Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Organozinc compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organozinc compounds in organic chemistry contain carbon to zinc chemical bonds. Organozinc chemistry is the science of organozinc compounds describing their physical properties, synthesis and reactions.

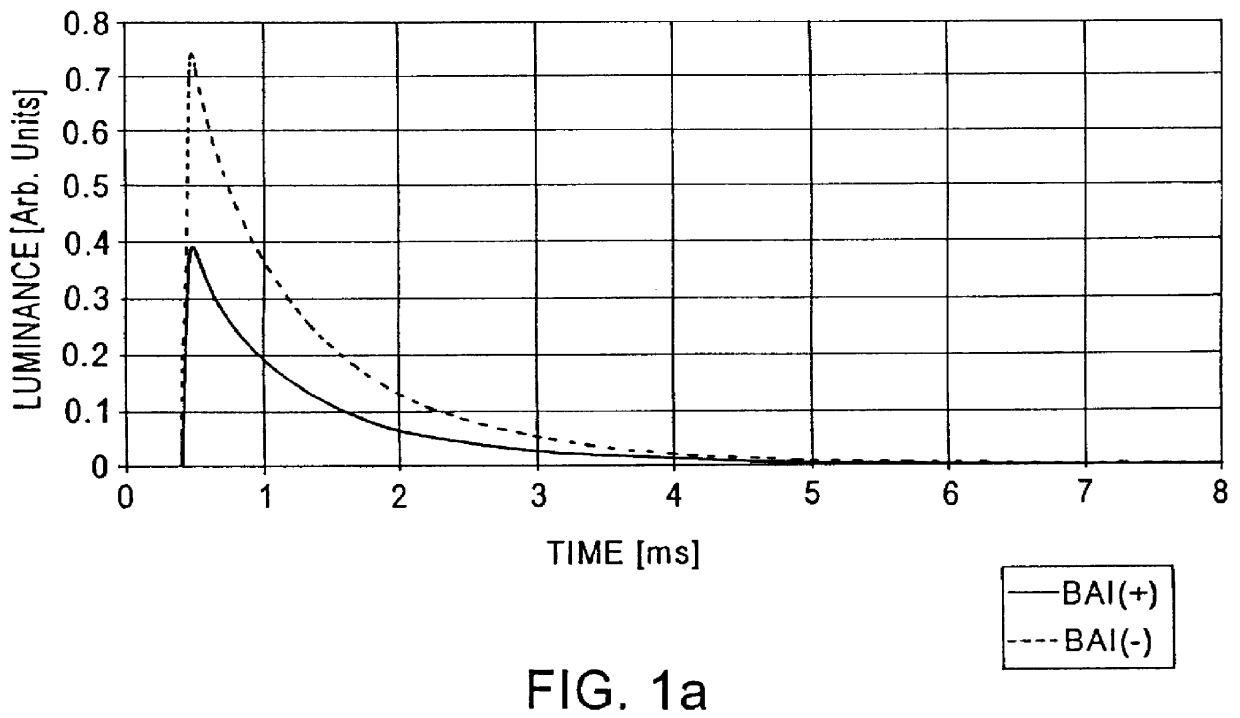

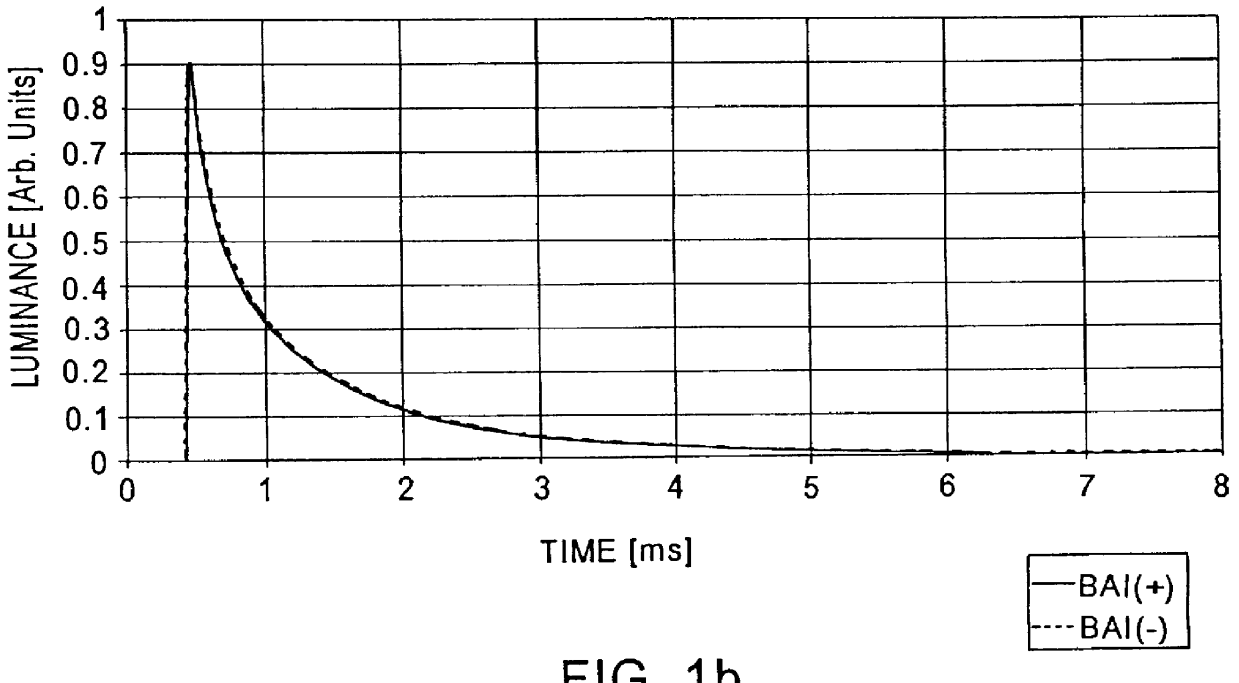

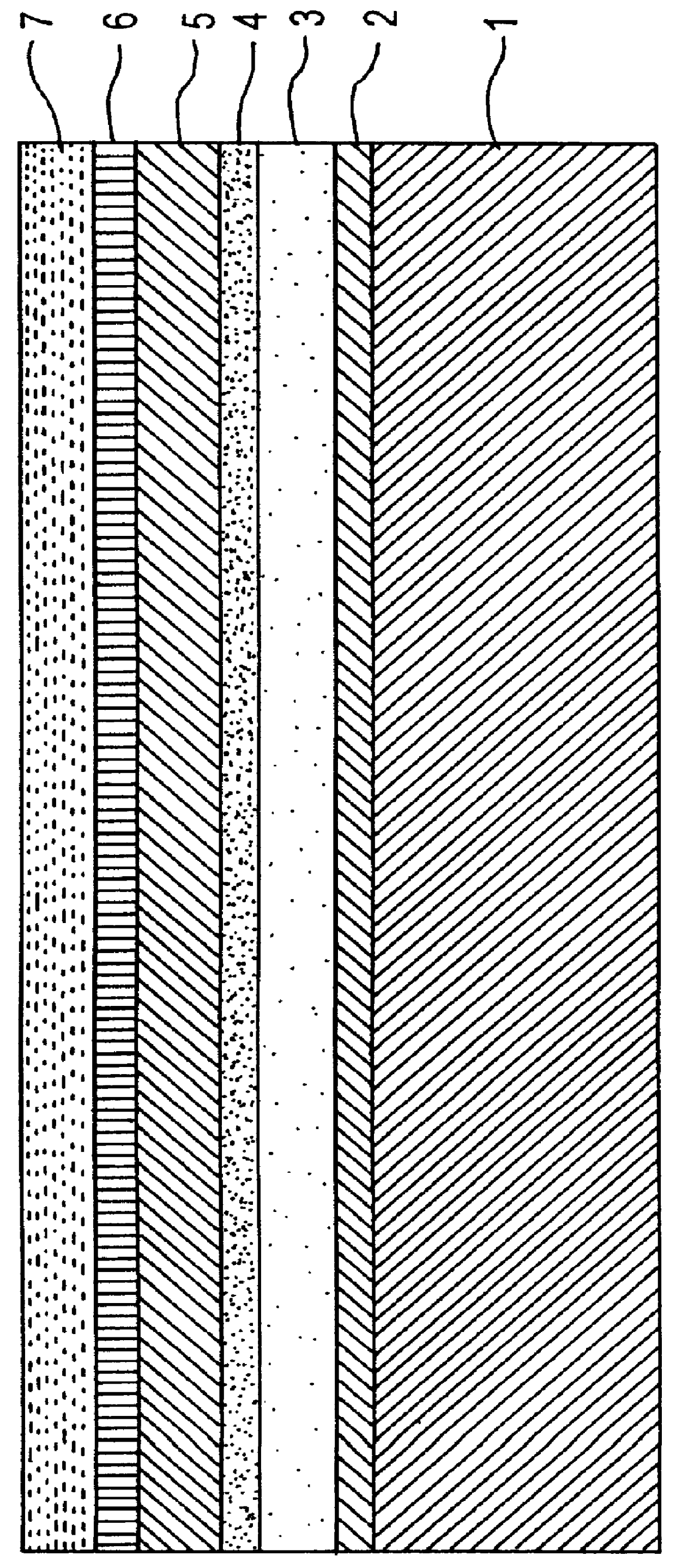

Method of growing a ZnS:Mn phosphor layer for use in thin-film electroluminescent components

InactiveUS6113977AImprove electroluminescence performanceSimple manufacturing processElectrical apparatusElectroluminescent light sourcesOrganozinc compoundFluorescence

The invention relates to a method of growing a ZnS:Mn phosphor layer suitable for use in thin-film electroluminescent components. According to the method, the ZnS:Mn phosphor layer is grown on a substrate by means of the ALE method using volatile zinc, sulfur and manganese compounds as the precursors. According to the invention, an organozinc compound such as diethylzinc or dimethylzinc is used as precursor for zinc, hydrogen sulfide or an organosulfur compound is used as precursor for sulfur, and an organomanganese compound or organic manganese complex compound is used as precursor for manganese. The invention provides a display component with drive-voltage-symmetrical light emission and stable characteristics of luminance level and turn-on voltage.

Owner:PLANAR SYSTEMS +1

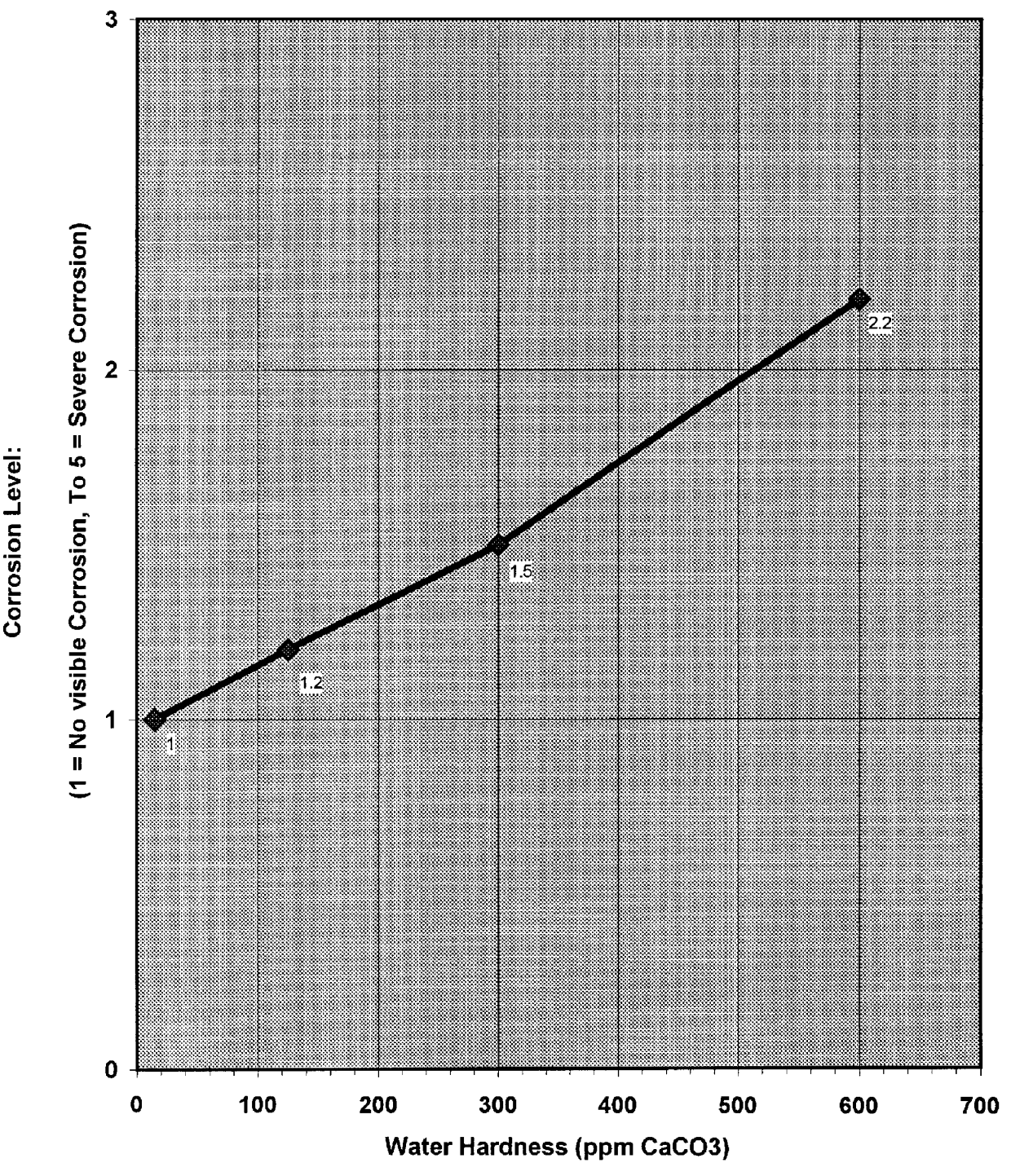

Liquid automatic dishwashing composition with glassware protection

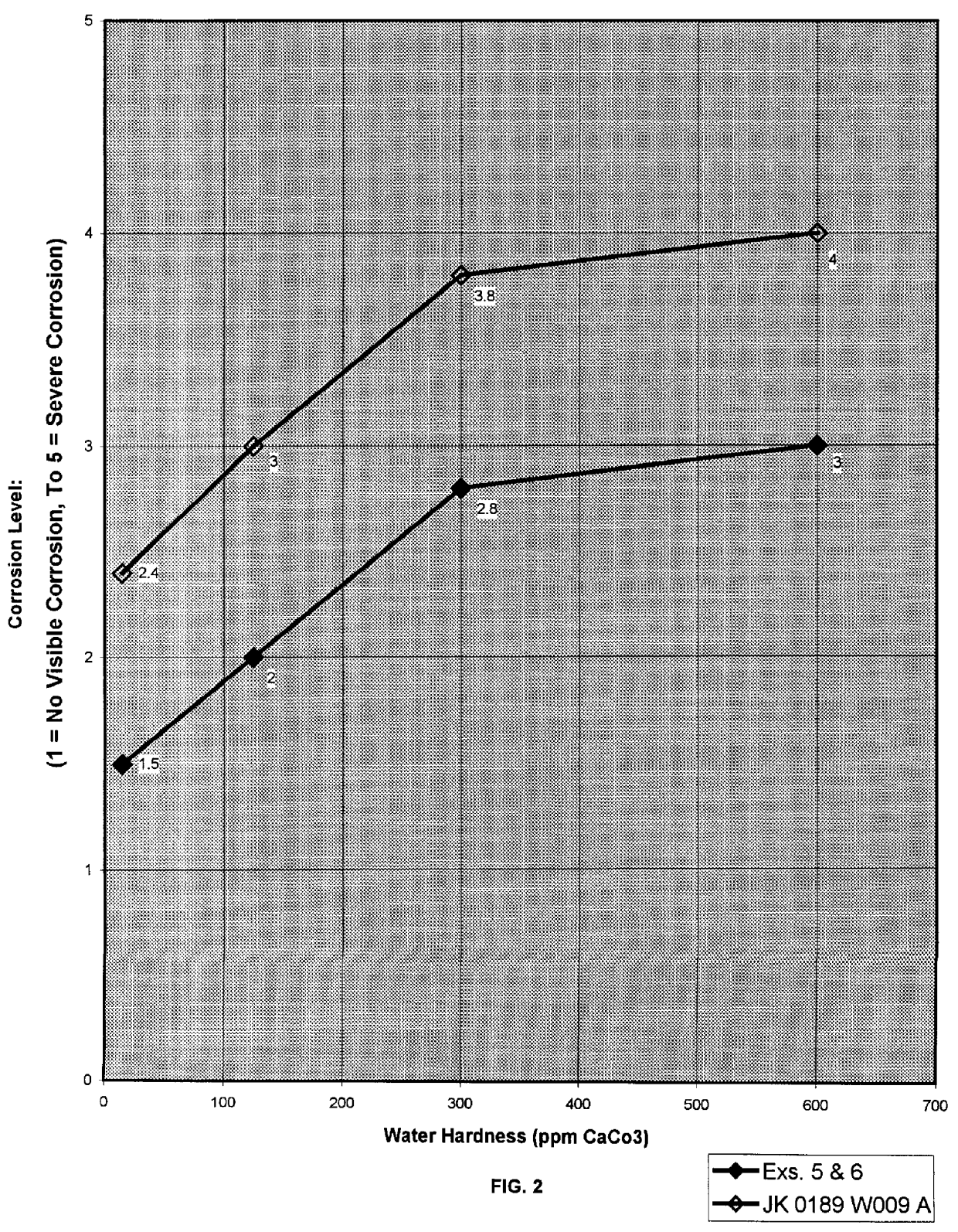

InactiveUS6083894AImproved dishwashing compositionOrganic detergent compounding agentsAnionic surface-active compoundsHigh concentrationOrganozinc compound

