Preparation method of titanium dioxide-zirconium oxide composite fibers

A titanium dioxide and composite fiber technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of reducing the photocatalytic contact area of titanium dioxide, reducing the contact area between titanium dioxide and degraded substances, and reducing the photocatalytic effect of titanium dioxide. Catalytic effect and other issues, to achieve full utilization of specific surface area, easy separation, and improved catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

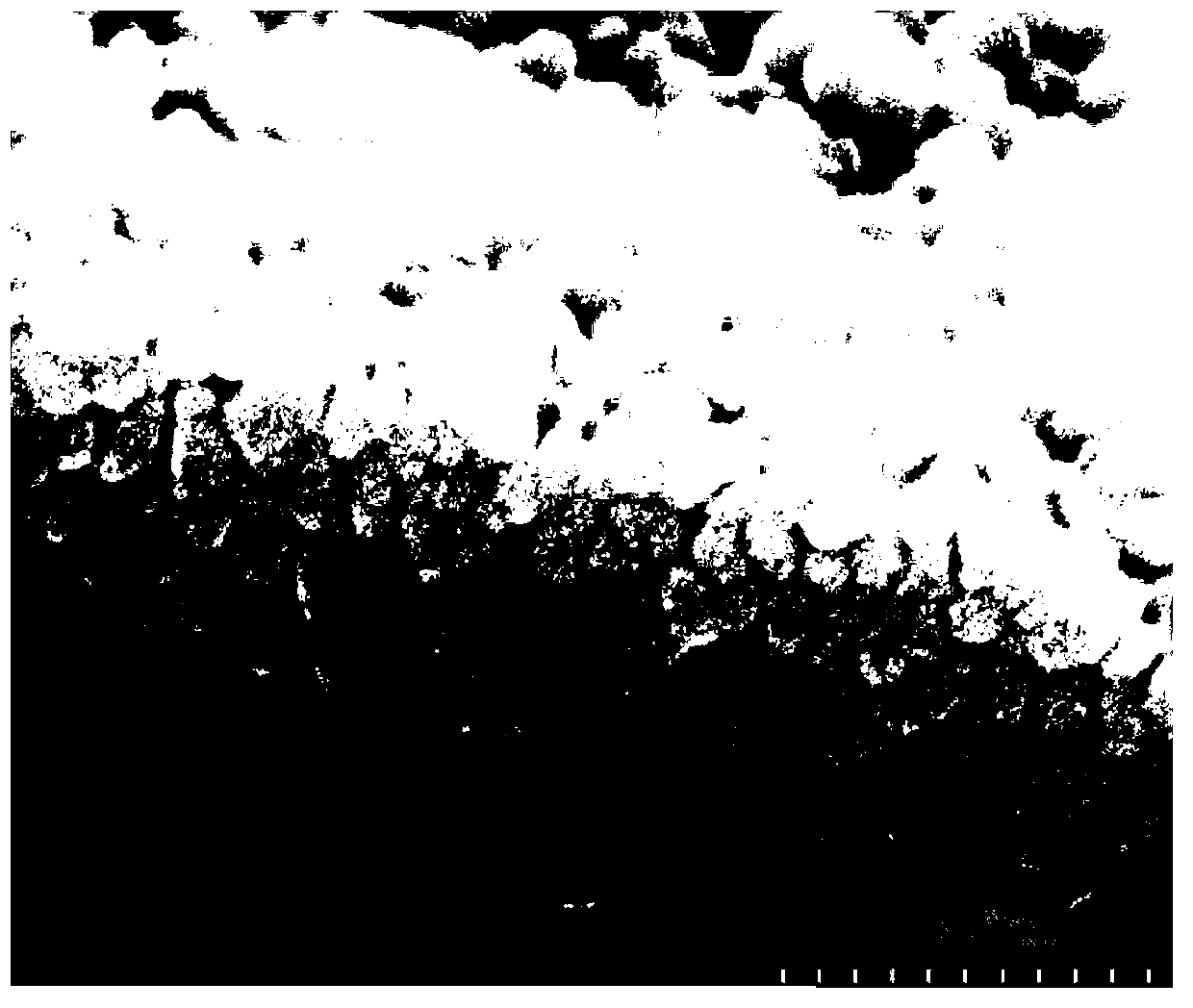

[0027] (1) Dissolve 2.41g of polyacetylacetonate zirconium (PAZ) and 30.60g of tetrabutyl titanate (molar ratio 1:9, molar ratio of zirconia to titania, the same below) in 100ml of anhydrous methanol, room temperature Stir for 30 minutes until completely dissolved, and mix well. Concentrate the mixed solution under reduced pressure at 32-37°C to remove part of the methanol solvent to obtain a sol with a viscosity of about 30 Pa·s, and let it stand at room temperature for 24 hours to homogenize and defoam to obtain a golden yellow spinnable solution.

