Phosphogypsum building block and preparation method thereof

A phosphogypsum and block technology, which is applied in the field of phosphogypsum blocks and their preparation, can solve the problems that the firmness of phosphogypsum is not strong enough, cannot be matched with cement, and the use range of phosphogypsum blocks is limited, so as to improve the use range, Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

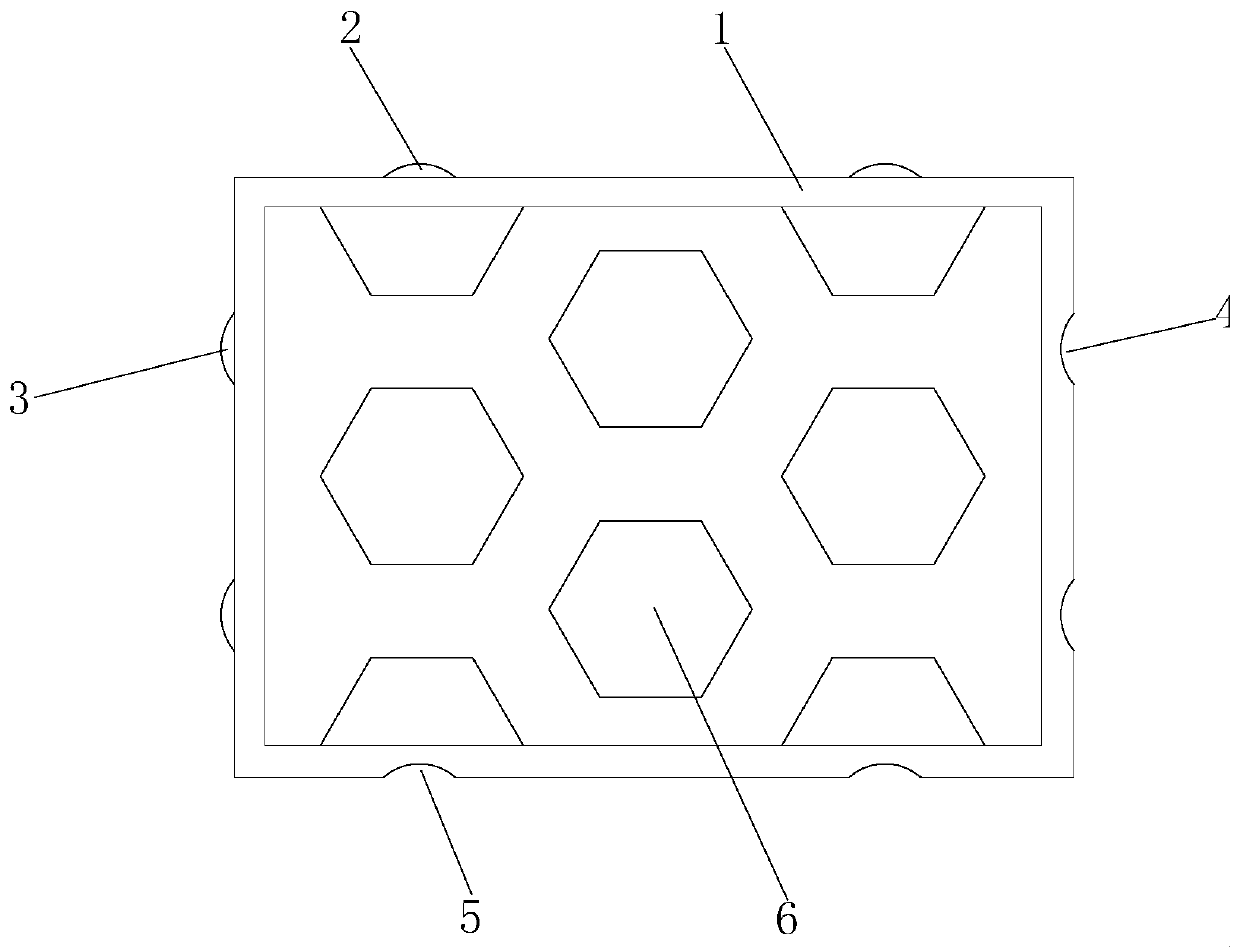

Image

Examples

Embodiment 1

[0032] The present invention relates to a preparation method of phosphogypsum blocks, including the following raw materials:

[0033] 50 parts of phosphogypsum, 20 parts of slag, 10 parts of fly ash, 5 parts of asbestos, 40 parts of water, 1 part of waterproofing agent, 2 parts of water reducing agent, 5 parts of dispersant and 3 parts of reinforcing agent.

[0034] S1, preparation

[0035] Prepare 50 parts of phosphogypsum, 20 parts of slag, 10 parts of fly ash, 5 parts of asbestos, 40 parts of water, 1 part of waterproofing agent, 2 parts of water reducing agent, 5 parts of dispersant and 3 parts of reinforcing agent according to the corresponding number of parts. Good, pass 50 parts of phosphogypsum, 20 parts of slag and 5 parts of asbestos through a pulverizer and pulverize into fine powder.

[0036] S2 puree processing

[0037] Put 50 parts of phosphogypsum, 20 parts of slag, 10 parts of fly ash, 5 parts of asbestos, and 40 parts of water into the mixer for stirring. The stirring ...

Embodiment 2

[0045] The present invention relates to a preparation method of phosphogypsum blocks, including the following raw materials:

[0046] 70 parts of phosphogypsum, 30 parts of slag, 20 parts of fly ash, 10 parts of asbestos, 60 parts of water, 3 parts of waterproofing agent, 4 parts of water reducing agent, 6 parts of dispersant and 8 parts of reinforcing agent.

[0047] S1, preparation

[0048] Prepare 70 parts of phosphogypsum, 30 parts of slag, 20 parts of fly ash, 10 parts of asbestos, 60 parts of water, 3 parts of waterproofing agent, 4 parts of water reducing agent, 6 parts of dispersant and 8 parts of reinforcing agent according to the corresponding number of parts. Good, and 70 parts of phosphogypsum, 30 parts of slag and 20 parts of asbestos are crushed into fine powder through a crusher.

[0049] S2 puree processing

[0050] Put 70 parts of phosphogypsum, 30 parts of slag, 20 parts of fly ash, 10 parts of asbestos, and 60 parts of water into the mixer for stirring. The stirring ...

Embodiment 3

[0058] The present invention relates to a preparation method of phosphogypsum blocks, including the following raw materials:

[0059] 60 parts of phosphogypsum, 25 parts of slag, 15 parts of fly ash, 7 parts of asbestos, 50 parts of water, 2 parts of water repellent, 3 parts of water reducing agent, 5.5 parts of dispersant and 6 parts of reinforcing agent.

[0060] S1, preparation

[0061] Prepare 60 parts of phosphogypsum, 25 parts of slag, 15 parts of fly ash, 7 parts of asbestos, 50 parts of water, 2 parts of waterproofing agent, 3 parts of water reducing agent, 5.5 parts of dispersant and 6 parts of reinforcing agent according to the corresponding number of parts. Good, pass 60 parts of phosphogypsum, 25 parts of slag and 6 parts of asbestos through a pulverizer to pulverize into fine powder.

[0062] S2 puree processing

[0063] Put 60 parts of phosphogypsum, 25 parts of slag, 15 parts of fly ash, 7 parts of asbestos and 50 parts of water into the mixer for stirring. The stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com