High-property polyhydroxyalkanoates (PHAs)/polybutylene succinate (PBS)/poly lactic acid (PLA) blend alloy

A high-performance, mixed-gold technology, applied in the field of materials, can solve the problems of low rigidity, poor toughness, and unsatisfactory mechanical properties, and achieve the effect of excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 50 parts of P3HB4HB (4HB molar content is 15%, weight average molecular weight is 1.2 million), 8.5 parts of PBS (molecular weight is 180,000), 40 parts of PLA (molecular weight is 250,000), 0.6 part of anti- Oxidizing agent tetrakis [methyl-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.2 parts of paraffin wax, 0.5 parts of heat stabilizer zinc stearate and 0.2 parts of chain extender Weigh it in proportion and mix it in a high-speed mixer for 3 minutes, then pump the mixed material into a 50°C drying oven for 4 hours, and finally put it into a twin-screw extruder for extrusion to obtain a blended alloy material.

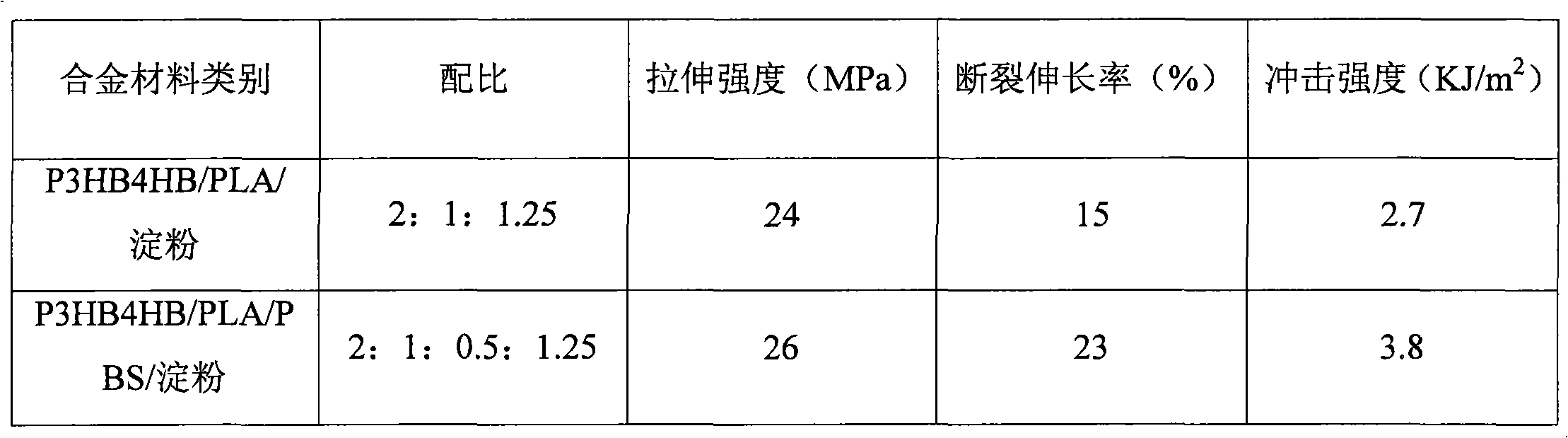

[0021] Under the same process, the mechanical properties of P3HB4HB / PBS / PLA alloy and P3HB4HB / PLA alloy are compared in Table 1.

[0022] Table 1

[0023] Alloy material category

Embodiment 2

[0025] Mix 64 parts of PHBV (HV molar content is 5%, molecular weight is 1.6 million) with 24 parts of PLA (molecular weight is 250,000), 10.1 parts of PBS (molecular weight is 180,000), 0.8 parts of antioxidant 3,5-di Tert-butyl-4-hydroxyphenyl propionate octadecanol ester, 0.5 part of lubricant erucamide, 0.6 part of heat stabilizer calcium stearate were weighed in proportion and put into a high-speed mixer and mixed for 4 minutes. Then the mixed material was pumped into a drying oven at 60° C. for drying for 3 hours, and finally put into a twin-screw extruder for extrusion.

[0026] Under the same process, the mechanical properties of PHBV / PBS / PLA alloy and PHBV / PLA alloy are compared in Table 2.

[0027] Table 2

[0028] Alloy material category

Embodiment 3

[0030] 40 parts of P3HB4HB (4HB molar content is 15%, molecular weight is 1.2 million) with 20 parts of PLA (molecular weight is 250,000) and 11.8 parts of PBS (molecular weight is 180,000), 26 parts of starch, 0.5 parts of antioxidant 2.6-di-tert-butyl-4-methylphenol and 0.7 part of antioxidant distearyl thiodipropionate, 0.3 part of lubricant paraffin and 0.5 part of lubricant erucamide, 0.2 part of antistatic agent Tetraalkylammonium salts, weighed in proportion and put into a high-speed mixer and mixed for 5 minutes, then pumped the mixed material into a drying oven at 70°C to dry for 4 hours, and finally put into a twin-screw extruder for extrusion , to obtain a blended alloy material.

[0031] Under the same process, the mechanical properties of P3HB4HB / PBS / PLA alloy and P3HB4HB / PLA alloy are compared in Table 3.

[0032] table 3

[0033]

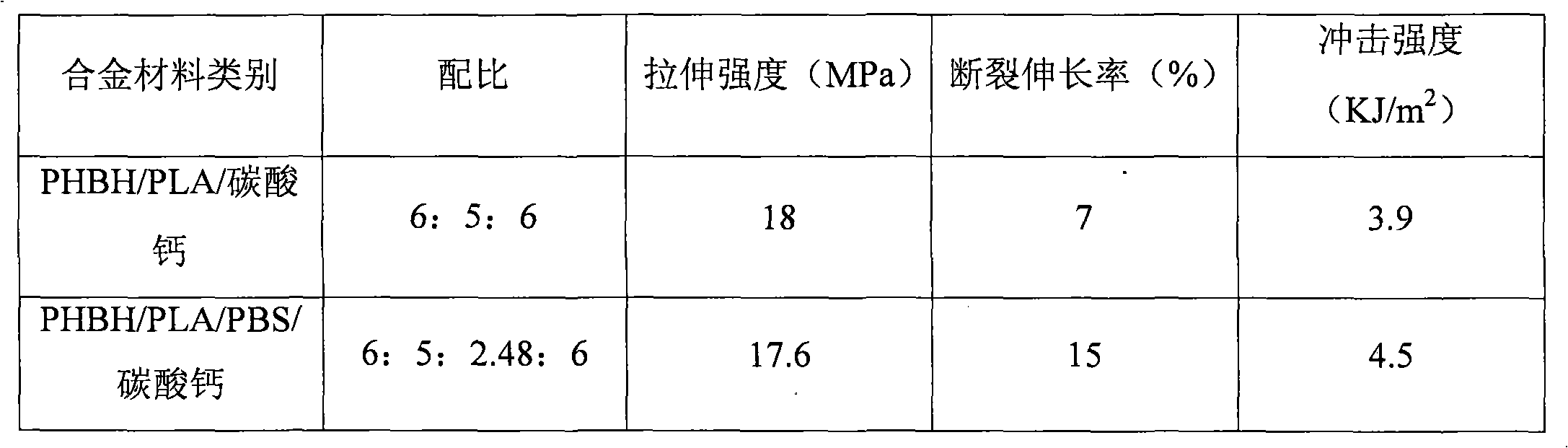

[0034] 30% PHBH (3-glycolic acid HH molar content is 15%, weight average molecular weight is 1.2 million), 12.4% PBS (molecular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com