Owner:JOHNSONDIVERSEY INC

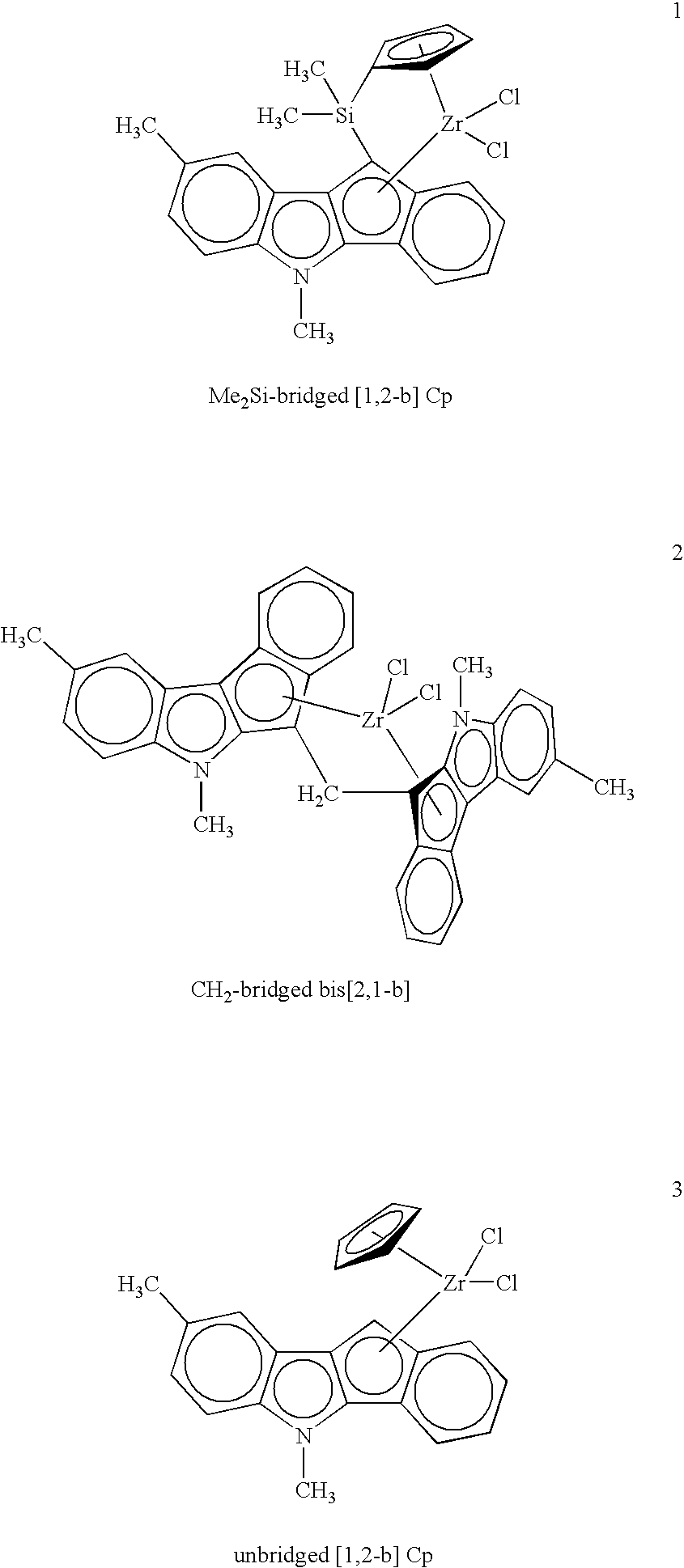

Olefin polymerization process

InactiveUS6933353B2High activityIncrease weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganozinc compoundOlefin polymerization

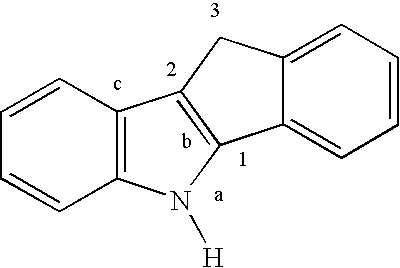

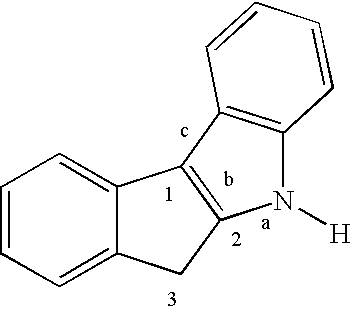

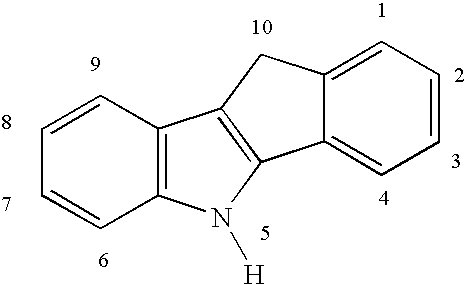

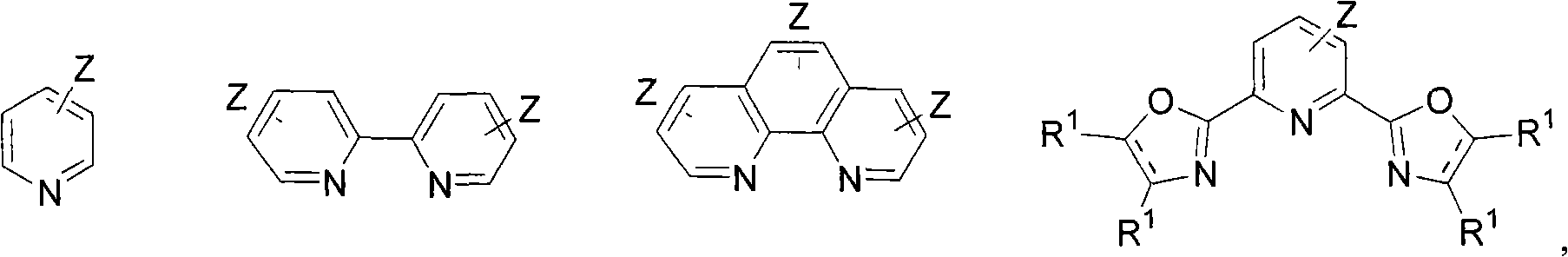

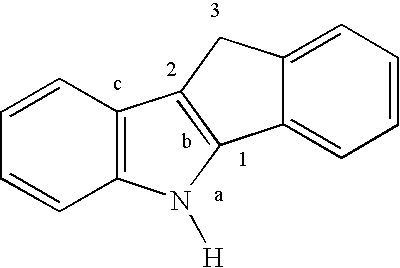

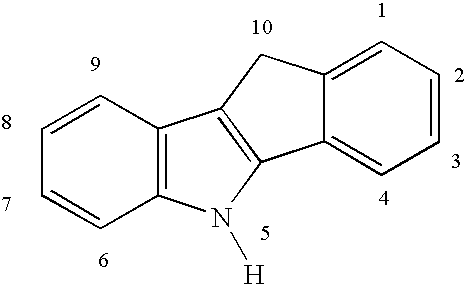

A method for preparing a supported organometallic complex is disclosed. An organometallic complex is combined with a support material that has been treated with an organozinc compound. The organometallic complex comprises a Group 3 to 10 transition metal and an indenoindolyl ligand that is bonded to the transition metal. Also disclosed is a process for polymerizing an olefin using the supported complex. Organozinc treatment of the support unexpectedly boosts catalyst activity and polyolefin molecular weight.

Owner:EQUSR CHEM LP

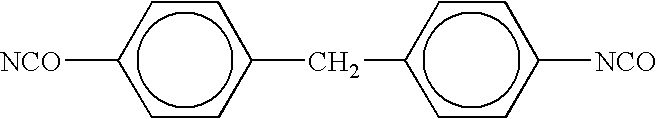

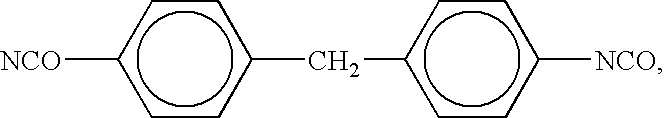

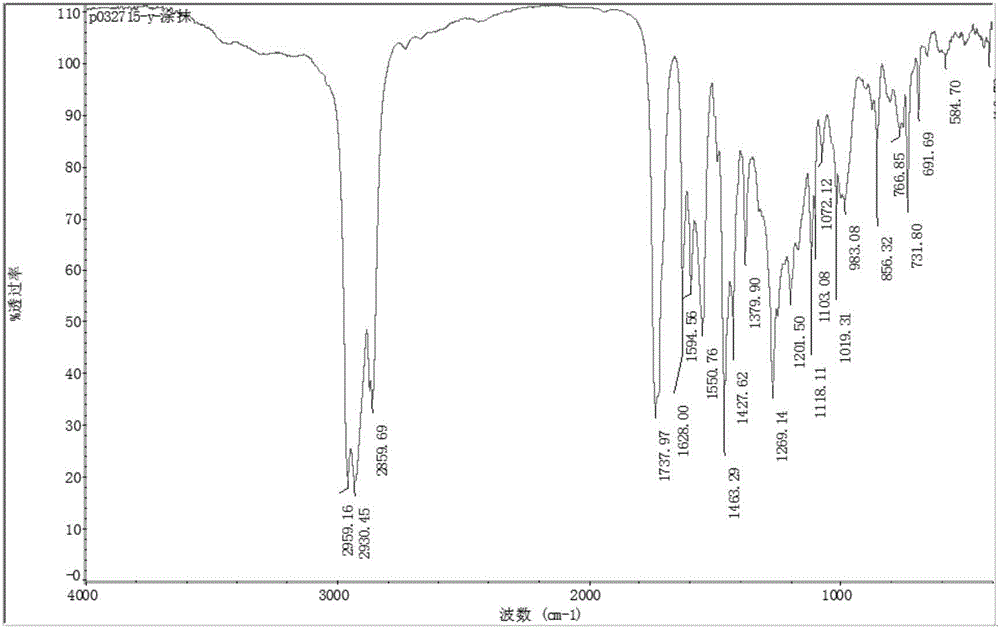

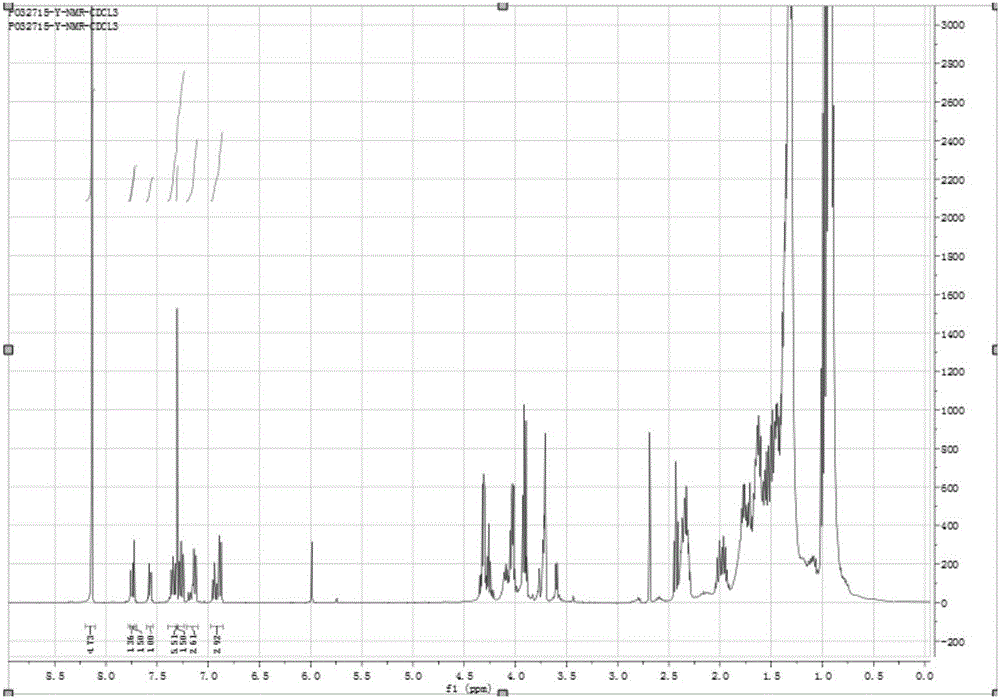

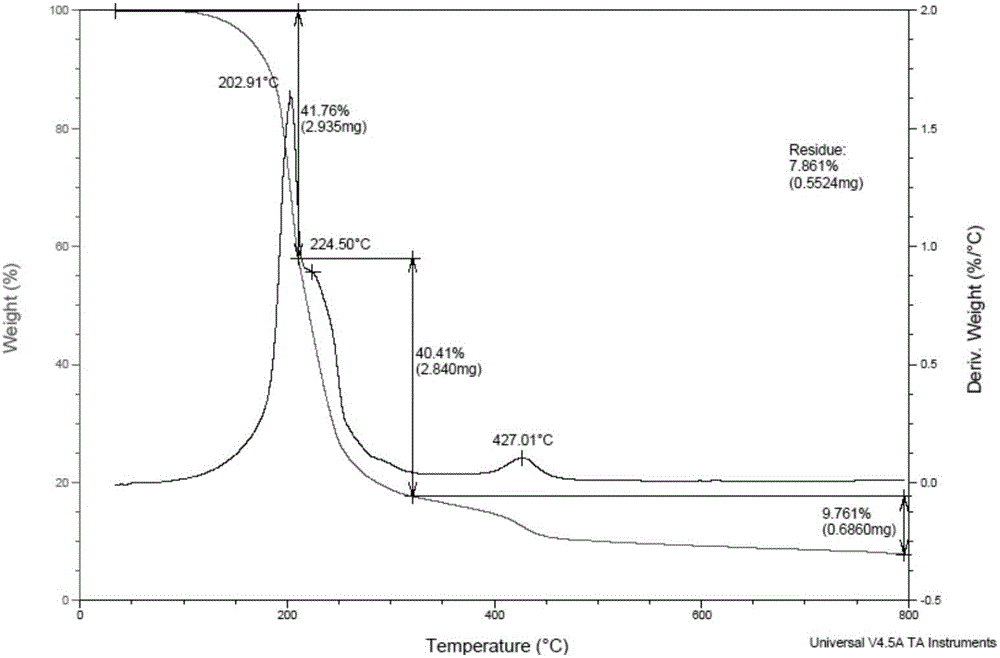

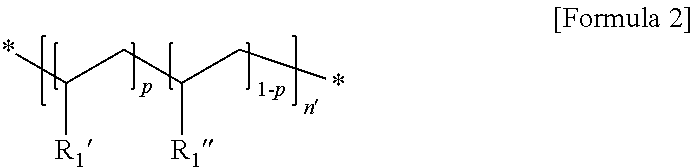

Polyurethane composition

InactiveUS20100255317A1Easy to operateExcellent melt moldabilityGroup 4/14 element organic compoundsSynthetic resin layered productsOrganozinc compoundHydrogen atom

[Problem] Provided are a nonadhesive polyurethane composition, which does not adhere to a molding apparatus and the like, is superior in melt-moldability and adhesion to silicone, and useful as a molded object, a composite molded object or an ink binder, and a molded object, a composite molded object, an ink binder and an ink composition, which are made therefrom.[Solving Means] A polyurethane composition containing polyurethane (A) containing, in a molecule, a structural unit (I) represented by the following formula (I);wherein R1 and R2 are each a hydrogen atom or a C1-6 alkyl group, in a proportion of 0.1-20 mass %, and metal compound (B) selected from an organic Zn compound, an organic Bi compound, an organic Ti compound and an organic Zr compound in a proportion of 0.1-2,000 ppm, a molded object comprised of the polyurethane composition, a composite molded object having a polyurethane composition layer and a silicone layer, an ink binder containing the polyurethane composition and an ink composition containing the polyurethane composition.

Owner:KURARAY CO LTD

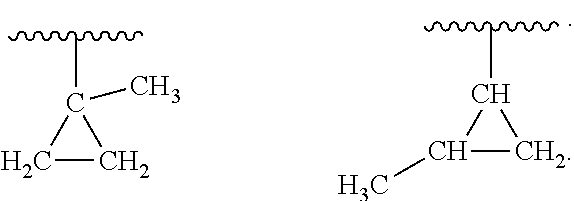

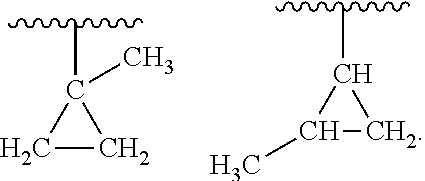

Process for producing alpha-olefin polymer

An α-olefin polymer having extremely high stereoregularity, exhibiting excellent fluidity and containing a decreased amount of catalyst residues in the polymer can be obtained industrially advantageously in accordance with a process for producing an α-olefin polymer which comprises homopolymerizing an α-olefin or copolymerizing two or more α-olefins in the presence of (A) a solid catalyst component comprising magnesium, titanium and a halogen, (B) an organoaluminum compound having a content of hydroaluminum compounds of 0.1% by weight or smaller and (C) an organozinc compound.A block copolymer of propylene comprising a homopolymer portion exhibiting high fluidity and a copolymer portion having a high molecular weight can be obtained in accordance with a process for producing a block copolymer of propylene which comprises polymerizing propylene in the presence of (A) a solid catalyst component comprising a titanium compound and an electron-donating agent, (B) an organoaluminum compound and (C) an organozinc compound to produce crystalline polypropylene and copolymerizing propylene and at least one of ethylene and α-olefins having 4 or more carbon atoms in the presence of the produced crystalline polypropylene.

