Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Organotitanium compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organotitanium compounds in organometallic chemistry contain carbon-to-titanium chemical bonds. Organotitanium chemistry is the science of organotitanium compounds describing their physical properties, synthesis and reactions. They are reagents in organic chemistry and are involved in major industrial processes.

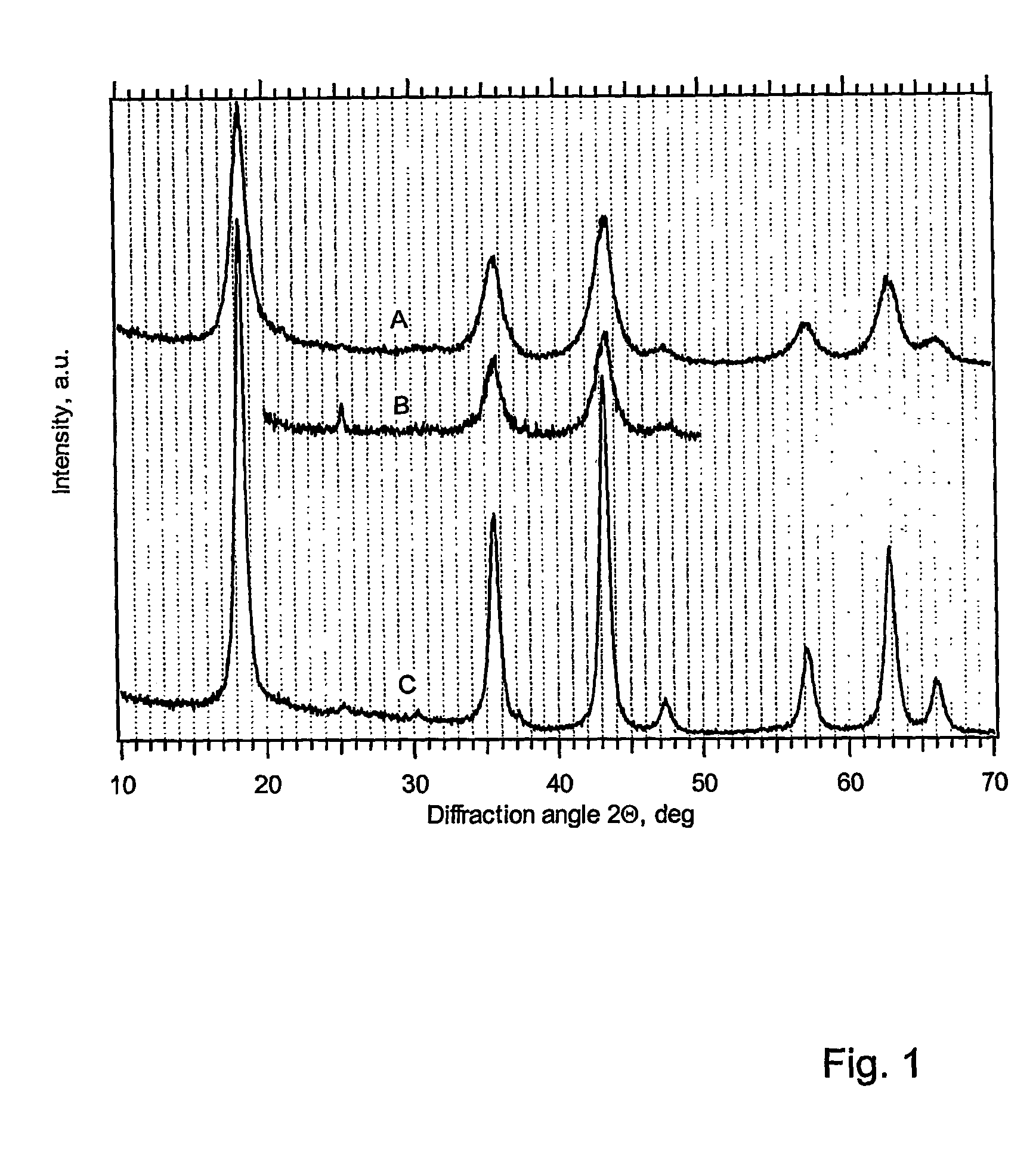

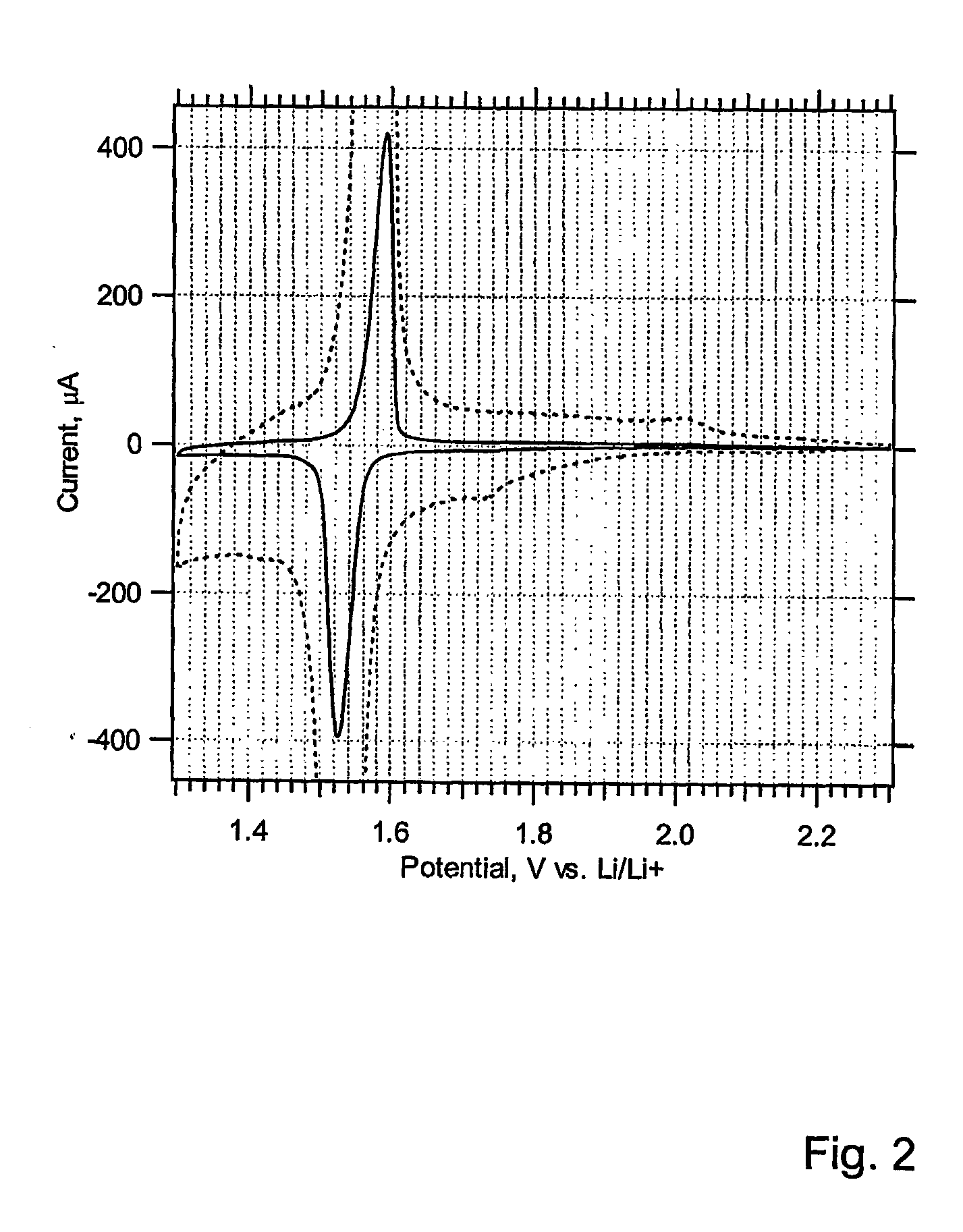

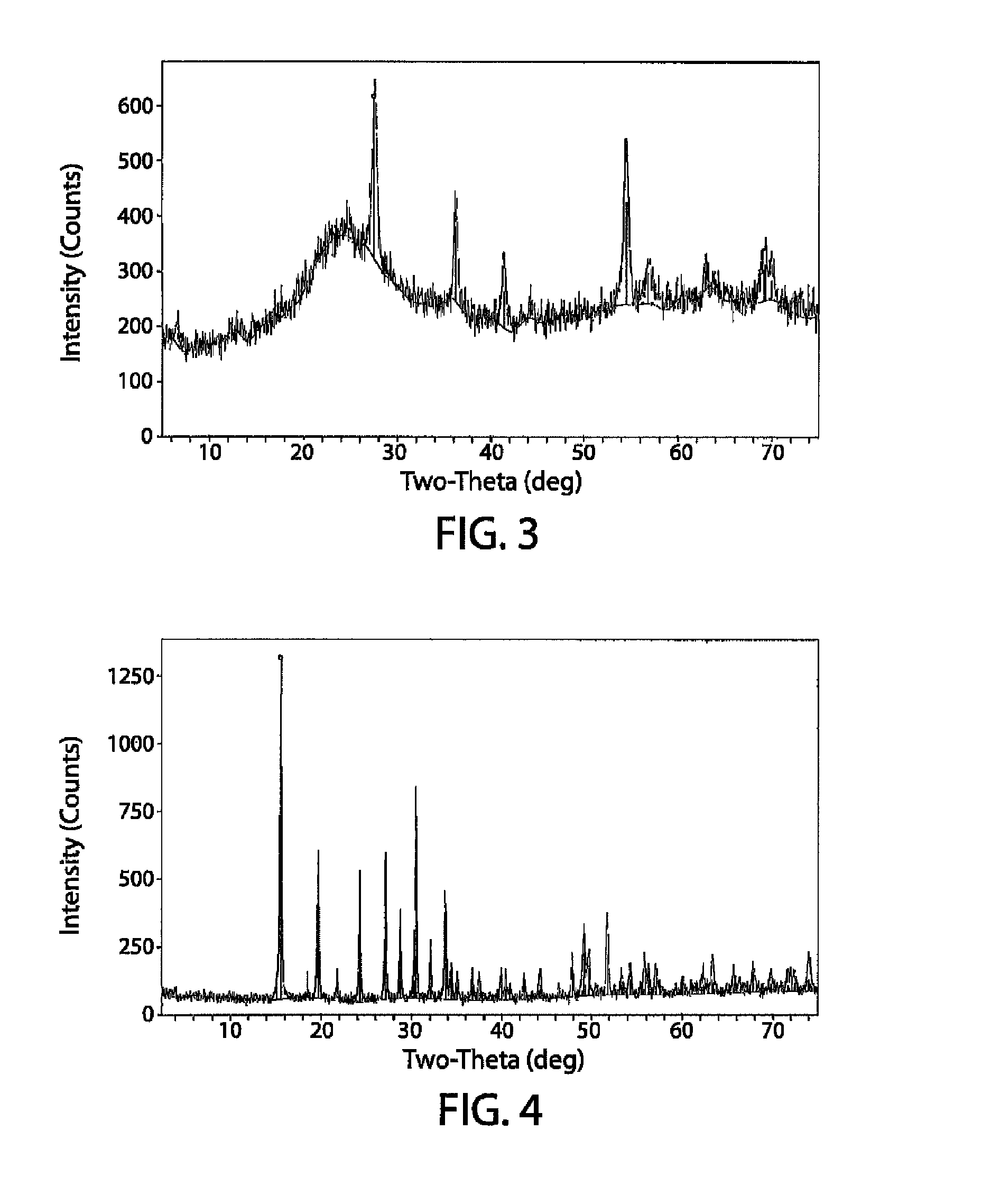

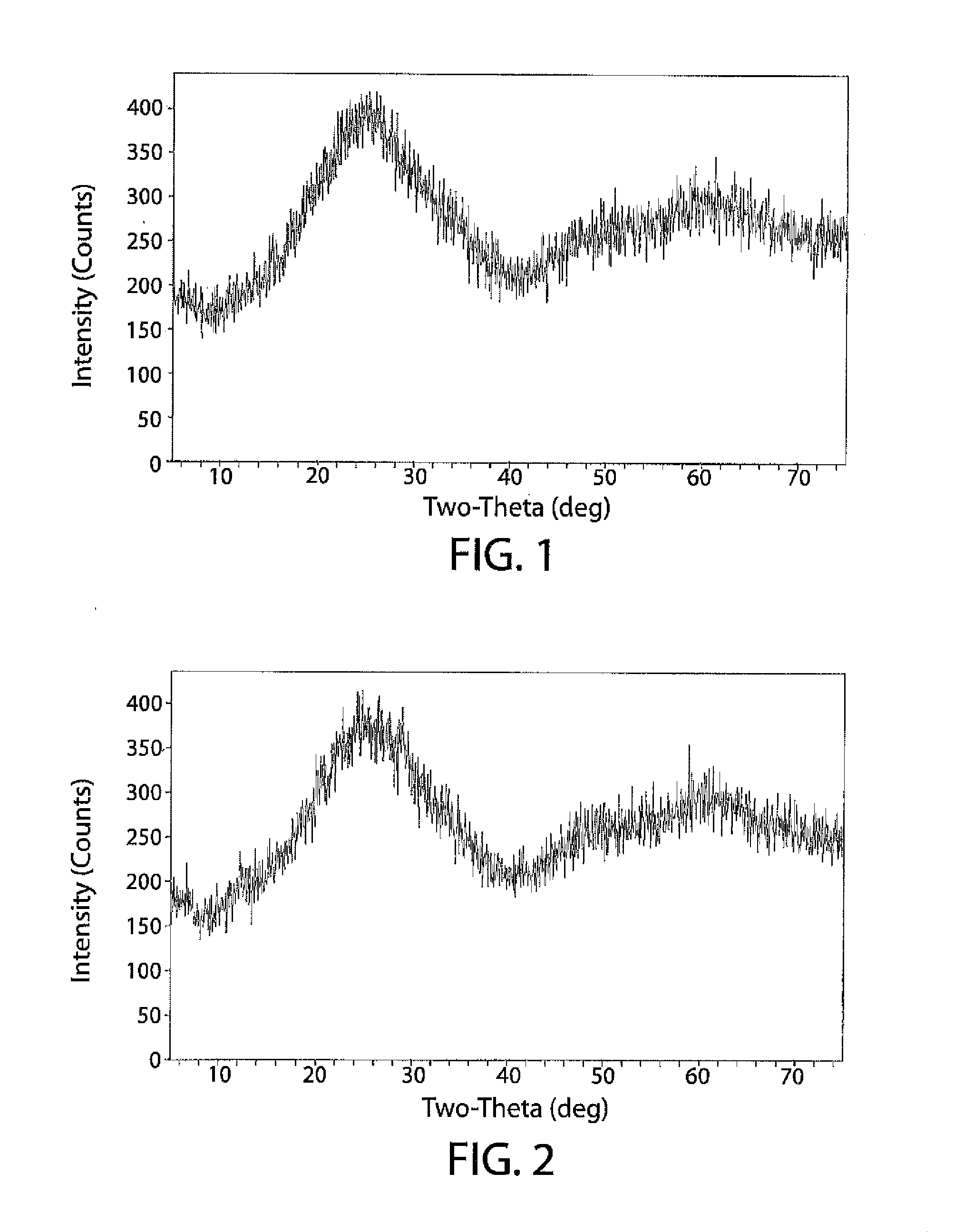

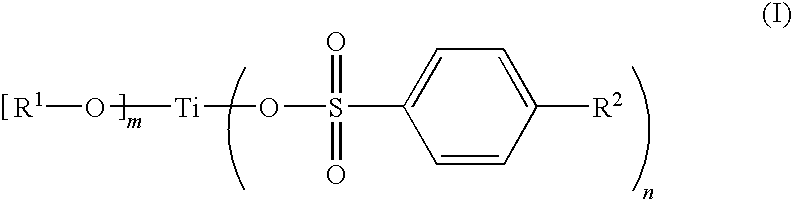

High performance lithium titanium spinel li4t15012 for electrode material

The invention concerns a process for producing a spinel compound of formula Li4Ti5O12, comprising a step of preparing a mixture of an organo-lithium compound selected from lithium alcoholates with an organo-titanium compound selected from titanic acid esters, in a liquid medium, and a step of hydrolyzing the mixture of said compounds. The invention also concerns a Li4Ti5O12 particulate material which may be produced according to the previous cited process and which has a BET surface area of at least 10 m<2> / g. The material is particularly useful in the manufacture of Lithium Ion batteries.

