Process method for preventing sand inclusion in through bolt hole of marine diesel engine

A marine diesel engine and through-bolt technology, which is applied in the field of marine diesel engines, can solve problems such as welding spatter, high welder skill requirements, and low efficiency, and achieve the effect of avoiding risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] A process method for preventing sand inclusion in a through-bolt hole of a marine diesel engine, comprising the following steps:

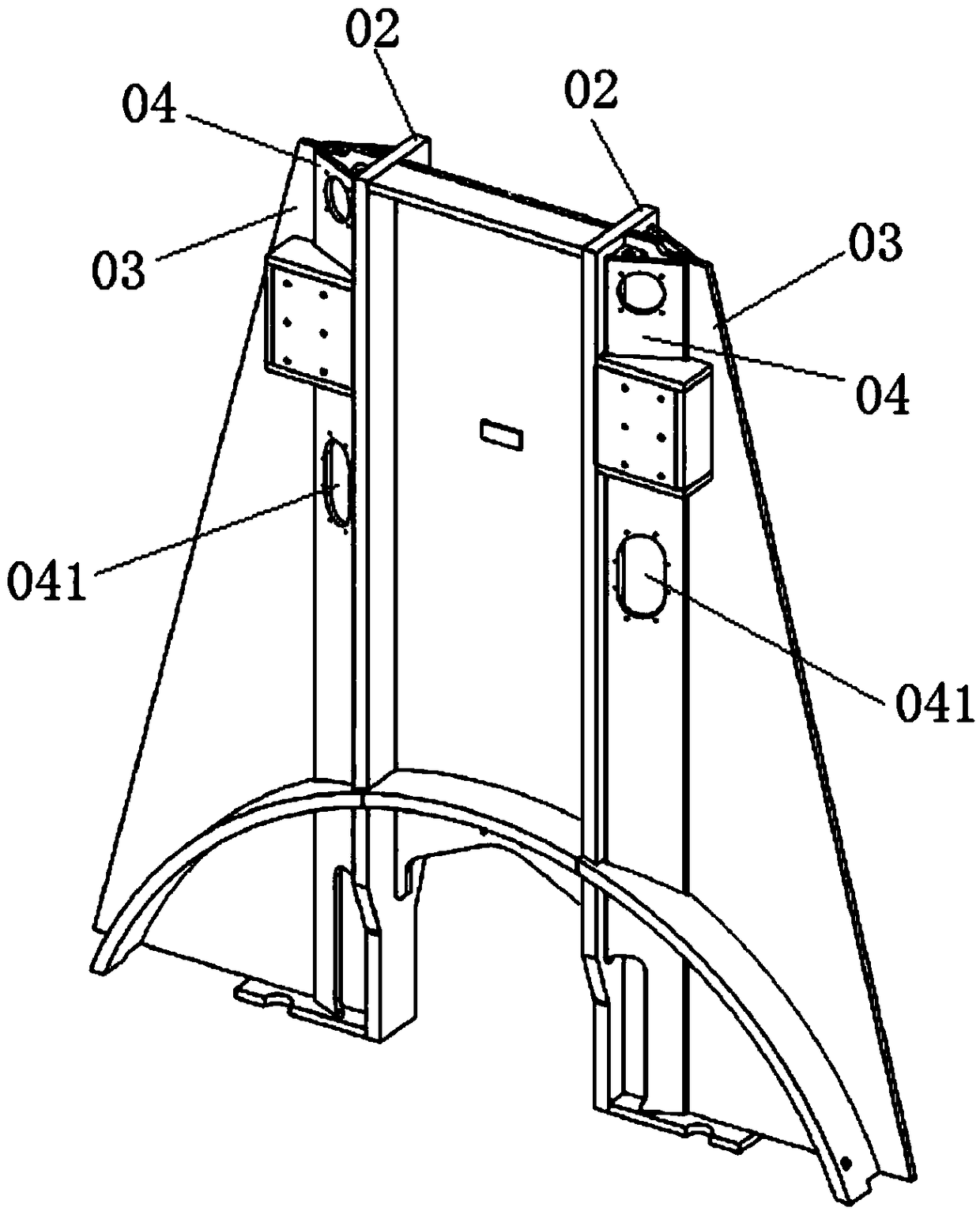

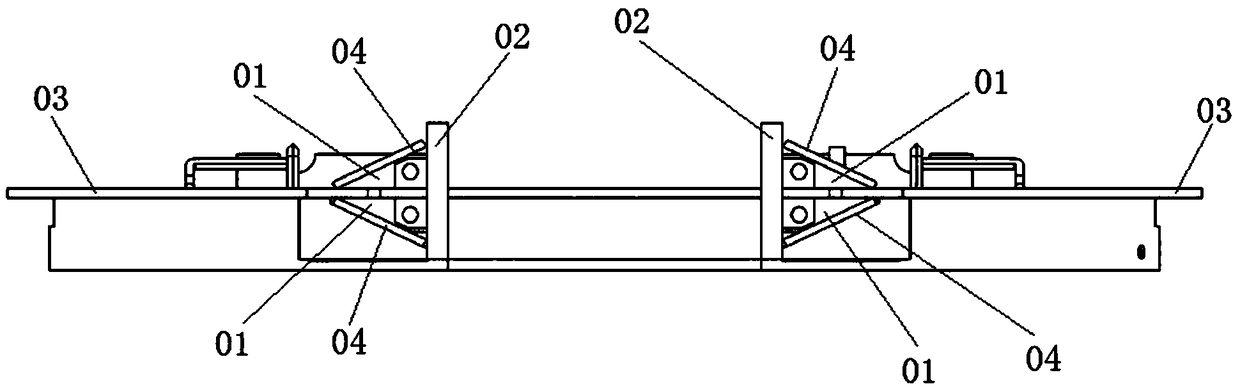

[0037] Step 1: Perform sandblasting pretreatment on the surfaces of triangular plate 04, wing plate 03, and guide rail plate 02; before sandblasting pretreatment, use ISO 8502-4Elcometer319 dew point meter to detect the ambient humidity and substrate temperature, and the humidity is less than 85 %, the substrate temperature is at least 3°C higher than the dew point;

[0038] Step 2: Weld the guide rail plate 02 and the wing plate 03, and then weld the two ends of the triangular plate 04 to the guide rail plate 02 and the wing plate 03 respectively. When welding, make the end of the triangular plate 04 close to the wing plate 03. After the welding is completed , clean up the welding slag and dirt at each welding ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com