Drilling device for sheet glass drilling

A drilling device and flat glass technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of large processing errors, equipment elimination, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

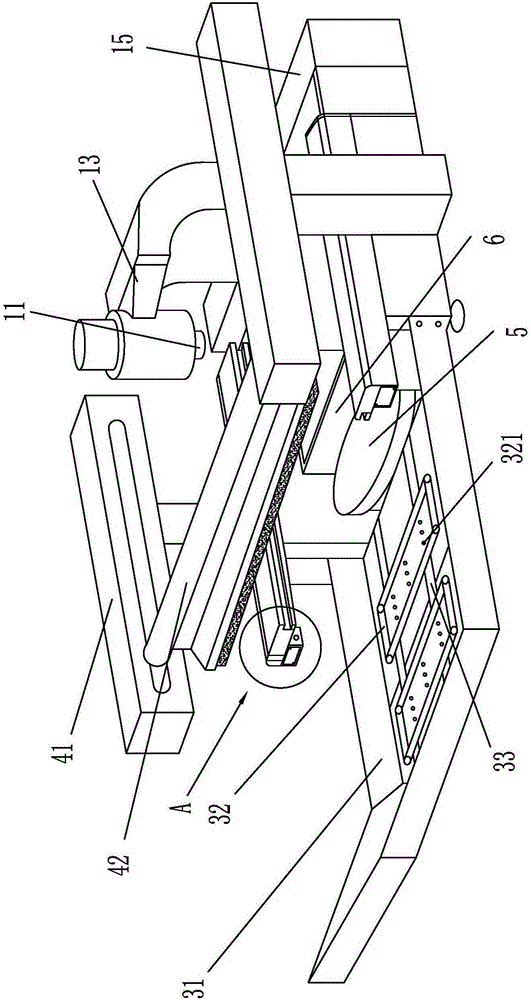

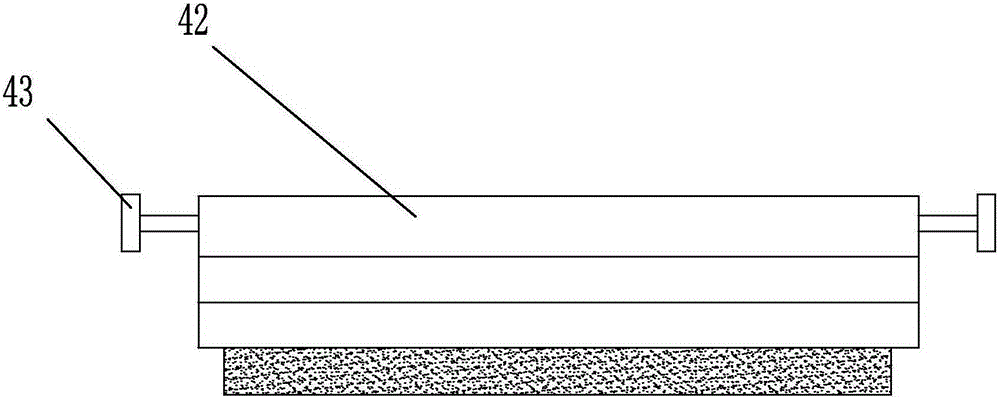

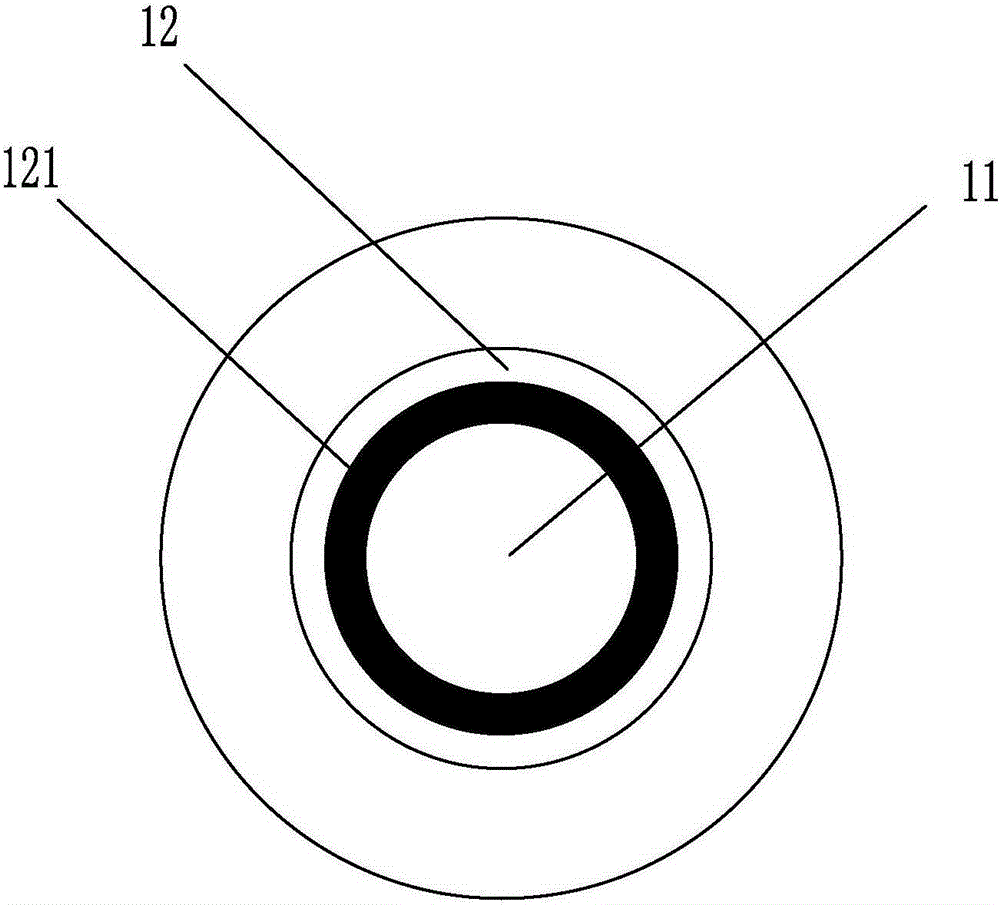

[0029] Such as Figure 1 to Figure 5As shown, a drilling device for flat glass drilling includes a drilling machine, a fixing mechanism, a feeding mechanism and a cleaning mechanism. The fixing mechanism is located between the drilling machine and the feeding mechanism, and the cleaning mechanism is located at the center of the fixing mechanism. Above, the drilling machine includes a drill bit and a moving mechanism, the drill bit is connected to the moving mechanism, the drill bit includes a drill bit body 11 and a heating device 12, and the heating device 12 is arranged around the drill bit body 11, and the heating device 12 includes an electromagnetic heater and a heat conduction sheet 121. The heater can increase the temperature in a very short time, which is safer than flame heating, and at the same time, the heating temperature can be transmitted to the surface of the flat glass more quickly through the heat conduction sheet 121 . The moving mechanism includes an X-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com