Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Avoid sand inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

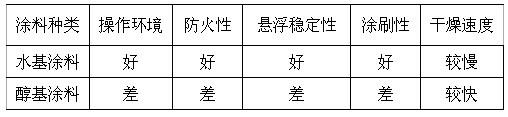

Sintering-strippable red cast iron coating and preparation method thereof

InactiveCN102601300APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresCrack resistancePreservative

The invention relates to a sintering-strippable low-cost red water-based cast iron coating, which is prepared by the following raw materials in percent by mass: 20-45 percent of bauxite powder or powder quartz, 0-25 percent of mullite powder, 1-6 percent of talcum powder, 1-5 percent of iron trioxide powder, 1-3 percent of suspending agent, 1.5-4.5 percent of organic binding agent, 1.5-6 percent of inorganic binding agent, 0.01-0.05 percent of wetting agent, 0.02-0.05 percent of preservative, 0.02-0.1 percent of defoaming agent, 0-0.5 percent of water reducing agent and 30-42 percent of tap water. The sintering-strippable low-cost red water-based cast iron coating has the characteristics that the raw materials are cheap and the source is wide; the product is low-cost, safe, environmental-friendly and convenient to transport; the brushing property, the flowing resistance and the leveling property of the product are good, the suspension percentage, the coating strength and the crack resistance are high and the gas evolution is low; and the sintering-stripping performance is excellent, the most part of the coating can be vastly stripped after castings are taken out of a casting box and are cooled, the defects of sand sticking, sand inclusion, sand drop, voids and the like existing the castings can be effectively avoided, and the castings with excellent surface quality can be obtained.

Owner:湖北省机电研究设计院股份公司

Method for preparing water-based coating for sand mold casting

InactiveCN102407279AExcellent overall performancePrevent sticky sandFoundry mouldsFoundry coresSodium carboxymethylcelluloseCarboxymethyl cellulose

The invention discloses a method for preparing a water-based coating for sand mold casting, wherein the coating is prepared from zircon powder, fused mullite powder, quartz powder, lithium based bentonite, flake graphite, silicon sol, sodium carboxymethyl cellulose, sodium alkyl benzene sulfonate, sodium sulfate, sodium carbonate, n-caprylic alcohol, fatty alcohol-polyoxyethylene ether and water;and the preparation method comprises the following steps: 1) firstly, uniformly mixing the zircon powder, the fused mullite powder and the quartz powder aggregates with a proper amount of water in anattrition mill so as to obtain a base material; 2) sequentially adding the silicon sol, the sodium carboxymethyl cellulose, the sodium alkyl benzene sulfonate, the sodium sulfate, the sodium carbonate, the n-caprylic alcohol and the fatty alcohol-polyoxyethylene ether into the wet base material which is mixed, then adding a proper amount of water into the obtained mixture; and 3) adding the rest of water into the attrition mill, uniformly stirring and grinding.

Owner:福建港星建筑材料集团有限公司

Expendable casting process method for heat-resistant steel perforated grate plate

An expendable casting process method for a heat-resistant steel perforated grate plate comprise employing a copolymerization material for foaming for preparing an expendable-casting-process heat-resistant steel perforated grate plate foam model, singly preparing a pouring gate, binding the heat-resistant steel perforated grate plate model with the pouring gate for combination, so as to form a combined model; putting the combined model in a special coating pool for three-time sagging of a coating and three-time baking, and controlling the accumulated thickness of the coating subjected to three-time baking to be 0.8 mm-1.5 mm; again combining the baked combined model in a negative-pressure sandbox by taking 10 models as a pouring body, and forming two pouring bodies; adding sand into the sandbox and compacting through shaking; vacuumizing the sandbox and performing oxygen-enriched combustion on the model to form a hollow shell; and finally performing casting. The casting method is simple in steps, convenient to operate, high in casting efficiency and good in effect, is capable of effectively improving the surface quality of the casting and preventing disadvantages that the casting generates burnt-on sand, sand inclusions, pores and carburets, and helps to reduce labor intensity and save production cost.