Owner:FRANCOIS SUGNAUX +1

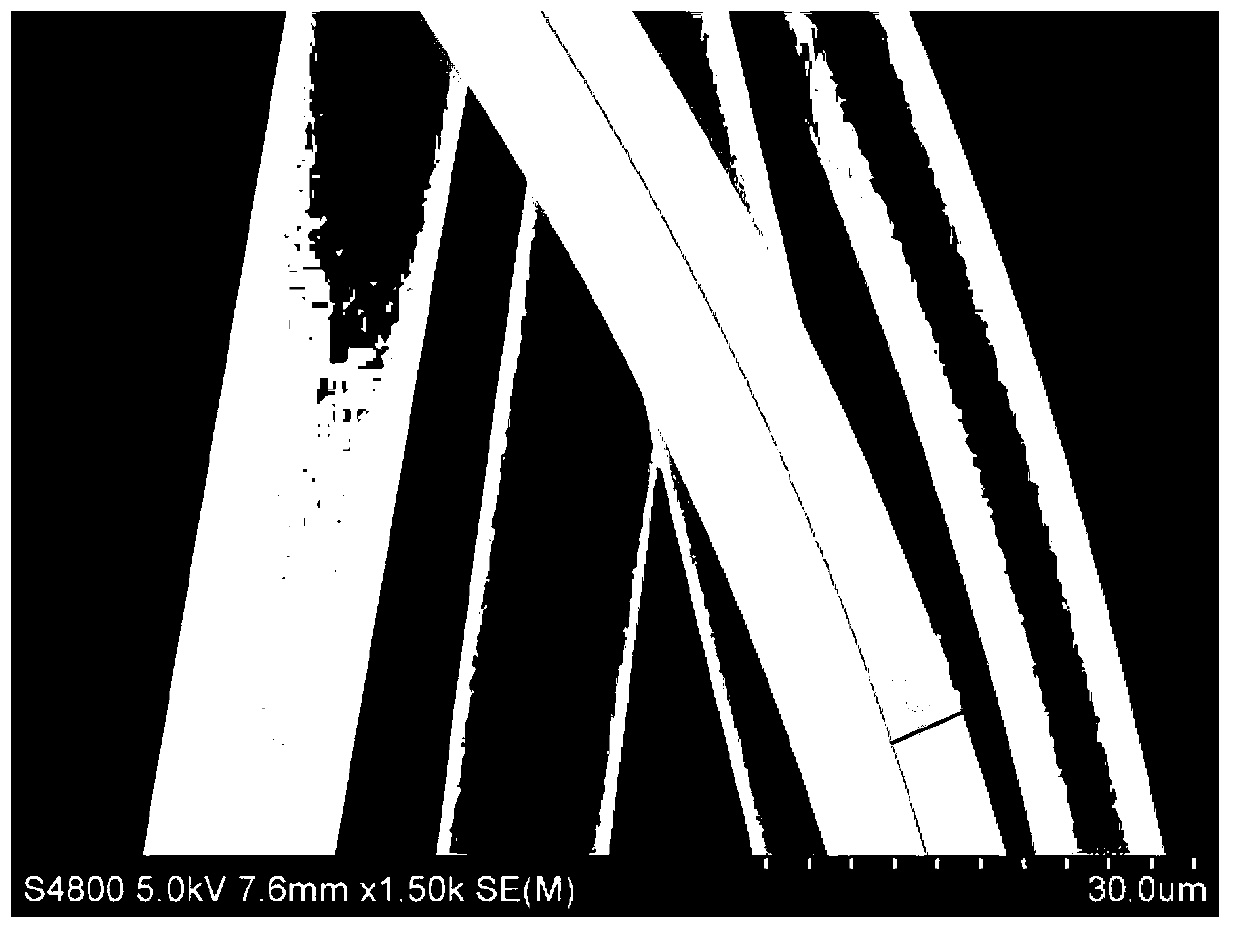

Active carbon fiber containing nano titanium dioxide particles and its preparation method and uses

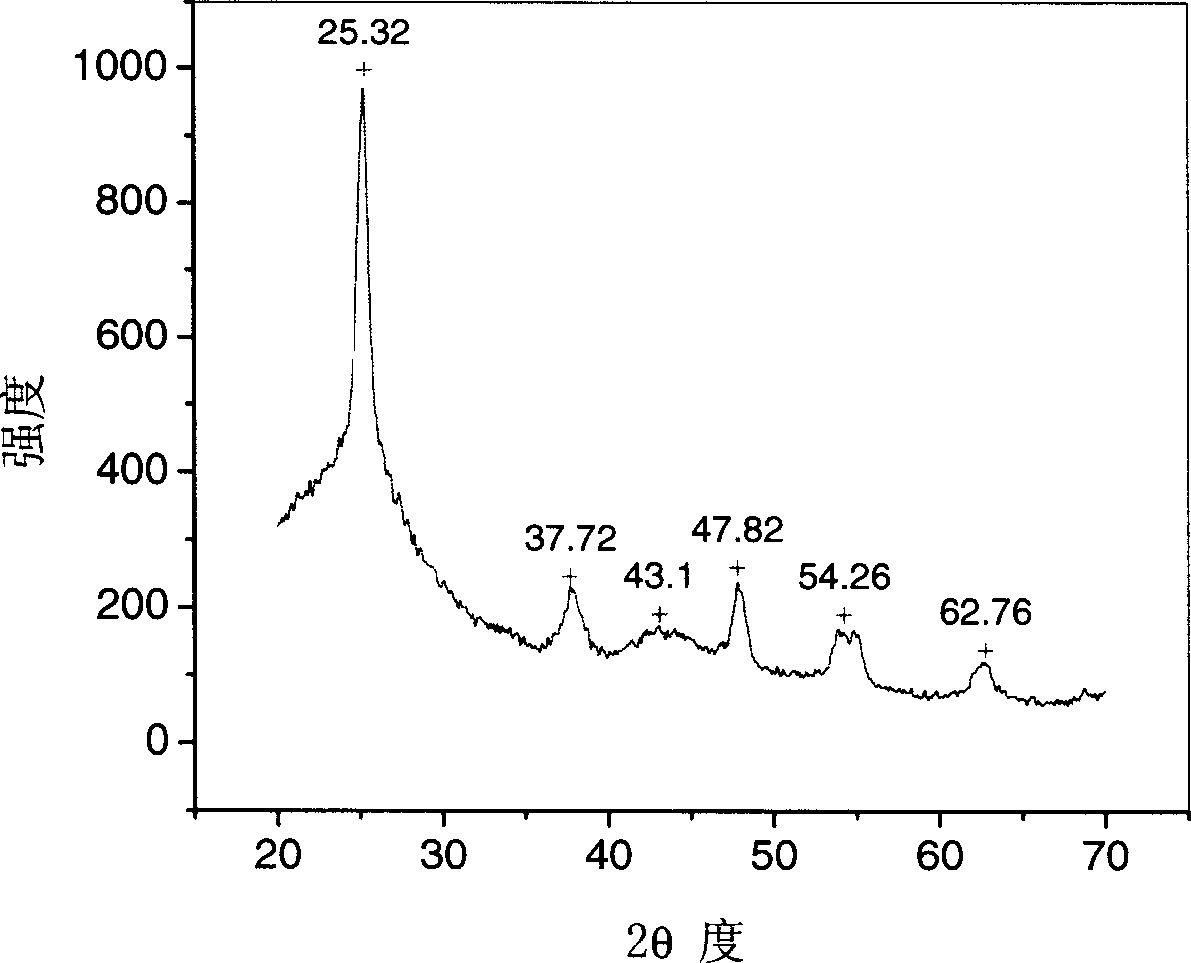

This invention relates to a method for preparing an activated carbon fiber of Titania particle having nanometer and its usage. The fiber is formed from the activated carbon fiber material loaded with the Titania particles, wherein the mass ratio of the Titania particles is 5~25%. The preparing method uses the sol-gel processing: a) hydrolyzing organic titanium compounds of the TiO2 to the TiO2 collosol, and depositing on the activated carbon fiber, b) drying the colloslo and getting the jel, c) annealing, and transforming to nanometer TiO2 particles compounded in the surface of the fiber, then getting the fiber. The fiber not only maintains the poriness but also enhances the optical catalytic activity of the Titania particle, and can be used for removing the volatile organic contaminant with low concentration, wherein its absorbance can reach to 500mg / g and its optical catalytic dissolution rate can reach to 36%.

