Glass fiber reinforced AES composite material and preparation method thereof

A technology of glass fiber and composite materials, which is applied in the field of glass fiber reinforced AES composite materials and its preparation, can solve the problems of mechanical properties, dimensional stability, and thermal deformation temperature that cannot meet engineering parts, achieve good rigidity, expand application fields, and improve Effect of heat deflection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of glass fiber reinforced AES composite material of the present invention comprises the steps:

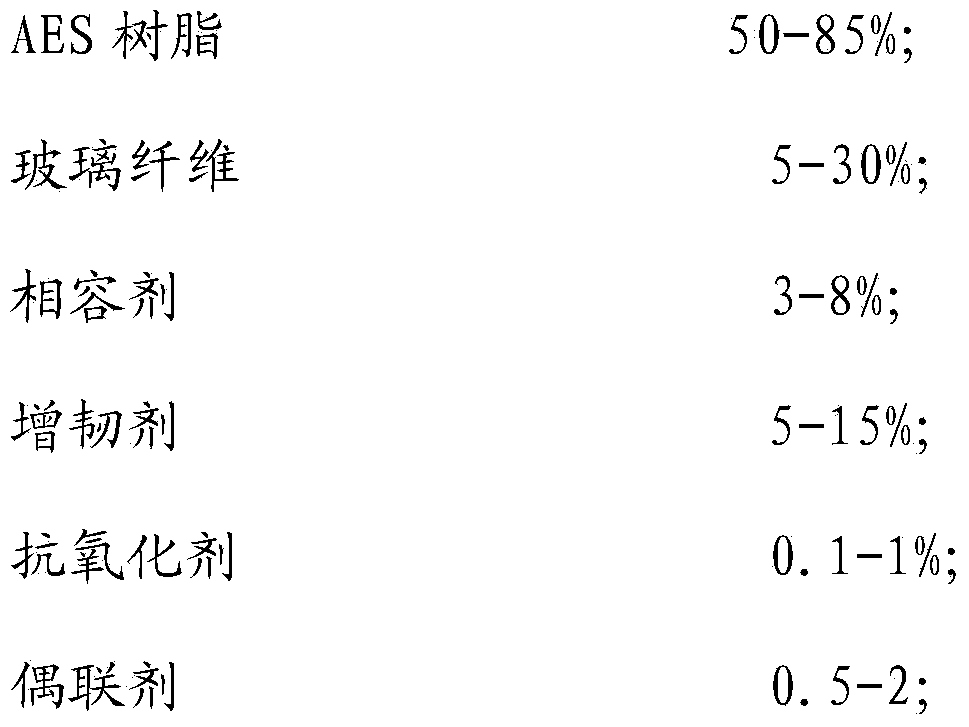

[0035] Step 1: Select raw materials according to weight percentage, raw materials include AES resin 50-85%, glass fiber 5-30%, compatibilizer 30-50%, toughening agent 5-15%, antioxidant 0.1-0.5%, coupling Agent 0.5-1.5%, lubricant 0.5-1%;

[0036] Step 2: Mix AES resin, compatibilizer, toughening agent, antioxidant, coupling agent and lubricant evenly to obtain mixed raw materials;

[0037] Step 3: extruding and granulating the above-mentioned mixed raw materials and glass fibers to obtain a glass fiber reinforced AES composite material.

[0038] In step 3, a twin-screw extruder is used for extrusion. The mixed raw materials are added at the main feeding port, and the glass fiber is added at the side feeding port. The above-mentioned mixture and glass fiber are accurately metered into the extruder, and fully melted under the shearing, conveying and m...

