Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

439results about How to "Good paintability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium composite oxide particle for positive electrode material of lithium secondary battery, and lithium secondary battery positive electrode and lithium secondary battery using the same

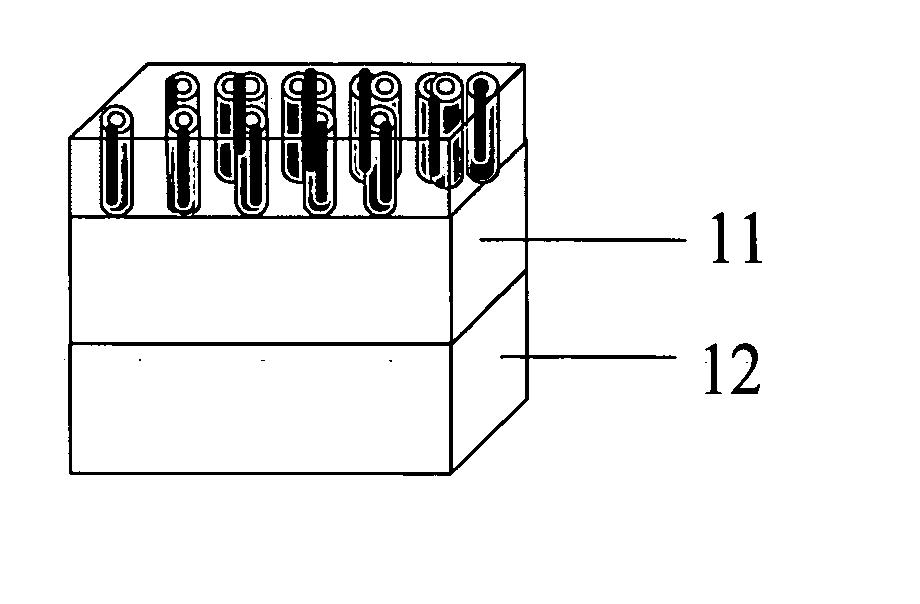

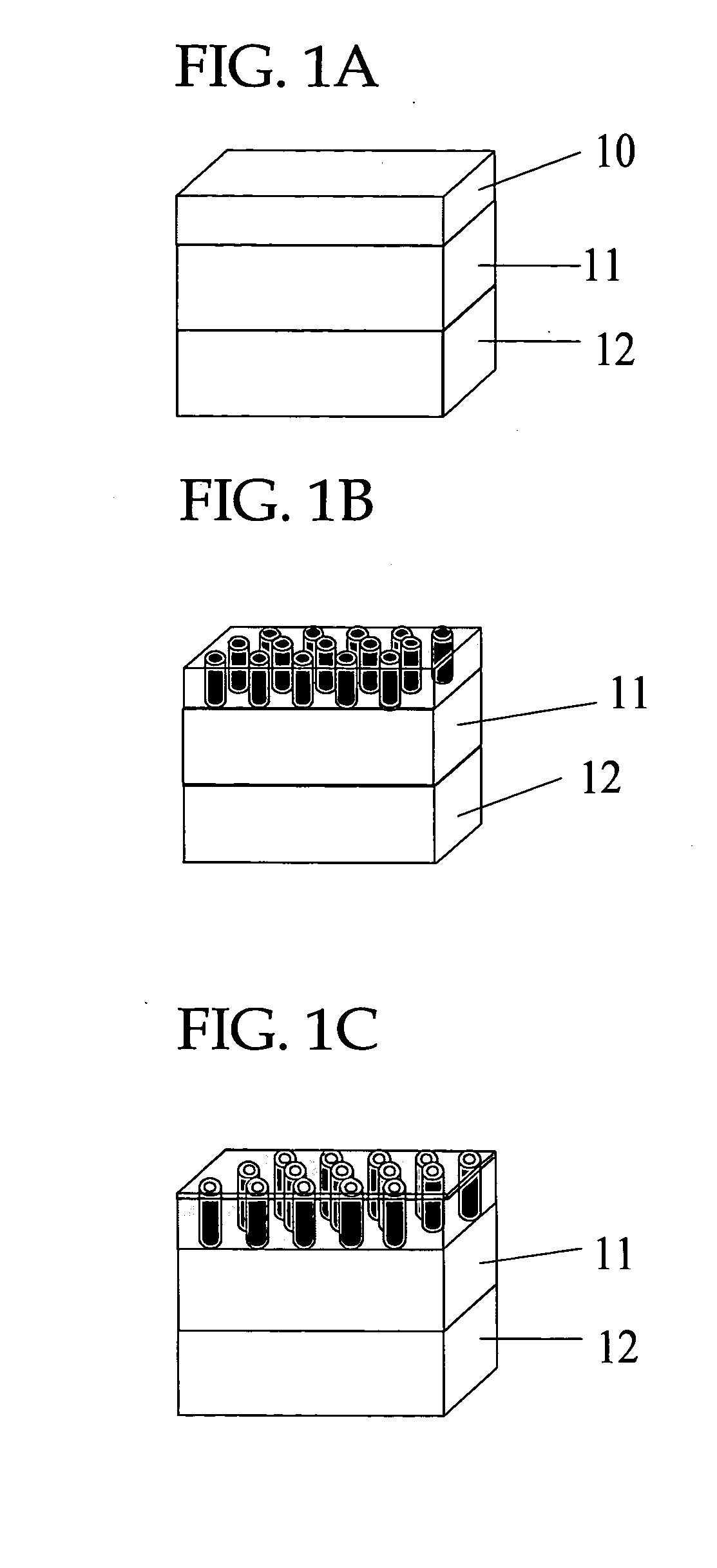

InactiveUS20060134521A1Improving low-temperature load characteristicGood paintabilityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsAlkali metal oxidesElectrical batteryComposite oxide

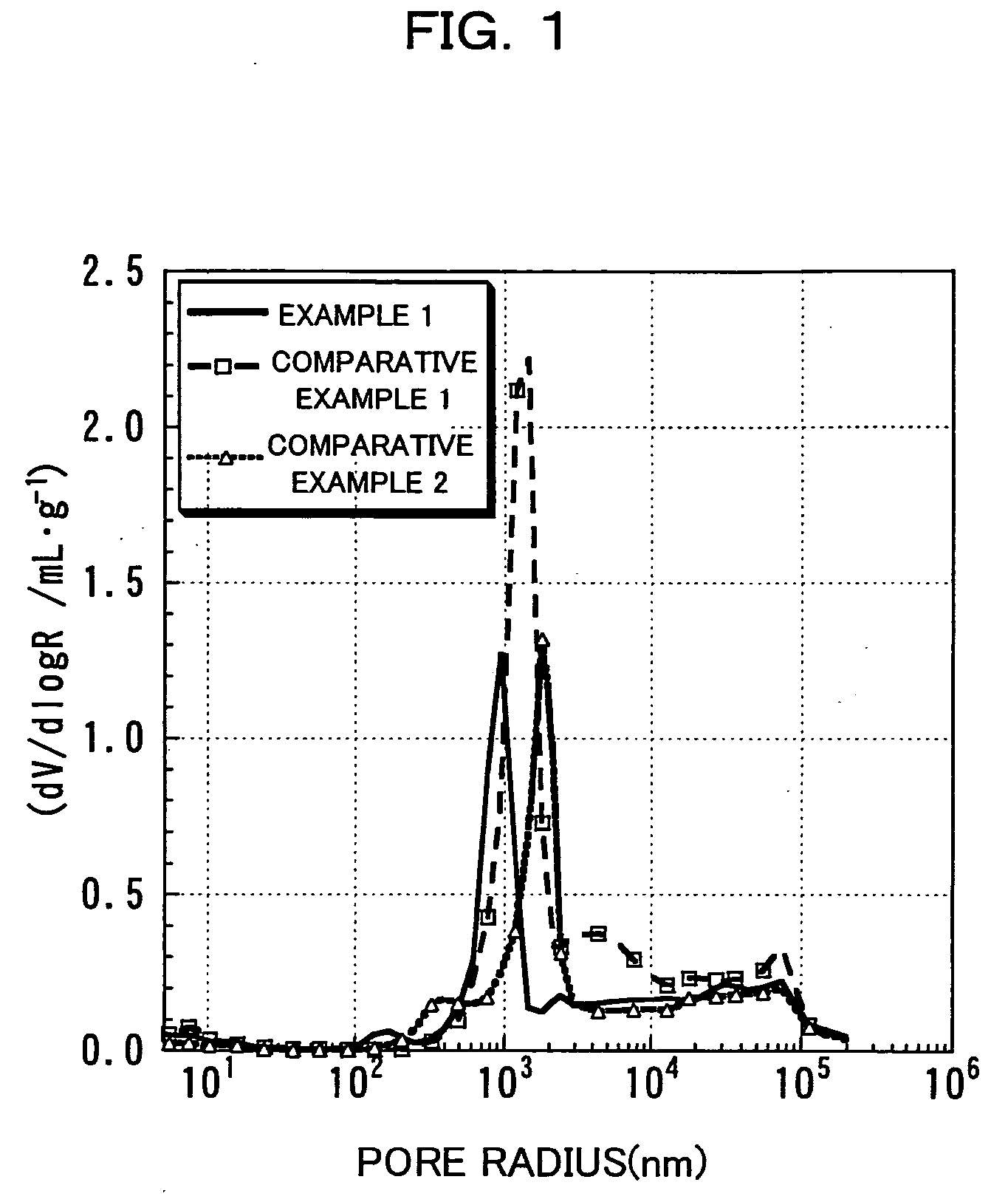

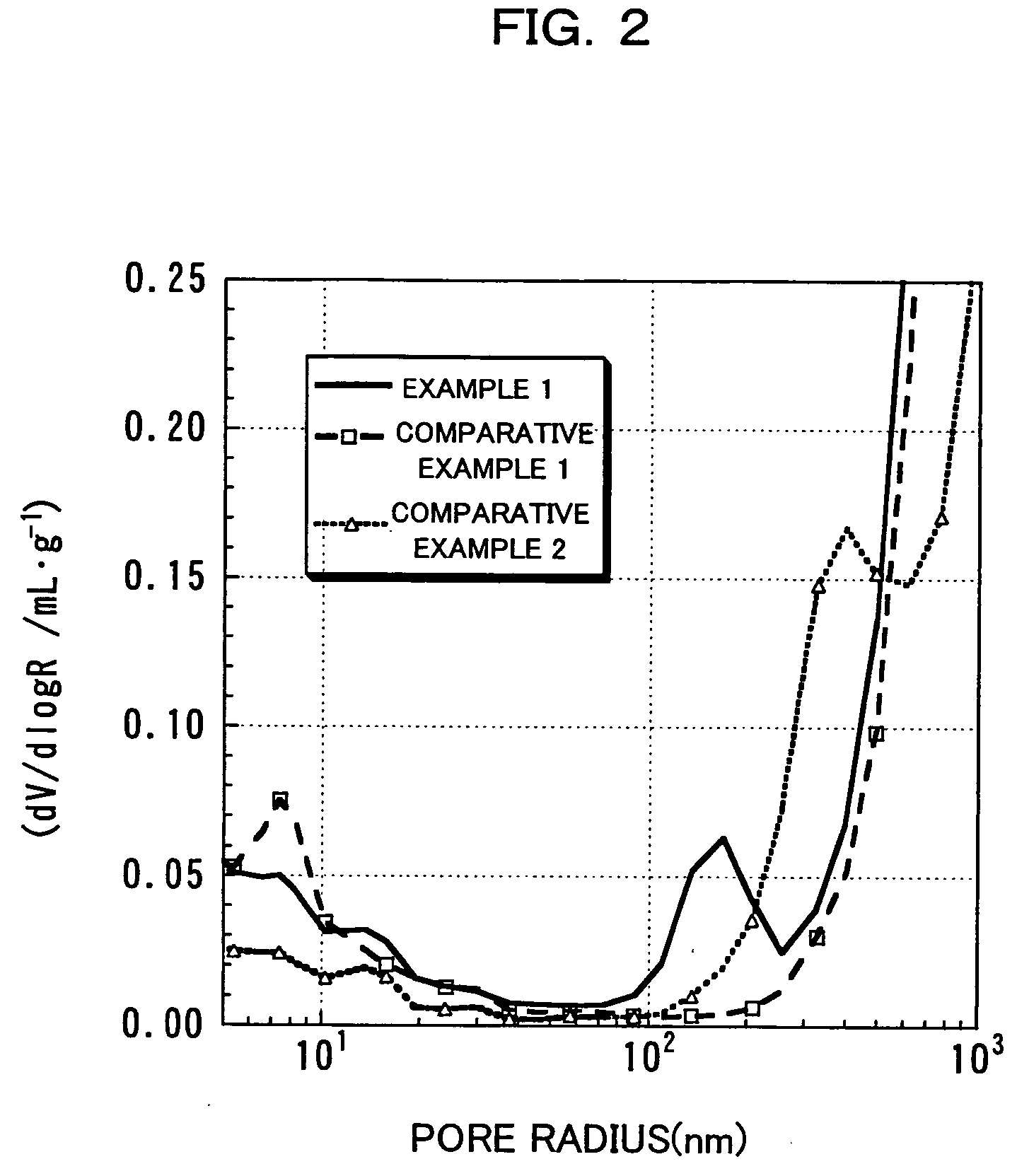

An excellent positive electrode material for a lithium secondary battery is provided that can increase low-temperature load characteristics of the battery as well as improving coatability. When measured by mercury intrusion porosimetry, the material meets Condition (A) and at least either Condition (B) or Condition (C). Condition (A) : on a mercury intrusion curve, the mercury intrusion volume from 50 MPa to 150 MPa is 0.02 cm3 / g or smaller. Condition (B): on the mercury intrusion curve, the mercury intrusion volume from 50 MPa to 150 MPa is 0.01 cm3 / g or larger. Condition (C): the average pore radius is within 10-100 nm, and the pore-size distribution curve has a main peak (with peak top at a pore radius of within 0.5-50 μm) and a sub peak (with peak top at a pore radius of within 80-300 nm).

