Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

242results about How to "Excellent overall performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing composite water-retaining agent by adopting plant straws

The invention provides a method for preparing a composite water-retaining agent by adopting plant straws, belonging to the technical field of high-polymer materials. In the invention, the biodegradable plant straws with wide sources and low prices are used as raw materials, and graft copolymerization is carried out on the plant straws and acrylamide, clay, and the like to obtain the composite water-retaining agent with good comprehensive performance, therefore, the cost of the water-retaining agent is effectively reduced, and a new path for the application of the plant straws is sought. Meanwhile, since the composite water-retaining agent also has higher gel strength and saline alkali tolerance, the service performance of the water-retaining agent is further improved, and the service life thereof is prolonged.

Owner:NORTHWEST NORMAL UNIVERSITY

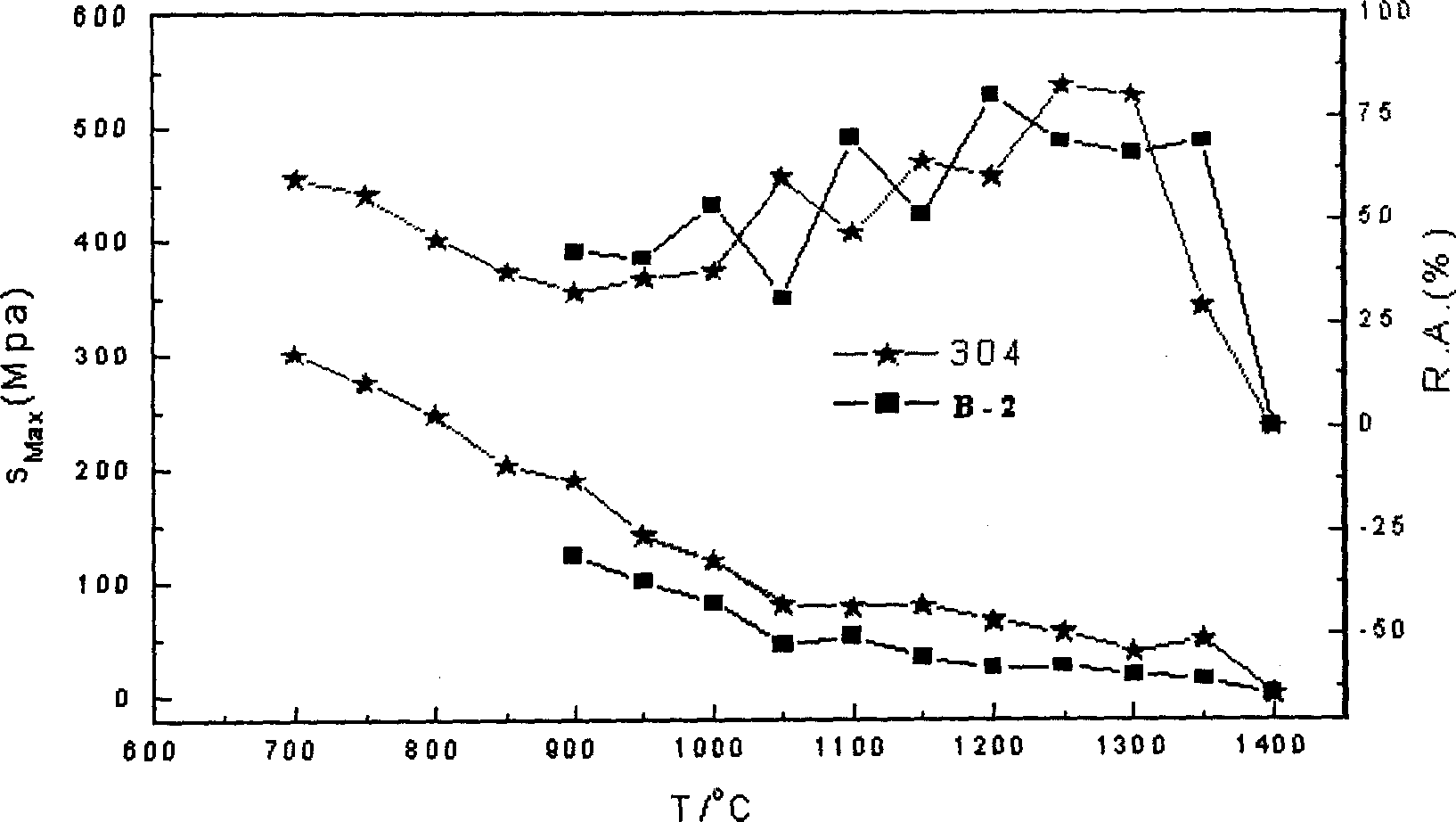

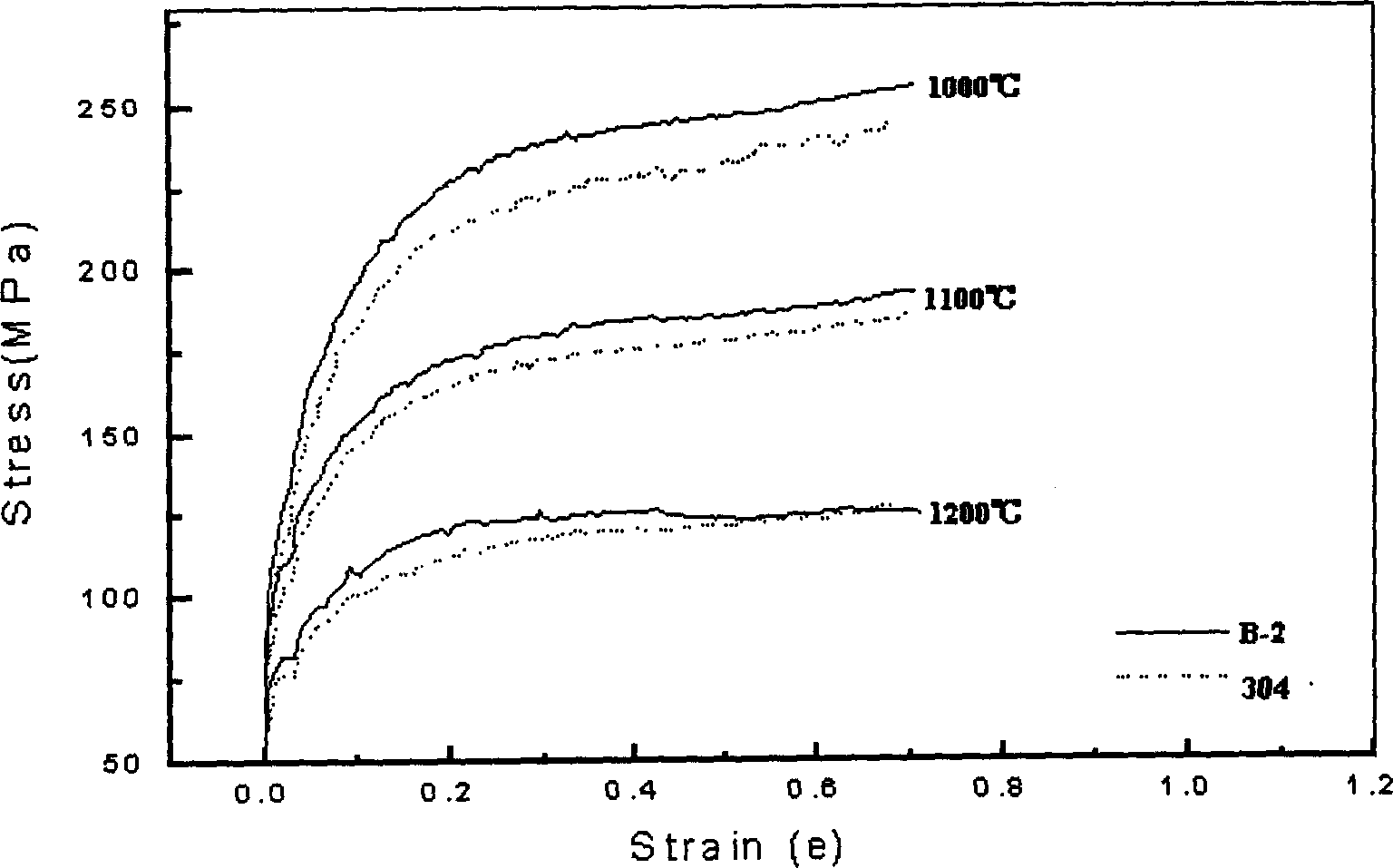

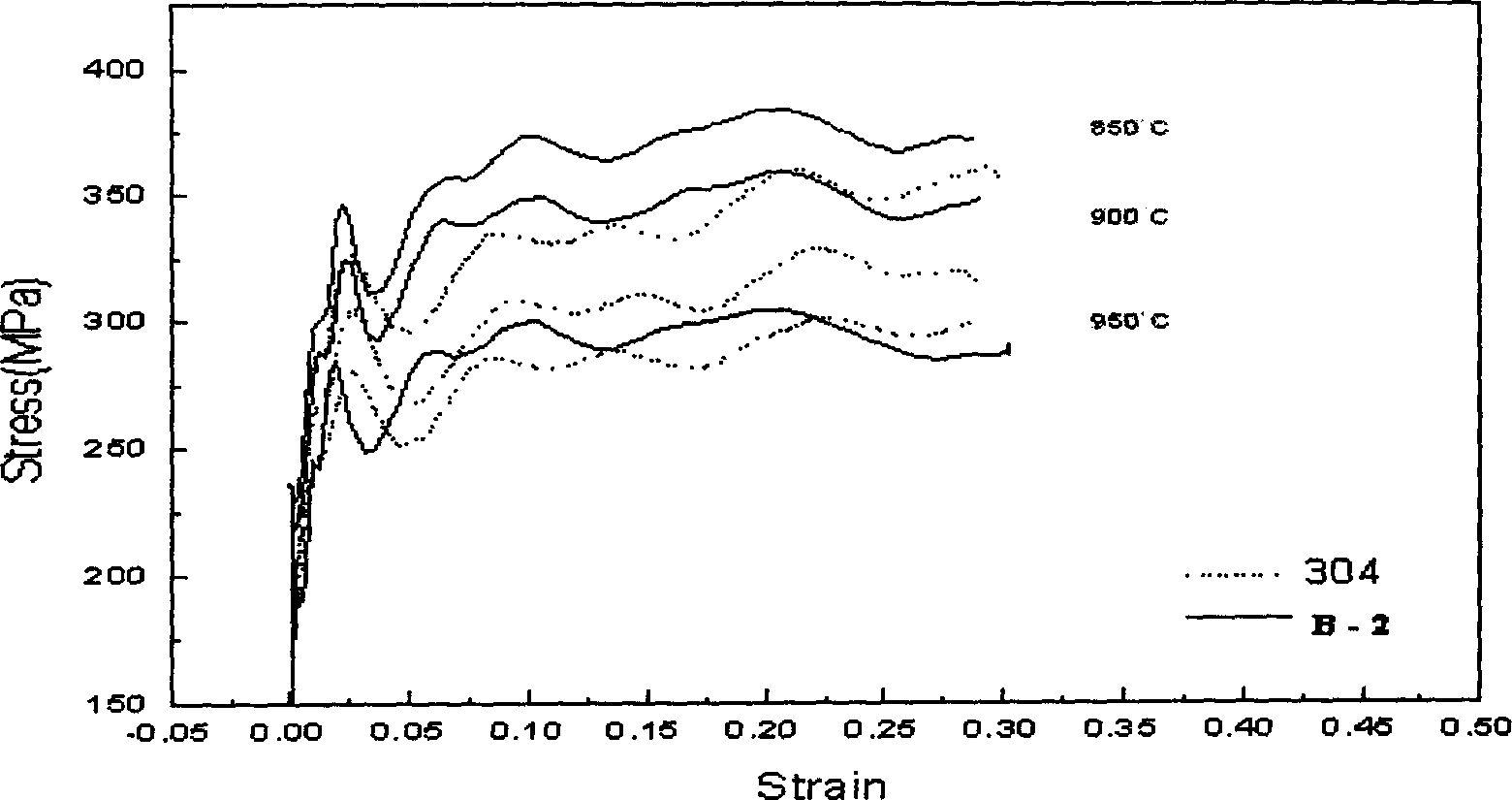

Nickel-saving RE-containing austenitic stainless steel and its prepn

InactiveCN1772942AExcellent overall performanceGood mechanical propertiesTemperature control deviceCasting safety devicesAustenitic stainless steelForging

The present invention belongs to the field of alloy steel, and is nickel-saving RE-containing austenitic stainless steel comprising C not more than 0.08 wt%, Si 0.3-0.8 wt%, Mn 5.0-8.5 wt%, S not more than 0.05 wt%, P not more than 0.04 wt%, Ni 3.0-5.5 wt%, Cr 14-19 wt%, Cu 1.0-4.0 wt%, N not more than 0.20 wt%, total O not more than 0.005 wt%, RE 0.05-0.3 wt% and Fe the rest. The preparation process of the stainless steel includes the technological steps of: smelting, casting at 1500-1650 deg.c, cogging at initial temperature of 1080-1240 deg.c and final forging temperature over 900 deg.c, rolling at initial temperature of 1100-1240 deg.c and final temperature over 900 deg.c, and solution treatment at 1050-1150 deg.c for 20-30 min. During the smelting, the molten steel has oxygen content not more than 50 ppm before RE is added, and RE is added in 30 sec before casting.

Owner:CENT IRON & STEEL RES INST

Cold-resistance super tough nylon polyolefin alloy and preparation method thereof

Owner:SHENZHEN KEJU NEW MATERIAL

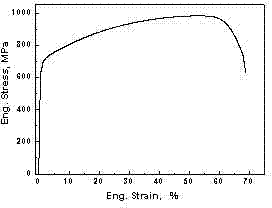

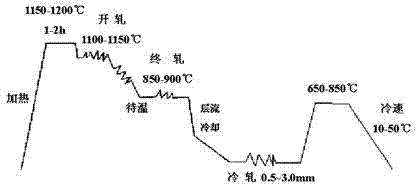

Nb, Ti alloyed low-carbon high-intensity high-plasticity TWIP steel and preparation method thereof

ActiveCN102312158AExcellent overall performanceBroad application prospectsSteel platesManufacturing sector

The invention, belonging to the field of high-intensity alloy steel, relates to a preparation method of a Nb, Ti alloyed low-carbon high-intensity high-plasticity twinning induced plasticity (TWIP) steel. The steel comprises the following ingredients: 0.05-0.10 wt% C, 23.5-27 wt% of Mn, 0.01-0.03wt% of Si, at most 1.0 wt% of Al, at most 0.01 wt% of P, at most 0.02 wt% of S, 1.0-2.5 wt% of Nb, 0.5-1.25 wt% of Ti, 0.02 -0.08 wt% of N, and the balance consisting of Fe and inevitable impurities. The preparation method comprises the following steps: melting the ingredients and then casting into a casting blank, heating the casting blank and then carrying out hot rolling at the opening rolling temperature of 1100-1150 DEG C with multiple passes and small press quantity to obtain the accumulated deformation degree of more than 60 % at the temperature of more than 950 DEG C, processing the casting blank in a finishing rolling mode at the temperature of 850-900 DEG C, after the hot rolling, rapidly cooling to 400-550 DEG C for reeling, carrying out cold rolling on the steel plate processed by hot rolling with the thickness of 0.5-3.0 mm, preserving the steel plate processed by cold rolling at the temperature of 650-850 DEG C for 3-30 min, and then rapidly cooling to room temperature with the cooling rate of 10-50 DEG C / s. The material prepared by the method can be applied in automobile manufacturing industry. The material has the yield strength of more than 550 MPa and the elongation rate of no less than 60 %, thereby obviously improving the ability of anti-collision and impact of automobile for the first time and greatly increasing the crashworthiness indexes.

