Bearing rotation torque test device

A test device and bearing technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of long time consumption, single test bearing specifications, inability to guarantee concentricity, etc., to avoid errors in test data, accurate and reliable test values, and expand the use of testing. range effect

Inactive Publication Date: 2016-08-03

CIXING GROUP

View PDF11 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Chinese patent 200910096442.X "Measuring device for bearing frictional torque under different axial loads and rotating speeds" also provides a measuring device for bearing frictional force, but after many measurements and uses, it is found that it still has some defects, such as assembly , Debugging, testing, and operation are very cumbersome, time-consuming, and inefficient. The test bearing has a single specification, and different positioning tooling needs to be designed, but the concentricity of the measurement cannot be guaranteed. The jitter and instability will occur during the measurement, making the measured Irregular mutations occur in the waveform, resulting in inaccurate measurement data and poor repeatability, so the practicability is not good

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0027] Example: It is known that the three sets of data detected in three times are A+B=X=10, B+C=Y=11, A+C=Z=9, and the single values of A, B, and C are obtained:

[0028] A+B+B+C=X+Y=21A+C=21-2B

[0029] A+C=9 is 21-2B=9

[0030] B=6A+B=10

[0031] A=4B+C=11

[0032] C=5

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

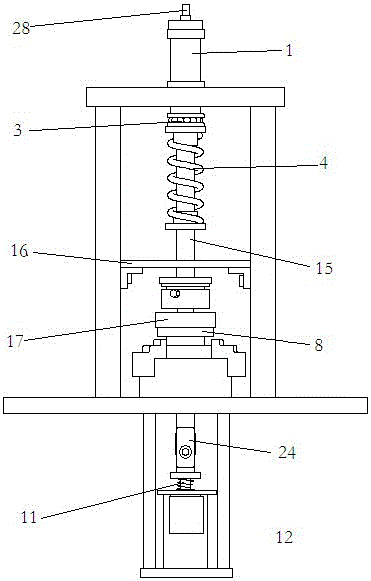

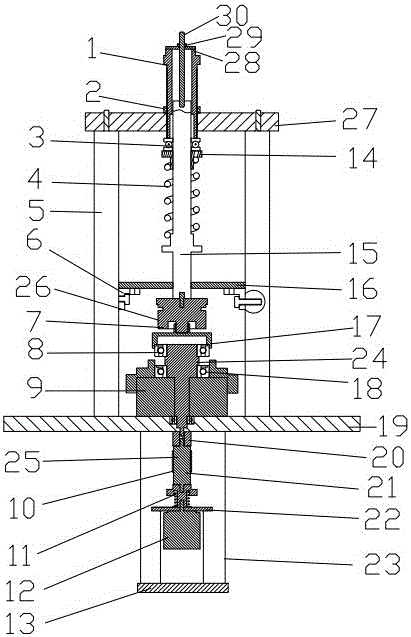

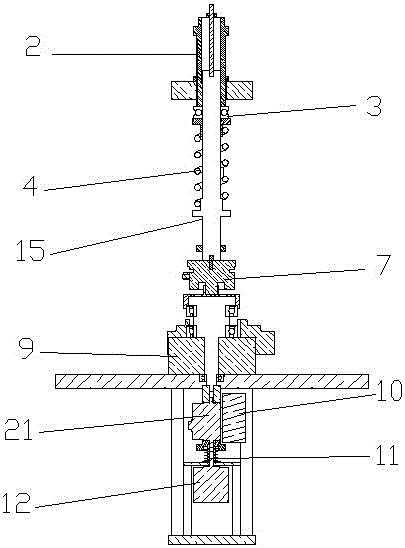

Login to View More Abstract

Provided is a bearing rotation torque test device. The center shaft of an axial loading member is connected with a thrust bearing and a spring spacer. A micro-load rod matches a pressure sensor connected with an axial loading sleeve. A measuring member is formed through clearance fit between the inner holes of two identical upper and lower detection bearings and a test shaft. The lower end of the test shaft is connected with an elastic coupler. The outer diameter of the upper detection bearing matches the axial loading sleeve mounted on the pressure sensor, and the outer diameter of the lower detection bearing matches a three-claw chuck mounted on a test bench. The shaft of a stepper motor is additionally equipped with a torque overload device, so damage to a torque sensor by detection overload is avoided. The thrust bearing, the spring spacer and the elastic coupler are provided with an aligning function, so the concentricity of the device is guaranteed. After loading, the three-claw chuck is released. The bearings are undirected, and are completely unaffected by tilting load and other pressures. The test values are more accurate. The trouble of detection tool replacement for test of bearings of different specifications is reduced. The problem that inaccurate values, poor repeatability and poor practicability are caused by loading deformation of the detection bearings is solved completely.

Description

technical field [0001] The invention relates to a bearing test device, in particular to a bearing rotation torque test device capable of bearing relatively large axial loads. Background technique [0002] Bearings are important basic components of various mechanical equipment, and the rotational torque of the bearing is one of the important technical indicators of the dynamic performance of the bearing. Torque plays an important and decisive role. Torque is the basic load form of various working machinery transmission shafts. It is closely related to the working capacity, energy consumption, efficiency, operating life and safety performance of power machinery. In order to reduce energy consumption and ensure bearing There is no blocking phenomenon when rotating, and the detection of bearing torque is very important for manufacturers and users. [0003] Chinese patent 200910096442.X "Measuring device for bearing frictional torque under different axial loads and rotating spee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M13/04

CPCG01M13/04

Inventor 符瑞斌苏达士徐翎杰刘艳超

Owner CIXING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com