Owner:MITSUBISHI CHEM CORP

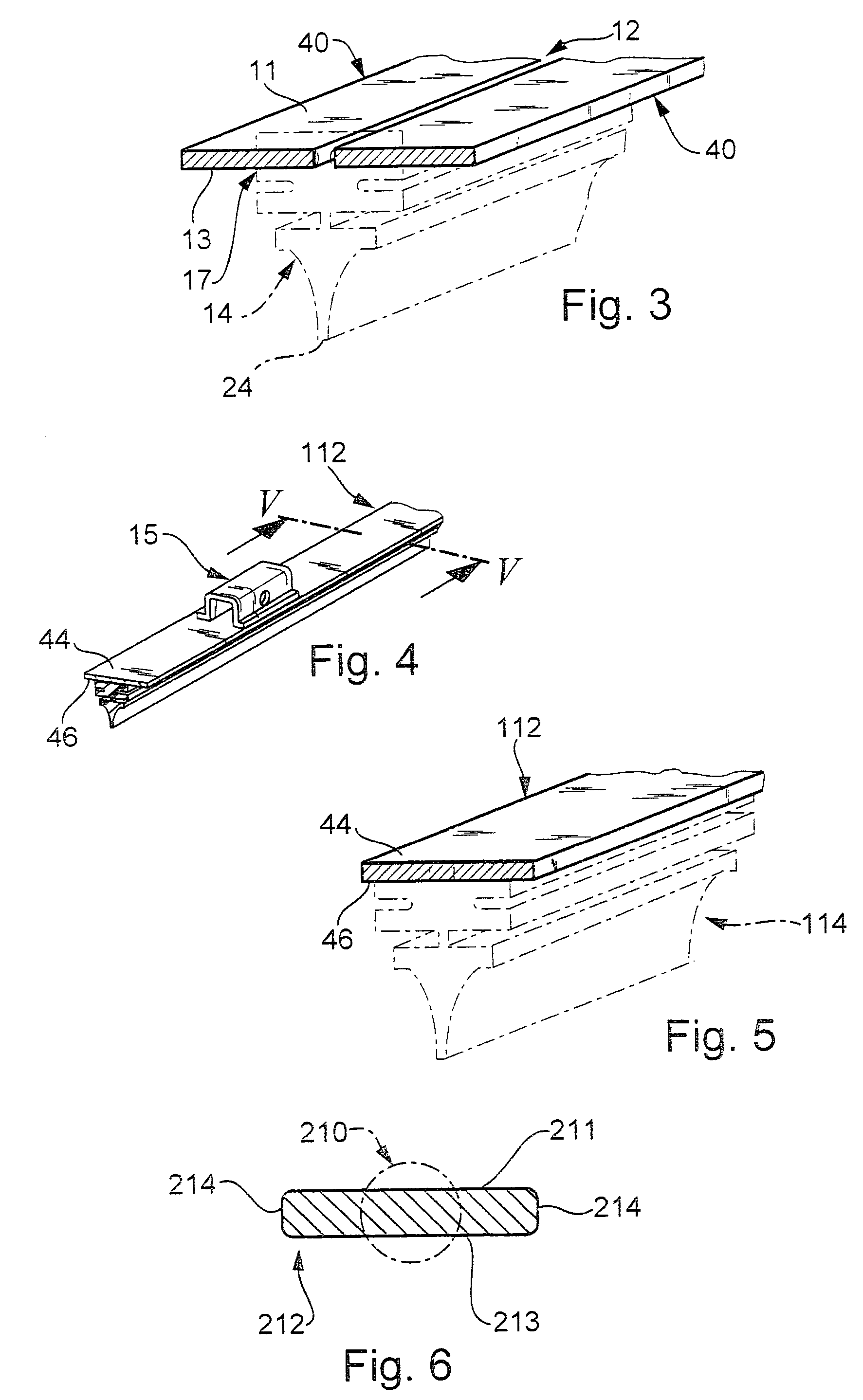

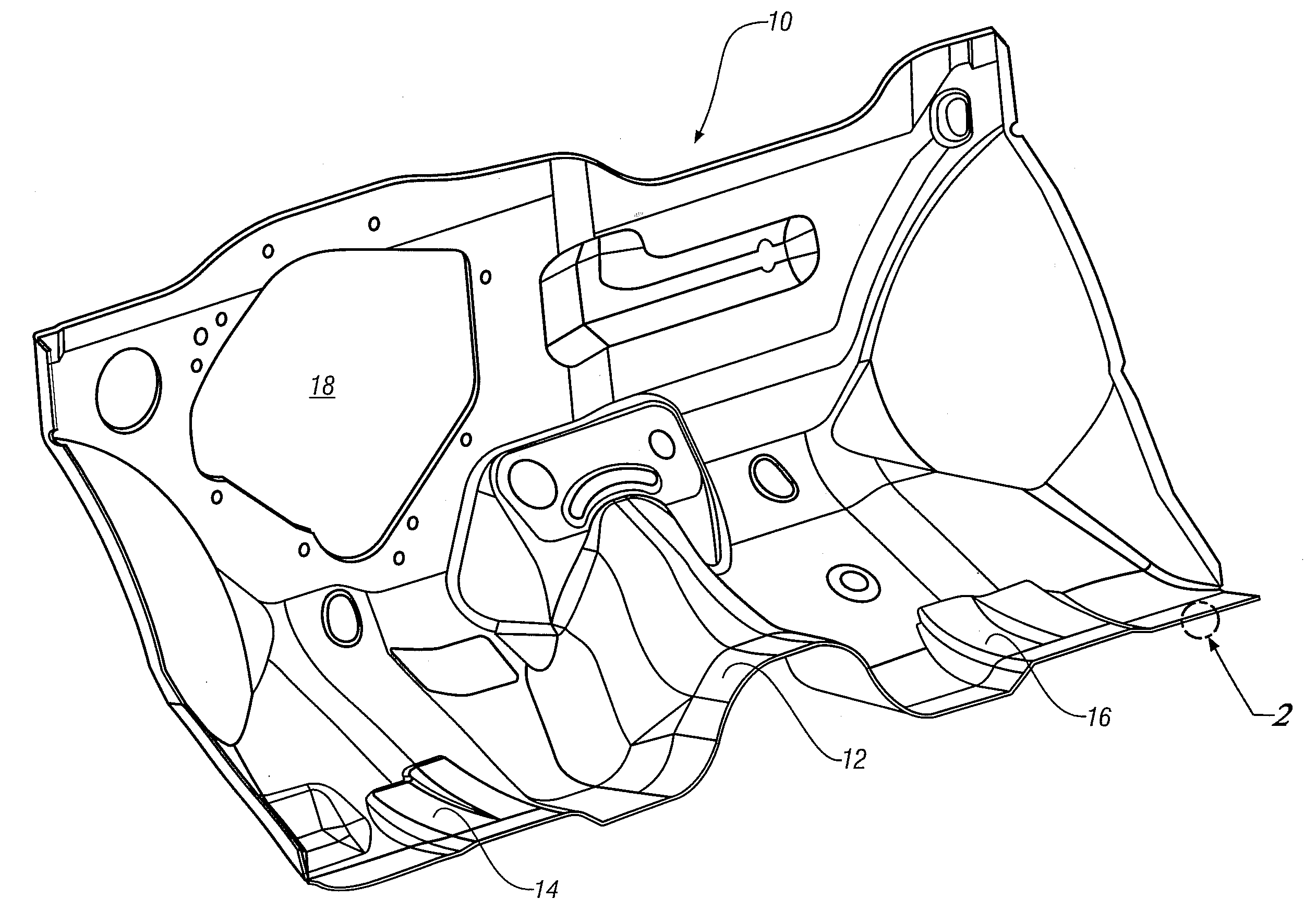

Wiper blade for cleaning glass panes, especially of motor vehicles, and method for the production of said wiper blade

InactiveUS20040025280A1Reduce adverse effectsImprove hardenabilityWindow cleanersVehicle cleaningMobile vehicleSulfur

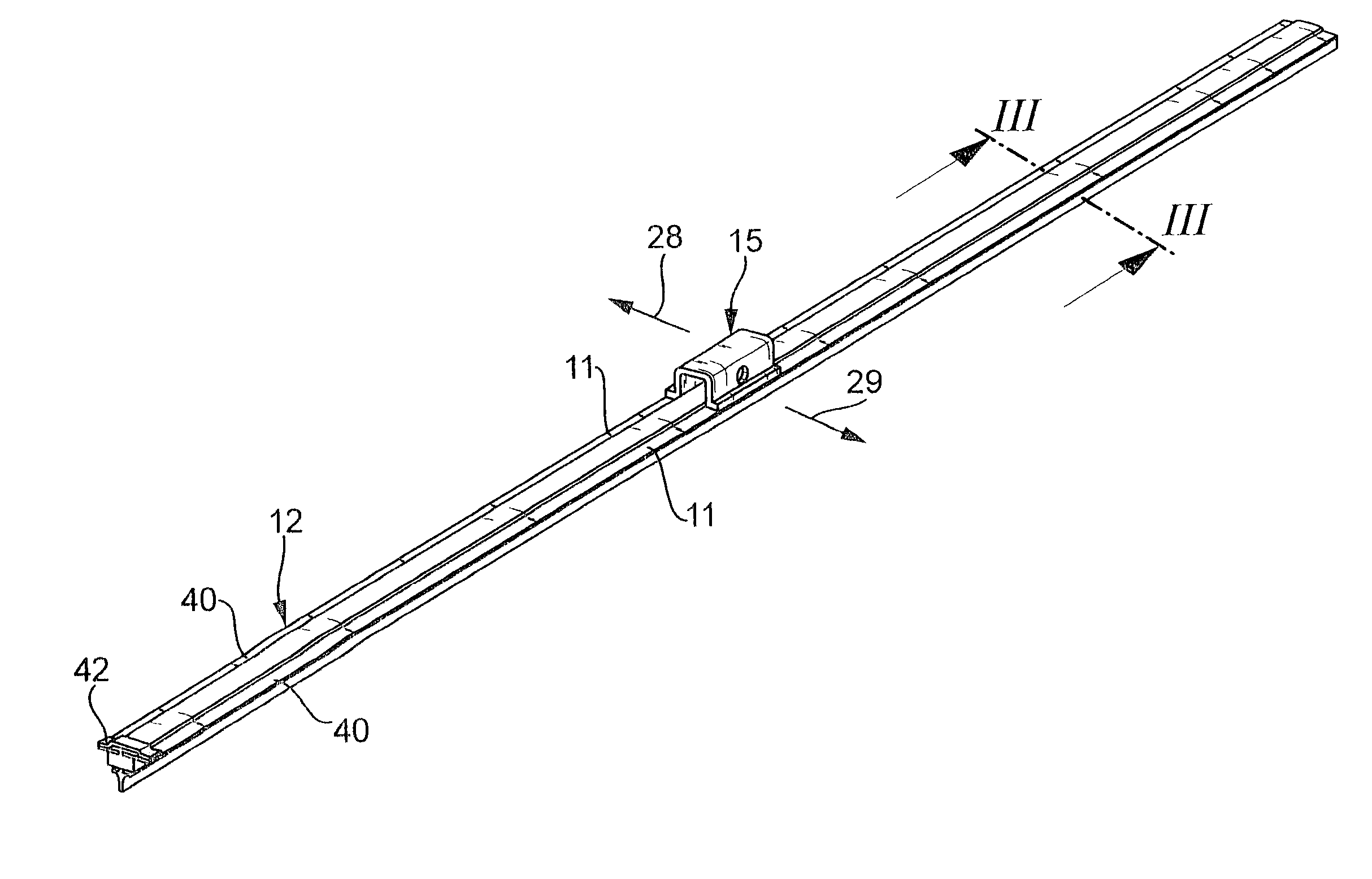

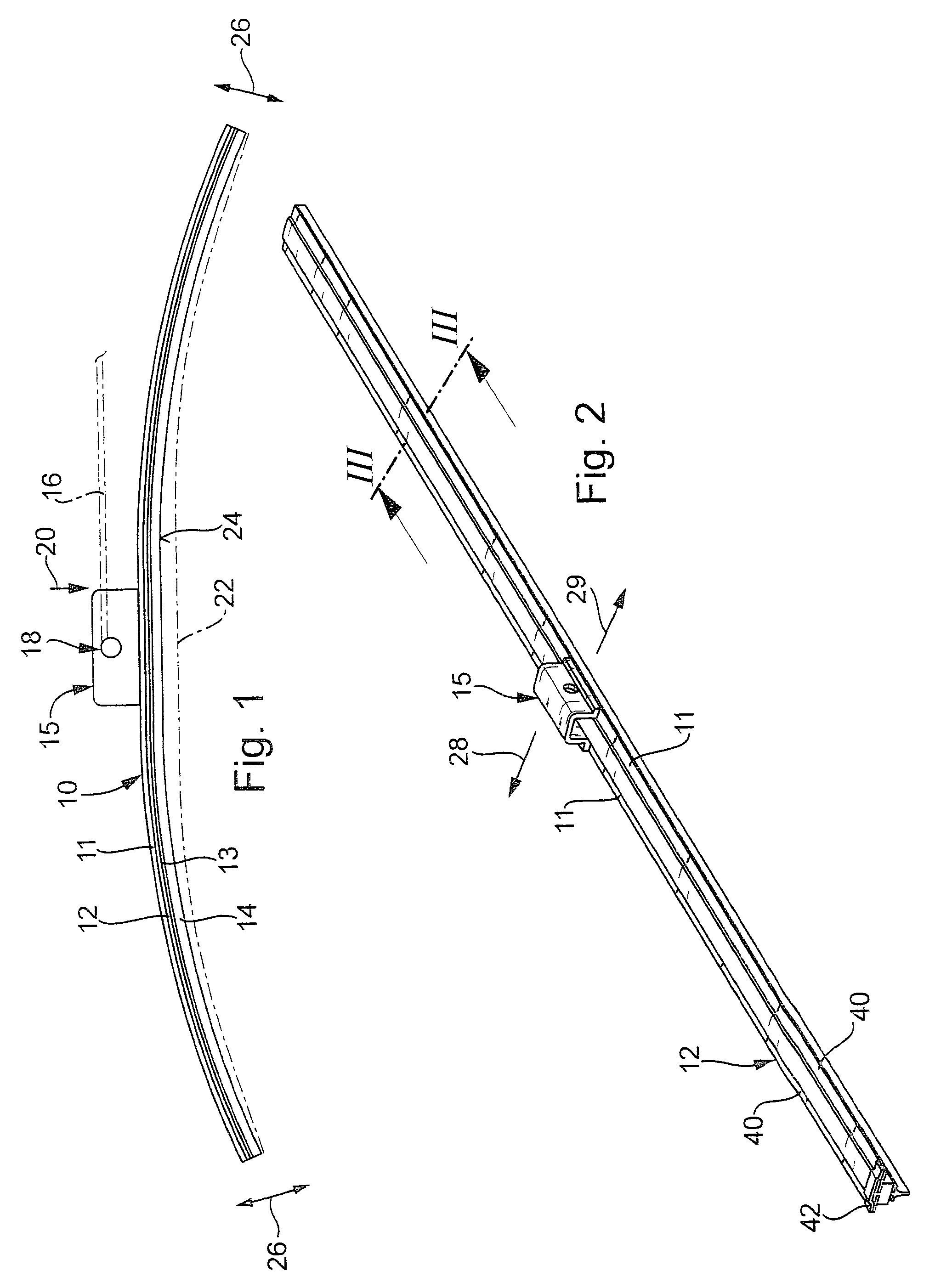

A wiper blade is proposed for cleaning windows, especially of motor vehicles, is proposed, which is provided with an elongated, rubber-elastic wiper strip that can be placed against the window, which wiper strip is disposed on the lower band face (13), oriented toward the window, of a bandlike-elongated support element (12) made from a spring-elastic steel, on whose other, upper band face (11) facing away from the middle, particularly in the middle portion of the support element, a device (15) for connecting the wiper blade to the free end, urged toward the window, of a driven wiper arm (16) guided on the motor vehicle is welded. It has proved particularly advantageous, in view of the demands made of the support element, if the support element is made from an alloyed quenched and tempered steel, which has the following alloy components: carbon (C), 0.18% to 0.36%; silicon (Si), 0.40% to 0.50 %; manganese (Mn), 1.10 % to 1.80%; phosphorus (P), 0.015% to 0.035%; and sulfur (S), 0.035% to 0.04%.