Owner:SHANGHAI JIAO TONG UNIV

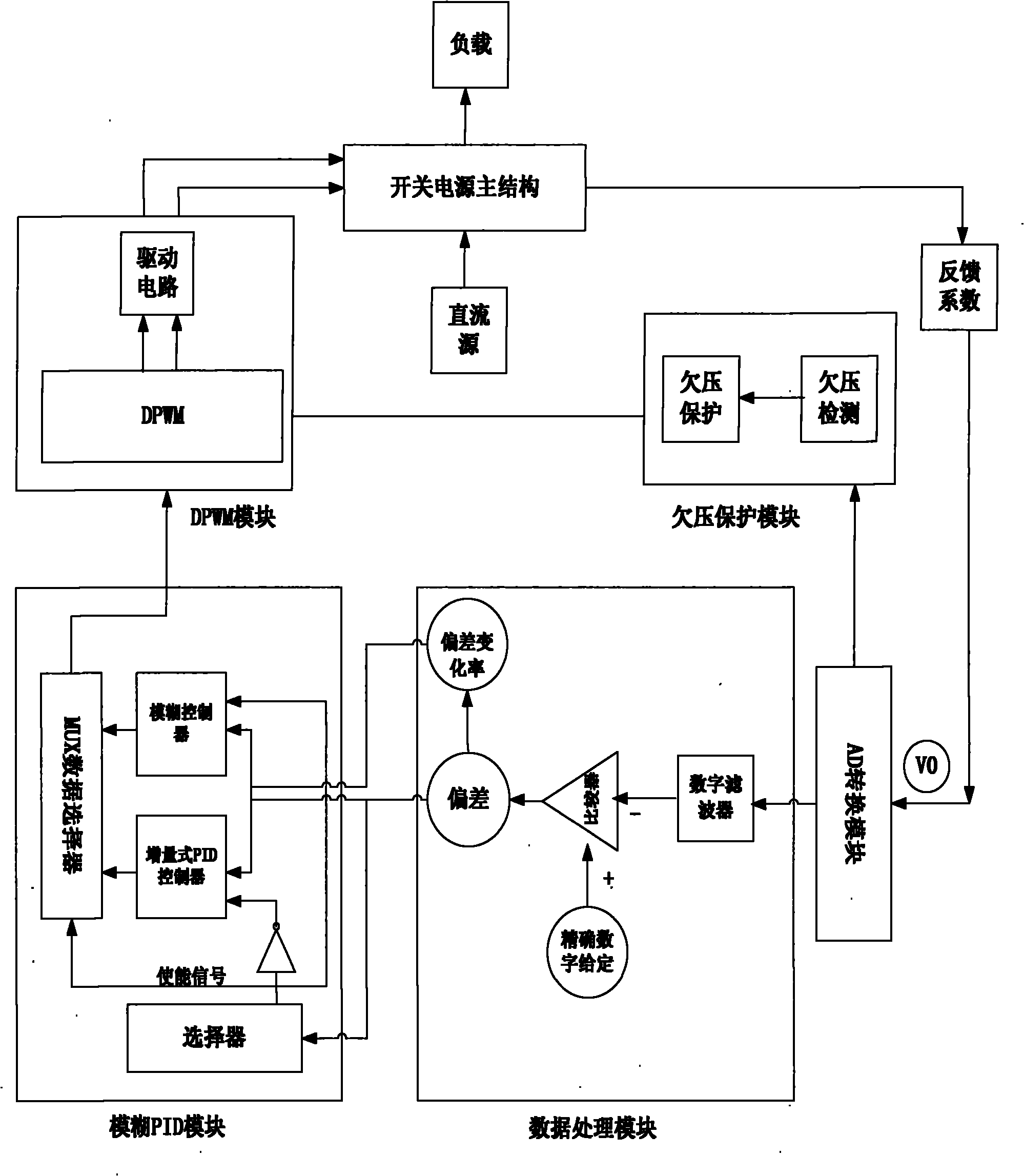

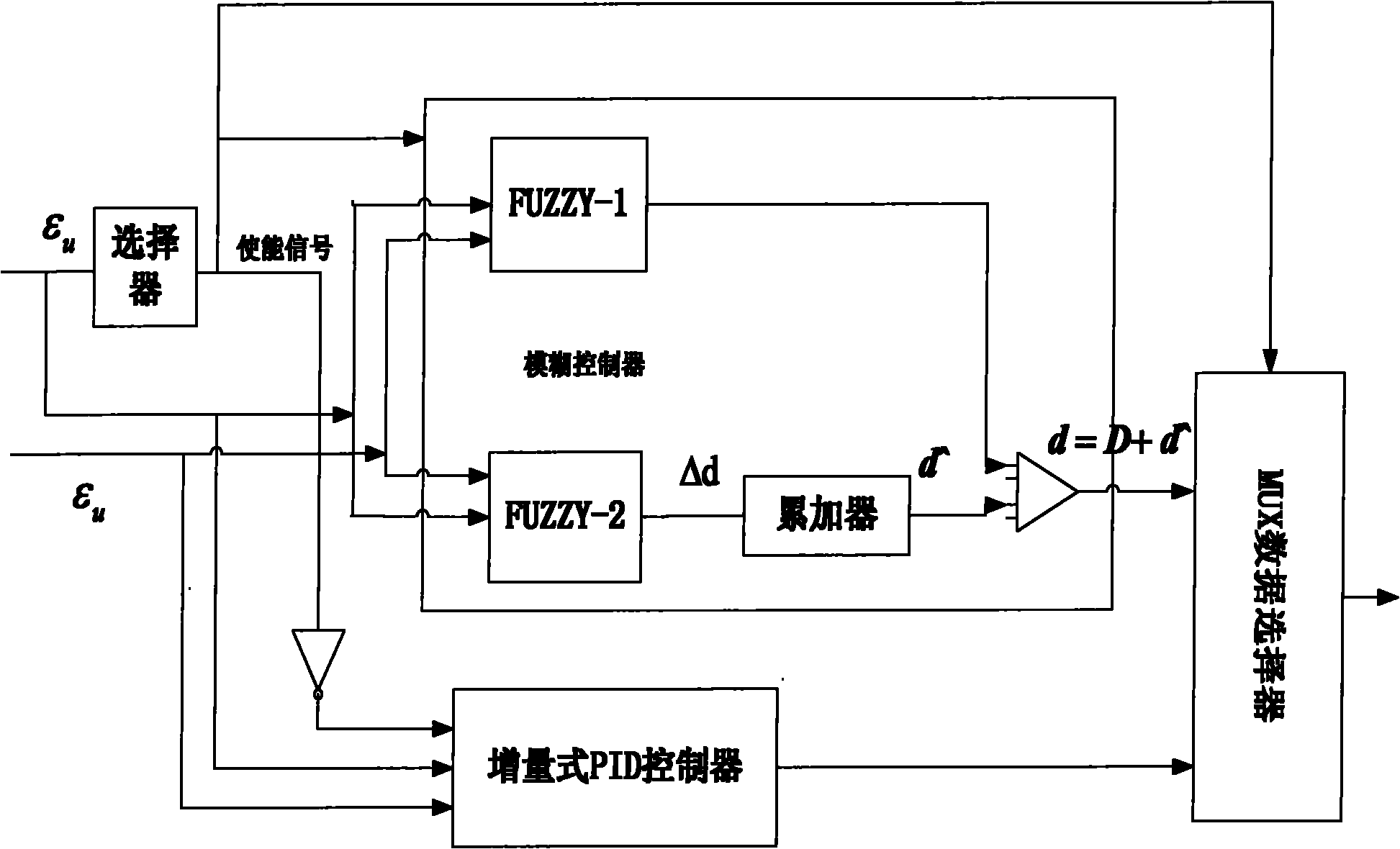

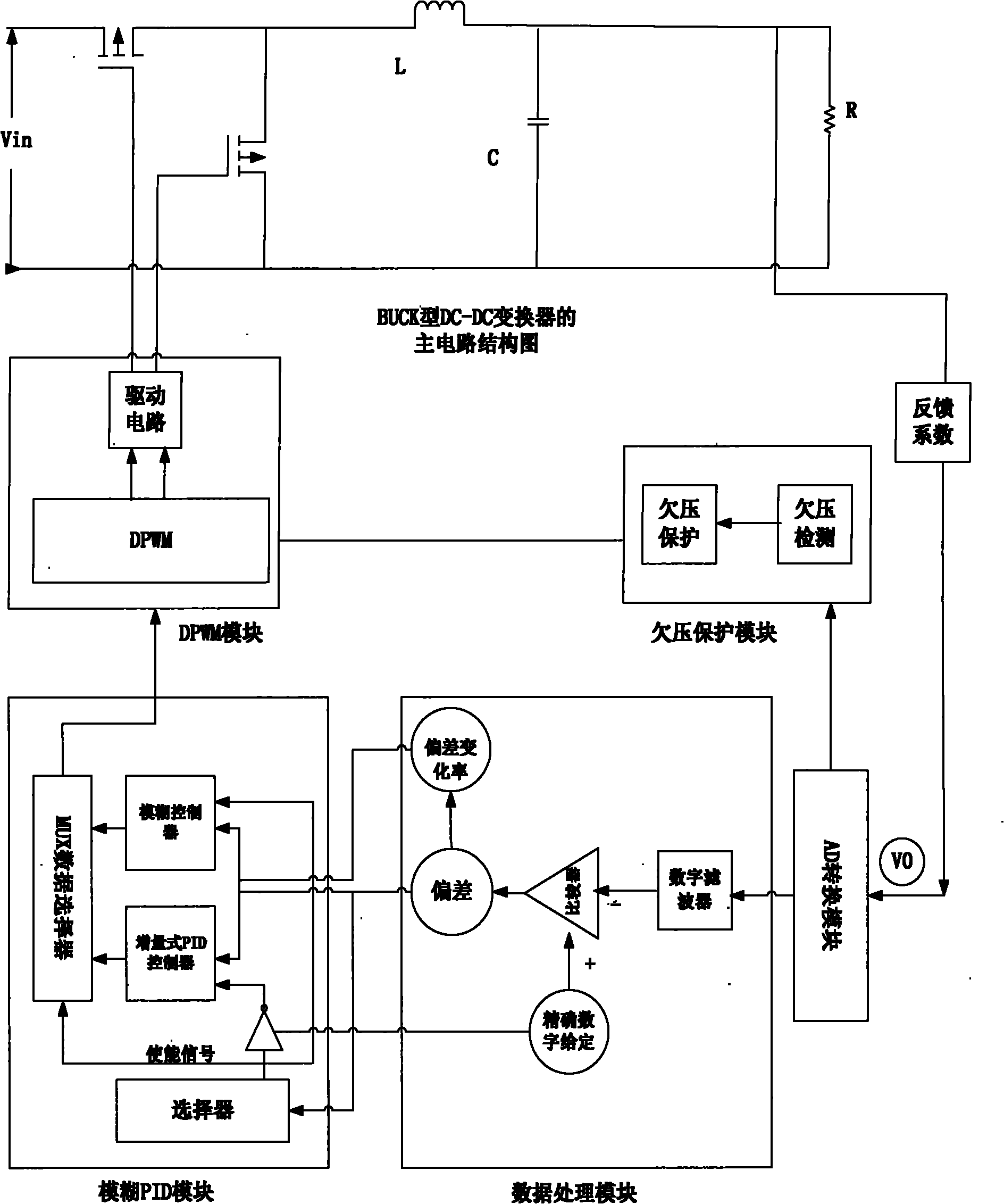

High transient response digital control system and method of switch power supply

ActiveCN101917119AExcellent overall performanceImprove transient responseDc-dc conversionControllers with particular characteristicsExecution controlVIT signals

The invention discloses a high transient response digital control system and a method of a switch power supply, the control system comprises a sampling module, an AD conversion module, a data processing module, a fuzzy PID module and a DPWM module, the control system is connected with a controlled switch power supply to form a closed-loop system, the sampling module samples output of the switch power supply, sampling output is converted to digital signals through A / D conversion, continuous digital signals enter the data processing module to be digitally filtered and to be compared with a set voltage value, the generated deviation and deviation variance rate are supplied to the fuzzy PID module, a control algorithm is carried out in the fuzzy PID module, an appropriate duty ratio is submitted to the DPWM output module, and PWM signals of a switch control pipe are generated and output, therefore, the switch pipe of the digital power supply can be controlled better to be used for stabilizing the voltage. Simultaneously, under-voltage detection is carried out on digital signals of the output voltage, and if the voltage is abnormal, PWM turnoff signals are sent out immediately to stop the system.

Owner:SOUTHEAST UNIV

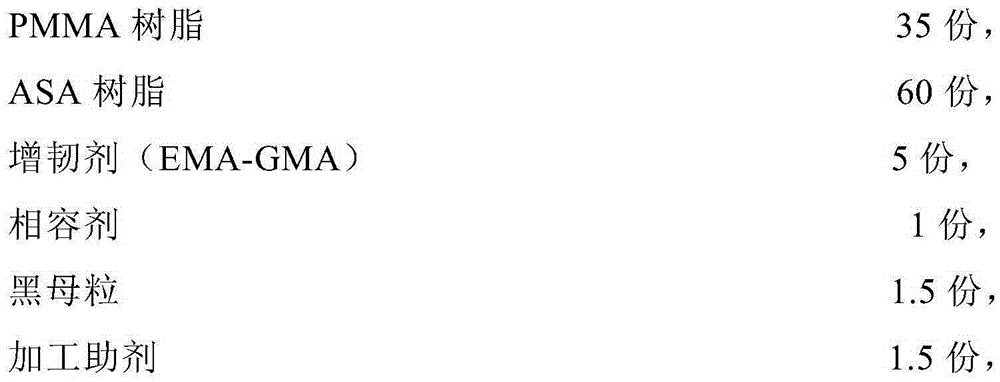

High-gloss spray-coating-free PMMA/ASA alloy resin composition and preparation method thereof

The invention relates to a high-gloss spray-coating-free PMMA / ASA alloy resin composition and a preparation method thereof. The PMMA / ASA alloy resin composition comprises the following components, by weight: 35-60 parts of PMMA resin, 30-60 parts of ASA resin, 5-20 parts of a toughening agent, 1-5 parts of a compatilizer, 0.5-2.0 parts of a black master batch and 0.6-1.5 parts of a processing additive. The preparation method includes the following steps: weighing the components according to the weight parts, mixing the components uniformly to prepare a premix, feeding the premix into a double-screw extruder, performing melt extrusion and performing cooling granulation to obtain the target product. Compared with materials in the prior art, the PMMA / ASA alloy resin composition is excellent in mechanical performance, is high in glossiness, is simple in preparation process, is prepared from easy-to-obtain raw materials and is low in cost.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

