Control method for increasing painting performance and surface quality of cold rolling automobile sheet

A surface quality and control method technology, which is applied in the field of steel production, can solve the problems of low paintability and corrosion resistance, and achieve the effects of improving surface quality and production efficiency, improving reactivity and paintability, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

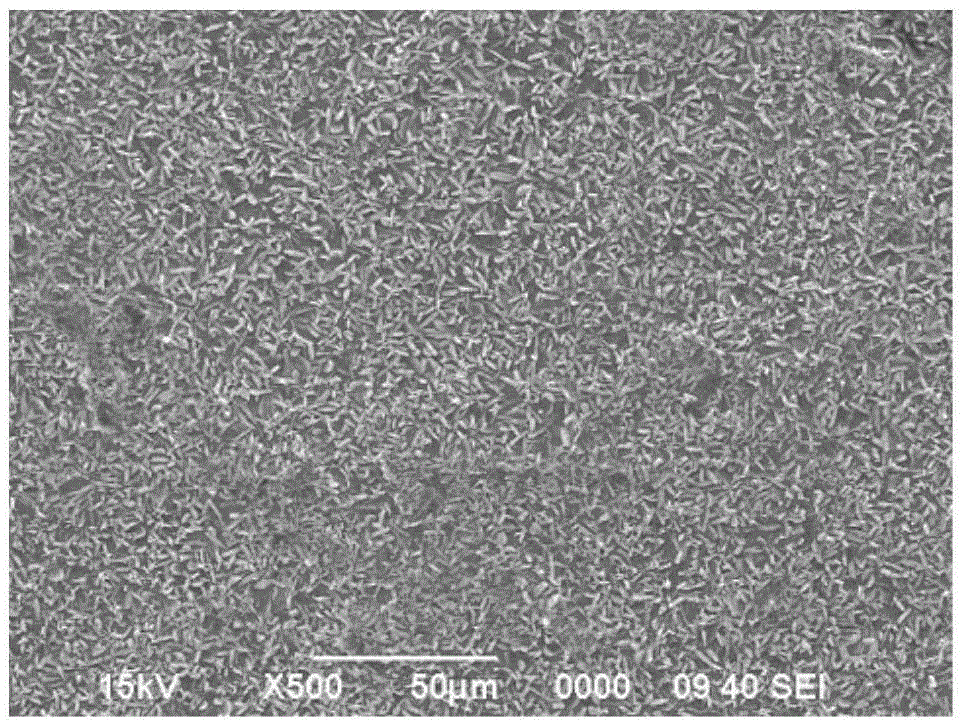

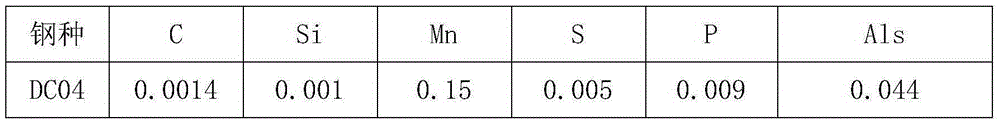

[0020] The embodiment of the present invention provides a DC04 cold-rolled automobile steel sheet, whose chemical composition is shown in Table 1, and its surface quality control method includes the following steps:

[0021] 1. Heat the casting slab, in which the residual oxygen content of the heating furnace is 5%, the continuous casting slab is in the furnace for 230 minutes, and the furnace temperature is 1180°C.

[0022] 2. The heated cast slab undergoes rough rolling and finish rolling to obtain hot rolled plates, wherein the rough rolling outlet temperature is 1050°C, the final rolling temperature is 920°C, and the coiling temperature is 660°C; descaling process is used to control the scale.

[0023] 3. The hot-rolled coil is cold-rolled to obtain a chilled coil, the cold-rolling reduction rate is 82.5%, and the residual oil content on one side is 180mg / m 2 .

[0024] 4. Subjecting the chilled coil to continuous annealing treatment to obtain strip steel. During continuous anneal...

Embodiment 2

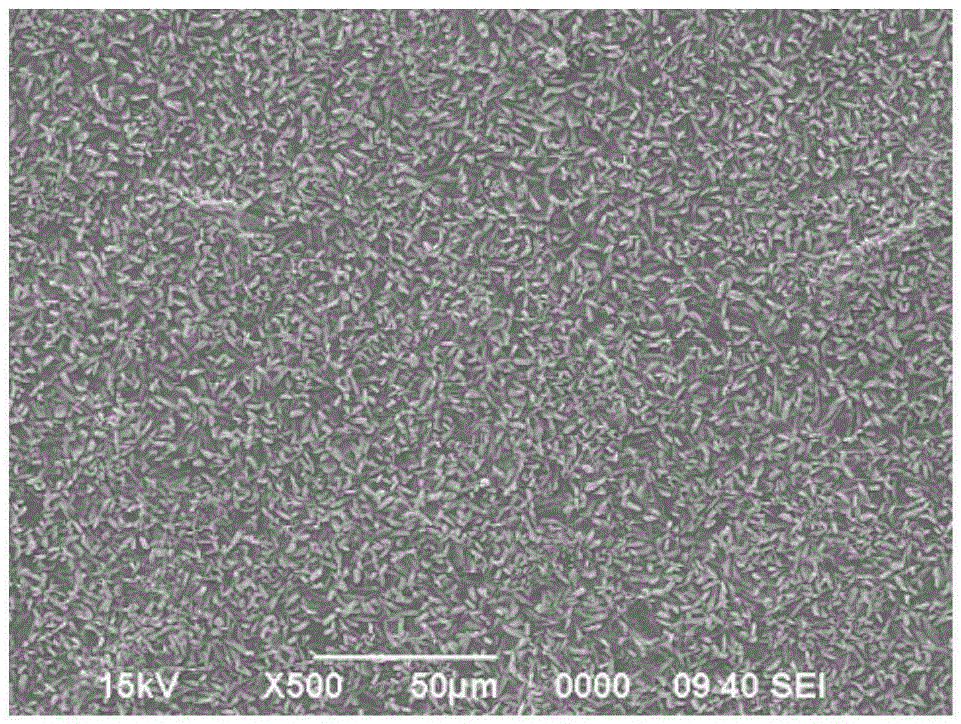

[0031] The embodiment of the present invention provides a DC04 cold-rolled automobile steel sheet, whose chemical composition is shown in Table 2, and its surface quality control method includes the following steps:

[0032] 1. Heat the casting slab, in which the residual oxygen content of the heating furnace is 6%, the continuous casting slab is in the furnace for 225 minutes, and the furnace temperature is 1180°C.

[0033] 2. The heated cast slab undergoes rough rolling and finish rolling to obtain hot-rolled plates, wherein the rough-rolling exit temperature is 1055°C, the final rolling temperature is 923°C, and the coiling temperature is 667°C; the descaling process is used to control the scale.

[0034] 3. The hot rolled coil is cold rolled to obtain a chilled coil, the cold rolling reduction ratio is 82.2%, and the residual oil content on one side is 160 mg / m2.

[0035] 4. Subjecting the chilled coil to continuous annealing treatment to obtain strip steel. During continuous anne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com