, the control unit controls the heating amount of the full width heating member based on the temperature detected by the end portion temperature detecting unit.

Owner:RICOH KK

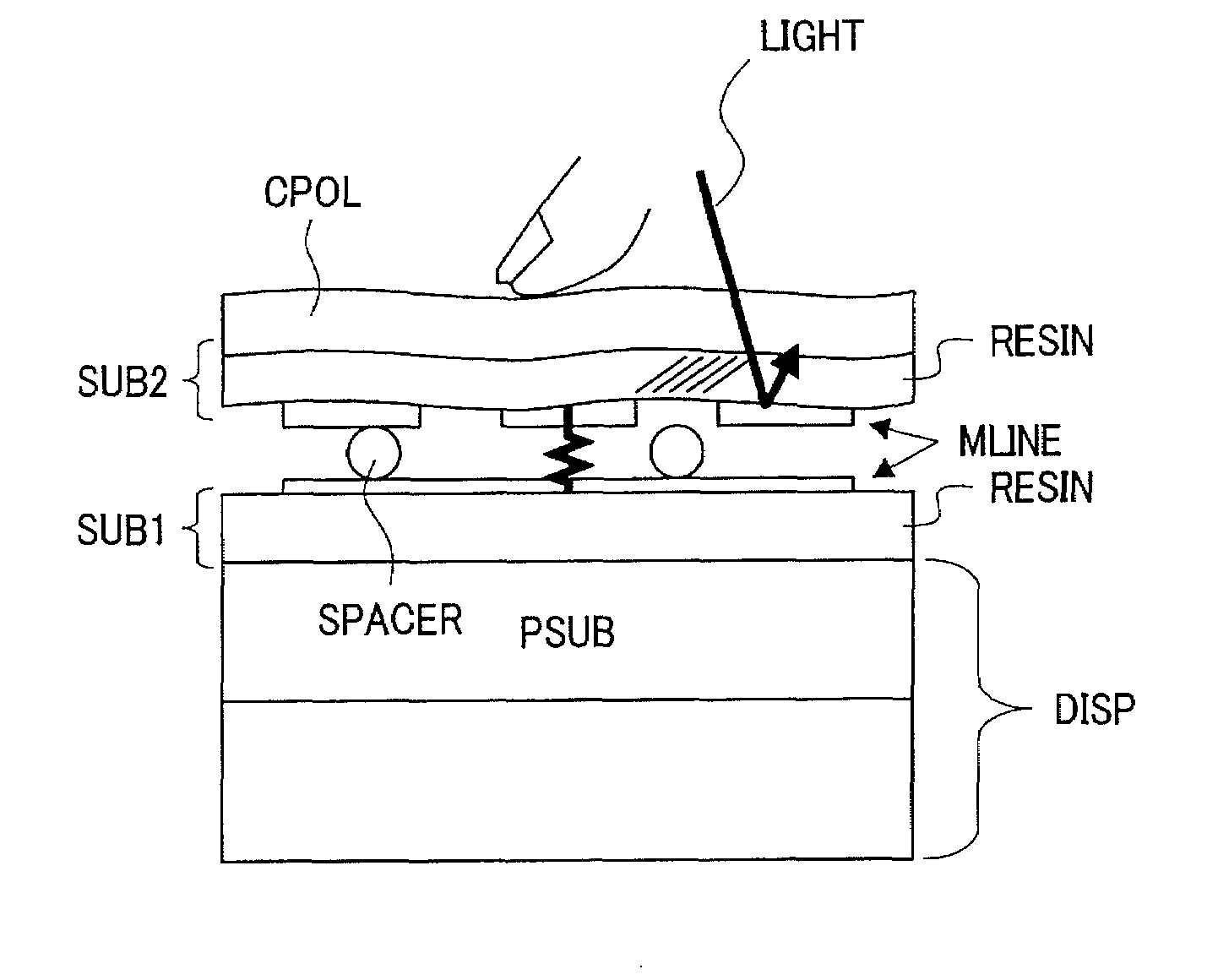

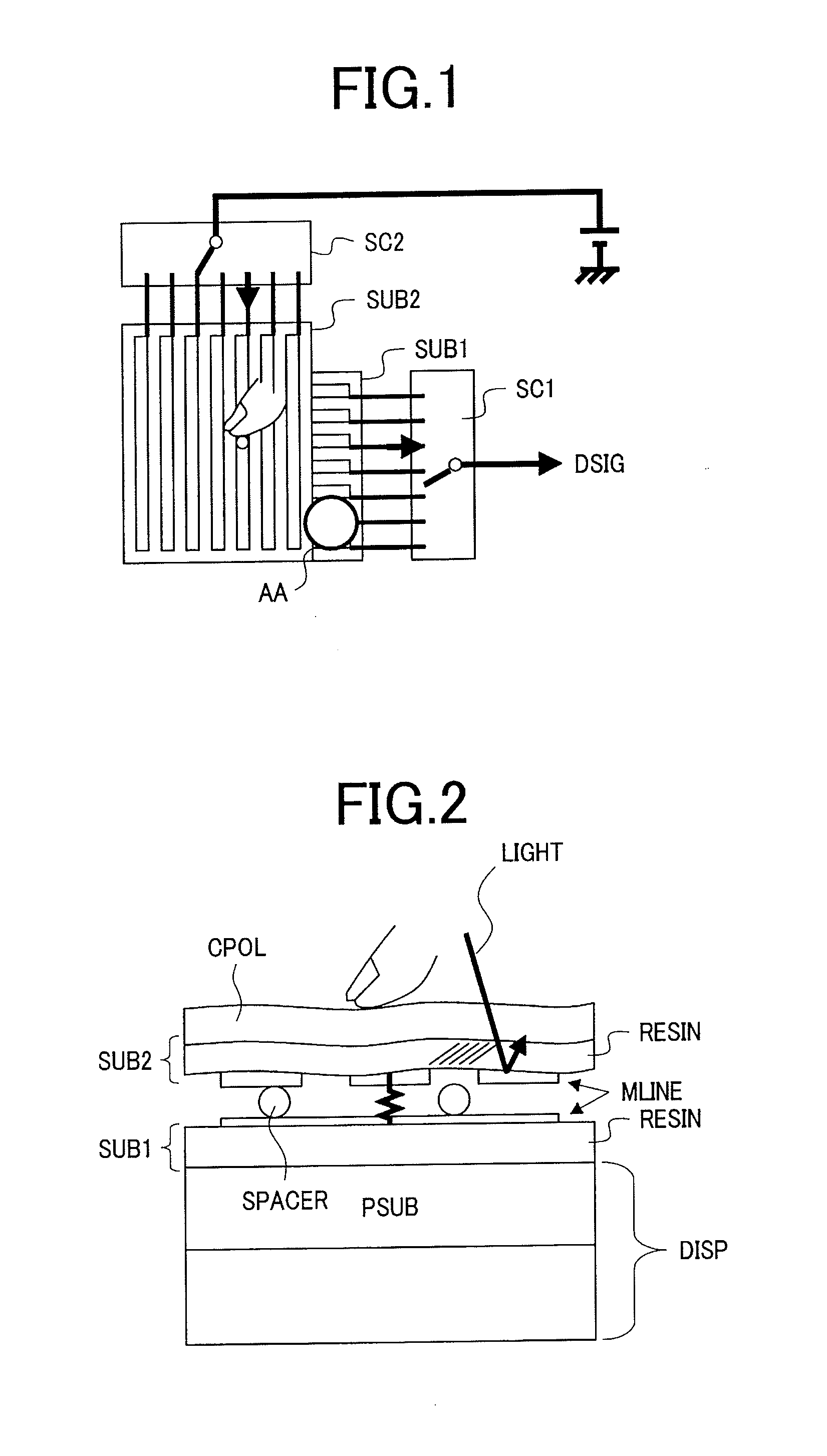

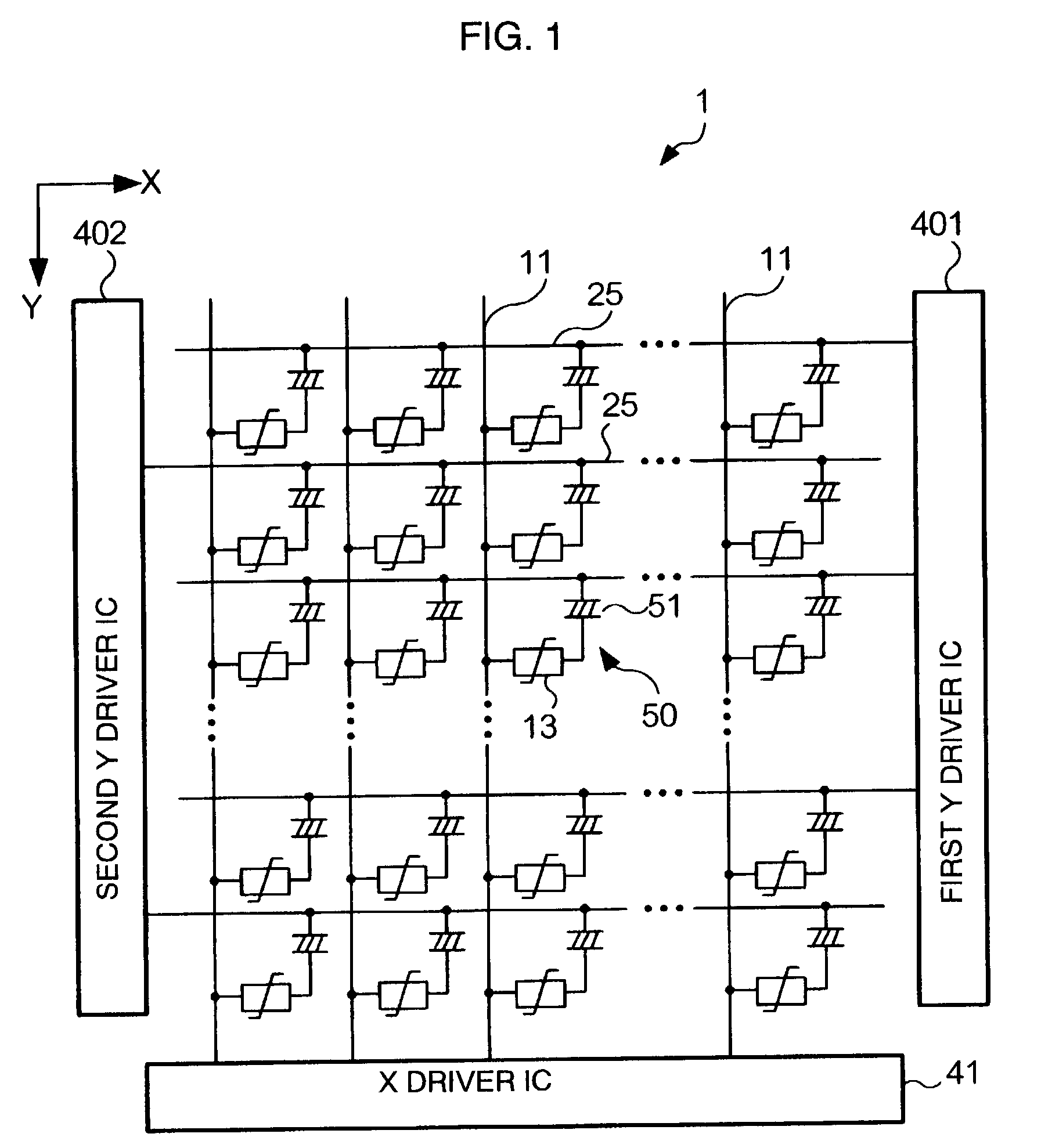

Display Device with Touch Panel

InactiveUS20080303798A1Improve accuracySuppress ambient light reflectionInput/output processes for data processingDisplay deviceEngineering

Suggested is a display device with a touch panel which adopts a novel detection structure. The display device with the touch panel includes: a touch panel including a pair of substrates provided with electrodes on opposing surfaces thereof, and a spacer for retaining a gap between the pair of substrates; and a display panel located on a back surface of the touch panel, in which one of the pair of substrates is provided with a metal wiring formed on a resin.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