Owner:SUN YAT SEN UNIV

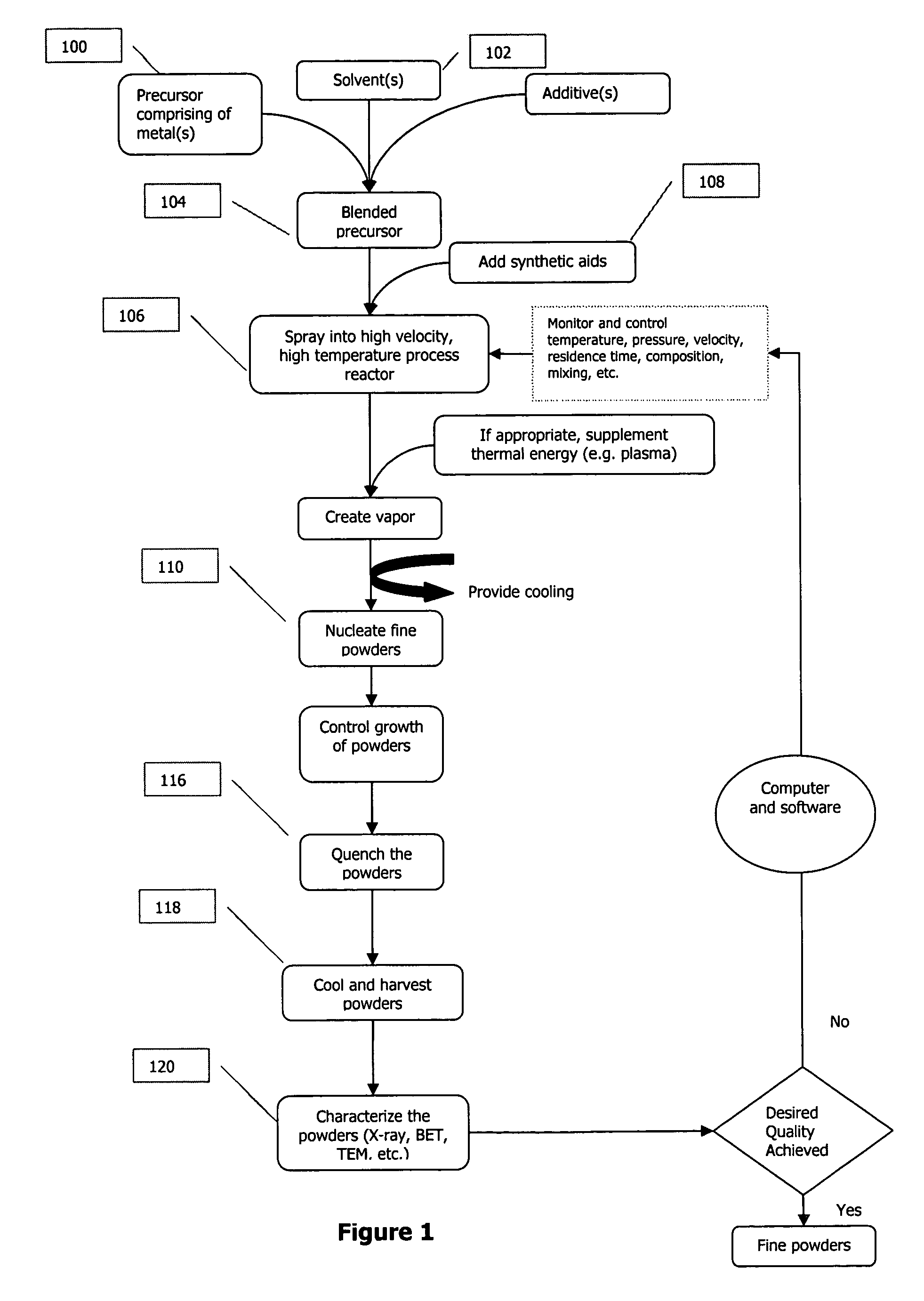

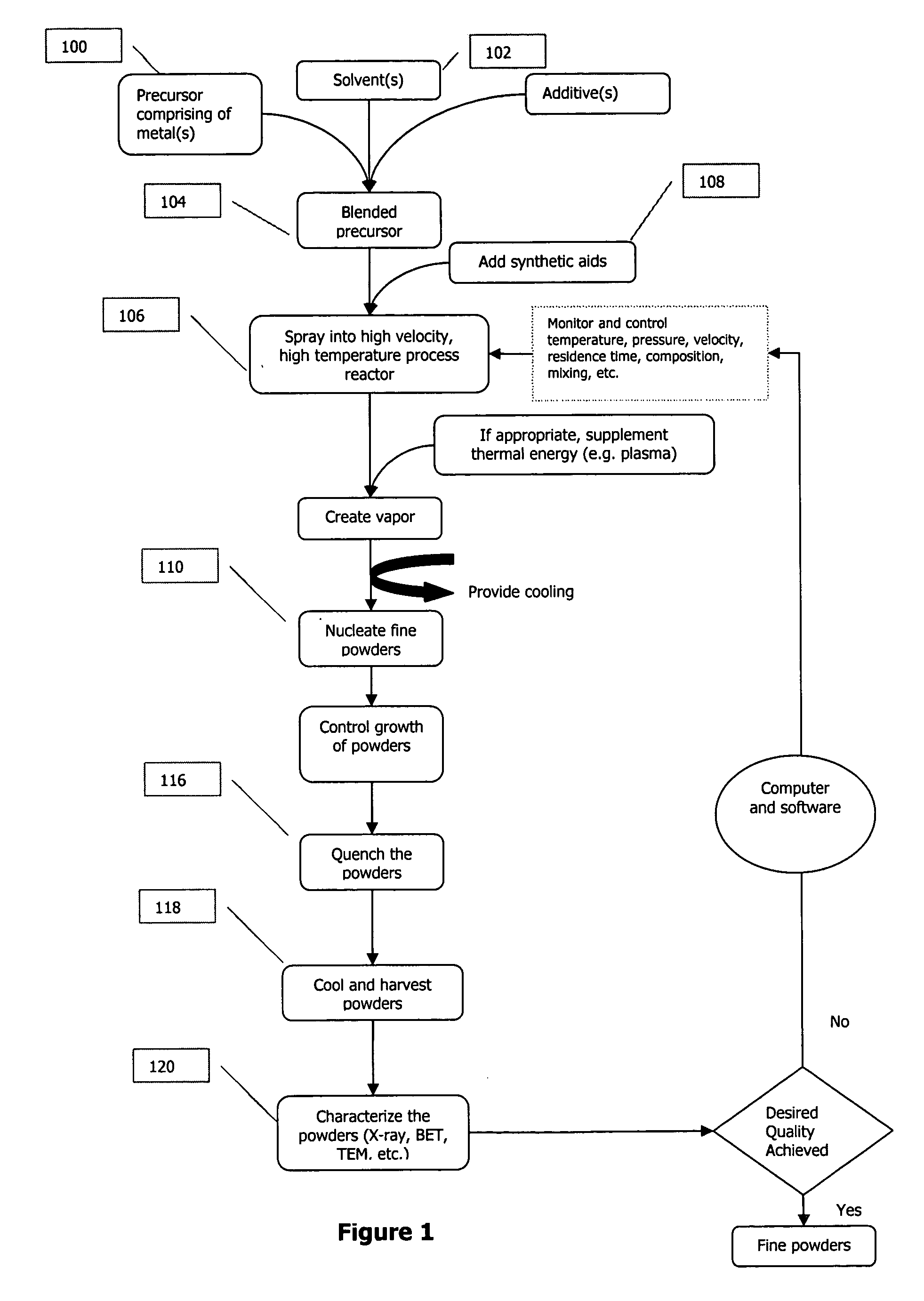

Titanium comprising nanoparticles and related nanotechnology

ActiveUS7232556B2Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

Titanium comprising nanoparticles and related nanotechnology

ActiveUS20050191492A1Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

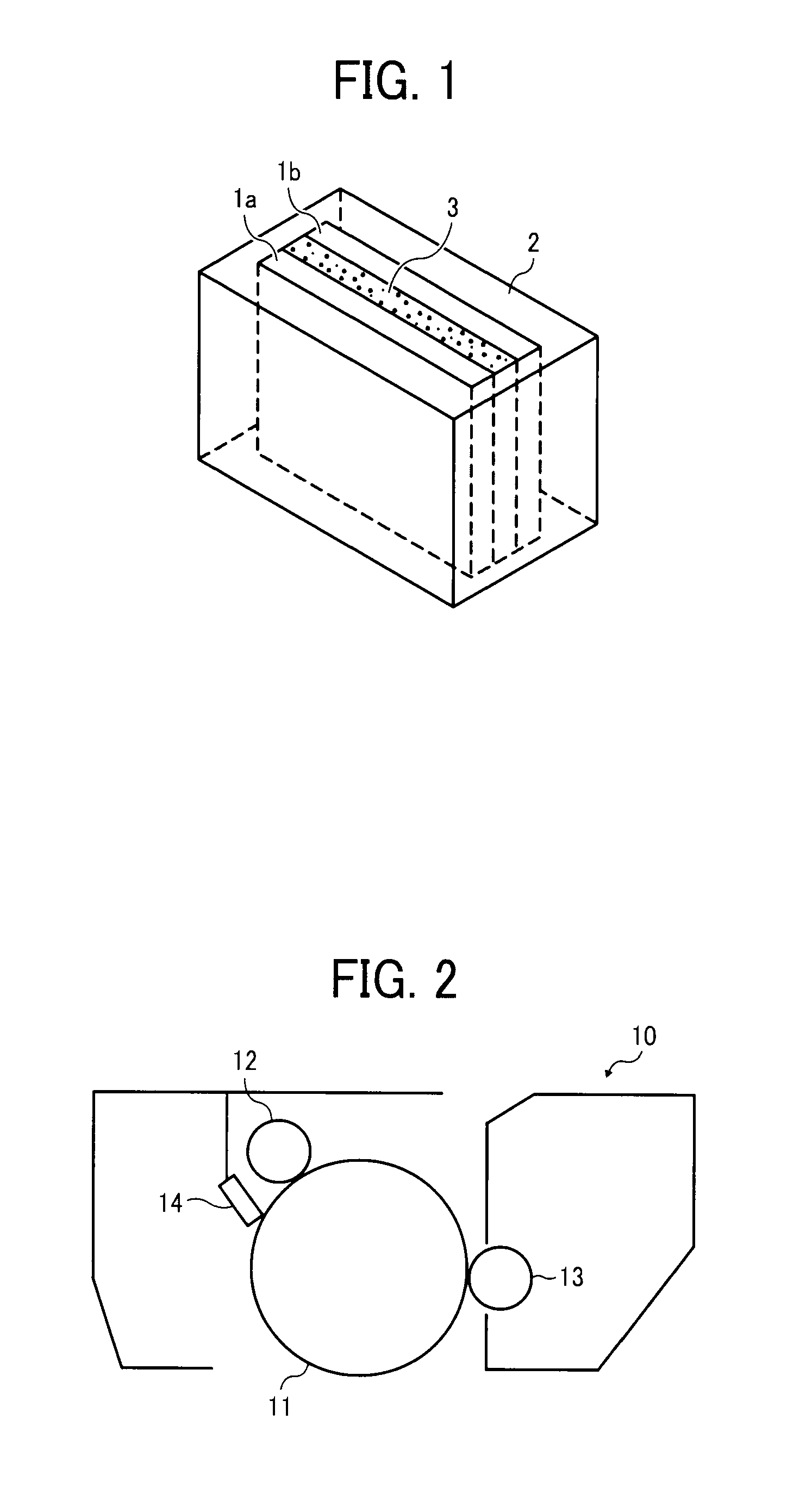

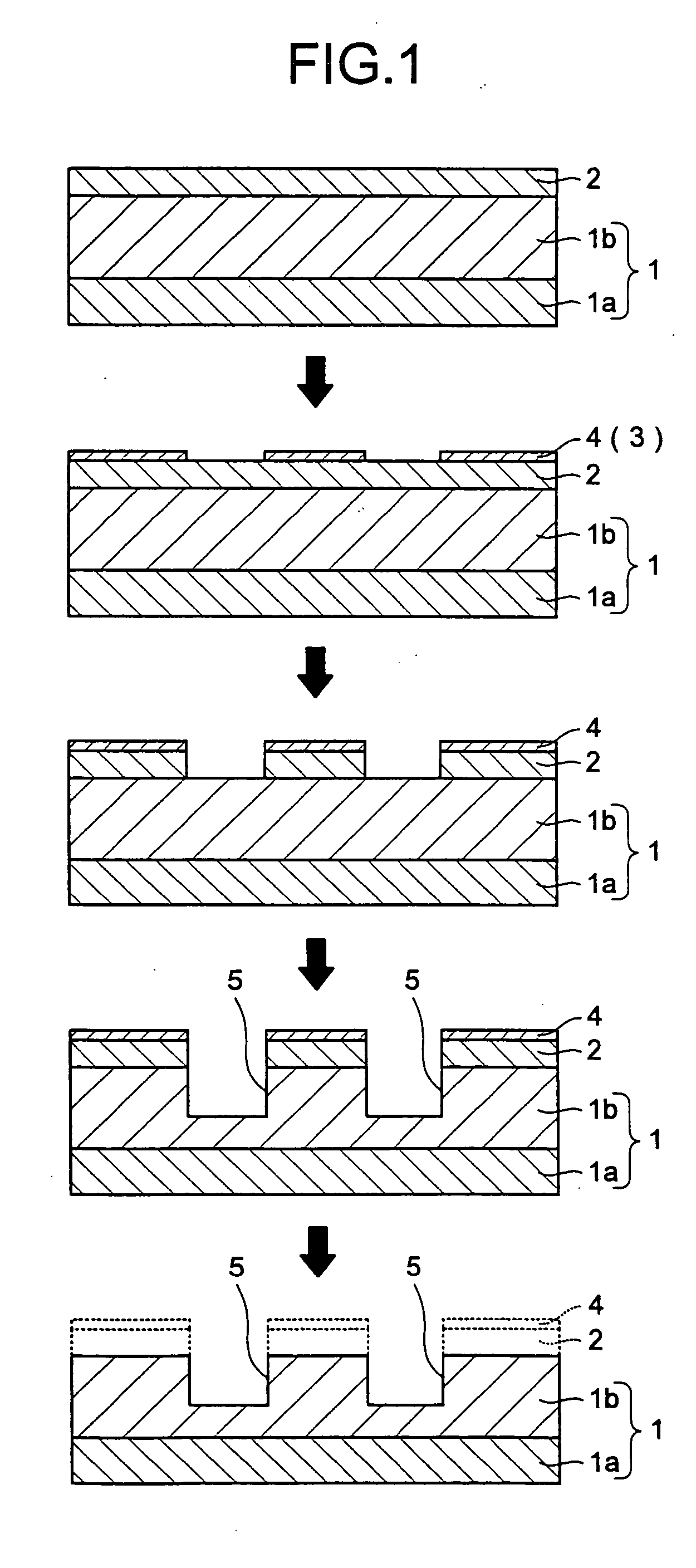

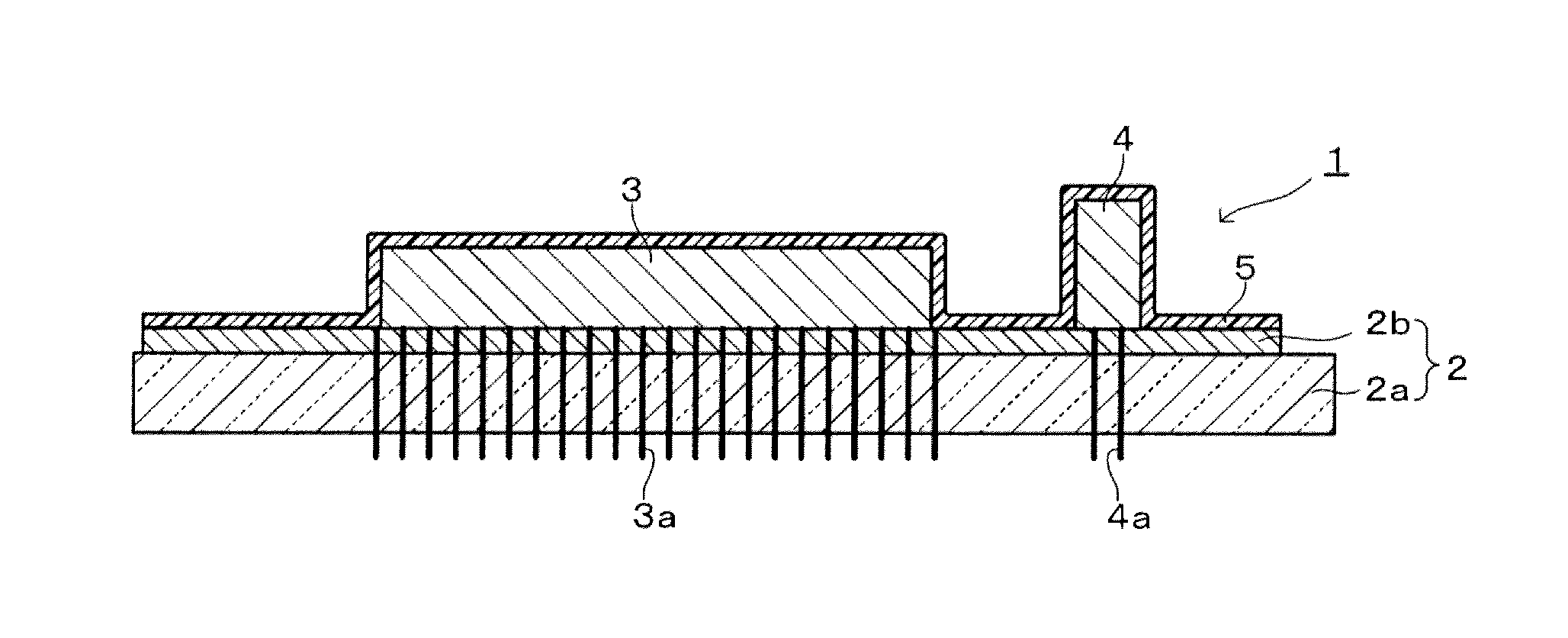

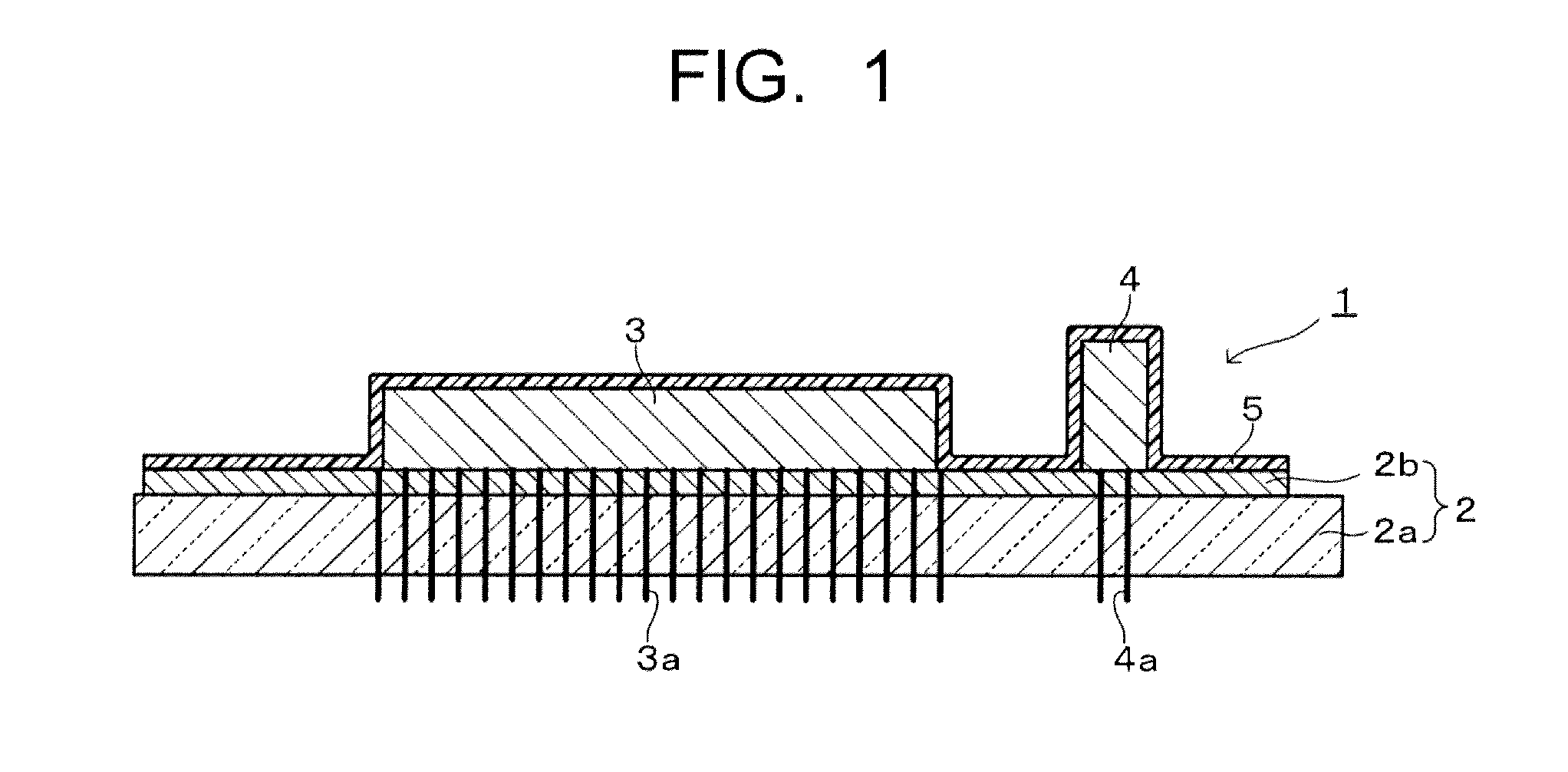

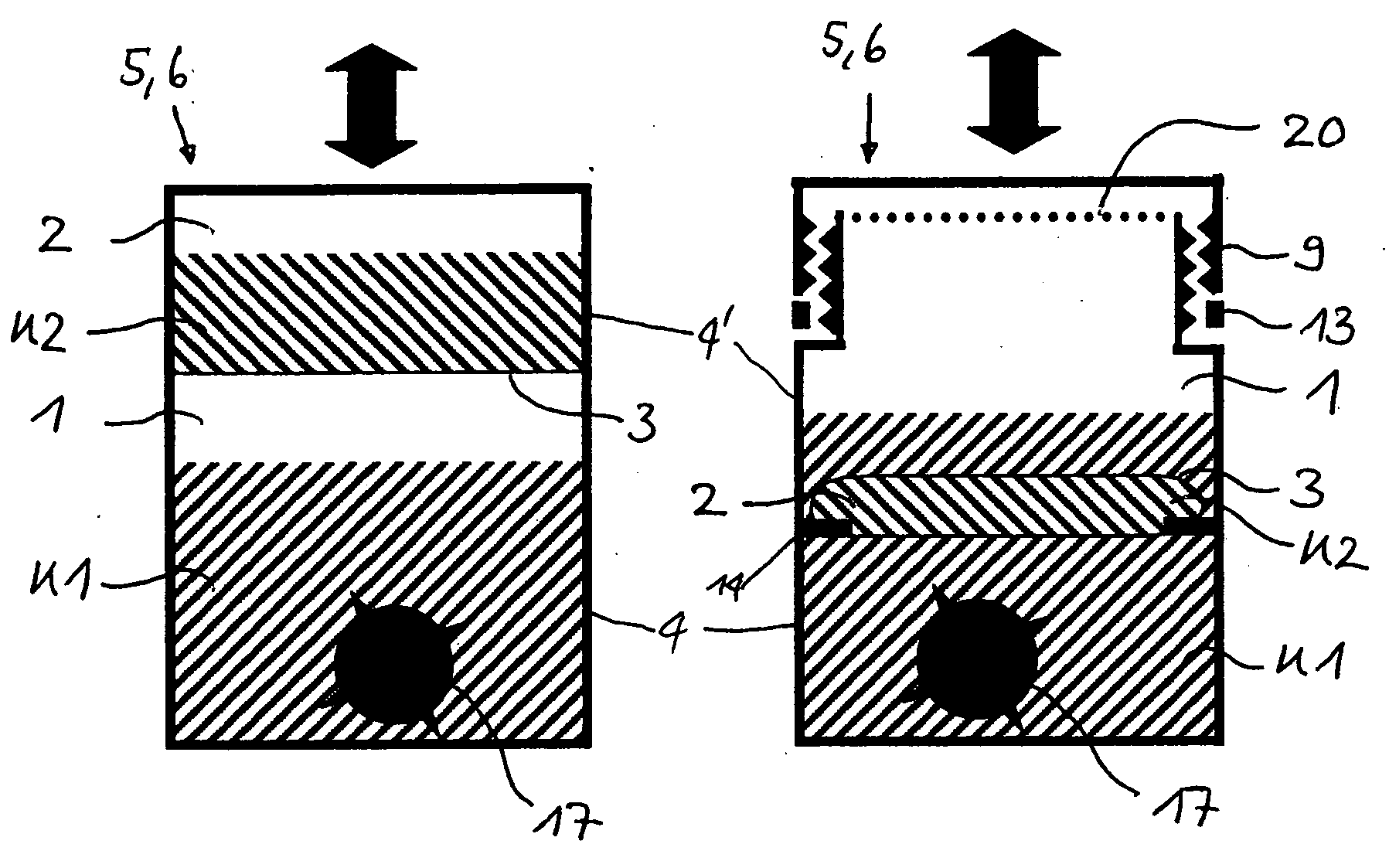

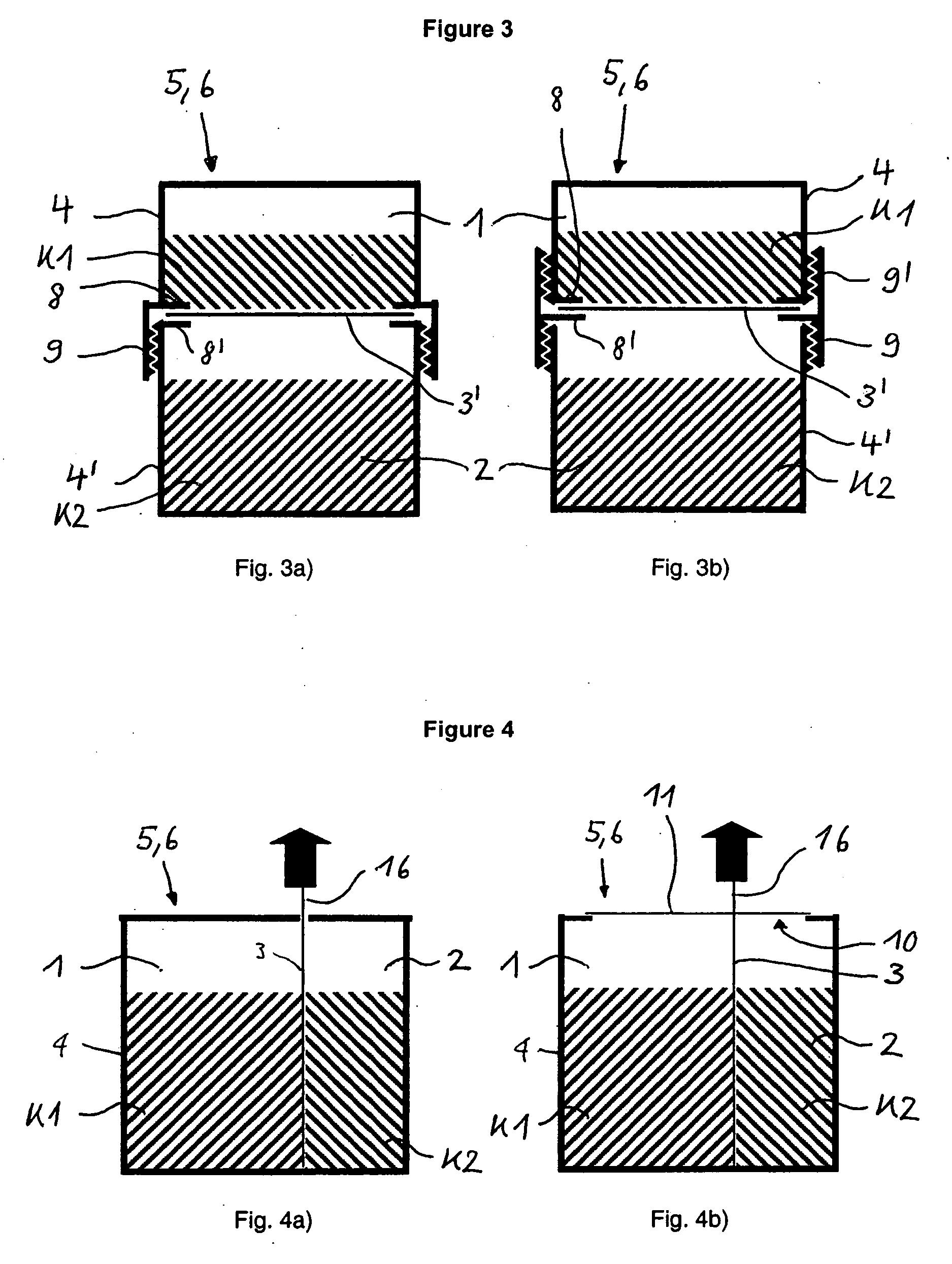

Two-Component Adhesion Promoter Composition and Use of Packaging Comprising Two Compartments

InactiveUS20080245271A1Stable storageEasy to produceGroup 4/14 element organic compoundsFibre treatmentOrganotitanium compoundPre treatment

The present invention discloses a two-component adhesion promoter composition for surface pretreatment, comprising two components, the first component, K1, comprising at least one hydrolyzable adhesion promoter substance A which is selected from the group comprising organosilicon compounds, organotitanium compounds, organozirconium compounds, and mixtures thereof; and the second component, K2, comprising at least one compound B which reacts with the adhesion promoter substance A or triggers or catalyzes condensation of the adhesion promoter substance A, and the first and the second components in the unopened state being present in two compartments (1, 2) separated from one another by at least one dividing wall (3). Additionally disclosed are the use of a pack (5) having two compartments (1, 2) which are separated from one another by a dividing wall, and a package (6) composed of a pack (5) and of a two-component adhesion promoter composition, in the compartments (1, 2) separated from one another by a dividing wall 3.