Owner:渠县金城合金铸业有限公司

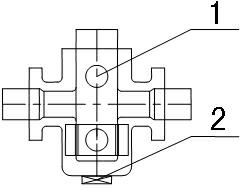

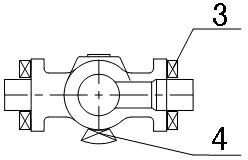

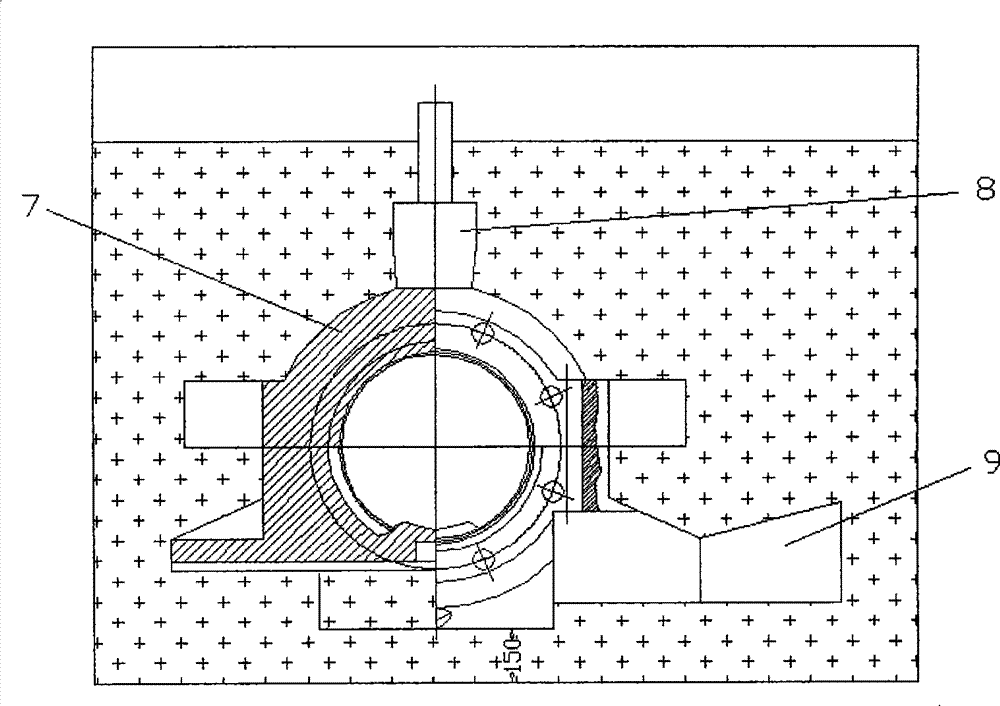

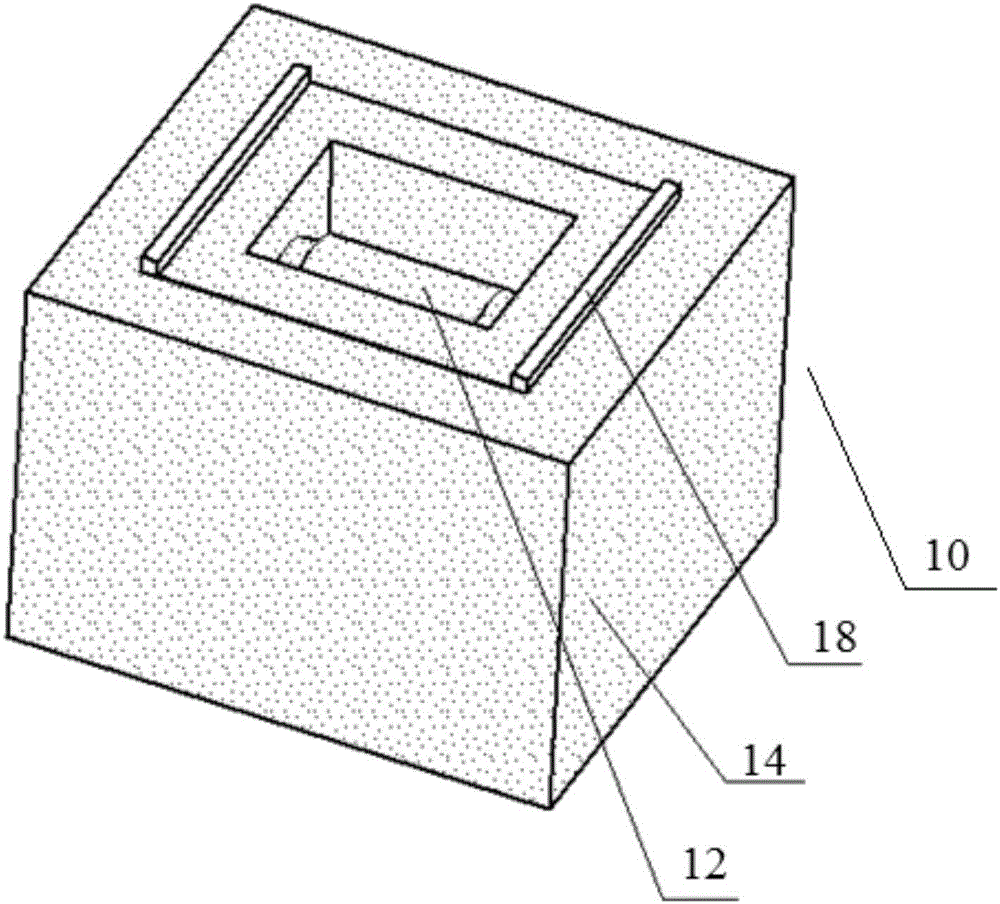

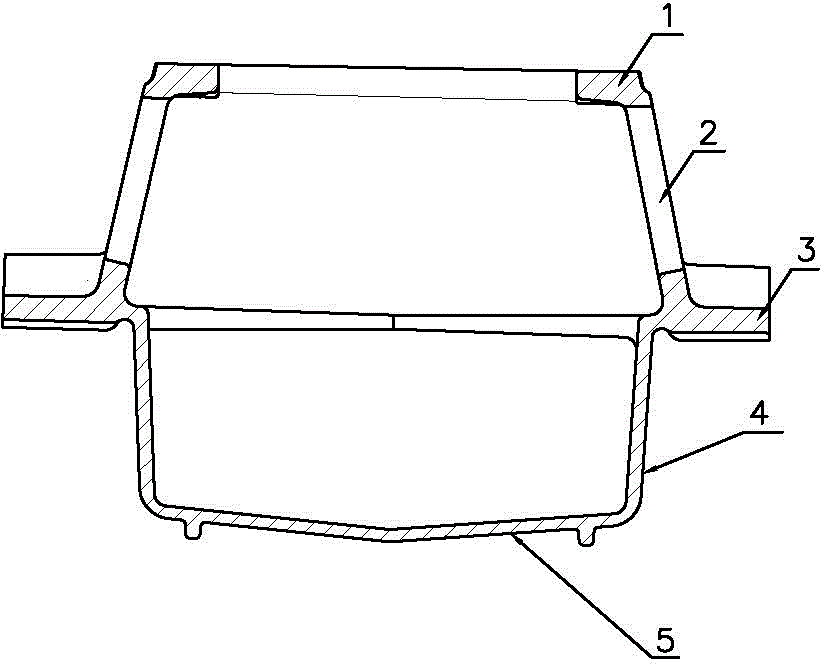

Method for casting valve body of heavy-calibre non-rising-stem flat valve

The invention discloses a method for casting a valve body of a heavy-calibre non-rising-stem flat valve. In the method, ester-cured water-glass sand is used for modeling to make a sand core, two RND 300 neck-down heating heat-insulation dead heads (1) are arranged at the valve belly part of the valve body of the sand core, six shaped chills (4) which are 90mm thick are arranged at the bottom of the valve belly part at a distance of 30mm, eight shaped chills (3) which are 70mm thick are arranged at an edge flange of the valve body, and a Phi 200*50mm shaped chill (2) is installed at the tail part of the valve body; the neck-down heating heat-insulation dead heads (1) perform feeding on the valve belly part of the valve body, the shaped chills (4) perform feeding on the bottom of the valve belly part, and the neck-down heating heat-insulation dead heads (1) at the valve belly part perform feeding on the shaped chills (3) of the edge flange of the valve body, and the shaped chill (2) performs feeding on the tail part of the valve body. In the invention, the neck-down heating heat-insulation dead heads are used for feeding, convenience is brought for gas cutting, the casting yield is increased, casting defects, such as sand inclusion, shrinkage porosity, cracks, sand blowholes, slag blowholes and the like, are avoided, and technical demands of customers are met.