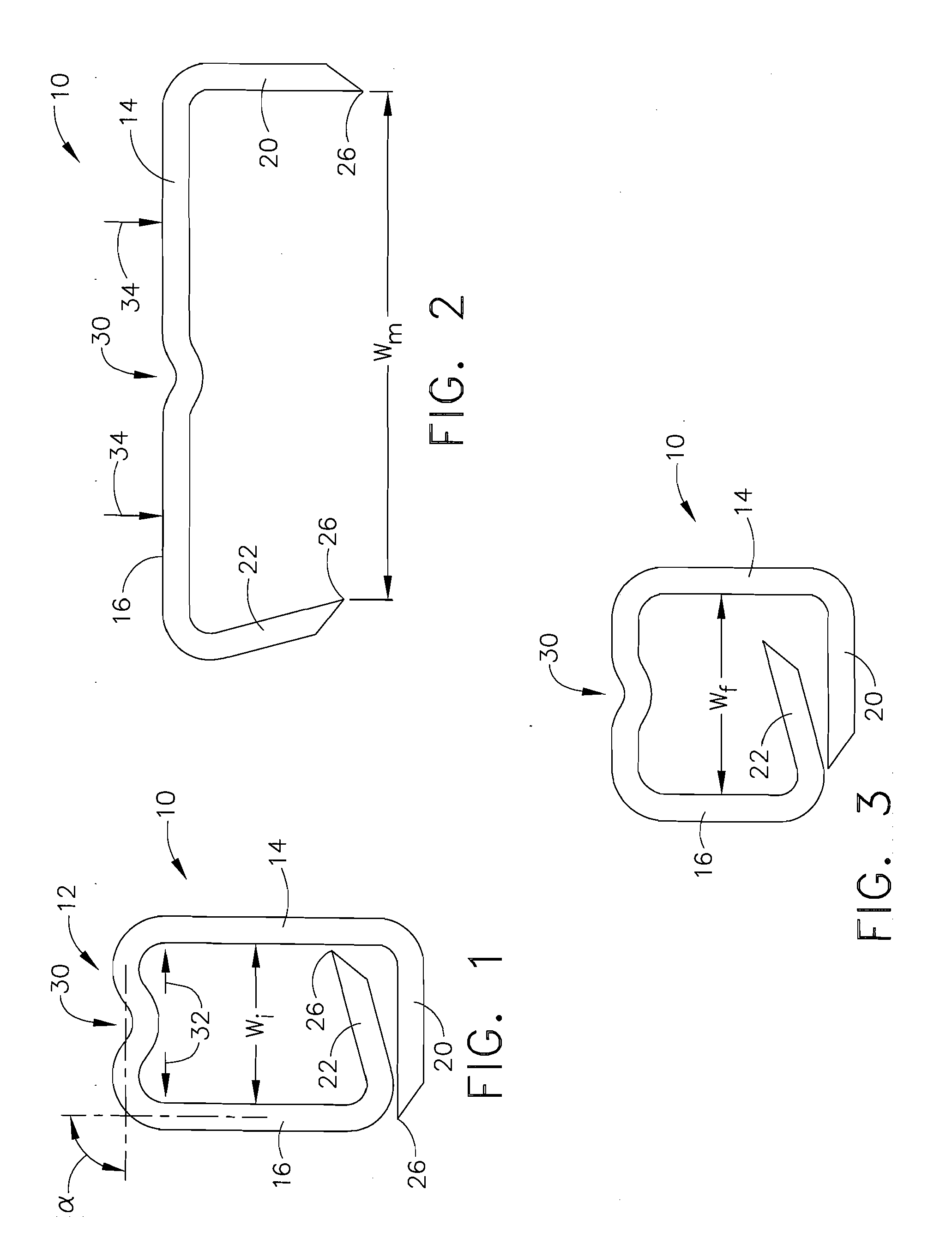

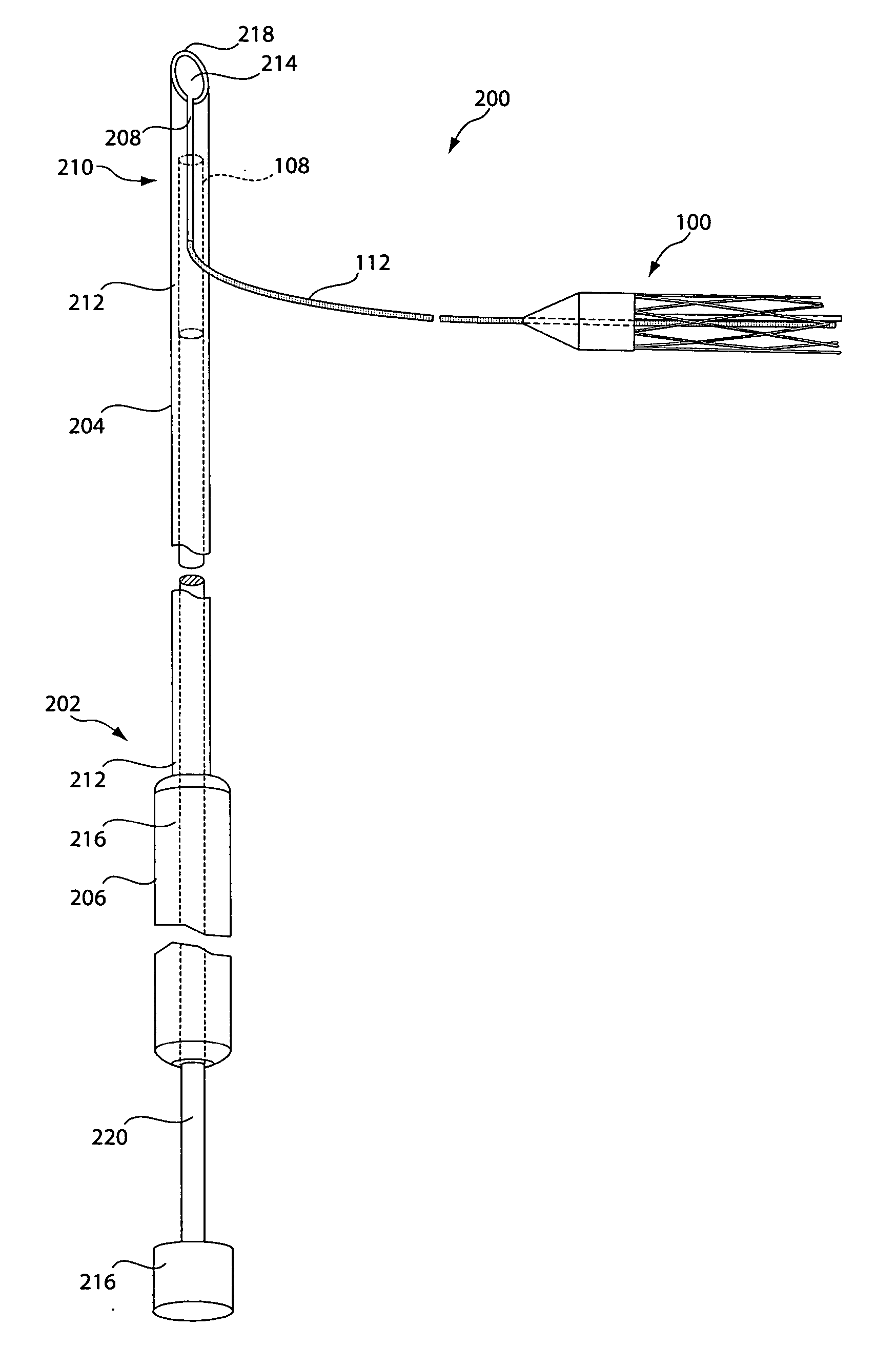

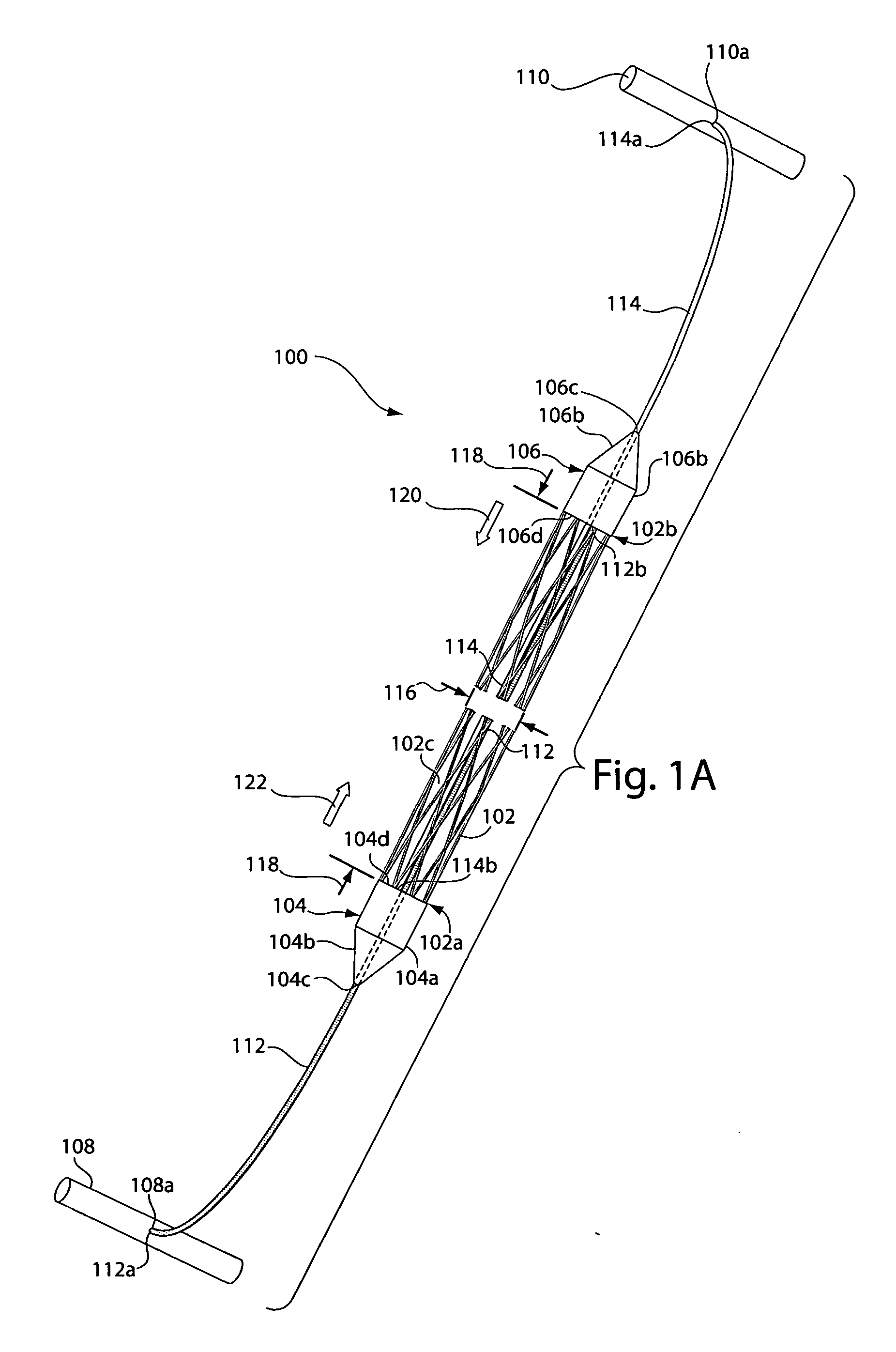

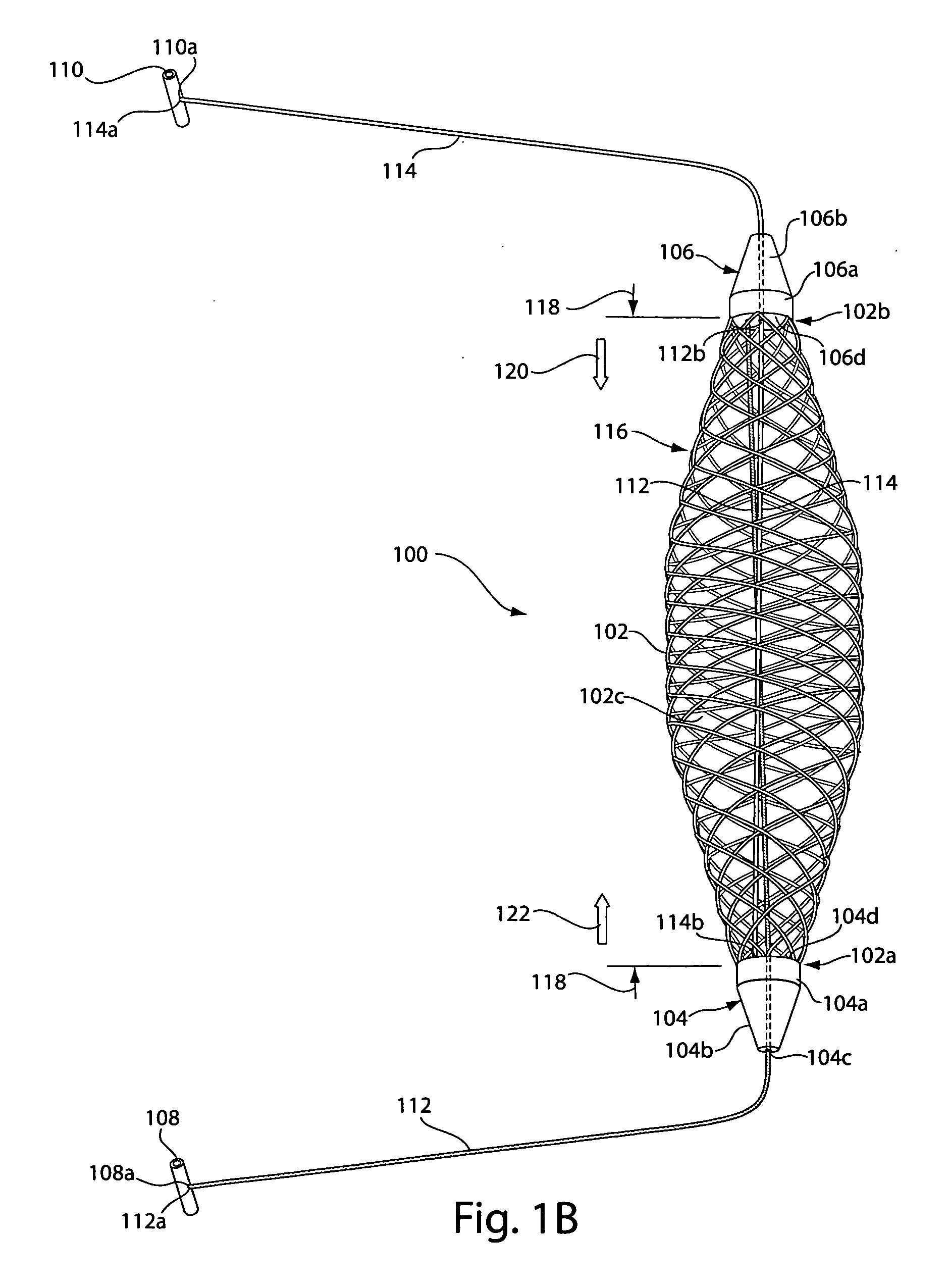

Tubular implantable sling and related delivery systems, methods and devices

ActiveUS20070038017A1Large widthIncrease the lengthSuture equipmentsAnti-incontinence devicesMedicineBiomedical engineering