Owner:TRABESINGER GERALD +3

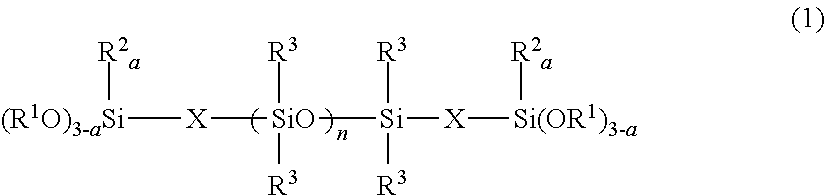

Carrier for two-component developer

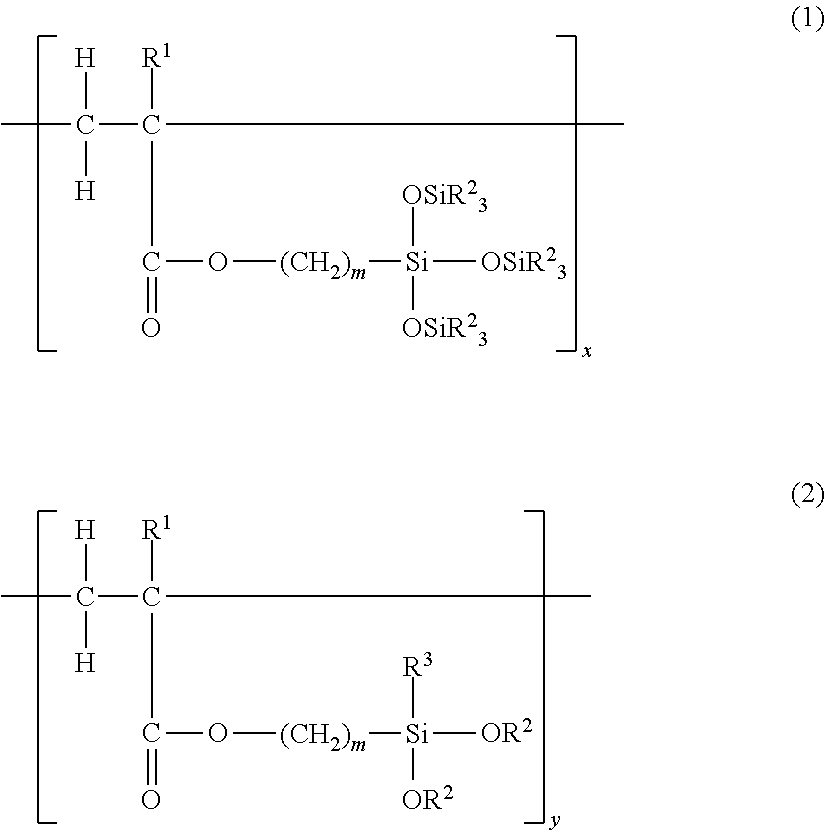

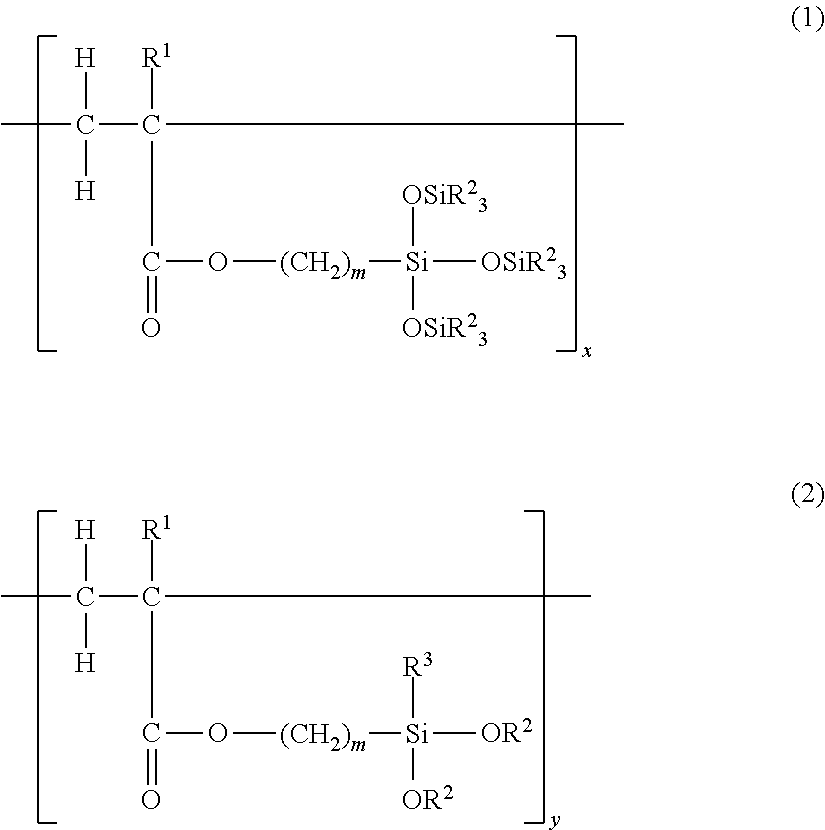

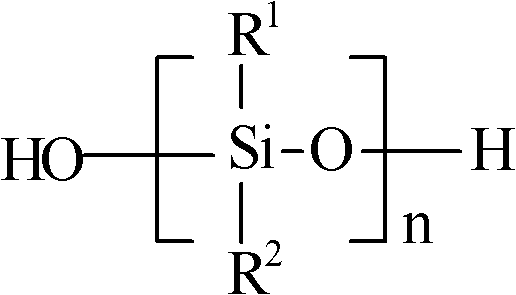

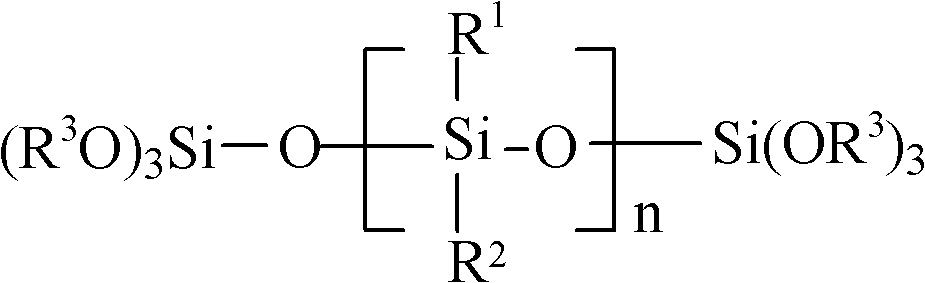

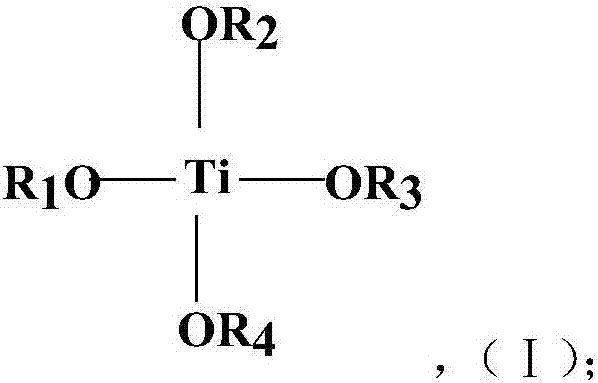

ActiveUS20110086307A1Good abrasionIncrease resistanceElectrographic process apparatusDevelopersCross-linkParticulates

A carrier, including a magnetic particulate core material and a resin layer on the core material, wherein the resin layer includes a resin obtained by heat treatment of a copolymer including a site derived from a monomer component having the following formula (1) and a site derived from a monomer component having the following formula (2), and includes a cross-linked material obtained by hydrolysis of the copolymer to produce a silanol group and condensation using an organotitanium compound:wherein R1 represents a hydrogen atom or a methyl group; m represents an alkylene group having 1 to 8 carbon atoms; R2 represents an alkyl group having 1 to 4 carbon atoms; R3 represents an alkyl group having 1 to 8 carbon atoms, or an alkoxy group having 1 to 4 carbon atoms; X represents 10 to 90 mol %; and Y represents 10 to 90 mol %.

Owner:RICOH KK

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Polyurethane elastomers, a process for the preparation thereof and the use thereof

InactiveUS20060293486A1Improve mechanical propertiesIncrease gas productionLithiumPolyurethane elastomer

The invention relates to polyurethane elastomers, a process for the preparation of these polyurethane elastomers and a the preparation of elastomeric molded parts comprising these polyurethane elastomers. These elastomers comprise the reaction product of a polyol component, chain extenders and / or crosslinking agents, one or more amine catalysts, a catalyst mixture which contains at least one organic titanium compound and at least one organic zinc compound, and optionally an organic lithium carboxylate and / or an organic bismuth carboxylate; with a polyisocyanate component.

Owner:BAYER MATERIALSCIENCE AG

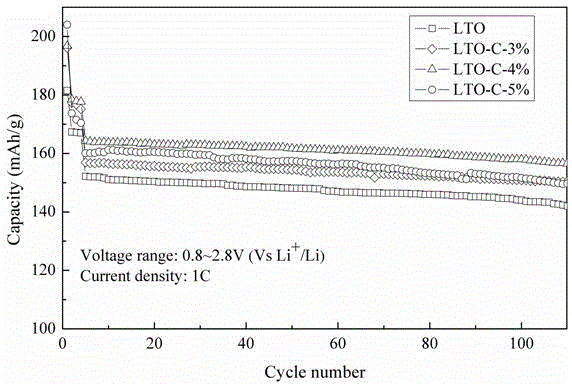

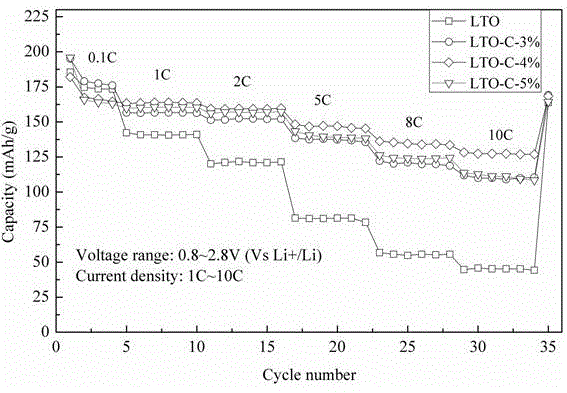

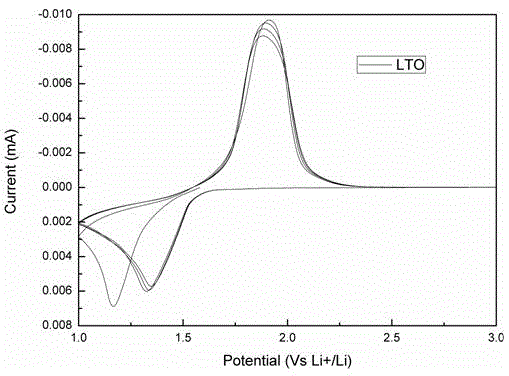

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

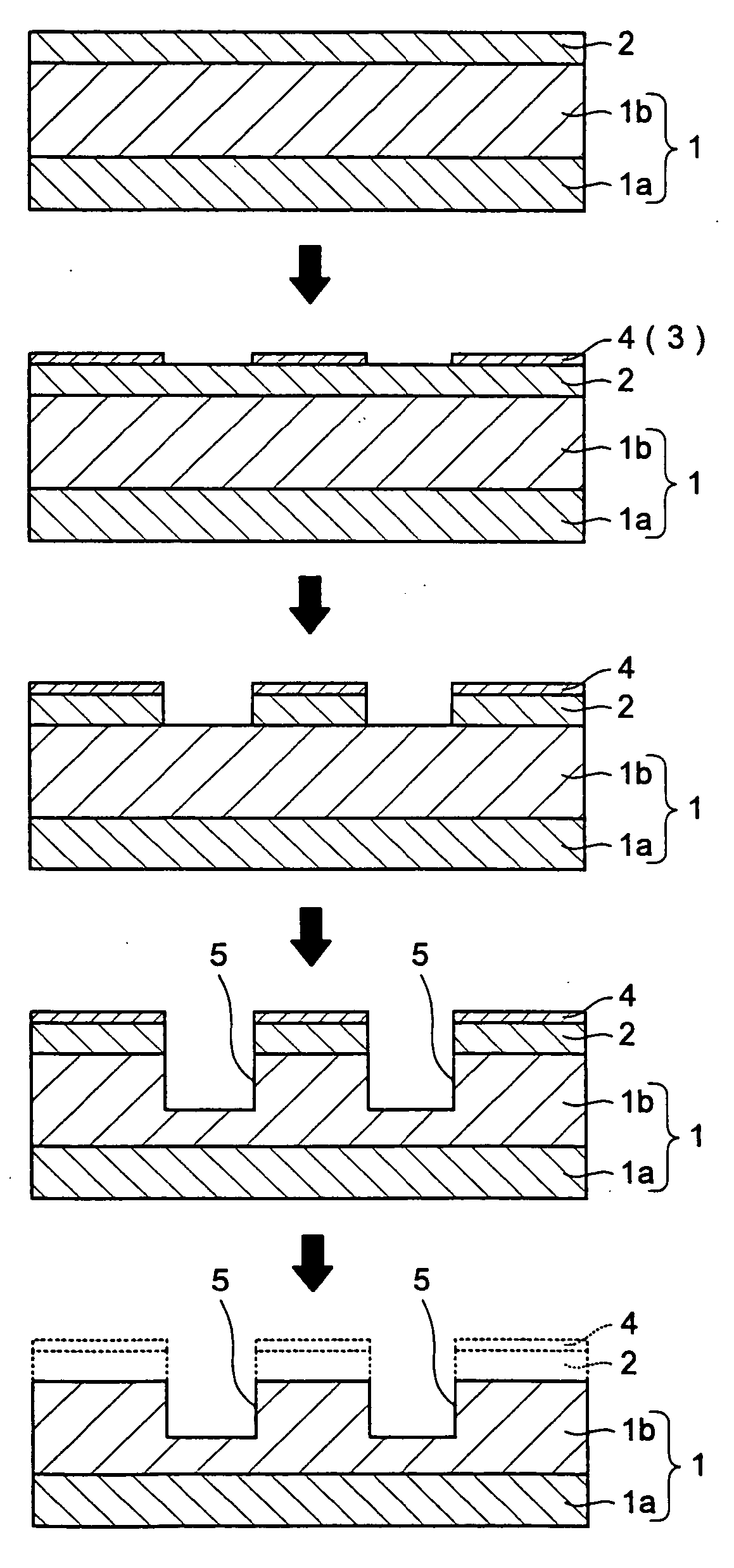

Undercoating layer material for lithography and wiring forming method using the same

InactiveUS20050112383A1Avoid damageEfficient utilization of materialLayered productsSemiconductor/solid-state device manufacturingResistAlkoxy group

An undercoating layer material for lithography, containing polysiloxane and an organotitanium compound having no alkoxy group; and a method for forming a wiring including a step of applying the undercoating layer material onto a substrate and curing to form an undercoating layer and forming a photoresist layer thereon; a step of removing by dry etching the exposed portion of the undercoating layer which is not covered with the photoresist pattern; a step of forming a predetermined wiring pattern using the photoresist pattern and the patterned undercoating layer as masks; and a step of removing the undercoating layer and photoresist pattern remaining on the substrate. The undercoating layer material is advantageous that the storage stability, the form of the lower portion of the resist pattern, and the burying properties are excellent and no voids are found.