Owner:JIANGSU JINSHI CASTING & FORGING

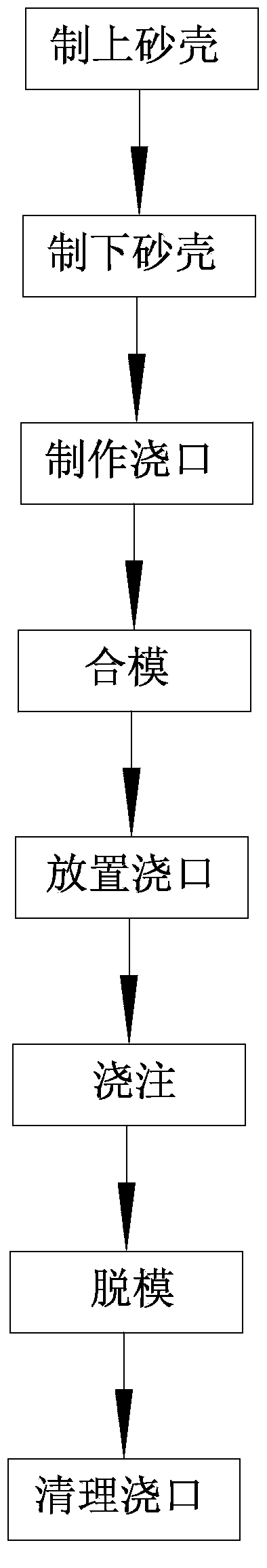

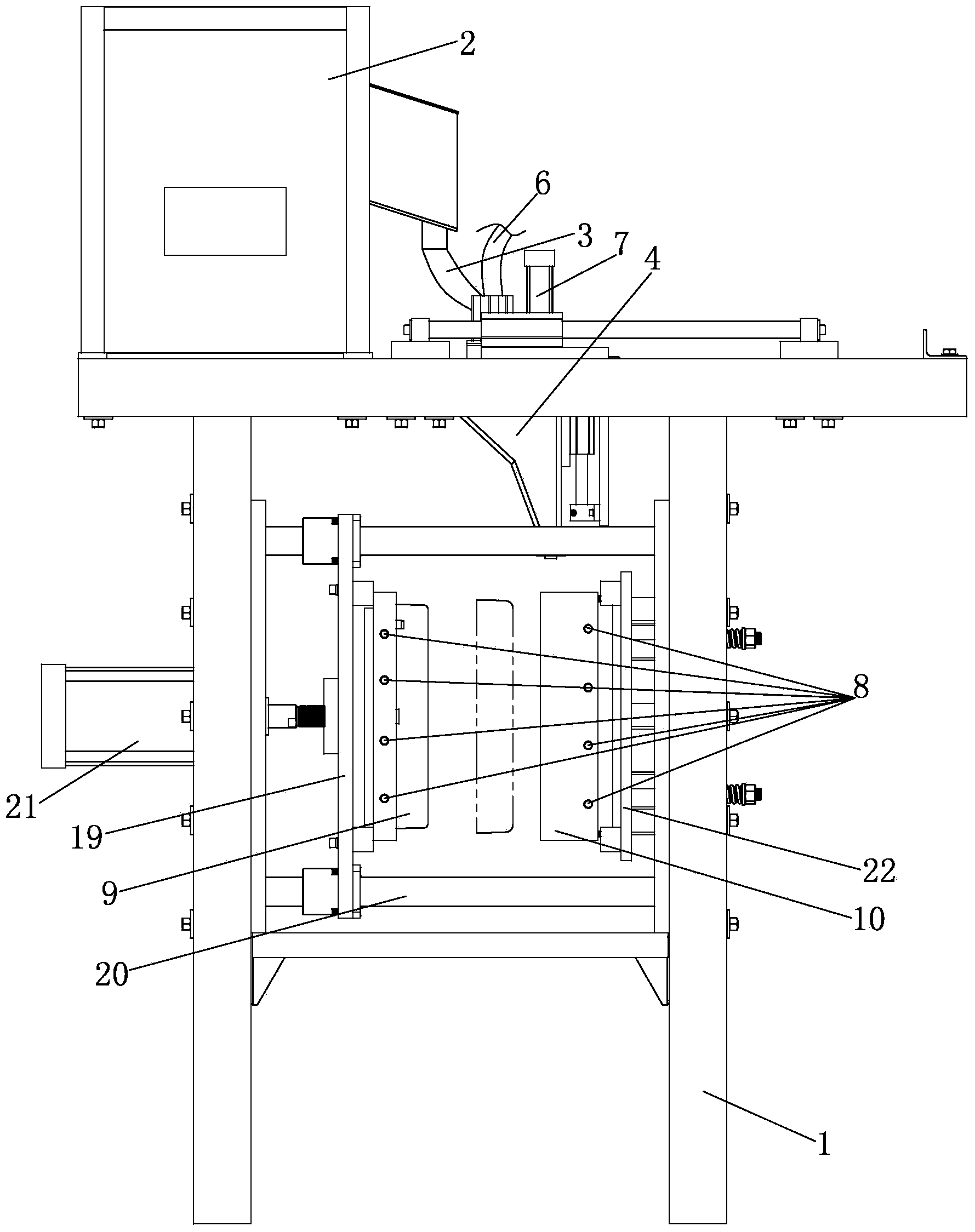

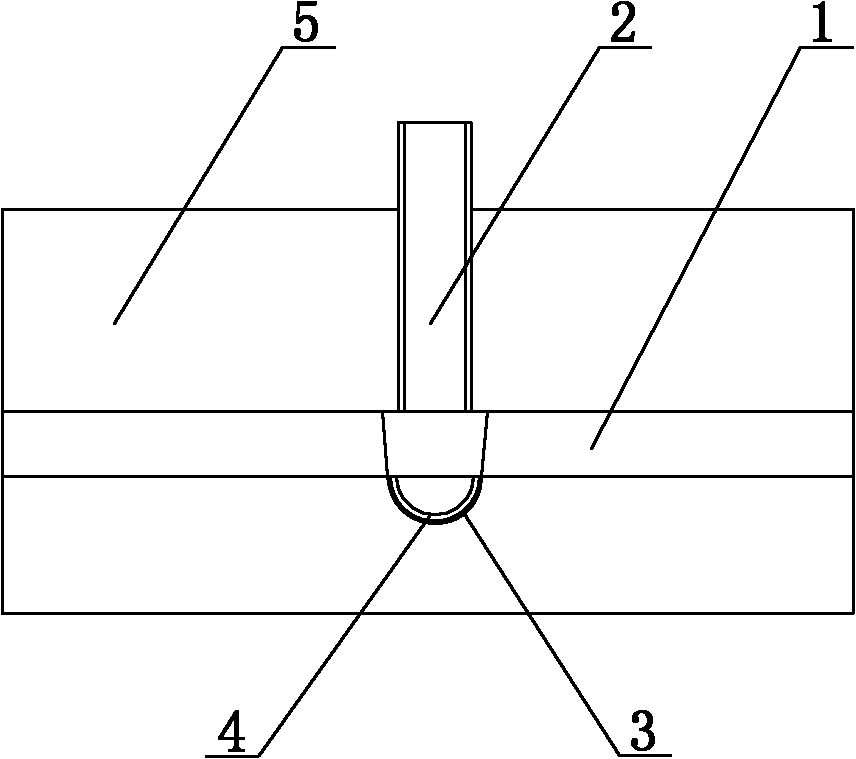

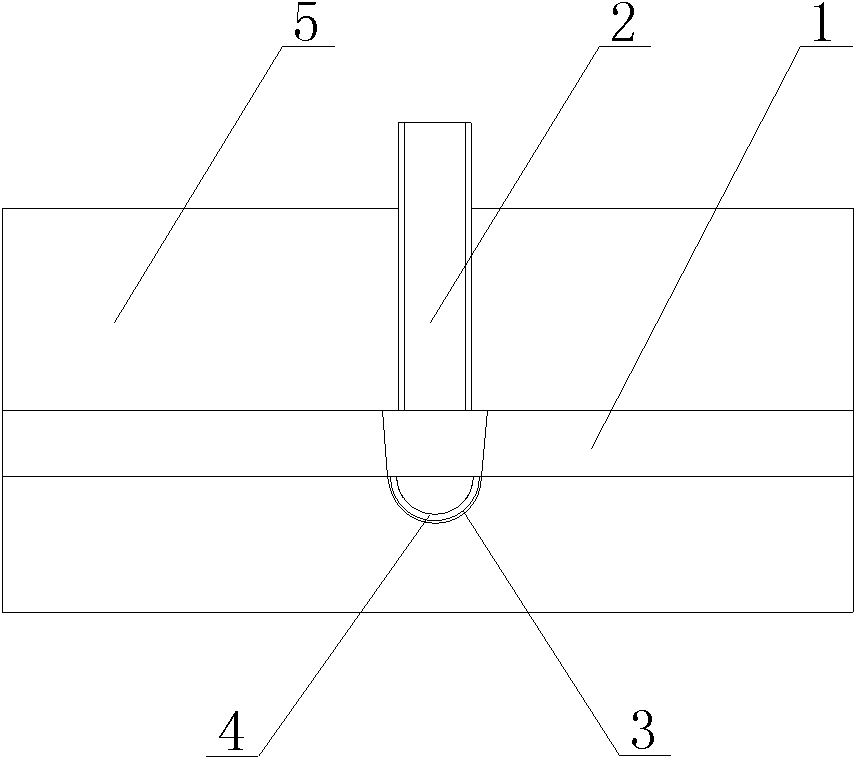

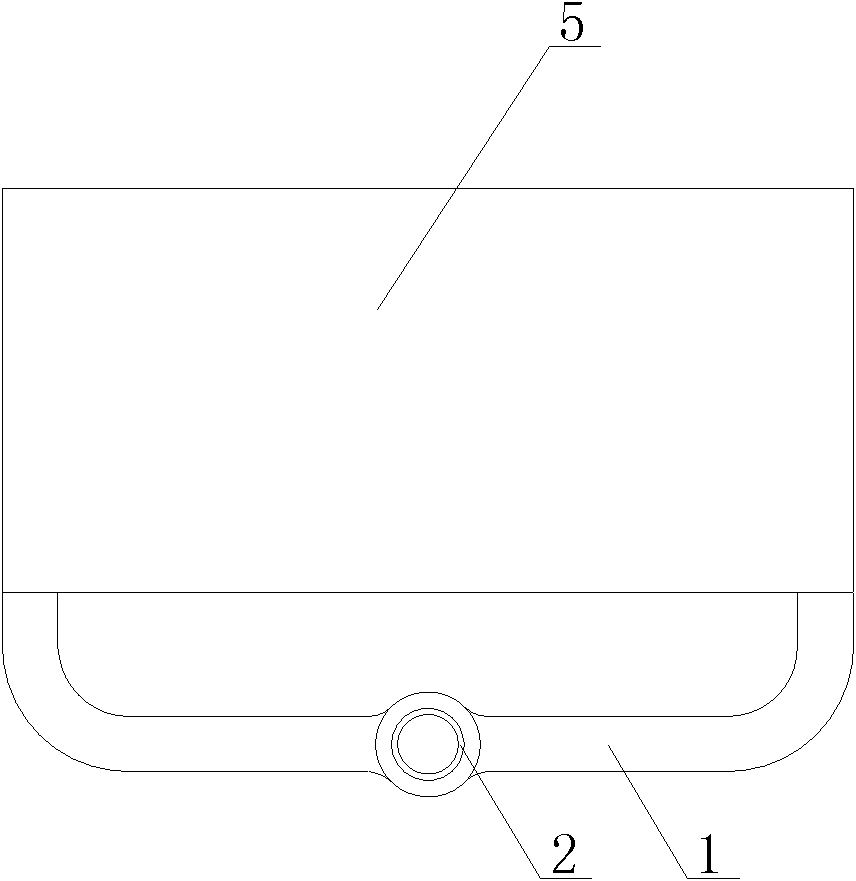

Casting method for flywheel

InactiveCN103639370APrevents the defect of blocking the sand injection nozzleImprove effective utilizationFoundry mouldsFoundry coresSlagRoughcast

The invention discloses a casting method for a flywheel. The casting method comprises the following steps: a, preparing an upper sand shell: manufacturing on a core shooting machine to prepare the upper sand shell; b, preparing a lower sand shell: manufacturing on another core shooting machine to prepare the lower sand shell; c, manufacturing a sprue; d, closing a die: putting the lower sand shell into a lower iron shell; covering the top of the lower sand shell with the upper sand shell; after closing the upper sand shell and the lower sand shell, forming a cavity for casting the flywheel; then covering a sprue section of the upper part of the upper sand shell with an upper iron shell; finally, tightly pressing the upper iron shell and the lower iron shell with a U-shaped clip; e, arranging the sprue; f, pouring; g, de-molding: taking out a flywheel casting blank; h, cleaning the sprue. According to the casting method for the flywheel, casting defects of sand clamping, slag clamping, air pores, loosening and the like in a traditional casting process can be effectively prevented; the casting method for the flywheel is efficient and low in cost; the effective utilization rate of molten iron is high; in a technological process, the core shooting machine is improved on the basis of outsourcing; the improved core shooting machine can be used for preventing the defect that a sand spraying nozzle is blocked by humid hardening of a sand covering film.

Owner:杨国强

Iron casting green sand and preparation method thereof

InactiveCN103567361APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresGlucose-Fructose SyrupMonopotassium phosphate

The invention discloses an iron casting green sand and a preparation method thereof. The iron casting green sand is prepared from the following raw materials in parts by weight: 80-90 parts of old sand, 10-20 parts of fresh sand, 3-5 parts of attapulgite, 2-4 parts of composite powder, 1.5-2.5 parts of graphite powder, 4-6 parts of sepiolite, 2-3 parts of alums, 3-4 parts of monopotassium phosphate, 2-3 parts of sodium tetraborate, 1.5-2.5 parts of magnesium oxide, 1-2 parts of glucose syrup, 1-1.5 parts of heavy oil and 3-7 parts of water. The iron casting green sand is reasonable in formula, low in cost and simple in preparation method, and sand burning and inclusion of iron casting can be effectively prevented. Besides, the surface of the iron casting prepared by using the green sand is smooth and clean, and the yield of the iron casting is greatly improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

High-quality molding sand

InactiveCN105903886ALow gas productionLow hygroscopicityFoundry mouldsFoundry coresHexamethylenetetramineTributyl citrate

The invention discloses high-quality molding sand. The high-quality molding sand is prepared by the following components: clay, modified sodium bentonite, aluminum sulfate, titanium dioxide, coconut shell activated carbon, sodium silicate, tributyl citrate, polyvinyl acetate, lignocellulose, nanometer attapulgite, brown fused alumina powder, modified thermoplastic phenolic resin, diatomaceous earth, starch, carboxymethylcellulose, sodium tripolyphosphate, urotropin and quartz sand. Through a mutual synergistic effect of the components with a specific ratio, the air permeability of the molding sand can be improved, the strength of the molding sand can be improved, the cost is low, the working procedure time is short, a molding sand sintered layer is thin and a sand adhesion phenomenon seldom occurs, the defects of shrinkage porosity and sand holes of castings are greatly reduced, the problems of sand clamping, recesses, scabs and box collapse caused by an expansion defect of the molding sand can be avoided, the pass percent and the yield of the castings are improved, the defective rate is reduced by 59%, a manufacturing process is simple and practicable, and the production pollution can be reduced.

Owner:HEFEI CITY TENVER PRECISION CASTING

Sand casting water-based coating

InactiveCN102397982AImprove performanceImprove the finishFoundry mouldsFoundry coresWater basedMullite

The invention discloses a sand casting water-based coating. The coating consists of the following components in part by weight: 20 to 30 parts of zircon powder, 15 to 20 parts of electro-fused mullite powder, 15 to 20 parts of quartz powder, 2 to 3 parts of lithium-based bentonite, 5 to 10 parts of flake graphite, 2 to 3 parts of silica sol, 0.5 to 0.8 part of sodium carboxymethylcellulose, 0.3 to 0.5 part of sodium alkyl benzene sulfonate, 0.4 to 0.6 part of sodium sulfate, 0.2 to 0.3 part of sodium carbonate, 0.2 to 0.3 part of n-octanol, 0.2 to 0.3 part of fatty alcohol-polyoxyethylene ether and 30 to 40 parts of water, wherein the granularity of the zircon powder, the electro-fused mullite powder and the quartz powder can be 200 to 320 meshes.

Owner:TANGSHAN DONGFANG HUASHENG GOOD WEAR RESISTING HIGH TECH

Novel energy-saving pouring gate pipe

InactiveCN101644358AHigh strengthEasy to makeFoundry mouldsFoundry coresWear resistanceUltimate tensile strength

The invention discloses a novel energy-saving pouring gate pipe cast by mixing clay, argil and bauxite. The pouring gate pipe has the advantages of light weight, favorable wear resistance, corrosion resistance, high integrated intensity and favorable integrated performance and can meet the requirements of industrial use. The pouring gate pipe greatly saves resources and energy, effectively avoidscasting defects such as adhering sand, sand inclusions, sand cuts, sand holes and the like, and enhances the cost and the quality of the casting.

Owner:于海峰

Knar clay moulding sand prevented from adhering to casting and preparation method of knar clay moulding sand

InactiveCN105478655AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresPhosphatePhosphoric acid

The invention discloses knar clay moulding sand prevented from adhering to a casting and a preparation method of the knar clay moulding sand. The knar clay moulding sand is prepared from, by weight, 24-38 parts of silica sand, 16-29 parts of high titanium slag, 14-22 parts of andalusite, 20-30 parts of basalt, 18-32 parts of kyanite, 10-15 parts of ceramic polishing slag, 9-16 parts of asbestos tailings, 45-55 parts of knar clay, 22-34 parts of salt gypsum, 12-18 parts of waste mortar, 10-15 parts of bone meal, 5-10 parts of aluminum dihydrogen phosphate and 300-400 parts of a modifying agent. The moulding sand prepared from the raw materials such as the knar clay, the silica sand, the ceramic polishing slag, the slat gypsum and the waste mortar according to a certain ratio has remarkable brittleness at the room temperature, and the sand is prevented from adhering to the surface of the casting, so that the casting with the high surface quality is obtained. Meanwhile, the moulding sand has high strength and thermal stability, can bear the action of various kinds of external force and high temperature and is suitable for production like steel casting, iron casting and casting of nonferrous alloy castings.

