Method for casting valve body of heavy-calibre non-rising-stem flat valve

A large-diameter, flat valve technology, applied in casting molding equipment, molds, mold components, etc., can solve the problems of large valve body wall thickness, low material utilization, uneconomical, etc., to meet technical requirements, good resistance Alkaline, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

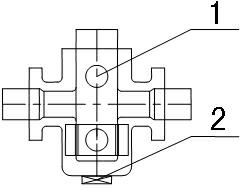

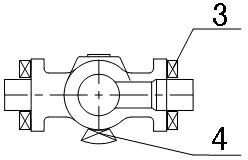

[0016] like Figure 1-2 As shown, the core is made of ester hardened sodium silicate sand molding, which is characterized in that two RND300 necking, heating and heat preservation risers 1 are installed on the valve belly of the sand core, and 6 pieces of 90mm thick and 30mm spacing are installed at the bottom of the valve belly. Formed cold iron 4, 8 pieces of 70mm thick formed cold iron 3 are installed on the side flange of the valve body, Ф25 mm air outlet is installed on the top of the side flange, and Ф200X50 mm formed cold iron 2 is installed at the tail of the valve body; among them, the valve belly of the valve body is made of Two RND300 necking, heating and heat preservation risers 1 are fed, the bottom of the valve belly is fed by a 90 mm thick formed cold iron 4, and the thickness of the valve body side flange is 70 mm formed by a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com