Owner:BOSTON SCI SCIMED INC

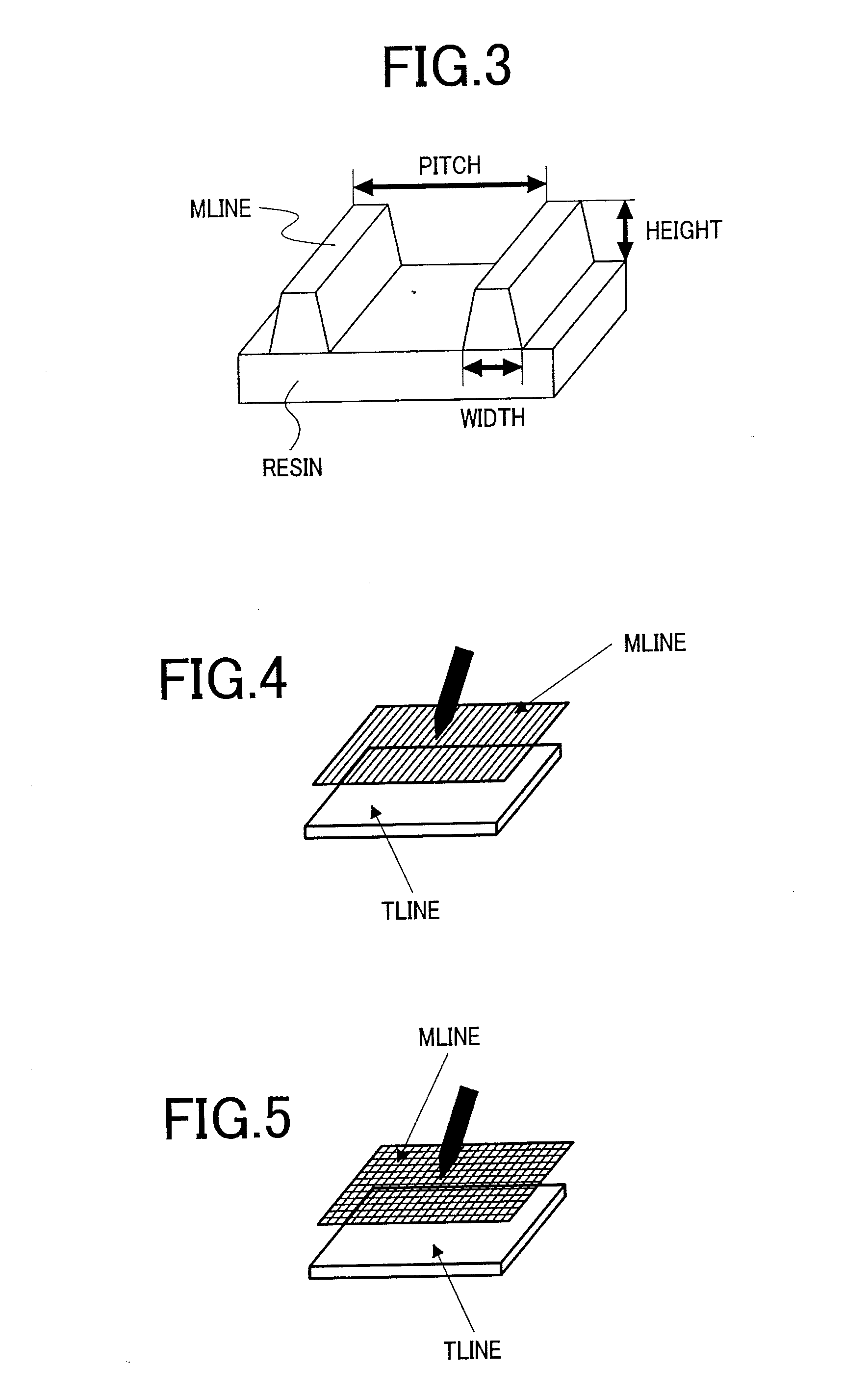

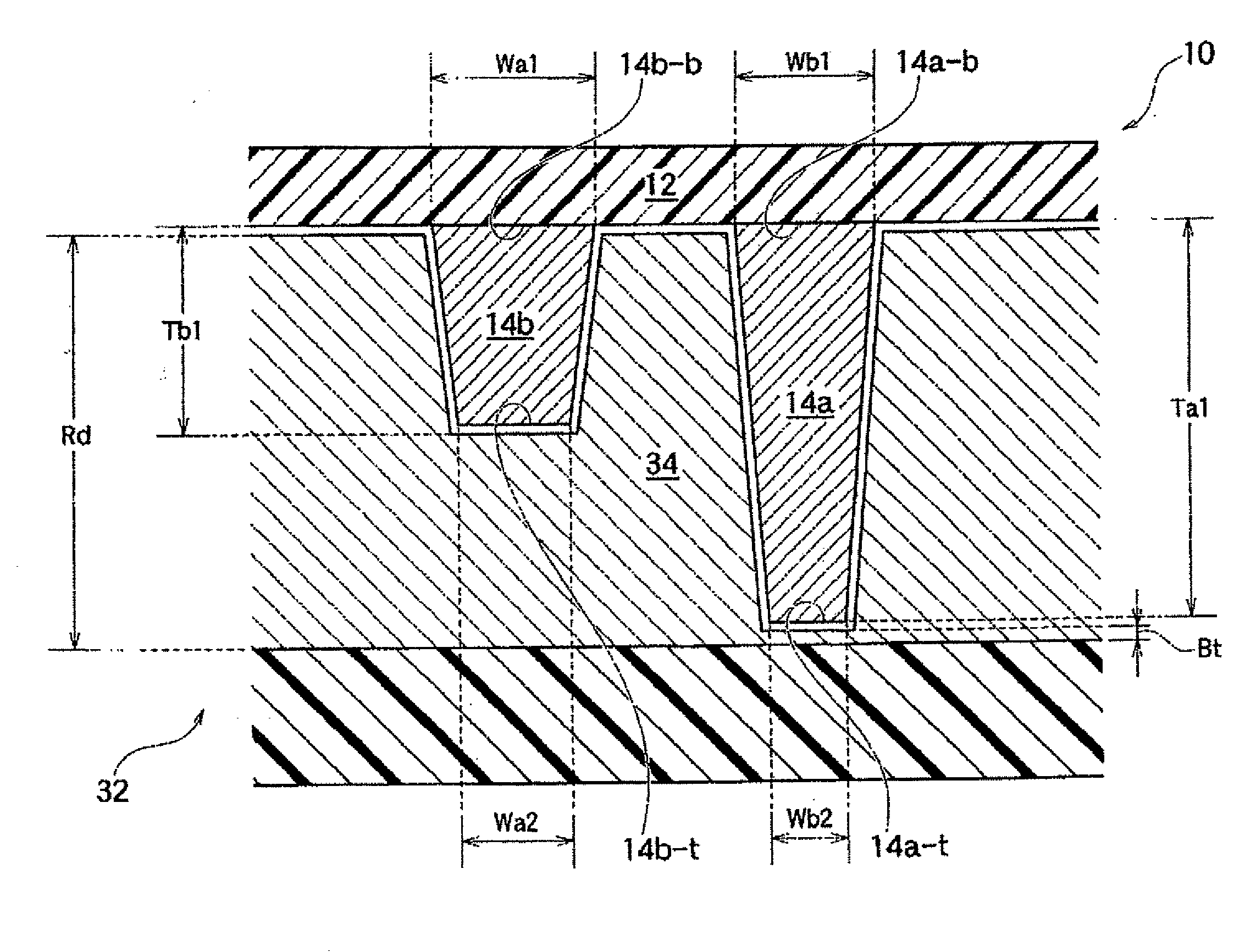

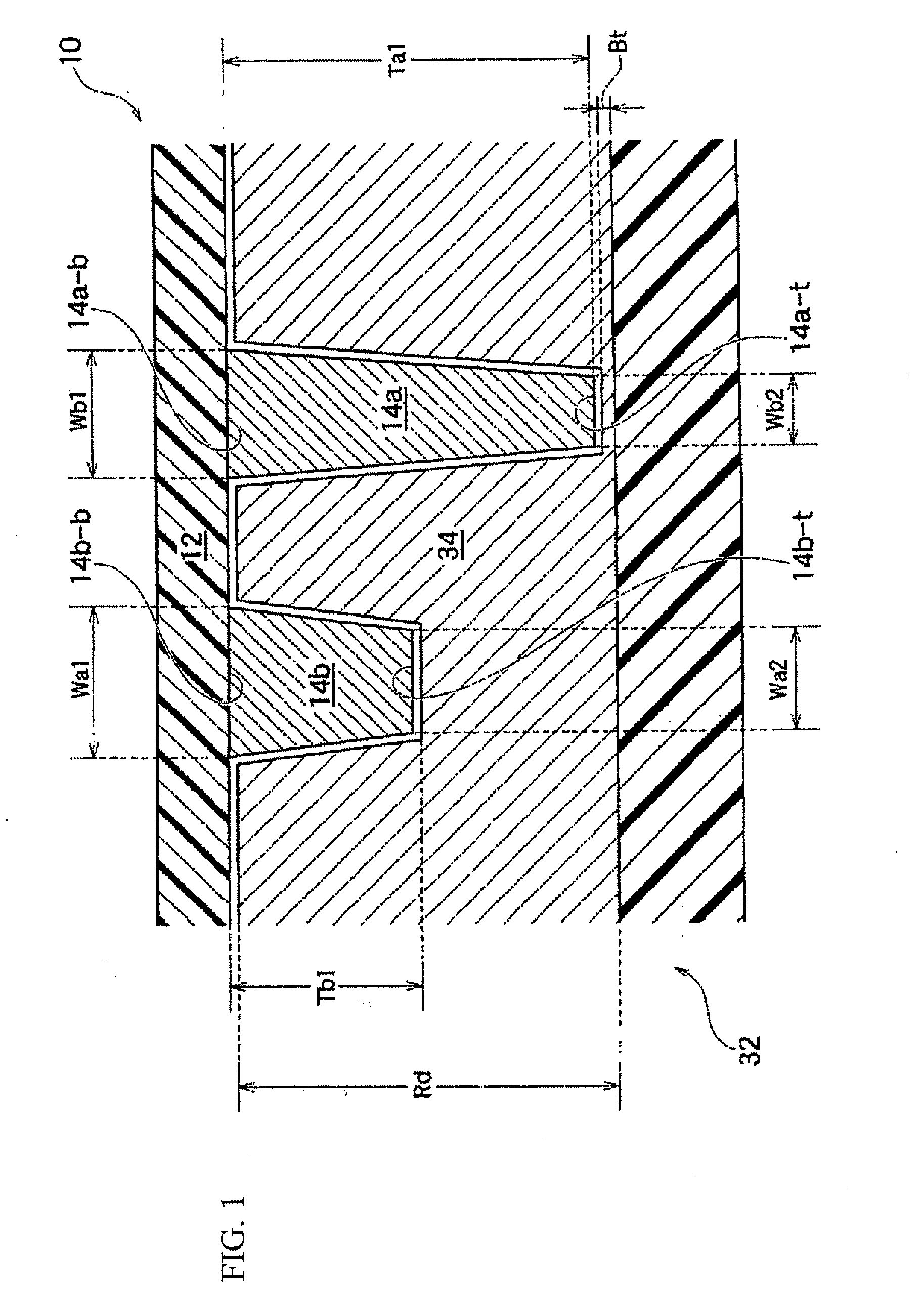

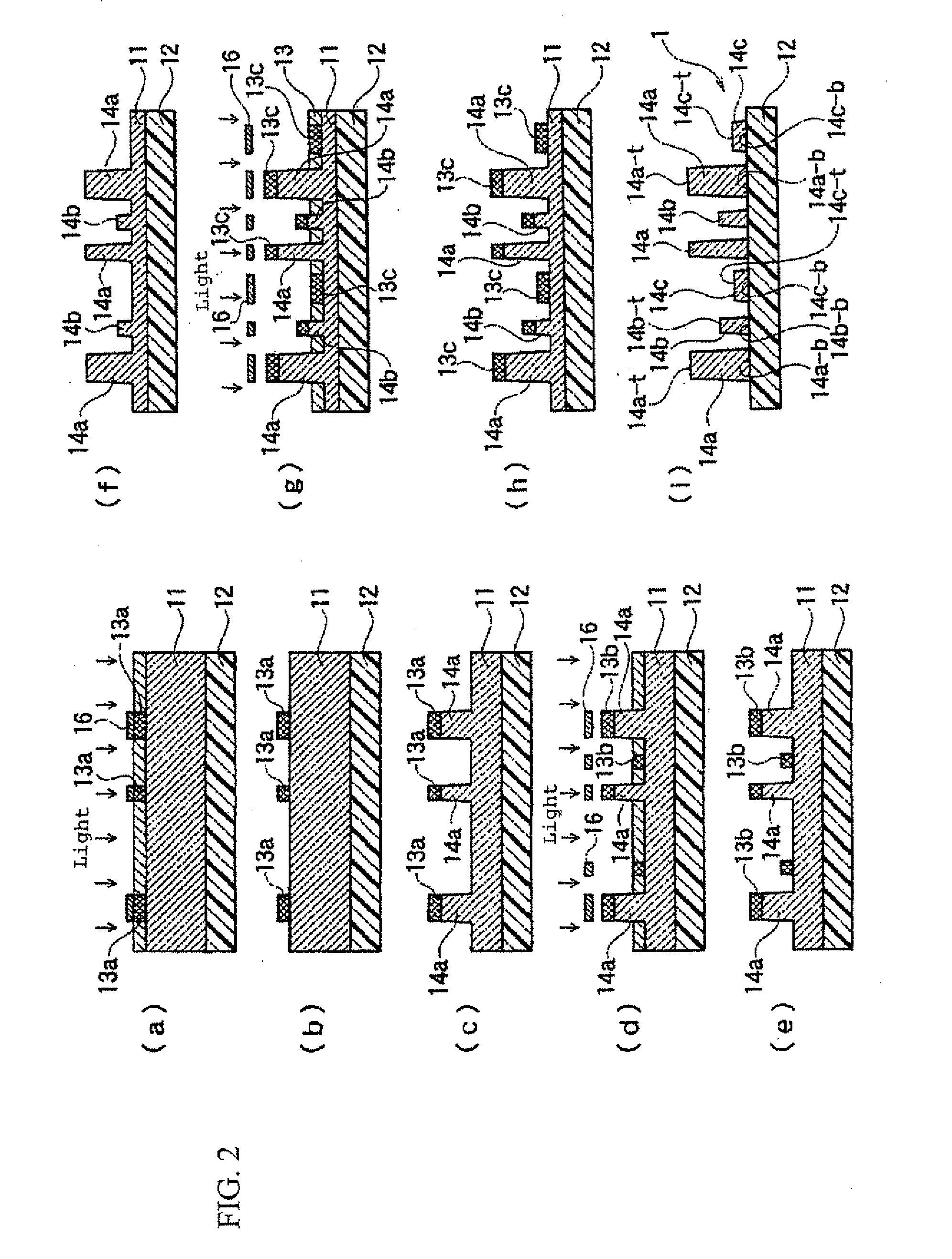

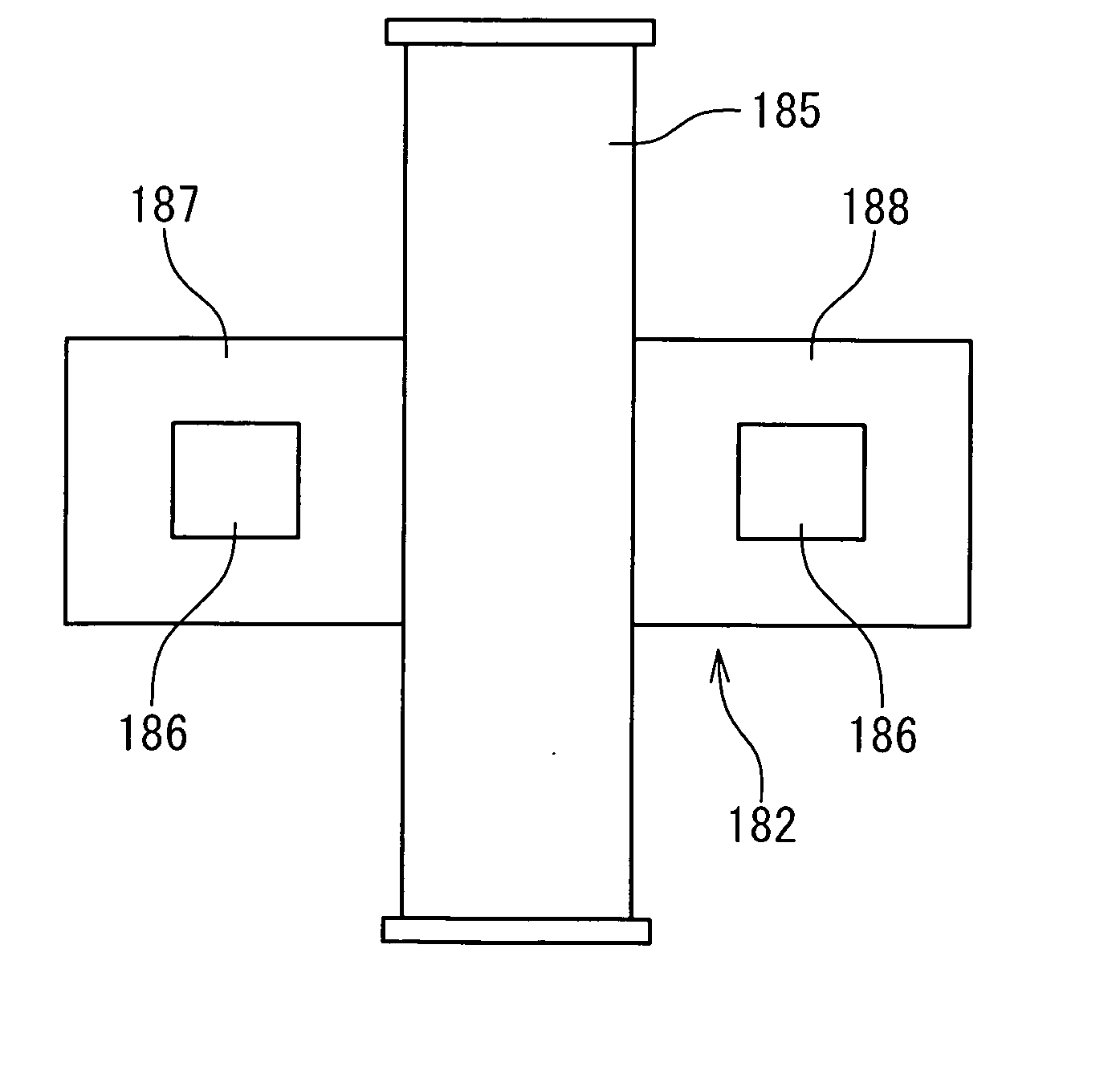

Mold for Wiring Substrate Formation and Process for Producing the Same, Wiring Substrate and Process for Producing the Same, Process for Producing Multilayered Laminated Wiring Substrate and Method for Viahole Formation