Owner:IDEMITSU KOSAN CO LTD

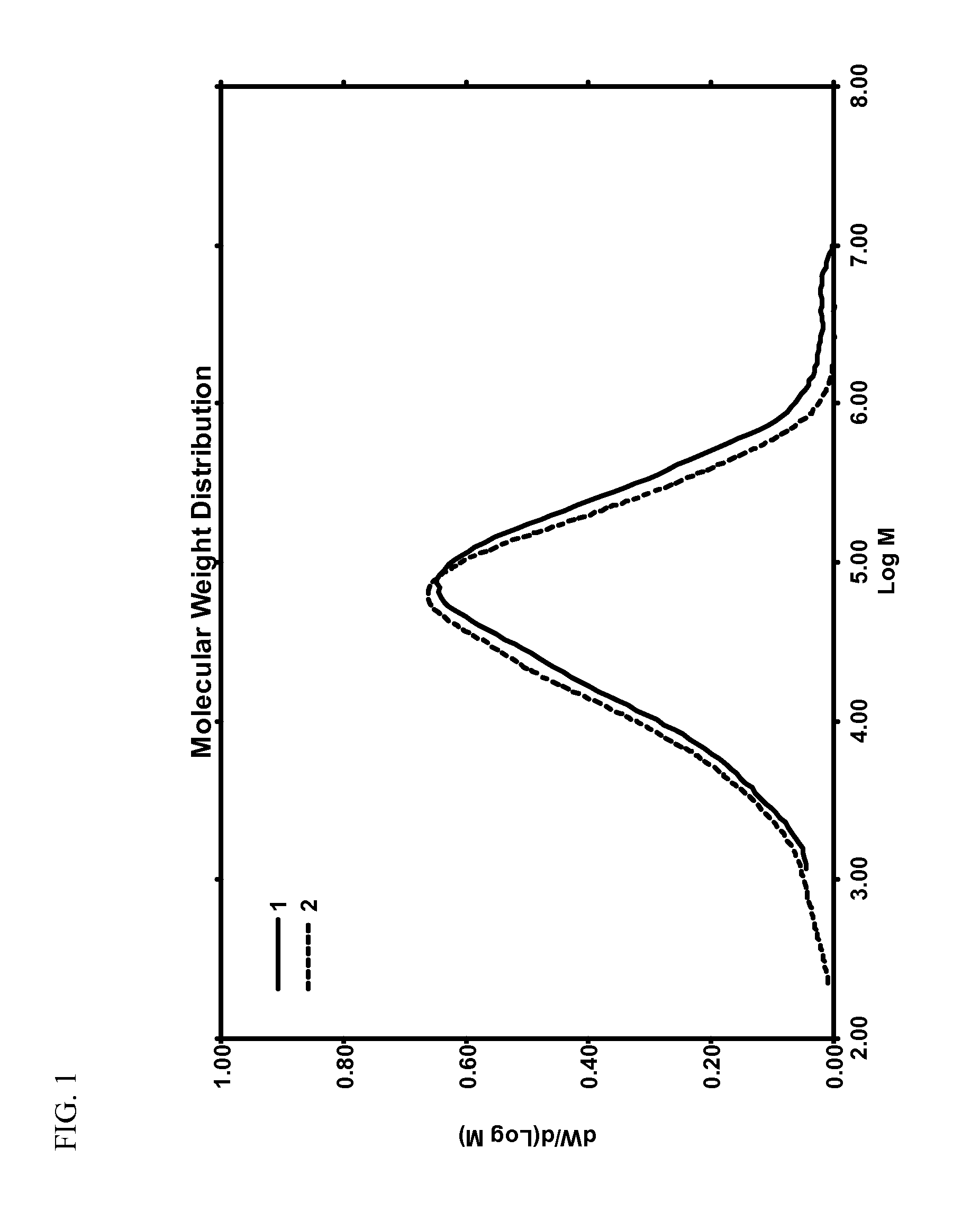

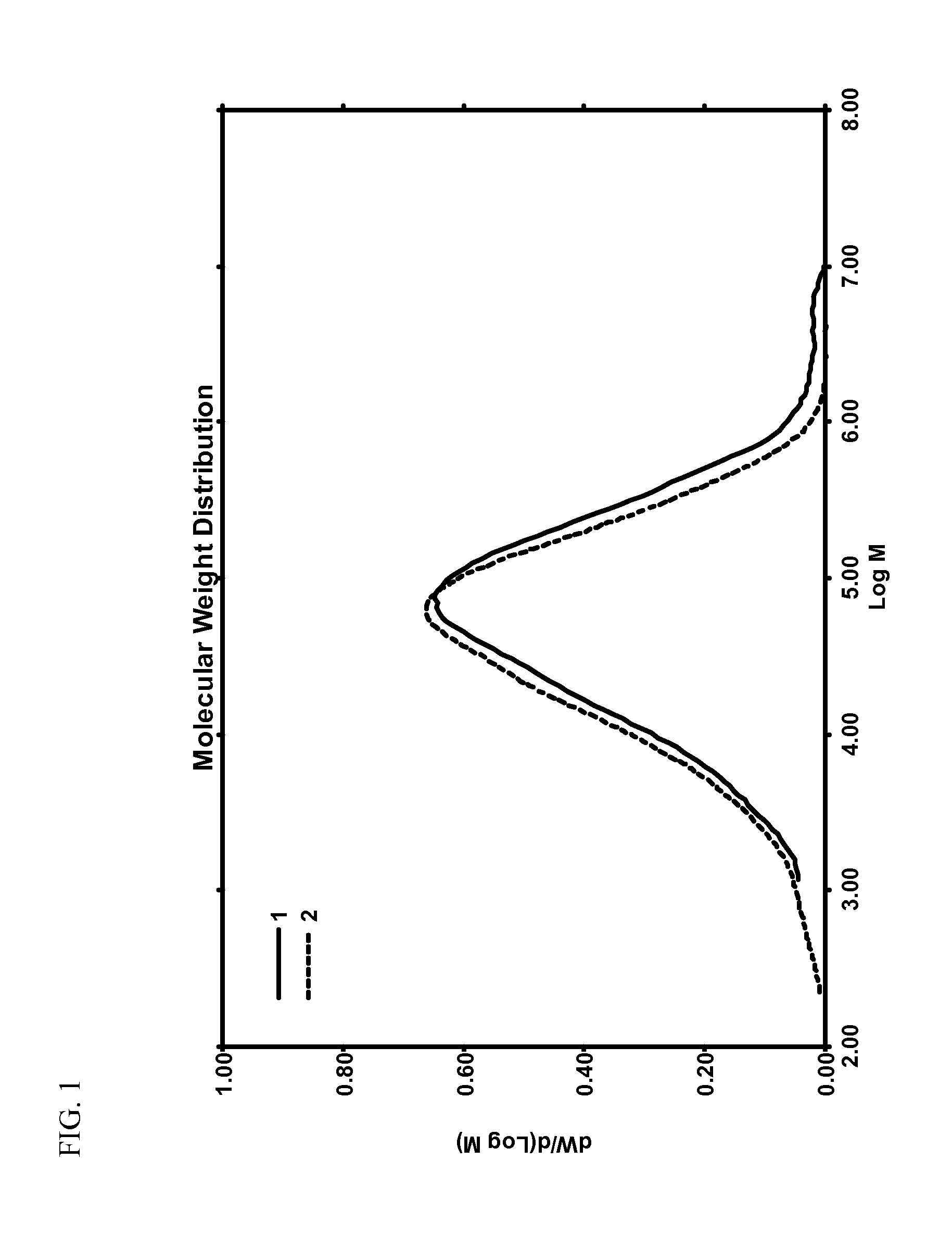

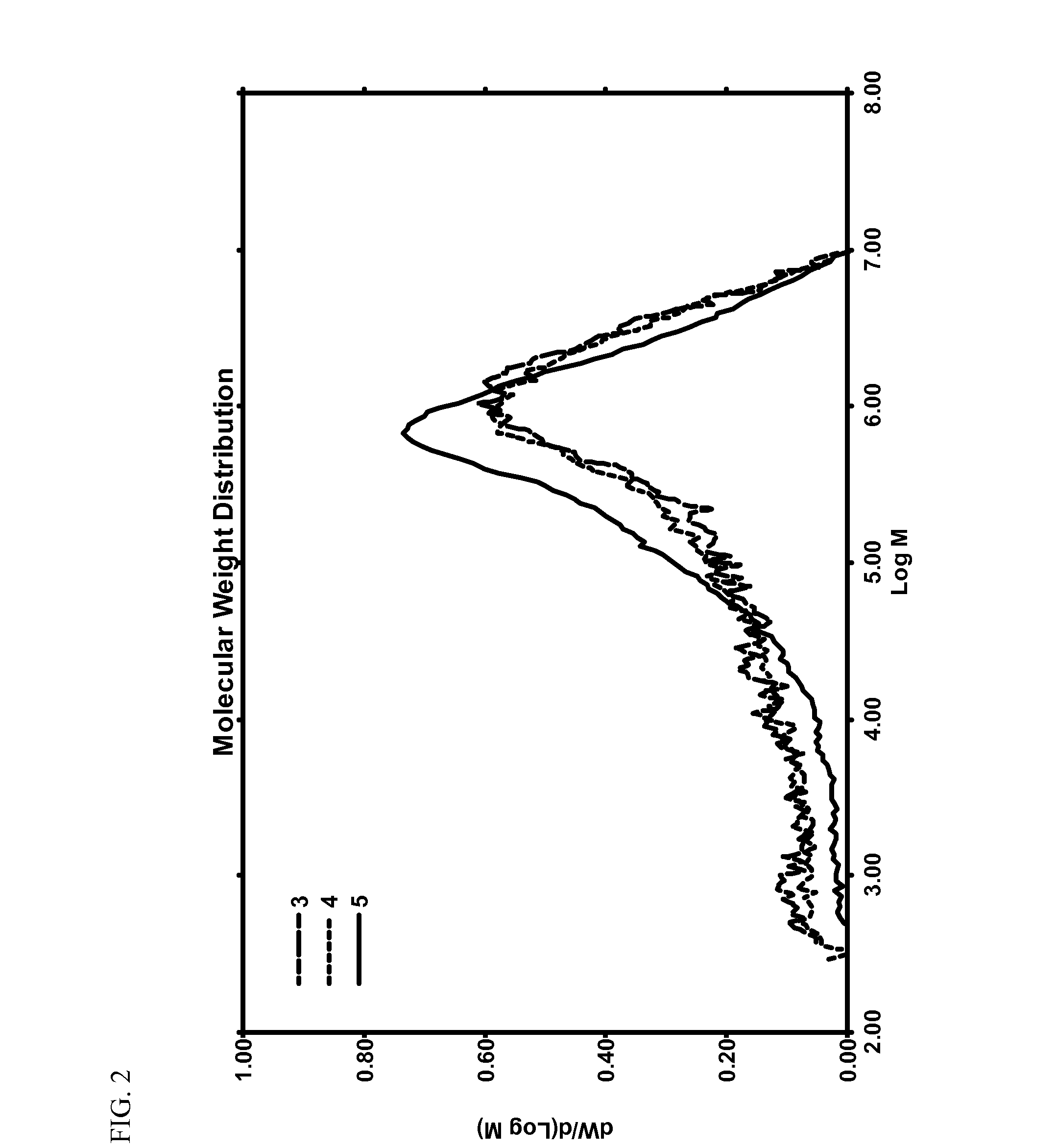

Olefin polymerization process with improved operability and polymer properties

Ethylene and optional comonomers are polymerized in the presence of an organozinc compound and a catalyst system to produce an ethylene polymer. The catalyst system comprises a bridged indenoindolyl Group 3-10 transition metal complex and an activator. The organozinc compound is used in an amount effective to increase the polymer bulk density compared with that observed in the absence of the organozinc compound. The organozinc compound can also narrow the particle size distribution of the polymer and the wt. % of polyolefin chunks produced. The operability of processes utilizing bridged indenoindolyl metal complexes is enhanced while maintaining desirably high polyolefin molecular weights.