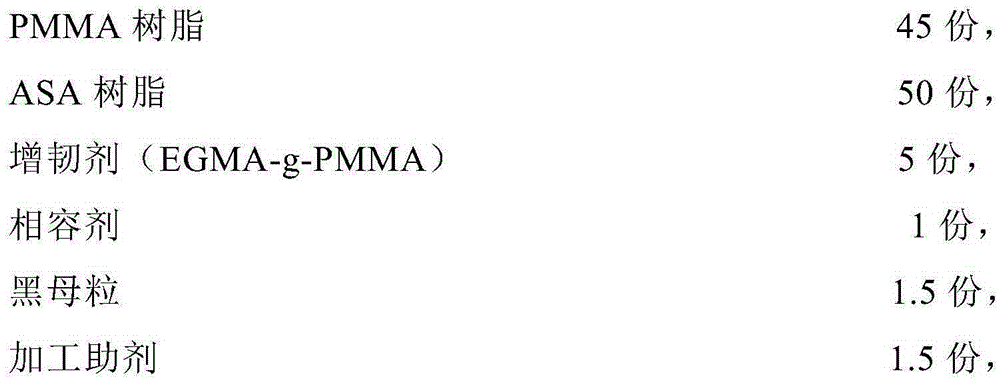

Method for preparing thermoplastic fiber-hybrid woven composite

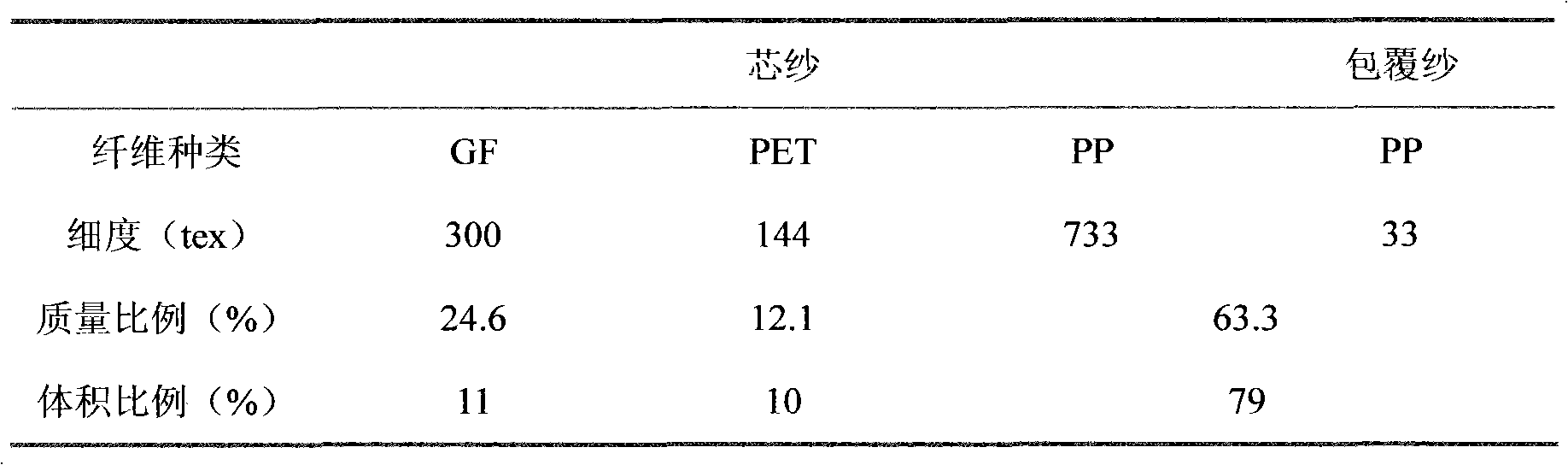

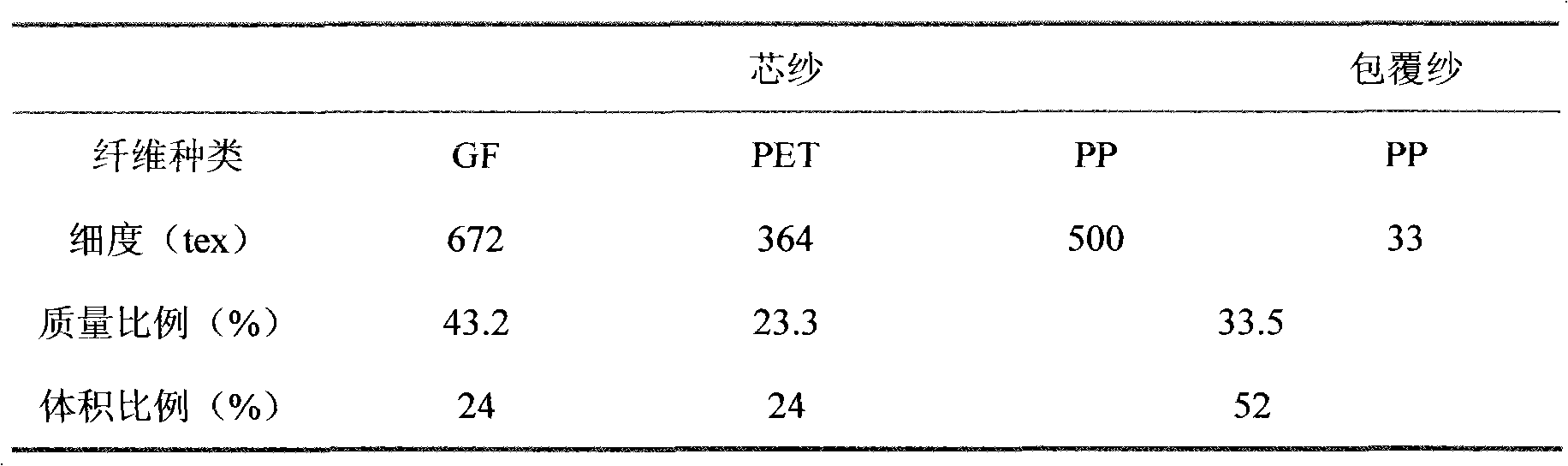

ActiveCN102152554AGood protectionExcellent overall performanceSynthetic resin layered productsLaminationYarnThermoplastic composites

The invention discloses a method for preparing a thermoplastic fiber-hybrid woven composite and is characterized by comprising the following three steps: preparing thermoplastic fasciated yarns, weaving a pre-manufactured composite and molding the woven composite, wherein the thermoplastic wrapping yarns consist of strengthened fibers and thermoplastic resin fibers which are mixed according to the volume by adopting a fiber wrapping technology, the thermoplastic fibers are 40 to 80 volume percent and the strengthened fibers are 20 to 60 volume percent; and then the thermoplastic resin fibers are uniformly covered on the strengthened fibers to form the thermoplastic wrapping yarns. The thermoplastic composite is a big trend in the further composite development and has a bright development prospect.

Owner:ZHEJIANG MAGLIA CASHMERE FAMILY CO LTD

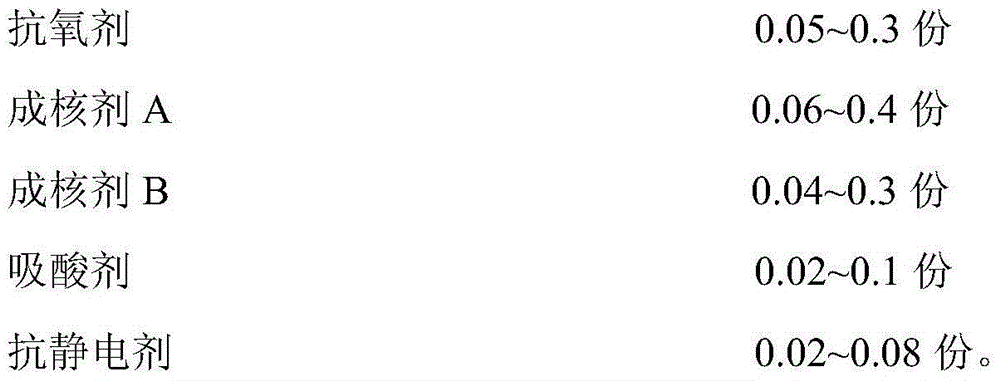

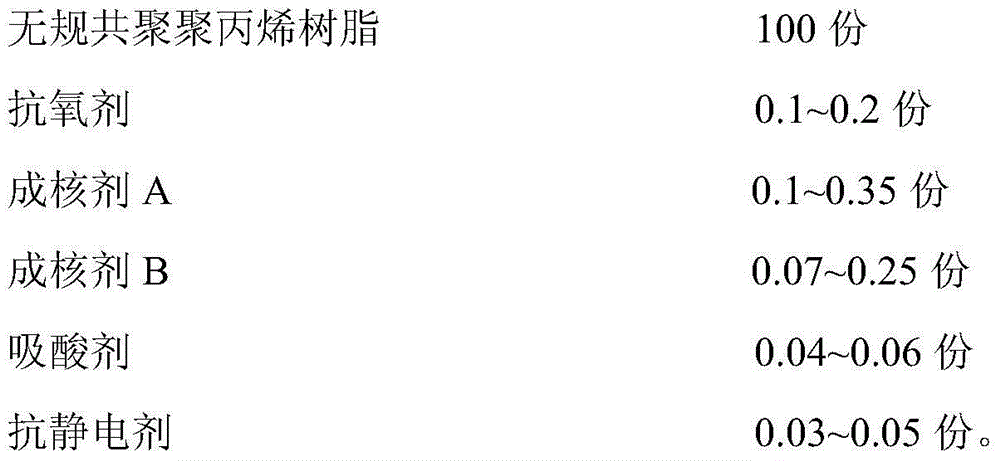

Polypropylene composition and preparation method thereof

The invention belongs to the field of polyolefin resin materials, and particularly relates to a polypropylene composition and a preparation method thereof. The polypropylene composition comprises the following raw materials in part by weight: 100 parts of a polypropylene resin random copolymer, 0.05-0.3 part of an anti-oxidant, 0.06-0.4 part of a nucleating agent A, 0.04-0.3 part of a nucleating agent B, 0.02-0.1 part of an acid acceptor and 0.02-0.08 part of an antistatic agent. According to the preparation method, a high-fluidity polypropylene random copolymer, which is obtained according to the hydrogen regulation method, is used as the basis resin; additives, such as the anti-oxidant, the acid acceptor, the antistatic agent, the nucleating agent A and the nucleating agent B, are added into the basis resin; after the basis resin and the additives are uniformly mixed by a high-speed stirring machine, the high-fluidity high-transparency polypropylene composition is obtained through double-screw extrusion pelletizing. The polypropylene composition is excellent in comprehensive performance, high in transparency and fluidity, resistant to warpage, and superior to a product of the degradation method in the aspects of appearance, color, lustre and smell. Therefore, the polypropylene composition can be applied to a large-scale transparent product and a complicated thin-wall product, and the warpage phenomenon during the production can be effectively avoided.

Owner:CHINA PETROLEUM & CHEM CORP

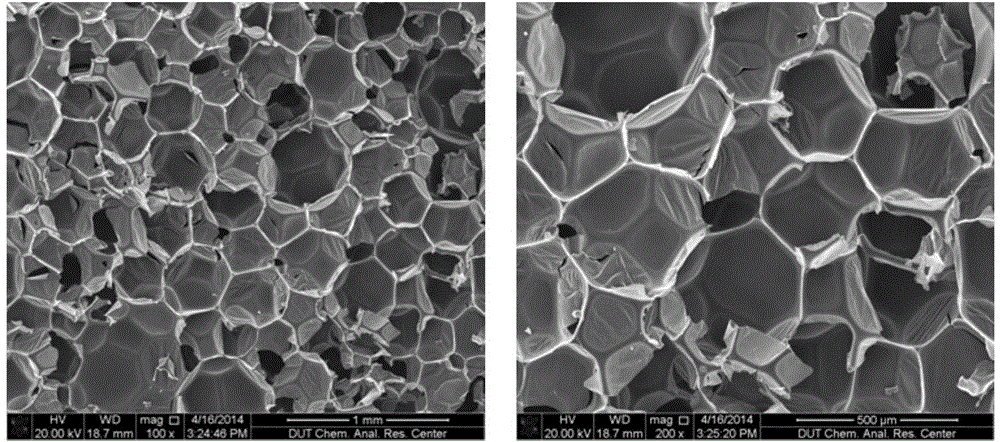

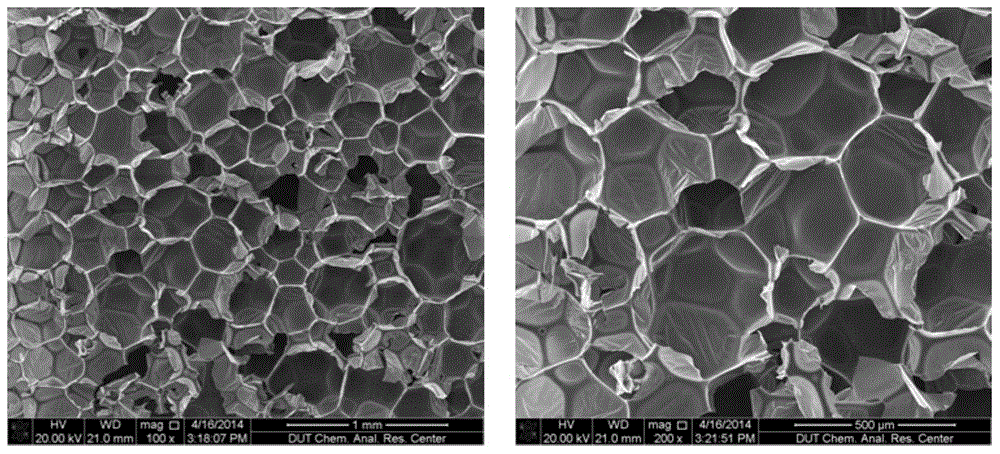

Flame-retardant polyurethane rigid foam plastic and preparation method and application thereof

The invention provides flame-retardant polyurethane rigid foam plastic. The plastic is prepared from, by weight, 100 parts of polyhydric alcohol, 98-130 parts of polyisocyanates, 5-100 parts of flame retardant, 0.01-5 parts of a catalyst, 0.001-5 parts of a foaming agent and 0.5-10 parts of silicone oil. The invention further provides a preparation method of the flame-retardant polyurethane rigid foam plastic. The preparation method comprises the steps of mixing polyhydric alcohol, flame retardant, the catalyst, the foaming agent and silicone oil, adding polyisocyanates, and conducting stirring, foaming and curing, or directly conducting spraying through spraying equipment, so that the flame-retardant polyurethane rigid foam plastic is obtained. The limit oxygen index (LOI) of the flame-retardant polyurethane rigid foam plastic prepared through the preparation method reaches 30 or above. The flame-retardant polyurethane rigid foam plastic is uniform in foam pore and good in mechanical performance, made of the non-halogen flame retardant, is environmentally friendly and widely applied to the fields of building heat preservation and insulation materials, petrochemical engineering storage tanks, pipe heat preservation, refrigeration houses and the like.

Owner:DALIAN UNIV OF TECH

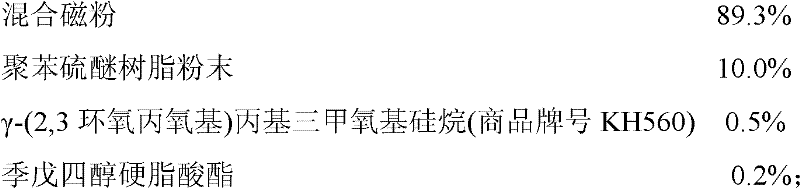

Injection molding permanent magnet composite material containing polyphenylene sulfide and preparation method thereof

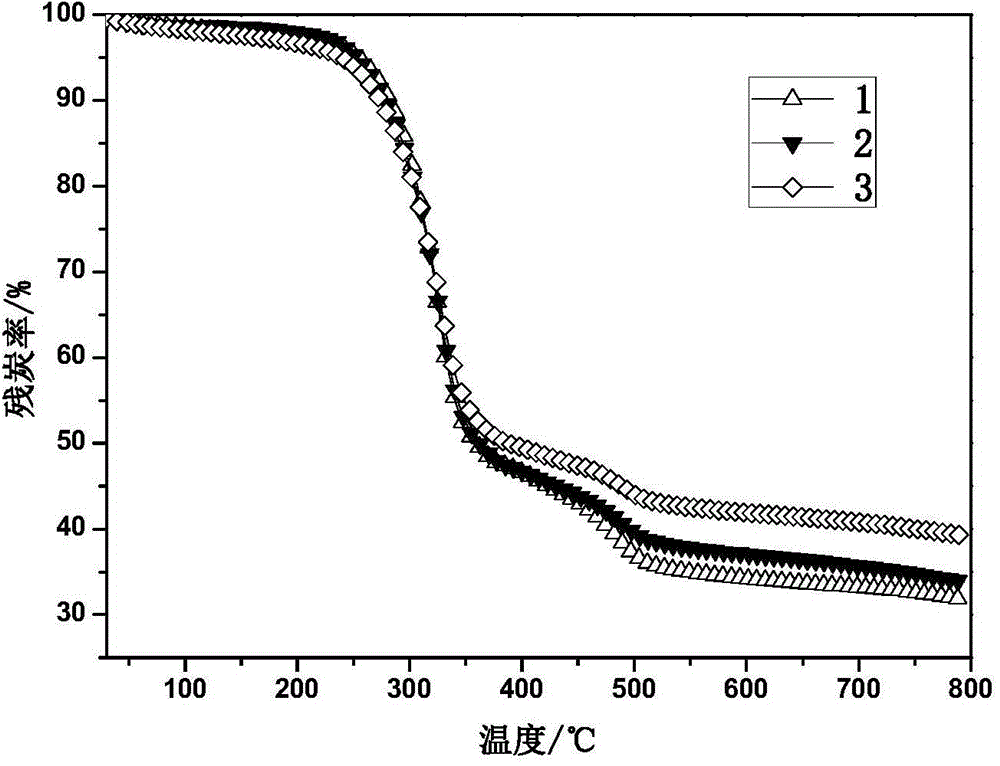

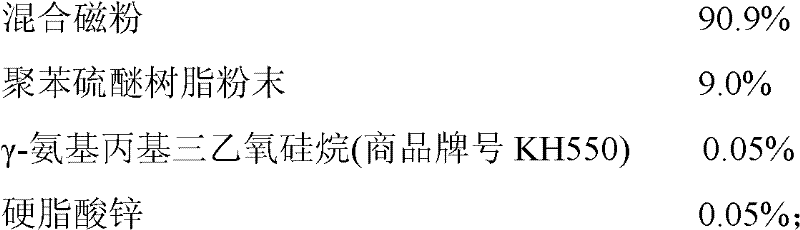

ActiveCN102504534AExcellent overall performanceExcellent magnetic propertiesMagnetic powderNeodymium iron boron

An injection molding permanent magnet composite material containing polyphenylene sulfide includes the following components by mass: 78% to 91% of mixed magnetic powder, 8% to 21% of polyphenylene sulfide resin and 0.05% to 1% of coupling agents. The mixed magnetic powder includes the following components by mass: 50% to 96% of neodymium iron boron permanent magnetic powder, 1% to 49% of samariumiron nitrogen permanent magnetic powder and 1% to 45% of ferrite permanent magnetic powder. A preparation method of the injection molding permanent magnet composite material includes the following processing steps: (1) preparing multi-element composite magnetic powder, (2) mixing and pelleting and (3) injection molding.