InactiveUS20090314525A1Large widthFacilitated releaseContact member manufacturingTransparent dielectricsEngineeringMultiple layer

A process for producing a wiring board is provided, comprising allowing a wiring board-forming mold, which comprises a support base and a mold pattern that is formed in a protruded shape on one surface of the support base wherein the sectional width of the mold pattern on the support base side is larger than the sectional width thereof on the tip side in the same section of the mold pattern, to penetrate into a curing resin layer to transfer the mold pattern, curing the curing resin layer, releasing the laminate from the mold, depositing a conductive metal, and polishing the deposited metal layer that to form a depressed wiring pattern, and a wiring board produced by this process. Further, described is a process for producing a wiring board, comprising bringing a precision mold having a mold pattern on a surface of a mold base into contact with a surface of a metal thin film formed on an organic insulating base, pressing the mold to form a depression having a shape corresponding to the mold pattern of the precision mold in the organic insulating base, thereafter forming a metal plating layer having a thickness larger than the depth of the depression to fill the plating metal in the depression, and then polishing the metal plating layer until the organic insulating base is exposed, to form a wiring pattern, and a wiring pattern produced by this process.

Owner:MITSUI MINING & SMELTING CO LTD

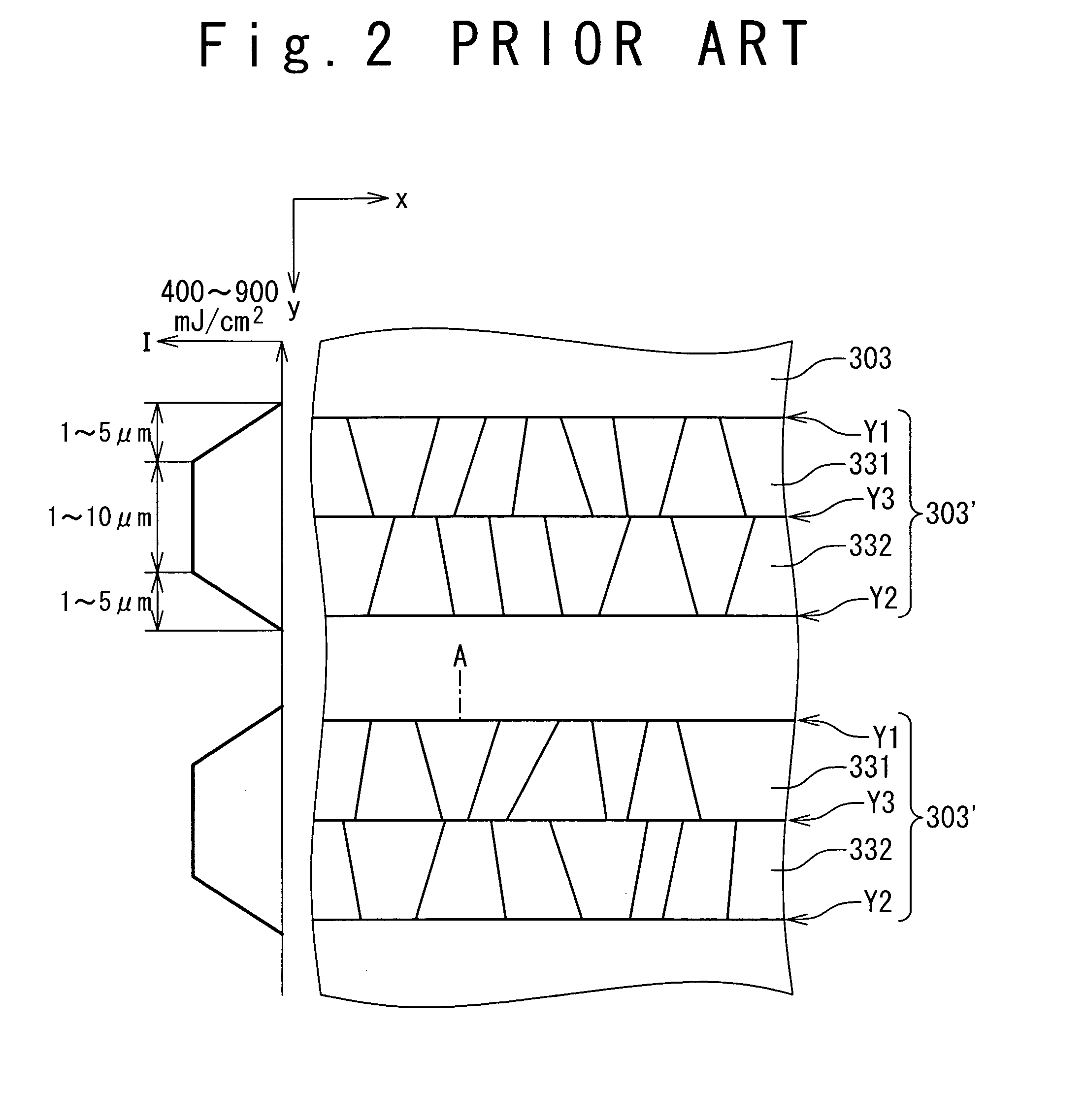

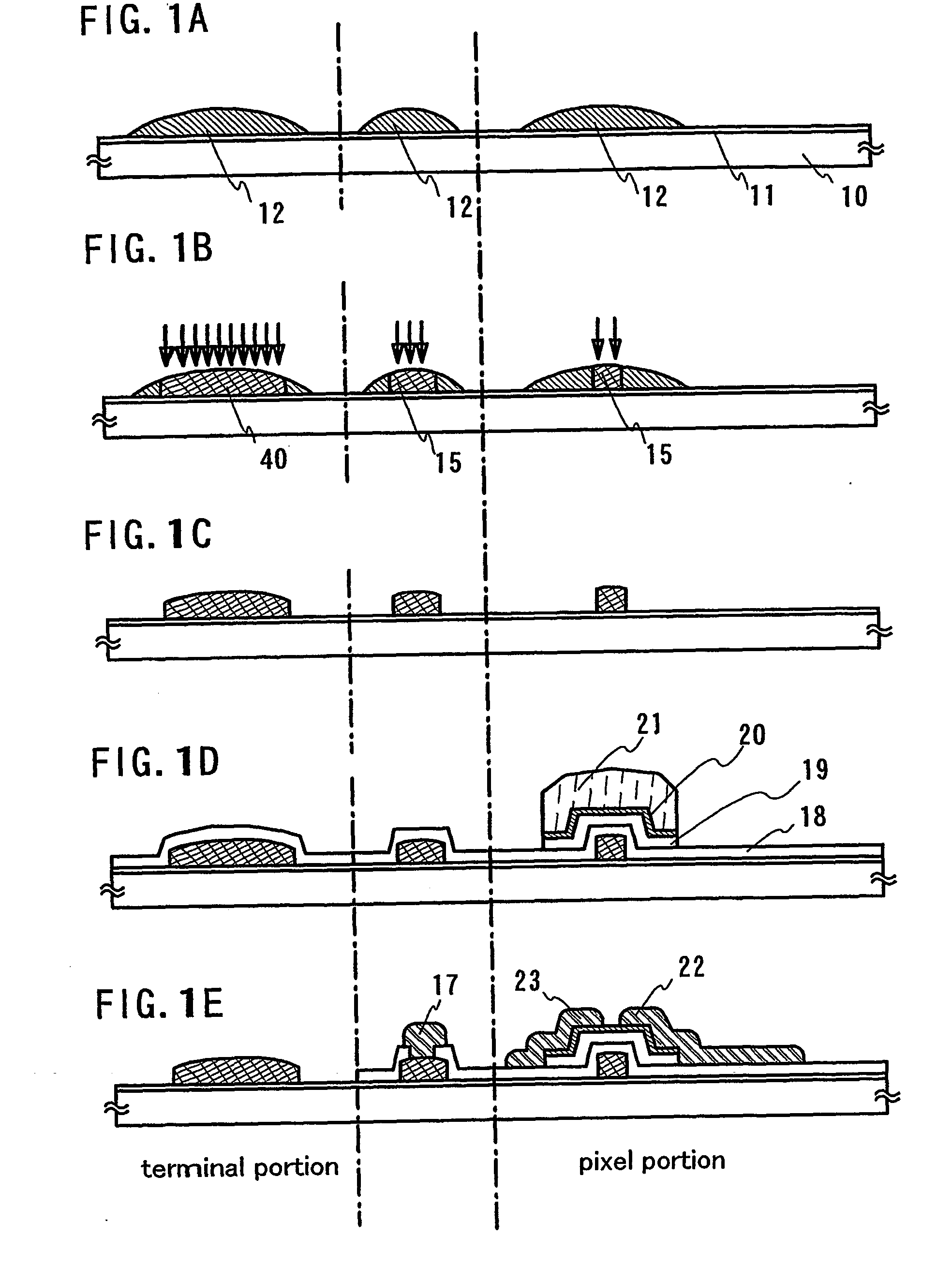

Method of and apparatus for manufacturing semiconductor thin film, and method of manufacturing thin film transistor

InactiveUS20050003591A1Reduce numberControl positionTransistorFrom gel stateAmorphous semiconductorsSemiconductor

A method of manufacturing a semiconductor thin film includes (A) forming an amorphous semiconductor film on a substrate, (B) irradiating a beam to a surface of the amorphous semiconductor film such that a predetermined region of the amorphous semiconductor film is melted and solidified to form a crystallized semiconductor film, and (C) scanning the beam in a first direction. A second direction is a direction on the surface of the amorphous semiconductor film perpendicular to the first direction. A length along the second direction of a cross section of the beam is substantially equal to or less than two times a width along the second direction of the crystallized semiconductor film.

Owner:VISTA PEAK VENTURES LLC

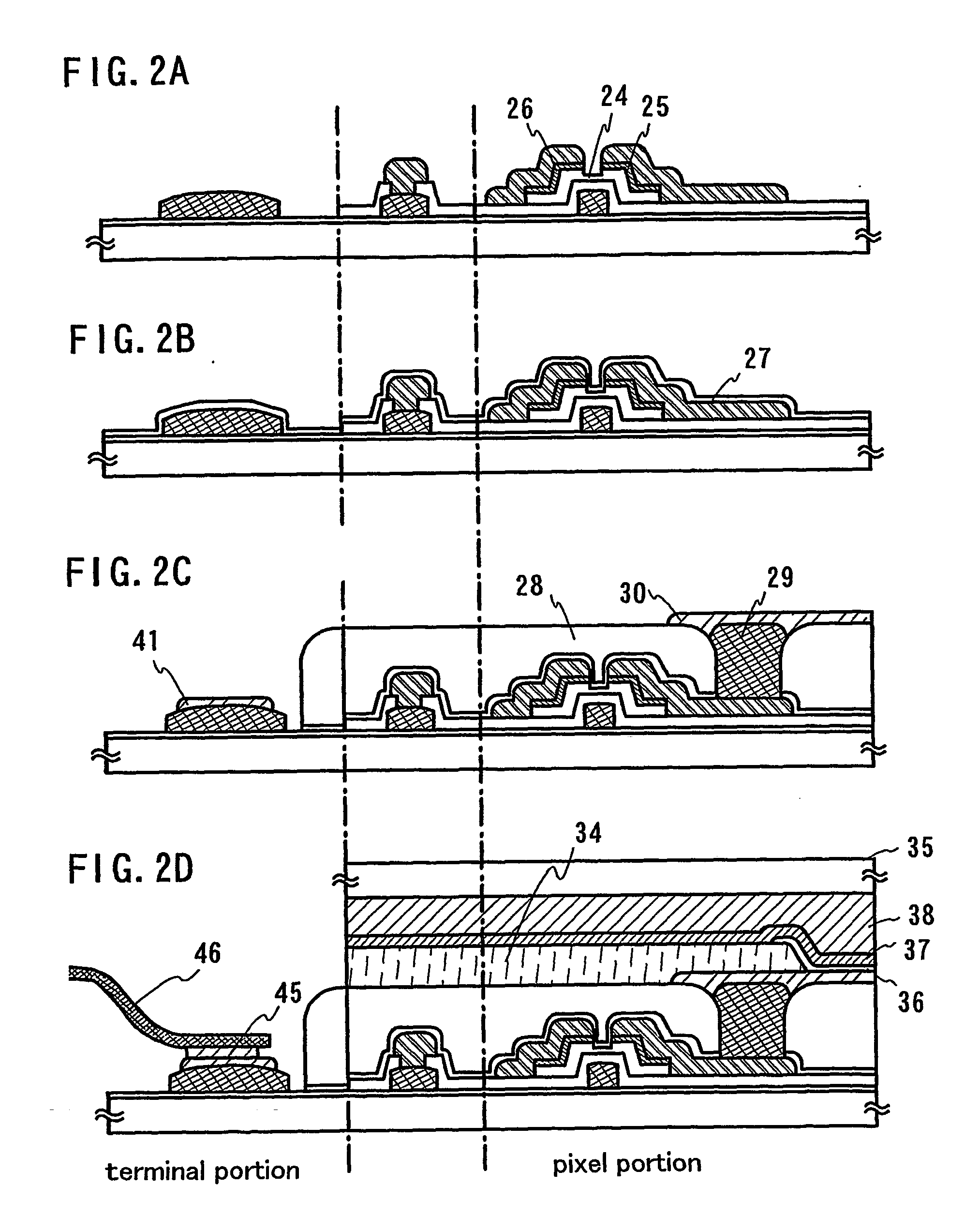

Electric appliance, semiconductor device, and method for manufacturing the same

InactiveUS20070093002A1Reduce drastically costReduce material usageTransistorElectroluminescent light sourcesDevice materialConductive materials

In the present circumstances, a film formation method of using spin coating in a manufacturing process is heavily used. As increasing the substrate size in future, the film formation method of using spin coating becomes at a disadvantage in mass production since a mechanism for rotating a large substrate becomes large, and there is many loss of material solution or waste liquid. According to the present invention, in a manufacturing process of a semiconductor device, a microscopic wiring pattern can be realized by delivering selectively photosensitive conductive material solution by droplet discharging, exposing selectively to laser light or the like, and developing. The present invention can reduce drastically costs since a patterning process can be shortened and an amount of material in a process of forming a conductive pattern can be reduced. Accordingly, the present invention can be applied to manufacture a large substrate.

