Long fiber reinforced polypropylene/PPE alloy material and its prepn and application

A technology of alloy materials and long fibers, which is applied in the field of polypropylene/polyphenylene ether alloy materials, can solve the problems of limited application and low mechanical properties, and achieve the effects of reducing classification work, improving application range, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

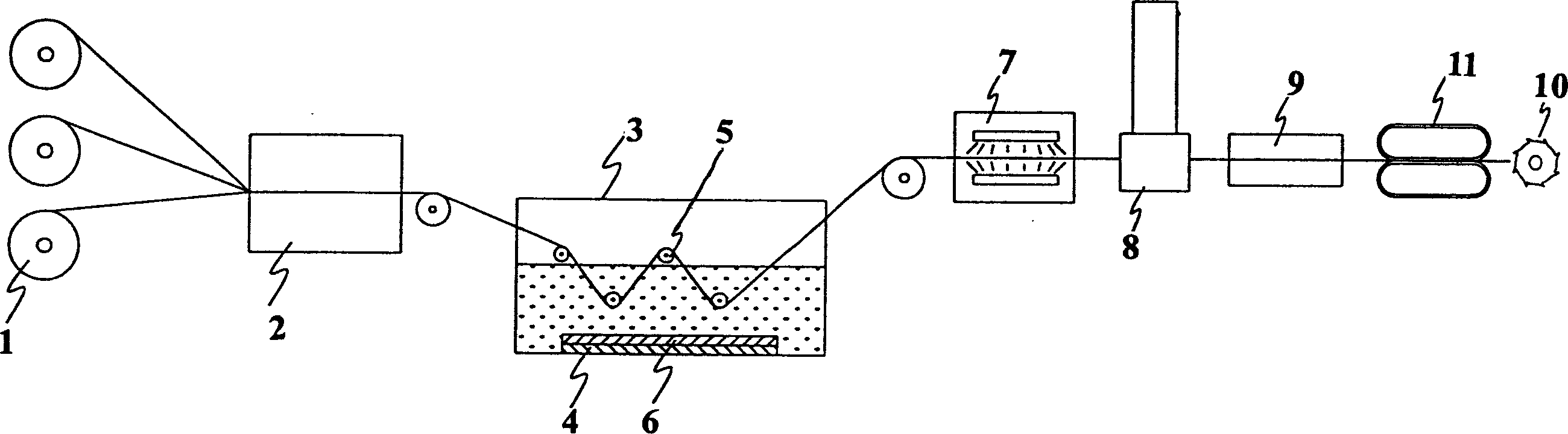

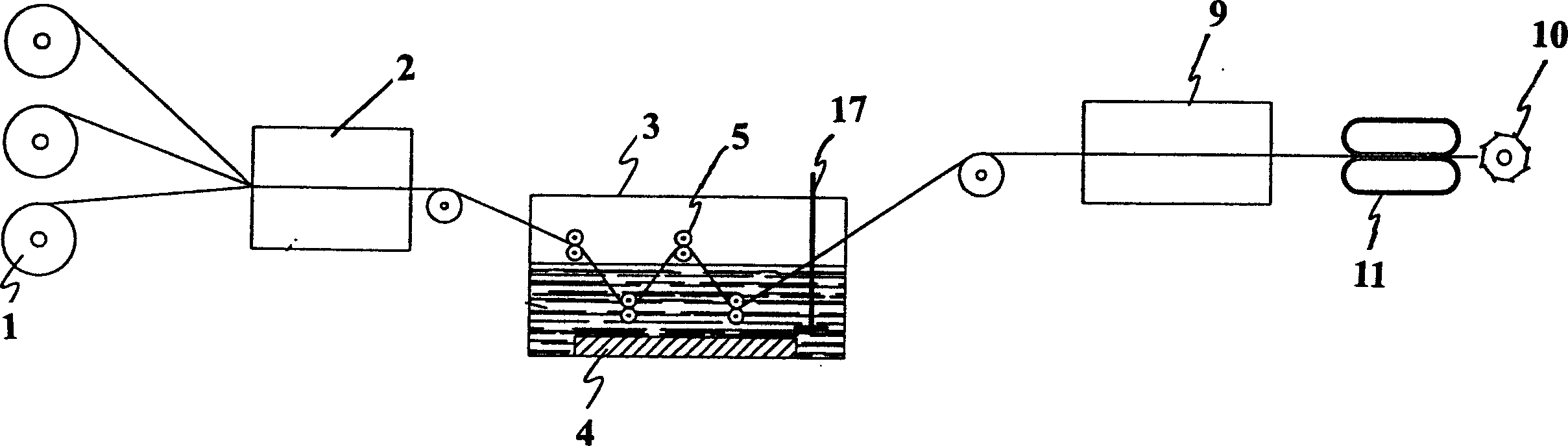

Method used

Image

Examples

Embodiment 1

[0038] The glass fiber is made into a polyphenylene ether prepreg by a powder impregnation process, and heated and cured at 230°C, and then the prepared prepreg is directly passed through the spiral coating die of a single-screw extruder, extruded The melt in the machine is polypropylene resin, mixed with antioxidant 1010 (tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) and compatibilizer maleic anhydride, and finally cut the extruded continuous glass fiber reinforced polypropylene / polyphenylene ether alloy material into 9mm pellets with a pelletizer.

[0039] The specific components are as follows:

[0040] Polypropylene resin 400

[0041] Polyphenylene ether resin 200

[0042] Continuous glass fiber 400

[0043] Antioxidant 1010 5

[0044] Maleic anhydride 5

[0045] Its properties are listed in Table 1.

Embodiment 2

[0047] The continuous glass fiber is passed through the melt impregnation tank, the melt in the tank is polypropylene and polyphenylene ether resin, and mixed with antioxidant 1010 (tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl ) propionic acid] pentaerythritol ester) and compatibilizer SMA (styrene-maleic anhydride random copolymer), and finally cut the extruded continuous glass fiber reinforced polypropylene / polyphenylene ether alloy material into 9mm with pelletizer of pellets.

[0048] The specific components are as follows:

[0049] Polypropylene resin 400

[0050] Polyphenylene ether resin 200

[0051] Continuous glass fiber 400

[0052] Antioxidant 1010 5

[0053] SMA (styrene-maleic anhydride random copolymer) 20

[0054] Its properties are listed in Table 1.

Embodiment 3

[0056] The continuous glass fiber is passed through the melt impregnation tank, the melt in the tank is polypropylene and polyphenylene ether resin, and mixed with antioxidant 1010 (tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl ) propionic acid)] pentaerythritol ester) and compatibilizer SEBS (styrene-ethylene-butylene-styrene block copolymer), and finally the continuous glass fiber reinforced polypropylene / polyphenylene ether The alloy material was cut into 9mm pellets. The glass fiber content is controlled at about 30%.

[0057] The specific components are as follows:

[0058] Polypropylene resin 200

[0059] Polyphenylene ether resin 500

[0060] Continuous glass fiber 300

[0061] Antioxidant 1010 5

[0062] SEBS 20

[0063] Its properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com