Owner:TOKYO OHKA KOGYO CO LTD

Crosslinkable compositions based on organosilicon compounds

InactiveUS20060276585A1Increase heightReduce coefficient of frictionFibre treatmentSynthetic resin layered productsEpoxyCompound a

A low friction composition containing addition-crosslinking organosilicon compounds, at least one oval to sphere-shaped solid and at least one laminar solid, and at least one component which is: a hydrocarbyl compound having at least 8 carbon atoms, optionally containing heteroatoms; a silane of the formula(RO)4-nSiXnwhere R is a monovalent C1-16 hydrocarbyl radical and X is R or is a functional C1-16 hydrocarbyl radical linking an epoxy or methacryloyloxy organic functional group and the silicon atom, an organozirconium or organotitanium compound of the formula (RO)4-nMXn where R and X are as defined above and M is Ti or Zr; and optionally, (4) an organic solvent.

Owner:WACKER CHEM GMBH

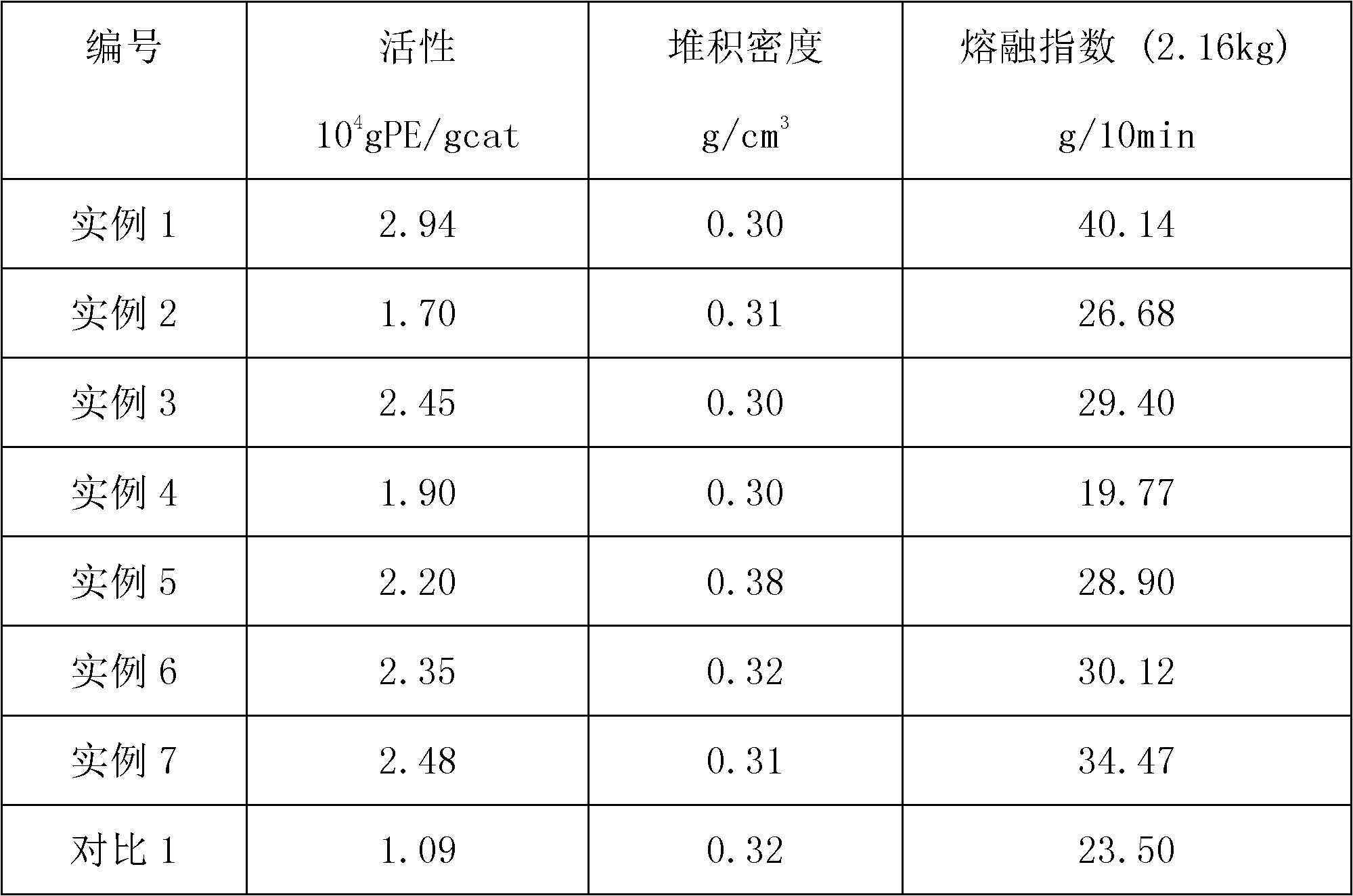

Preparation method of catalyst component for ethylene polymerization or copolymerization and catalyst thereof

InactiveCN102875707AHigh catalytic activityNarrow particle size distributionSolid componentOrganotitanium compound

The invention relates to a preparation method of a catalyst component for ethylene polymerization or copolymerization and a catalyst thereof. The method comprises the following steps: (1) at a temperature of 50-90DEG, dissolving magnesium halide in a solvent system containing an organic epoxy compound and an organic phosphorus compound to form a uniform solution; adding an organic alcohol compound during or after the solution formation and leaving them to react for certain time so as to obtain a reaction solution; (2) in the presence of an organic titanium compound and at a temperature of -30DEG C-0DEG C, subjecting the solution and a titanium compound to a contact reaction, or adding the organic titanium compound after the contact reaction of the solution obtained in step (1) and the titanium compound, and raising the temperature of the mixture slowly to 50-120DEG C, leaving solids to precipitate gradually and form particles, after certain period of reaction, removing the unreacted material and the solvent, and conducting washing with an inert diluent so as to obtain a solid component; and (3) suspending the solid component in certain amount of the inert diluent, performing a contact reaction with an organic aluminium compound under a temperature of 0DEG C-50DEG C, and after certain reaction time, removing the inert diluent, thus obtaining the catalyst component. The catalyst provided in the invention has high catalytic activity and good hydrogen response.

Owner:CHINA PETROLEUM & CHEM CORP +1

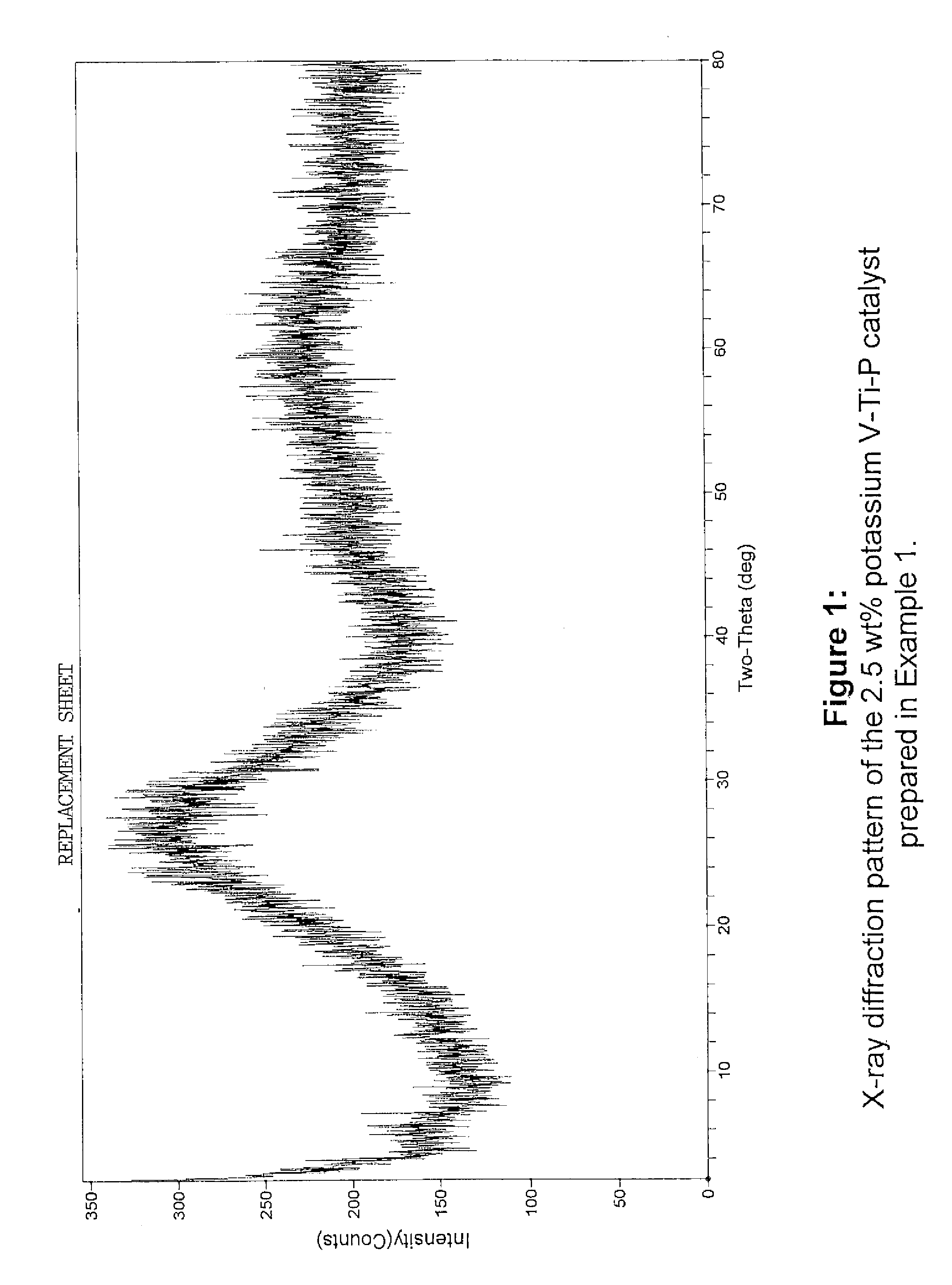

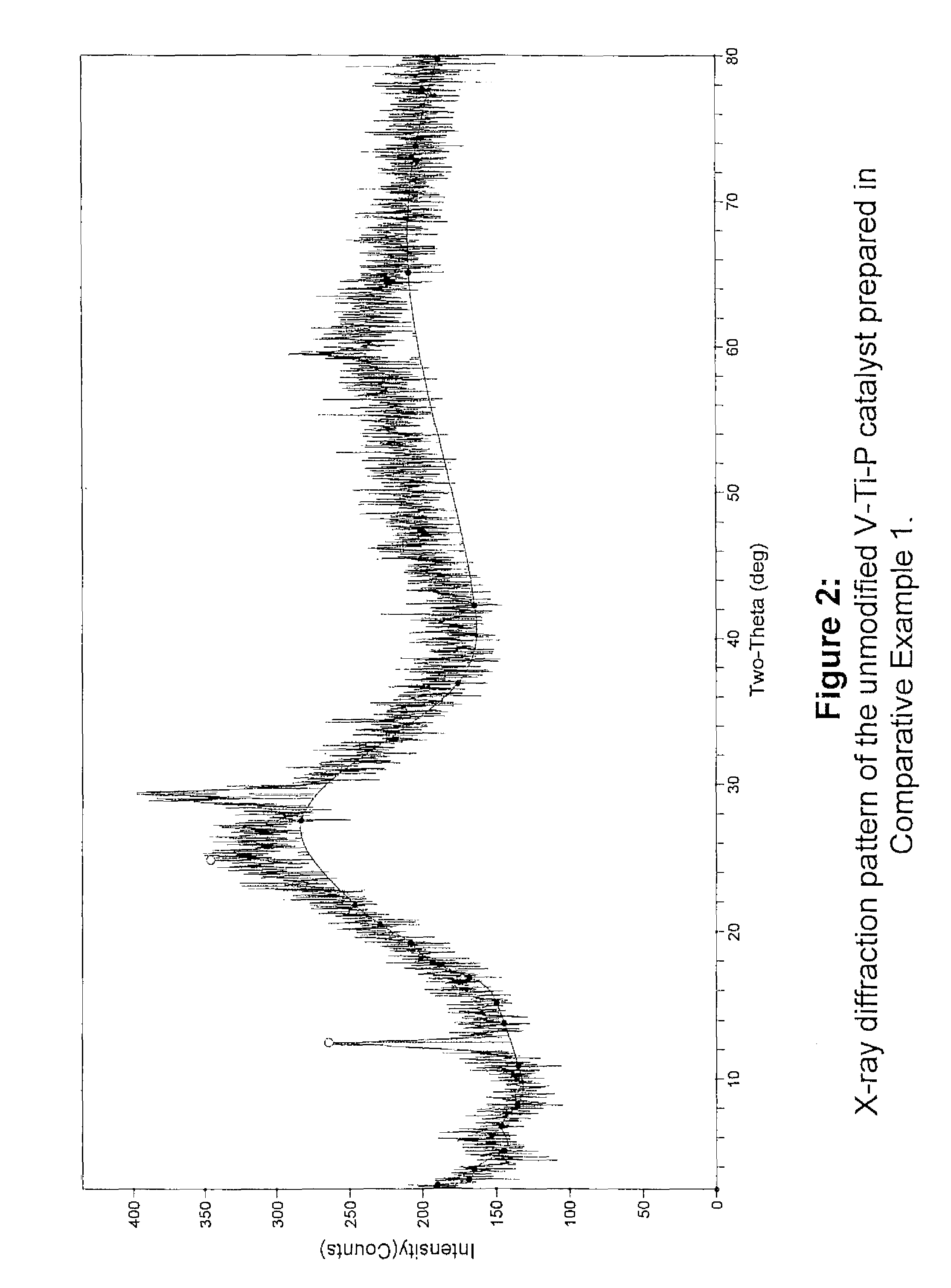

Process for preparing V-Ti-P catalysts for synthesis of 2,3-unsaturated carboxylic acids

ActiveUS8765629B2Organic compound preparationOrganic chemistry methodsOrganotitanium compoundChemistry

The invention relates to a catalyst composition comprising a mixed oxide of vanadium, titanium, and phosphorus. The titanium component is derived from a water-soluble, redox-active organo-titanium compound. The catalyst composition is highly effective at facilitating the vapor-phase condensation of formaldehyde with acetic acid to generate acrylic acid, particularly using an industrially relevant aqueous liquid feed.