Owner:SEMICON ENERGY LAB CO LTD

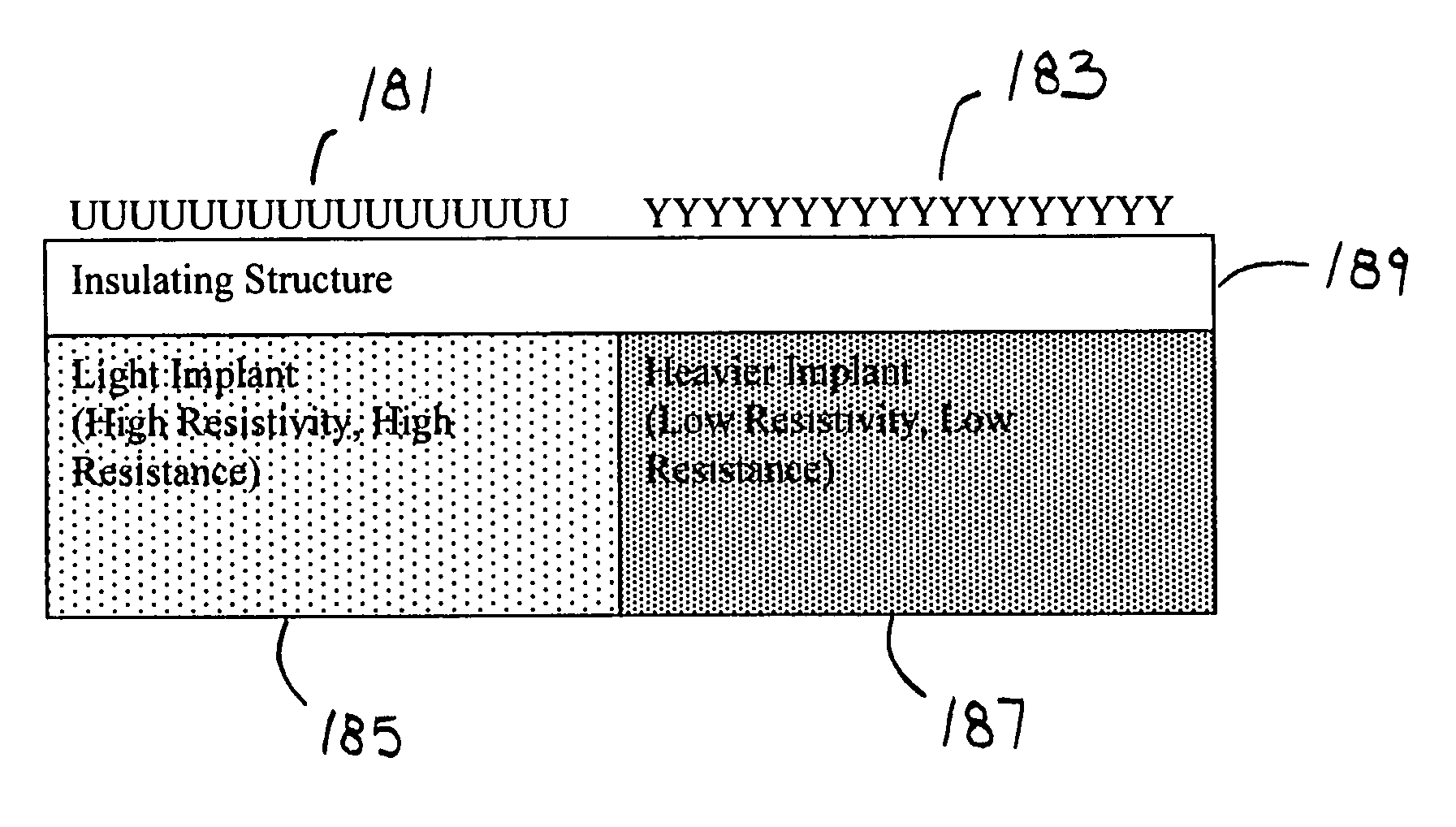

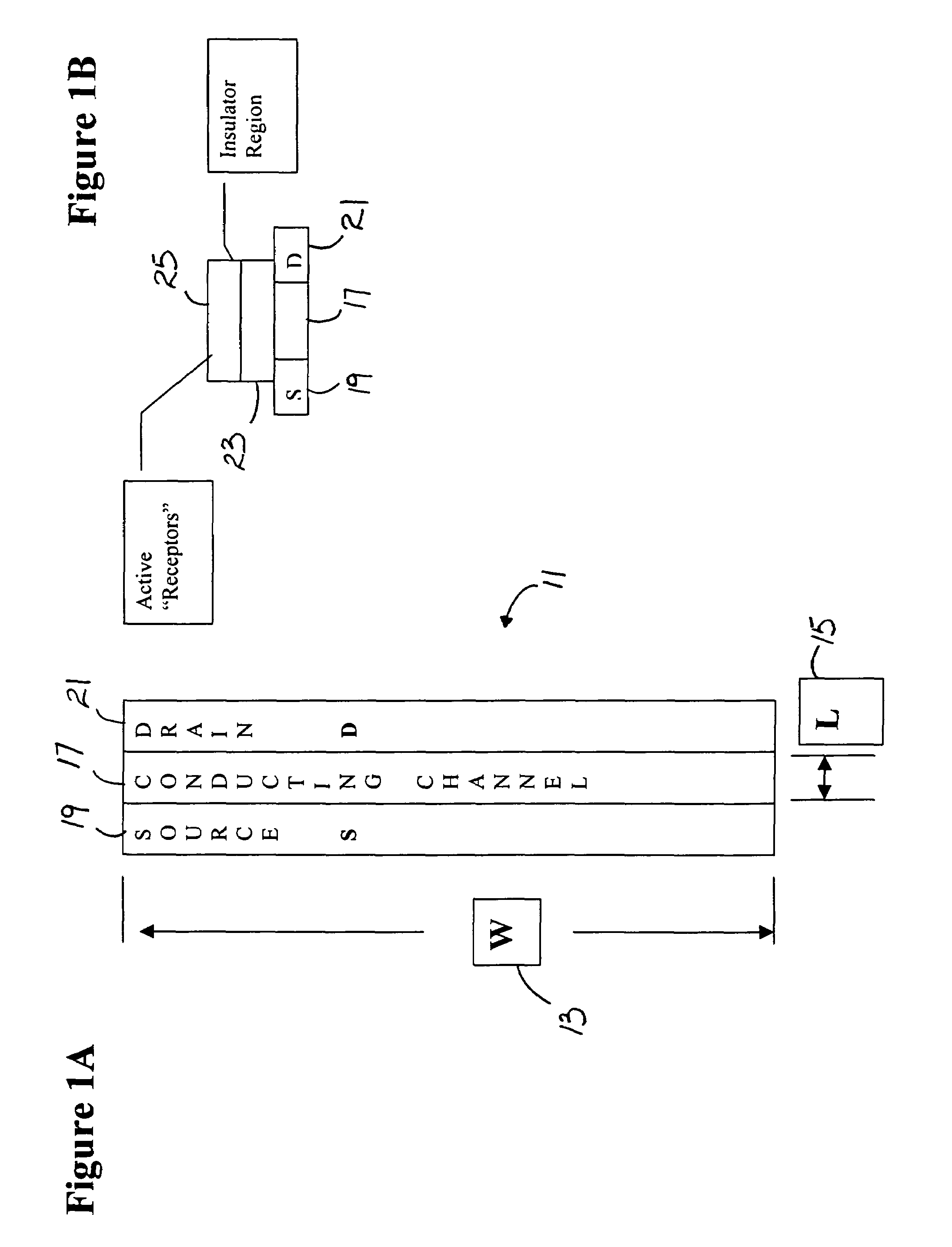

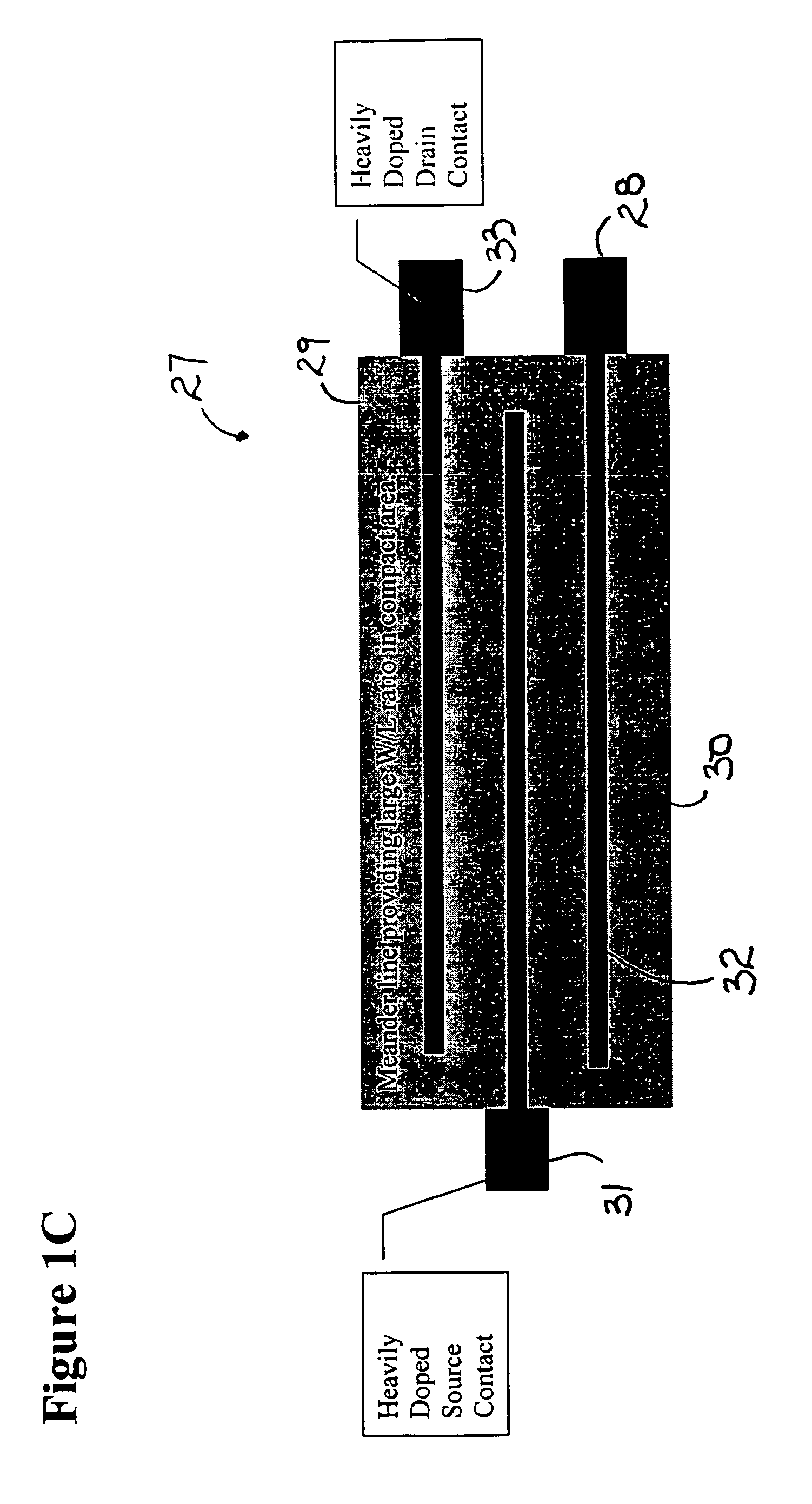

Ultrasensitive biosensors

ActiveUS7692219B1Reduce sensitivityHigh sensitivityMicrobiological testing/measurementNanoinformaticsEngineeringConducting channel

The present invention is a biosensor apparatus that includes a substrate, a source on one side of the substrate, a drain spaced from the source, a conducting channel between the source and the drain, an insulator region, and receptors on a gate region for receiving target material. The receptors are contacted for changing current flow between the source and the drain. The source and the drain are relatively wide compared to length between the source and the drain through the conducting channel.

Owner:UNIV OF HAWAII

Liquid crystal panel, manufacturing method therefor, and electronic equipment

InactiveUS20030053022A1Reliable conductionEasy to manufactureNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal panel 1 has a configuration in which an element substrate 10 including routing wiring 16 and a counter substrate 20 including scanning lines 25 are adhered with a sealing material 30 therebetween and, in addition, a liquid crystal is injected between both substrates through a liquid crystal injection hole 30a formed in the sealing material 30. The scanning lines 25 are brought into conduction with the routing wiring 16 through conducting particles 32 dispersed in the sealing material 30. However, the scanning lines 25, which have end portions reaching the neighborhood of the liquid crystal injection hole 30a, among the plurality of scanning lines 25, are brought into conduction with the routing wiring 16 through conducting particles 32 dispersed in a vertical conduction portion 37 or through the conducting particles 32 in both the sealing material 30 and the vertical conduction portion 37.