Embodiment 1

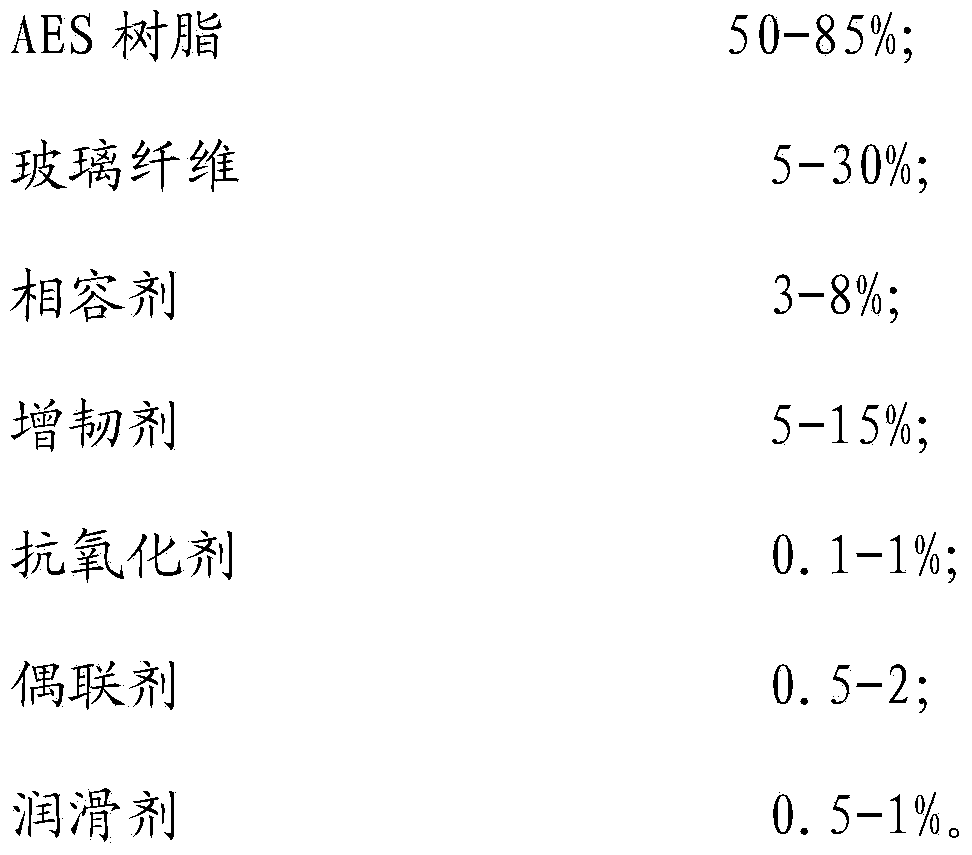

[0044] The components and weight percentages of the glass fiber reinforced AES composite material of the present embodiment are:

[0045]

[0046]

[0047] Among them, the brand of AES resin is DGK-ND140UV of De High Technology; the compatibilizer is SMA MPC1501; the AES glass fiber is Jushi glass fiber 526; the coupling agent is KH550 of DuPont; the toughening agent is HR181 of Korea Kumho Petrochemical; antioxidant Irganox 1010 and 168 refined for CIBA; the lubricant is domestic EBS.

[0048] Mix AES resin, compatibilizer, toughening agent, antioxidant, coupling agent, and lubricant evenly and add them to a high-speed mixer, and mix thoroughly for 10-20 minutes to obtain mixed raw materials. The above-mentioned mixed raw materials and glass fibers are extruded and granulated. The mixed raw materials are added at the main feeding port of the twin-screw extruder, and the glass fiber is added at the side feeding port. The length-to-diameter ratio of the screw of the twi...

Embodiment 2

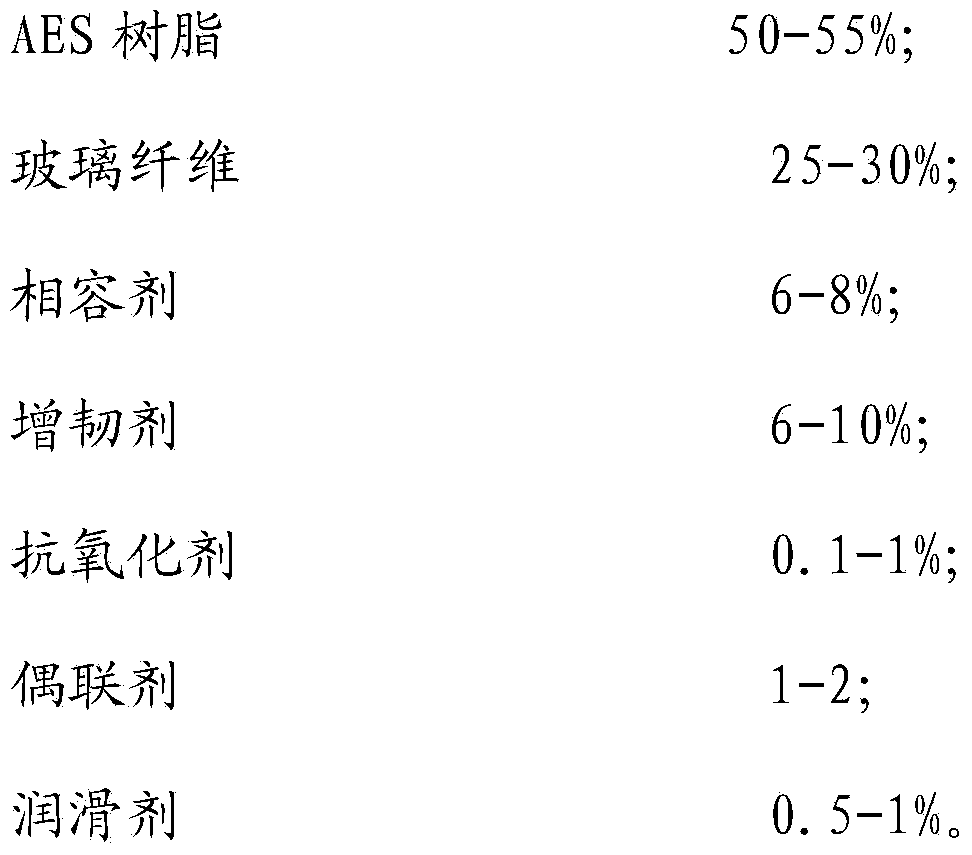

[0053] The components and weight percentages of the glass fiber reinforced AES composite material of the present embodiment are:

[0054]

[0055] Among them, the brand of AES resin is DGK-ND140UV of De High Technology; the compatibilizer is SMA MPC1501; the AES glass fiber is Jushi glass fiber 526; the coupling agent is KH550 of DuPont; the toughening agent is HR181 of Korea Kumho Petrochemical; antioxidant Irganox 1010 and 168 refined for CIBA; the lubricant is domestic EBS.

[0056] Mix AES resin, compatibilizer, toughening agent, antioxidant, coupling agent, and lubricant evenly and add them to a high-speed mixer, and mix thoroughly for 10-20 minutes to obtain mixed raw materials. The above-mentioned mixed raw materials and glass fibers are extruded and granulated. The mixed raw materials are added at the main feeding port of the twin-screw extruder, and the glass fiber is added at the side feeding port. The length-to-diameter ratio of the screw of the twin-screw extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com