Magnesium aluminum spinel-corundum-Sialon complex phase high-temperature resistant material and preparation method thereof

A magnesia-aluminum spinel and high-temperature-resistant technology, which is applied in the field of refractory materials, can solve the problems of secondary waste with low added value, and achieve the effect of excellent comprehensive performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

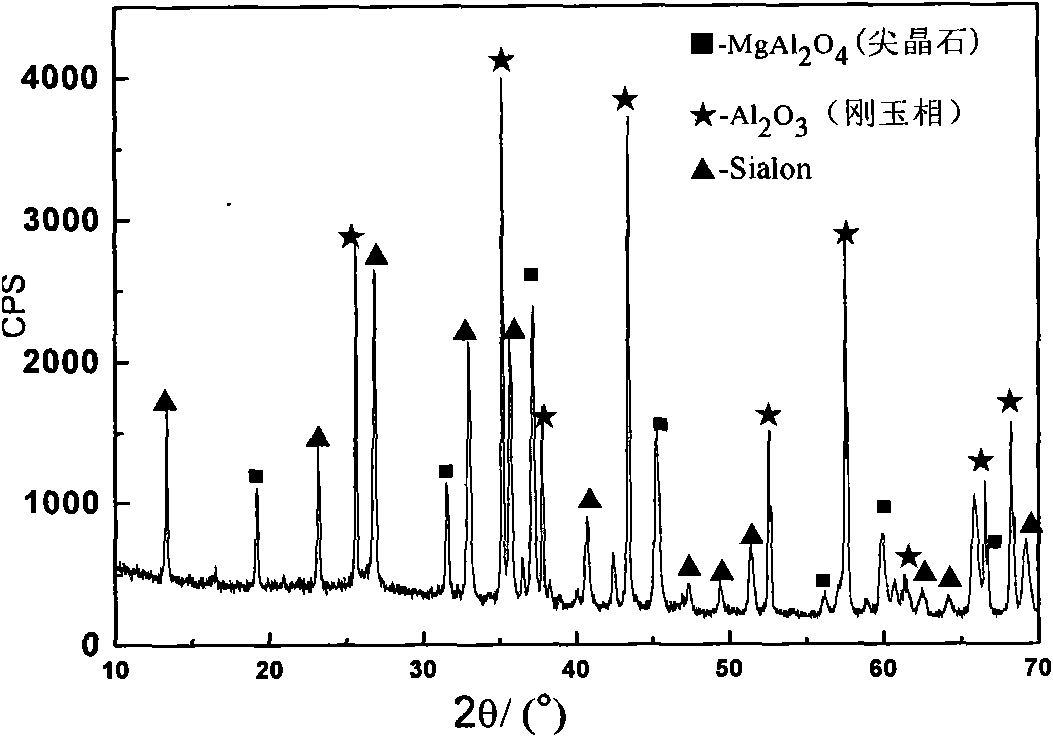

Embodiment 1

[0022] raw material:

[0023] The chemical composition of fly ash from a power plant in Shanxi is (w): Al 2 o 3 40.37%, SiO 2 52.45%, Fe 2 o 3 2.36%, CaO 0.75%, MgO 0.54%, loss on ignition 1.56%, other 1.97%, the amount added accounts for 40% of the total mass fraction of ingredients;

[0024] The chemical composition of aluminum ash from an aluminum plant in Shanghai is (w): Al 2 o 3 18.02%, AlN 14.13%, Al 28.62%, MgO7.1%, SiO 2 5.9%, Fe 2 o 3 4.0%, CaO 2.8%, Na 2 O 2.6%, TiO 2 1.6%, loss on ignition 12.8%, other 2.43%, the added amount accounts for 55% of the total ingredients mass fraction;

[0025] The chemical composition of magnesite produced in Liaoning is (w): MgO 44.66%, Al 2 o 3 0.33%, SiO 2 1.35%, CaO1.52%, Fe 2 o 3 0.51%, loss on ignition 50.40%, and the addition accounts for 5% of the total batching mass fraction.