Owner:SEIKO EPSON CORP

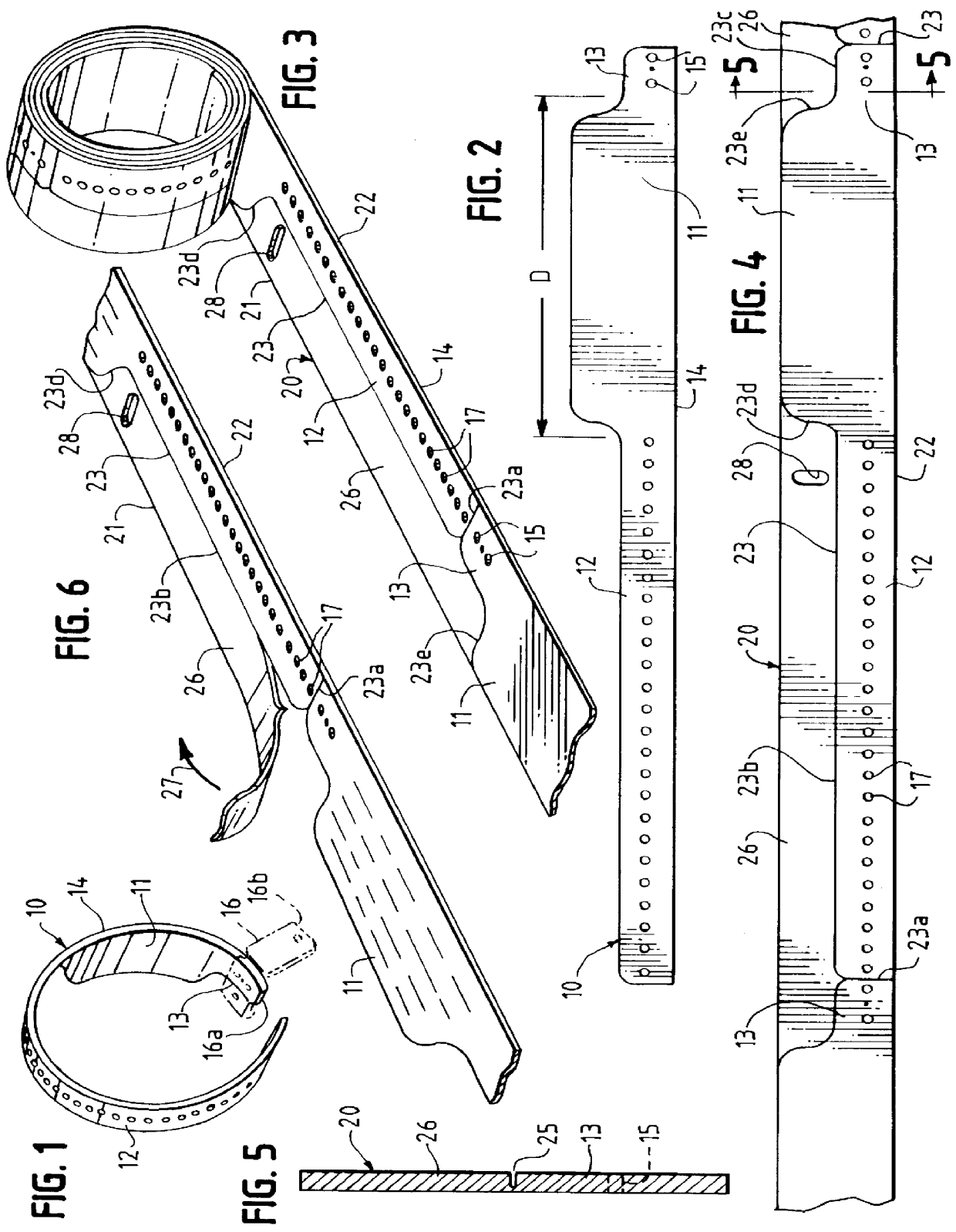

Imprintable tape with tear lines defining asymmetrical identification bracelets

InactiveUS6058637ADisadvantage be eliminatedEasy to masterStampsPerson identificationEngineeringWeakness

A machine-imprintable tape, most advantageously provided in roll or coil form, is disclosed. The tape has lines of weakness constituting tear lines that define a longitudinal series of asymmetric identification bracelets, each bracelet having a generally rectangular imprintable portion, an elongated strap portion at one end of the imprintable portion, and a connecting tab portion at the opposite end of the imprintable portion. The imprintable portion has a width equal to that of the tape; the strap and tab portions are substantially narrower and are arranged along one side edge of the tape to leave removable waste sections extending along only the opposite side edge of the tape. To control advancement of the tape through a printer, each waste section may be provided with a locator opening detectable by an optical sensor of the printer.