Owner:SICHUAN UNIV

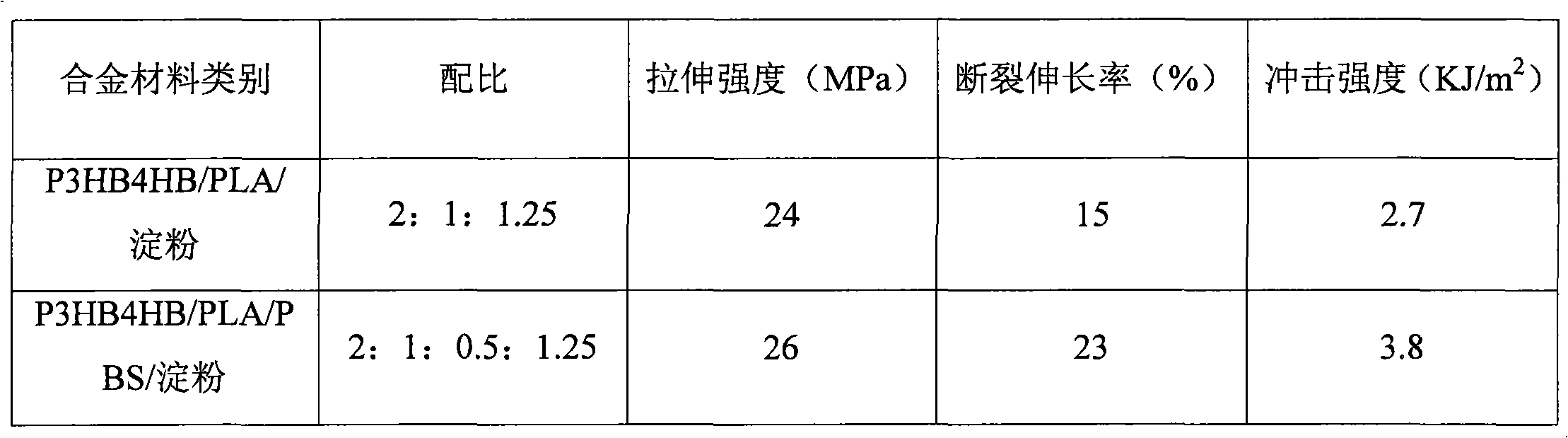

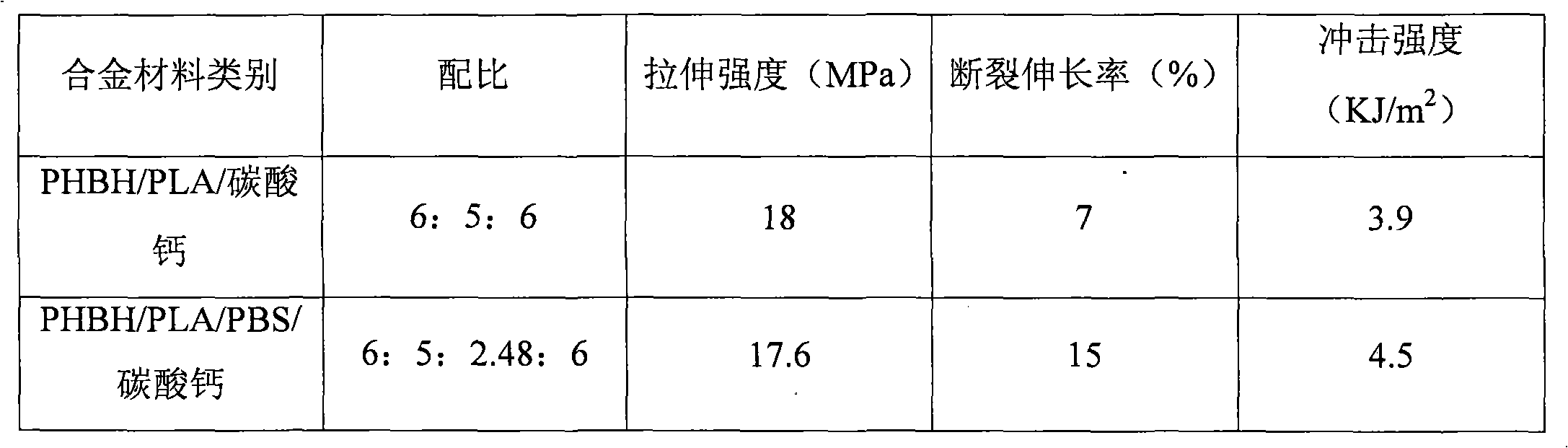

High-property polyhydroxyalkanoates (PHAs)/polybutylene succinate (PBS)/poly lactic acid (PLA) blend alloy

ActiveCN101987914AExcellent overall performanceImprove performancePolybutylene succinateCompatibilization

The invention discloses a high-property polyhydroxyalkanoates (PHAs) / polybutylene succinate (PBS) / poly lactic acid (PLA) blend alloy, which comprises PHAs as a body, PBS as a wild phase, PLA as a compatibilization phase, and other components. The blend alloy provided by the invention has higher compatibility and higher mechanical properties, and can be widely applied to film blowing products, blow molding products, extrusion products, injection molding products, foaming products and spinning products.

Owner:SHENZHEN ECOMANN BIOTECH

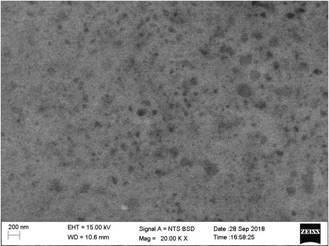

Nylon 66 nano composite material and preparation method thereof

The invention discloses a composite nanometer material and making method of polyhexamethylene adipamide (nylon 66), which comprises the following parts: 100wt% nylon 66, 5-20wt% elastic body and 5-30wt% inorganic nanometer particle, wherein these materials are blended to fuse and squeeze under 260-280 deg. c. The invention balances the rigidity, flexibility and fire resistance and size stability, which expands the applying domain of nylon 66.

Owner:EAST CHINA UNIV OF SCI & TECH

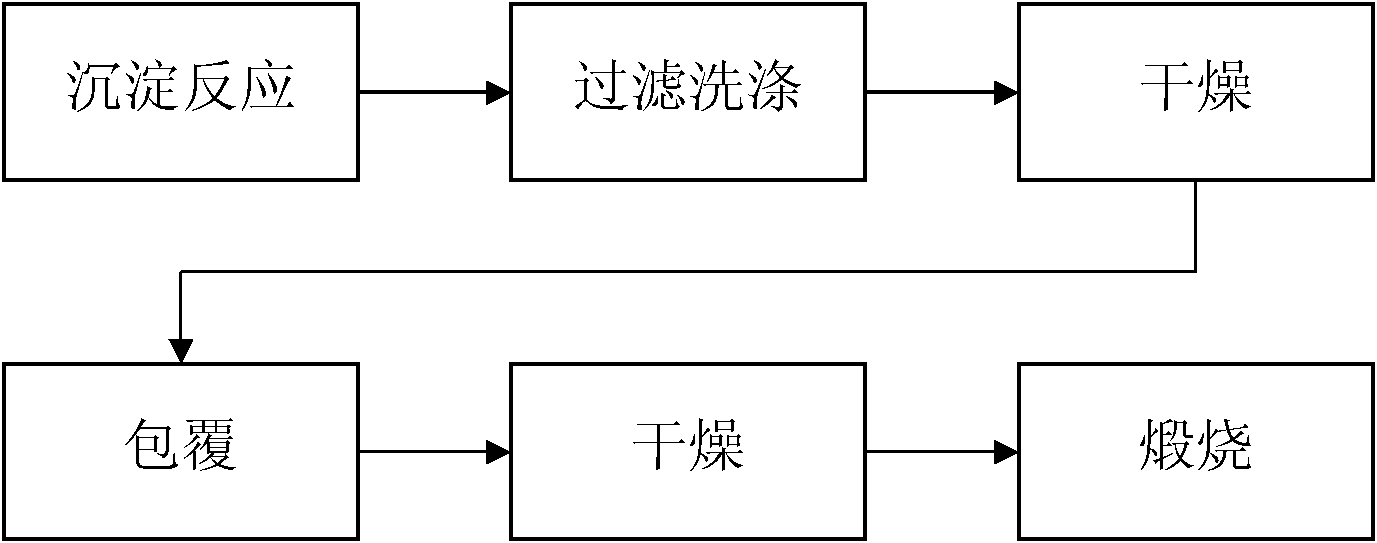

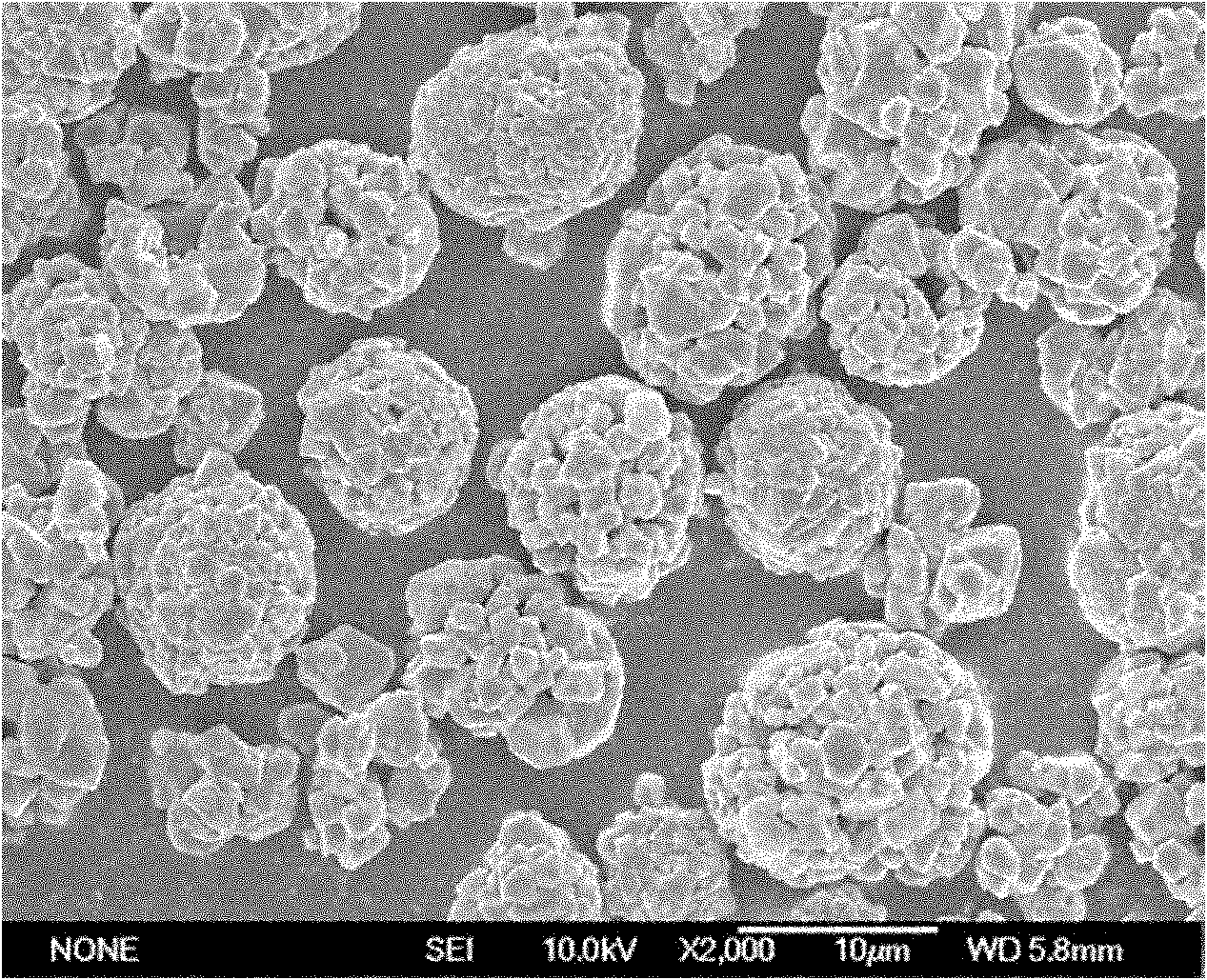

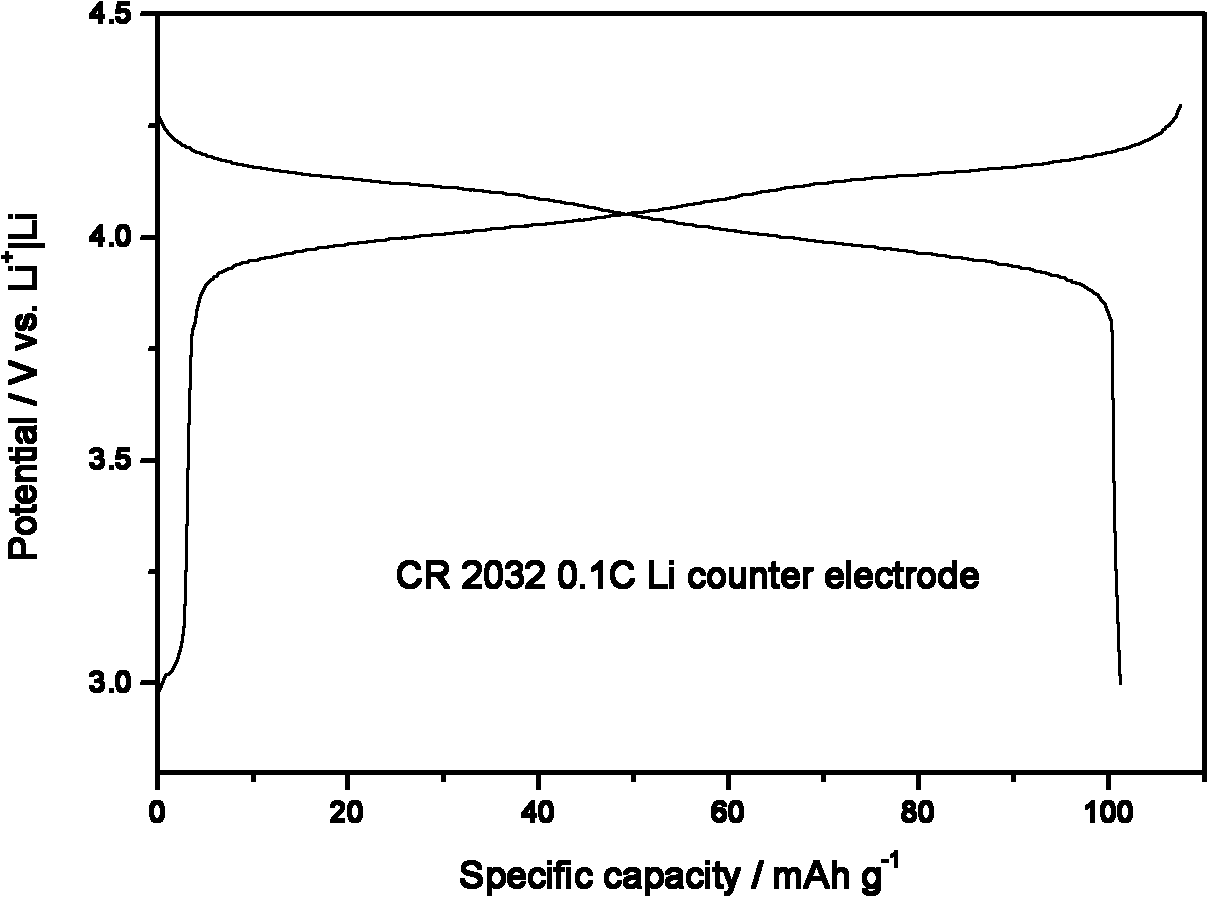

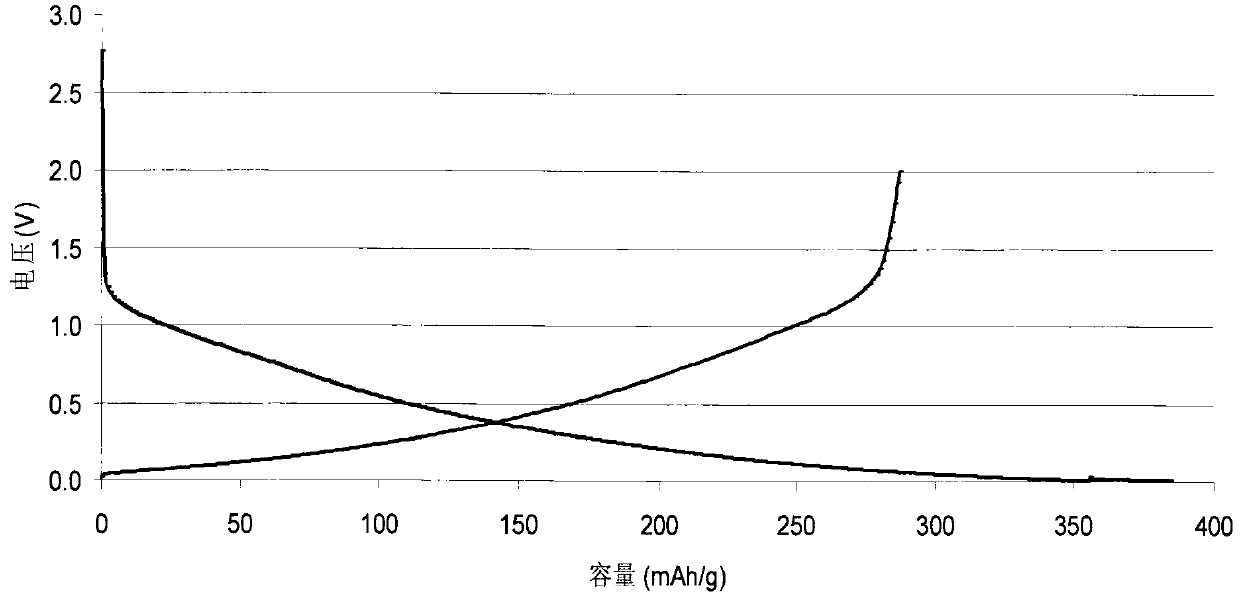

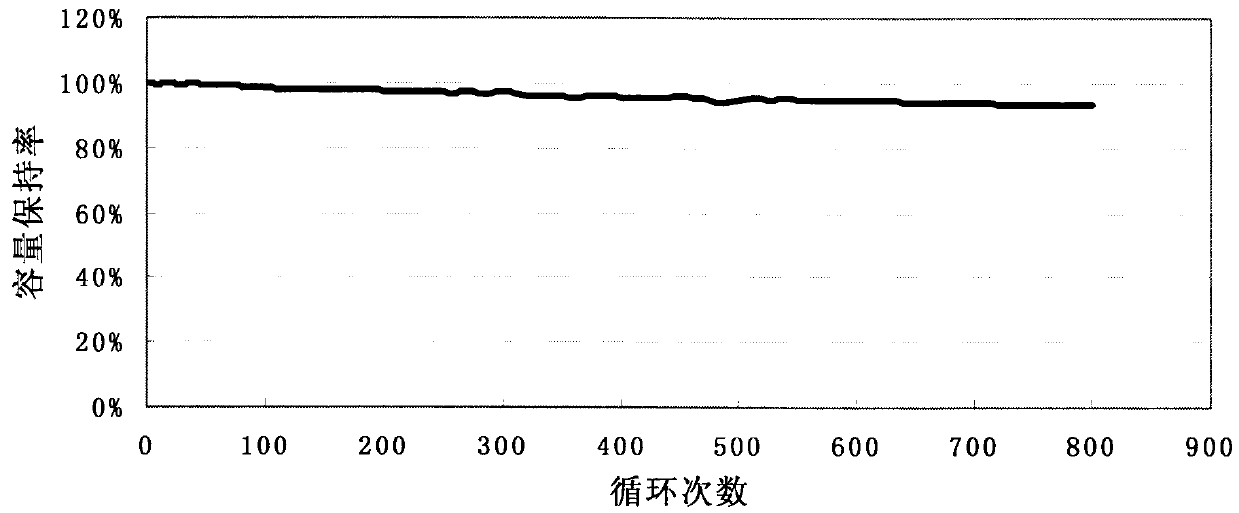

Method for preparing high-temperature lithium manganate material for lithium ion power battery