Owner:安徽创奇乐智能游乐设备有限公司

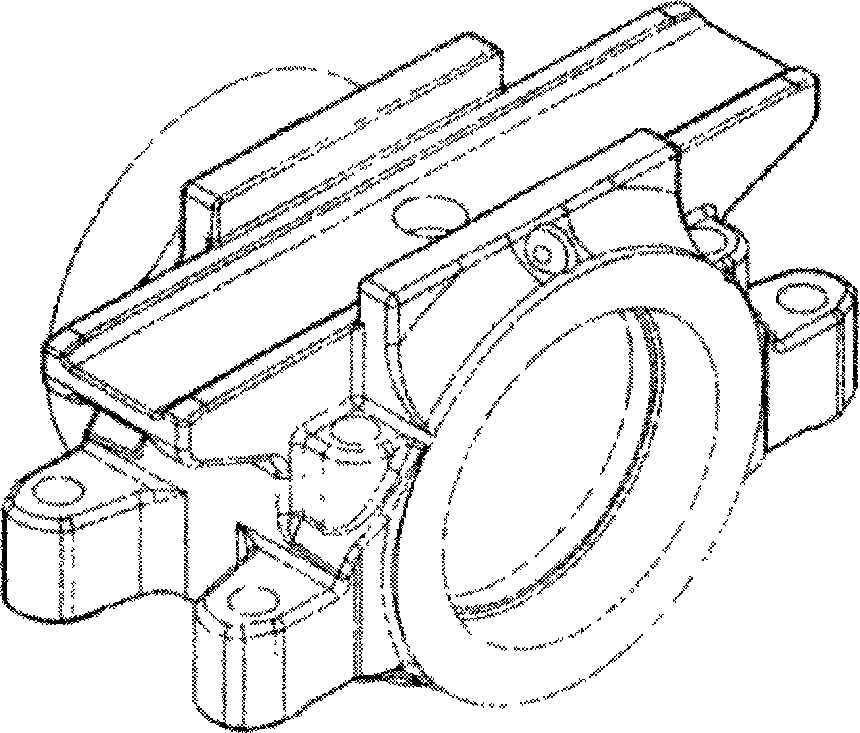

Method for casting bearing seat

InactiveCN103056306AGuaranteed integrityQuality improvementFoundry mouldsFoundry coresProduction rateStructure property

The invention discloses a method for casting a bearing seat. The method comprises the following steps of: (1) manufacturing a mold for the bearing seat, and forming a sprue, a riser and an exhaust port in the mold; (2) manufacturing a sand mold by adopting resin sand, and coating a zircon sand fast-dry coating on the surface of the sand mold; (3) closing a box, drying the sand mold, putting a sprue cup on the sprue of the mold, and putting a riser cup on the riser; (4) putting raw materials into an electric furnace and performing smelting to obtain a casting melt, wherein the raw materials comprise 60 percent of waste steel, 30 percent of sprue and riser returns and 10 percent of new iron, and the smelting temperature is 1,600 DEG C; (5) forming a casting, wherein the casting temperature is 1,550 DEG C, and the casting time is 4 minutes; and (6) performing heat preservation and cooling on the casting, cleaning after cooling, and thus obtaining a bearing seat casting, wherein the temperature of cooling water is less than or equal to 80 DEG C. By adopting the method for casting the bearing seat, the productivity for manufacturing the bearing seat casting is high, the running cost is low, and the produced casting is good in structure property and excellent in overall performance.

Owner:QINGDAO SANHESHAN CASTING GROUP

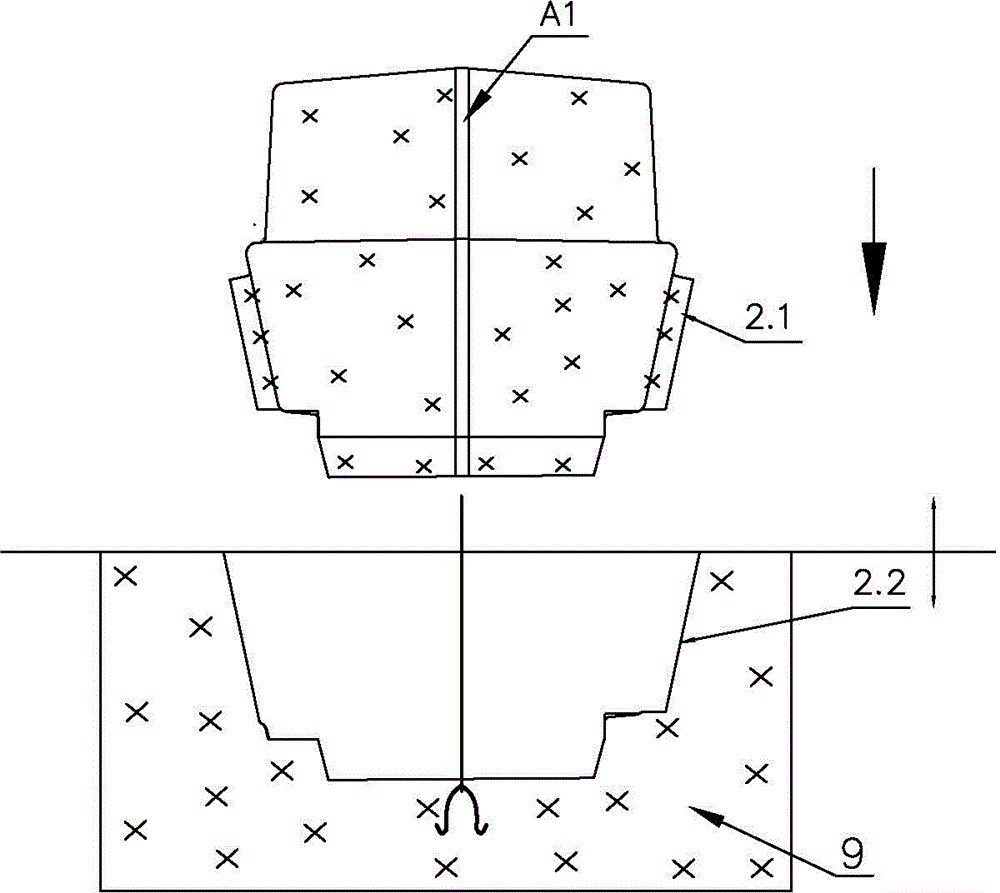

Evanescent mode vacant-shell casting technique of double-saddle balance shaft shell

InactiveCN104275438AIncreased sturdinessImprove stabilityFoundry mouldsFoundry coresMetallurgyEvanescent mode

The invention relates to an evanescent mode vacant-shell casting technique of a double-saddle balance shaft shell. The evanescent mode vacant-shell casting technique comprises the following steps: (1) producing a double-saddle balance shaft shell and a riser foam mold by foaming copolymerization (STMMA), independently producing a pouring gate, bonding a double-saddle balance shaft shell module and the pouring riser to form a combined model; (2) roasting the combined model in a roasting room at the temperature of 50 to 60 DEG C for 24h; (3) placing the roasted combined model into a high-temperature-resisting and high-strength paint pool to be painted, then roasting the combined model in the roasting room, painting and roasting the combined model for four times, and controlling the thickness at 1.2mm to 1.8mm; (4) combining the roasted combined models again on an iron rack in a way that four combined models form on pouring body, and roasting the combined model; (5) boxing, filling sand and compacting; (6) vacuumizing a sand box, and burning the model in rich oxygen to form a vacant shell; and (7) casting.

Owner:渠县金城合金铸业有限公司

Easily-collapsing green sand

InactiveCN105903890AImprove performanceAvoid sand inclusionsFoundry mouldsFoundry coresTributyl citrateMaterials science

The invention discloses easily-collapsing green sand. The collapsible wet mold sand is prepared by the following components: clay, modified sodium bentonite, aluminum sulfate, titanium dioxide, coconut shell activated carbon, sodium silicate, tributyl citrate, polyvinyl acetate, lignocellulose, nanometer attapulgite, brown fused alumina powder and quartz sand. Through a mutual synergistic effect of the components with a specific ratio, the air permeability of the green sand can be improved, the strength of the green sand can be improved, the cost is low, in the working procedure time is short, a molding sand sintered layer is thin, a sand adhesion phenomenon seldom occurs, the casting surface quality is high, the surfaces are easy to clean, collapsibility of old sand is good and the reuse rate is high, the defects of shrinkage porosity and sand holes of castings are greatly reduced, the problems of sand clamping, recesses, scabs and box collapse caused by an expansion defect of green sand can be avoided, the pass percent and the yield of the castings are improved, the production cost is reduced, and the easily-collapsing green sand has extremely high economic benefits, and can be widely applied.

Owner:HEFEI CITY TENVER PRECISION CASTING

High-thermal-conductivity composite modified sodium silicate sand for pump valve castings, and preparation method thereof

InactiveCN105414459AExcellent normal temperature wet strengthGood thixotropy and rheologyFoundry mouldsFoundry coresLubricationSodium silicate

The invention discloses high-thermal-conductivity composite modified sodium silicate sand for pump valve castings. A modified sodium silicate binder in the sodium silicate sand is higher in constant-temperature wet strength, thixotropy and rheological property compared with a conventional modified sodium silicate binder, high in reaction binding activity, and green and environment-friendly, and the dosage of sodium silicate is lower; in addition, beryllium oxide in raw materials is capable of effectively improving the thermal conductivity of moulding sand, and preventing sand inclusion of the castings, and bentonite-supported nano-calcium fluoride has lubrication and reinforcement effects in case of being dispersed in sand materials, and capable of forming a non-stick impermeable layer, preventing sand sticking of the castings, and improving the surface quality of the castings; and the composite modified sodium silicate sand is excellent in comprehensive performance, uniform in strength, high in casting quality, and capable of meeting the pouring requirements of the high-accuracy pump valve castings.

Owner:合肥李诺新材料贸易有限公司

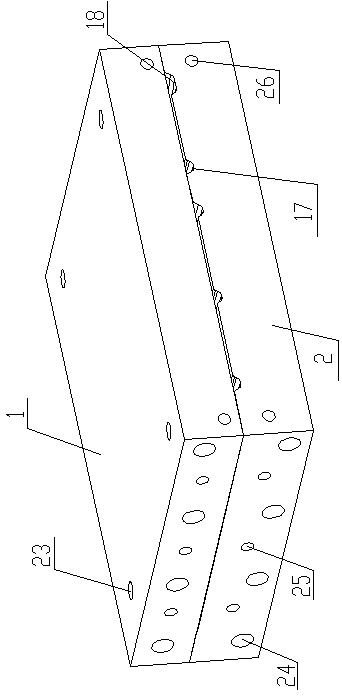

Process method for preventing sand inclusion in through bolt hole of marine diesel engine

ActiveCN108907614AAvoid sand inclusionsAvoid the risk of chemical tilesPulp and paper industryPre treatment

The invention discloses a method for preventing sand inclusion in a through bolt hole of a marine diesel engine. The process method includes the following steps: the first step of conducting sandblasting processing on the surfaces of a triangular plate, a wing plate and a guide rail plate; the second step of welding the guide rail plate and the wing plate and then welding two ends of the triangular plate respectively to the guide rail plate and the wing plate; the third step of installing a protective baffle at the angle between the triangular plate and the wing plate; the fourth step of performing overall sandblasting processing on the through bolt hole where the protective baffle is installed; the fifth step of removing the protective baffle and a baffle jacking plate after the overall blasting is completed and cleaning the area protected by the protective baffle to remove surface rust and loose deposits; the sixth step of conducting overall painting on the through bolt hole. The protective baffle is arranged in the angle area of the triangular plate and the wing plate during overall sandblasting, sand inclusion in the angle area is avoided during sandblasting clearing, and the risk of the whole machine tiling is avoided.

