Modified PA6 (Polyamide6) material for laser marker

A laser laser engraving and modification technology, applied in the field of composite materials, can solve the problems of difficult PA6, limited application, poor laser marking performance, etc., to achieve the effect of improving impact resistance and solving poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

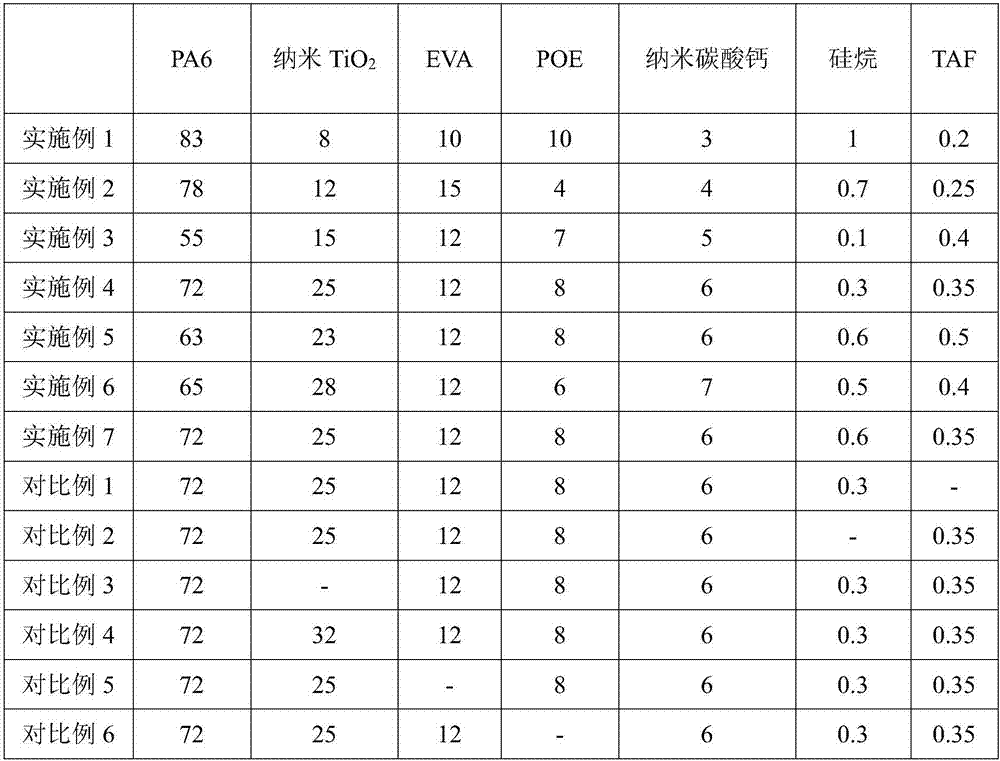

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

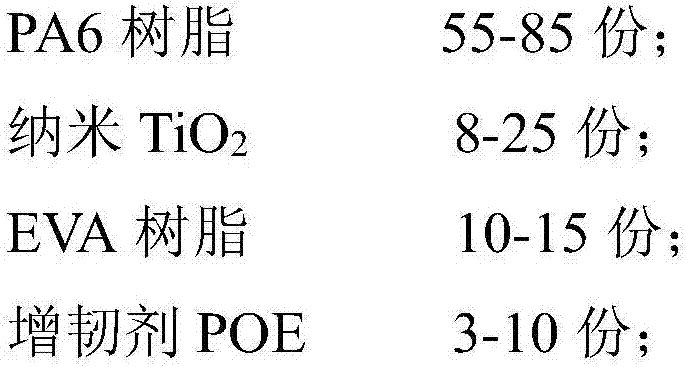

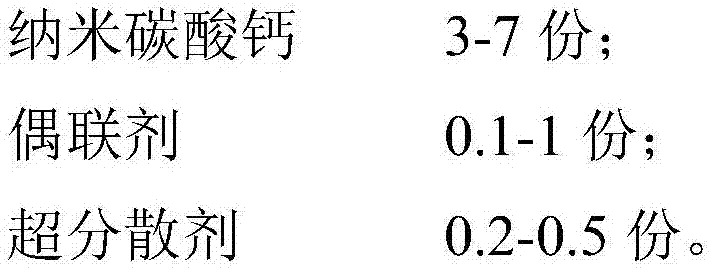

[0020] Weigh the raw materials according to the formula amounts of each embodiment in the following table 1, add the weighed samples into the high mixer, rotate at a speed of 1000 rpm, and mix for 20 minutes. After fully mixing, the premix is obtained, and then the premix is The mixed material is transferred to the twin-screw extruder. The extrusion temperature of the twin-screw extruder is: 180°C in the first zone, 190°C in the second zone, 180°C in the third zone, and 170°C in the fourth zone. Rotate at 600 rpm, extrude and granulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com