Owner:EQUSR CHEM LP

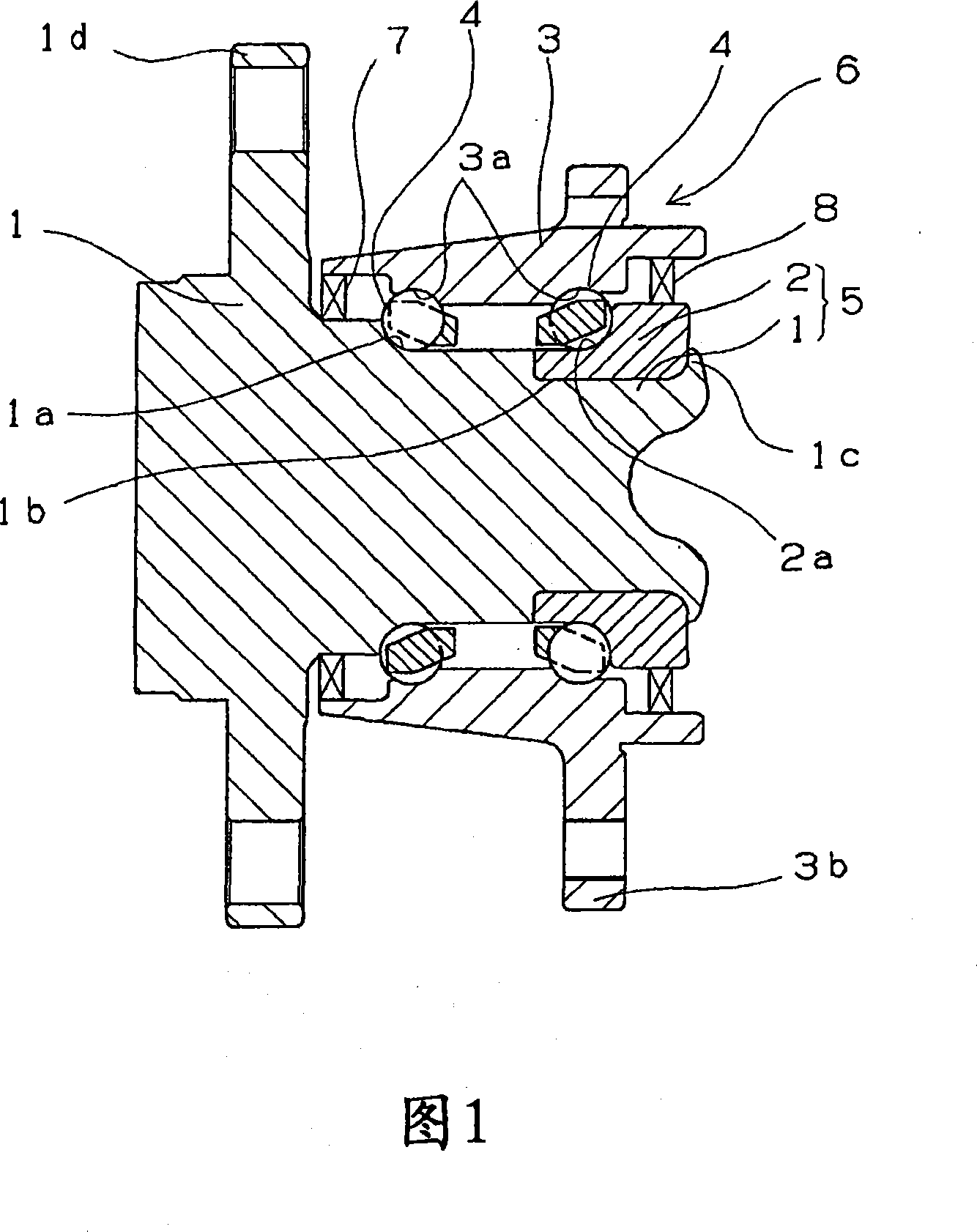

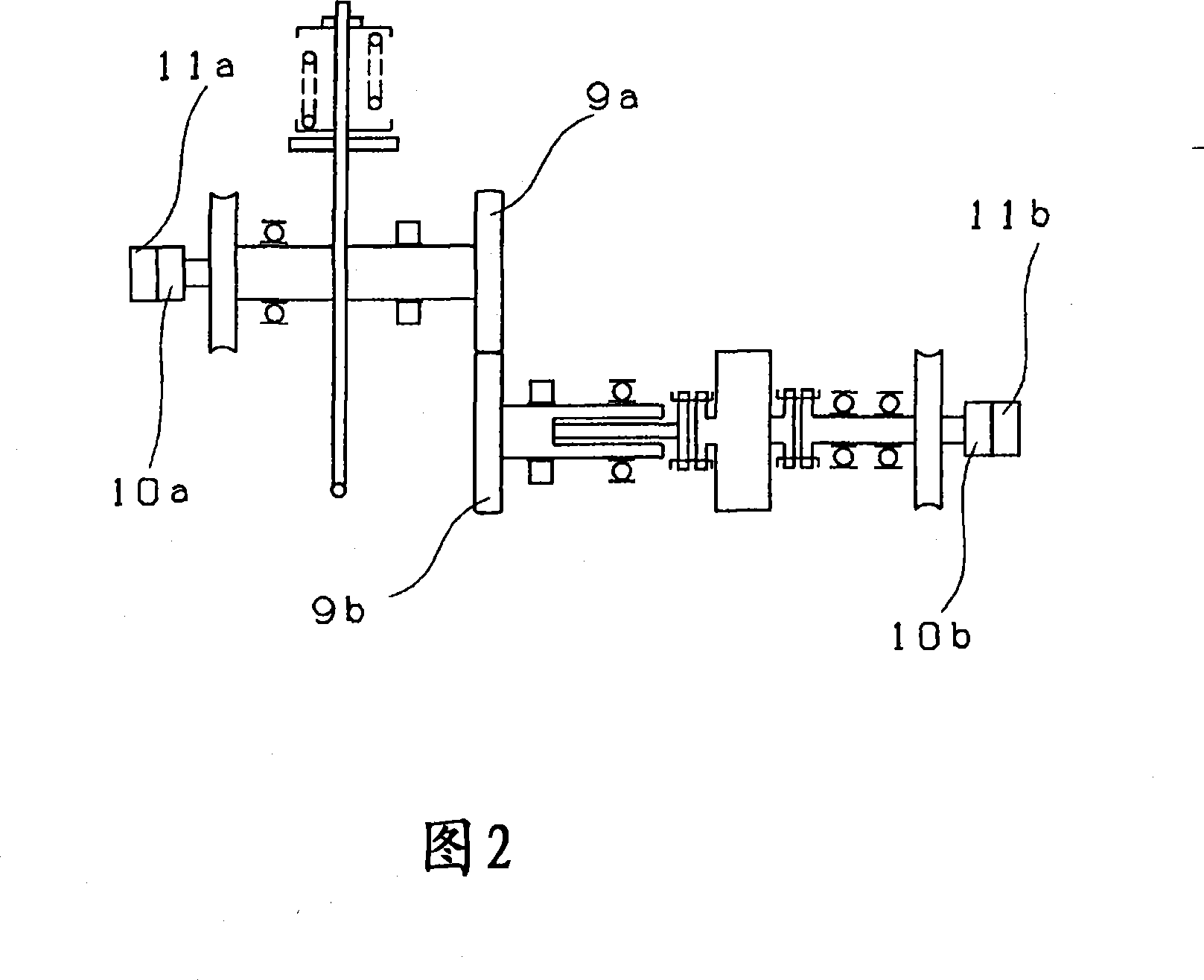

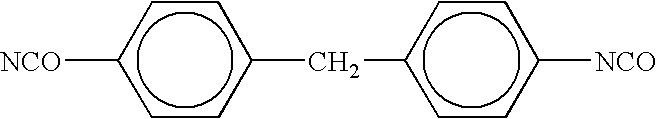

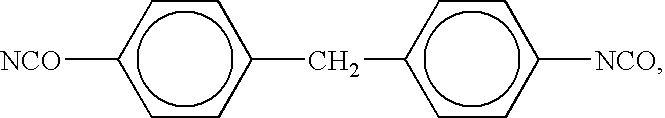

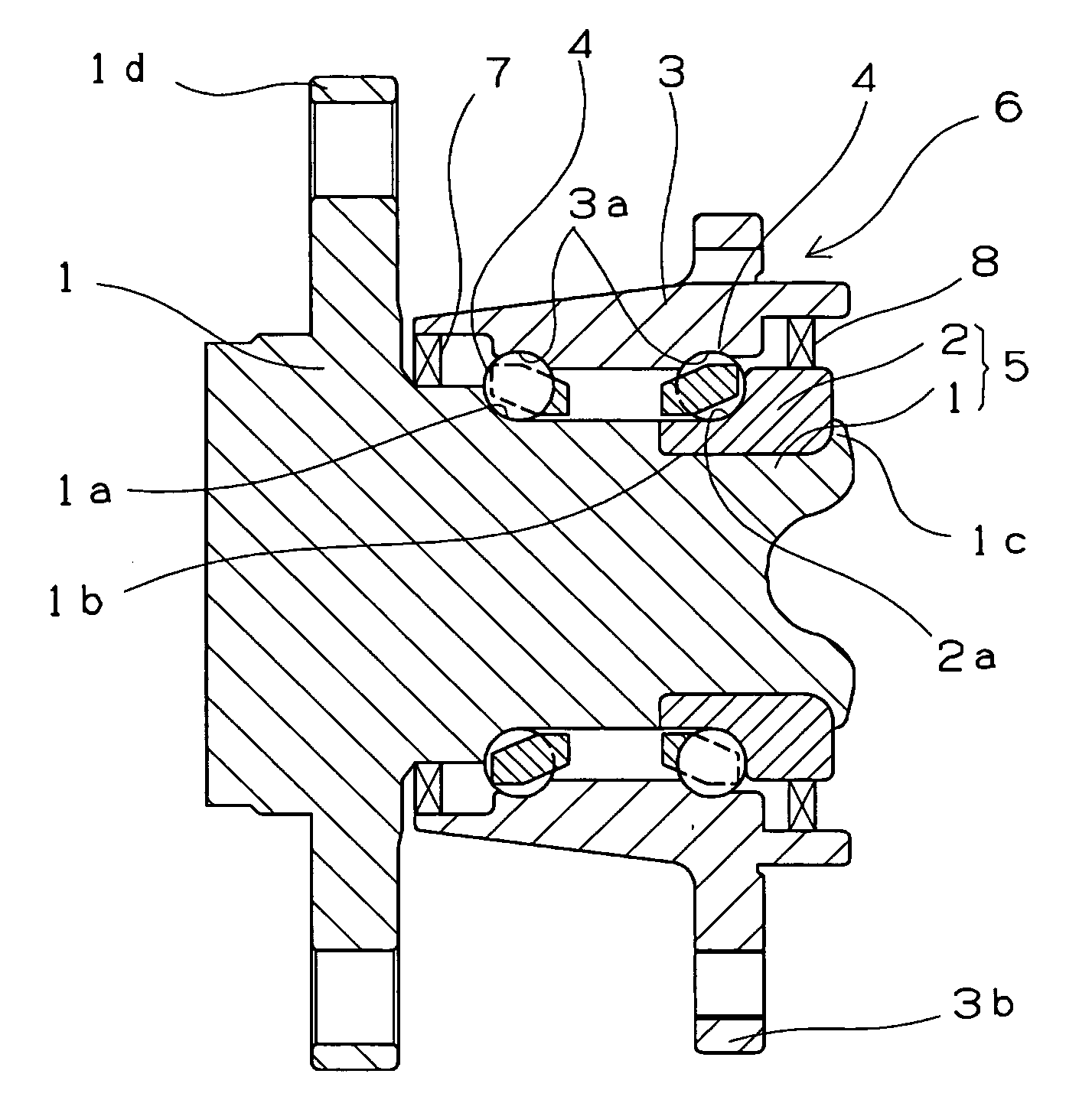

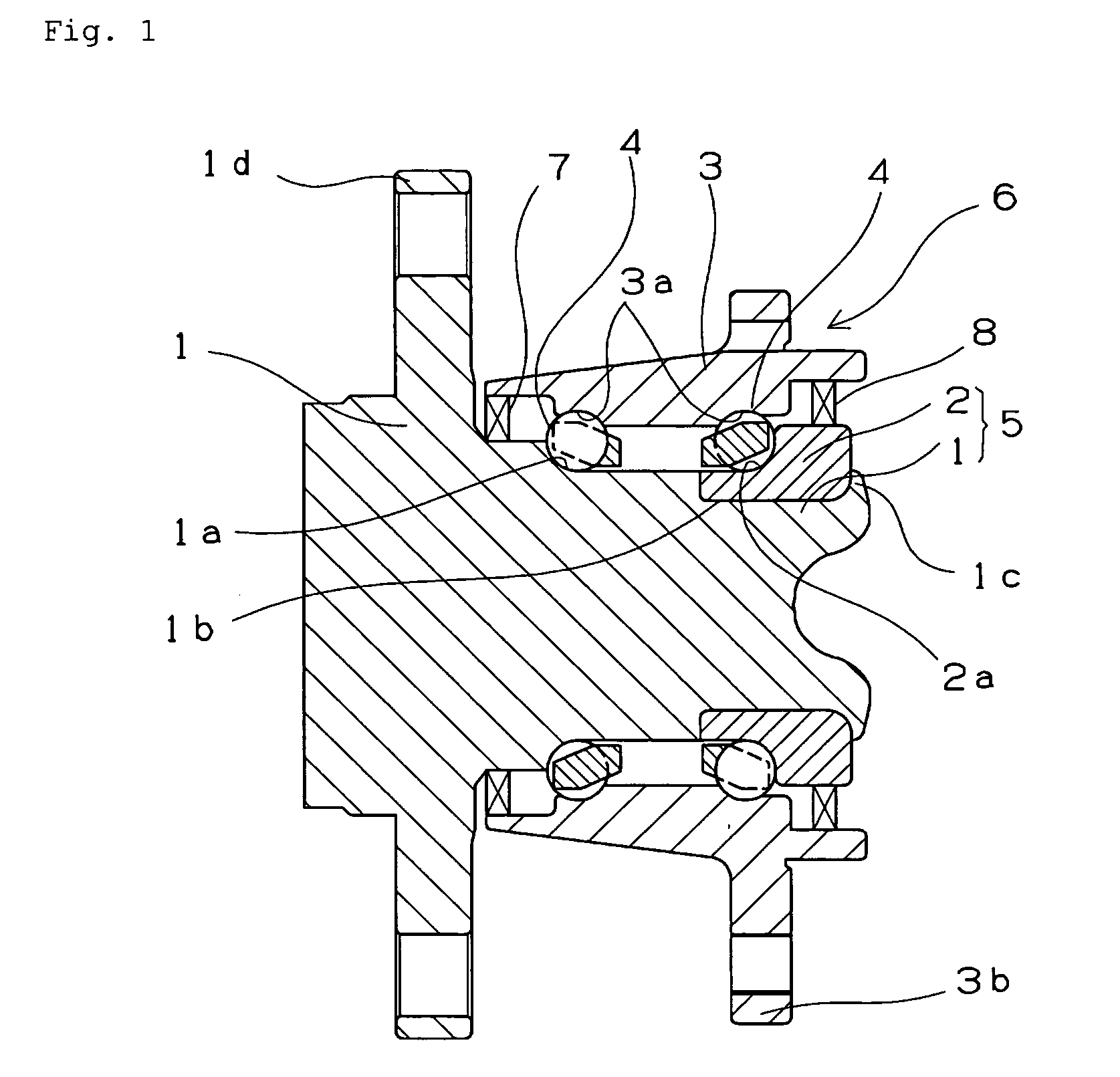

Rolling device employing lubricating grease composition and electric power steering apparatus employing the rolling device

InactiveUS20090065287A1Good effectHigh viscoelasticityBearing componentsThickenersOrganozinc compoundElectric power steering

A rolling device is provided which employs a lubricating grease composition which considerably diminishes irregular friction fluctuations occurring on rolling / sliding friction surfaces, shows stable low-torque characteristics in a wide temperature range, can retain a sufficient oil film even at high temperatures, has along life, and contains a novel thickener. Also provided is an electric power steering apparatus employing the rolling device.The rolling device is characterized by employing a lubricating grease composition comprising: a thickener which is a mixed thickener comprising a mixture of (a) one or more diurea compounds which are one or more aliphatic diurea compounds having an average molecular weight of 500-750 in which 10-70% by mole of the linear hydrocarbon groups are unsaturated components, the aliphatic diurea compounds having been produced using as a raw material one or more primary amines having a total amine value in the range of 200-400, (b) at least one fatty acid metal salt, and (c) at least one amide compound selected from the group consisting of aliphatic amides and aliphatic bisamides represented by formulae (I) and (II):R1CONH2 (I)R1CONHR2NHCOR1 (II)(wherein R1 represents a saturated or unsaturated alkyl group having 15-17 carbon atoms and R2 represents a methylene group or an ethylene group), the proportions of (a) and of (b) and (c) satisfying the relationship:a / (b+c)=0.2−10provided that(1) the proportion of ingredient (a) is 1-10,(2) the proportion of ingredient (b) is 0.5-2.5, and(3) the proportion of ingredient (c) is 0.5-2.5,the amount of the thickener being 2-30% by weight, based on the whole composition;(d) a base oil which is a lube base oil having a pour point of −25° C. or lower and comprising a synthetic hydrocarbon oil as the main component; and (e) an additive which is a mixture comprising an organomolybdenum complex, an organozinc compound of a dithiocarbamic acid, and an organozinc compound of dithiophosphoric acid, the amount of the additive being 1-7% by weight, based on the whole composition.

Owner:JTEKT CORP

Use of hydrogen and an organozinc compound for polymerization and polymer property control

Methods of controlling polymerization reactions using a synergistic amount of hydrogen and an organozinc compound are disclosed. The resulting polymers have lower molecular weights and higher melt flow indices.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polyurethane elastomers, process of their preparation and their use

The invention relates to polyurethane elastomers, a process for the preparation of these polyurethane elastomers and a the preparation of elastomeric molded parts comprising these polyurethane elastomers. These elastomers comprise the reaction product of a polyol component, chain extenders and / or crosslinking agents, one or more amine catalysts, a catalyst mixture which contains at least one organic titanium compound and at least one organic zinc compound, and optionally an organic lithium carboxylate and / or an organic bismuth carboxylate; with a polyisocyanate component.

Owner:BAYER MATERIALSCIENCE AG

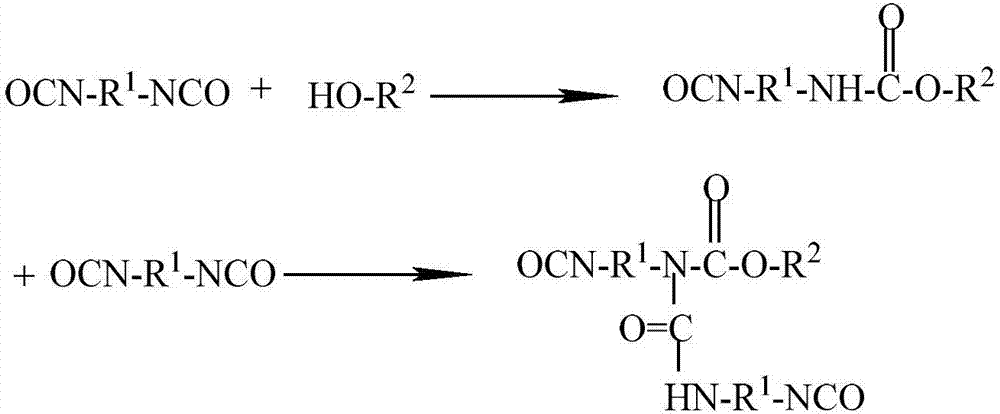

Modified polyisocyanate composition and preparation method thereof

The invention provides a modified polyisocyanate composition and a preparation method thereof. The preparation method comprises the following steps: (1) enabling monohydric alcohol to react with polyisocyanate under a heating condition, carrying out heating while stirring; and (2) further adding the polyisocyanate, carrying out secondary reaction in the presence of a catalyst under the heating condition to generate a polyisocyanate composition, wherein the catalyst is selected from any one or two of an organic zinc compound, an organic tin compound, an organic alkali metal salt, tertiary amine and a salt compound thereof. The polyisocyanate composition with certain allophanate content is prepared from monohydric alcohol-modified polyisocyanate with a special functional group; polyurethane resin prepared from the polyisocyanate composition can show special functionality of the monohydric alcohol; meanwhile, the rebound resilience of the polyurethane resin is improved; and the modified polyisocyanate composition has the characteristics of high hydrophobicity and photocuring property.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