ActiveCN102074682AImprove Uniformity and ReliabilityExcellent overall performanceCell electrodesChemistrySolid matter

The invention provides a method for preparing a high-temperature lithium manganate material for a lithium ion power battery. The method comprises the following steps of: 1) preparing a bivalent manganese soluble salt, a doping element soluble salt and a precipitator serving as raw materials into aqueous solution, putting into a reaction kettle to fully react at the temperature of between 1 and 55DEG C and controlling the pH value of a reaction system to be between 8 and 12; 2) filtering after the reaction is finished, and washing a solid matter; 3) blowing to dry an obtained intermediate product at the temperature of between 90 and 150 DEG C; 4) adding a dispersing agent and a coating agent and coating in the reaction kettle; 5) filtering and drying to obtain a precursor; and 6) mixing the precursor and a lithium source according to a proportion, calcining in an oxidation atmosphere at the temperature of between 600 and 1,000 DEG C for 2 to 12 hours, crushing and sieving to obtain a product. The lithium manganate material prepared by the method has high high-temperature adaptability; and the capacity holding ratio exceeds 90 percent after the lithium manganate material is cycled at a high rate for 100 times at the temperature of 45 DEG C.

Owner:TIANJIN B&M SCI & TECH

High ductility climate resistant solder stick with tensile strength of 600MPa

ActiveCN1923431AGood atmospheric corrosion resistanceExcellent overall performanceWelding/cutting media/materialsSoldering mediaFerromanganeseDuctility

The invention relates to a high-flexibility welding bar whose tensile strength is 600MPa. Wherein, its components comprise that marble at 6-42;derbyshire spar at 16-22;ferrotitanium at 9-12;medium-carbon ferromanganese at 4-6; ferrosilicium at 1-3;synthetic mica at 1-3;micro silicon powder at 1-3;iron powder at 12-18;chrome metal at 1-2;copper powder at 0.5-1; nickel at 1-2;molybdenum at 0.3-0.8; and titanium white at 2-5. The inventive product has better corrosion resistance, with better low-temperature impact flexibility at -40Deg. C; and its yield strength is higher than 500MPa;tensile strength is higher than 600MPa; extensibility is higher than 20%;and (-40Deg. C) Akv>=60J.

Owner:BAOSHAN IRON & STEEL CO LTD +1

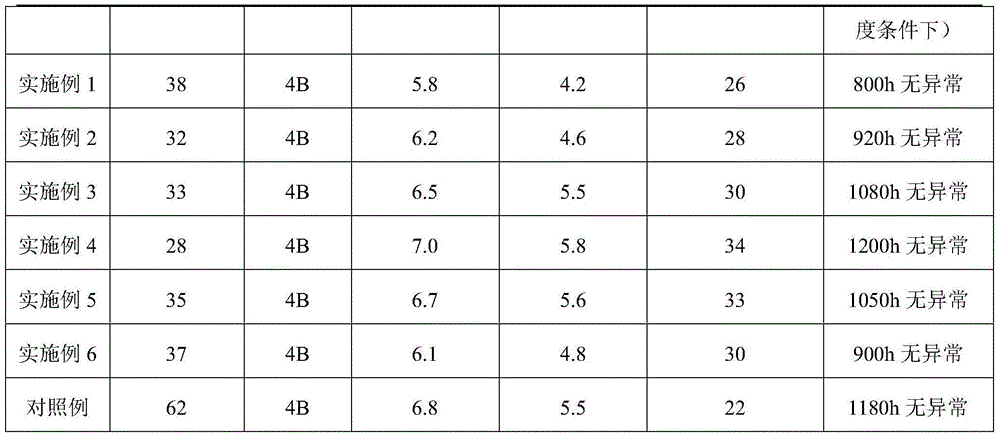

Anti-aging sealant and preparation method thereof

ActiveCN104356981AExcellent overall performanceGood sealing effectNon-macromolecular adhesive additivesOther chemical processesChemistryTriethanolamine

The invention discloses an anti-aging sealant and a preparation method thereof. The sealant comprises the following components in parts by weight: 20-30 parts of coumarone indene resin, 5-10 parts of polysulfide rubber, 5-10 parts of nitrile-butadiene rubber, 8-15 parts of tert-butyl phenol-formaldehyde resin, 3-7 parts of silicon dioxide, 2-6 parts of chlorosulfonated polyethylene, 2-7 parts of butyl acrylate, 1-5 parts of aluminum powder, 3-7 parts of sodium metasilicate, 2-8 parts of phosphate, 1-4 parts of triethanolamine, 1-5 parts of boron nitride, 0.5-2 parts of paraffin, 1-3 parts of 2,4-dihydroxy benzophenone and 0.8-3 parts of butyl p-hydroxy benzoate. The preparation method comprises the following steps: adding the components into a reaction kettle, uniformly mixing, heating to 120-140 DEG C under vacuum conditions, stirring to react for 120-180 minutes, and cooling to room temperature. The sealant disclosed by the invention has the advantages of favorable aging resistance and excellent adhesive property, and is more suitable for the field of solar energy.

Owner:邯郸市三泰胶业有限公司

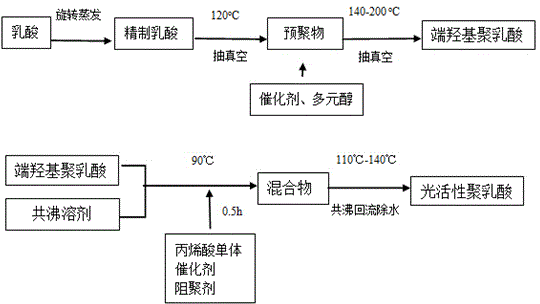

Photoactive polylactic acid acrylate degradation material

InactiveCN104004143AExpand the scope of applicationExcellent overall performanceInksOrganic non-macromolecular adhesivePrepolymerPhotoinitiator

The invention relates to a photoactive polylactic acid acrylate degradation material. Lactic acid and polyol are used as raw materials, and are processed through a melt polycondensation technology to prepare a hydroxyl-terminated polylactic acid prepolymer, and an acrylic acid monomer reacts with the hydroxyl-terminated polylactic acid prepolymer to prepare double bond-terminated photoactive polylactic acid acrylate. The molecular weight and the molecular structure of the photoactive polylactic acid acrylate can be adjusted by adjusting the kind and amount of polyol in order to improve the product performances. The prepared photoactive polylactic acid acrylate can be combined with an active diluent and a photoinitiator in order to realize crosslinking curing under UV irradiation, improve the thermal stability after curing and reduce the degradation rate. A one-step method is combined with a UV light curing technology in the invention, so a new approach is provided for the preparation of the photoactive polylactic acid acrylate degradation material, and a new direction is provided for the reasonable utilization of one-step synthesized low molecular weight polylactic acid.

Owner:HUBEI UNIV OF TECH

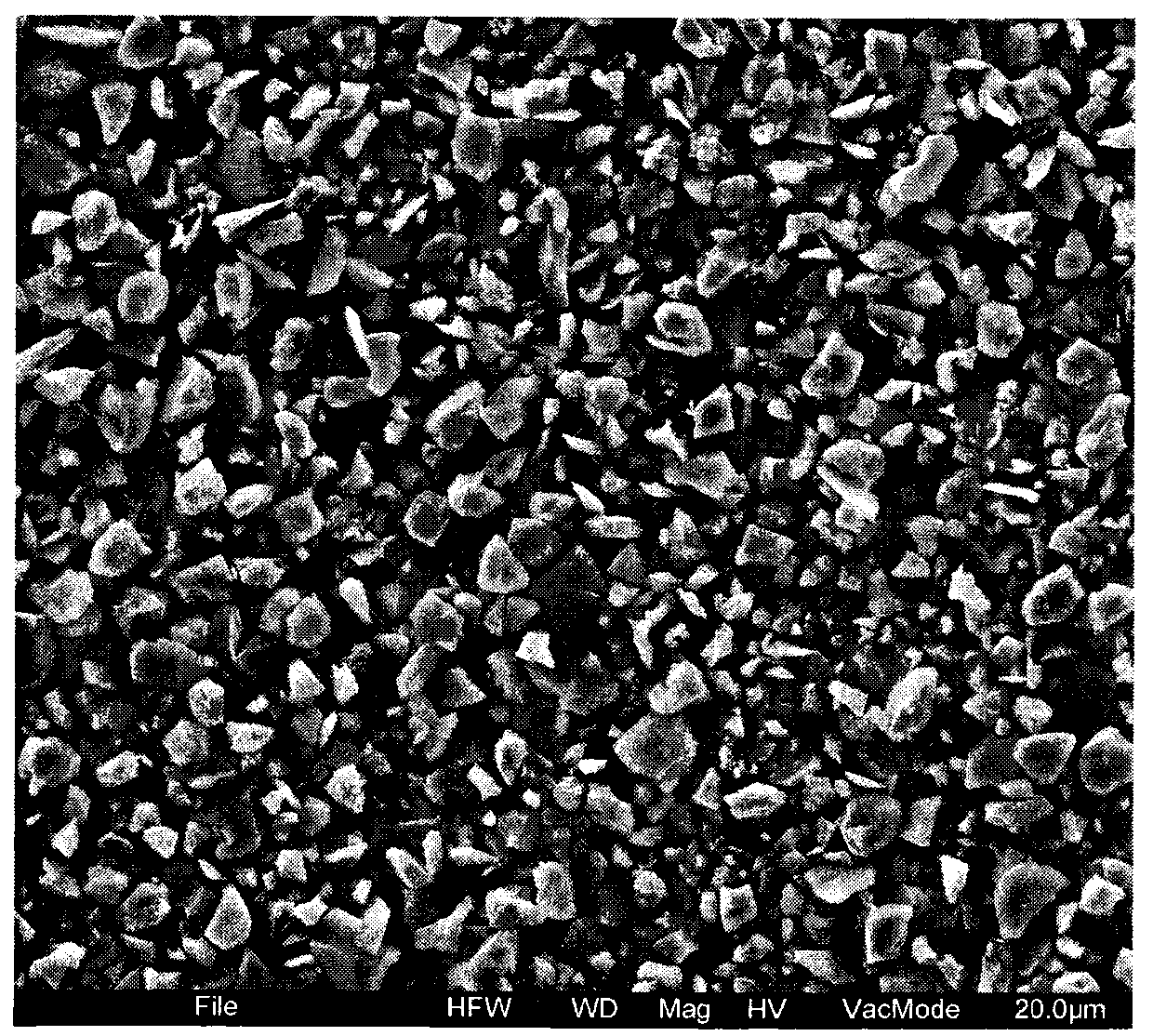

Surface-modified hard-carbon negative electrode material and preparation method thereof

ActiveCN103303896AImprove discharge capacityExcellent overall performanceElectrode manufacturing processesCarbon preparation/purificationAsphaltElectrolyte

The invention discloses a preparation method for a surface-modified hard-carbon negative electrode material. The preparation method comprises the following steps: (1) subjecting asphalt and a cross-linking agent to cross-linking polymerization and successively carrying out crushing and grading so as to obtain a hard-carbon precursor with a volume mean particle size D50 of 8 to 10 mu m; (2) coating a coating agent on the surface of the hard-carbon precursor; (3) carrying out carbonizing treatment; and (4) carrying out ball milling and grading. The invention further provides the surface-modified hard-carbon negative electrode material prepared by using the method. The surface-modified hard-carbon negative electrode material provided by the invention has high discharge capacity and initial charge and discharge efficiency, good heavy-current charge and discharge performance, good cycle performance, good security, good adaptability to an electrolyte and other additives and stable properties, and different batches of the prepared material barely show a difference. The preparation method provided by the invention has the advantages of easiness, feasibility, wide sources of raw materials and low cost.