Owner:中船发动机有限公司

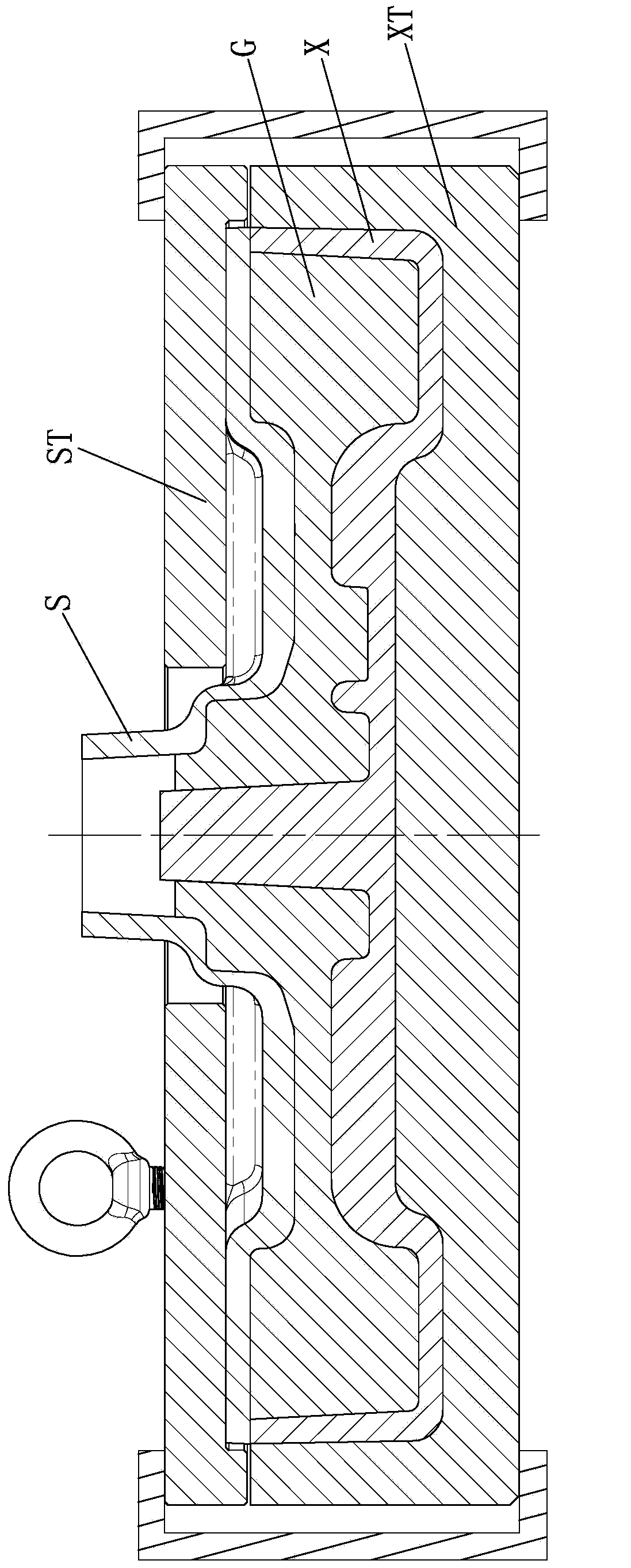

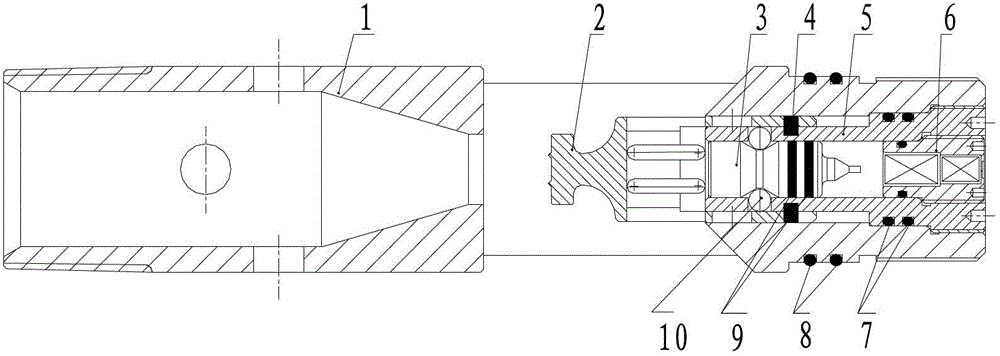

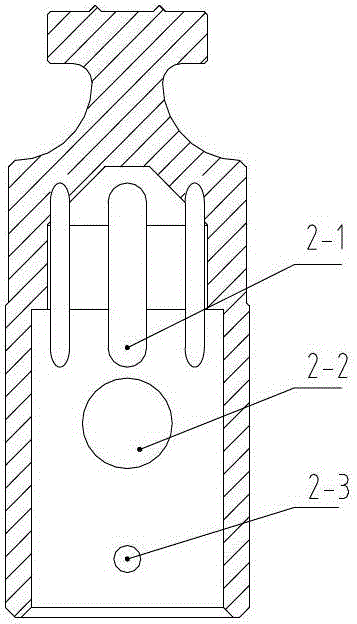

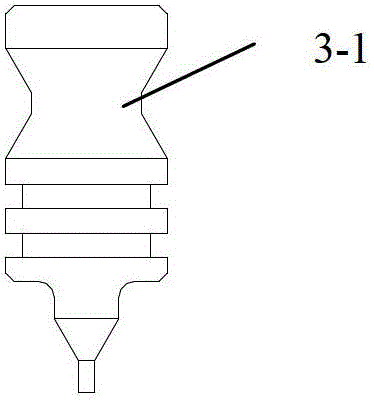

Impact unlocking safe initiation device for initiation perforating gun in well completion operation of oil and gas well

The invention relates to an impact unlocking safe initiation device for an initiation perforating gun in the well completion operation of an oil and gas well. The impact unlocking safe initiation device is characterized in that the impact unlocking safe initiation device comprises a body, an impact sleeve, a firing pin, a safety pin, a support seat, an initiator and steel balls. The impact unlocking safe initiation device adopts the connection relations as follows: the support seat is embedded in a hollow cylindrical post of the impact sleeve, is positioned under a slotted hole, and is fixed by the safety pin through a small round through hole formed in the impact sleeve and a blind hole formed in the support seat; the firing pin is installed at the upper end of the support seat, the wasp waist part of the firing pin is flush with the two through holes of the support seat, the two steel balls are embedded in the through holes to lock the firing pin, and the lower end of the support adopts screw threads to fix the initiator; seal rings are arranged between the support seat and two sealing grooves formed in the middle of the firing pin; in addition, the support seat equipped with the impact sleeve, the firing pin, the steel balls and the safety pin is mounted from a male thread end of the body, and is fixedly connected with the body. The impact unlocking safe initiation device achieves safety and detonation, improves the security of ground operators for perforating operation, and is suitable for mass production.

Owner:WUHUA ENERGY TECH CO LTD

Pollution-free environment-friendly casting molding sand and preparation method thereof

InactiveCN110052570AImprove breathabilityEnhanced wet tensile strengthFoundry mouldsFoundry coresFoundryMaterials science

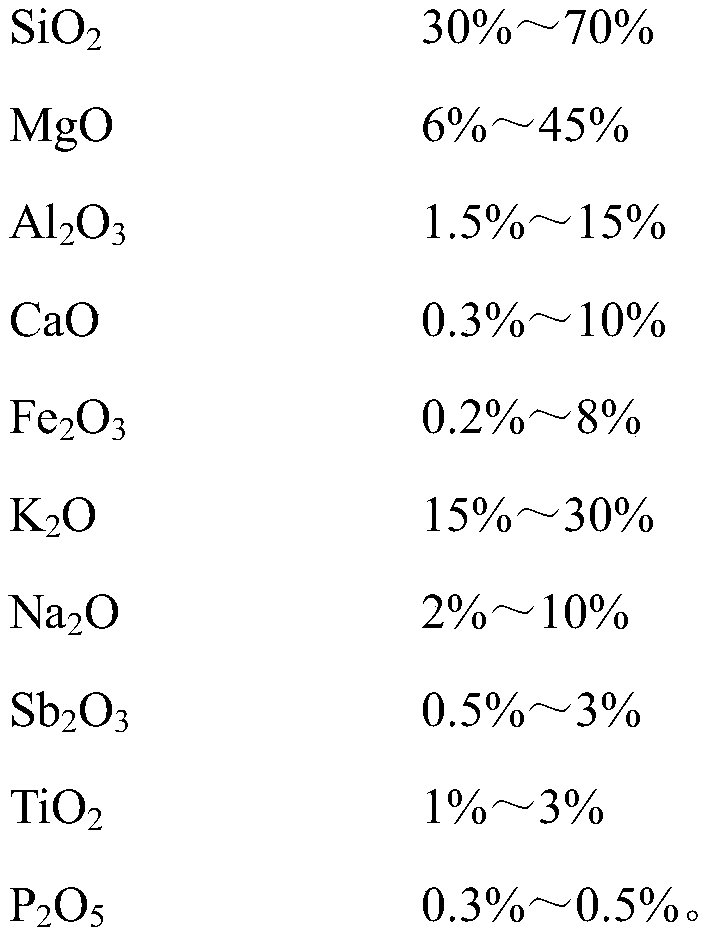

The invention discloses pollution-free environment-friendly casting molding sand and a preparation method thereof. The pollution-free environment-friendly casting molding sand comprises, by weight, 30%-70% of SiO2, 6%-45% of MgO, 1.5%-15% of Al2O3, 0.3%-10% of CaO, 0.2%-8% of Fe2O3, 15%-30% of K2O, 2%-10% of Na2O, 0.5%-3% of Sb2O30, 1%-3% of TiO2 and 0.3%-0.5% of P2O5. The environment-friendly foundry molding sand developed and produced from the demands which meet the national industrial policies such as environment protection, cost advantages and improvement of the production efficiency and the finished product rat.

Owner:蔡旭斌 +1

Casting process of diesel engine bearing seat

InactiveCN102756080AGuaranteed integrityQuality improvementFoundry mouldsFoundry coresDiesel engineWater temperature

The invention discloses a casting process of a diesel engine bearing seat. The casting process comprises the following steps: making a mold of the diesel engine bearing seat; preparing a manufacturing tool; forming a pouring gate, a dead head and an exhaust port in the mold; putting resin sand into the mold so as to model the resin sand; patching the modeled resin sand mold; brushing a coating at the surface of the resin sand mold; arranging and closing the resin sand mold; lifting the resin sand mold; putting a pouring cup at the pouring gate of the mold; putting a dead head cup at the dead head; pouring molten iron into a cavity of the resin sand mold by a crane ladle for pouring; and introducing water into the cavity to cool the resin sand mold after the pouring, wherein the water temperature is controlled not to exceed 80 DEG C through controlling the flow of cooling water. The casting process of the diesel engine bearing seat, disclosed by the invention, has the advantages of capability of improving cast quality, short production period and low production cost.

