Evanescent mode vacant-shell casting technique of double-saddle balance shaft shell

A balancing shaft and lost foam technology, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of lack of fire resistance stability of refractory aggregates, easy deformation of combined models, and insufficient shape of models. Widely popularized and applied, the effect of eliminating residual foam slag and improving firmness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described now in conjunction with accompanying drawing.

[0024] see Figure 1-3 , the process steps of the lost foam hollow shell casting method of the double horse riding balance shaft housing of the present invention are as follows:

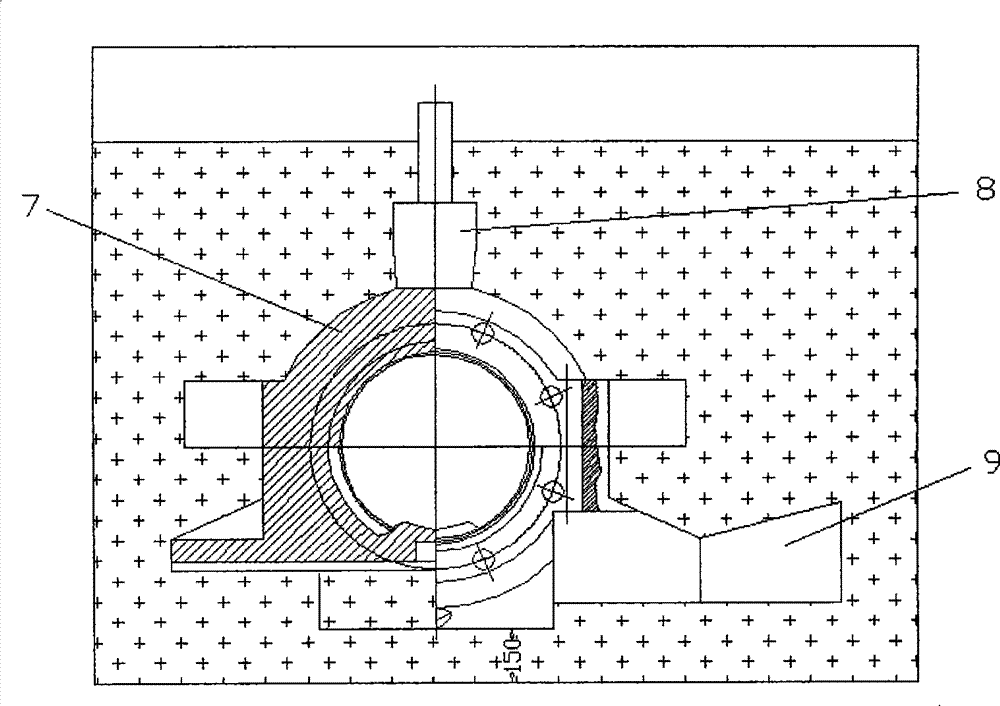

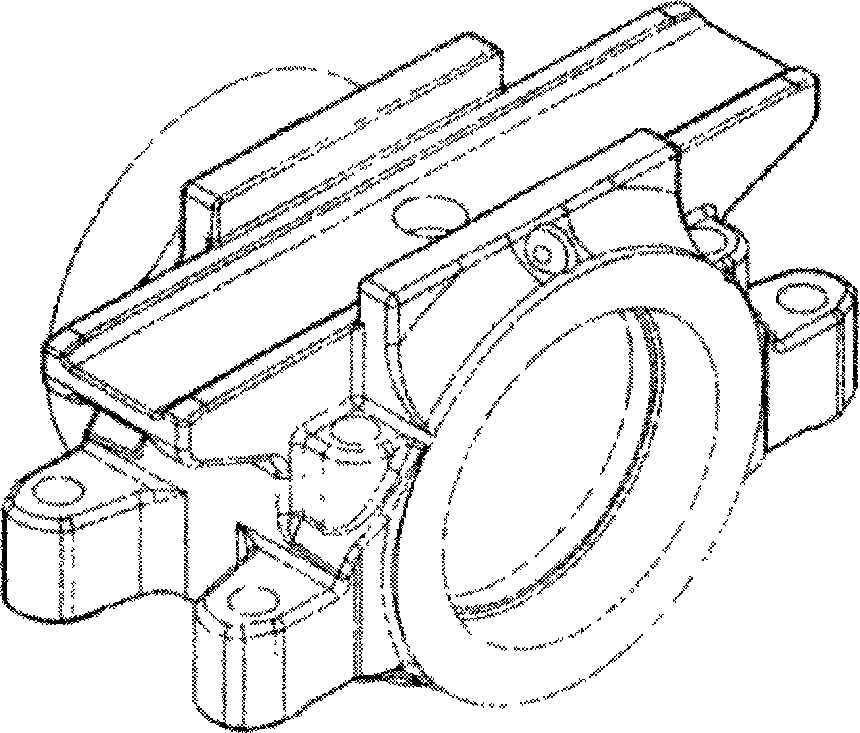

[0025] 1. Firstly, use the copolymer material (STMMA) to foam to make the lost foam model with the same shape as the double riding balance shaft shell casting and the riser. The copolymer material (STMMA) foams well, and it is not easy to produce pores and will not damage the casting. The surface quality is affected, the gate is made separately, and the model 7, the riser 8, and the gate 9 are bonded together to form a combined model ( figure 1 ), the gate 9 is set on the side of the combined model, which is beneficial to casting and reduces the probability of air holes.

[0026] 2. Put the combined model into the baking room for baking, the temperature of the baking room is 50°C-60°C, and the bak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com