Owner:EASTMAN CHEM CO

PROCESS FOR PREPARING V-Ti-P CATALYSTS FOR SYNTHESIS OF 2,3-UNSATURATED CARBOXYLIC ACIDS

The invention relates to a catalyst composition comprising a mixed oxide of vanadium, titanium, and phosphorus. The titanium component is derived from a water-soluble, redox-active organo-titanium compound. The catalyst composition is highly effective at facilitating the vapor-phase condensation of formaldehyde with acetic acid to generate acrylic acid, particularly using an industrially relevant aqueous liquid feed. Additionally, the catalyst composition is catalytically active towards the formation of acrylic acid from methylene diacetate and methacrylic acid from methylene dipropionate; both reactions are carried out with high space time yields.

Owner:EASTMAN CHEM CO

Silicone rubber composition for fabric coating and coated fabric

InactiveUS20100190396A1Strong adhesionImprove manufacturing process efficiencyLayered productsPedestrian/occupant safety arrangementOrganotitanium compoundTitanium

A silicone-rubber composition for coating textile fabrics characterized in that the silicone-rubber composition is a solventless hydrosilylation reaction-curable composition, has a viscosity at 25° C. in the range of 100 to 500 Pa·s, and contains an alkoxysilane that contains a methacrylic group or an acrylic group and a zirconium chelate compound, but does not contain an organic titanium compound. And a textile fabric coated with the silicone-rubber composition for coating textile fabrics.

Owner:DOW CORNING TORAY CO LTD

Titanium and zirconium mixtures and emulsions for use in preparing gypsum wallboard

ActiveUS20100152347A1Use minimizedReduce moistureGroup 4/14 element organic compoundsDuplicating/marking methodsWaxEmulsion

Provided herein are mixtures, emulsions and other additives for use in manufacturing gypsum wallboard. The mixtures and emulsions may be wax-based emulsions or wax-free mixtures or emulsions, with wax-based emulsions including water, at least one wax, a dispersant which may include sulfur or a sulfur-containing group, and an additive comprising an organic titanium compound or organic zirconium compound. Mixtures may also be prepared including water, a dispersant; and an additive comprising an organic titanium compound or organic zirconium compound. Gypsum slurries may be prepared using such emulsions and mixtures and / or through addition of an organic titanium compound or organic zirconium compound.

Owner:OU HENRY

Room-temperature-curable polyorganosiloxane composition and electric/electronic apparatus

InactiveUS20150140346A1Low viscosityGood paintabilityLayered productsCoatingsSilane compoundsCross-link

This room-temperature-curable polyorganosiloxane composition contains: (A) 100 parts by mass of polyorganosiloxane consisting of: (A1) 10 to 80 parts by mass of a both ends alkoxysilyl group-terminated polyorganosiloxane and (A2) 90 to 20 parts by mass of a partial hydrolysis condensate (the number of Si atoms is 10 to 200) of a silane compound expressed by a general formula: R4bSi(OR)4-b; (B) 0.1 to 15 parts by mass of a silane compound or a partial hydrolysis condensate thereof (the number of Si atoms is 1 or more and less than 10) as a cross-linking agent; and (C) 0.1 to 15 parts by mass of an organic titanium compound as a curing catalyst. It has low viscosity and good coatability without a solvent, and forms a cured coating film excellent in scratch resistance.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

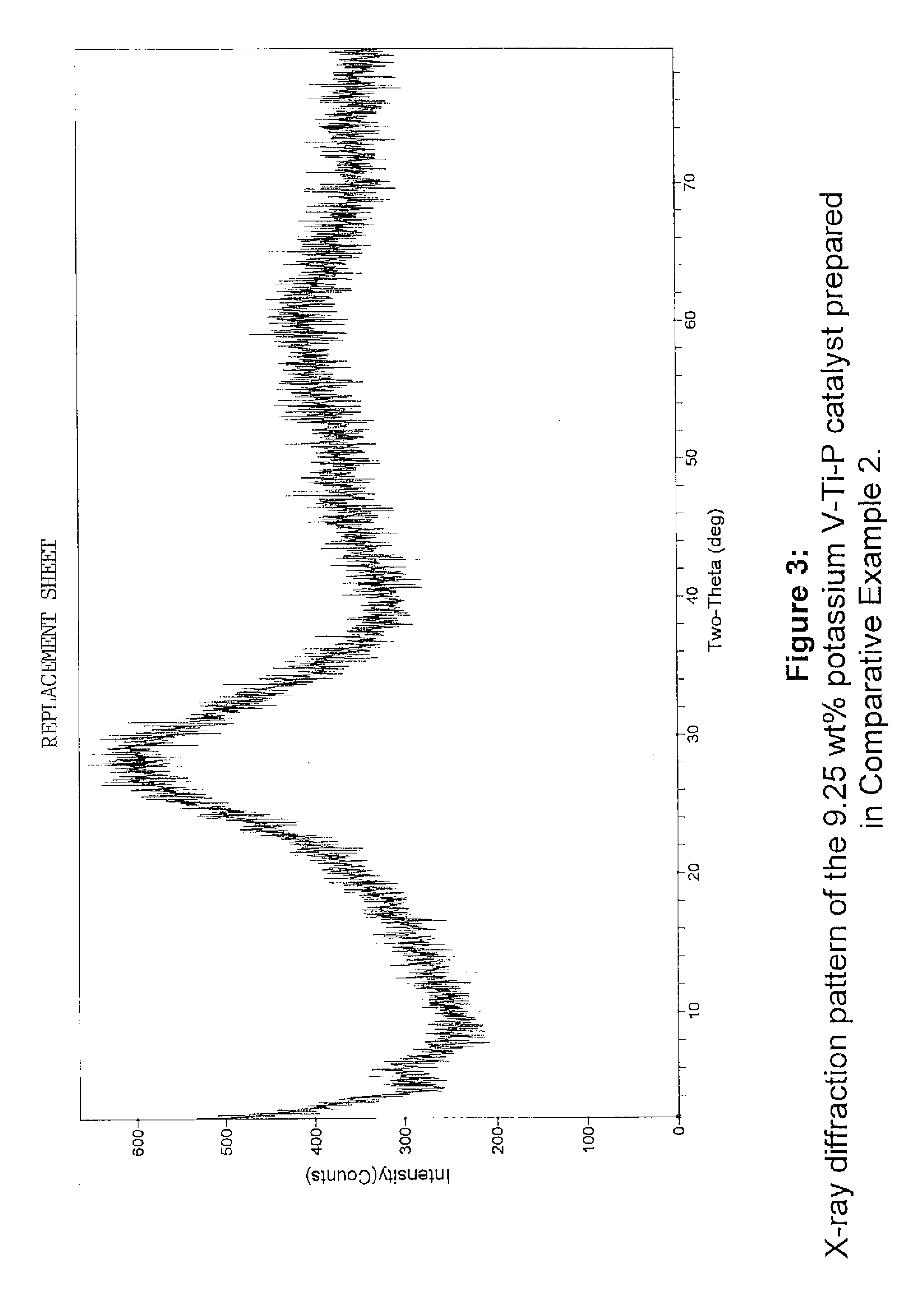

PROCESS FOR PREPARING MODIFIED V-Ti-P CATALYSTS FOR SYNTHESIS OF 2,3-UNSATURATED CARBOXYLIC ACIDS

ActiveUS20130072716A1Organic compound preparationOrganic chemistry methodsOrganotitanium compoundAlkali metal

The invention relates to a catalyst composition comprising a mixed oxide of vanadium, titanium, and phosphorus modified with alkali metal. The titanium component is derived from a water-soluble, redox-active organo-titanium compound. The catalyst composition is highly effective at facilitating the vapor-phase condensation of formaldehyde with acetic acid to generate acrylic acid, particularly using an industrially relevant aqueous liquid feed.

Owner:EASTMAN CHEM CO

Adhesion promoting compound

ActiveUS20130157020A1Reduce scrap rateReduce chanceDecorative surface effectsDuplicating/marking methodsPolymer scienceSolvent based

The present invention is drawn to adhesion promoters comprising an organotitanium compound and a polyamide, for use in solvent-based liquid inks and coatings for flexible packaging, including non-direct food packaging, uses of such adhesion promoters, methods of using such adhesion promoters, inks and coating comprising such adhesion promoters and articles printed with the inks and coatings comprising such adhesion promoters, for example, a laminated printed article (20) comprising a printed image (1) on a substrate (2) and superimposed with an overlay (3) wherein the printed image (1) is prepared from inks or coatings comprising the adhesion promoters.

Owner:SUN CHEMICAL BV

Preparation method of PBS (poly butylenes succinate)

The invention relates to a preparation method of PBS (poly butylenes succinate). The preparation method comprises the following steps: adopting succinic acid and butanediol with the molar ratio of (1.2-2.2): 1 as the raw materials; carrying out negative pressure esterification reaction for about 3.5 hours at the pressure of 40-80 kPaA and the temperature of 135-160 DEG C; afterwards, carrying out polycondensation reaction for about 2.5 hours at the pressure of 2-4 kPaA and the temperature of 170-210 DEG C to prepare the PBS with high molecular weight, wherein the whole reaction is carried out under the condition of catalyst existence; the catalyst is a titanium-phosphorus coordination composite catalyst generated through carrying out coordination reaction on raw materials, namely, organic phosphorus compounds and organic titanium compounds; the molar ratio of the catalyst dosage to the succinic acid dosage is 0.03%-3%. According to the PBS with high molecular weight prepared through the preparation method, the number-average molecular weight is 100 thousand or above, the tensile strength is 36 MPa or above, and the elongation at rupture is 250% or above.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

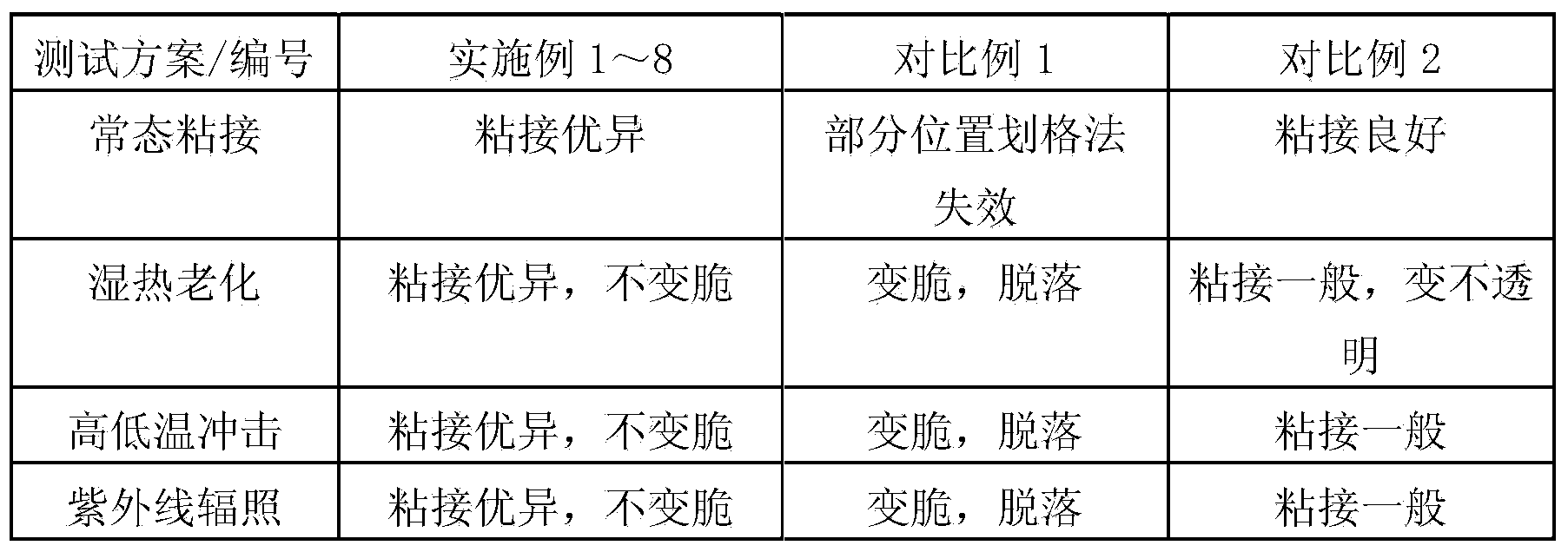

Method for improving adhesion property and prolonging service life of acrylic coating

The invention discloses a method for improving the adhesion property and prolonging service life of acrylic coating. The method comprises the steps of: adding organic titanium compound into the acrylic coating, wherein the organic titanium compound content is 0.05-3% of the weight of the acrylic coating; adding organosilicon tackifier which has Si-H, Si-CH3 obtained through substituting -H by CH3, or Si-C2H5 obtained through substituting -H by -C2H5, epoxy group or alkoxy group in the molecular structure, wherein the organosilicon tackifier content is 0.05-5% of the weight of the acrylic coating; adding a water removing agent into the acrylic coating, wherein the water removing agent content is 0.1-5% of weight of the acrylic coating. The method has the advantages that the performances of normal adhesion, wet-heat adhesion and adhesion after high / low-temperature impact of the acrylic coating to glass, plastic, metal and other substrates are improved, and meanwhile, the weather ability and hydrophobicity of the coating are also improved, the moisture transmittance of the coating is reduced, and the service life of the coating is prolonged.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