Owner:陆宝庆

Molding sand for high-density models and preparation method of molding sand

InactiveCN105983644AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresActivated sludgePolyethylene glycol

The invention discloses molding sand for high-density models and a preparation method of the molding sand. The molding sand is prepared from raw materials in parts by weight as follows: 27-39 parts of cement slurry, 64-76 parts of yellow loam, 22-34 parts of xonotlite, 15-25 parts of epistilbite, 41-53 parts of quartz sand, 16-24 parts of olivine, 8-16 parts of activated sludge dry powder, 5-10 parts of coke powder, 10-15 parts of yellow phosphorus ore, 14-22 parts of colloidal graphite powder, 5-10 parts of molybdenum disilicide, 7-11 parts of calcium lignosulphonate, 8-12 parts of polyethylene glycol and 450-550 parts of a modifier. The molding sand has the relatively high wet compressing strength and thermal tensile strength and further had the excellent gas permeability, liquidity and thermal resistance, the preparation technology of the molding sand is simple, the manufacturing cost is low, and the molding sand is suitable for large-scale popularization and application to the high-density models.

Owner:安徽创奇乐智能游乐设备有限公司

High-green-compression-strength green moulding sand for iron casting and preparation method of high-green-compression-strength green moulding sand

The invention discloses high-green-compression-strength green moulding sand for an iron casting and a preparation method of the high-green-compression-strength green moulding sand. The high-green-compression-strength green moulding sand is prepared from, by weight, 38-52 parts of imvite, 42-64 parts of natural manganese sand, 24-36 parts of silico-calcium slag, 19-31 parts of titanaugite, 16-24 parts of granite waste, 10-15 parts of asbestos wool, 15-25 parts of cancrinite, 11-19 parts of fibrolite, 8-12 parts of barium metaphosphate, 6-9 parts of polyester propylene glycol, 5-7 parts of polyamide polyamine epichlorohydrin resin and 510-570 parts of a modifying agent. By means of the raw materials such as the natural manganese sand, the silico-calcium slag, the asbestos wool, the barium metaphosphate, the polyester propylene glycol and the polyamide polyamine epichlorohydrin resin, on the basis of guaranteeing that the moulding sand has good breathability, the green compression strength of the moulding sand is remarkably improved, and box crushing, swelling and leaking can be effectively avoided. The prepared moulding sand has the advantages of being high in green compression strength, good in breathability and plasticity and the like, and is suitable for the iron casting and wide in application prospect.

Owner:安徽创奇乐智能游乐设备有限公司

High-strength and high-temperature-resistance molding sand and preparation method thereof

InactiveCN105478654AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresBrickCalcium formate

The invention discloses high-strength and high-temperature-resistance molding sand and a preparation method thereof. The high-strength and high-temperature-resistance molding sand is prepared by the following raw materials in parts by weight: 14-22 of allophane, 24-38 of attapulgite, 12-18 of obsidian, 10-15 of baddeleyite, 8-14 of waste brick chips, 5-10 of refining slag, 16-24 of emery, 9-16 of glauconite, 7-11 of calcium formate, 5-10 of nanometer magnesium titanate, 4-7 of polyethylenimine, and 270-330 of modifying agents. The molding sand, prepared with allophane, obsidian, baddeleyite, waste brick chips, refining slag, emery and the like as main raw materials, is better in thermal stability and higher in refractoriness, and is added with calcium formate, nanometer magnesium titanate, polyethylenimine and the like to improve the green compression strength and the wet tensile strength. The prepared molding sand is excellent in breathability, fluidity, strength, collapsibility and high-temperature resistance; and a casting produced by the molding sand is smooth in surface and low in rejection rate.