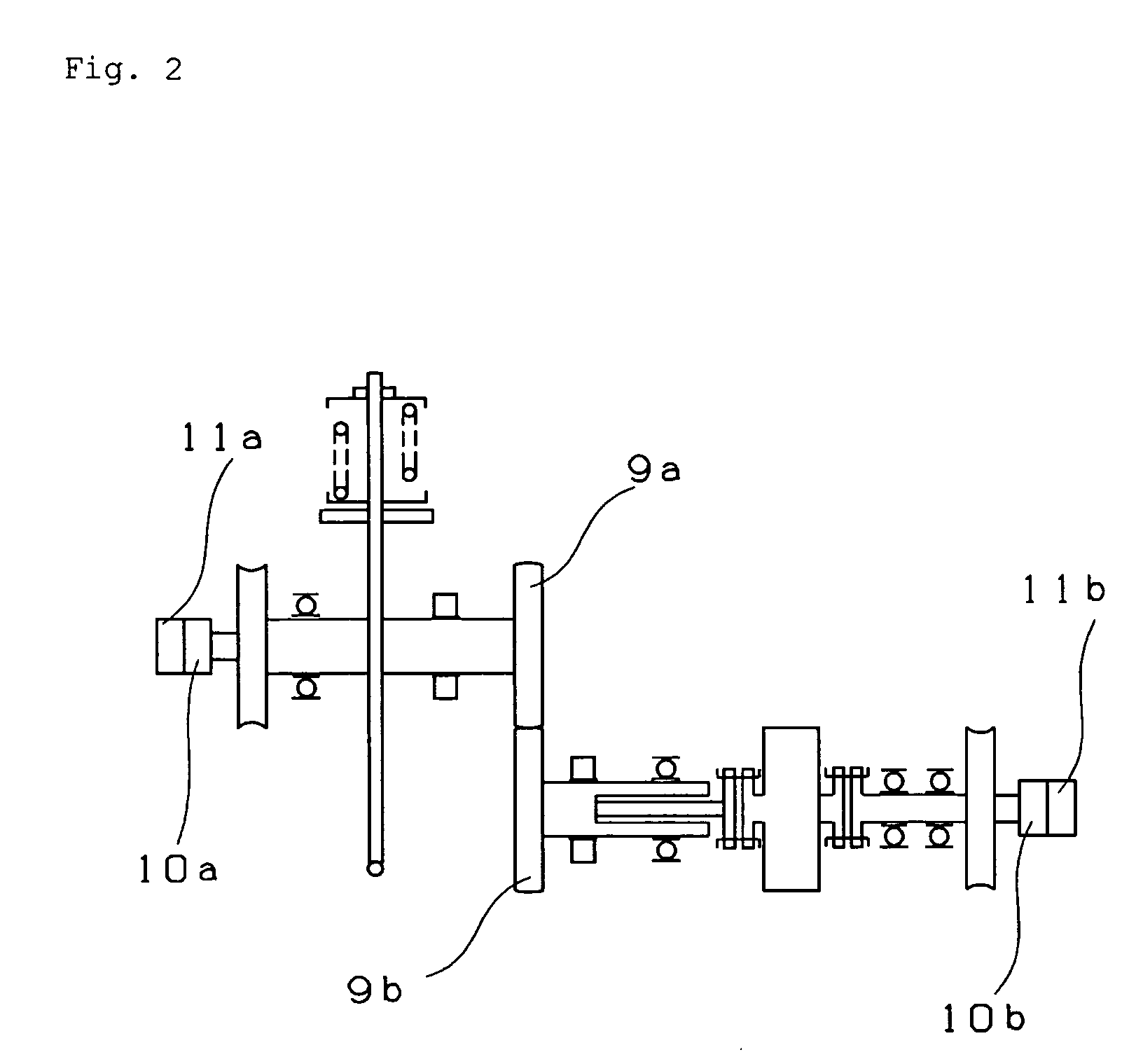

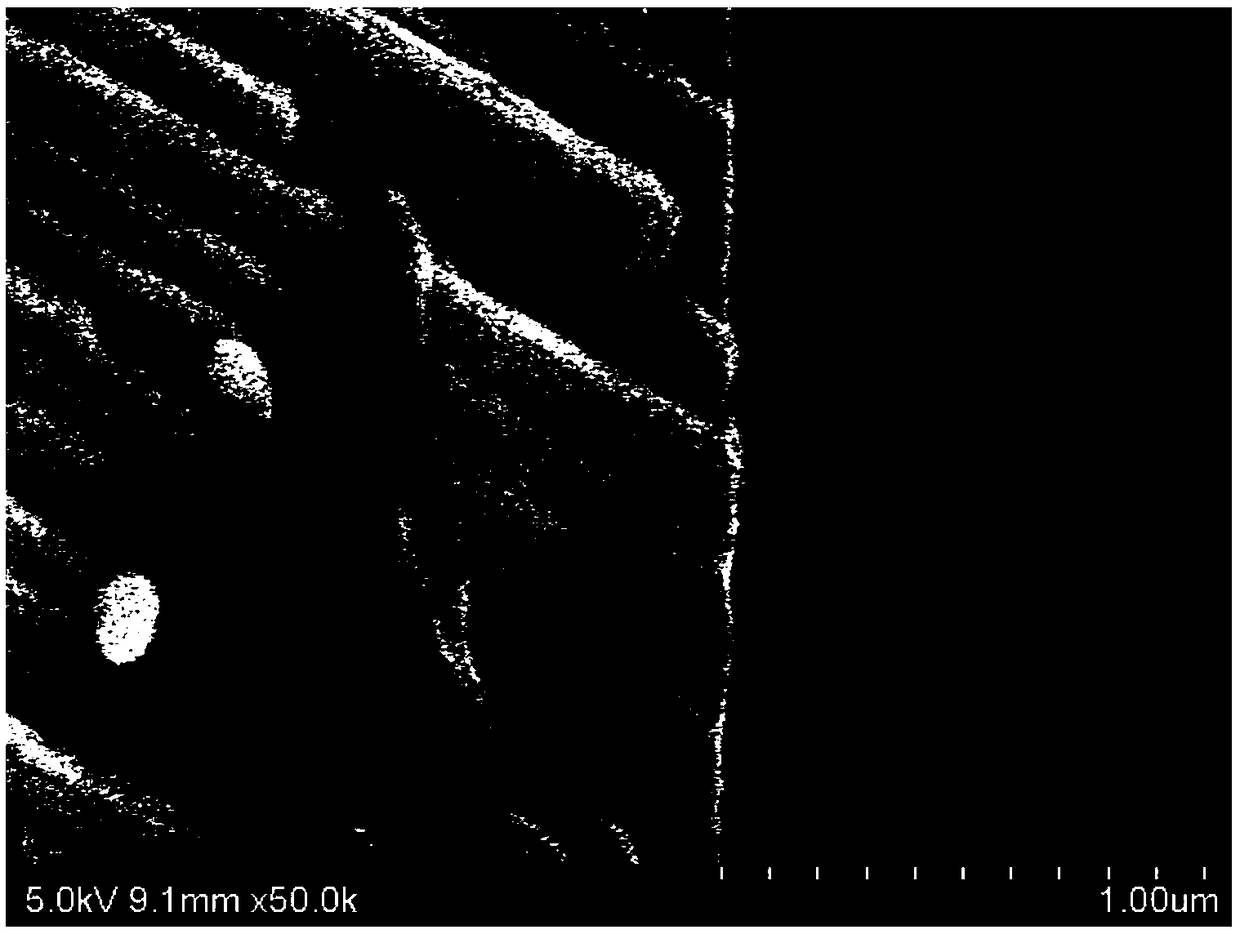

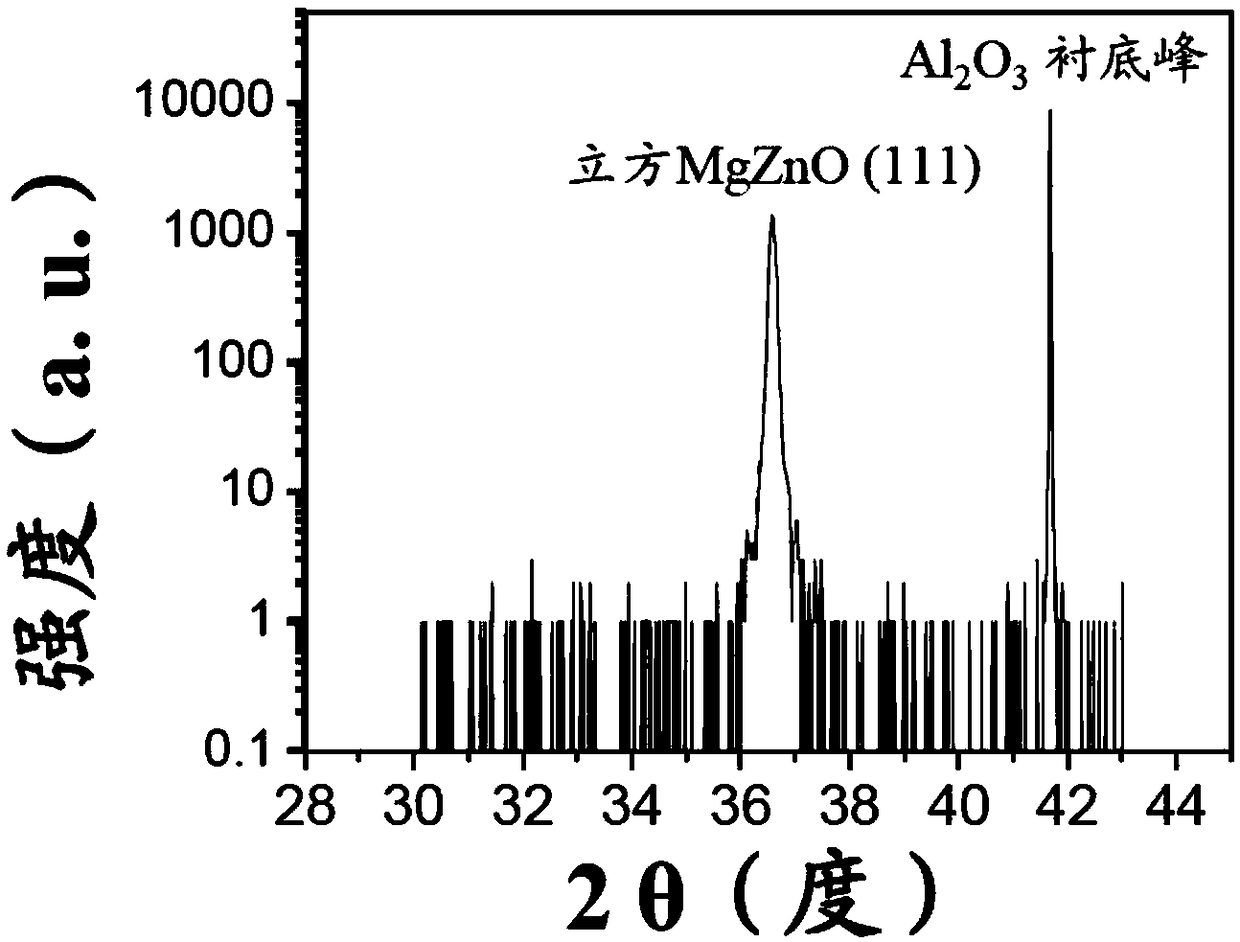

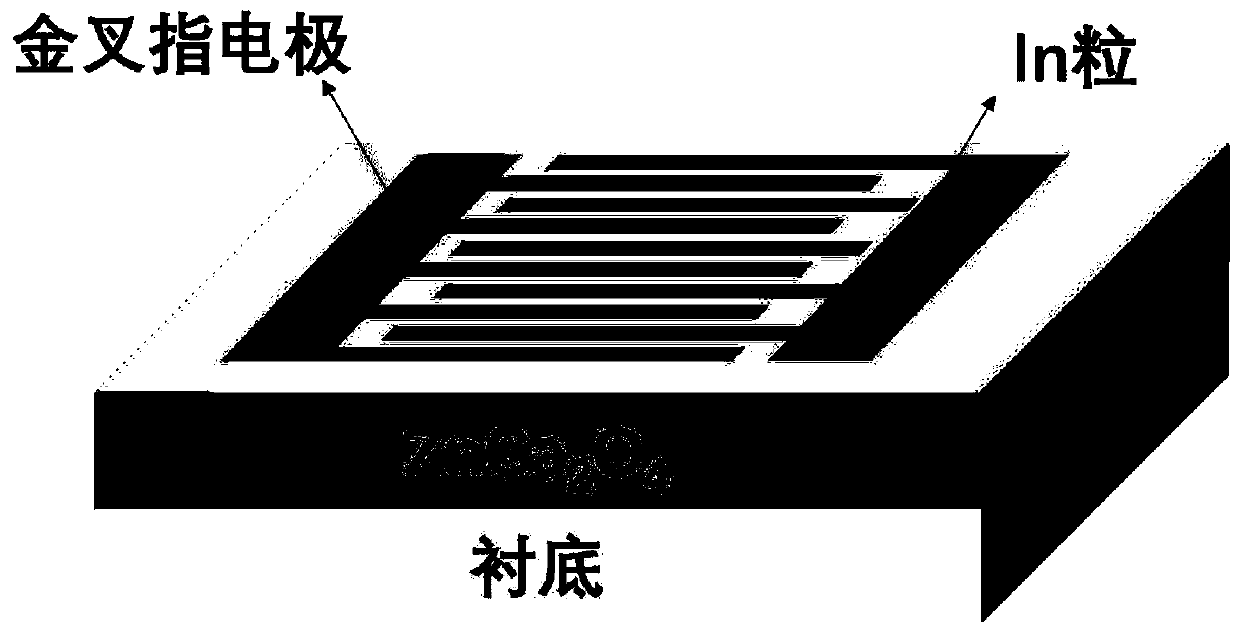

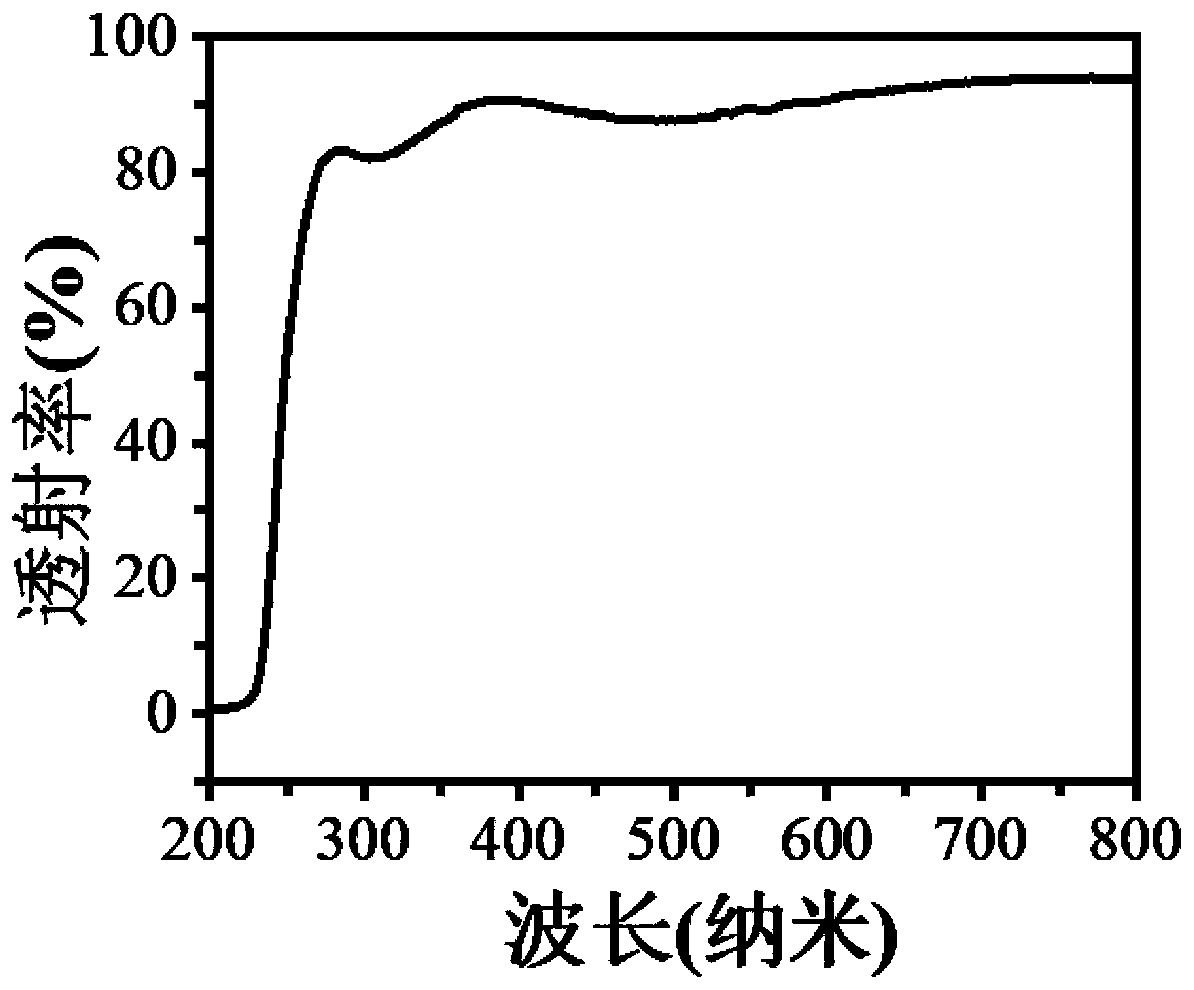

ZnMgO ultraviolet detector

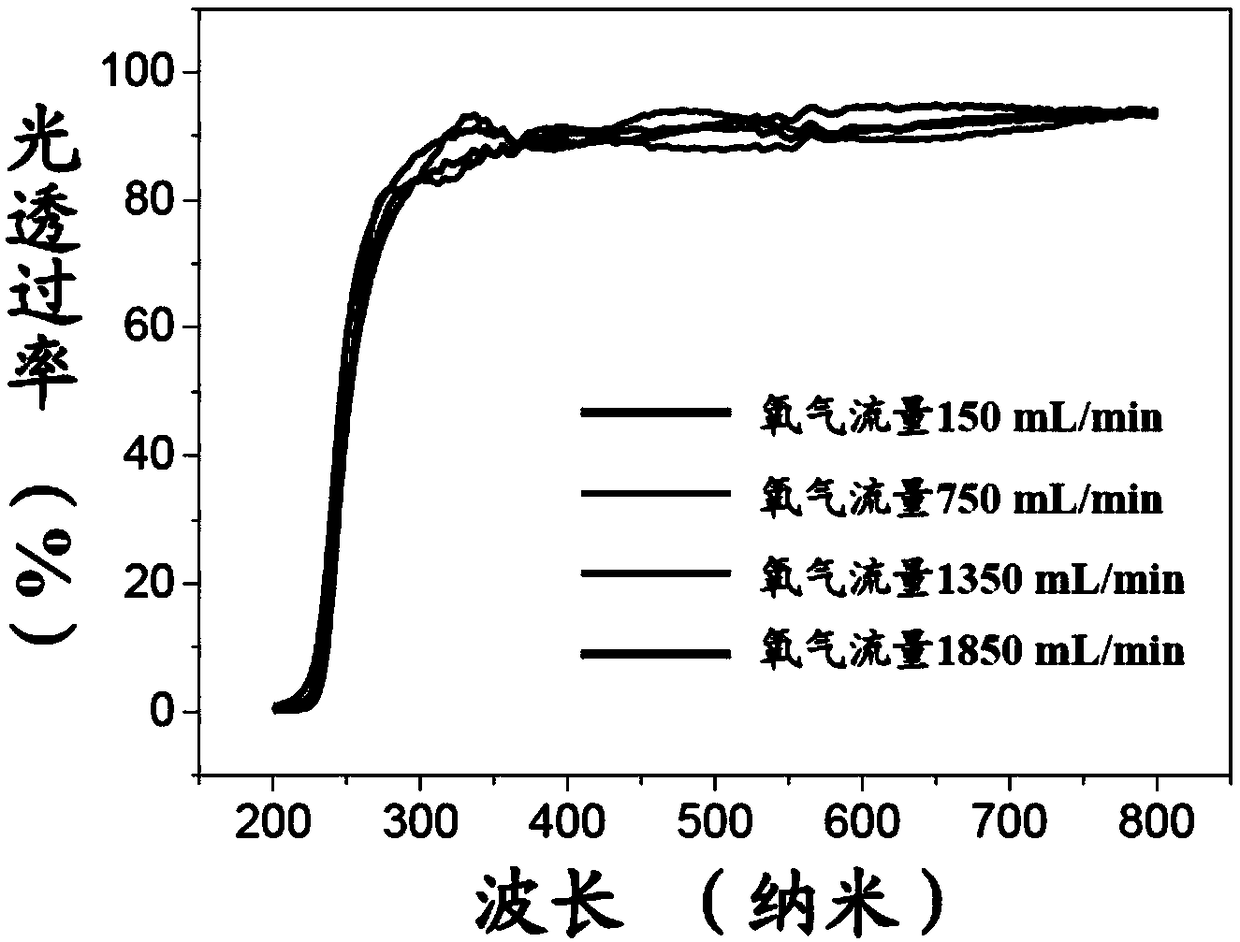

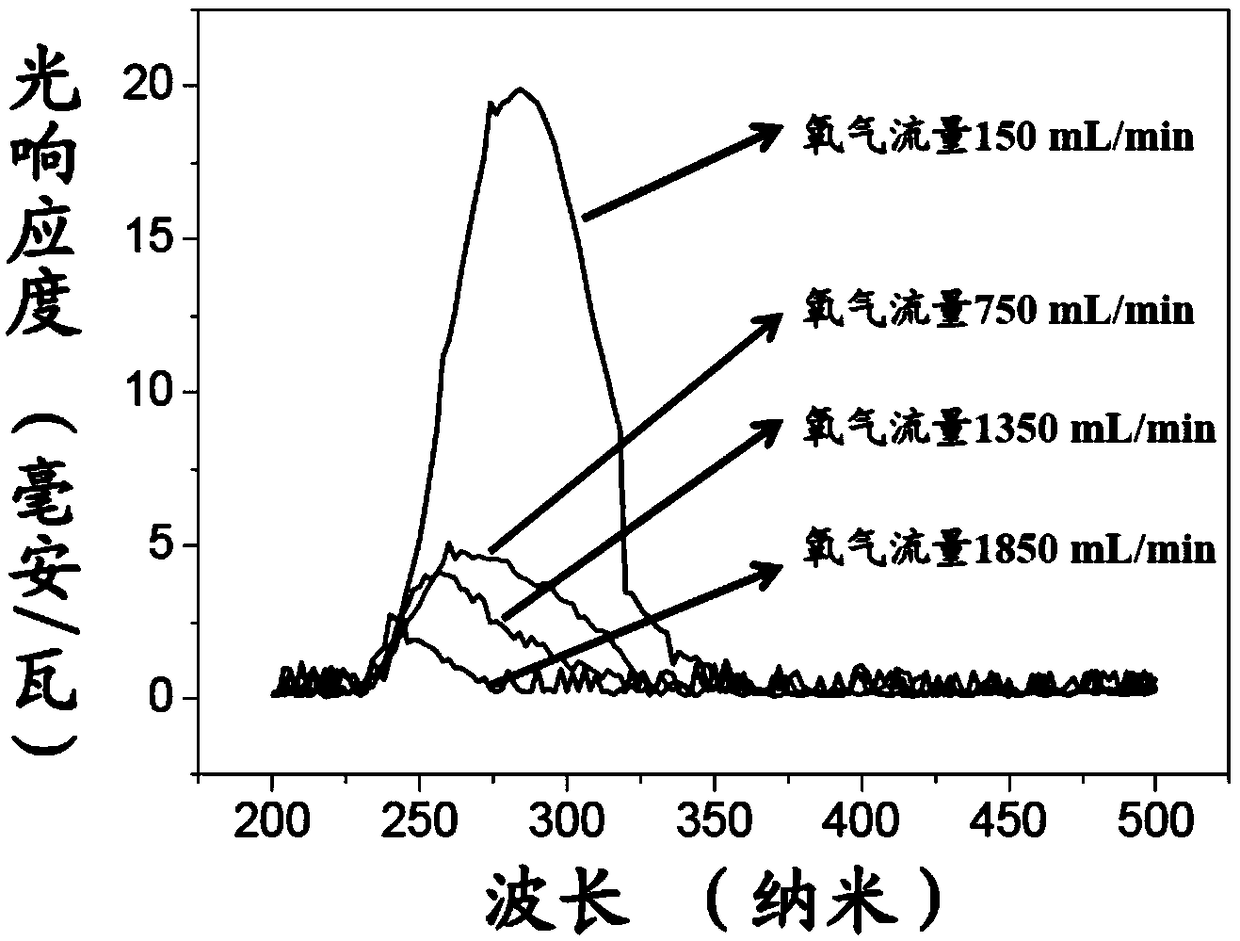

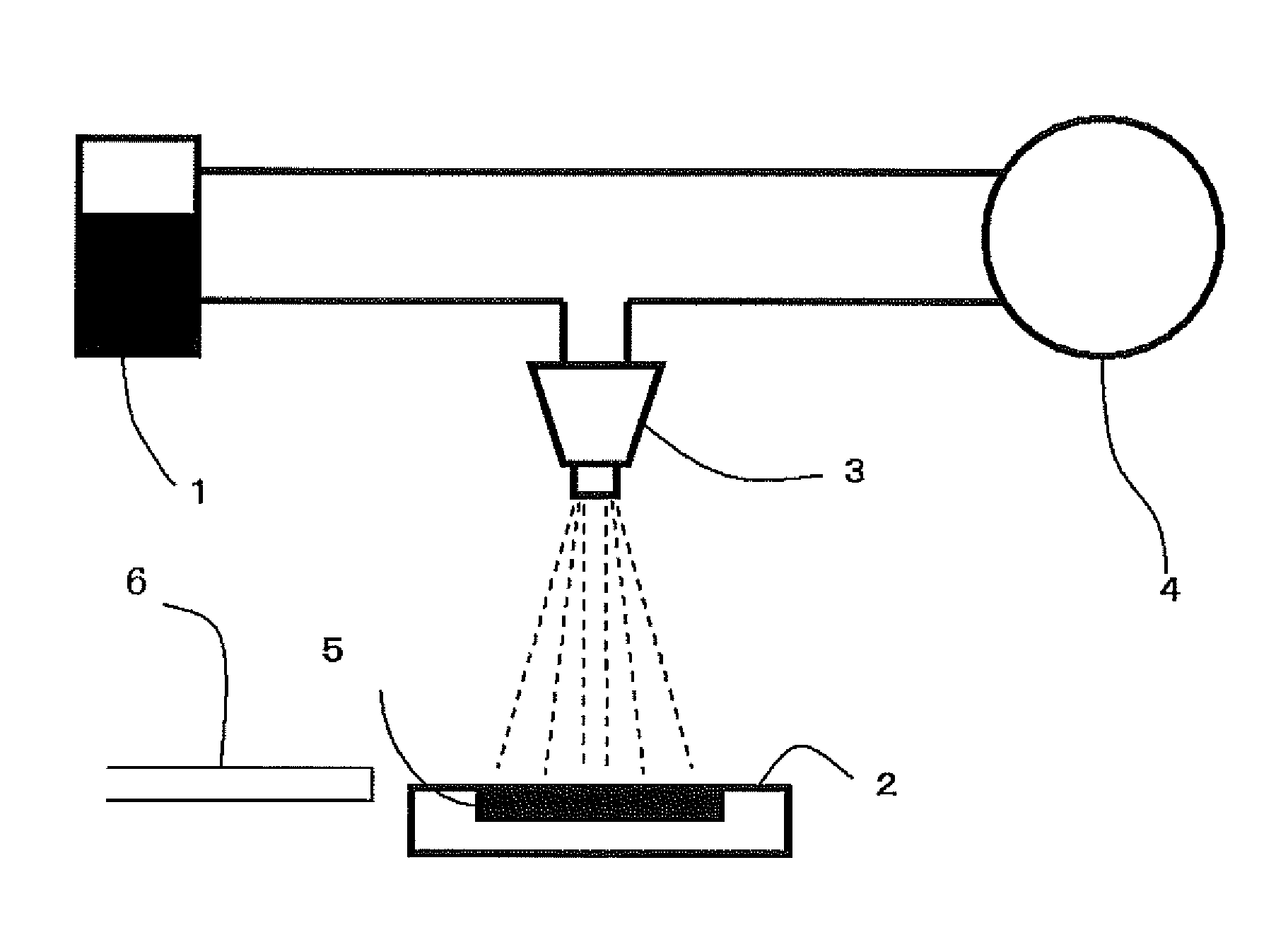

ActiveCN108922930AGood light effect abilityImprove crystal qualitySemiconductor devicesOrganozinc compoundZinc compounds

The invention provides a ZnMgO ultraviolet detector, which comprises a ZnMgO thin film layer, wherein a crystal structure of the ZnMgO thin film layer is a cubic phase; the ZnMgO thin film layer is aprepared according to the following method of growing the ZnMgO thin film layer in metal organic compound chemical vapor deposition equipment into which oxygen is introduced by employing an organic zinc compound as a zinc source and an organic magnesium compound as a magnesium source. Compared with the prior art, the ZnMgO ultraviolet detector has the advantages that a ZnMgO thin film is preparedby using a metal organic compound chemical vapor deposition method, the airflow of the ZnMgO thin film is parallel to a substrate and the growth temperature is relatively low, so that the prepared ZnMgO thin film layer has the characteristics of being high in crystal quality, free of phase separation and steep in absorption cutoff edge, the ultraviolet detector comprising the ZnMgO thin film layerhas relatively good light effect capacity, a light response cutoff edge of a device can be adjusted without adjusting the light absorption cutoff edge of the ZnMgO thin film layer, the preparation process is simple and the reaction process is easy to control.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

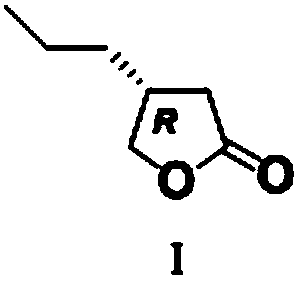

Synthesizing method of butyrolactone derivative

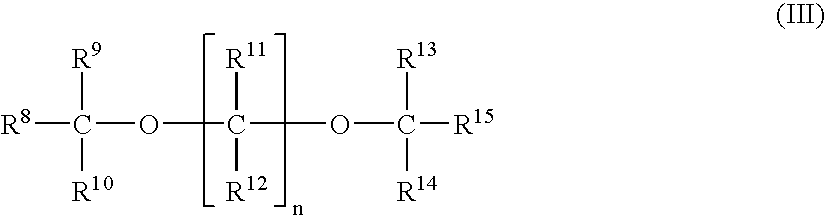

The invention discloses a synthesizing method of a butyrolactone derivative. The synthesizing method comprises the following steps of (1) activating (R)-2-propyl-ethylene oxide shown in a formula (II)by a titanium reagent, and performing addition reaction by an organic zinc compound, so as to obtain a compound shown in a formula (III); (2) performing molecular lactone exchange reaction on the compound shown in the formula (III) under the acid condition, so as to obtain the butyrolactone derivative shown in a formula (I). The synthesizing method has the advantages that the synthesizing steps are simple, the production cost is low, the selectivity of areas is strong, and the yield rate is high; the synthesizing route is shown in the description.