Owner:ROBERT BOSCH GMBH

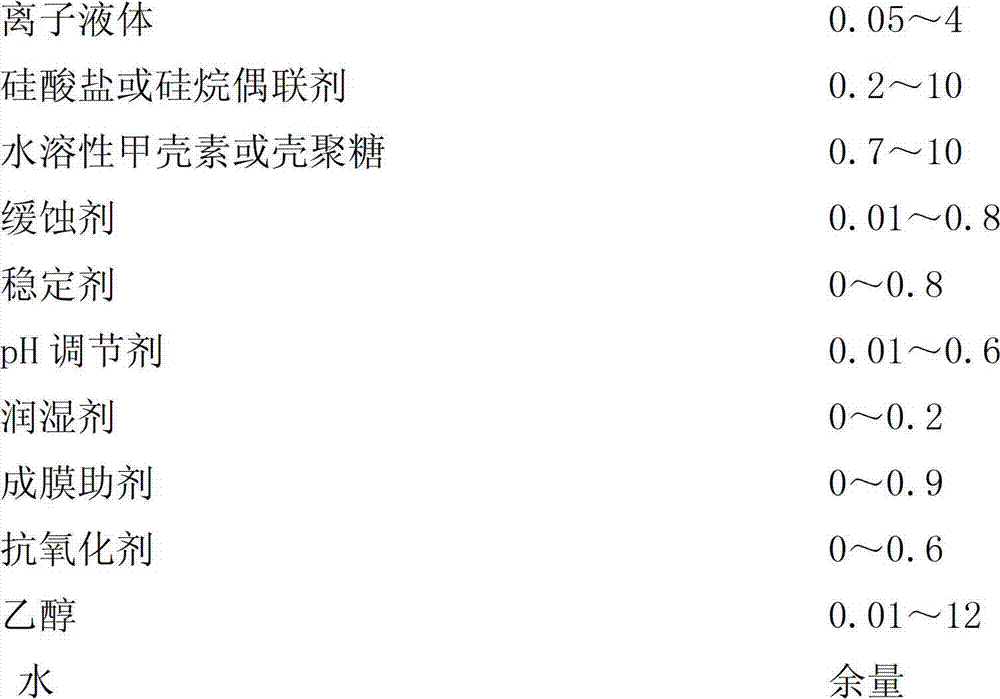

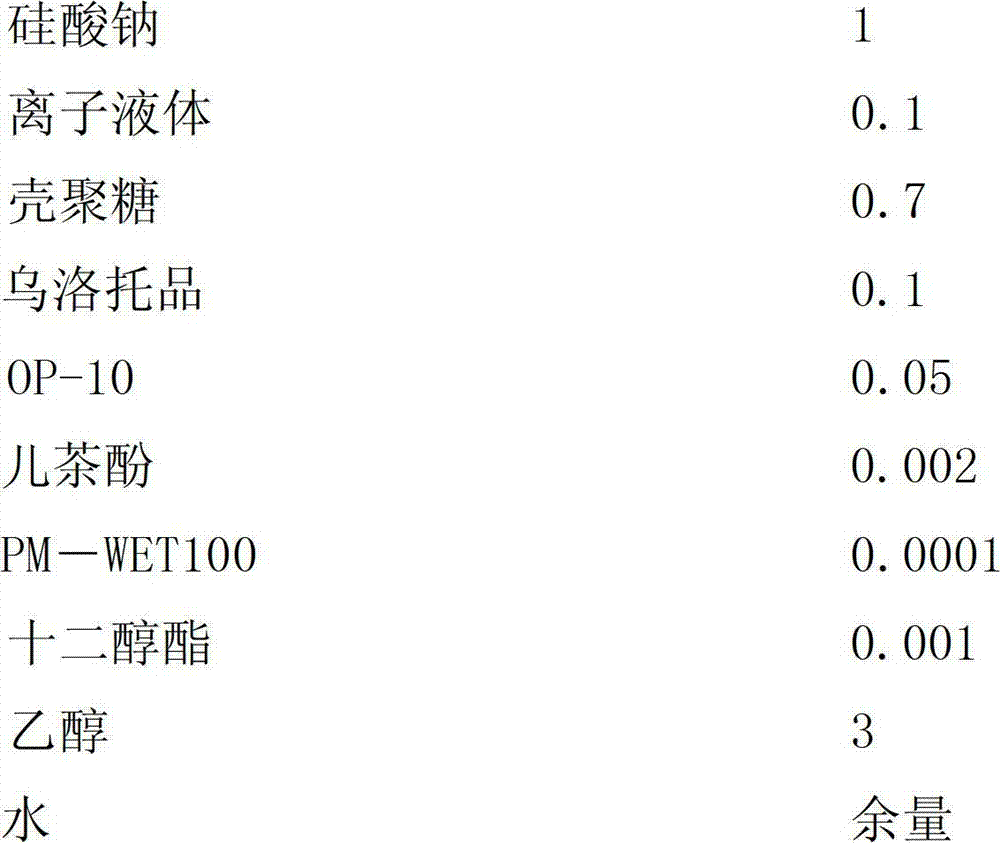

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Concrete formulation

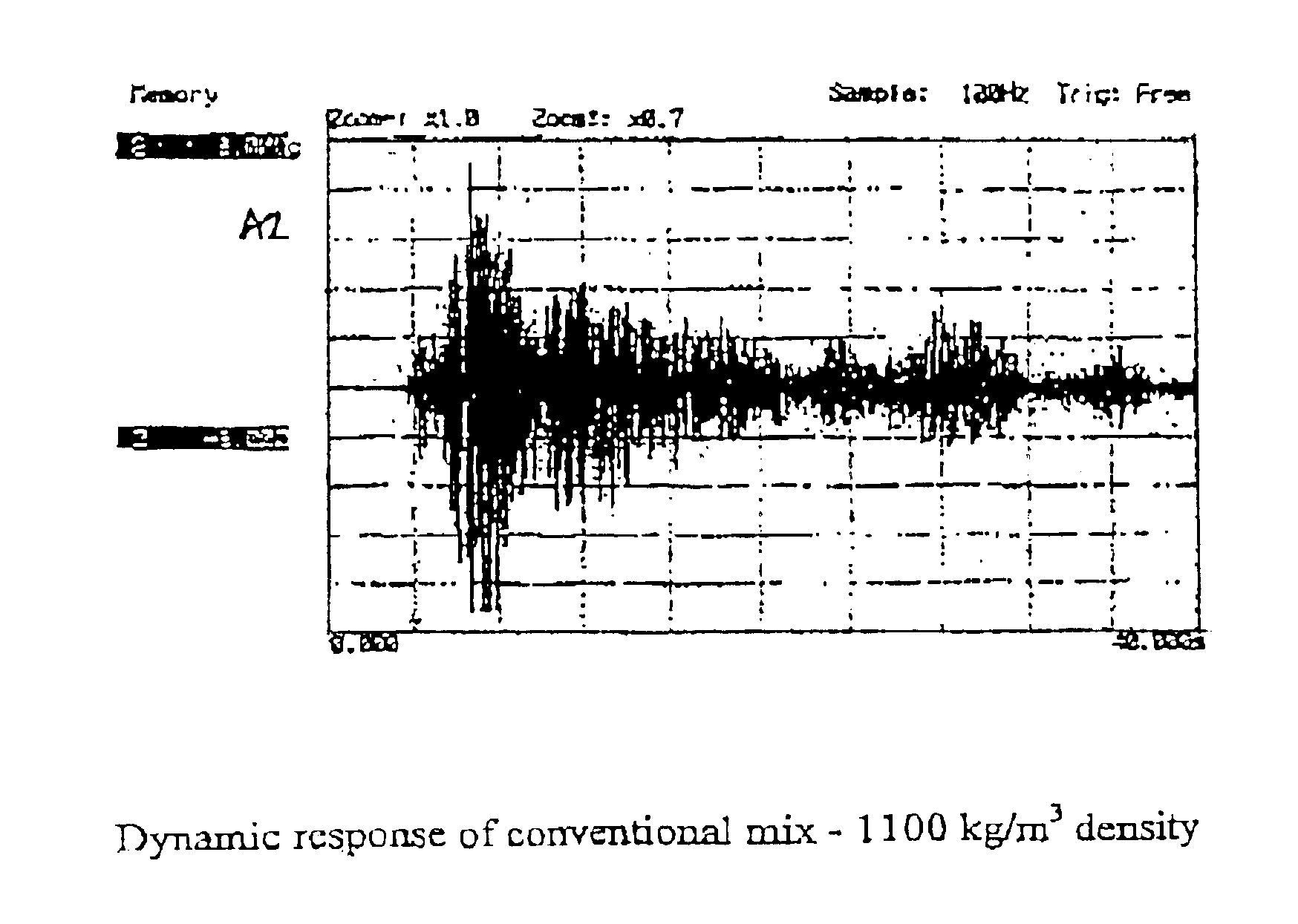

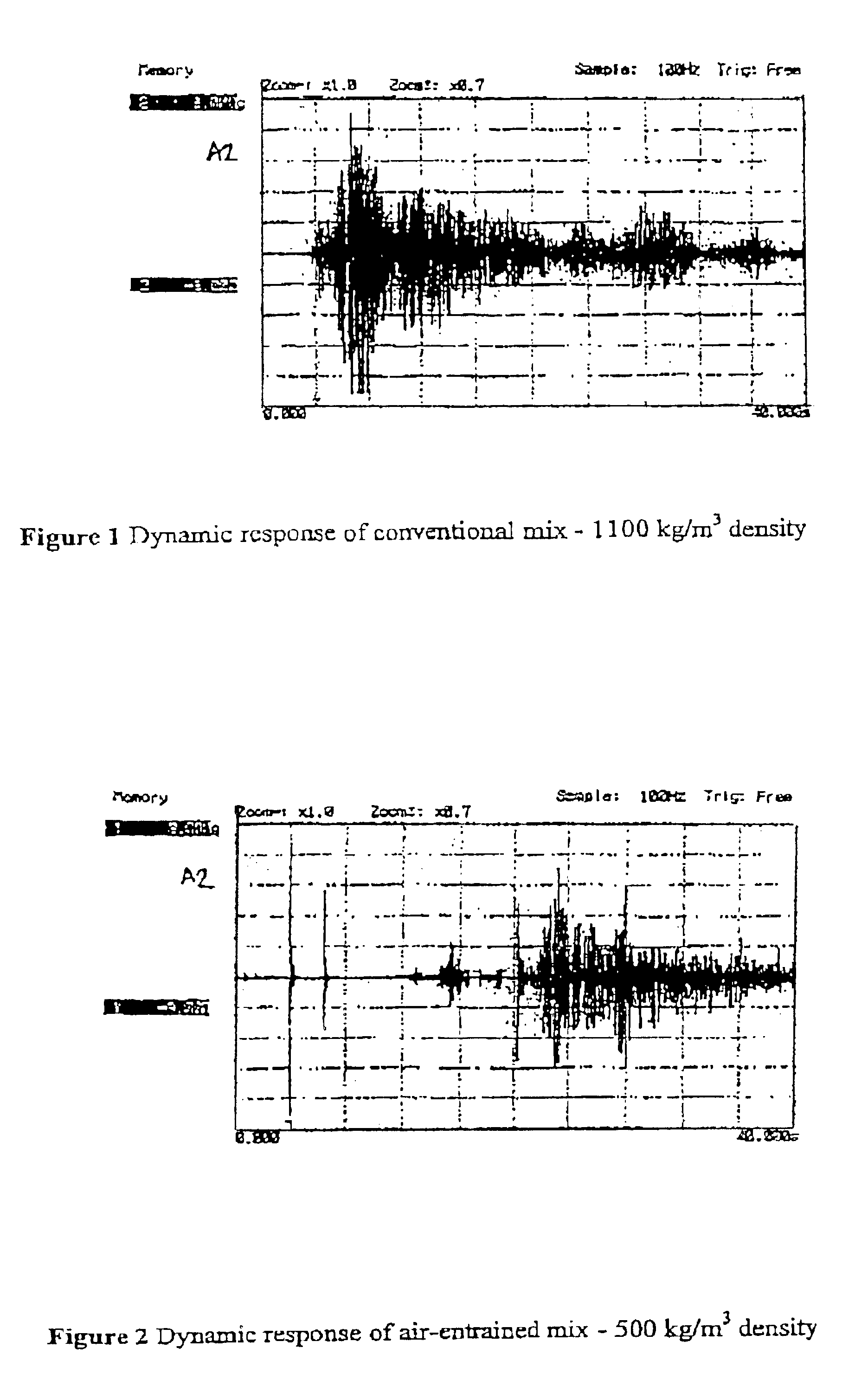

InactiveUS6875266B1Compromise structural integrityNegating intended effectCeramicwareSolid waste managementPolystyreneOrganic polymer

An additive for use in the preparation of lightweight concrete, said additive including a blend of from around 40% to 99% of organic polymeric material and from 1% to around 60% of an air entraining agent. The additive is particularly suitable for the preparation of lightweight concrete which uses polystyrene aggregate. It provides for excellent dispersion of the polystyrene aggregate and improved bond between the polystyrene aggregate and surrounding cementitious binder. The resultant lightweight concrete formulation may be pumped and is particularly suitable for sandwich wall construction.

Owner:JAMES HARDIE TECH LTD

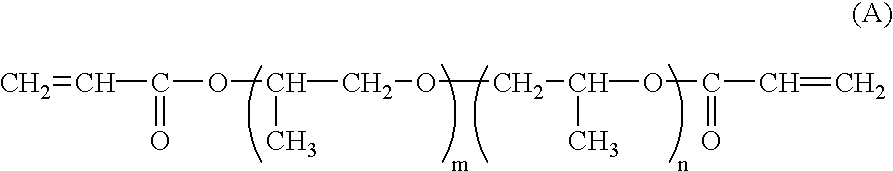

Resin composition and three-dimensional object

InactiveUS20030059708A1Good paintabilityGood lookingAdditive manufacturing apparatusOptical articlesSolubilityMeth-

A photocurable resin composition suitable for use in three-dimensional photofabrication comprising (A) a cationically polymerizable organic compound, (B) a cationic photoinitiator, and (C) a (co)polymer obtainable by (co)polymerization of monomers comprising at least one (meth)acrylate-group comprising monomer. A process for producing a three-dimensional object which comprises the use of a washing agent having a Hansen-solubility between 27-35 (Mpa)½.

Owner:DSM IP ASSETS BV +2

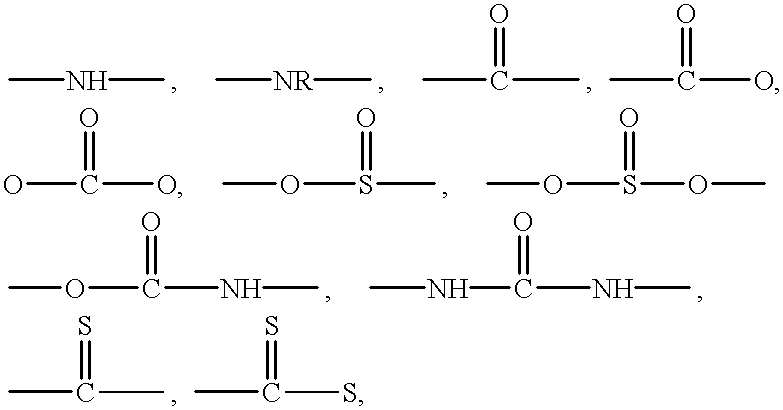

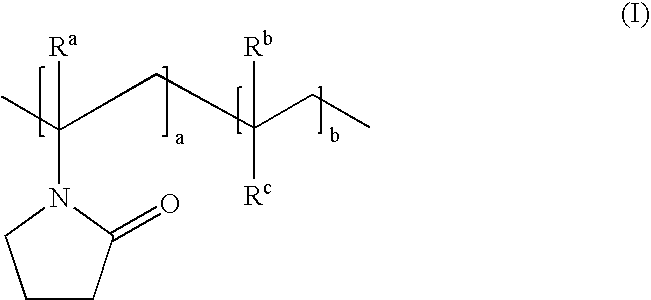

Dyeable polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6127480AGood paintabilityExcellent mold flowabilityEngine sealsCellulosic plastic layered productsPolymer sciencePolyolefin

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

Enamel steel for cold rolling water heater and manufacturing method thereof

InactiveCN101684532AGood explosivenessGood formabilityTemperature control deviceMetal rolling arrangementsEconomic benefitsSurface roughness

The invention discloses enamel steel for a cold rolling water heater and a manufacturing process thereof. The enamel steel for cold rolling water heater comprises components as follows in percentage by weight: C: 0.01%-0.08%. Si: less than or equal to 0.03%, Mn: 0.10%-0.60%, P: less than or equal to 0.02%, S: 0.003%-0.02%, N: 0.001%-0.006%, AIs: less than or equal to 0.04%, Ti: 0.02%-0.12%, and the balance of ferrum and unavoidable impurities, wherein excess Ti content in steel is equal to Ti-(4*C+3.43*N=1.5S) which is less than or equal to 0. The manufacturing process is characterized in that the heating temperature of billet steel is 1160-1300 DEG C; the hot rolling finish rolling temperature is 850-950 DEG C; the coiling temperature of steel plates is 660-760 DEG C; the cold rolling draft is 60%-80%; the annealing temperature is 760-880 DEG C; the temperature preservation time is 60-200s; rapid cooling speed rate is 15-45 DEG C / s, planishing elongation is 0.7%-1.8%; and surface roughness is 0.7-1.9 micrometres. The invention has the advantages of excellent formability, enamel-spreadable property, pressing resistance, weldability and fish-scaling resistance, stable yield strength after enamelfiring, less cost increase, stable effect and significant economic benefits.