Owner:安徽创奇乐智能游乐设备有限公司

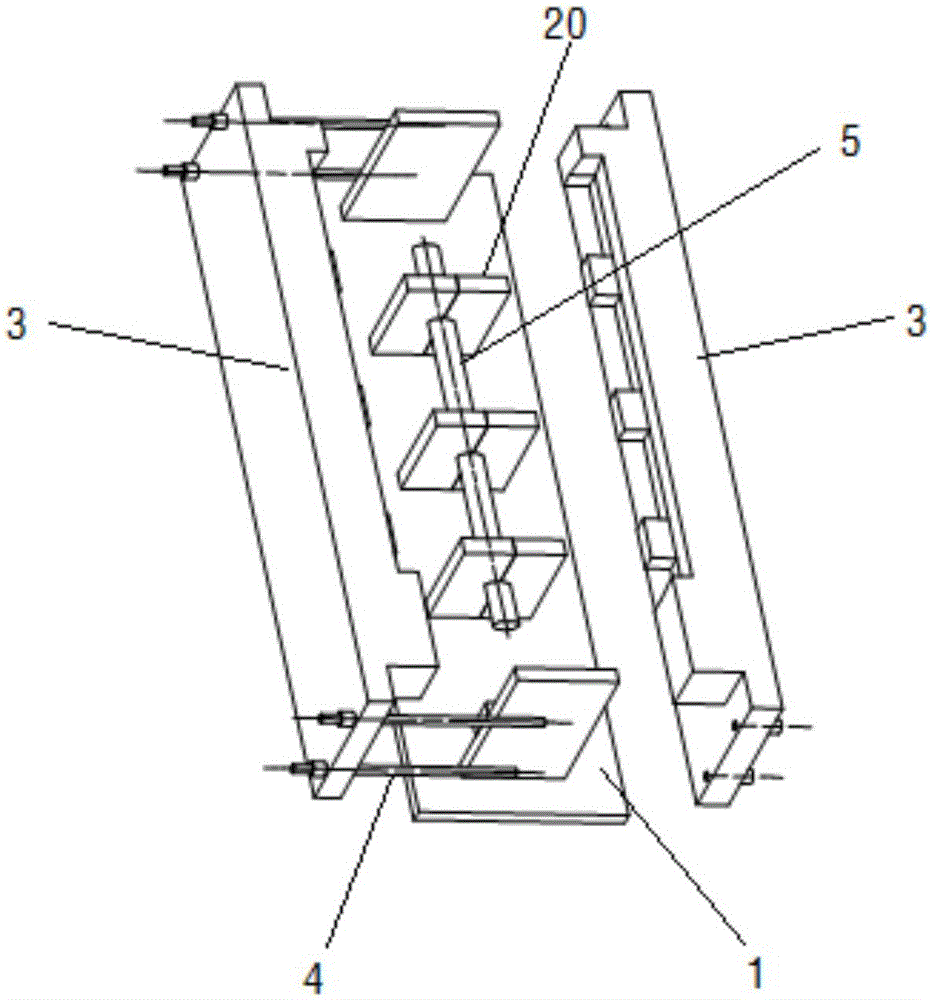

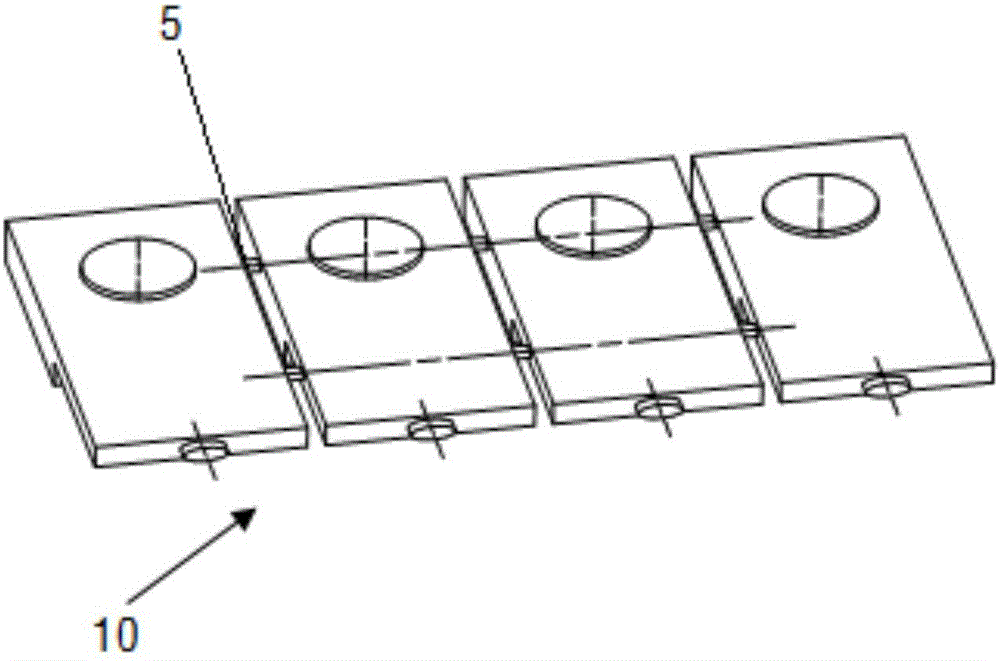

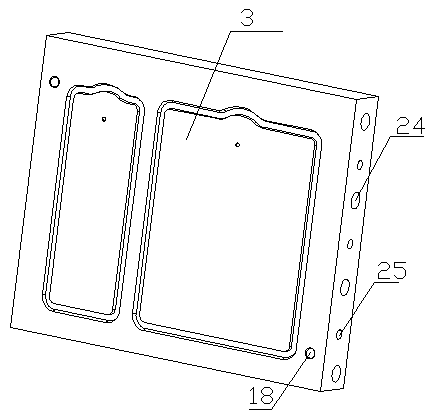

Core box for producing conjoined sand core and method thereof

Owner:KOCEL EQUIP

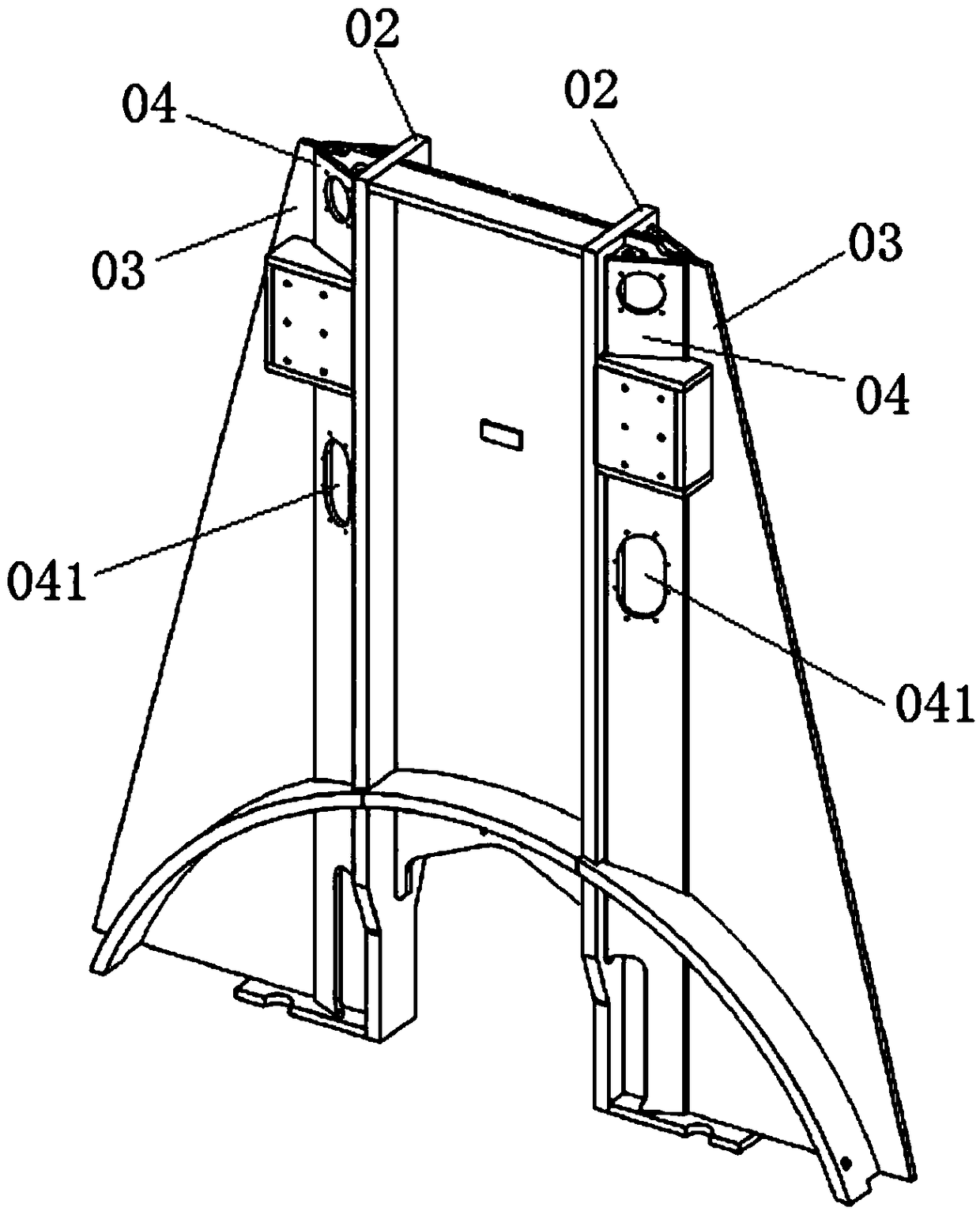

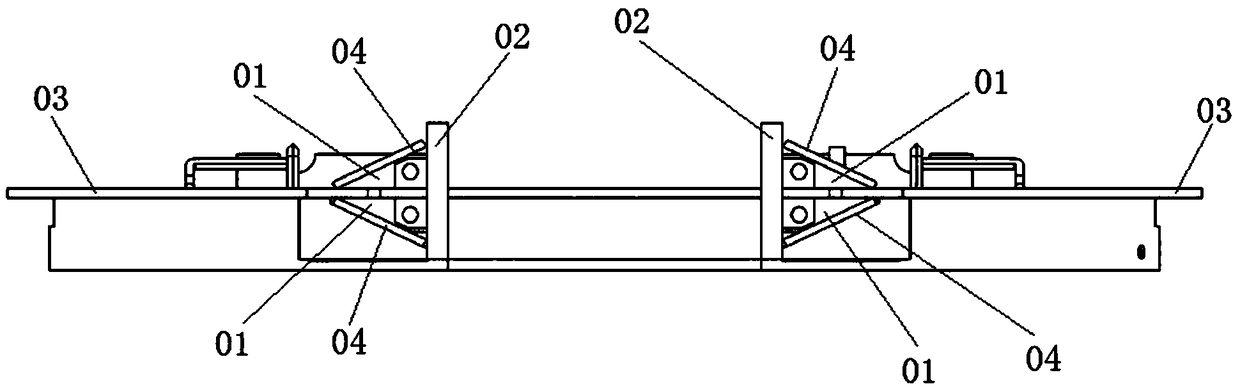

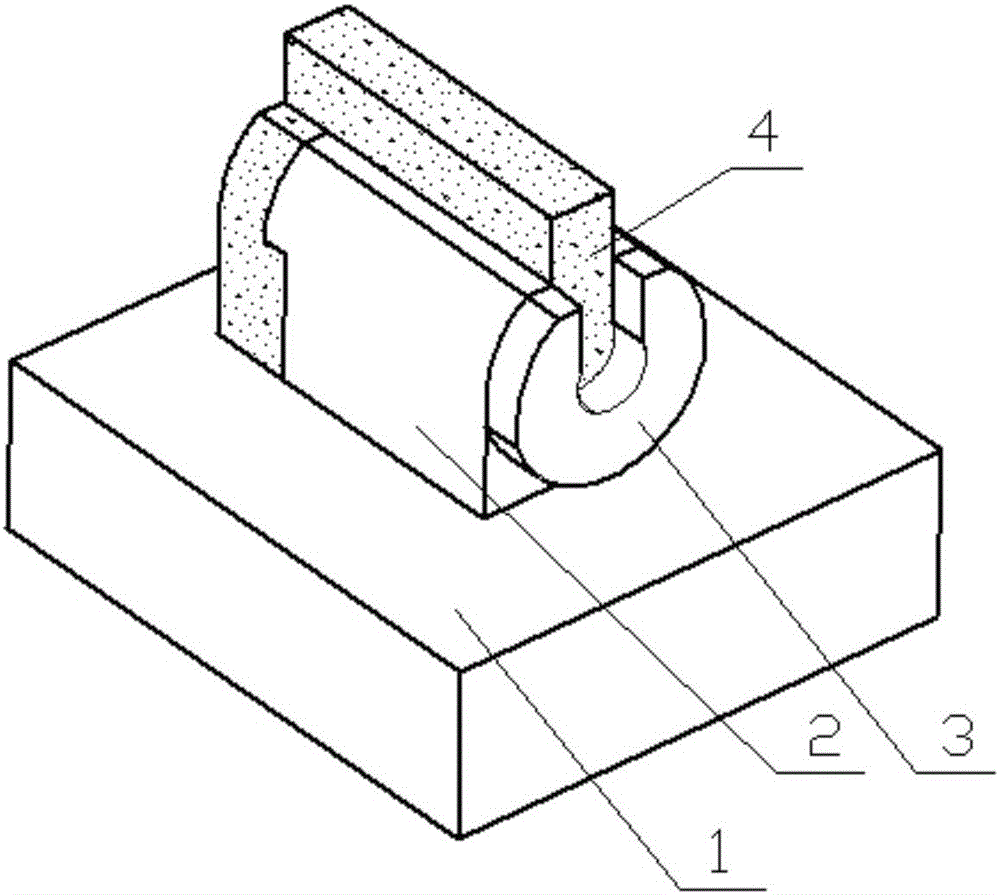

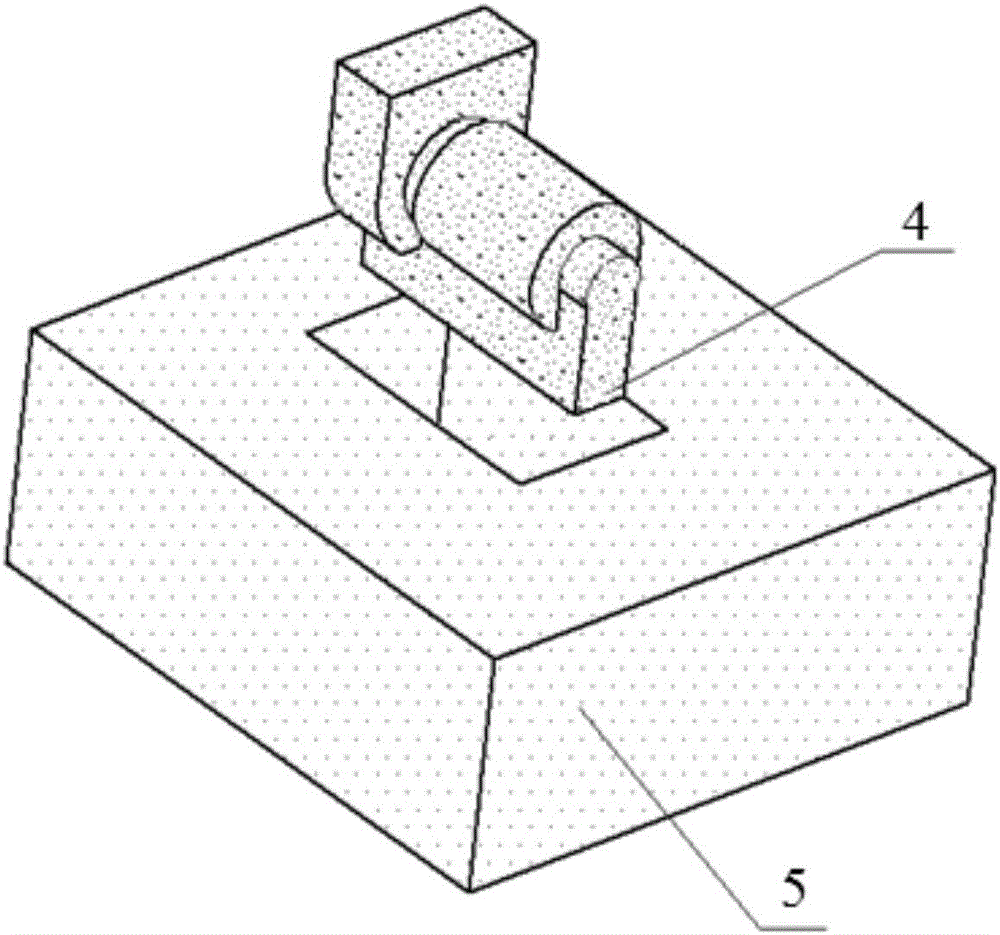

Forming method of jaw part of machine tool piece

ActiveCN106378422AReduce the difficulty of operationAvoid sizeFoundry mouldsFoundry coresSlagCasting defect

The invention provides a forming method of a jaw part of a machine tool piece. The forming method of the jaw part of the machine tool piece comprises the steps of forming a sand core through 3D (three dimensional) printing, wherein the sand core is formed by a jaw sand core structure and a sand core outer mold formed on the outer part of the jaw sand core structure so as to jointly form the jaw part to be cast; installing the sand core into a sand mold sample, placing the sand core and the sand mold sample into a sand box, and filling sand; and demolding the sand mold sample, and casting. According to the forming method of the jaw part of the machine tool piece provided by the invention, the casting defects such as sand inclusion and slag inclusion of the jaw part of the machine tool piece, and unevenness of wall thickness can be prevented, and the casting quality is improved.