Owner:安徽华胜医药科技有限公司

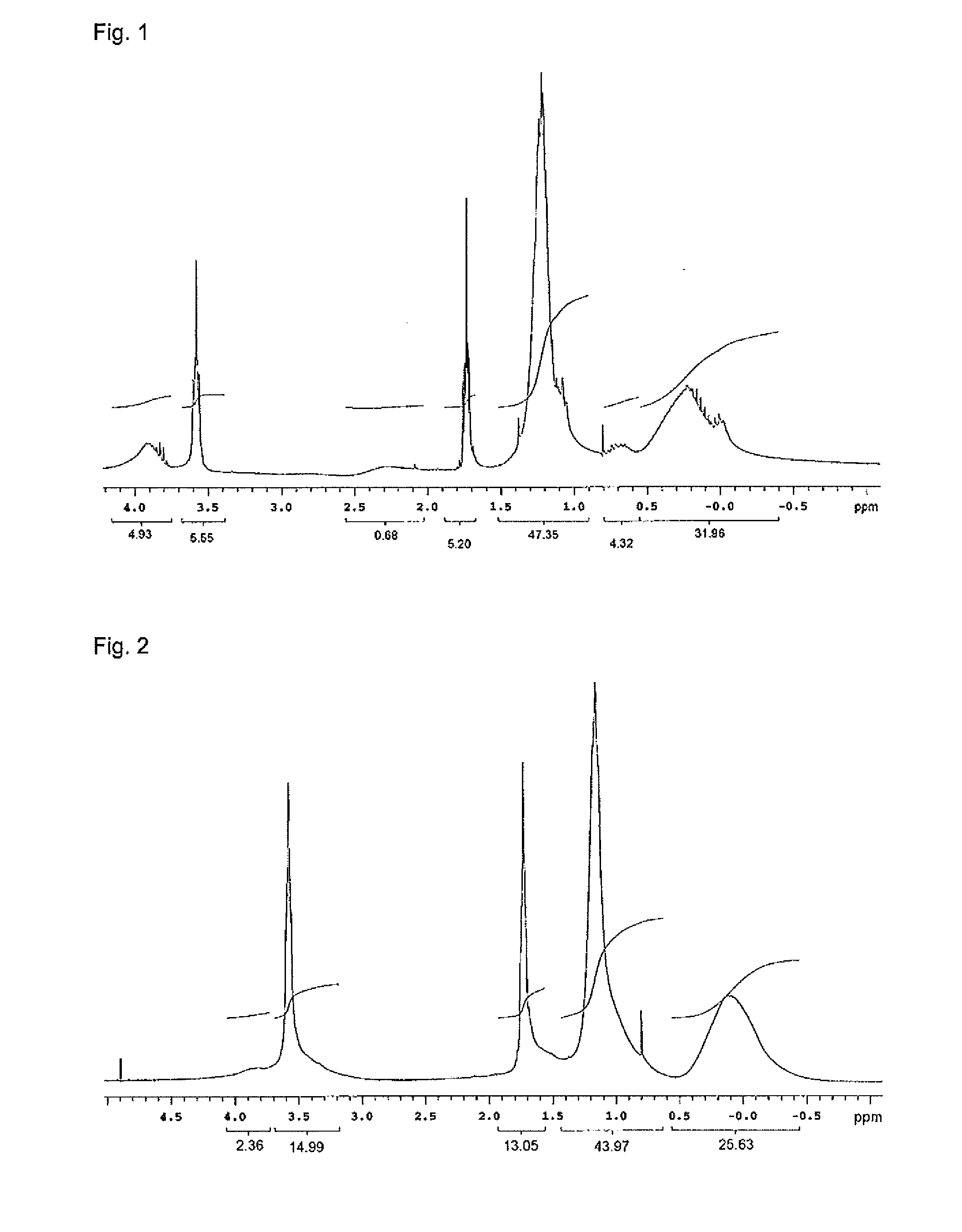

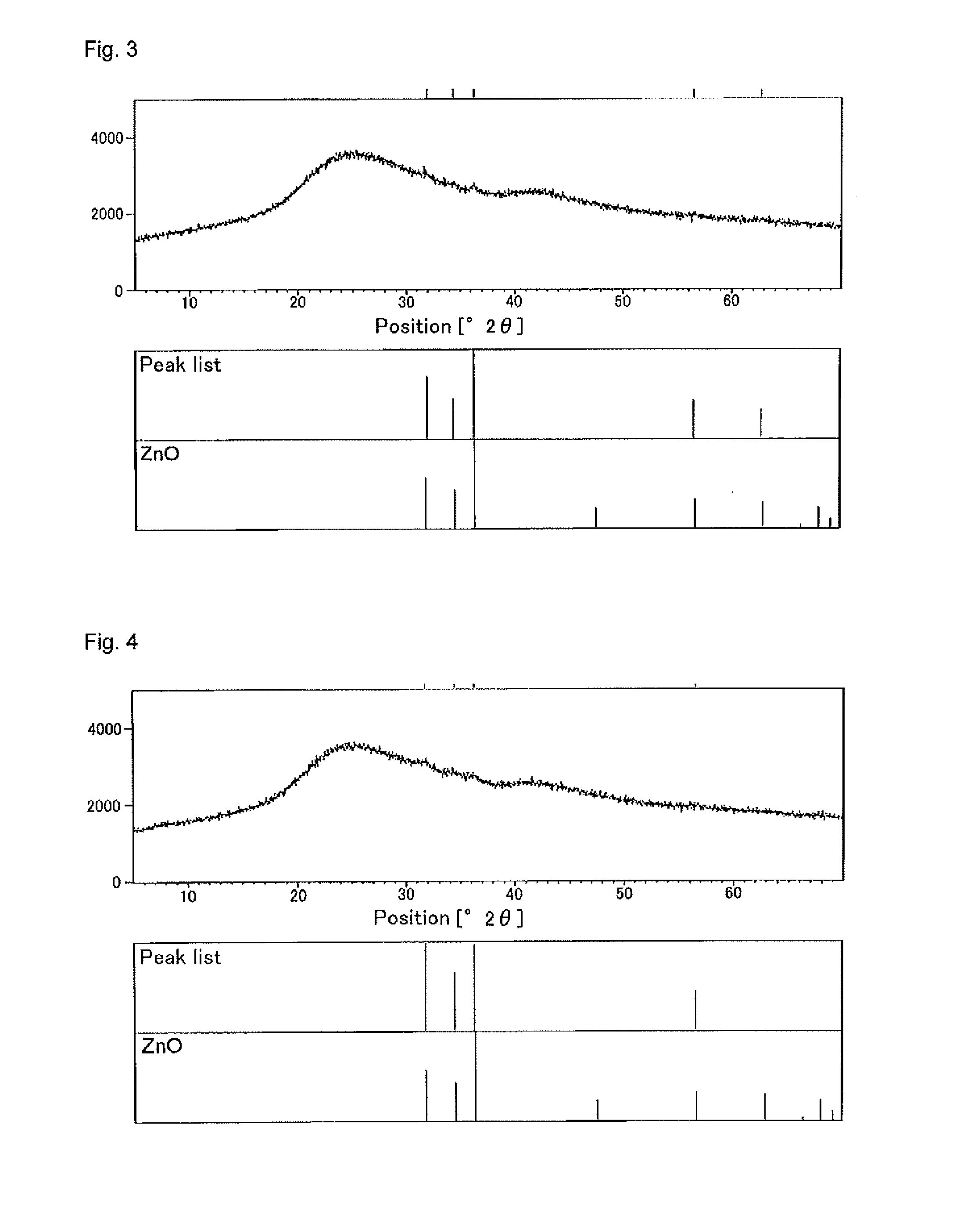

Composition for manufacturing doped or undoped zinc oxide thin film and method for manufacturing zinc oxide thin film using same

ActiveUS20120094019A1Easy to handleLow resistivityZinc oxides/hydroxidesPretreated surfacesOrganozinc compoundZinc compounds

Disclosed is a composition for forming a zinc oxide thin film, which contains an organic zinc compound as a starting material, is not ignitable, and can be easily handled. The composition for forming a zinc oxide thin film is capable of forming a transparent zinc oxide thin film which is not doped or doped with a group 3B element by being heated at 300° C. or less. Also disclosed is a method for obtaining a transparent zinc oxide thin film, which is not doped or doped with a group 3B element, using the composition. Specifically, the composition for forming a zinc oxide thin film contains a product which is obtained by partially hydrolyzing an organic zinc compound by adding water to the organic zinc compound or a solution of the organic zinc compound and a group 3B element compound. In cases when a group 3B element compound is contained, the molar ratio of the group 3B element compound to the organic zinc compound is within the range of 0.005-0.3. The composition is applied to a substrate surface and then heated, thereby forming a zinc oxide thin film which is doped with the group 3B element.

Owner:TOSOH FINECHEM CORP

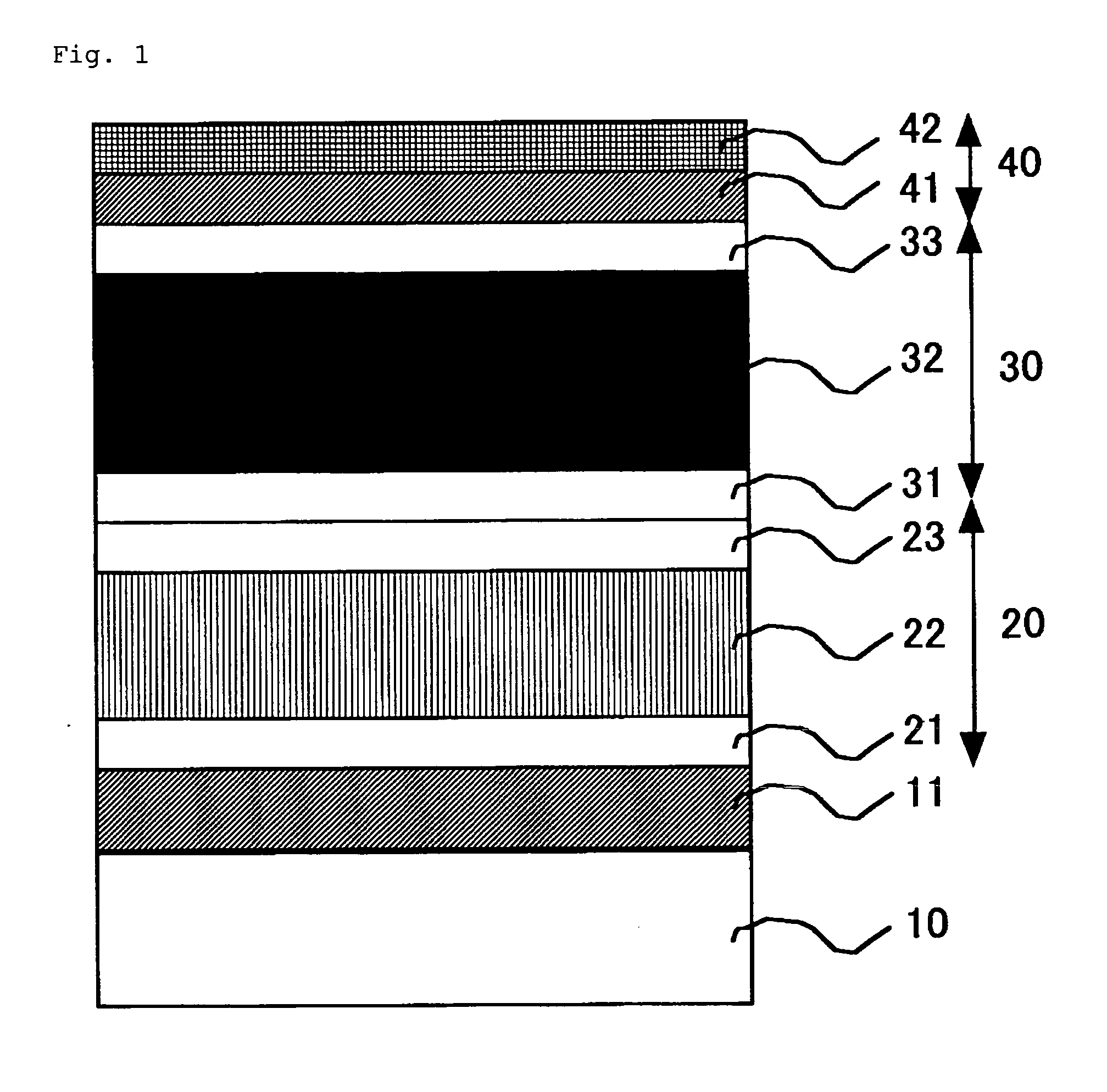

Process for producing transparent conductive film and process for producing tandem thin-film photoelectric converter

The present invention provides a method for making a transparent conductive film, which contains zinc oxide as a main component and which has high transmittance, low resistivity, and excellent surface morphology, highly uniformly and simply, using an inexpensive dilution gas, and also provides a method for making a tandem thin-film photoelectric converter including the method for making the transparent conductive film. A method for making a transparent conductive film according to the present invention includes introducing an organozinc compound, a dilution gas, and an oxidizing agent into a deposition chamber to form a transparent conductive film containing zinc oxide as a main component on a substrate disposed in the deposition chamber, wherein the dilution gas is hydrogen. Since hydrogen has high thermal conductivity and is inexpensive, it is possible to provide a transparent conductive film having excellent characteristics with low cost.

