Enamel steel for cold rolling water heater and manufacturing method thereof

A technology for enamel steel and water heaters, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of unstable welding performance, affecting welding performance, and decreasing yield strength, etc. The effect of grain growth and yield strength stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

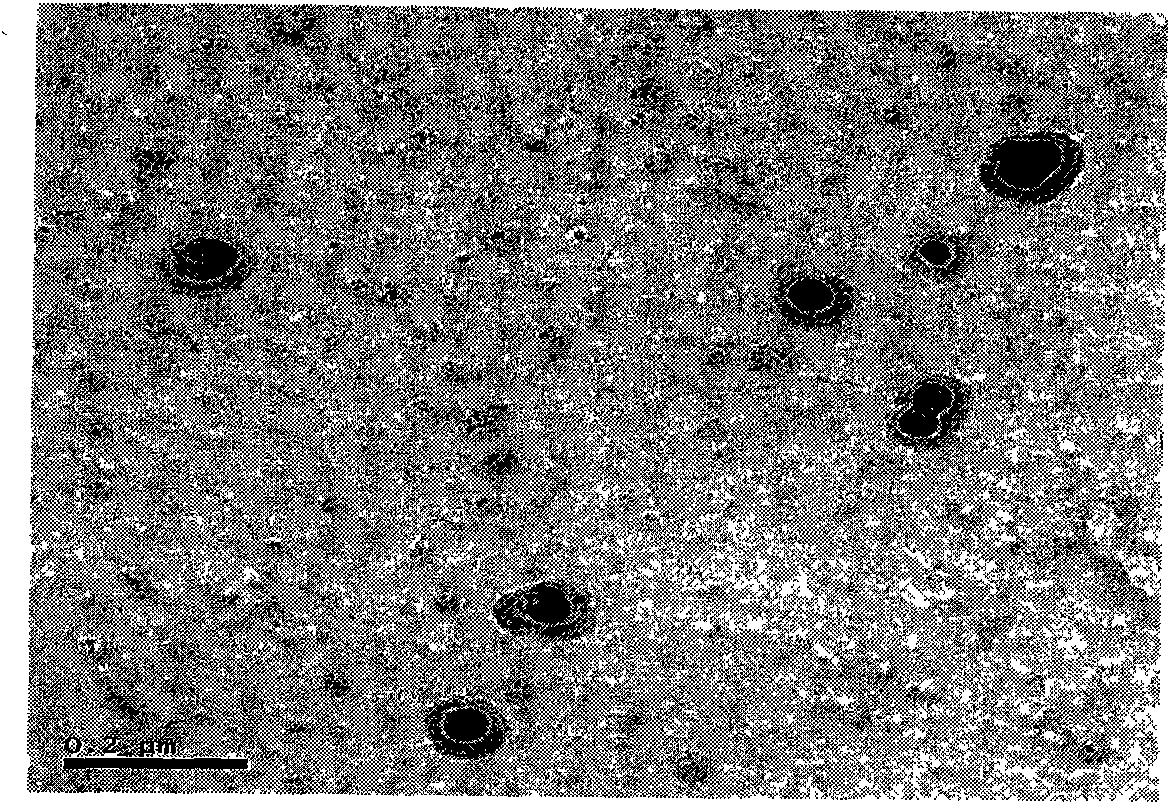

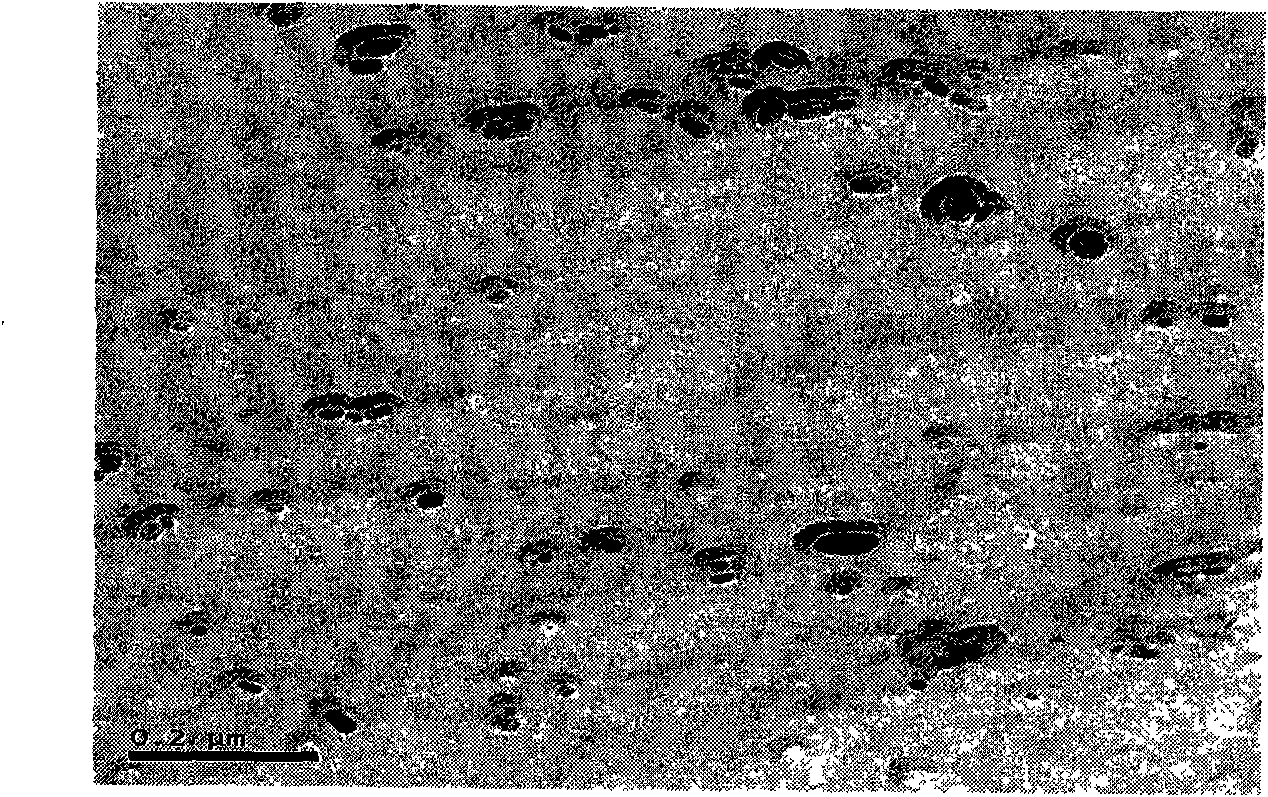

Image

Examples

specific Embodiment approach

[0047] According to the application of the new product, the present invention optimizes the composition of the steel, and divides several elements into two groups of technical solutions, as shown in the table below, when the requirements for the strength level are low and the requirements for the stamping and welding ability of the water heater manufacturer are not high. Use group A, and use group B when the application requires high strength and the water heater manufacturer has good stamping and welding capabilities.

[0048] Chemical composition (the balance is iron and unavoidable impurities, wt, %)

[0049]

C

Si

mn

P

S

N

Al S

Ti

Nb

A

0.01~

0.04

≤

0.03

0.10~

0.60

≤

0.02

0.003

~

0.02

0.001

-

0.006

≤

0.04

0.02

~

0.06

≤

0.04

B

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com