Owner:ANGANG STEEL CO LTD

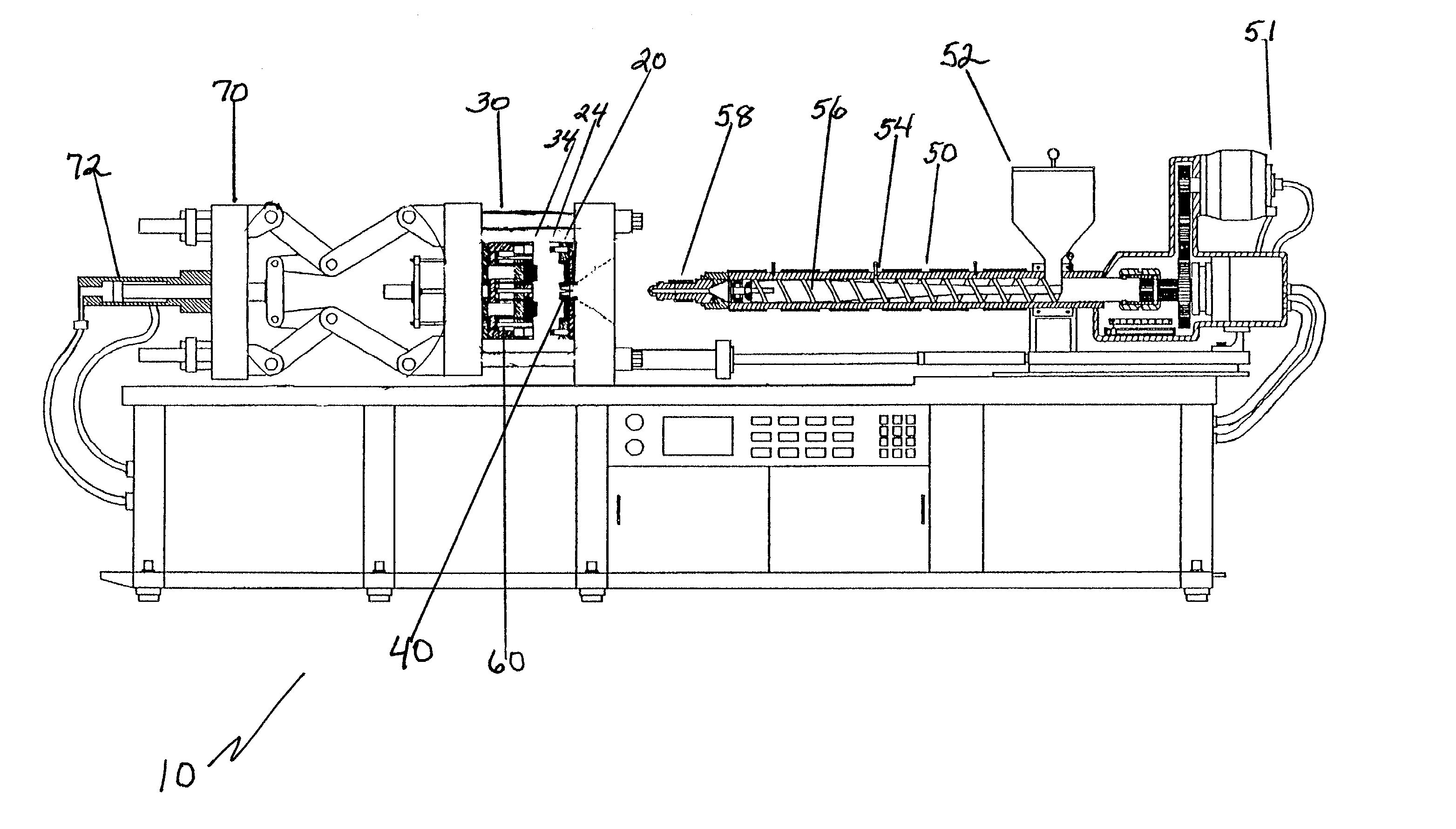

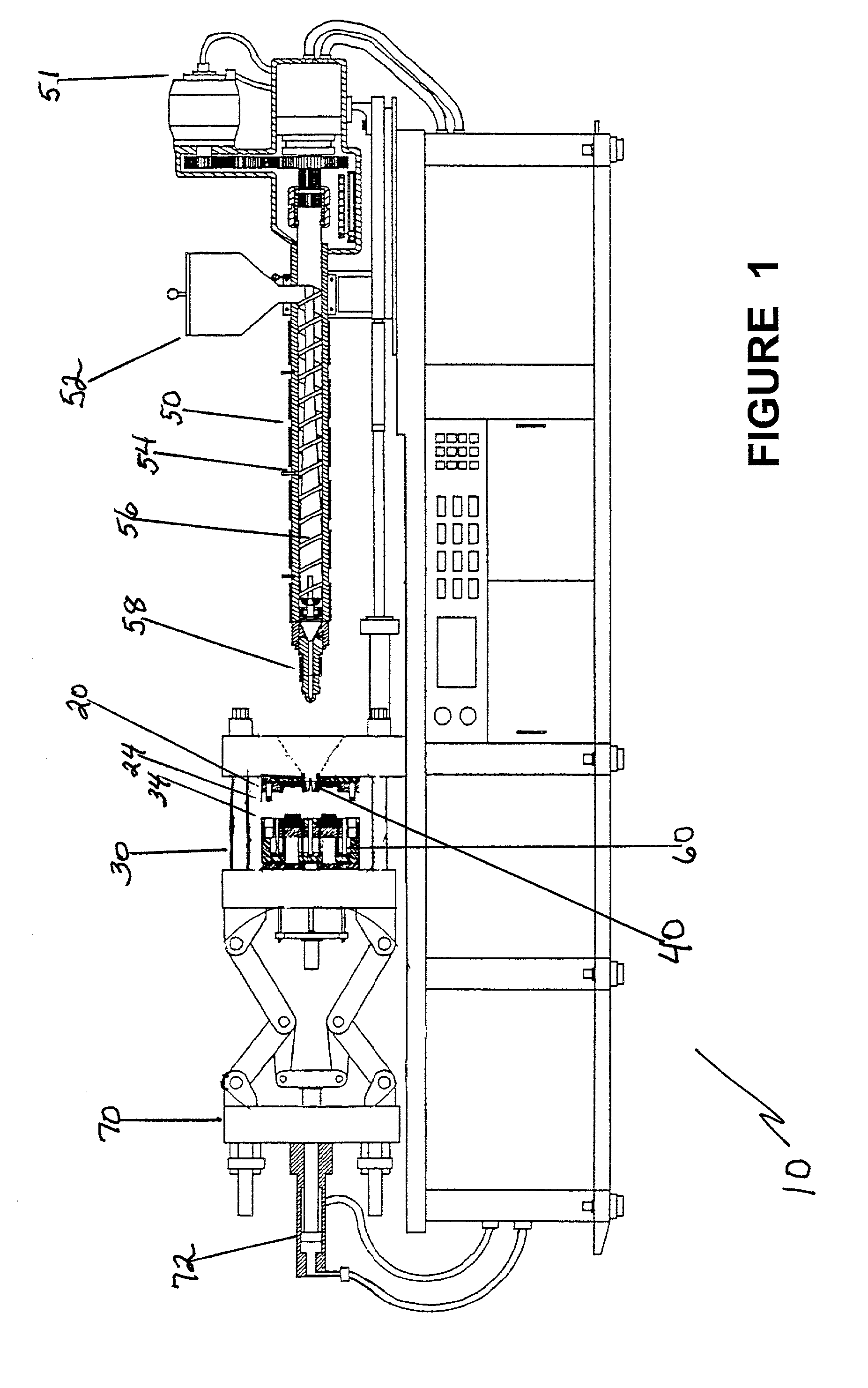

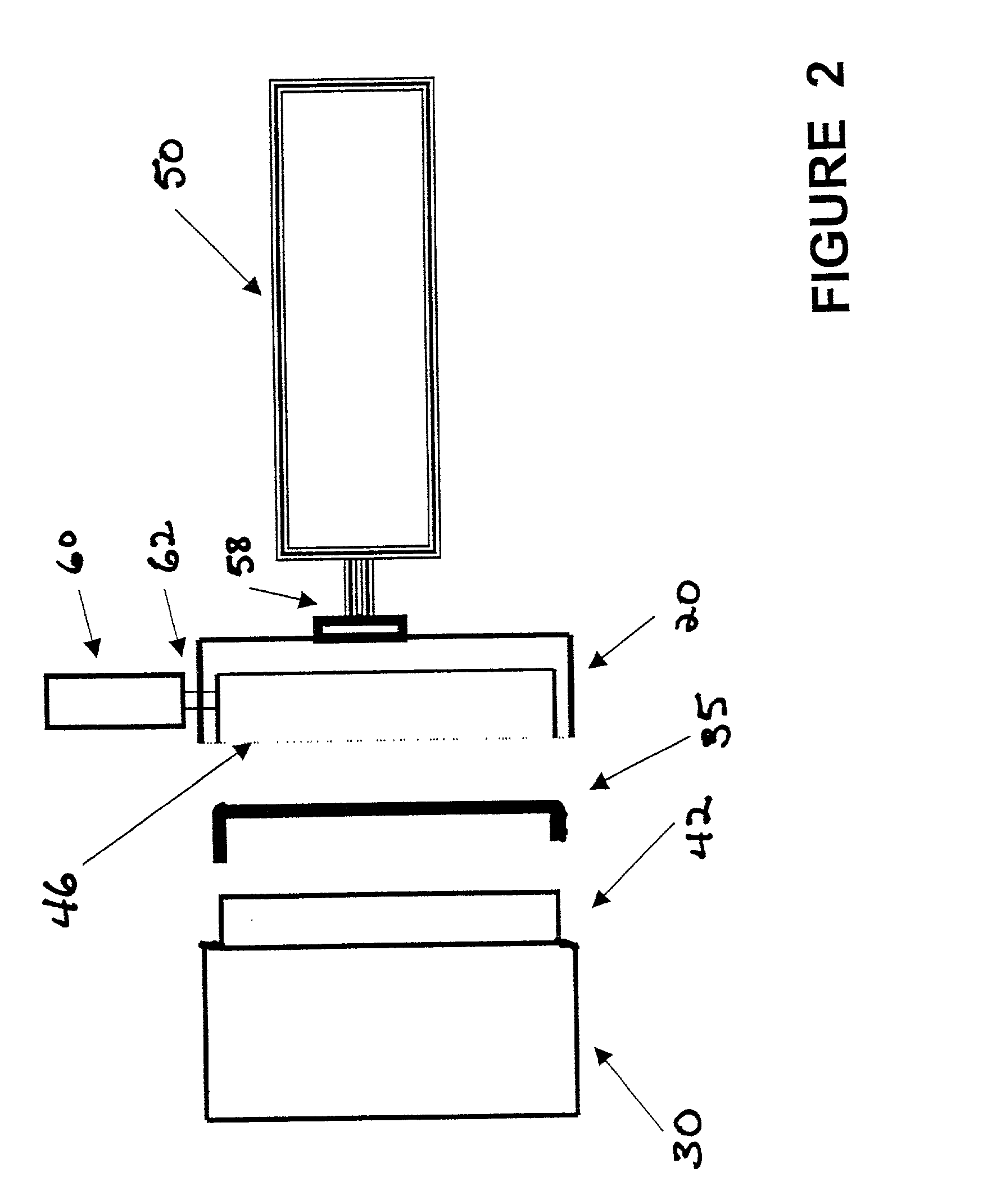

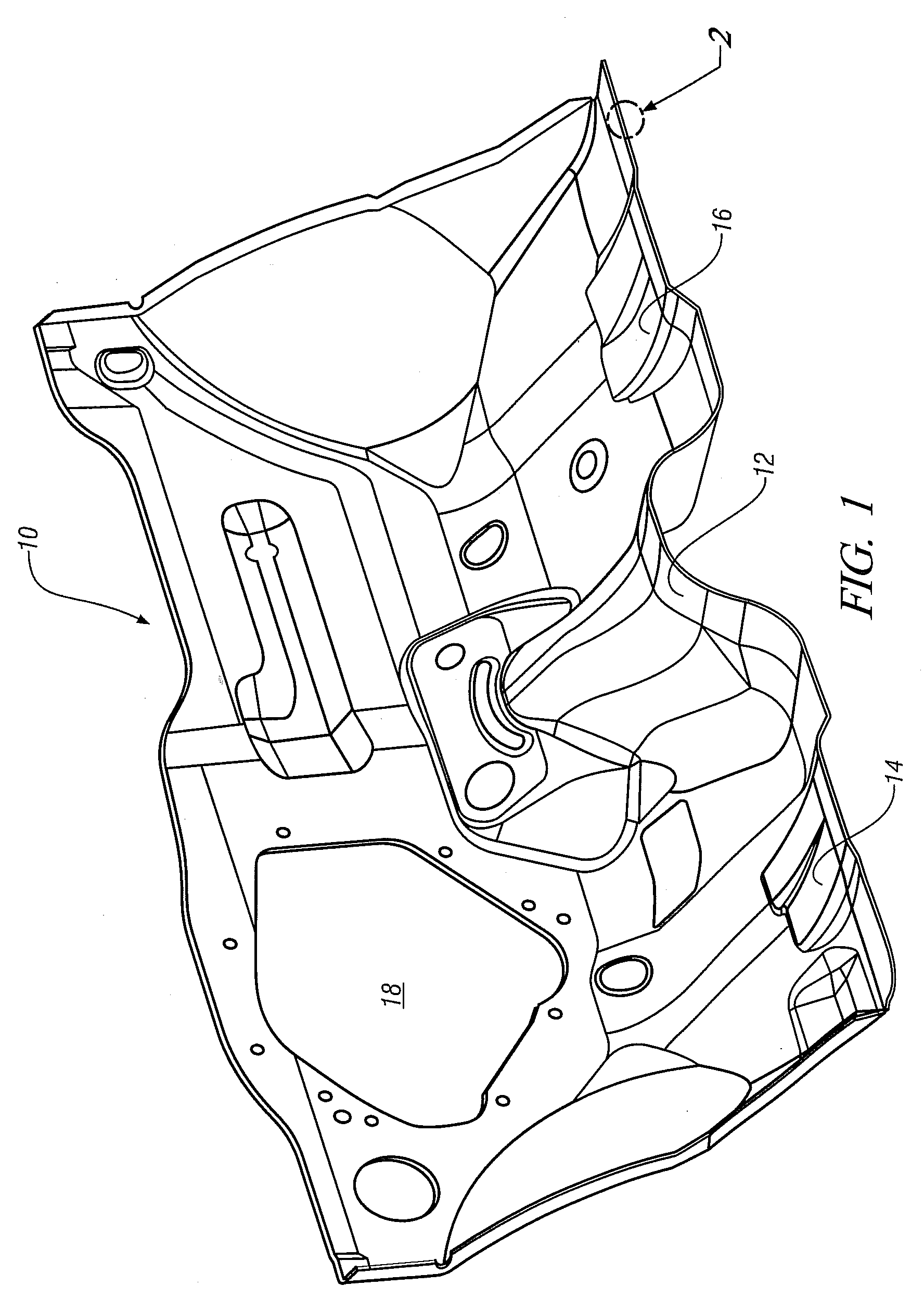

Optimization of in-mold coating injection molded thermoplastic substrates

InactiveUS20020039656A1Reduce pressureIncrease coverageLiquid surface applicatorsMouldsPolyolefinShell molding