Owner:KANEKA CORP

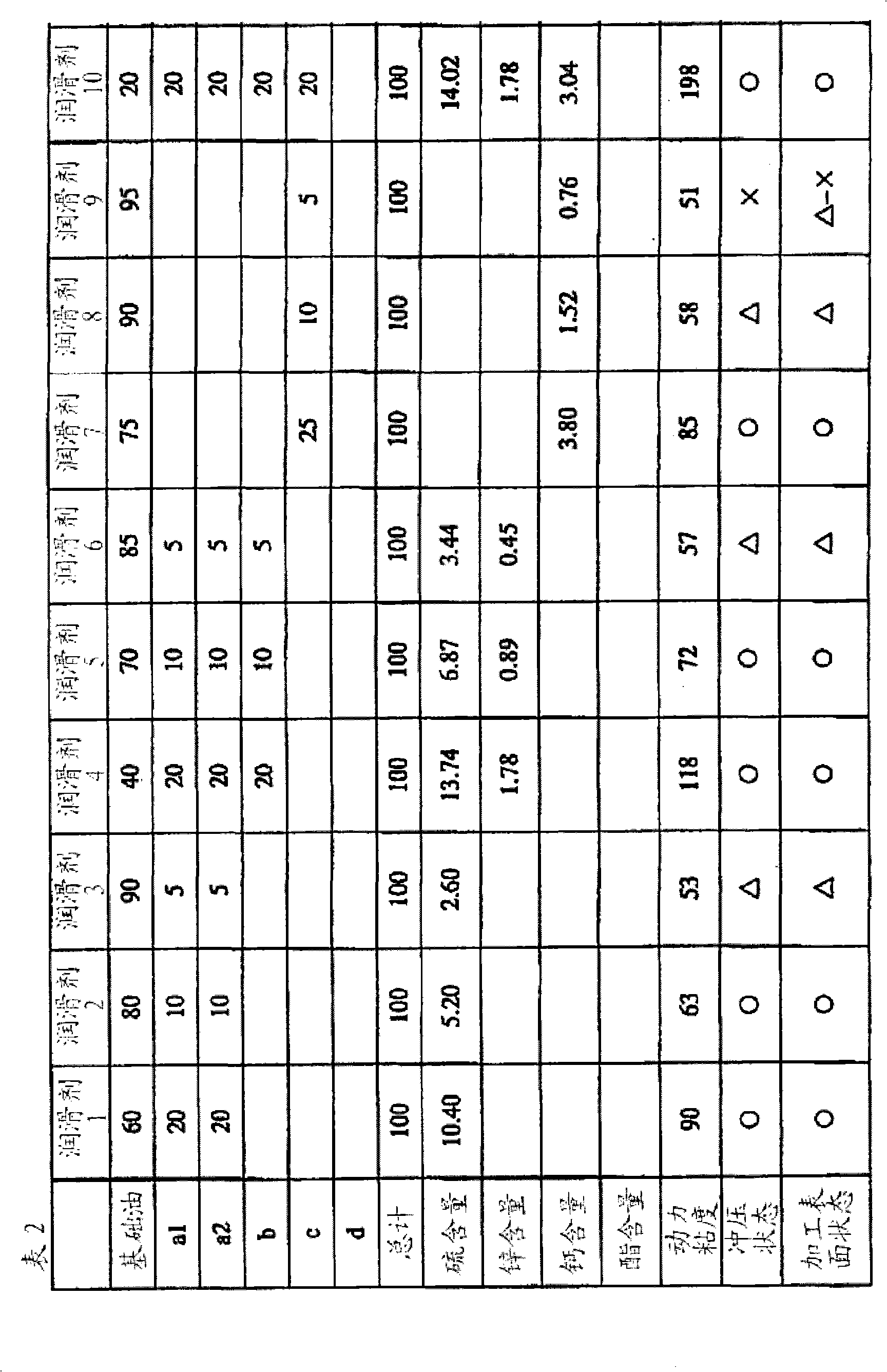

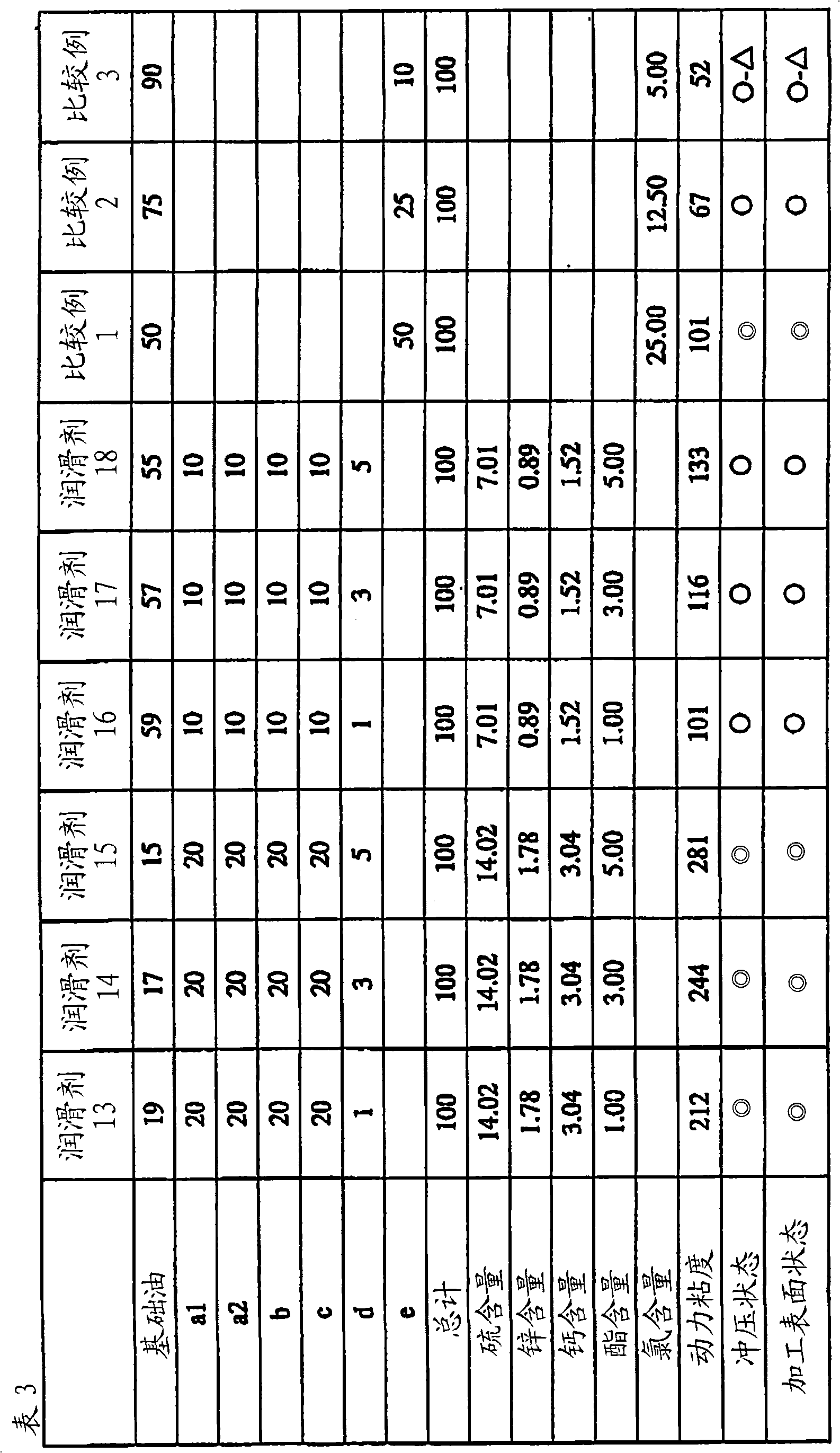

Lubricant for metallic material working and a method of press working a metallic material

To provide a lubricant for metallic material working and a method of press working a metallic material that makes it possible to improve the working accuracy of a press worked product and prolong the life of the die assembly beyond prior levels of life. [Solution] A lubricant for metallic material working comprises a mixture of a sulfur-based extreme pressure agent, an organic zinc compound, a calcium-based additive, and an ester compound, with lubricant base oil. The sulfur-based extreme pressure agent has a sulfur content of 5% by weight or higher based on the total weight of the lubricant. The organic zinc compound has a zinc content of 0.5% by weight or higher based on the total weight of the lubricant. The calcium-based additive has a calcium content of 0.5% by weight or higher based on the total weight of the lubricant. And the ester compound occupies a content of 1.0% by weight or higher based on the total weight of the lubricant. Additionally, the solution includes a method of press working a metallic material that employs such a lubricant.

Owner:TOYOTA BOSHOKU KK

Use of Hydrogen and an Organozinc Compound for Polymerization and Polymer Property Control

Methods of controlling polymerization reactions using a synergistic amount of hydrogen and an organozinc compound are disclosed. The resulting polymers have lower molecular weights and higher melt flow indices.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

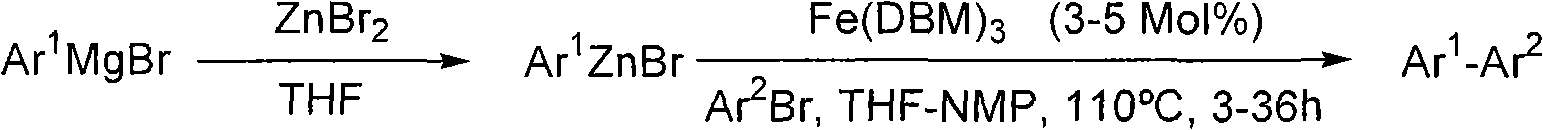

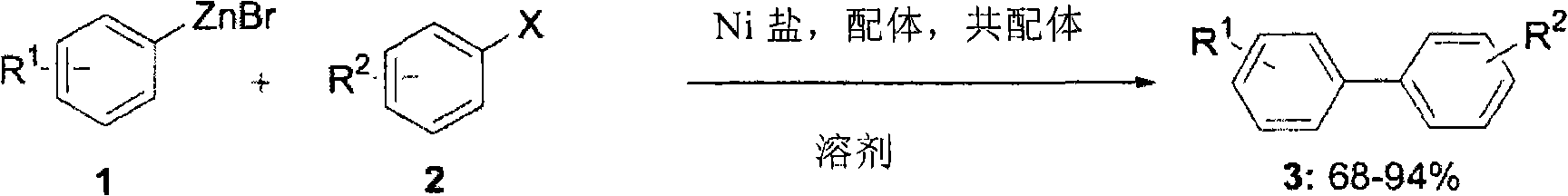

Nickel or iron catalysed carbon-carbon coupling reaction of arylenes, alkenes and alkines

According to the invention, organozink compounds of R<1>-Ar<1>-ZnY (1) type are convertible, with different functionalised aryl halides R<2>-Ar<2>-X (2) in the presence of Ni or Fe catalytic quantities in a polar solvent or a polar solvent mixture, into a polyfunctional biarylene of R<1>-Ar<1>-AR<2>-R<2> (3) type. The type (1) organic compounds are obtainable by a transmetallisation reaction of aryl-magnesium halides or lithium-aryl compounds, for example with ZnBr2.

Owner:SALTIGO GMBH

Olefin polymerization process

InactiveUS20050010004A1High activityIncrease weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganozinc compoundPolyolefin

A method for preparing a supported organometallic complex is disclosed. An organometallic complex is combined with a support material that has been treated with an organozinc compound. The organometallic complex comprises a Group 3 to 10 transition metal and an indenoindolyl ligand that is bonded to the transition metal. Also disclosed is a process for polymerizing an olefin using the supported complex. Organozinc treatment of the support unexpectedly boosts catalyst activity and polyolefin molecular weight.

Owner:EQUSR CHEM LP

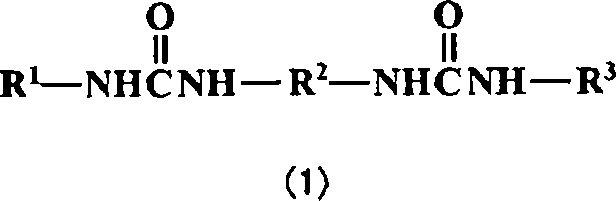

Grease for hub bearings and hub bearing

InactiveCN101194003ASuppresses surface-originated peelingSolution to short lifeBearing componentsThickenersOrganozinc compoundCarbamate

The present invention provides a hub bearing, made of carbon steel for machine structural use, which has a long life even in a strict lubricating condition by improving the resistance to peeling starting from the surface. A grease for the hub bearing contains a base oil, a thickener, and an organozinc compound which is at least one compound selected from dithiozinc carbamate and dithiozinc phosphate. The base oil is a mineral oil or a mixed oil of a mineral oil and a synthetic hydrocarbon oil. The thickener is a urea compound shown by the following formula (1) and is contained at 1 to 40 mass % for the entire grease. The grease for the hub bearing is enclosed in the hub bearing. (In the formula (1), R 2 indicates an aromatic hydrocarbon group having 6 to 15 carbon atoms, and R 1 and R 3 indicate at least one hydrocarbon group selected from an alicyclic hydrocarbon group and an aromatic hydrocarbon group.

Owner:NTN CORP

Rolling device employing lubricating grease composition and electric power steering apparatus employing the rolling device

A rolling device employing a lubricating grease composition containing a thickener which is a mixture of (a) one or more diurea compounds made from one or more primary amines and a diisocyanate; (b) at least one fatty acid metal salt; (c) at least one amide compound selected from the group consisting of aliphatic amides and bisamides, where the proportions of (a), (b) and (c) satisfy the relationship: a / (b+c)=0.2−10 provided that (1) the proportion of ingredient (a) is 1-10, (2) the proportion of ingredient (b) is 0.5-2.5, and (3) the proportion of ingredient (c) is 0.5-2.5, and the amount of the thickener is 2 to 30% by weight, based on the lubricating grease composition; (d) a base oil which is a lube base oil having a pour point of −36 to −67.7° C. that includes a synthetic hydrocarbon oil as the main component; and (e) 1-7% by weight of an additive mixture containing an organomolybdenum complex, an organozinc compound of a dithiocarbamic acid, and an organozinc compound of dithiophosphoric acid.

Owner:JTEKT CORP

Novel PVC heat stablizer

A novel PVC heat stabilizer is characterized by at least comprising the following raw materials in parts by weight: 10 to 30 parts of organic zinc compound, 2 to 10 parts of organic tin compound, 20 to 40 parts of phthalic acid ester, 10 to 30 parts of alkyl acid ester, 10 to 30 parts of phosphite, 5 to 20 parts of chloromethoxyl fatty acid methyl ester, 1 to 5 parts of phenol, and 2 to 8 parts of 2-ethyl hexanol, wherein the organic tin compound comprises 1 to 4 sulfur atoms.

Owner:邵卫东

Grease for Hub Bearing and Hub Bearing

InactiveUS20090136172A1Prevent peelingSolution to short lifeRoller bearingsHubsOrganozinc compoundCarbamate

The present invention provides a hub bearing, made of carbon steel for machine structural use, which has a long life even in a strict lubricating condition by improving the resistance to peeling starting from the surface. A grease for the hub bearing contains a base oil, a thickener, and an organozinc compound which is at least one compound selected from dithiozinc carbamate and dithiozinc phosphate. The base oil is a mineral oil or a mixed oil of a mineral oil and a synthetic hydrocarbon oil. The thickener is a urea compound shown by the following formula (1) and is contained at 1 to 40 mass % for the entire grease. The grease for the hub bearing is enclosed in the hub bearing.(In the formula (1), R2 indicates an aromatic hydrocarbon group having 6 to 15 carbon atoms, and R1 and R3 indicate at least one hydrocarbon group selected from an alicyclic hydrocarbon group and an aromatic hydrocarbon group.)