Owner:SHANGHAI SHANSHAN TECH CO LTD +1

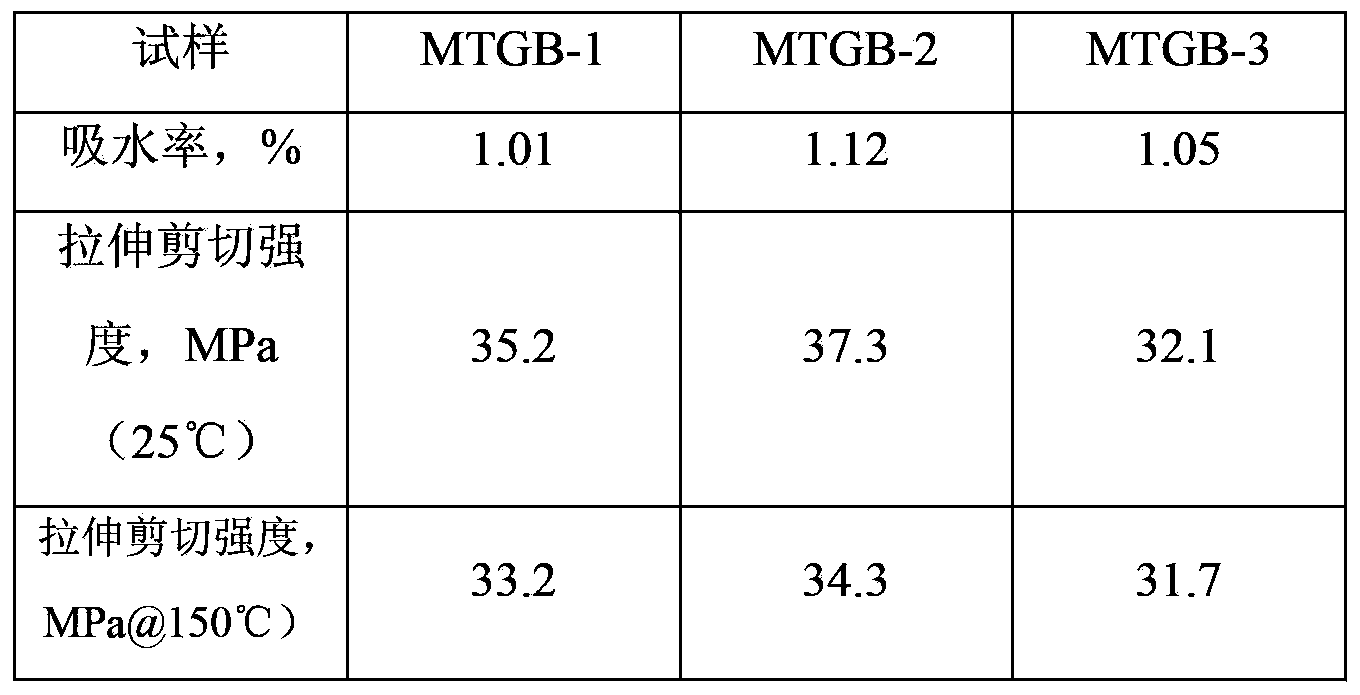

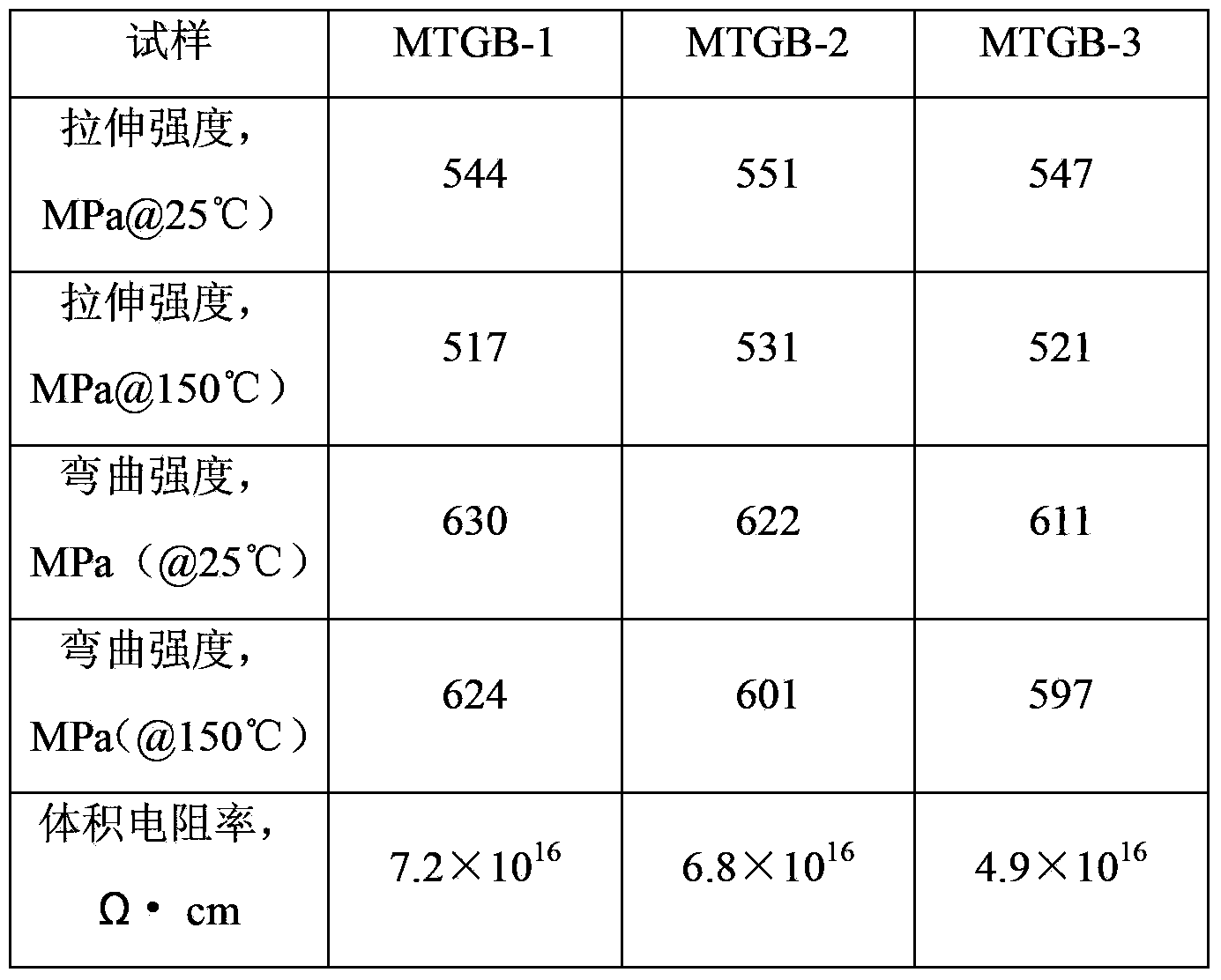

TGBAPOPP type matrix resin used for preparing advanced composite and preparation method of TGBAPOPP type matrix resin

The invention relates to TGBAPOPP type matrix resin used for preparing an advanced composite and a preparation method of the TGBAPOPP type matrix resin. The TGBAPOPP type matrix resin comprises N, N, N', N'-quadriglycidyl-2, 2-double[4-(4-amidogenphenoxy) phenyl]dimethylmethane, o-cresol-formaldehyde epoxy resin, 2, 2-double[4-(4-maleimidephenoxy) phenyl]dimethylmethane, N-isopropyl-N'-phenyl ursol, 2, 2, 4-trimethyl-1, 2-di-hydrogenationquinoline, curing agent and organic curing agent, wherein the mass ratio of all the components is 100: (50-100): (10-30): (2-5): (2-5): (60-100) : (500-900). The TGBAPOPP type matrix resin, disclosed by the invention, has excellent overall performance and excellent wettability to glass fiber, carbon fiber, basalt fiber and aramid fiber, can be used for preparing advanced composites with excellent overall performance, and has a broad application prospect.

Owner:DONGHUA UNIV +1

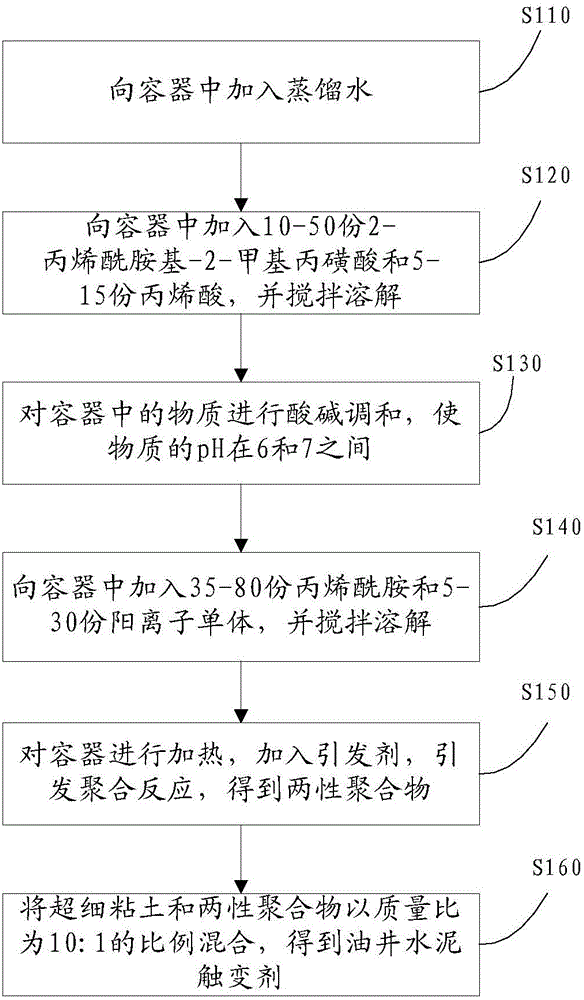

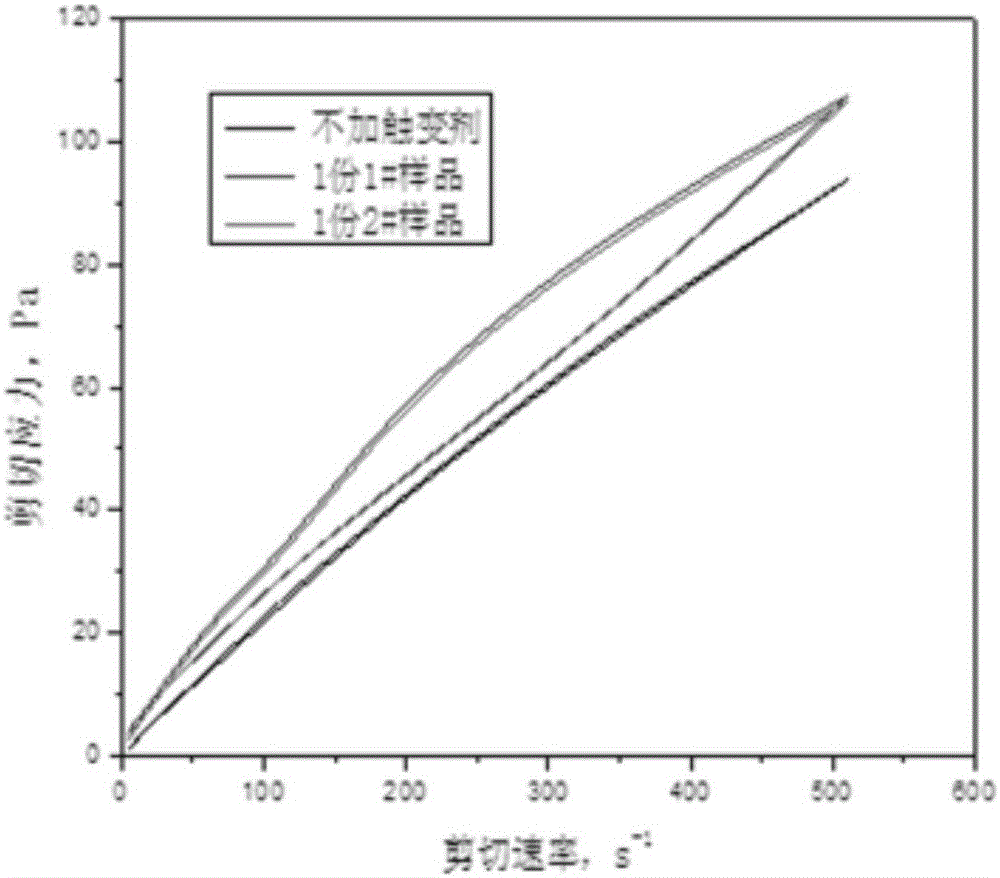

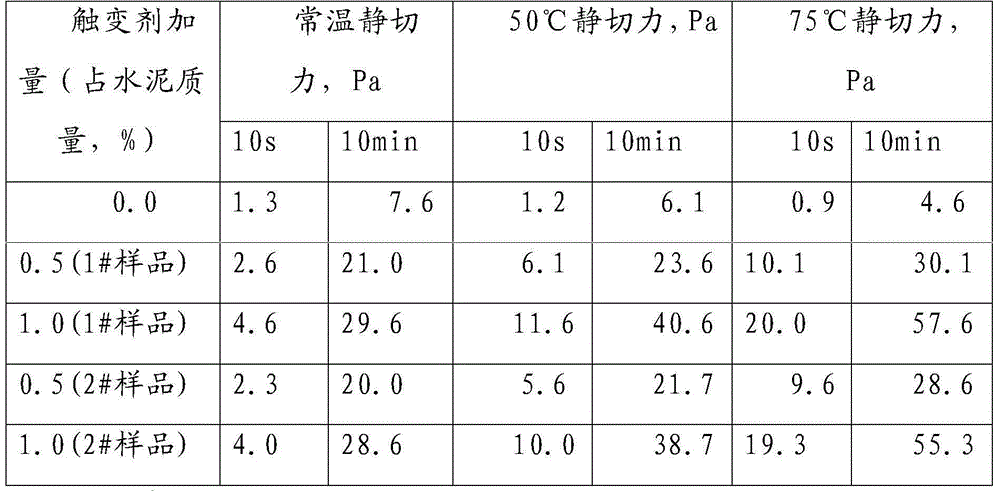

Oil well cement thixotropic agent and preparation method thereof

ActiveCN105018055AImprove thixotropyExcellent overall performanceDrilling compositionOil wellAcrylic acid

The invention relates to the technical field of oil well cement additives, and discloses an oil well cement thixotropic agent and a preparation method thereof. The method comprises the following steps: adding distilled water into a container; adding 10-50 parts of 2-acrylamido-2-methylpropanesulfonic acid and 5-15 parts of acrylic acid into the container, and dissolving by stirring; regulating the pH value of the substance in the container to 6-7; adding 35-80 parts of acrylamide and 5-30 parts of cationic monomer, and dissolving by stirring; heating the container, and adding an initiator to initiate the polymerization reaction to obtain an amphoteric polymer; and mixing superfine clay and the amphoteric polymer in a mass ratio of 10:1 to obtain the oil well cement thixotropic agent. The oil well cement thixotropic agent solves the technical problem of low thixotropy, low sensitivity to temperature and low comprehensive properties in the oil well cement thixotropic agent in the prior art, and better implements the technical effects of plugging the loss zone and preventing the fluid cross flow.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

High voltage direct current cable insulation material

InactiveCN103665525AGood physical propertiesExcellent overall performancePlastic/resin/waxes insulatorsPartial dischargePower flow

The invention provides a high voltage direct current cable insulation material, which comprises the following components in parts by weight: 100 parts of LDPE (Low-density Polyethylene), 1-2 parts of CPE (Chlorinated Polyethylene), 0.5-1.5 parts of BaTiO3, 0.6-1.5 parts of conductive potassium titanate whisker, 1-2.5 parts of a cross-linking agent, and 0.1-0.5 part of an antioxygen. A semiconductive polyolefin shielding material prepared from the high voltage direct current cable insulation material has the advantages of ultra-smooth surface feature, good physical property and excellent overall performance; electric current is effectively output to form a favorable uniform electric field, and partial discharge or insulation breakdown caused by severe electric field concentration due to surface defects of a semiconductive shielding layer is prevented; ionized charge and injected charge are absorbed in a deep trap, so that charge accumulating in a local area is avoided, space charge accumulation in a cable insulation material is restrained, and electrical conductivity of the cable insulation material is reduced.

Owner:WUXI JIANGNAN CABLE

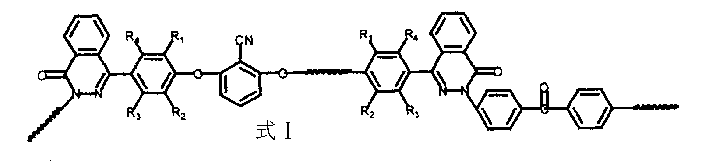

Polyether nitrile ketone containing phthalazine biphenyl structure and its preparation method

A polyarylether nitrileone containing diazanaphthalenone dibenzene structure is prepared from dihalophenyl methylnitrile, biphenol containing diazanaphthalenone bibenzene structure and dihalodiphenyl ketone through high-temp polymerizing in non-protonic polar solvent under existance of catalyst which is the salt of alkali metal or alkali-earth metal. Its advantages are high molecular weight, high toughness and strength, high resistance to high temp, and excellent electric performance.

Owner:DALIAN UNIV OF TECH +1

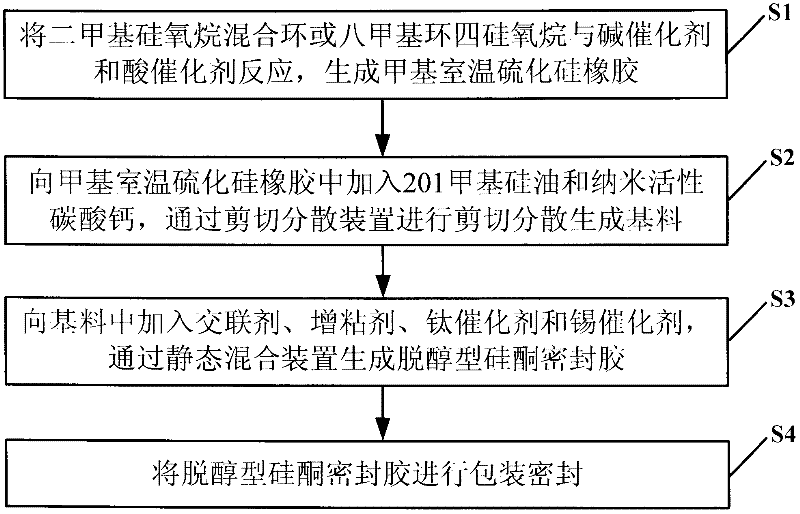

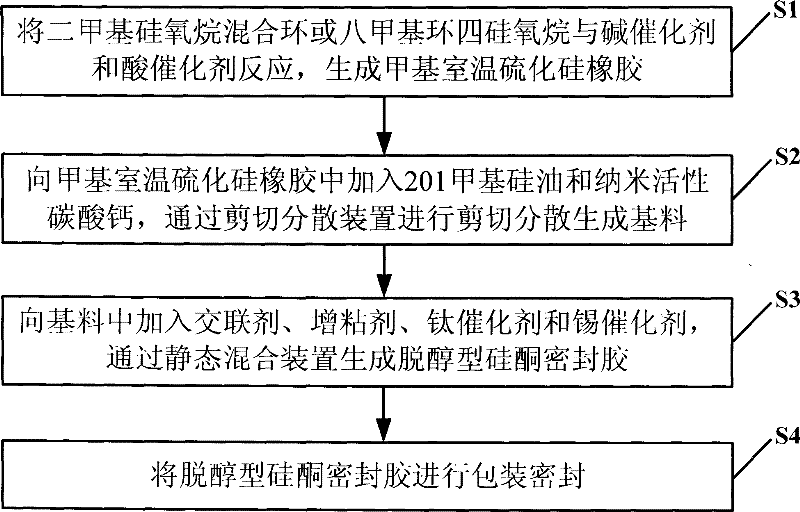

Dealcoholization type silicone sealant and production method thereof

ActiveCN102643626AGood storage stabilityExcellent overall performanceNon-macromolecular adhesive additivesOther chemical processesChemistryAdhesive cement

The invention provides a dealcoholization type silicone sealant which comprises the following components by mass percent: 48-51% of dimethyl siloxane hybrid ring or octamethyl cyclotetrasiloxane, 3-5% of 201 methyl silicone oil, 38-40% of nano active calcium carbonate, 5-5.5% of pigment, 3.5-4.5% of cross-linking agent, 1-1.2% of thickening agent, 1.3-2% of titanium catalyst and 0.1-0.15% of tin catalyst. The invention also provides the production method of the dealcoholization type silicone sealant. The dealcoholization type silicone sealant and the production method thereof are suitable for continuous production; the produced adhesive cement is excellent in performance, good in storage stability and superior in combination property; furthermore, the product quality is improved, the loss is reduced, the energy is saved and the work environment of workers is improved.