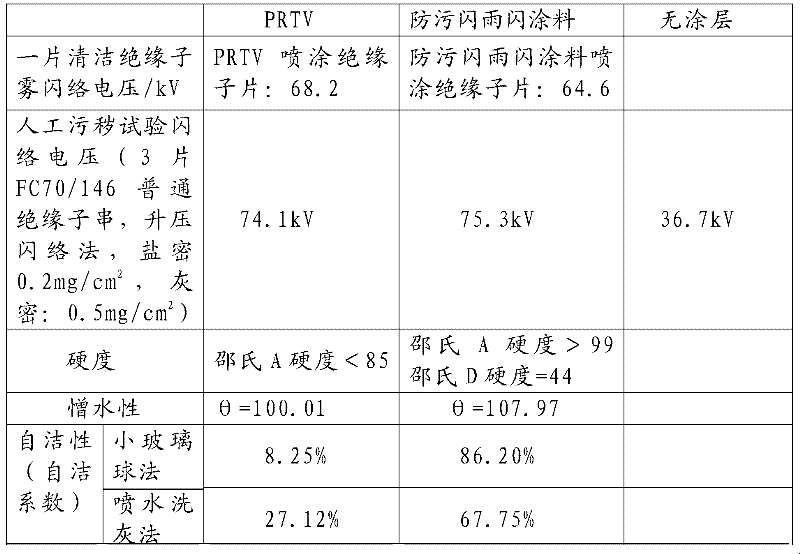

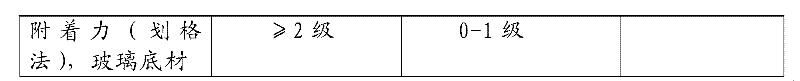

Pollution/rain flashover resistant paint and preparation method thereof

ActiveCN102391752AImprove adhesionImprove wear resistanceAntifouling/underwater paintsPaints with biocidesSilanesOrganotitanium compound

The invention discloses a pollution / rain flashover resistant paint. The paint comprises the following components in parts by weight: 40-50 parts of silicon rubber, 40-50 parts of MQ silicon resin, 50-80 parts of a solvent, 5-20 parts of fillers, 50-70 parts of silicone acrylate resin, 0.5-3 parts of a curing agent and 3-6 parts of catalysts, wherein the silicon rubber is hydroxyl-terminated polydialkylsiloxane; the MQ silicon resin is methyl hydrogen-containing MQ silicon resin with M-Q ratio being 0.6-0.9; the solvent is one or mixture of butyl acetate, ethyl acetate and methyl acetate; the fillers are one or more of nano calcium carbonate, fumed silica, titanium dioxide and silica micropowder, which are subjected to surface modification treatment by silane; the curing agent is zirconiumisooctoate, cobalt isooctoate or cobalt naphthenate; and the catalysts are tin compounds or organic titanium compounds. The invention also discloses a preparation method of the pollution / rain flashover resistant paint.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Polyurethane elastomers, process of their preparation and their use

The invention relates to polyurethane elastomers, a process for the preparation of these polyurethane elastomers and a the preparation of elastomeric molded parts comprising these polyurethane elastomers. These elastomers comprise the reaction product of a polyol component, chain extenders and / or crosslinking agents, one or more amine catalysts, a catalyst mixture which contains at least one organic titanium compound and at least one organic zinc compound, and optionally an organic lithium carboxylate and / or an organic bismuth carboxylate; with a polyisocyanate component.

Owner:BAYER MATERIALSCIENCE AG

Two-component adhesion promoter composition and use of packaging comprising two compartments

ActiveUS20080283425A1Stable storageEasy to produceGroup 4/14 element organic compoundsNon-macromolecular adhesive additivesOrganotitanium compoundOrganosilicon

The present invention discloses a two-component adhesion-promoter composition for surface pretreatment, comprising two components, the first component, K1, comprising at least one hydrolyzable adhesion promoter substance A which is selected from the group comprising organosilicon compounds, organotitanium compounds, organozirconium compounds, and mixtures thereof; and the second component, K2, comprising at least one compound B which reacts with the adhesion promoter substance A or triggers or catalyzes condensation of the adhesion promoter substance A, and the first and the second components in the unopened state being present in two compartments (1, 2) separated from one another by at least one dividing wall (3).Additionally disclosed are the use of a pack (5) having two compartments (1, 2) which are separated from one another by a dividing wall, and a package (6) composed of a pack (5) and of a two-component adhesion promoter composition, in the compartments (1, 2) separated from one another by a dividing wall 3.

Owner:SIKA TECH AG

Process for preparing modified V-Ti-P catalysts for synthesis of 2,3-unsaturated carboxylic acids

ActiveUS8883672B2Organic compound preparationOrganic chemistry methodsOrganotitanium compoundAlkali metal

The invention relates to a catalyst composition comprising a mixed oxide of vanadium, titanium, and phosphorus modified with alkali metal. The titanium component is derived from a water-soluble, redox-active organo-titanium compound. The catalyst composition is highly effective at facilitating the vapor-phase condensation of formaldehyde with acetic acid to generate acrylic acid, particularly using an industrially relevant aqueous liquid feed.

Owner:EASTMAN CHEM CO

Preparation method of titanium dioxide-zirconium oxide composite fibers

ActiveCN103127923AHigh photocatalytic activityImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberOrganotitanium compound

The invention relates to a preparation method of titanium dioxide-zirconium oxide composite fibers, which comprises the following steps: dissolving polyacetylacetonatozirconium in an alcohol solvent, adding 95-5 mol% of zirconium oxide and 5-95 mol% of titanium dioxide into an organic titanium compound, and concentrating at 32-45 DEG C under reduced pressure until the solution viscosity reaches 10-50 Pa.s, thereby obtaining a spinning solution; and carrying out centrifuging spinning to obtain titanium dioxide-zirconium oxide composite precursor gel fibers, and carrying out high-heat treatment to obtain the high-quality titanium dioxide-zirconium oxide composite fibers. The titanium dioxide-zirconium oxide fibers can be reprocessed into fiber cloth, paper or any other shape; and on the premise of keeping the catalytic activity, the specific area can be fully utilized, and the photocatalysis effect is good.

Owner:山东德艾普节能材料有限公司

Catalyst for producing polytrimethylene terephthalate, and preparation method and application thereof

The invention relates to a catalyst for producing polytrimethylene terephthalate in order to mainly solve the problem of deficiency of catalysts for producing polytrimethylene terephthalate with lowcontent of cyclic dimer in the prior art. Reactants containing a titanium compound, straight-chain diol, hydroxycarboxylic acid and a metal organic salt are used in the invention, wherein the metal element of the metal organic salt is at least one metal element selected from magnesium, aluminum, zinc and zirconium. A preparation method of the catalyst comprises the following steps: reacting the organic titanium compound with the saturated straight-chain diol and hydroxycarboxylic acid at 10-150 DEG C for 0.1-24 h, adding the metal organic salt to the obtained product, carrying out a reaction at 10-150 DEG C for 0.1-24 h, and removing low-carbon alcohol and / or water in the obtained system to obtain the catalyst for producing polytrimethylene terephthalate The method well solves the problem,and can be used in the industrial production of polytrimethylene terephthalate with low content of the cyclic dimer.

Owner:CHINA PETROLEUM & CHEM CORP +1

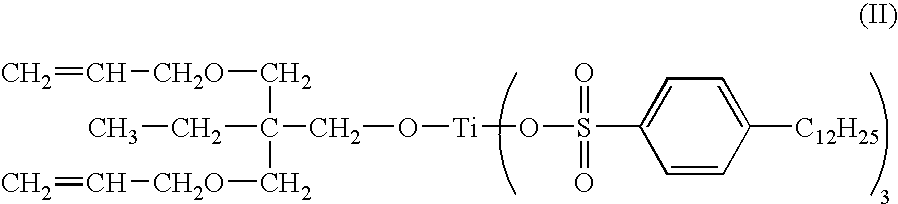

Micro/nano-scale sheet type titanium polyester catalyst and application thereof

The invention belongs to the technical field of titanium polyester catalysts and in particular relates to a micro / nano-scale sheet type titanium polyester catalyst and the application thereof. The micro / nano-scale sheet type titanium polyester catalyst provided by the invention comprises an organic titanium compound and a dispersing medium, wherein the structural formula of the organic titanium compound is Tix(OR1O)y(OOCC6H4COO)zH4. The invention further provides the titanium polyester catalyst for esterification reaction, transesterification and / or polycondensation reaction in catalytic polyester synthesis. Compared with the traditional polyester catalyst antimony acetate, the titanium polyester catalyst provided by the invention has the advantage that the reaction speed in the polycondensation stage is increased by more than 60%; compared with the titanium or titanium composite polyester catalyst, the titanium polyester catalyst provided by the invention has the advantage of good compatibility with the polyester; the micro / nano-scale sheet type titanium polyester catalyst provided by the invention has the advantages of low agglomeration, hydrolysis resistance, high temperature resistance and the like and is an efficient and stable polyester catalyst with low toxicity.

Owner:上海慧翌新材料科技有限公司

Biodegradable polyester composite catalyst, as well as preparation method and using method thereof

InactiveCN103333328ASimple preparation processSimple and fast operationOrganotitanium compoundTitanium

The invention relates to the technical field of catalysts for biodegradable polyester and discloses a biodegradable polyester composite catalyst, as well as a preparation method and a using method thereof. The biodegradable polyester composite catalyst comprises the following raw materials in parts by weight: 50-98 parts of organic titanium compound, 1-30 parts of organic silicon compound and 0-10 parts of cocatalyst, and the biodegradable polyester composite catalyst is obtained through the following method: firstly stirring and uniformly mixing the organic titanium compound in the required quantity with the organic silicon compound in the required quantity, and then continuously stirring and uniformly mixing the cocatalyst in the required quality with the organic titanium compound in the required quantity and the organic silicon compound in the required quantity to get the biodegradable polyester composite catalyst. The biodegradable polyester composite catalyst disclosed by the invention has the characteristics of simple preparation process, simplicity and convenience in operation, lower preparation cost and easiness in industrial production, and by adopting the biodegradable polyester composite catalyst obtained in the invention, the reaction time is shortened, and the polyester with good color phase and high molecular weight can be prepared.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK +1

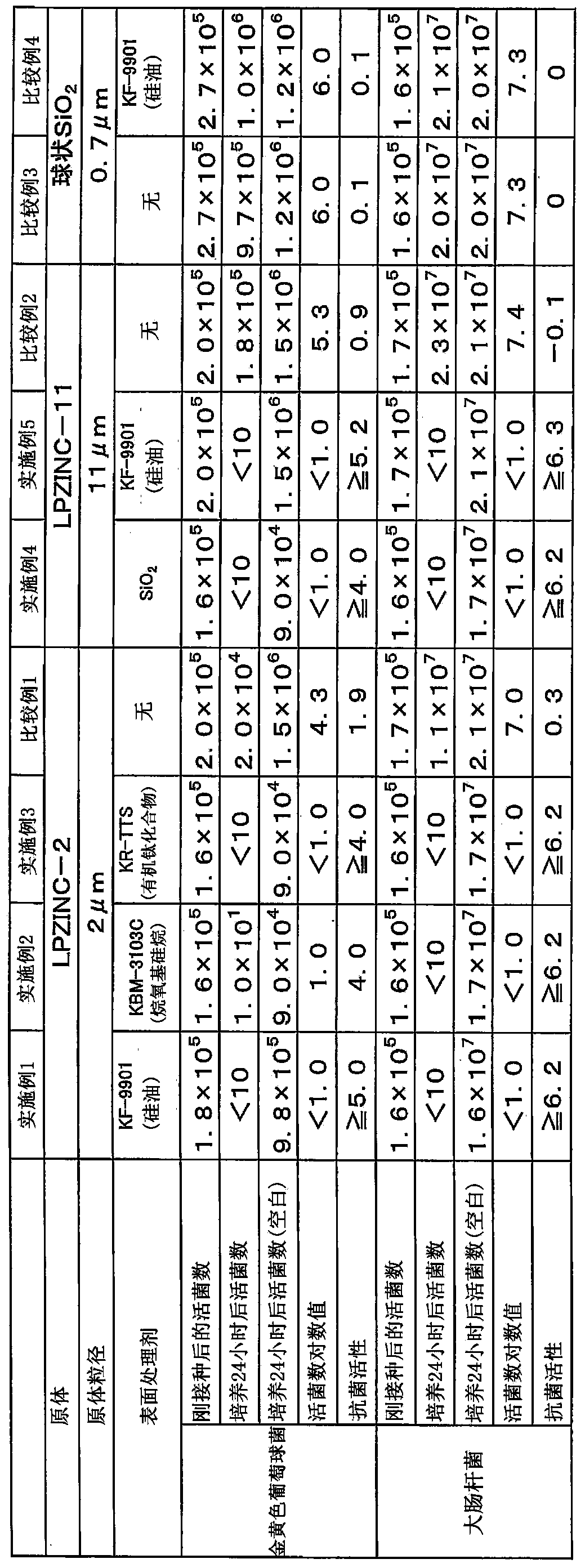

Surface-treated zinc oxide powder, anti-bacterial agent, and anti-bacterial composition

InactiveCN103974906AImprove antibacterial propertiesCosmetic preparationsBiocideOrganotitanium compoundSilicon oxide

Provided is a zinc oxide powder having an average particle diameter of 1.1 mum or more and having an anti-bacterial activity; an anti-bacterial agent comprising the zinc oxide powder; and an anti-bacterial composition containing the anti-bacterial agent. A surface-treated zinc oxide powder which has an average particle diameter of 1.1 mum or more and of which the surface is treated with at least one compound selected from silicon oxide, a silicone oil, an organosilicon compound and an organotitanium compound.

Owner:SAKAI CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com