Nylon/polyphenylene sulfide alloy material and preparation method thereof

A technology of polyphenylene sulfide and alloy materials, which is applied in the field of nylon modification, can solve the problems that the addition ratio affects the mechanical properties of materials, the cost of laser marking agents is expensive, and easy to produce color stains, etc., to achieve good laser marking effects, excellent The effect of laser marking performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8 and comparative example 1-3

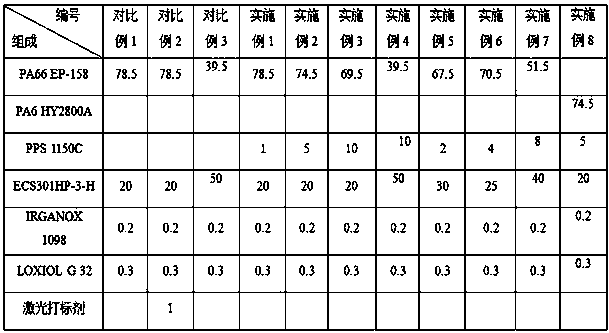

[0047] Weigh PA66 resin, PA6 resin, PPS, glass fiber, antioxidant and lubricant according to the formula dosage of comparative examples 1~3 and specific examples 1~8 described in Table 1, and put the above-mentioned components into mixing Mix in the machine until it is uniform to obtain a premix; then put the obtained premix into a twin-screw extruder for melting and mixing, and extrude and granulate to obtain a PA66 / PPS alloy material; the screw of the twin-screw extruder The aspect ratio is 40~48:1, the barrel temperature is 270~300℃, and the screw speed is 300~450rpm. The performance test of the alloy material is carried out, and the test results are shown in Table 2:

[0048] Table 1 The amount of components used in Comparative Examples 1-3 and Examples 1-8 (parts by weight)

[0049]

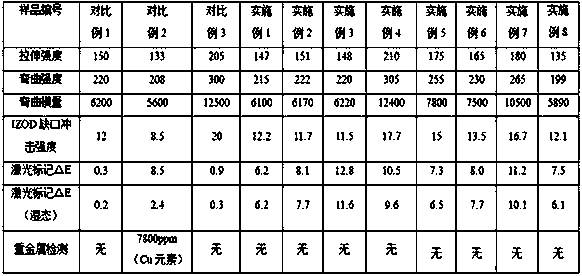

[0050] Table 2 Performance test results

[0051]

[0052] From Examples 1-8 and Comparative Examples 1 and 3, it can be seen that adding 1-10 parts of PPS can significantly improve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com