Owner:锋泾(中国)建材集团有限公司

Production method of 350 MPa grade cold rolled magnetic pole steel

InactiveCN1904114ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionUltimate tensile strength

This invention relates to a process of producing 350MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot

Owner:WUHAN IRON & STEEL (GROUP) CORP

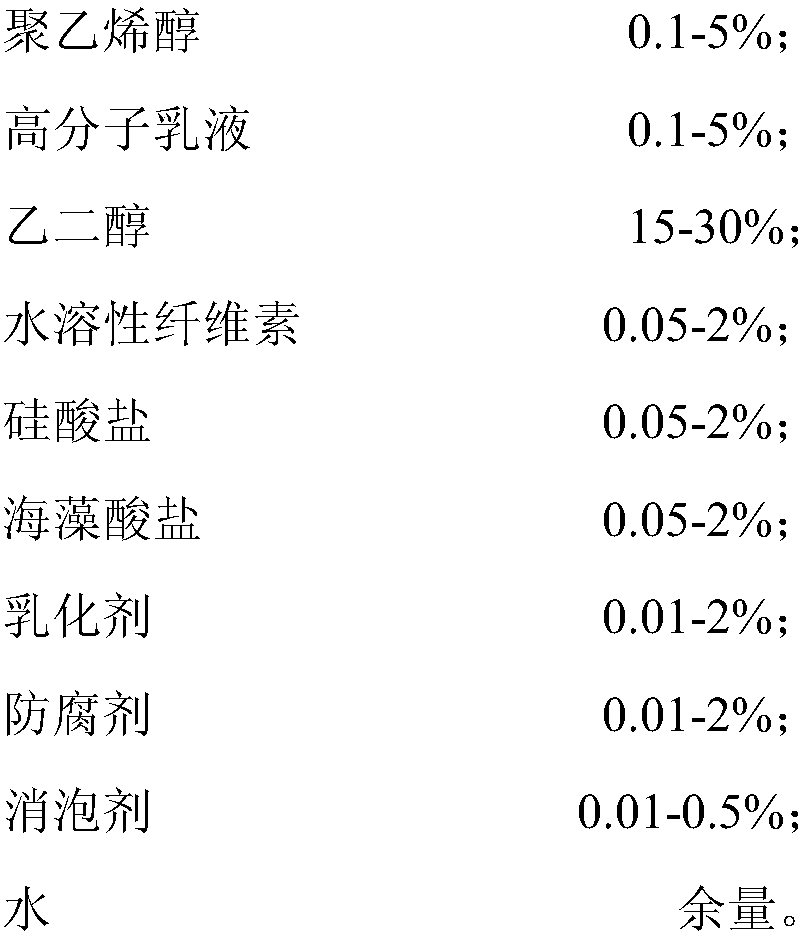

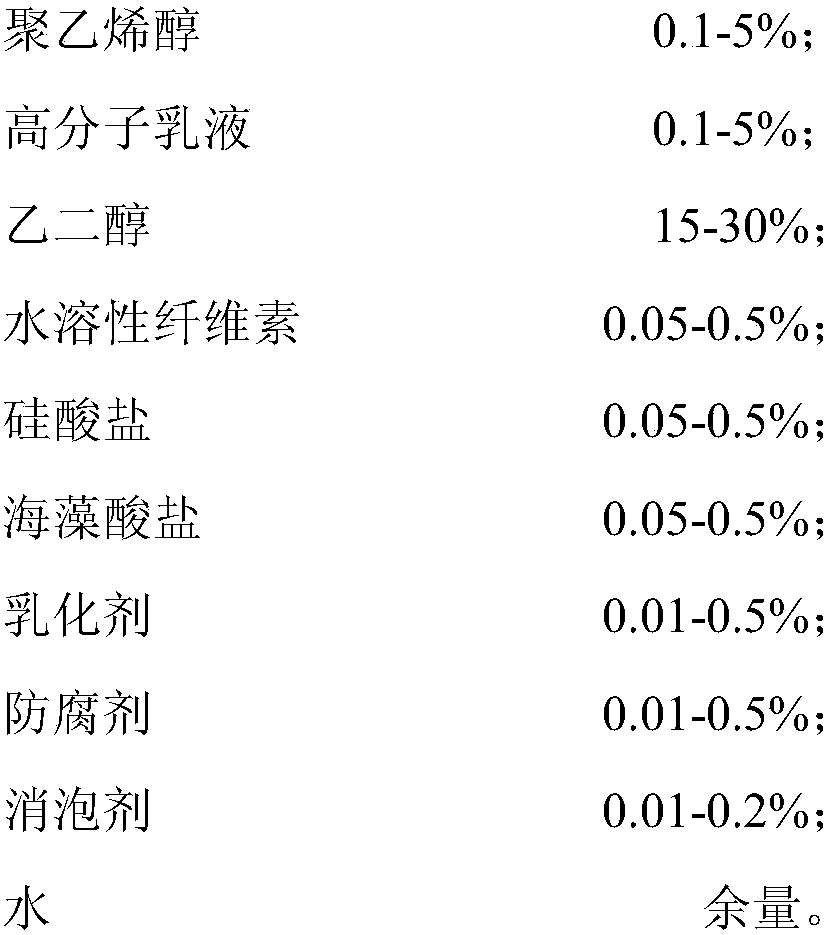

Road dust suppressant as well as preparation method and application thereof

InactiveCN108587568AExcellent overall performanceGood dust suppression effectOther chemical processesChemistryEmulsion

The present invention discloses a road dust suppressant as well as a preparation method and application thereof, and belongs to the field of environmental protection for flying dust prevention and control. The present invention provides a novel road dust suppressant, which comprises the following components in percentage by weight: 0.1-5% of polyvinyl alcohol, 0.1-5% of high-molecular emulsion, 15-30% of ethylene glycol, 0.05-2% of water-soluble cellulose, 0.05-2% of silicate, 0.05-2% of alginate, 0.01-2% of emulsifier, 0.01-2% of preservative, 0.01-0.5% of defoamer and the balance of water. The road dust suppressant of the present invention, with particular components in particular proportions, can meet the standard requirements in tests on physical and chemical indexes and properties, and is safe, environmentally friendly, and very suitable for the control of flying dust pollution of roads such as urban roads, construction roads and the like. Thus, an effective solution is provided for improving the atmospheric environment and reducing the haze pollution.

Owner:BEIJING RUI HONGXING TECH CO LTD

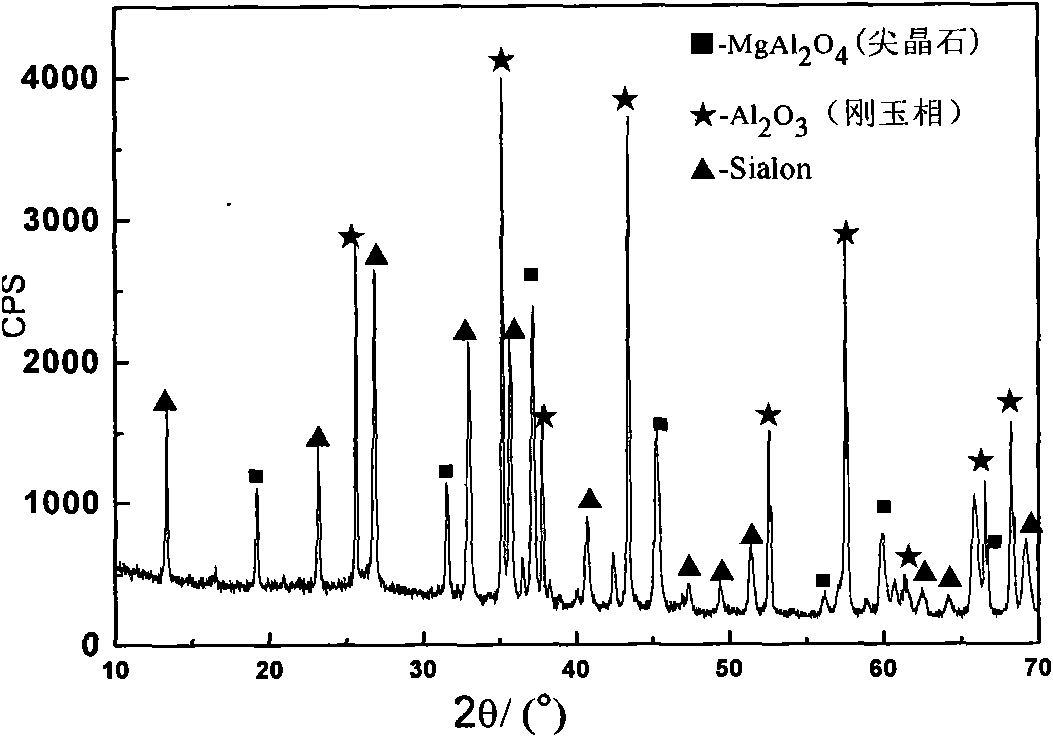

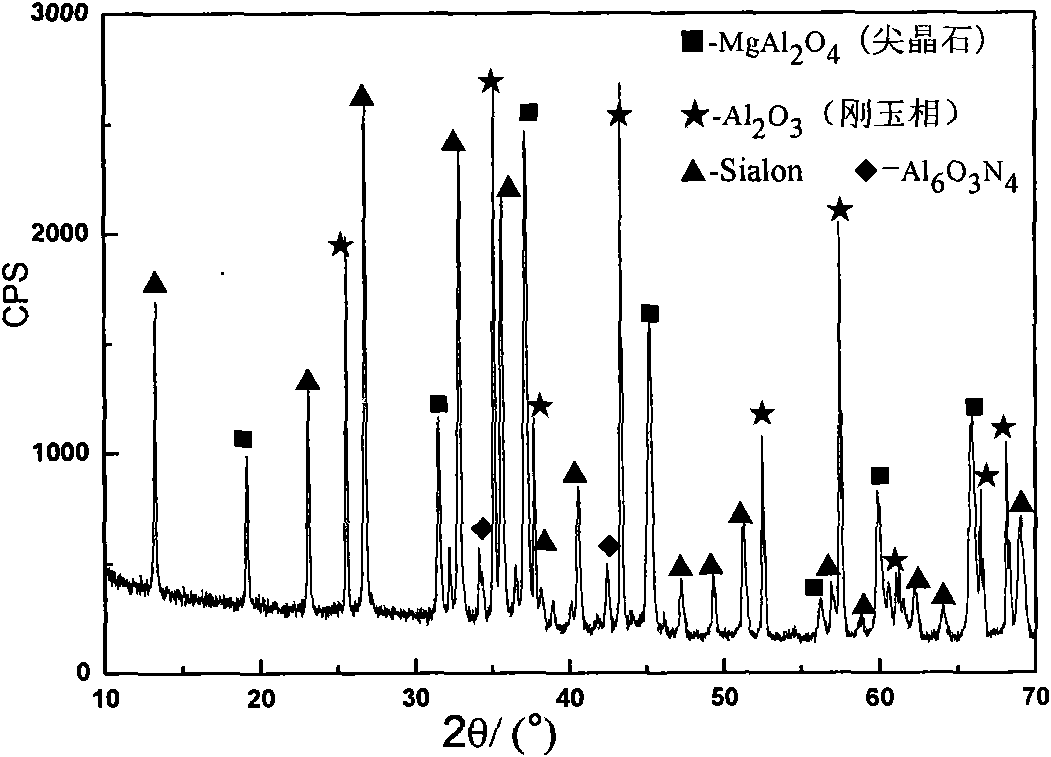

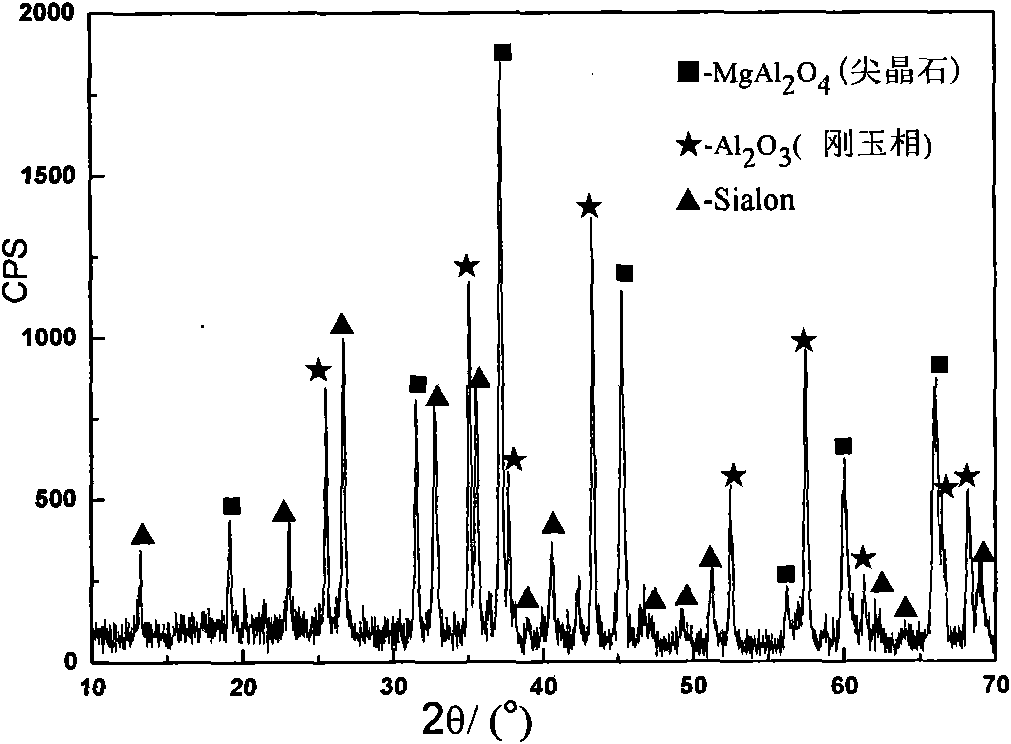

Magnesium aluminum spinel-corundum-Sialon complex phase high-temperature resistant material and preparation method thereof

The invention relates to a magnesium aluminum spinel-corundum-Sialon complex phase high-temperature resistant material and a preparation method thereof, belonging to the technical field of high-temperature resistant material. The main raw materials of the complex phase high-temperature resistant material contain high-aluminum fly ash, aluminum ash and magnesite. The main raw materials are mixed according to the following percentages: 0.1% to 90% of high-aluminum fly ash, 0.1% to 99% of aluminum ash and 0.1% to 40% of magnesite. The metallic aluminum in the aluminum fly ash is used as reducingagent. The magnesium aluminum spinel-corundum-Sialon complex phase high-temperature resistant material is acquired by adding binding material for forming after ball milling and mixing with dry methodand then performing aluminothermic reduction reaction under nitrogen atmosphere at 1350 DEG C to 1700 DEG C. The prepared complex phase high-temperature resistant material of the invention has the advantages of heat-resistant property, spalling resistance property and scour erosion-resisting property. The invention can efficiently lower the cost of magnesium aluminum spinel-corundum-Sialon complexphase high-temperature resistant material and find a new way to comprehensively use high-aluminum fly ash, aluminum ash and magnesite.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Production method of 250 MPa grade cold rolled magnetic pole steel

InactiveCN1904113ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionMetallurgy

This invention relates to a process of producing 250MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot rolling steps: the start rolling temperature 1050-1100DEG C,end rolling temperature 840-880DEG C,cooling to 640-700DEG C for coiling. (3)cooling to 70DEG C below for acid picking. (4)cold rolling steps; (5) bell furnace anneal; controlling temperature 660-680DEG C (6) temper rolling, then the products. Account to weight the main chemical composition is: C 0.03-0.09%,Si 0.10-0.30%,Mn 0.30-0.70%,Nb 0.015-0.025 %,Als 0.01-0.07%,P <=0.025%,S <=0.010%, Fe the rest.