Owner:OMNOVA SERVICES

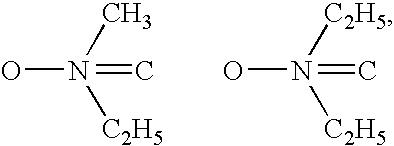

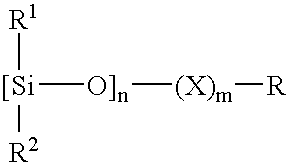

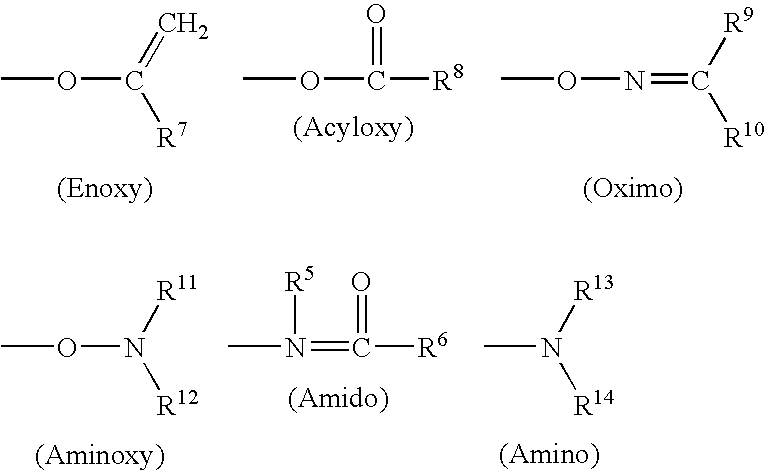

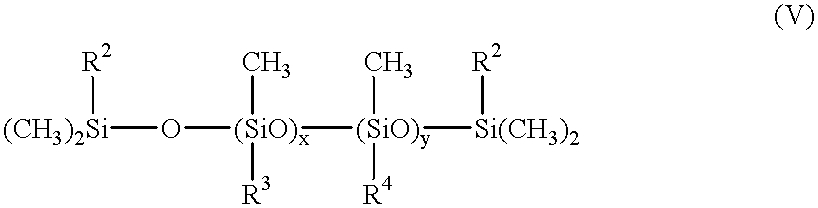

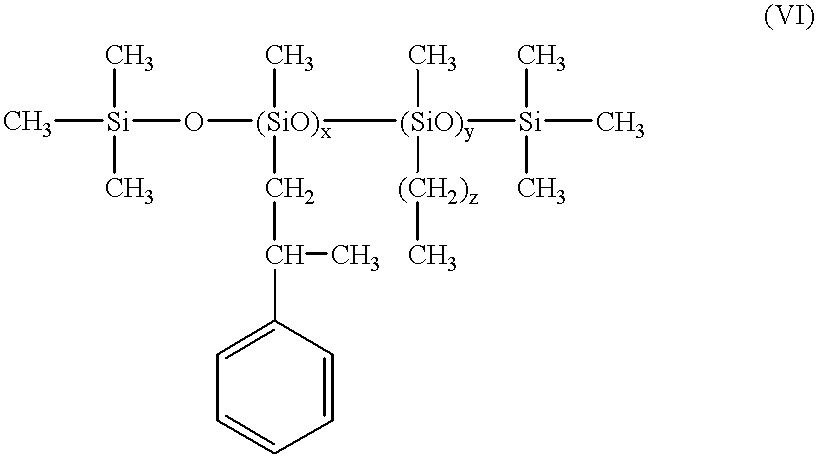

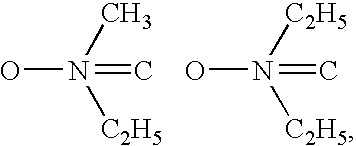

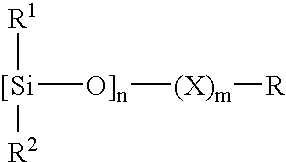

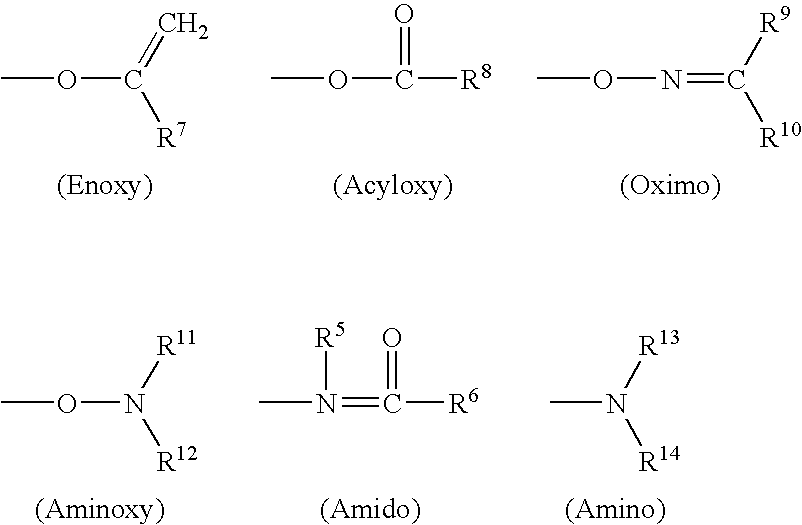

Highly elastomeric and paintable silicone compositions

InactiveUS20050288415A1Good paintabilityGood weather resistanceSpecial tyresCoatingsSealantPolymer chemistry

Highly elastomeric, curable, paintable silicone compositions are provided. The paintable silicone compositions comprise an organopolysiloxane, a silicone functional crosslinker, and an organic polymer. The highly elastomeric, curable, paintable silicone compositions have an elongation of at least 150% and are useful as paintable sealants and caulks.

Owner:TREMCO INC

Underwater epoxy adhesive and preparation method thereof

InactiveCN101619201AEasy to prepareStrict workmanshipNon-macromolecular adhesive additivesEpoxy resin adhesivesSodium BentoniteDiluent

The invention relates to an underwater epoxy adhesive and a preparation method thereof; the adhesive contains A component and B component and comprises the following components by weight percent: 15-23% of epoxy resin E-51, 15-23% of epoxy resin E-44, 6-8% of epoxy active diluent, 2-5% of flexibilizer 304 resin, 13-20% of talcum powder, 6-9% of calcium oxide, 1.5-2.0% of organic bentonite, 2-4% of titanium dioxide, 0.5-1.0% of coupling agent, 0.3-1.0% of dispersant, 0.3-1.0% of defoaming agent, 10-15% of 1085 curing agent, 5-10% of 810 curing agent and 1.5-2.2% of curing accelerator; wherein, B component comprises 1085 curing agent, 810 curing agent and curing accelerator and the remainder is A component. The preparation method comprises the following steps: separately stirring the A component and the B component to disperse evenly, adding the B component in the A component to mix evenly and obtaining the underwater epoxy adhesive. The preparation method is simple, the product brushability is good, the curing rate is fast, the bonding strength is high, and the adhesive is resistant to water and the corrosion of acid and base and can not pollute the environment. The adhesive can be widely used to bond various building materials in the water and mending the concrete crack.

Owner:QINGDAO PACIFIC OCEANEERING CO LTD

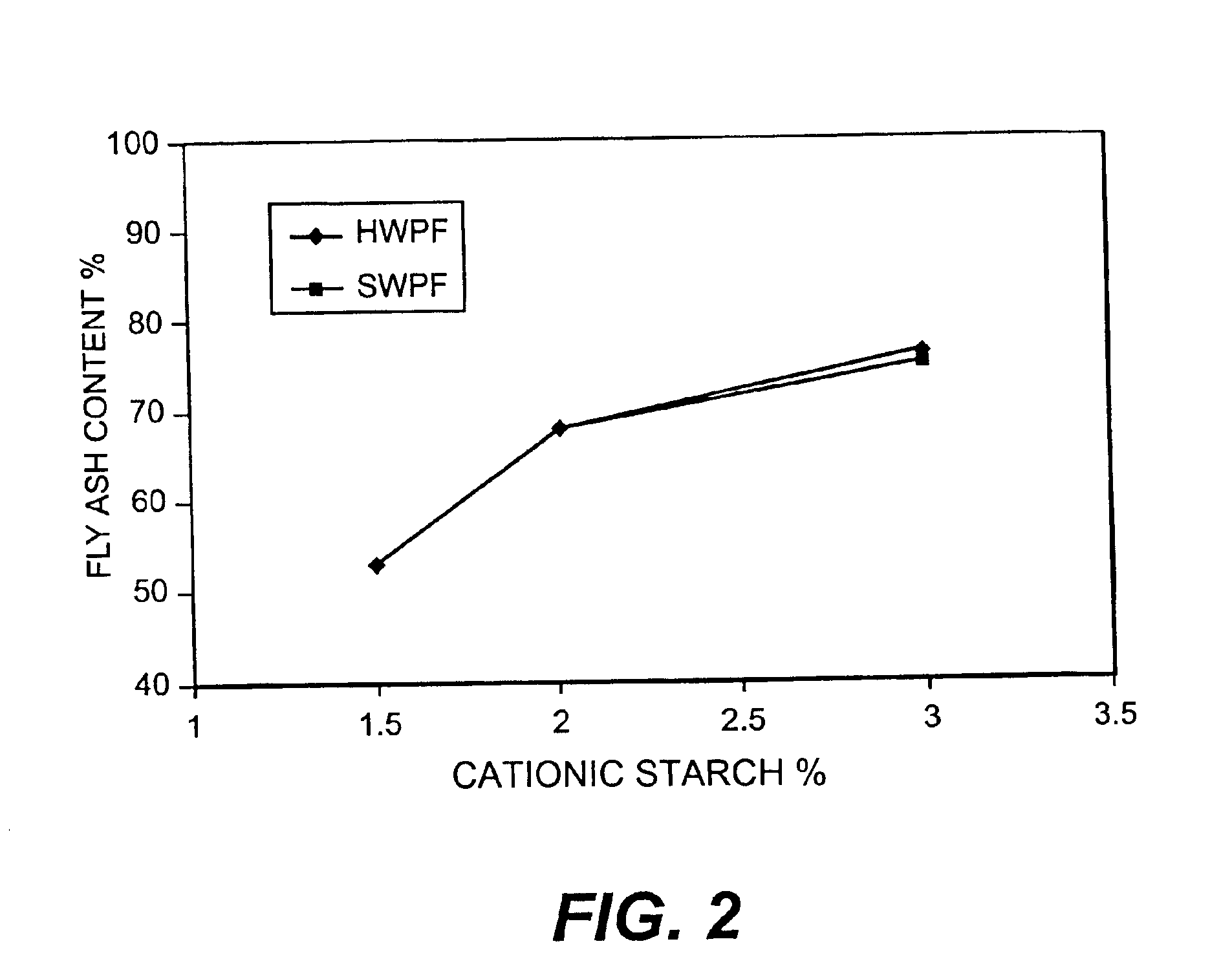

Fiber reinforced mineral-based materials and methods of making the same

InactiveUS6933038B2Reduce Shrinkage ProblemsGood paintabilityFibreboardNatural cellulose pulp/paperCement pasteFiber reinforcement

Owner:GEORGIA TECH RES CORP

Carbon nanotube composite material, magnetic material and production thereof

InactiveUS20050255313A1Magnetic homogeneityImprove fill rateCarbon compoundsNanoinformaticsCarbon nanotubeChemical modification

A carbon nanotube composite material contains a carbon nanotube and a continuous layer of a metal covering the inner surface of the carbon nanotube. It is produced by forming a metallic matrix layer and treating the metallic matrix layer to form plural nanoholes in the metallic matrix layer to thereby form a nanohole structure, the nanoholes extending in a direction substantially perpendicular to the plane of the metallic matrix layer; forming carbon nanotubes inside the nanoholes; and covering inner surfaces of the carbon nanotubes with a continous layer of a metal. It has a well controlled small size, has excellent and uniform physical properties, is resistant to oxidation of the metal with time, is highly chemically stable, has good durability enabling repetitive use, has good coatability, high wettability and dispersibility with other materials, is easily chemically modified, is easily handled and is useful in various fields.

Owner:FUJITSU LTD +1

Resin composition and three-dimensional object

InactiveUS6685869B2Good paintabilityGood lookingAdditive manufacturing apparatusOptical articlesSolubilityMeth-

Owner:DSM IP ASSETS BV +2

Sintering-strippable red cast iron coating and preparation method thereof

InactiveCN102601300APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresCrack resistancePreservative

The invention relates to a sintering-strippable low-cost red water-based cast iron coating, which is prepared by the following raw materials in percent by mass: 20-45 percent of bauxite powder or powder quartz, 0-25 percent of mullite powder, 1-6 percent of talcum powder, 1-5 percent of iron trioxide powder, 1-3 percent of suspending agent, 1.5-4.5 percent of organic binding agent, 1.5-6 percent of inorganic binding agent, 0.01-0.05 percent of wetting agent, 0.02-0.05 percent of preservative, 0.02-0.1 percent of defoaming agent, 0-0.5 percent of water reducing agent and 30-42 percent of tap water. The sintering-strippable low-cost red water-based cast iron coating has the characteristics that the raw materials are cheap and the source is wide; the product is low-cost, safe, environmental-friendly and convenient to transport; the brushing property, the flowing resistance and the leveling property of the product are good, the suspension percentage, the coating strength and the crack resistance are high and the gas evolution is low; and the sintering-stripping performance is excellent, the most part of the coating can be vastly stripped after castings are taken out of a casting box and are cooled, the defects of sand sticking, sand inclusion, sand drop, voids and the like existing the castings can be effectively avoided, and the castings with excellent surface quality can be obtained.

Owner:湖北省机电研究设计院股份公司

Thermal insulative coating and preparing method thereof

InactiveCN1583895AIsolated conductionGood weather resistanceFireproof paintsPetrochemicalMaterials science

The sun-proof coating of a kind of heat insulation and method of preparing, are suitable for various kinds of vehicles, shipping, all kinds of pots in the petrochemical industry, the trough, the appearance of the pipeline, and the outer walls of all kinds of buildings, the covering, the appearance of the tarpaulin insulates against heat, decorate and scribble to decorate using; Insulate against heat sun-proof coating join 1-30% of the hollow ceramic thermal insulator in invention this, form one pre -pressing vacuum layer things surface put to paint, a very ettective one isolate the sun ray radiation hot and heat radiation of air conduct, differ by with temperature not external inside not painting by object that put 4-8deg.C, great reduction energy very consume, the heat insulation coating of this invention has the good one and is able to bear the waiting, wearability is waterproof, since clean.

Owner:吕艺

Paintable organopolysiloxane mold release compositions and processes for their use

InactiveUS6294007B1Good paintabilityFacilitated releaseOther chemical processesCoatingsOrganic solventPolymer chemistry

Silicone mold release compositions which are a stable blend of hydrophobic-modified organopolysiloxane and an aminoorgano- or mercaptoorgano-functional organopolysiloxane, or a solution in organic solvent of a stable or unstable blend, provide exceptional mold release properties while retaining paintability of molded parts.

Owner:WACKER SILICONES

Long fiber reinforced polypropylene/PPE alloy material and its prepn and application

The long fiber reinforced polypropylene / PPE alloy material has oriented fibers in the length over 4 mm and in netted configuration, and thus greatly raised shock resistance, rigidity, creeping resistance and size stability. What is more important is that the material may be mixed with many kinds of other material and thus has wide application range. The material may be prepared through powder soaking process, smelting soaking process, etc. The long fiber reinforced polypropylene / PPE alloy material of the present invention has excellent tensile, bending and anti-shocking performance, and may be used in manufacturing automobile part, pipe, valve part, electric tool, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Production method of water based paint special for lost foam

InactiveCN101288897ANo pollution in the processImprove adhesion strengthFoundry mouldsFoundry coresWater basedFiber

The invention provides a production method for water-based coating which is specially used for lost die. The composition of the water-based coating comprises: amorphous graphite powder, flaky graphite powder, bentonite, hydroxymethyl fiber, milk-white glue, corn starch, dextrin and BY adhesive. The composition proportion is 50% of the amorphous graphite powders, 50% of flaky graphite powders, 5-10% of bentonite, 3-5% of hydroxymethyl fiber, 1.5-3% of milk-white glue, 3-5% corn starch, 3-5% of dextrin and 2-3% of the BY adhesive. The method of the invention solves the problems that the currently usually used lost die is easy to cause that the casting is easy to be deformed, cracked, delaminated, stuck with sand on the surface, non-smooth and difficult to remove the stuck sand, thereby affecting the quality of the casting and being suitable for application in the casting production of the lost die.