Owner:PRECISION DYNAMICS CORPORATION

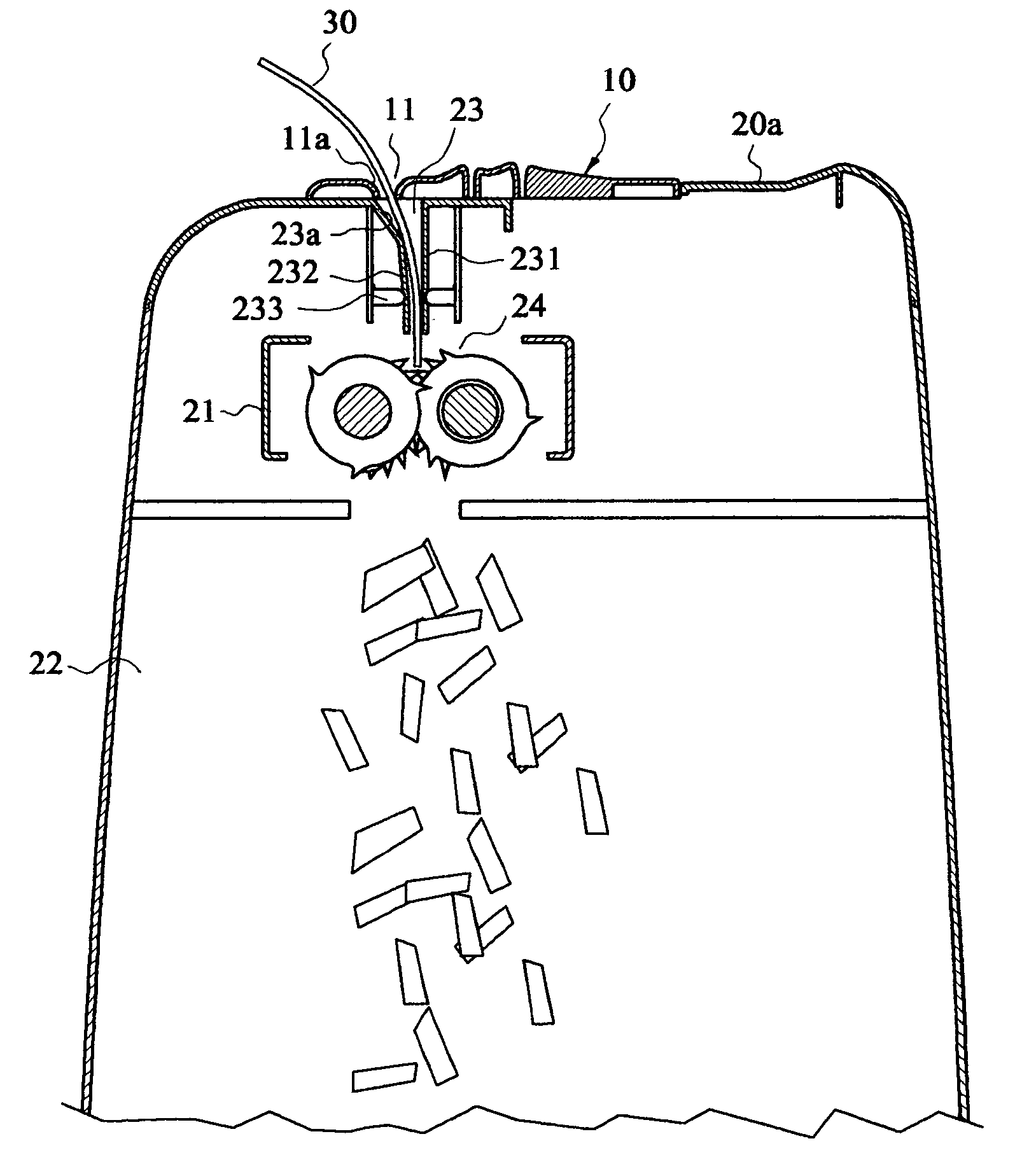

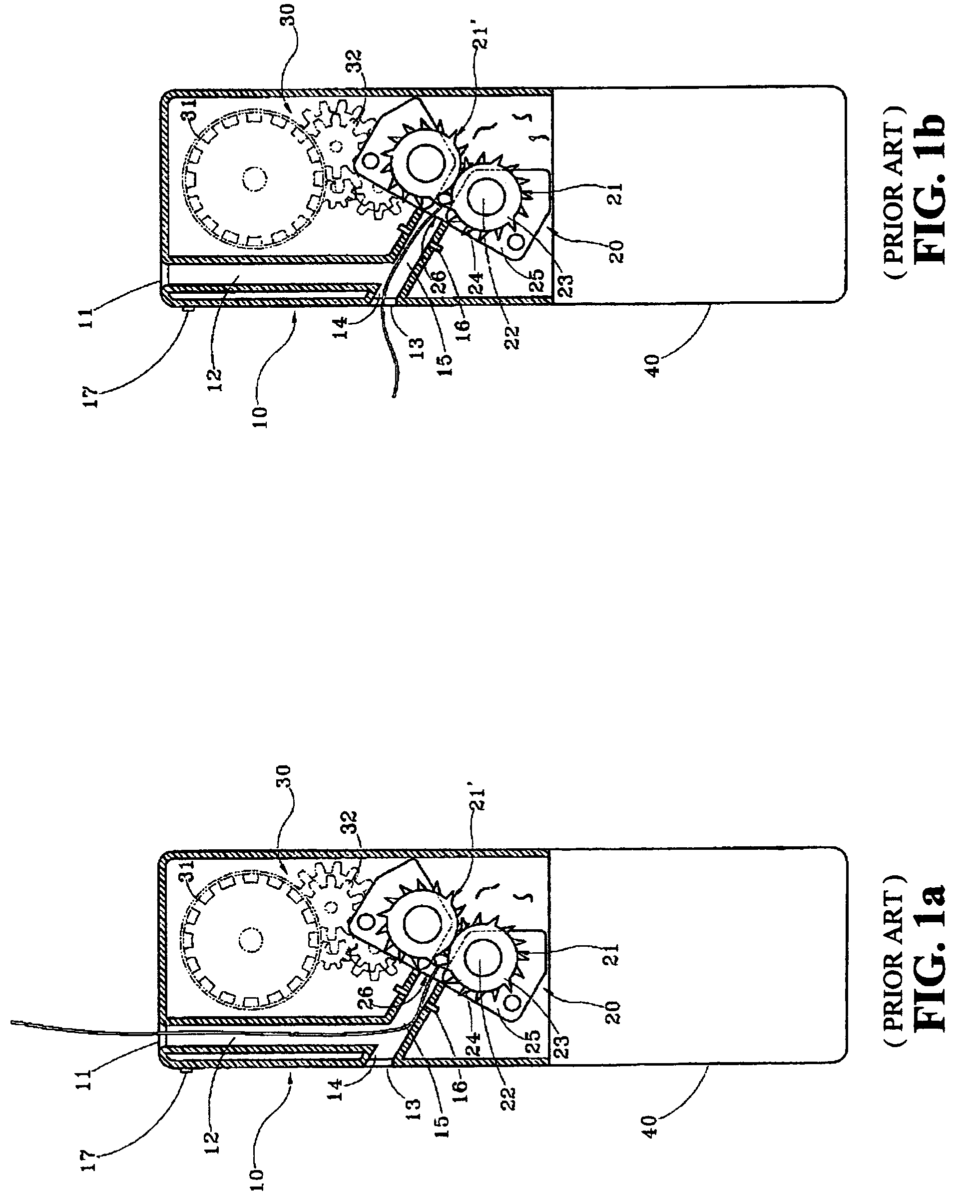

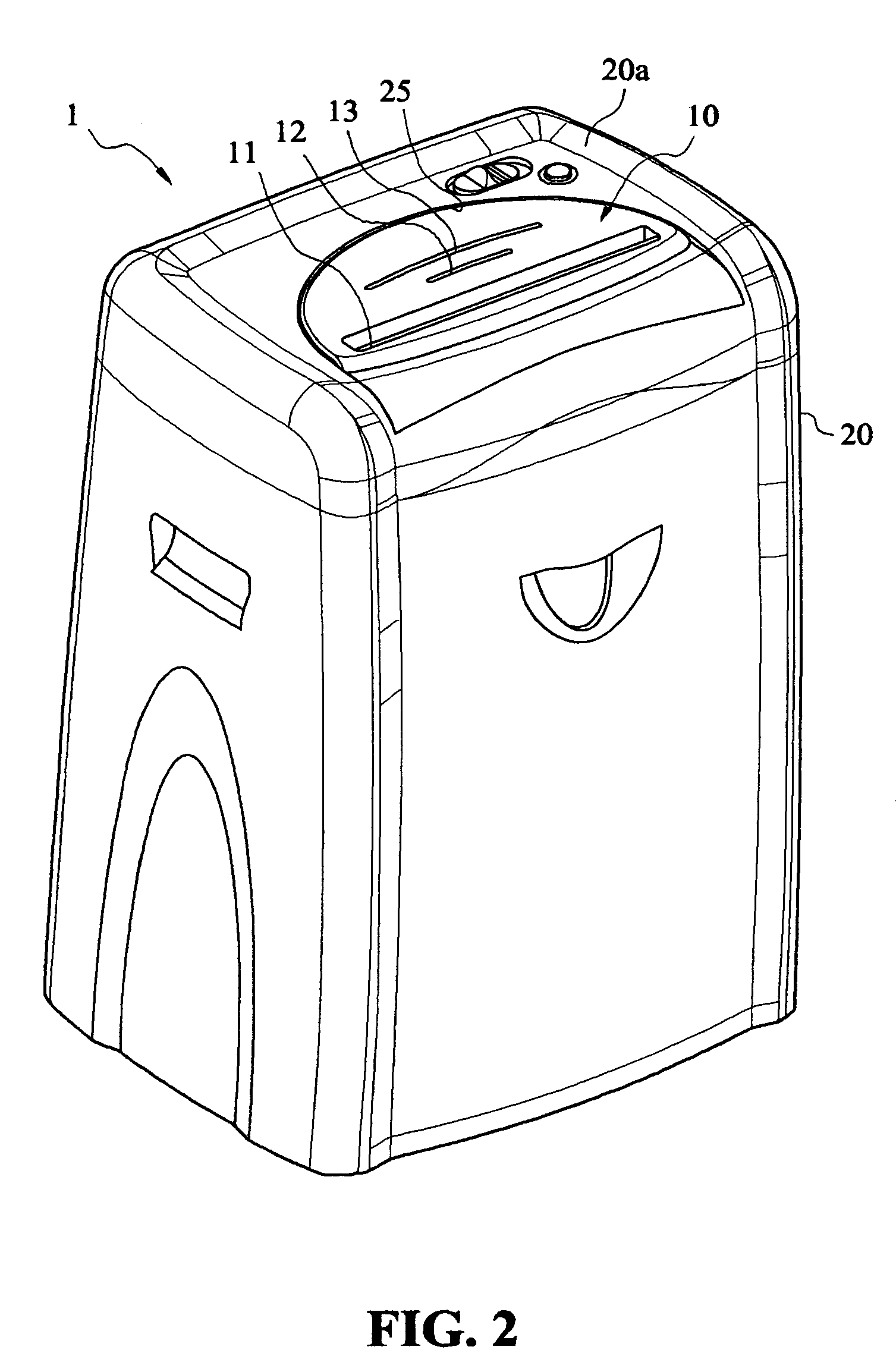

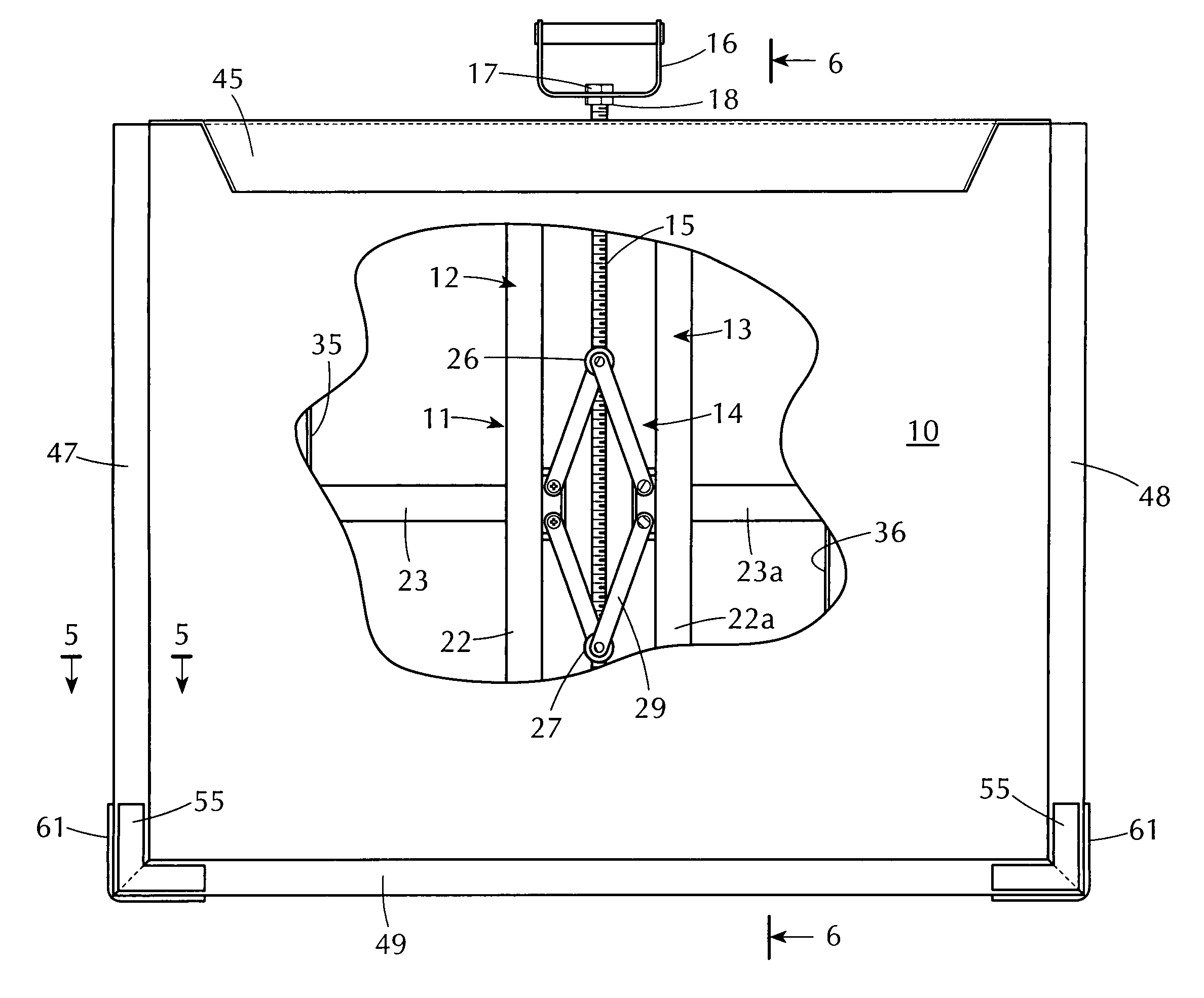

Multifunctional paper shredder

InactiveUS7213780B2Improve the problemLarge widthGrinding machine componentsCocoaInterior spaceImpeller

Disclosed is a sliding panel structure of a multifunctional paper shredder, the paper shredder includes a housing having an interior space, an installing section at the top, an accommodating space at the bottom, and a feeding slot under the installing section. A pair of rolling blade wheels are disposed under the feeding slot which has a pressing wall surface extended vertically downward and aligned with the middle of the rolling blade wheels. An accommodating section is defined at the top of the housing, and a positioning section having at least one sliding groove is disposed at an inner side of the accommodating section. A sliding panel, having a plurality of slots is slidably installed in the accommodating section, having a positioning pin disposed in the positioning section correspondingly, and at least one slide pin embedded into the sliding groove for guiding the movement of the sliding panel.

Owner:AURORA GLOBAL INVESTMENT

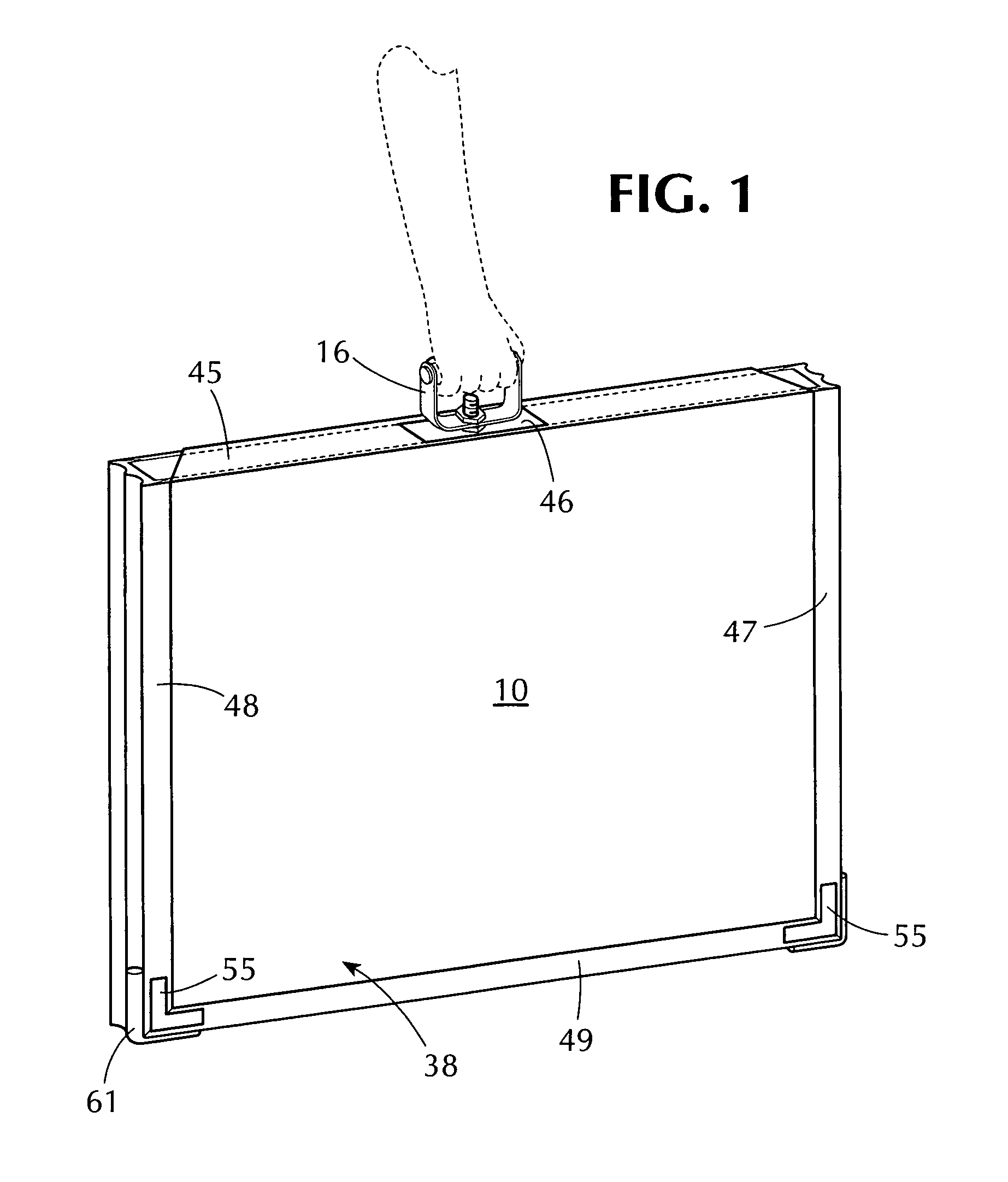

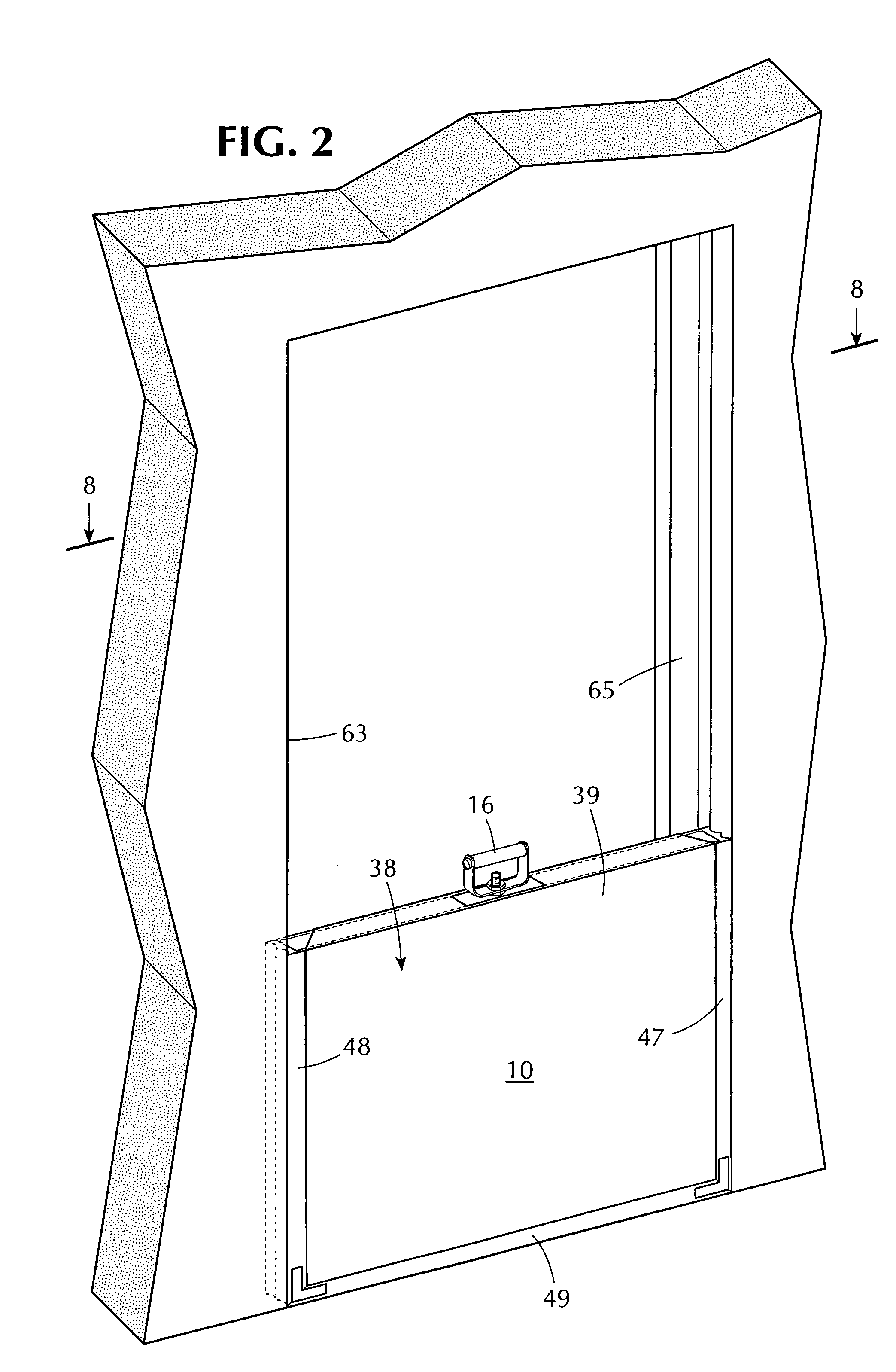

Portable flood barrier panel

ActiveUS7523589B1Easy to installEasy to removeFlood panelsShutters/ movable grillesEngineeringMullion

An Adjustable flood-resistant barrier for removable installation in a window or door opening or the like. A laterally adjustable frame is received within an elastic envelope and can be laterally expanded to engage the sides and bottom of the opening. An adjusting mechanism includes a shaft, which projects upward above the top of the frame, approximately in the center thereof, and mounts a handle for both carrying the panel and rotating the shaft to effect width adjustments of the panel. An improved peripheral seal minimizes the likelihood of leakage at the corners. For wide openings, mullions are provided to support central areas and to increase downward sealing pressures in the center of the panel. Mullions can also be positioned between an opposed pair of barrier panels for closing off unusually wide openings.

Owner:PRESRAY

System for cutting the cornea of an eye

A system for cutting the cornea of an eye, includes a moveable member with a cutting blade at one end, a pivot element and a cutting guide restraint. A mechanism for oscillating the moveable member around the pivot element and a cutting guide are configured to engage the cutting guide restraint on the moveable member and thereby limit the degree of angular movement of the cutting blade as the moveable member oscillates about the pivot element. A positioning system is configured to advance the moveable member with respect to the cutting guide such that the shape of the cutting guide determines the shape of a cut made by the cutting blade. A suction ring for stabilizing the cornea and an applanating plate for flattening the cornea usually complete the system.