Owner:NINGXIA KOCEL MOLD

High-bonding-strength modified water glass sand for pump valve casting and manufacturing method of high-bonding-strength modified water glass sand

InactiveCN105436395AExcellent normal temperature wet strengthImprove thixotropyFoundry mouldsFoundry coresEnvironmental resistanceUltimate tensile strength

The invention discloses high-bonding-strength modified water glass sand for a pump valve casting. A modified water glass bonding agent in the water glass sand is superior to a conventional water glass bonding agent in normal-temperature and normal-humidity strength, thixotropy and the rheological property are better, reaction bonding activity is high, and environment friendliness is achieved; the modified water glass bonding agent improves the bonding strength greatly together with yttrium oxide sol, the use amount of water glass is greatly reduced, and scattering cleaning and recycling of sand are easier; in addition, permeability resistance of the surface of molding sand can be effectively improved through sericite powder added in the sand, and defects on the surface of the casting due to molten metal permeation are avoided; and nanometer calcium fluoride loaded by bentonite is scattered in sand and has the effects of lubricating and strengthening, a non-stick permeation-preventing layer can be formed, and sand clamping and sand sticking of the casting are further prevented. The composite modified water glass sand is good in comprehensive performance, and the high-quality pump valve casting can be manufactured.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Pouring channel capable of preventing sand drop

InactiveCN102091760AAvoid sand sheddingAvoid sand inclusionsFoundry mouldsFoundry coresMolten metalMetallurgy

The invention provides a pouring channel capable of preventing sand drop, comprising a runner connected with a casting chamber, and a sprue connected with the runner; wherein the bottom of the sprue is provided with an arc platform, and a pouring gate bowl is arranged on the arc platform. Molten metal rushes into the pouring gate bowl at the bottom of the sprue from the top of the sprue, so that sand drop is prevented, the sand is prevented from being contained in the casting, and quality of the casting is improved.

Owner:SUFA HENGDIAN MACHINERY CNNC

High-fluidity clay green molding sand used for steel casting and preparation method thereof

InactiveCN105562583AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresAdditive ingredientPhosphate

The invention discloses high-fluidity clay green molding sand used for a steel casting and a preparation method thereof. The high-fluidity clay green molding sand is made from, by weight, 25-40 parts of zircon sand, 18-32 parts of chromite residues, 11-19 parts of petrol coke powder, 14-26 parts of rectorite, 5-10 parts of waste molasses, 15-25 parts of vermiculite, 33-47 parts of nacrite, 9-18 parts of white onxy, 5-10 parts of spinel, 7-11 parts of ultra-fine aluminum silicate, 5-10 parts of tricalcium phosphate and 320-380 parts of improver. According to the high-fluidity clay green molding sand used for the steel casting and the preparation method thereof, the zircon sand and the nacrite are adopted as the main ingredients, and the chromite residues, the petrol coke powder, the rectorite, the white onxy, the spinel and other raw materials are added, so that the prepared clay green molding sand is made to have excellent fluidity; sand grains can easily move towards one another under the action of external force or gravity; the high-fluidity clay green molding sand further has good plasticity, gas permeability, collapsibility and heat stability.

Owner:安徽创奇乐智能游乐设备有限公司

Method for preventing sand cut of furan resin sand and blacking scab

ActiveCN105149520AProtect surface strengthEliminates sand wash and paint peelingFoundry mouldsFoundry coresFuranMoisture

A manufacturing technology for preventing sand cut of furan resin sand and blacking scab comprises the following steps: a, sand molding: 40-70-mesh natural silica sand is adopted, the addition of resin is 0.8 percent of the mass of silica sand, the addition of a curing agent is 0.32 percent of the mass of silica sand, and sand is manufactured into a 40*40 mm cylindrical test cube; b, demolding and drying: when the strength of a sand mold reaches 0.5 Mpa to be capable of supporting demolding of the sand mold, direct demolding is performed, after demolding, the drying temperature is adjusted to be 105 DEG C, drying is performed for 20 min, and the temperature is increased to dry moisture so as to accelerate hardening; c, brushing and drying of a coating; brushing and drying of the water-based coating are carried out in the way of drying for 10 min at 350 DEG C; d, sand mold hardening: hardening of the sand mold is accelerated, and drying of the sand mold is performed for 20 min at 105 DEG C; e, strength test; and f, casting verification. The method has the beneficial effects that the casting rejection rate is lowered and the later-period casting processing cost is reduced.

Owner:KOCEL EQUIP

High-pouring-precision composite modified sodium silicate-bonded sand for pump valve casting and preparation method thereof

InactiveCN105414460AExcellent normal temperature wet strengthImprove thixotropyFoundry mouldsFoundry coresThermal expansionThermal stability

The invention discloses high-pouring-precision composite modified sodium silicate-bonded sand for a pump valve casting. Compared with conventional modified sodium silicate binding agents, modified sodium silicate binding agents in the sodium silicate-bonded sand have more excellent normal-temperature wet strength, better thixotropy and rheological property and higher binding speed, and are environmentally friendly, and the use amount of sodium silicate is small. In addition, aluminum titanate added into the sand is low in coefficient of thermal expansion, so that the thermal stability and air permeability of the sand form are improved, and the melt pouring precision is improved; bentonite-loaded nano calcium fluoride is dispersed into the sand to achieve the lubricating and reinforcing effects, a non-stick impermeable layer is formed, and the casting is prevented from carrying and adhering to the sand. The composite modified sodium silicate-bonded sand is excellent in comprehensive performance, compact in structure, rapid in scatter cleaning and high in casting precision and can meet the pouring requirements of the high-precision pump valve casting.

Owner:合肥李诺新材料贸易有限公司

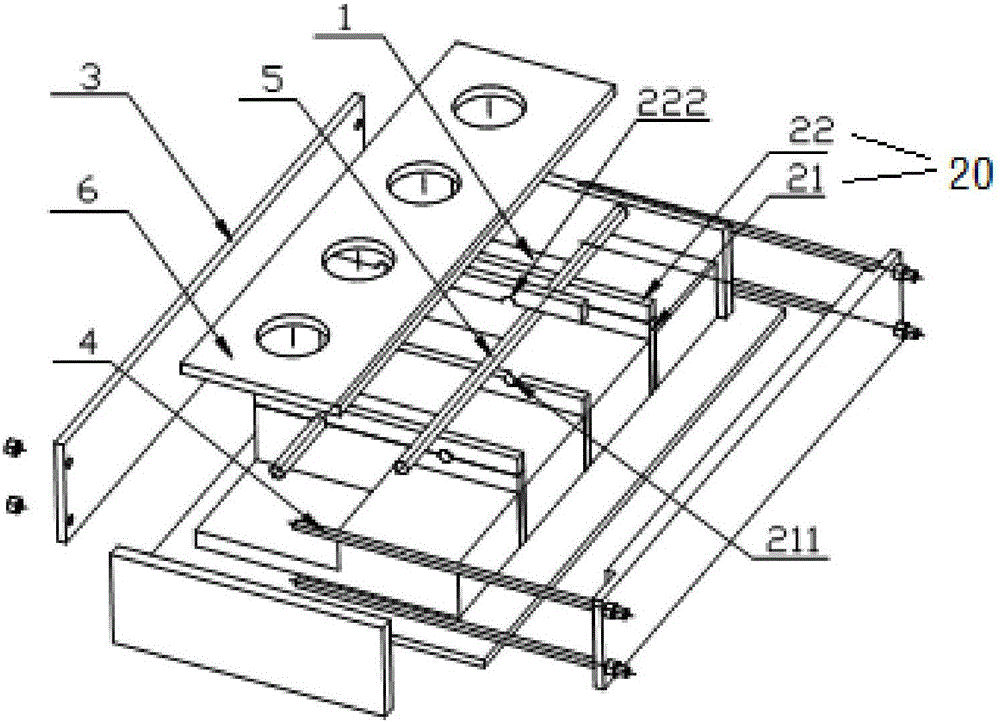

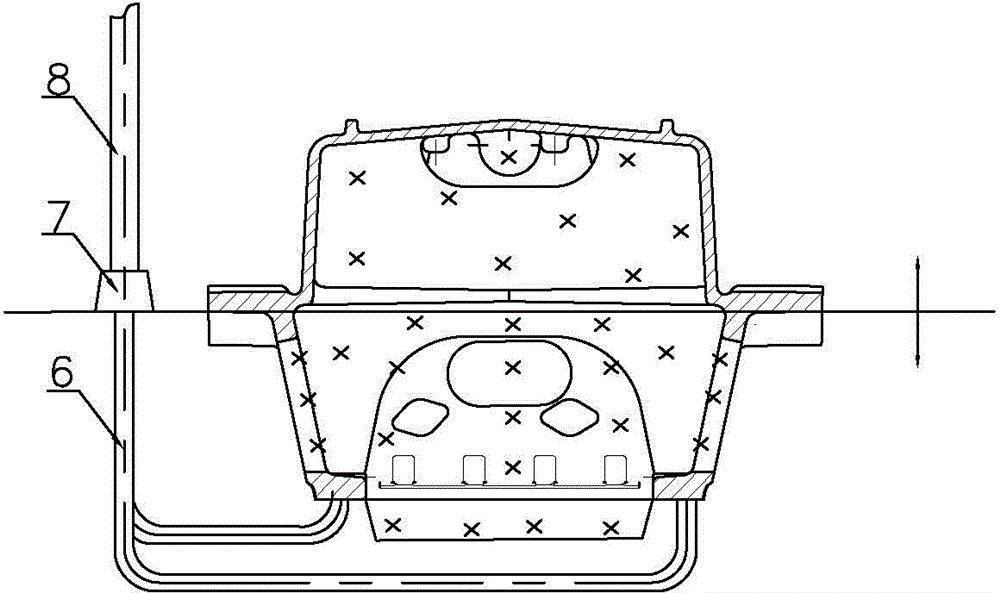

Sand mold structure of oil pan casting

InactiveCN104384444AAvoid rubbing sandAvoid edge shearing on square doorsFoundry mouldsFoundry coresMaterials scienceFlange

The invention relates to a sand mold structure of an oil pan casting, belonging to the technical field of casting. The sand mold structure comprises an upper sand mold, a lower sand mold and a mold core, wherein cavities corresponding to flange plates of the oil pan casting are vertically arranged in the upper sand mold and the lower sand mold respectively; the parting surfaces of the upper sand mold and the lower sand mold are vertical to the forming surfaces corresponding to the top plane and the bottom surface of the casting respectively; forming structures corresponding to square doors on two side walls of the oil pan casting are correspondingly arranged on the upper side of the upper sand mold and the lower side of the lower sand mold, respectively; a section mold pouring system of the oil pan casting adopts a bottom pouring system which comprises a sprue, a cross gate and an ingate, and the inlet of the ingate is formed in the bottom side of a flange cavity of the lower sand mold. According to the sand mold structure of the oil pan casting, the defects of sand inclusion and pores existence at the thin wall of the casting can be effectively avoided by changing the positions of the parting surfaces of the mold and the angle of the rotating cavity, and thus the quality and the dimensional precision of the oil pan casting can be improved.

Owner:KOCEL EQUIP

Strip-shaped steel coated sand mold

PendingCN109226682AShorten the timeAvoid sand inclusionsFoundry mouldsMoulding machinesComposite material

Owner:YUZHOU KUNLUN MOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com