High-density ultra-strength petroleum compression fracture proppant and preparation method thereof

A fracturing proppant and petroleum technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of land occupation, environmental pollution, etc., and achieve the goal of saving resources, increasing oil production, and good practical prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

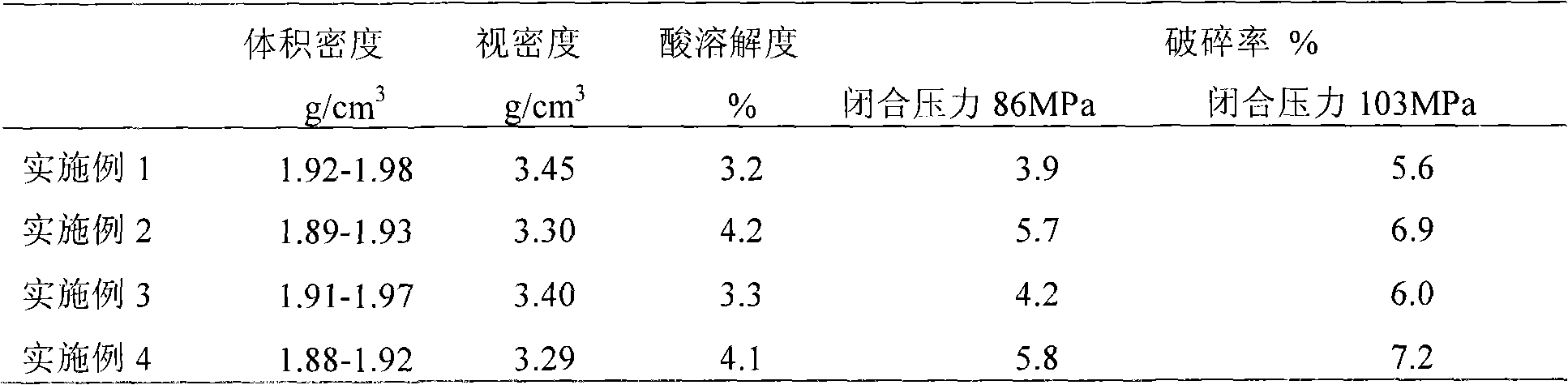

Examples

Embodiment 1

[0032] A petroleum fracturing proppant, the raw materials are as follows in mass parts: 90 parts of waste alumina adsorbent, 2 parts of titanium oxide, 1 part of talc, 1 part of barium carbonate, and 6 parts of ceramic clay.

[0033] 1. Add 90 parts of waste alumina adsorbent powder, 2 parts of titanium oxide, 1 part of talc, 1 part of barium carbonate and 6 parts of ceramic clay into the ball mill, and add 0.3% of the total weight of raw materials as a ball milling aid tripolyphosphoric acid Sodium, add water and ball mill for 10-12 hours to obtain a uniform slurry. The solid content of the slurry is 60wt%.

[0034] 2. Dry and granulate the slurry prepared in step 1 in a spray drying tower to obtain a powder;

[0035] 3. Form the powder obtained in step 2 into a semi-finished proppant with a particle size of 30-50 mesh on a sugar-coated ball forming machine;

[0036] 4. Dry the semi-finished product obtained in step 3, and burn it in a shuttle kiln at a temperature of 1580°...

Embodiment 2

[0038] 1. Add 86 parts of waste alumina adsorbent powder, 2 parts of titanium oxide, 1 part of light calcium carbonate, 1 part of talc, 2 parts of manganese oxide and 8 parts of ceramic clay to the ball mill, and add 0.3% of the total weight of raw materials Sodium tripolyphosphate as a ball milling aid, add water and ball mill for 10-12 hours to obtain a uniform slurry. The solid content of the slurry is 60wt%.

[0039] 2. Dry and granulate the slurry prepared in step 1 in a spray drying tower to obtain a powder with a certain particle size;

[0040] 3. Form the powder obtained in step 2 into a semi-finished proppant with a particle size of 20-40 mesh on a sugar-coated ball forming machine;

[0041] 4. Dry the semi-finished product obtained in step 3, and burn it in a tunnel kiln at a temperature of 1500°C. The fired proppant is milled in a ball mill with water for 2 hours, and then dried to obtain a smooth-surfaced oil fracturing proppant product.

Embodiment 3

[0042] Example 3: A petroleum fracturing proppant, the mass percentage of raw materials is as follows: 92 parts of waste alumina adsorbent, 1 part of titanium oxide, 2 parts of dolomite, and 5 parts of ceramic clay. The preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com