Owner:QINGDAO HAILONG MACHINERY GRP

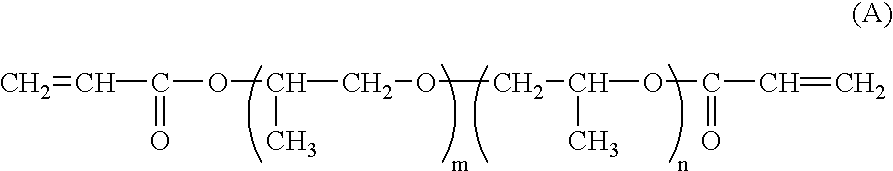

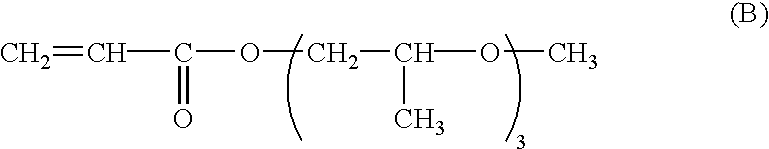

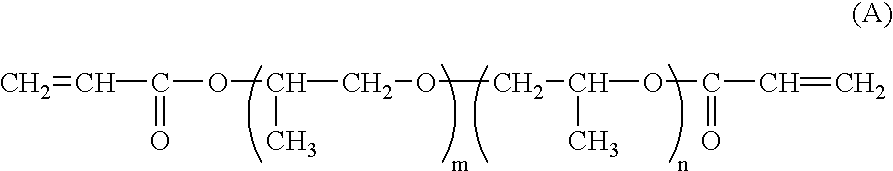

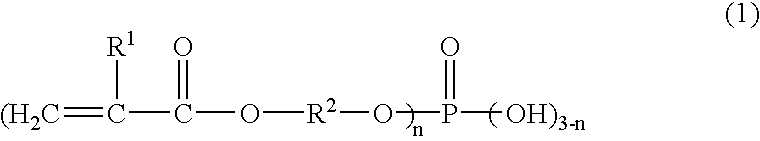

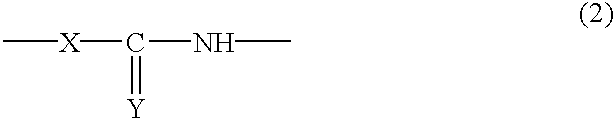

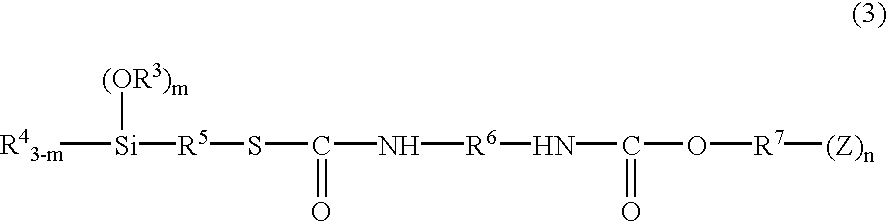

Resin composition comprising inorganic particles and polymerizable phosphates and the products prepared therefrom

A resin composition comprising: (A) particles prepared by bonding at least one oxide of an element selected from the group consisting of silicon, aluminum, zirconium, titanium, zinc, germanium, indium, tin, antimony, and cerium, and an organic compound which includes a polymerizable unsaturated group, (B) a polymerizable acid phosphate and (C) a compound other than the compound (B) having at least two polymerizable unsaturated groups in the molecule.

Owner:DSM NV +2

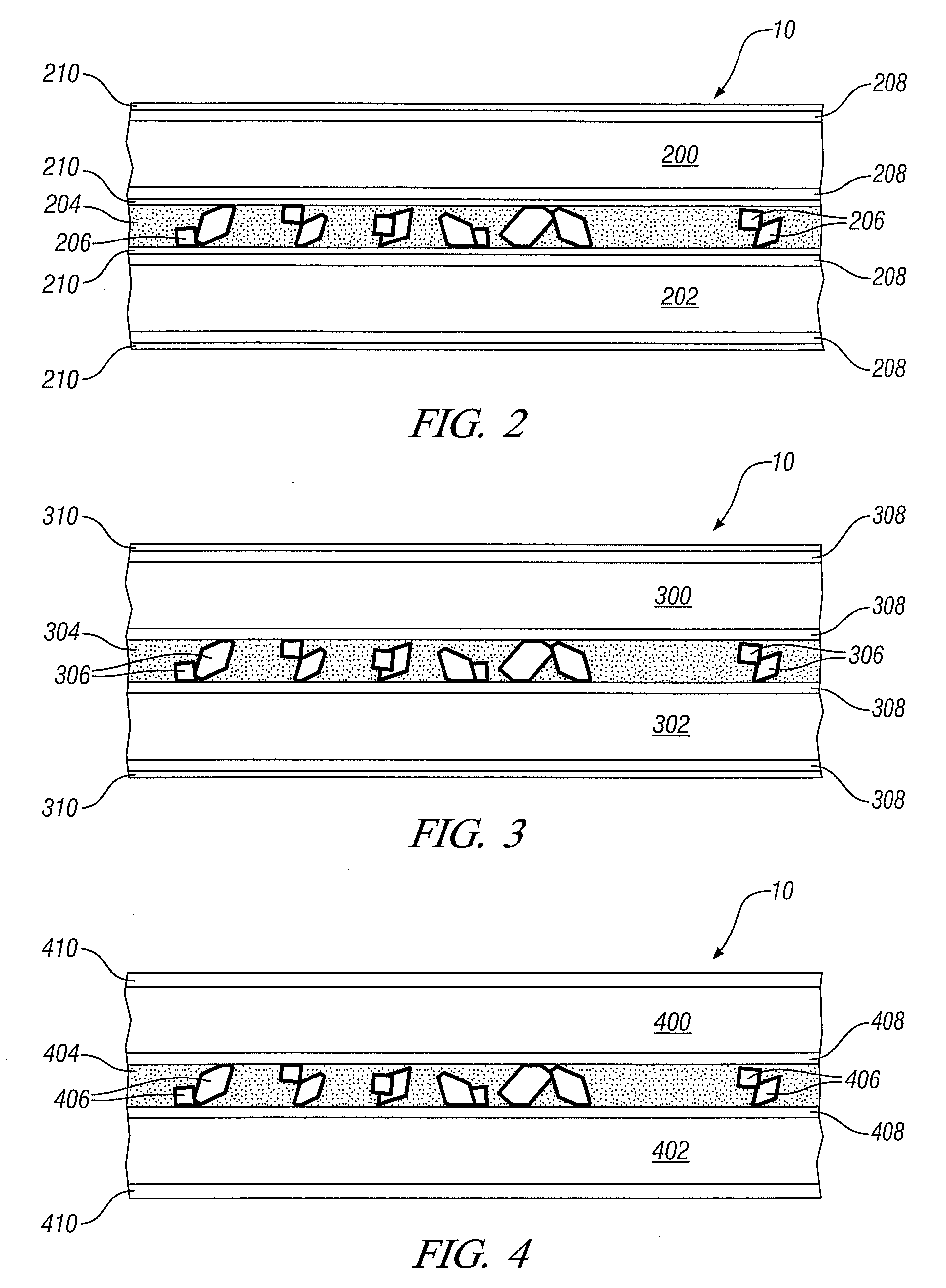

Corrosion resistant laminated steel

InactiveUS20100035080A1Improve corrosion resistanceEasy to shapeMetallic material coating processesThin material handlingSheet steelSolderability

Outer steel sheet-viscoelastic core laminates are often subject to corrosion in moisture-containing environments. Zinc-based alloys of aluminum, or of aluminum and magnesium, may be beneficially applied to the inner faces of the steel sheets or to both the inner and outer sheet faces. Substantially pure zinc coatings may be applied over the zinc-based alloys or over an otherwise bare outer steel sheet surface. Combinations of such zinc-based alloy coatings and substantially pure zinc coatings improve the corrosion resistance of the steel sheet-polymer core laminates while maximizing weldability and paintability.

Owner:GM GLOBAL TECH OPERATIONS LLC

Environmentally preferred high solids, low viscosity flock adhesives

InactiveUS6924000B2Low in VOCsGood paintabilityLayered productsPolyureas/polyurethane adhesivesFiberElastomer

An environmentally preferred flock adhesive composition containing low molecular weight prepolymers of isocyanate terminated polyether and / or polyalkadiene polyols is disclosed. The prepolymers are free of residual volatile isocyanate (<1000 ppm) without blocking the isocyanate thereby providing favorable effects on viscosity, cure kinetics, and safety. The flock adhesive composition preferably contains an aromatic nitroso compound an epoxy novolak resin and a catalyst. The adhesive compositions can be made at high solids, with minimal co-solvent, while maintaining low viscosity, which is favorable to environmental regulations aimed at reducing solvent emissions. Furthermore, the solvents can be non-HAP and non-photochemically reactive. The adhesive composition can be utilized for the application of flocking fibers to various elastomer substrates.

Owner:LORD CORP

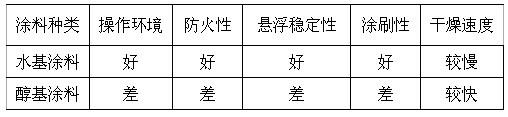

Magnesium aluminium spinel powder alcohol-based coating for heavy section steel castings and preparation method thereof

The invention discloses a magnesium aluminum spinel powder alcohol-based coating for heavy section steel castings, and relates to a casting coating. The alcohol-based coating comprises the following components in percentage by weight: 55 to 60 percent of magnesium aluminium spinel powder, 0.5 to 1.2 percent of binder, 0.11 to 0.18 percent of suspended thickening agent, 1.1 to 1.8 percent of suspending agent, 2.7 to 4.2 percent of fluxing agent, and the balance of organic solvent. In the magnesium aluminum spinel powder alcohol-based coating, the particle size of the magnesium aluminum spinel powder is between 270 and 320, and Al2O3 is more than or equal to 78 percent. The magnesium aluminum spinel powder is synthesized by electric smelting technology, has the characteristics of low expansion and high smelting point, and meets the requirement of serving as refractory aggregate of the coating for the steel castings; and the magnesium aluminum spinel powder has obvious price and resource advantages than zircon powder.

Owner:CHINA YITUO GROUP

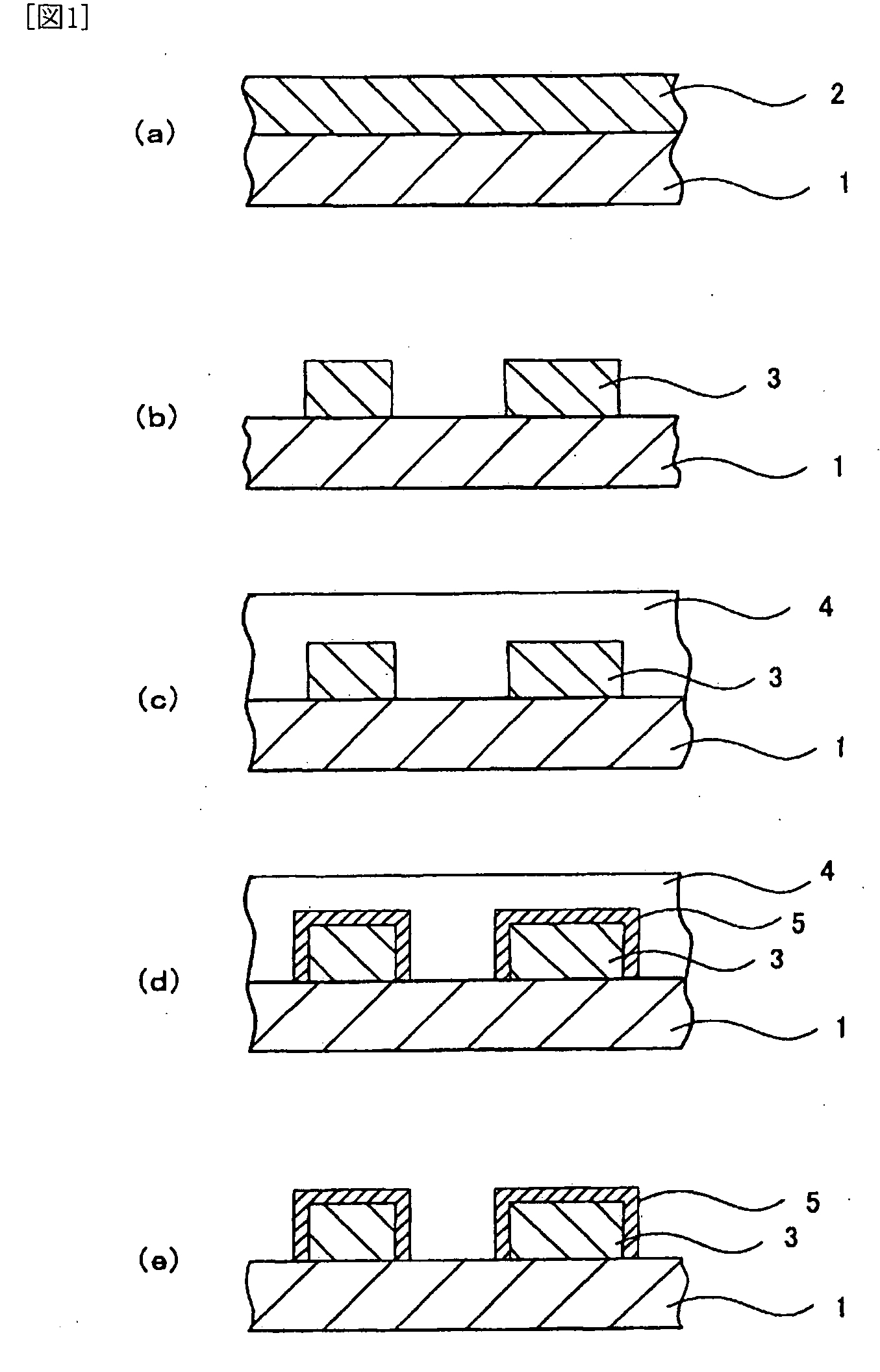

Water Soluble Resin Composition and Method for Pattern Formation Using the Same

InactiveUS20080193880A1Efficient preparationHigh yieldPhotosensitive materialsRadiation applicationsResistHigh density

In the present invention, in a water soluble resin composition for use in a method for pattern formation in which a covering layer is provided on a resist pattern formed of a radiation-sensitive resin composition capable of coping with ArF exposure to increase the width of the resist pattern and thus to realize effective formation of higher density trench or hole pattern, the size reduction level of the resist pattern layer can be further increased as compared with that in the prior art technique, and, in addition, the size reduction level dependency of the coarse-and-fine resist pattern can be reduced. A method for pattern formation using the water soluble resin composition is also provided. The water soluble resin composition which is usable for the method for pattern formation applicable to ArF excimer laser irradiation comprises a water soluble resin, an acid generating agent capable of generating an acid upon heating, a surfactant, a crosslinking agent, and a water-containing solvent.

Owner:MERCK PATENT GMBH

Water-base paint specially for disappearing cast mold

InactiveCN1375365AGood paintabilityGood variable characteristicsFoundry mouldsFoundry coresBrown iron oxideEmulsion

The water-base dissolving mould casting special-purpose coating is formed from 700-850 portions of alumina, 150-300 portions of diatomaceous earth, 20-30 portions of bentonite, 0.5-2.,0 portions of industrial sodium carbonate, 5-15 portions of cellulose sodium, 30-40 portions of white emulsion, 10-20 portions of aluminium sulfate, 20-30 portions of iron oxide, 20-30 portions of starch, 0.1-0.2 portion of washing powder and 700-800 portions of water. Said coating possesses good imbibition property, good transmutation and flowability, uniform coating layer, high strength and other advantages.