[0026] Raw material pretreatment:

[0027] The above-mentioned raw materials are finely ground through a 200-mesh sieve by...

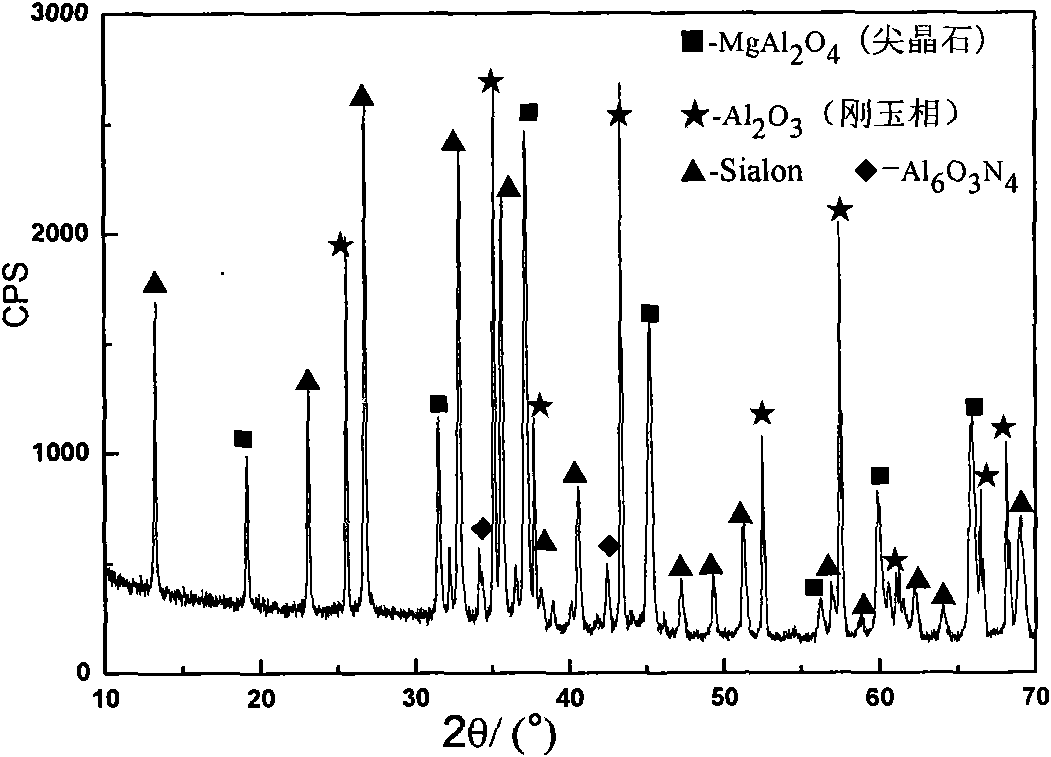

Embodiment 2

[0036] raw material:

[0037] Fly ash from a power plant in Beijing, its chemical composition (w): SiO 2 54.30%, Al 2 o 3 35.40%, Fe 2 o 3 1.50%, CaO 1.80%, MgO 0.70%, loss on ignition 4.30%, other 2.0%, the amount added accounts for 38% of the total mass fraction of ingredients;

[0038] The chemical composition of aluminum ash from an aluminum plant in Hebei is (w): Al 2 o 3 21.05%, AlN 11.03%, Al 29.55%, MgO12.5%, SiO 2 5.0%, Fe 2 o 3 3.8%, CaO 3.4%, Na 2 O 1.6%, TiO 2 1.2%, loss on ignition 8.77%, other 2.10%, accounting for 52% of the total mass fraction of ingredients;

[0039] The chemical composition of magnesite produced in Liaoning is (w): MgO 44.66%, Al 2 o 3 0.33%, SiO 2 1.35%, CaO1.52%, Fe 2 o 3 0.51%, loss on ignition 50.40%, and the addition accounts for 10% of the total batching mass fraction.