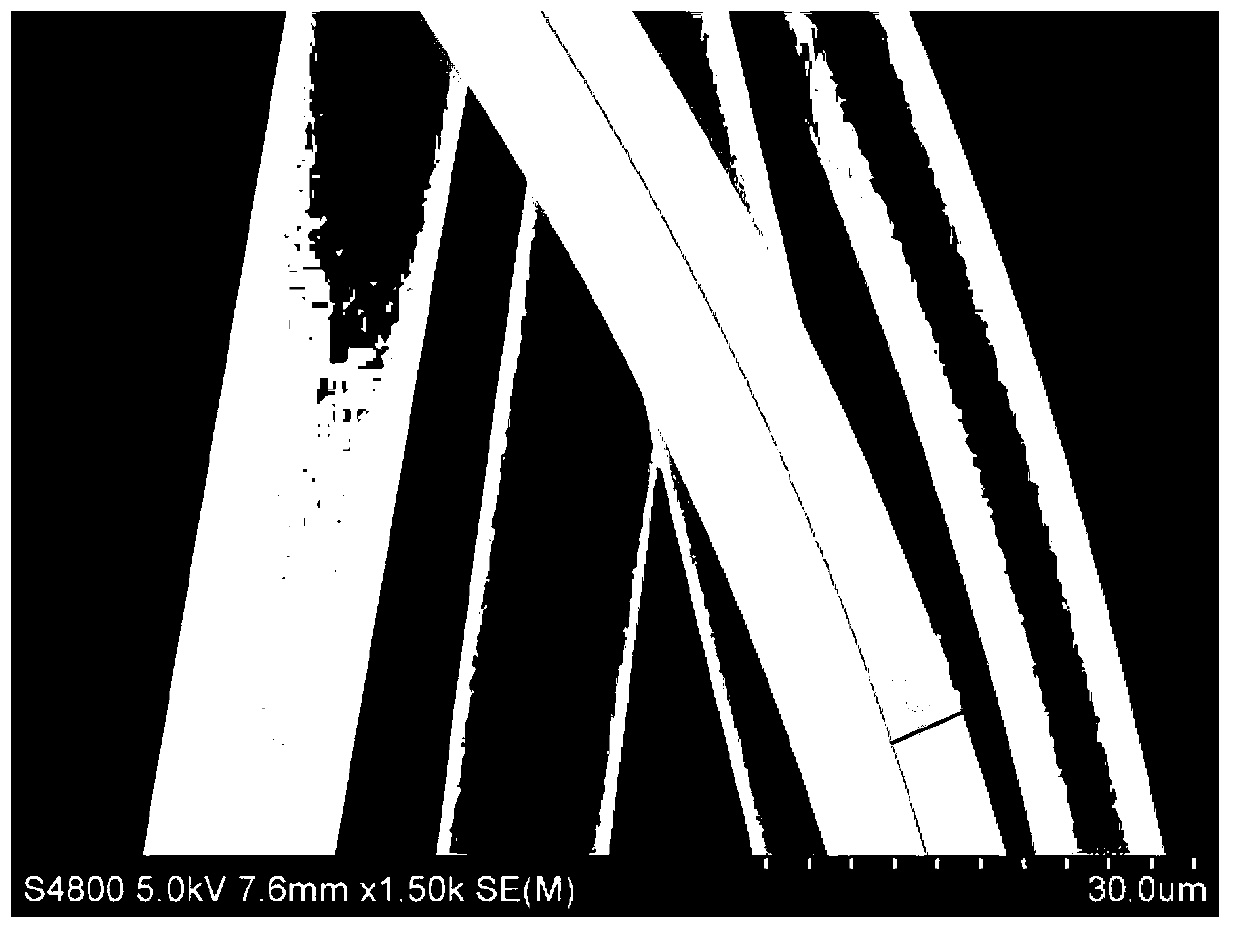

[0028] (2) Pour the spinnability solution obtained in (1) into the centrifugal spinning disk, and spin by centrifugal spinning method, at a temperature of 10°C, a centrifuge speed of 10000r / min, and a spinning hole line speed of 50m / s, under the condition that the spinning hole diameter is 0.5 mm, the spinning liquid is thrown out from the spinning hole at high speed to obtain titania-zirconia composite precursor fibers. Precur...

Embodiment 2

[0032] As described in Example 1, the difference is that 4.82g PAZ and 27.20g tetrabutyl titanate (molar ratio 2:8) were successively dissolved in 100ml of anhydrous methanol, stirred at room temperature for 30min until completely dissolved, mixed evenly, and then Concentrate under reduced pressure and evaporate part of methanol to obtain spinnable sol. The obtained titania-zirconia composite fiber has the effect of photocatalytic degradation of methyl orange as follows: Figure 5 shown, namely Figure 5 The bottom curve in 20%ZrO 2 -TiO 2 .

Embodiment 3

[0034] As described in Example 1, the difference is that 1.205g PAZ and 33.32g tetrabutyl titanate (molar ratio 5:95) were successively dissolved in 100ml of anhydrous methanol, stirred at room temperature for 30min until completely dissolved, mixed evenly, and then Concentrate under reduced pressure and evaporate part of methanol to obtain spinnable sol. The obtained titania-zirconia composite fiber has the effect of photocatalytic degradation of methyl orange as follows: Figure 5 shown, namely Figure 5 Middle curve 5%ZrO 2 -TiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com