Owner:黄述哲 +2

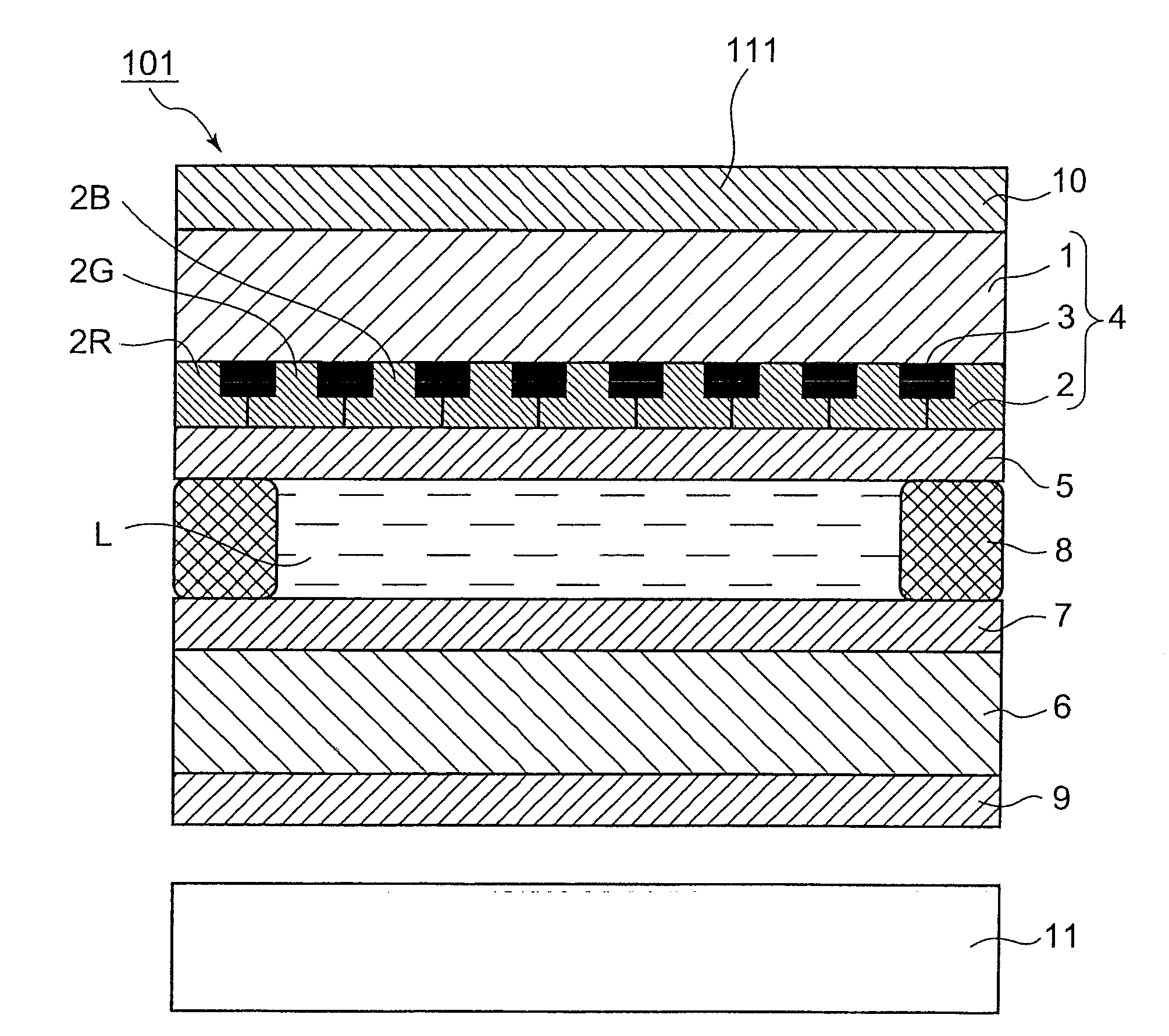

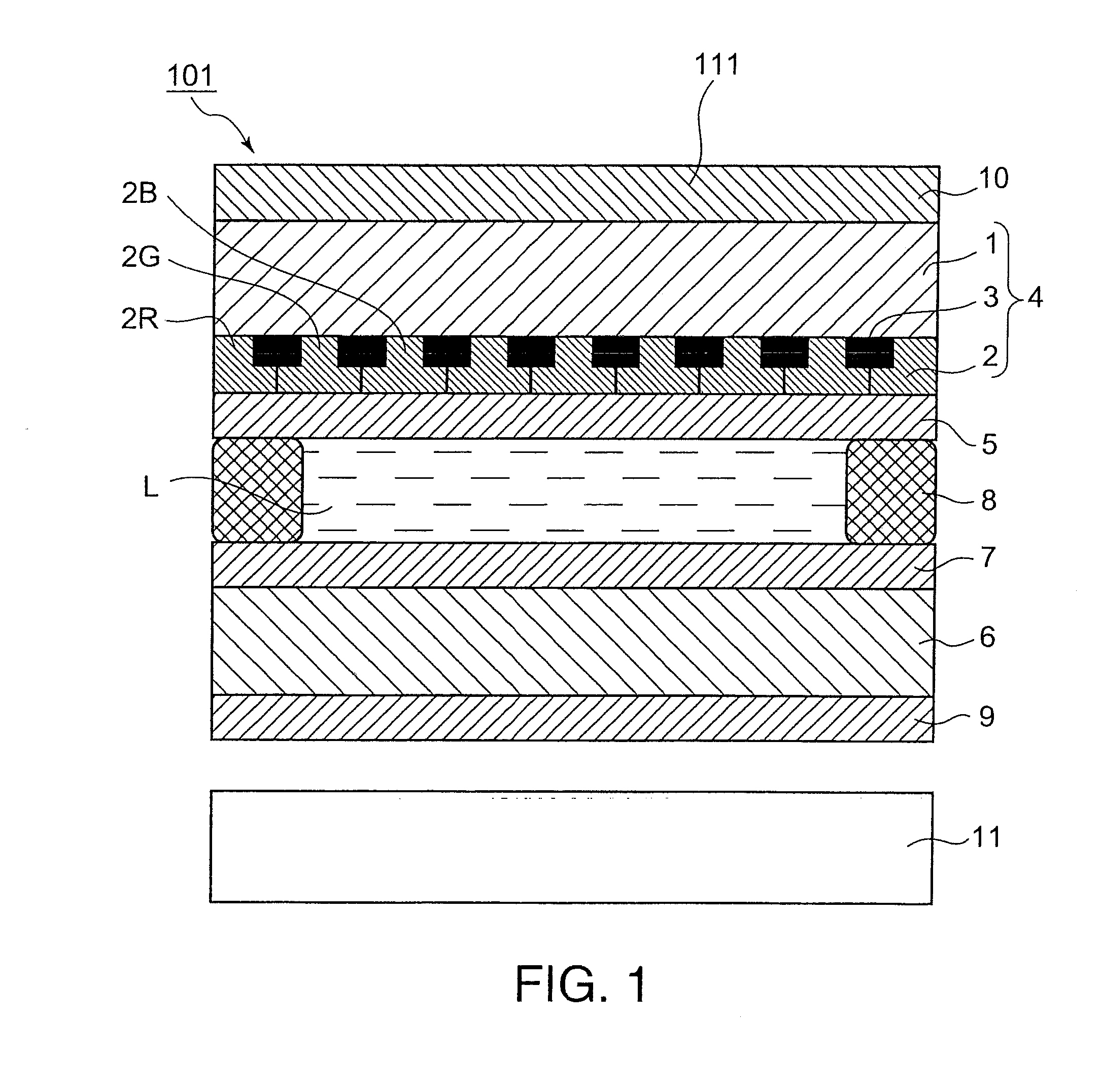

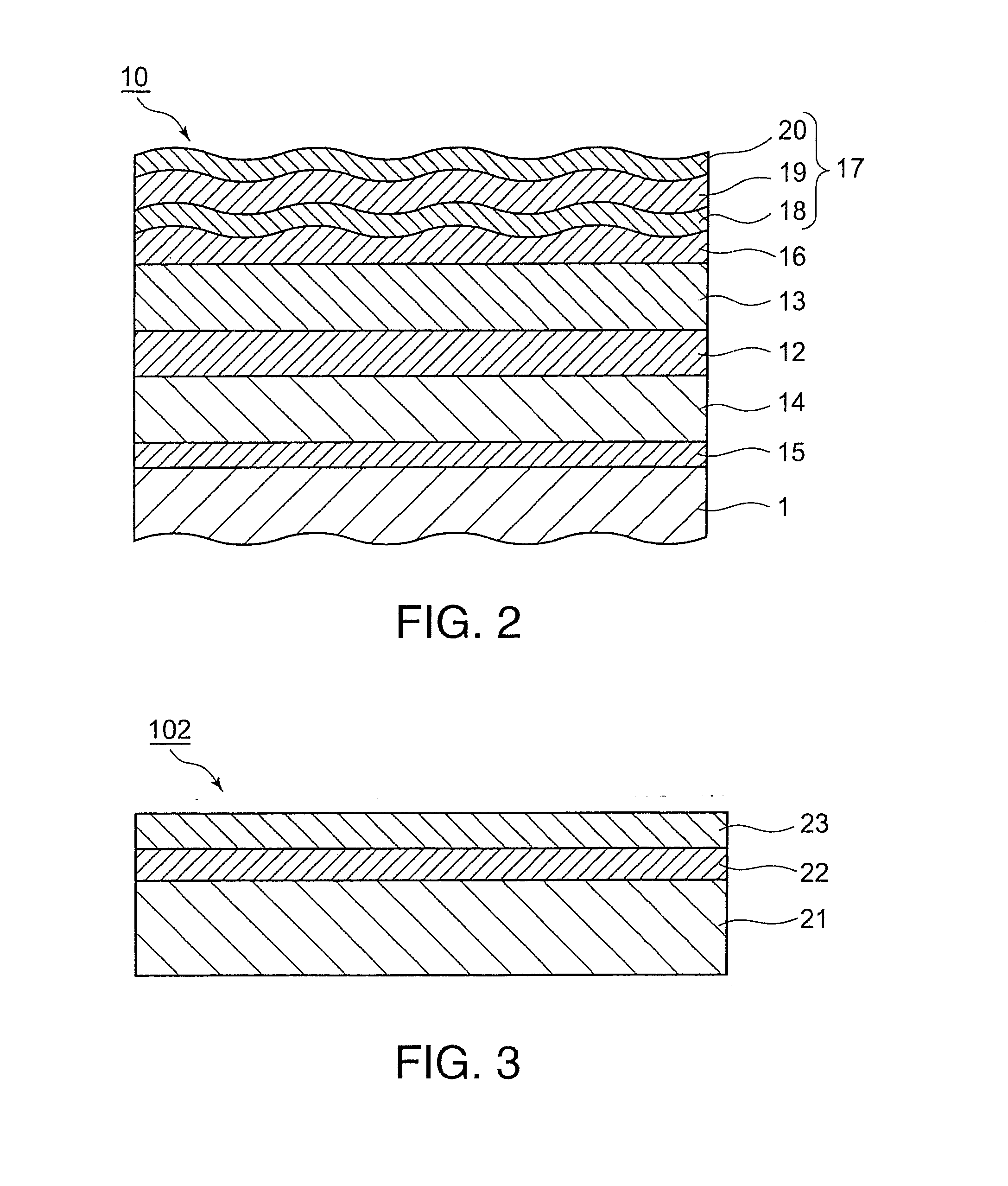

Coating Composition, Its Coating Film, Antireflection Film, and Image Display Device

ActiveUS20080187732A1Lowering in strengthReducing and eliminating activityGlass/slag layered productsWood layered productsCoated membraneElectron hole

This invention provides a coating composition that can form a coating film having an eliminated or reduced photocatalytic action-derived deterioration and can form a coating film having a lowered haze value, has excellent dispersibility and dispersion stability in a coating liquid form, has excellent storage stability, and also has excellent coatability. The coating composition is characterized by comprising at least the following four components (1) to (4): (1) titanium dioxide fine particles with eliminated or reduced photocatalytic activity which is obtained by surface treating titanium dioxide fine particles doped with cobalt capable of capturing free electrons and / or holes, with a zinc chelate compound capable of capturing free electrons and / or holes, (2) a binder component, (3) a dispersant, and (4) an organic solvent.

Owner:DAI NIPPON PRINTING CO LTD

Highly elastomeric and paintable silicone compositions

ActiveUS20080312369A1Good paintabilityGood weather resistanceDyeing processCoatingsSealantPolymer chemistry

Highly elastomeric, curable, paintable silicone compositions are provided. The paintable silicone compositions comprise an organopolysiloxane, a silicone functional crosslinker, and an organic polymer. The highly elastomeric, curable, paintable silicone compositions have an elongation of at least 150% and are useful as paintable sealants and caulks.

Owner:TREMCO CPG INC

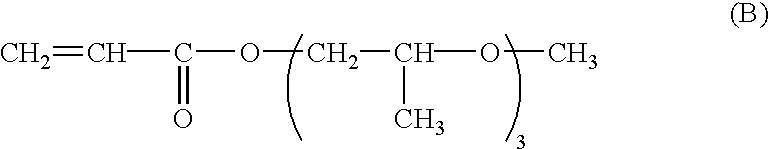

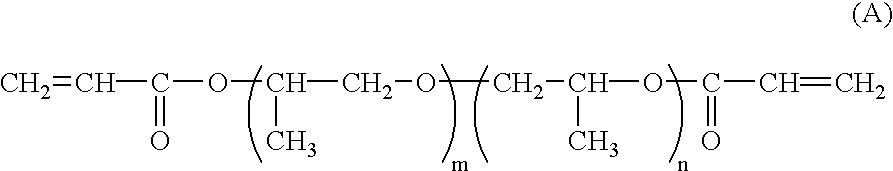

Antifoaming agent of non-silicone in use for aqueous glue of composite film

This invention discloses a method for preparing an antifoaming agent for aqueous laminated film glue. The antifoaming agent comprises: carrier (mainly mineral oil) 65-90 wt.%, main antifoaming agent (white carbon black, fatty acid metal soap, amide and MQ resin) 1-15 wt.%, auxiliary antifoaming agent (modified polyether, R1O(EO)x (PO)yR2) 2-20 wt.%, and emulsifier (nonionic surfactant with HLB value of 8-10) 3-15 wt.%. The method comprises: (1) stirring the primary antifoaming agent and the auxiliary antifoaming agent in the carrier, heating to 140-150 deg.C, and keeping for 2 h; (2) rapidly cooling to 70-80 deg.C, keeping for 40 min, cooling to 50 deg.C, adding the emulsifier, and stirring uniformly. The antifoaming agent has such advantages as high safely and high performance, and can be used in aqueous laminated film glue, paint, oil ink, coating cloth, etc.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