Owner:WUHAN IRON & STEEL (GROUP) CORP

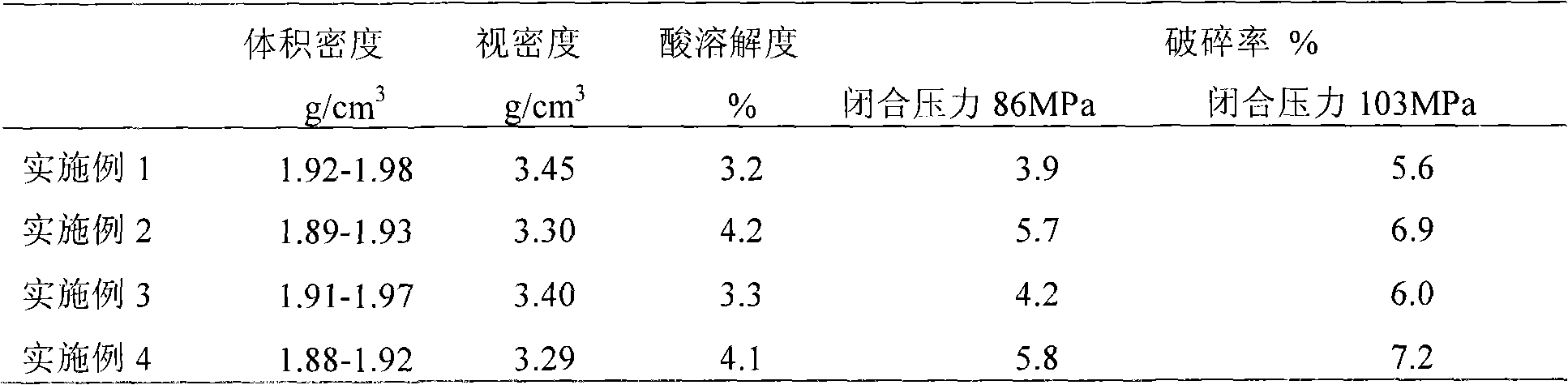

High-density ultra-strength petroleum compression fracture proppant and preparation method thereof

InactiveCN101580706AExcellent overall performanceIncrease oil productionFluid removalPetroleumOil well

The invention relates to a high-density ultra-strength petroleum compression fracture proppant and a preparation method thereof. The petroleum compression fracture proppant is prepared from waste alumina adsorbent taken as a main raw material and small amount of sintering aid and ceramic clay by milling, pelletizing and sintering. The petroleum compression fracture proppant prepared from the waste alumina adsorbent replacing industrial alumina has the characteristics of high density, ultra strength and acid resistance, has the volume concentration between 1.88 and 1.98, the apparent density between 3.20 and 3.50, the percentage of damage under 86MPa of closing pressure between 2.60 and 3.90 percent, the percentage of damage under 103MPa of closing pressure between 4.60 and 8.4 percent and the acid resistance between 3.40 and 5.20 percent, has excellent comprehensive performance, and can be used for petroleum compression fracture of deep oil wells.

Owner:JINGANG NEW MATERIALS

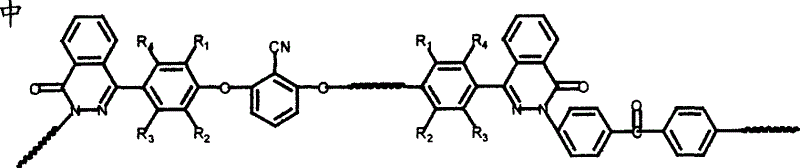

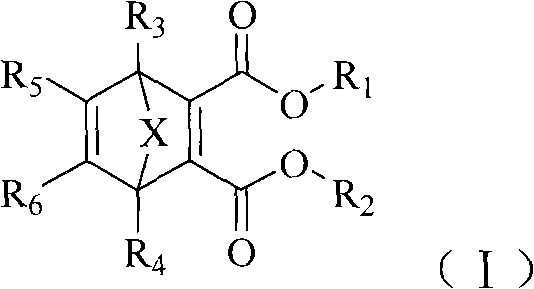

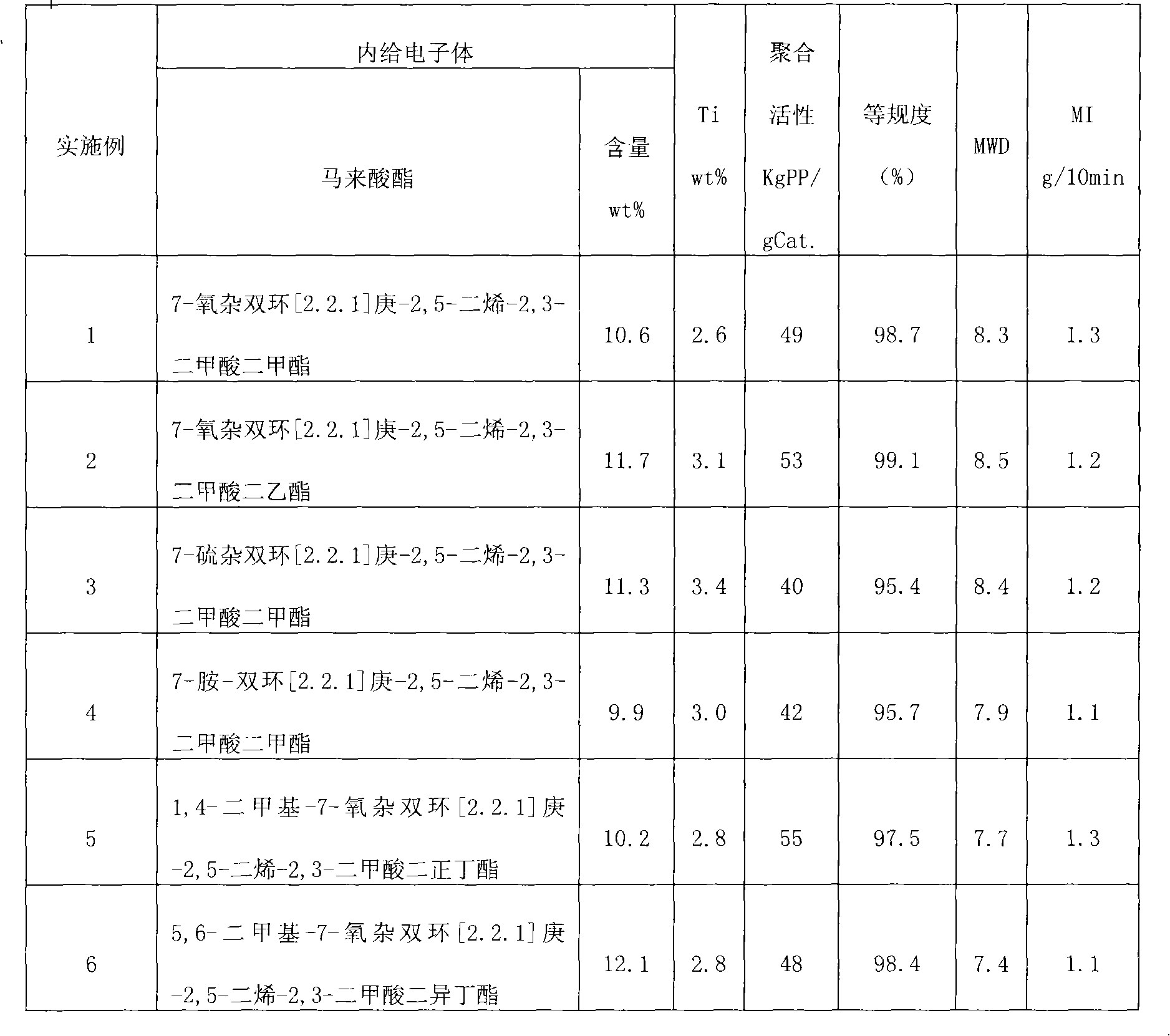

Ziegler-Natta catalyst

The invention discloses a Ziegler-Natta catalyst, which concretely comprises the following components of: (a) 10-25% of magnesium by weight, 1-10% of titanium by weight, 40-60% of halogen by weight and 1-30% of catalyst component of at least one maleic acid ester selected from the general formula (I) by weight; (b) alkyl aluminum compounds; and (c) optionally, an external electron donor. Because a maleic acid ester compound with a special structure is adopted to be the external electron donor, the catalyst with excellent combination property is obtained, when the catalyst is used for propylene copolymerization, satisfactory copolymerization yield can be obtained, and the polymer has higher stereospecificity.

Owner:PETROCHINA CO LTD

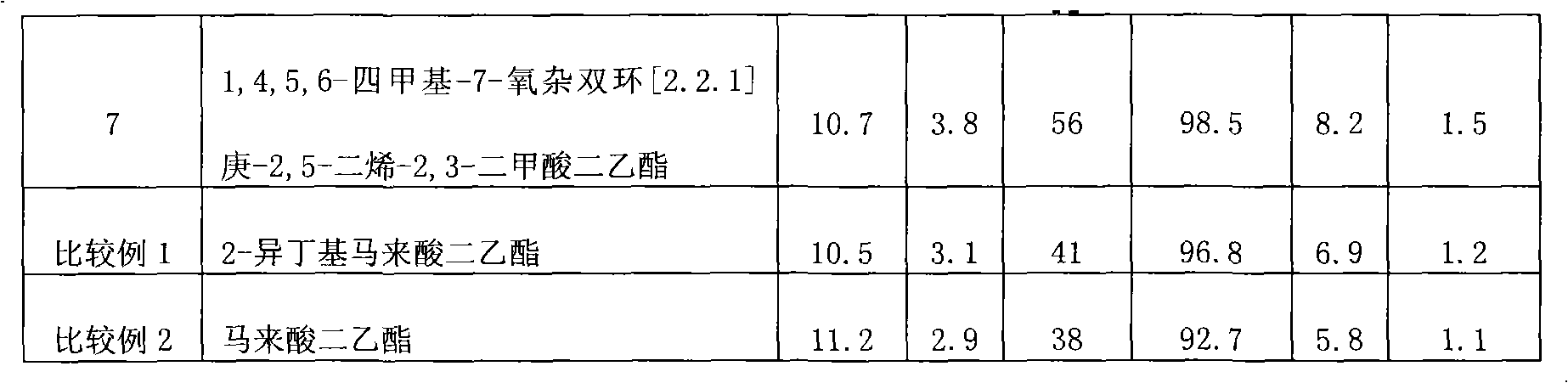

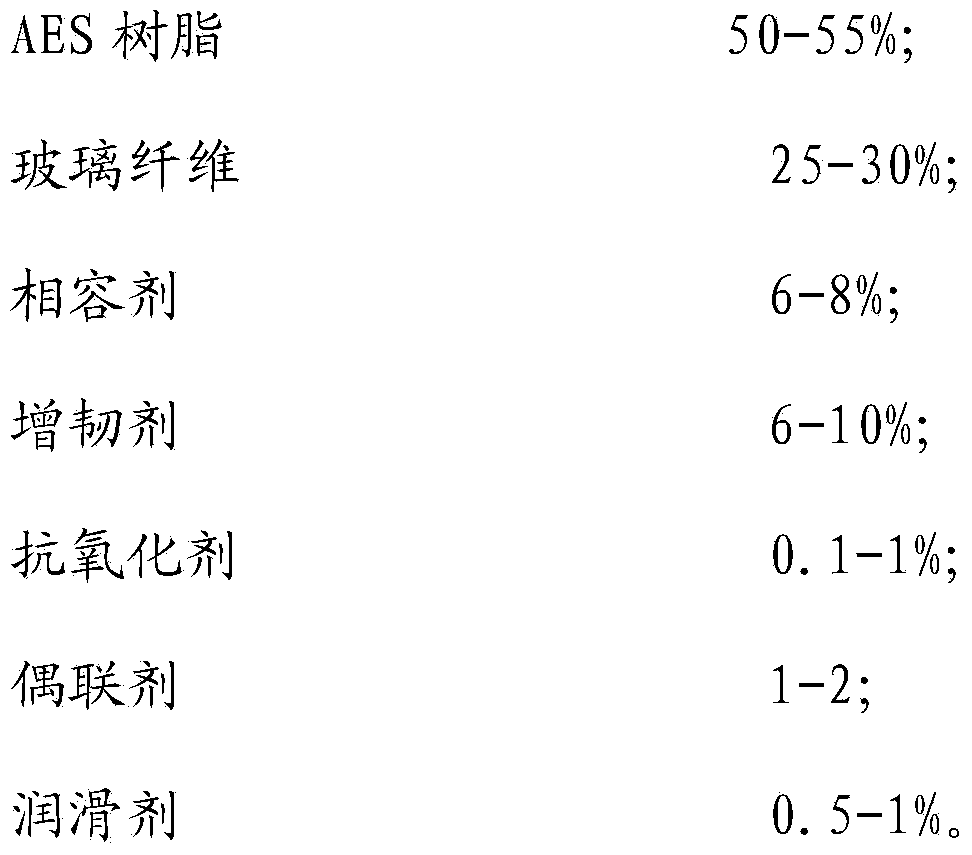

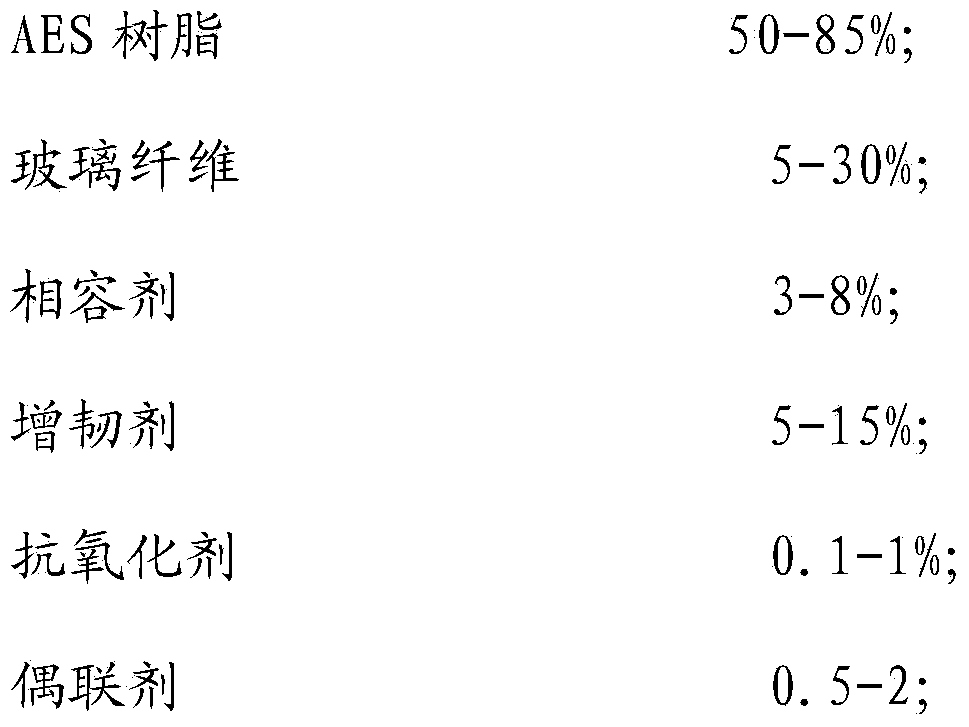

Glass fiber reinforced AES composite material and preparation method thereof

InactiveCN103740027AExcellent overall performanceHigh strengthHeat deflection temperatureAntioxidant

The invention discloses a glass fiber reinforced AES composite material and a preparation method thereof. The glass fiber reinforced AES composite material comprises the following ingredients by weight percent: 50-85% of AES resin, 5-30% of glass fiber, 3-8% of a compatilizer, 5-15% of a flexibilizer, 0.1-1% of an antioxidant, 0.5-2% of a coupling agent, and 0.5-1% of a lubricating agent. The glass fiber reinforced AES composite material has excellent overall performance, high strength, preferable rigidity, high-temperature resistance, preferable forming property and stable size; by adding the glass fiber, the heat deflection temperature of the composite material can be improved, the coefficient of linear expansion and the molding shrinkage of the material can be reduced, and therefore the application field of the AES material is expanded.

Owner:ANHUI KEJU NEW MATERIALS

Method for preparing nanometer ceramic particle dispersion enhancing copper-based composite material through multi-step ball milling and multi-step gas phase reduction

ActiveCN109136615AExcellent overall performanceReasonable control processCeramic particleCopper matrix

The invention discloses a method for preparing a nanometer ceramic particle dispersion enhancing copper-based composite material through multi-step ball milling and multi-step gas phase reduction. Dispersed distribution of nanometer ceramic particles in an ultrafine grain copper matrix can be realized by a multi-step ball milling and multi-step gas phase reduction as well as discharging plasma sintering technology combined mode and a reasonable control process. The method is a brand new copper-based composite material preparation method; the problem that uniform dispersion of a nanometer enhancing phase in the matrix cannot be realized effectively in the process of directly adding nanometer enhancing phase particles and mixing with copper powder can be solved; the ceramic particle dispersion enhancing copper-based composite material with excellent mechanical property and high electric conductivity can be obtained.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com