[0040] Raw material pretreatment:

[0041] The above-mentioned raw materials are finely ground through a 200-mesh sieve by vibrating mill, s...

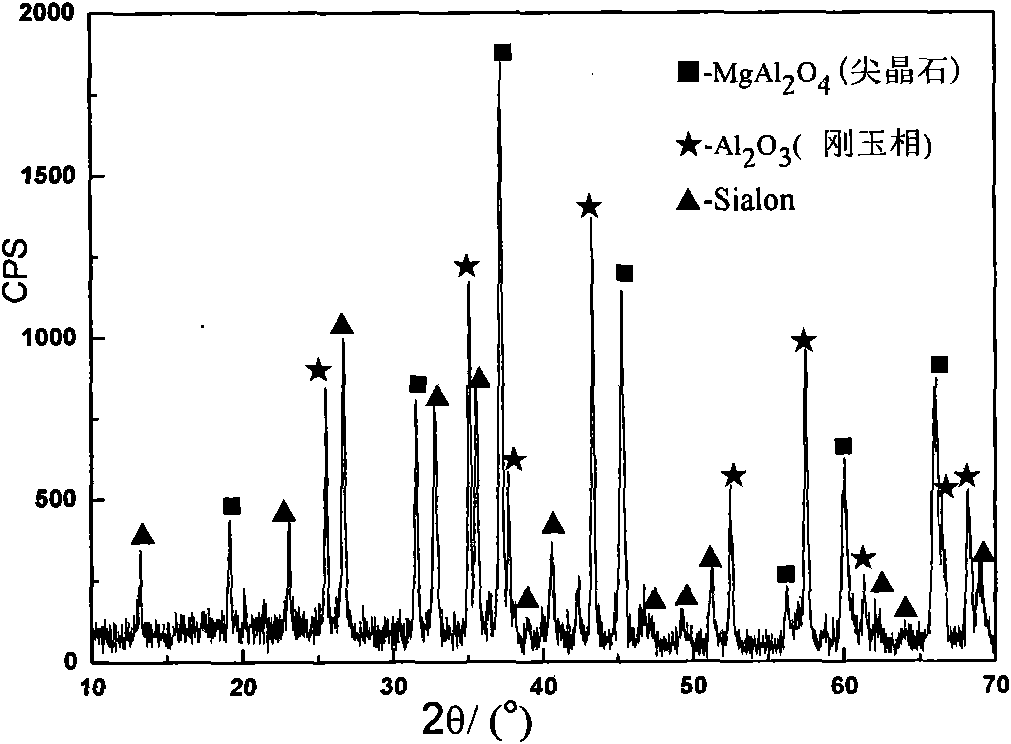

Embodiment 3

[0050] raw material:

[0051] The chemical composition of fly ash from a power plant in Shanxi is (w): Al 2 o 3 40.37%, SiO 2 52.45%, Fe 2 o 3 2.36%, CaO 0.75%, MgO 0.54%, loss on ignition 1.56%, other 1.97%, the added amount accounts for 41% of the total mass fraction of ingredients;

[0052] The chemical composition of aluminum ash from an aluminum plant in Hebei is (w): Al 2 o 3 21.05%, AlN 11.03%, Al 29.55%, MgO12.5%, SiO 2 5.0%, Fe 2 o 3 3.8%, CaO 3.4%, Na2 O 1.6%, TiO 2 1.2%, loss on ignition 8.77%, other 2.10%, aluminum ash accounts for 59% of the total batching mass fraction.

[0053] The chemical composition of magnesite produced in Liaoning is (w): MgO 44.66%, Al 2 o 3 0.33%, SiO 2 1.35%, CaO1.52%, Fe 2 o 3 0.51%, loss on ignition 50.40%, and the addition accounts for 5% of the total batching mass fraction.

[0054] Raw material pretreatment:

[0055] The above-mentioned raw materials are finely ground through a 200-mesh sieve by vibrating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com