Owner:YICHIEH SHIUEY M D

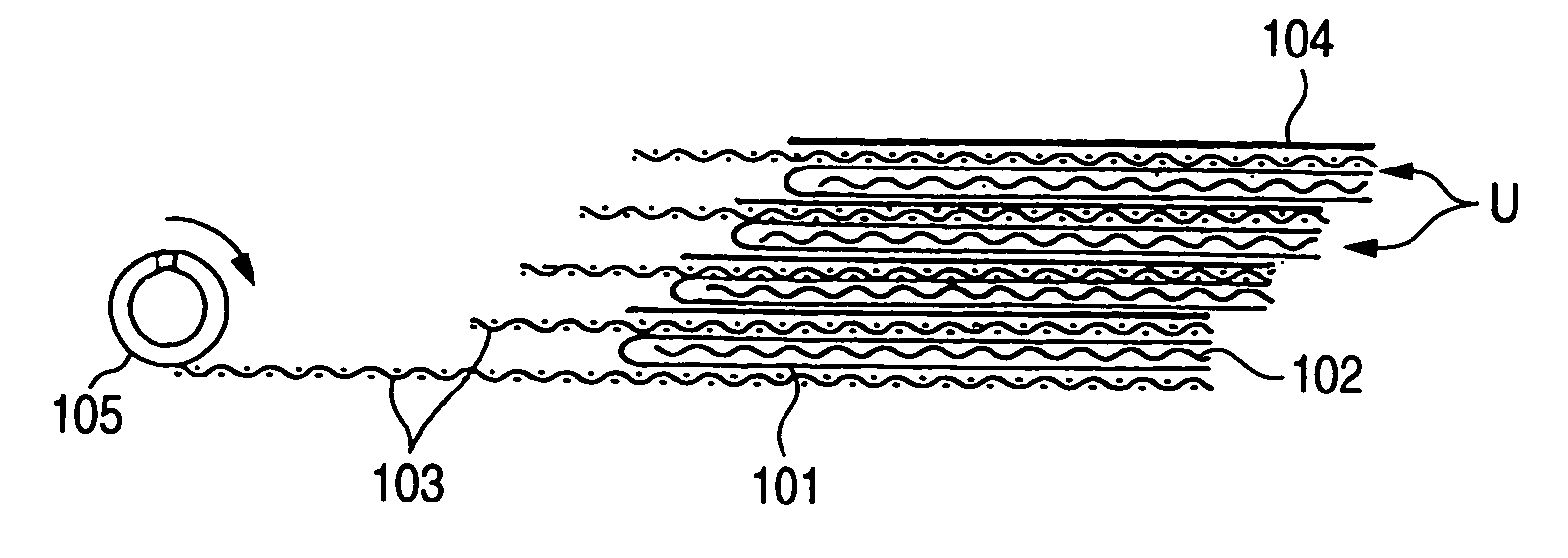

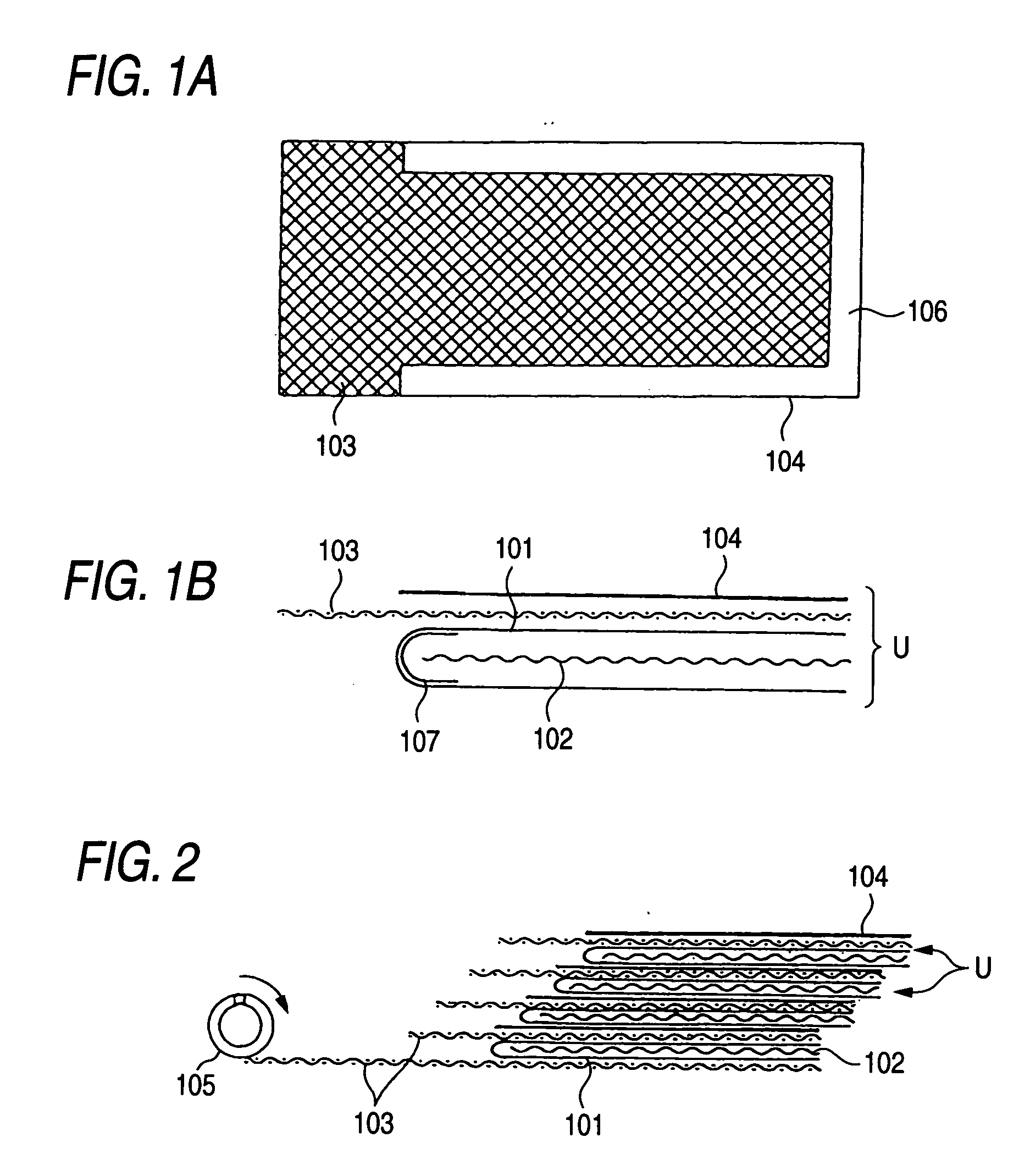

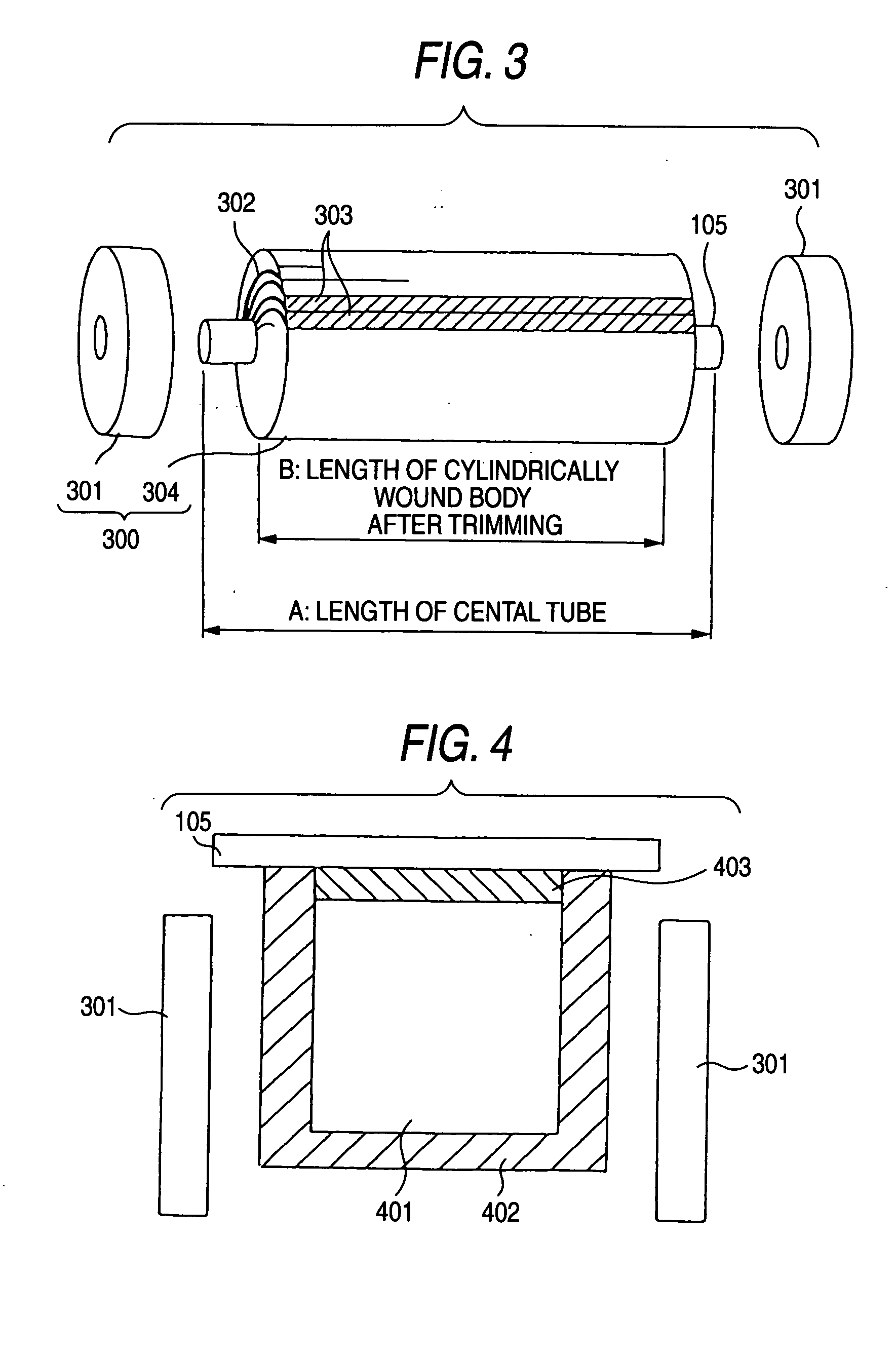

Spiral membrane element and method of manufacturing the same

InactiveUS20050077229A1Reduce total pressure lossReduce manufacturing costSemi-permeable membranesDispersed particle filtrationAdhesiveMembrane surface

A spiral membrane element having an enlarged effective membrane surface area without having its separation performance lowered, while maintaining the sealing property of any sealing portion of a cylindrically wound body, and a manufacturing method of the same are disclosed. The spiral membrane element includes a cylindrically wound body comprising a perforated central tube and, spirally wound therearound, a separation membrane, a feed-side passage material and a permeation-side passage material in a laminated state, and a sealing portion for preventing a feed-side fluid and a permeation-side fluid from being mixed together, wherein the sealing portion formed at each of both ends of the cylindrically wound body is spirally formed with a substantially constant width by an adhesive and has a trimmed section formed on its whole end surface, and the cylindrically wound body has a ratio of its length to the length of the central tube of 0.96 to 1.00, and a ratio of an ineffective membrane surface area to the entire membrane surface area of 0.02 to 0.10.

Owner:NITTO DENKO CORP

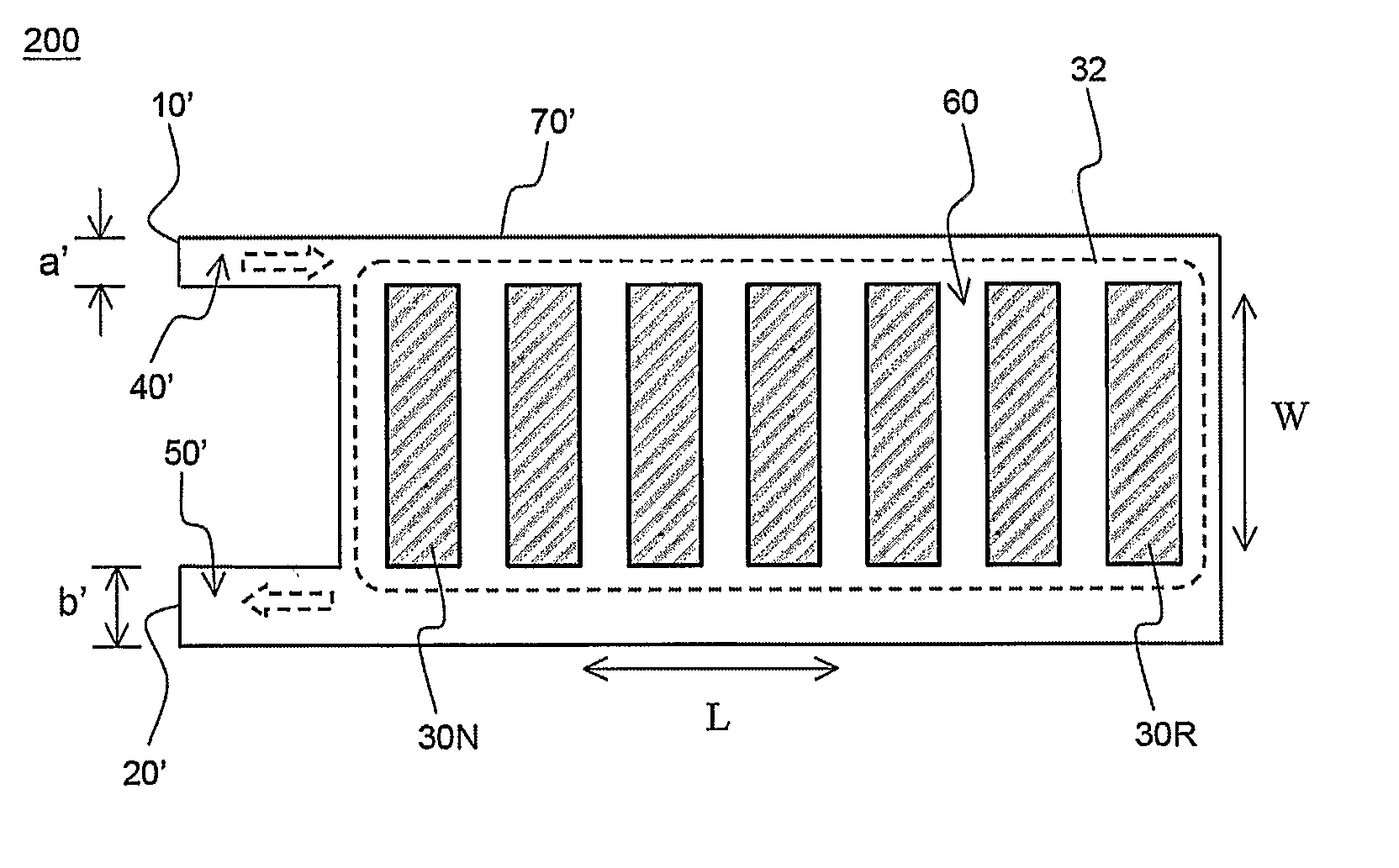

Middle or large-sized battery pack case providing improved distribution uniformity in coolant flux

ActiveUS20100203376A1Increase heightLarge widthCell temperature controlLi-accumulatorsEngineeringBattery cell

Disclosed herein is a middle- or large-sized battery pack case in which a battery module having a plurality of stacked battery cells, which can be charged and discharged, is mounted, wherein the battery pack case is provided with a coolant inlet port and a coolant outlet port, which are disposed such that a coolant for cooling the battery cells can flow from one side to the other side of the battery module in the direction perpendicular to the stacking direction of the battery cells, and the battery pack case is further provided with a flow space (‘inlet duct’) extending from the coolant inlet port to the battery module and another flow space (Outlet duct’) extending from the battery module to the coolant outlet port, the inlet duct having a vertical sectional area less than that of the outlet duct.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com