Nb, Ti alloyed low-carbon high-intensity high-plasticity TWIP steel and preparation method thereof

A high-strength, alloying technology, applied in the field of high-strength alloy steel, can solve problems such as impracticability, and achieve the effects of improving impact resistance and collision resistance, low production cost, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

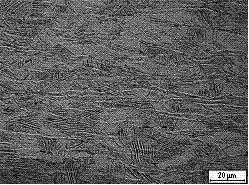

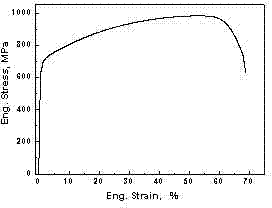

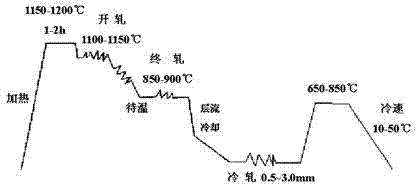

[0056] Table 1 lists the main components in Examples 1 to 6 of the present invention, wherein in addition to the listed main components in each example, 0.02wt% Si and 0.10wt% Al are added. In order to better illustrate the present invention by comparison, Table 1 also lists the composition of other 8 groups of TWIP steels prepared for comparative research in the present invention to compare and illustrate the composition range determined by the present invention. Each embodiment and comparative example in table 1 have all adopted preparation process system uniformly, and the performance of the material prepared under this process system is also listed in table 1, and the concrete preparation process adopted is:

[0057] The hot rolling start temperature is 1130~1150°C, the temperature is 950°C to 900°C, the final rolling temperature is 880°C, and the cooling rate is 25°C / s to 500°C for coiling. The cumulative reduction of cold rolling is in the range of 50-80%, and the thickn...

Embodiment 3

[0064] The difference between embodiment 3 and comparative examples 6 and 7 is that the Mn content is different. It can be seen that in comparative example 6, when the Mn content was reduced to 22wt%, a small amount of ε martensite appeared in the tissue at room temperature. The appearance of the brittle phase directly leads to a significantly lower plasticity of the material. On the other hand, in Comparative Example 7, since the Mn was too high, the decrease in the yield strength was relatively large.

Embodiment 4

[0065] Comparing Example 4 with Comparative Example 8, when the N content is high, microcracks appear, and the strength and plasticity are significantly reduced.

[0066] Examples 1-6 and Comparative Examples 1-8 are mainly to illustrate the influence of ingredients on the structure and performance under the same preparation process. In the present invention, steel plates of different strength levels can also be prepared by adjusting the process system under the above-mentioned composition system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com