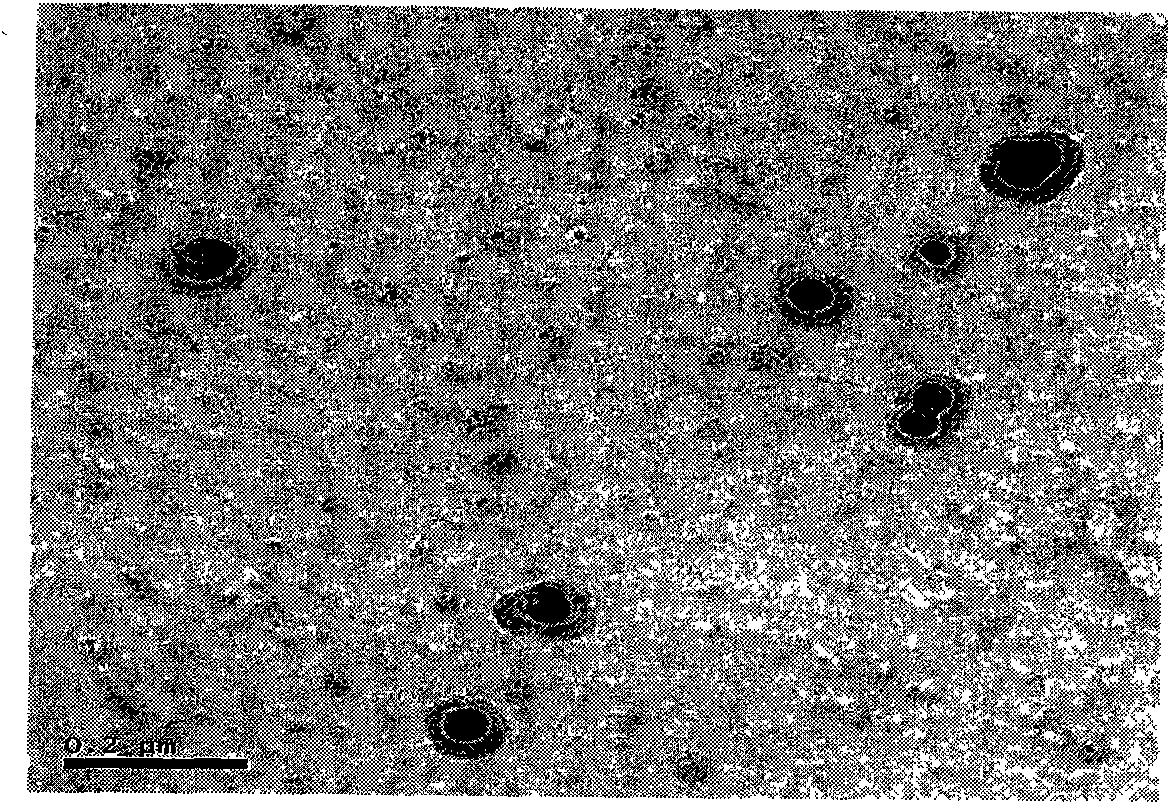

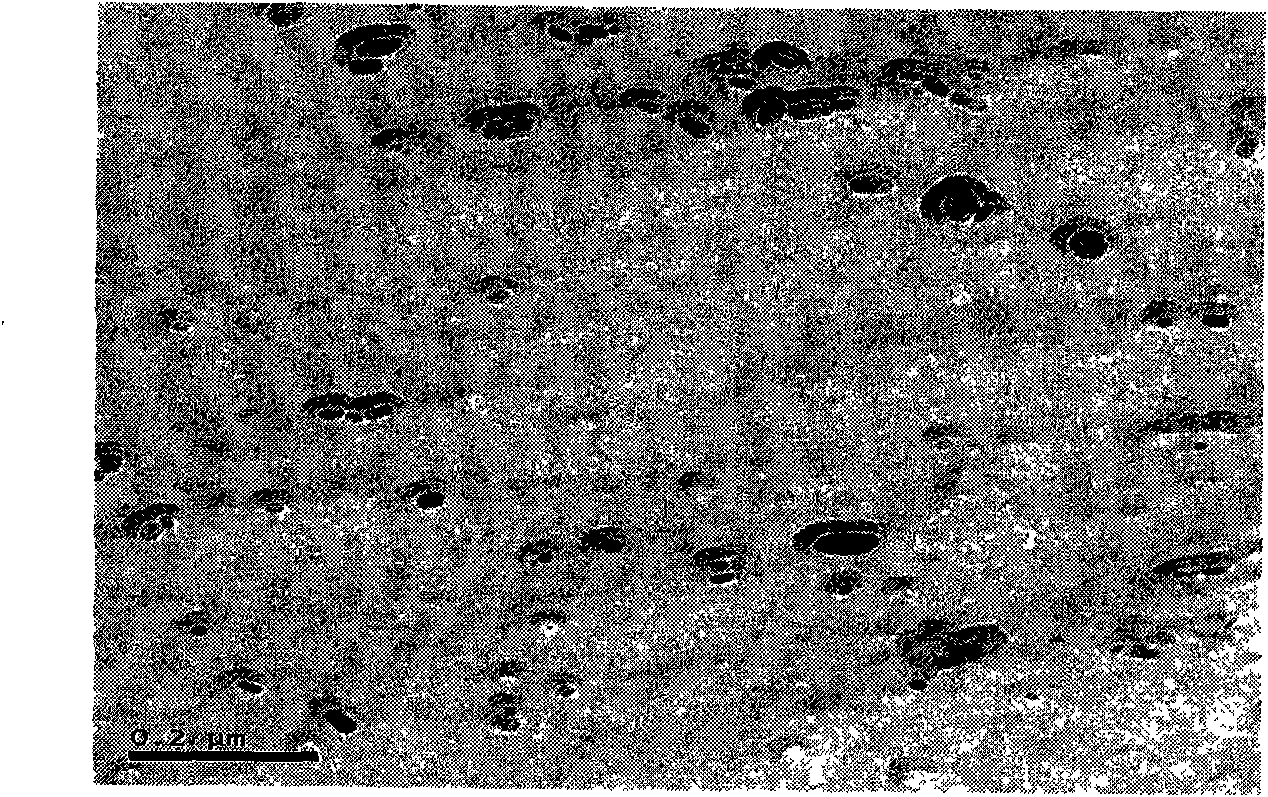

Nanoparticle, method of producing nanoparticle and magnetic recording medium

InactiveUS7066978B2Not easily coagulated with each otherImprove coatabilityNanostructure applicationMaterial nanotechnologySaline waterOrganic solvent

A method of producing a nanoparticle, the method comprising: a reducing step of adding an reverse micelle solution (II) obtained by mixing a water-insoluble organic solvent containing a surfactant with an aqueous metal salt solution to an reverse micelle solution (I) obtained by mixing a water-insoluble organic solvent containing a surfactant with an aqueous reducing agent solution, to carry out a reducing reaction; and a maturing step of raising the temperature of the reduced mixture to mature the reduced mixture is provided. A method of producing a plural type alloy nanoparticle, the method comprising producing a nanoparticle made of a plural type alloy through a reducing step of mixing one or more reverse micelle solutions (I) containing a metal salt with an reverse micelle solution (II) containing a reducing agent to carry out reducing treatment and a maturing step of carrying out maturing treatment is also provided.

Owner:FUJIFILM HLDG CORP +1

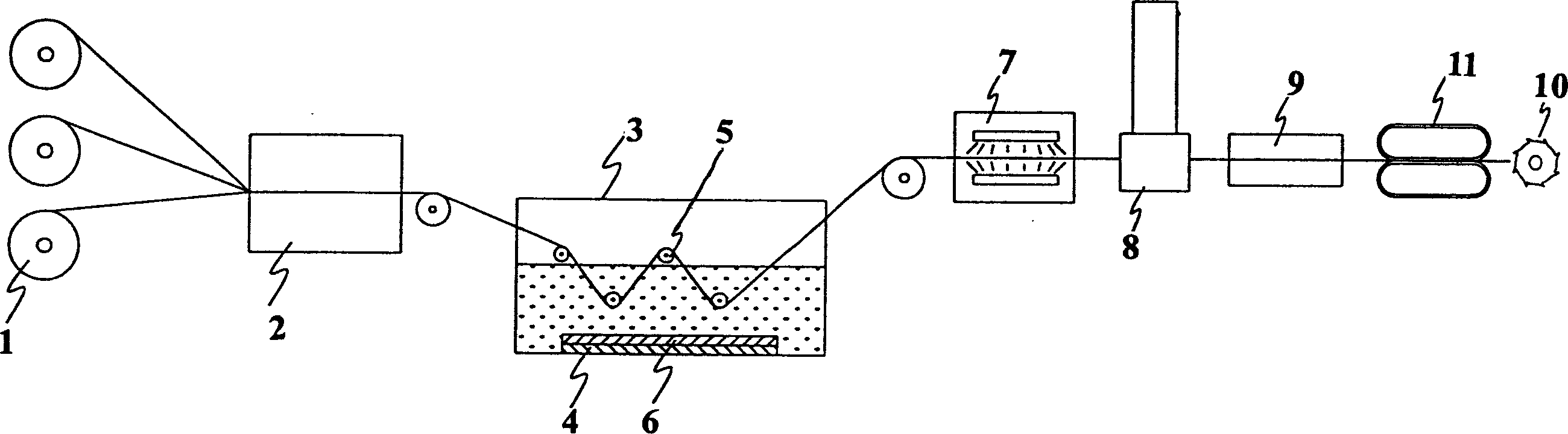

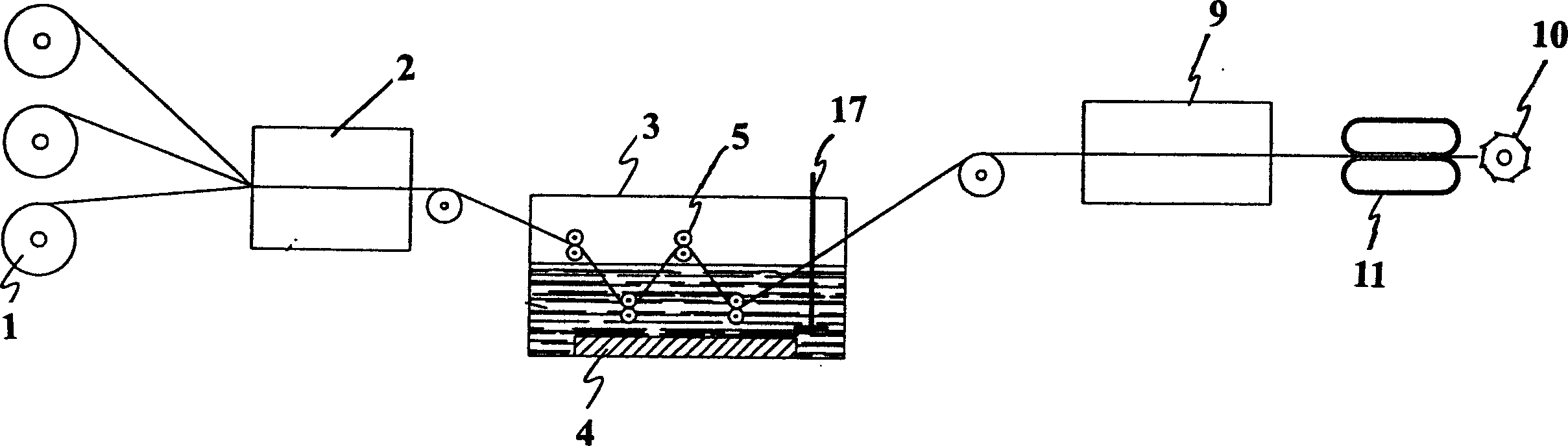

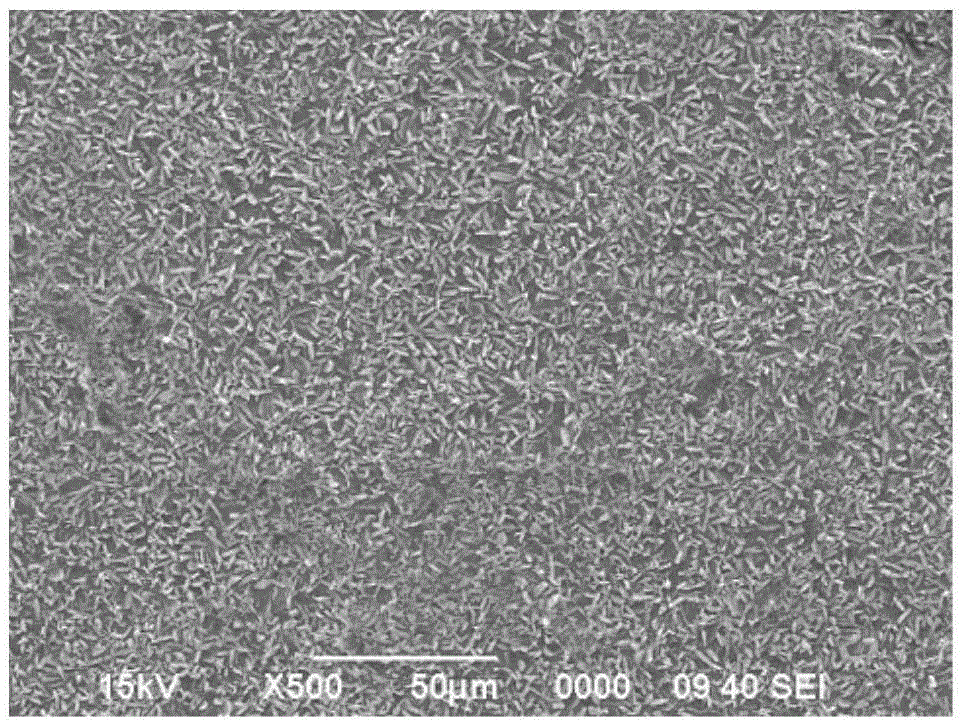

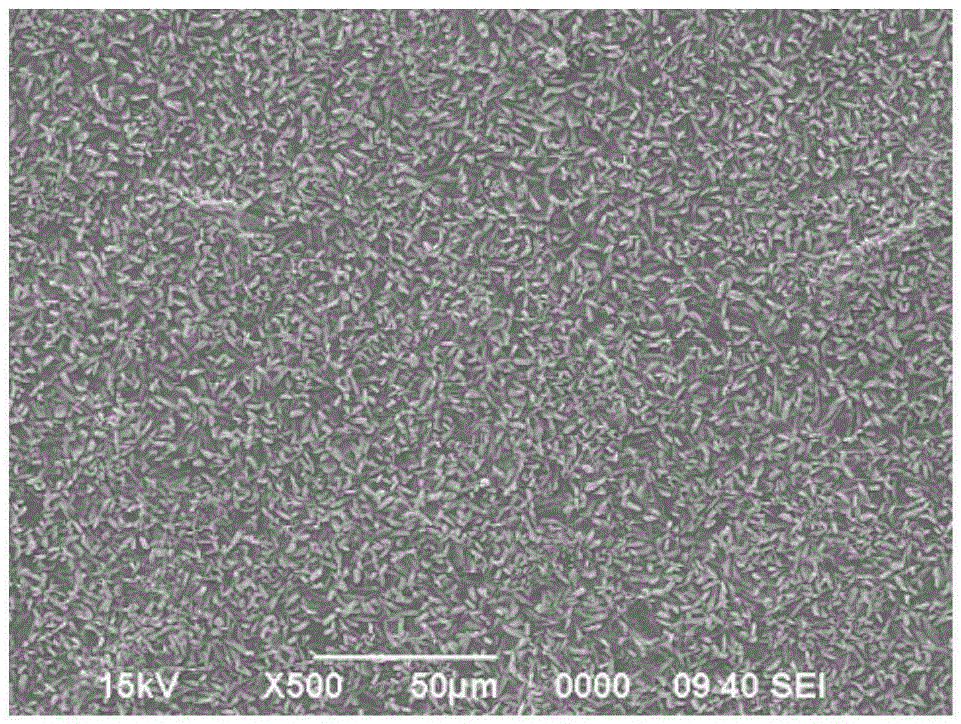

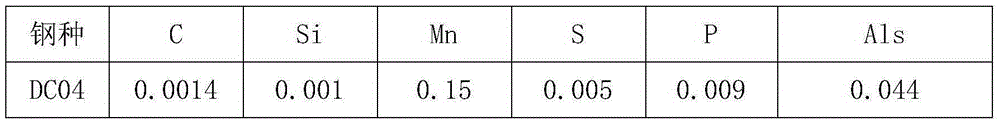

Control method for increasing painting performance and surface quality of cold rolling automobile sheet

The invention relates to a control method for increasing the painting performance and the surface quality of a cold rolling automobile sheet, which belongs to the technical field of steel production and is suitable for IF (Interstitial-Free) steel cold rolling automobile sheets. The control method comprises the steps of controlling components of continuous casting slabs; improving a reheating schedule of the continuous casting slabs, wherein the time inside a furnace is from 160 to 290 min, and the tapping temperature is from 1130 to 1220 DEG C; adjusting a dephosphorization process, wherein the pressure of each dephosphorization point is from 17 to 22 MPa; optimizing rolling temperature, wherein the outlet temperature for rough rolling is from 1020 to 1100 DEG C, and the final rolling temperature is from 900 to 940 DEG C; optimizing a continuous annealing process, wherein the O content of each zone of the furnace is from 0 to 20 ppm, the dew point temperature is from -70 to -40 DEG C, the H2 content is from 2% to 5%, the continuous annealing heating temperature is from 760 to 830 DEG C, an Ra value is from 0.7 to 1.3 mum after flattening, and an Rpc value is from 60 to 130. The control method has the advantages that existing equipment does not need to be upgraded, the components of the casting slabs are designed, and the processes are optimized, so that the surface quality and the painting performance of the cold rolling automobile sheet are effectively increased.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com