Slitting device for dried kiwi fruit processing

A technology of kiwi fruit and inserting, applied in metal processing and other directions, can solve the problems of time-consuming and laborious, affecting efficiency, manual cutting danger, etc., and achieve the effect of reducing risk, improving cutting efficiency and high cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

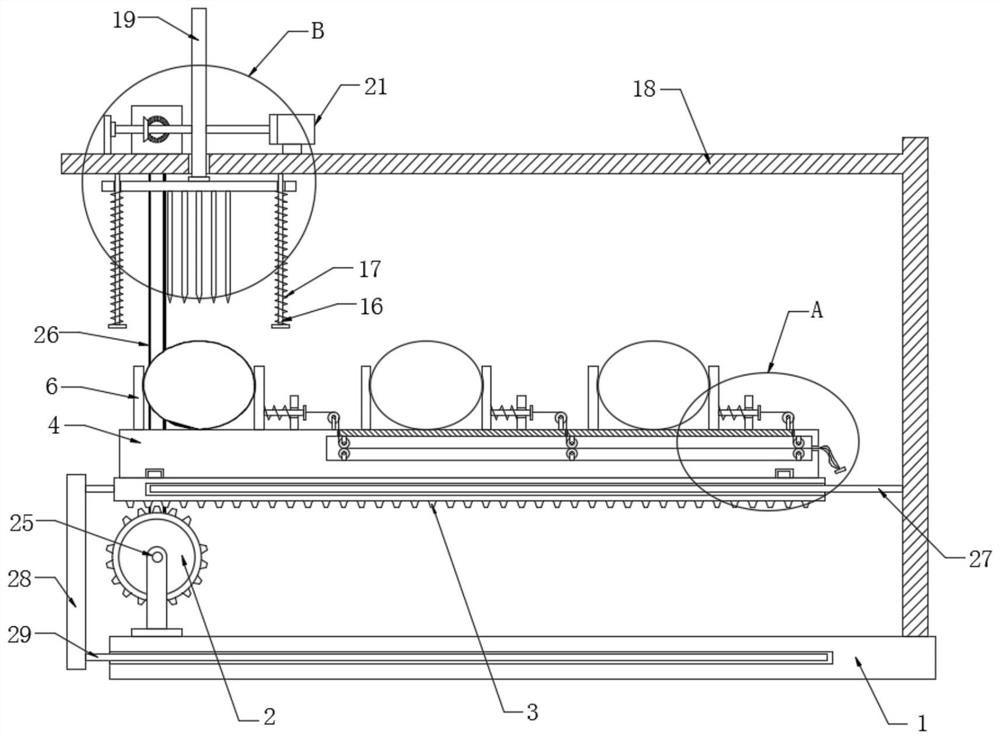

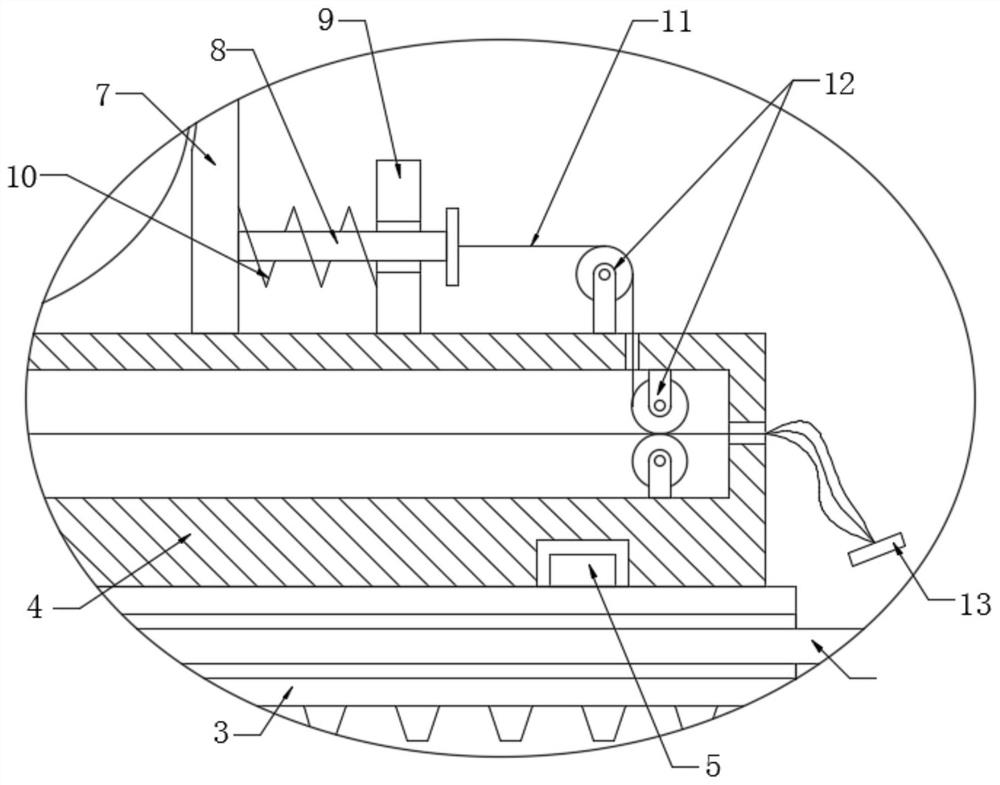

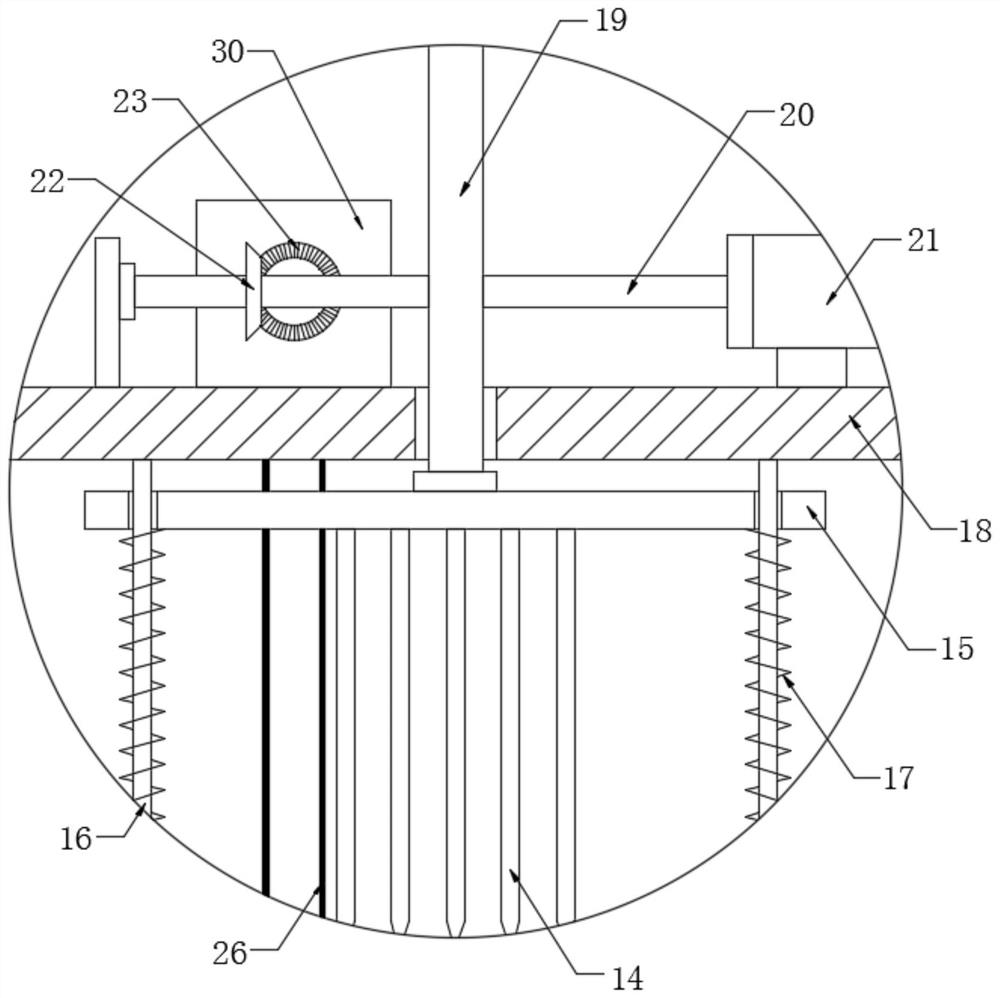

[0023] refer to Figure 1-5 , a cutting device for dried kiwifruit processing, comprising a base 1, an incomplete gear 2 is provided on the upper side of the base 1, a rack 3 is engaged with the upper end of the incomplete gear 2, a support plate 4 is provided on the upper side of the rack 3, and The left and right sides of the lower end of the support plate 4 are provided with card slots 5 corresponding to the racks 3, the support plate 4 is inserted on the rack 3, the upper side of the support plate 4 is provided with a number of cutting knives 14, and the upper ends of the cutting knives 14 are fixedly connected with knife holders Plate 15, on knife seat plate 15 left and right sides, all run through fixed rod 16, and fixed rod 16 is provided with spring two 17, and fixed rod 16 upper ends are fixedly installed with support 18, and the lower end of support 18 is fixedly installed on the base 1, and knife The upper side of the seat plate 15 is provided with a cam 19, and the...

Embodiment 2

[0025] refer to Figure 1-5 , in this embodiment, it is basically the same as Embodiment 1, and more optimally, a plurality of fixed splints 6 are fixedly installed on the upper end of the support plate 4, and the right side of the fixed splint 6 is correspondingly provided with a movable splint 7, and the lower end of the movable splint 7 is connected to the support Plate 4 fits, movable splint 7 right end is provided with connecting rod 8, and connecting rod 8 right side runs through vertical plate 9, and vertical plate 9 lower end is fixedly installed on support plate 4 upper end, and connecting rod 8 is sleeved with spring 10, and spring The left and right ends of -10 are respectively fixedly connected to the movable splint 7 and the vertical plate 9, and the right end of the connecting rod 8 is provided with a stay cord 11, and the stay cord 11 runs through the upper end and the right end of the support plate 4, and the corresponding stay cord 11 at the support plate 4 upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com