Owner:NTN CORP

ZnMgO thin film and preparation method thereof

ActiveCN108962732AImprove crystal qualityLow growth temperatureFinal product manufactureSemiconductor/solid-state device manufacturingOrganozinc compoundZinc compounds

The invention provides a preparation method of a ZnMgO thin film. The preparation method includes the step of taking an organic zinc compound as a zinc source and an organic magnesium compound as a magnesium source and enabling a ZnMgO thin film to grow on a substrate in a metal organic compound chemical vapor deposition apparatus to which oxygen is introduced. Compared with the prior art, the method has the advantages that a metal organic compound chemical vapor deposition method is adopted to prepare a ZnMgO thin film, and the growth temperature is low, so that the prepared ZnMgO thin film has the characteristics of high crystalline quality, no phase separation, steep absorption edge and the like. The preparation method of the invention has potential application prospects in preparationmethods of photoelectric devices. Moreover, the preparation process is simple and the reaction procedure is easy to control.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

ZnGa2O4 ultraviolet detector and preparation method thereof

InactiveCN111081799AImprove crystal qualityReduce dark currentFinal product manufactureSemiconductor devicesOrganozinc compoundZinc compounds

The invention provides a ZnGa2O4 ultraviolet detector. The ZnGa2O4 ultraviolet detector comprises a substrate, a ZnGa2O4 thin film and a metal interdigital electrode which are sequentially compounded,wherein the ZnGa2O4 thin film is obtained by taking an organic zinc compound as a zinc source, an organic gallium compound as a gallium source and high-purity oxygen as an oxygen source and depositing on the surface of a substrate by utilizing a metal-organic compound chemical vapor deposition method. According to the invention, the ZnGa2O4 thin film is prepared by using a metal-organic compoundchemical vapor deposition method, and the prepared ZnGa2O4 thin film layer is enabled to have the characteristics of high crystallization quality, no phase splitting, steep absorption cut-off edge andthe like by increasing oxygen flow, increasing oxygen partial pressure and reducing oxygen defects, so that the ultraviolet detector containing the ZnGa2O4 thin film layer has relatively low dark current and relatively high responsivity.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

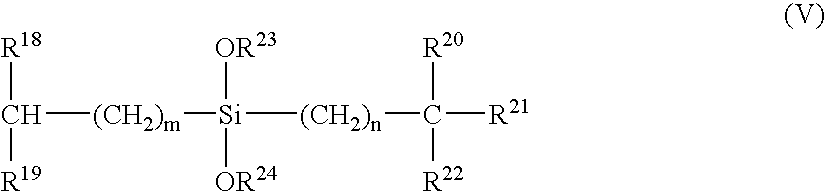

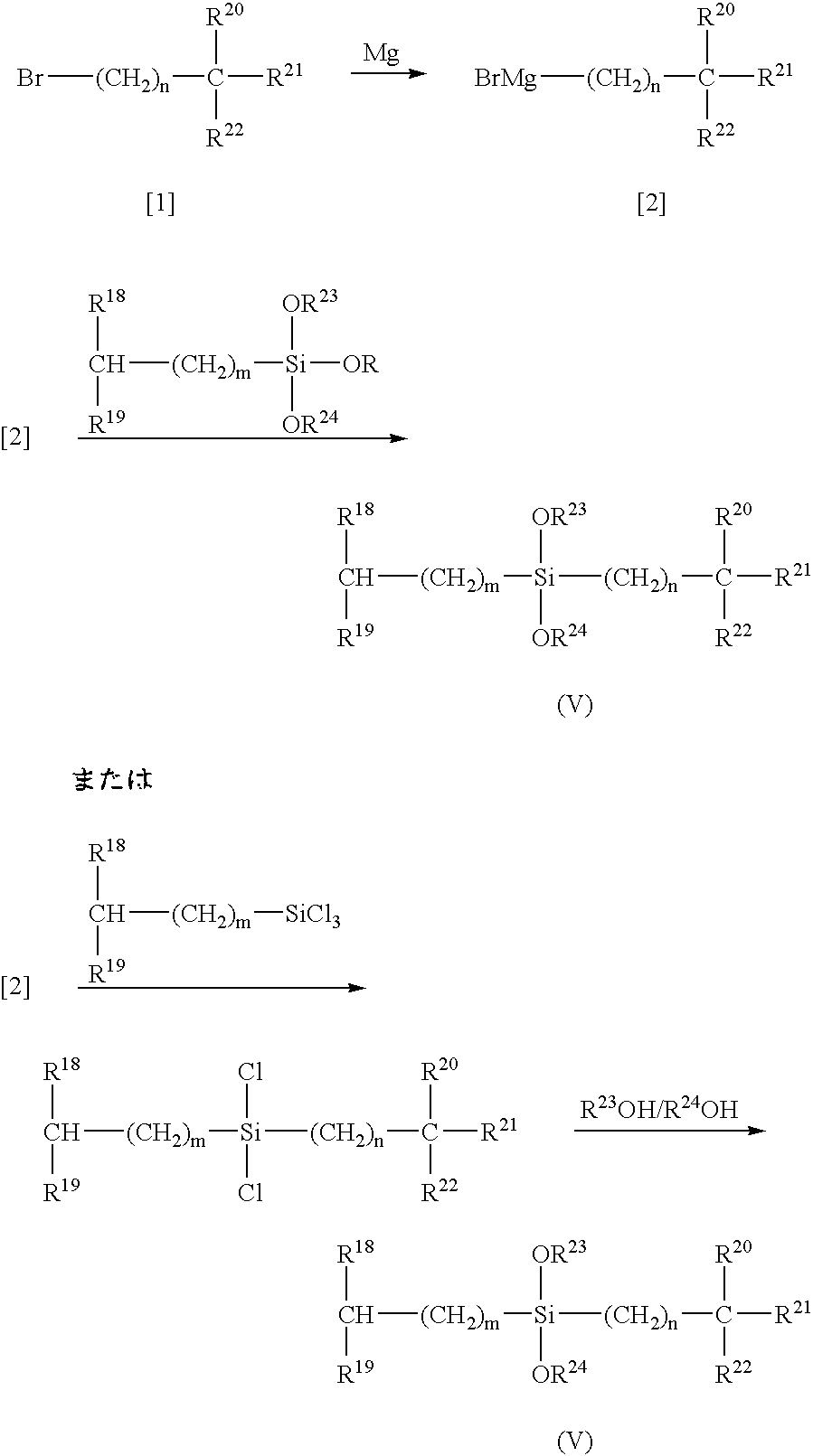

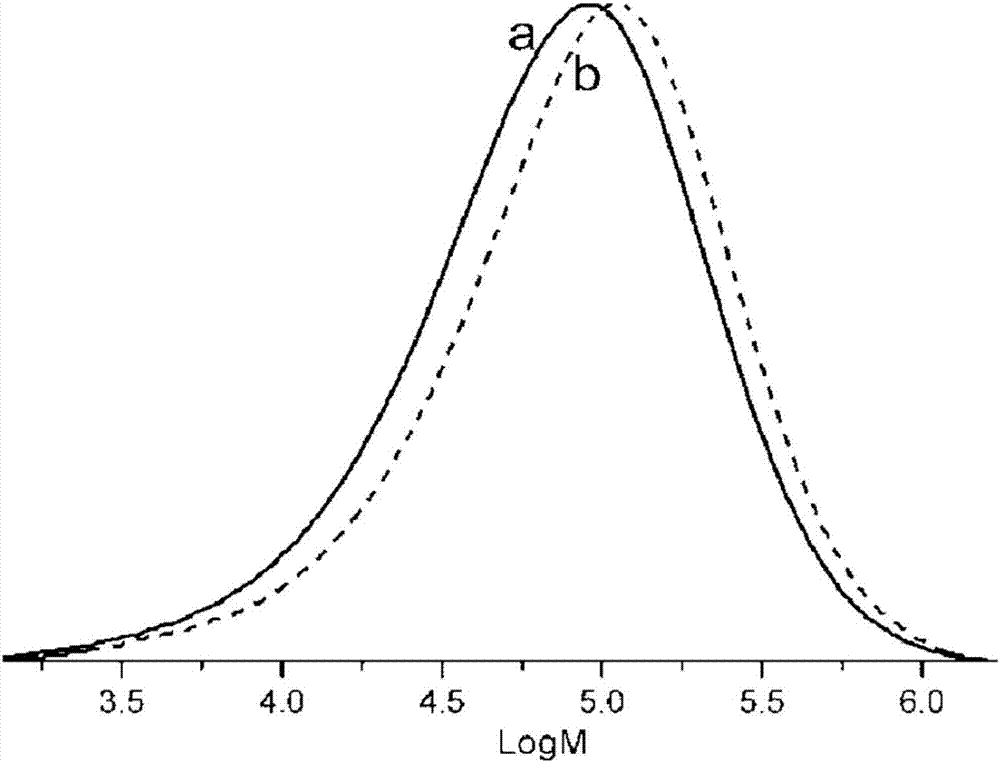

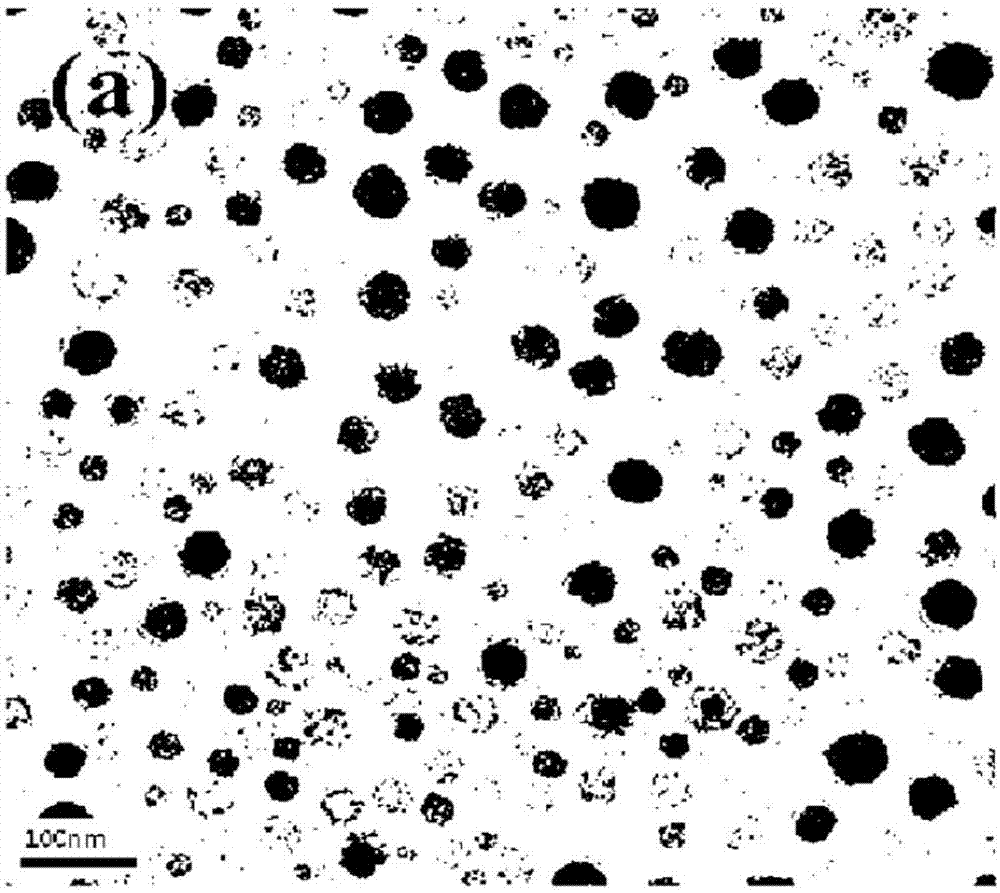

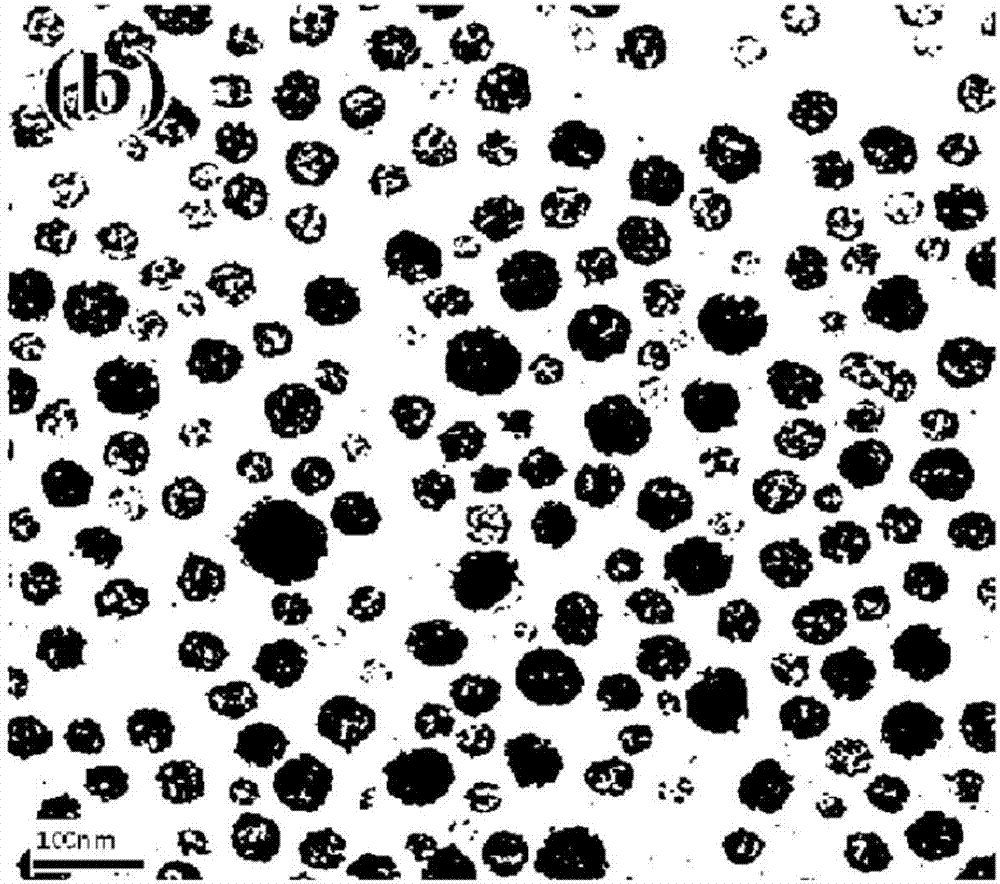

Organic zinc compound comprising polyolefin-polystyrene block copolymer, and method for preparing same

The present invention relates to an organic zinc compound comprising a styrene-based polymer or a polyolefin-polystyrene block copolymer at both ends. Also, the present invention relates to a method for preparing the organic zinc compound, the method preparing an intermediate by coordination-polymerizing an olefin monomer using a transition metal catalyst, and then performing anionic polymerization by inserting an alkyllithium compound, an amine ligand, and a styrene-based monomer into the intermediate. Accordingly, the present invention can provide a method for preparing a commercially useful styrene-based polymer or polyolefin-polystyrene block copolymer directly from an olefin monomer and a styrene monomer in a one-pot manner.

Owner:LG CHEM LTD

PVC preparation process for wire plastic particles

InactiveCN109354808ASuitable for a wide rangeGood heat resistance and high temperature resistanceOrganozinc compoundPolyester

The invention discloses a PVC preparation process for wire plastic particles. The preparation process includes the following materials: by weight, 50-150 parts of PVC resin, 10-15 parts of a thermal stabilizer, 30-60 parts of epoxy resin, 30-60 parts of thermoplastic polyester, 5 parts of a foaming agent, 10 parts of a toughening agent, 2 parts of an antioxidant, 1 part of a lubricant and 10-30 parts of vinyl chloride resin. The thermal stabilizer includes, by weight, 10-30 parts of organic zinc compound, 2-10 parts of organic tin compound, 20-40 parts of phthalates, 10-30 parts of alkyl esters, 10-30 parts of phosphite ester, 5-20 parts of chloro-methoxy fat diethylene glycol dinitrate, 1-5 parts of phenol and 2-8 parts of 2-ethylhexanol. The toughening agent includes a mixture of methylmethacrylate-butadiene and styrenic terpolymer (MBS), and the antioxidant is 2,6-tertiary butyl-4 methylphenol. The wire plastic particles prepared by the process are obviously superior to common PVCplastic granules on the market, have good heat resistance and high temperature resistance, high insulation capacity, high aging resistance and good toughness, and are suitable for wider electric wireindustry.

Owner:广东正品智慧科技股份有限公司

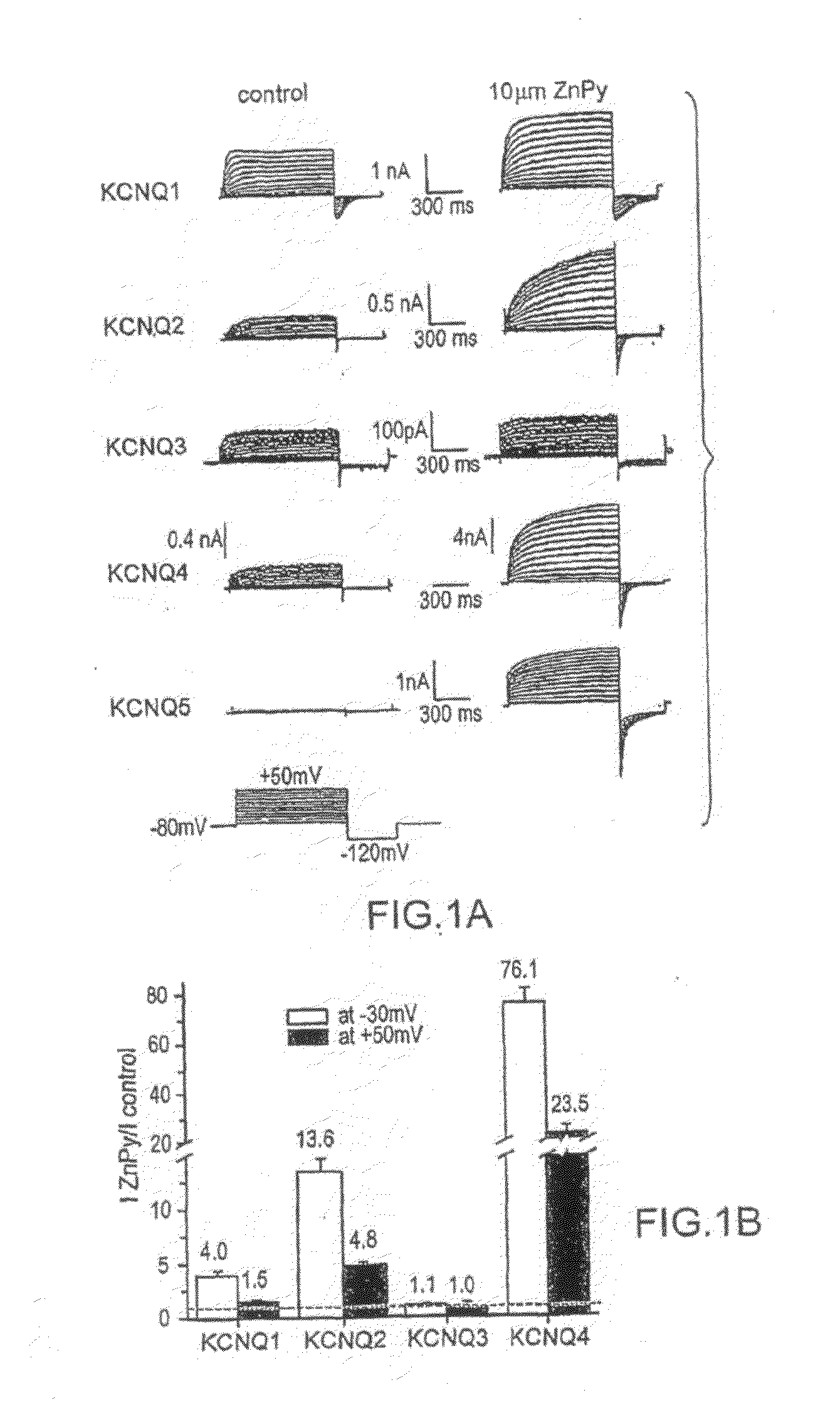

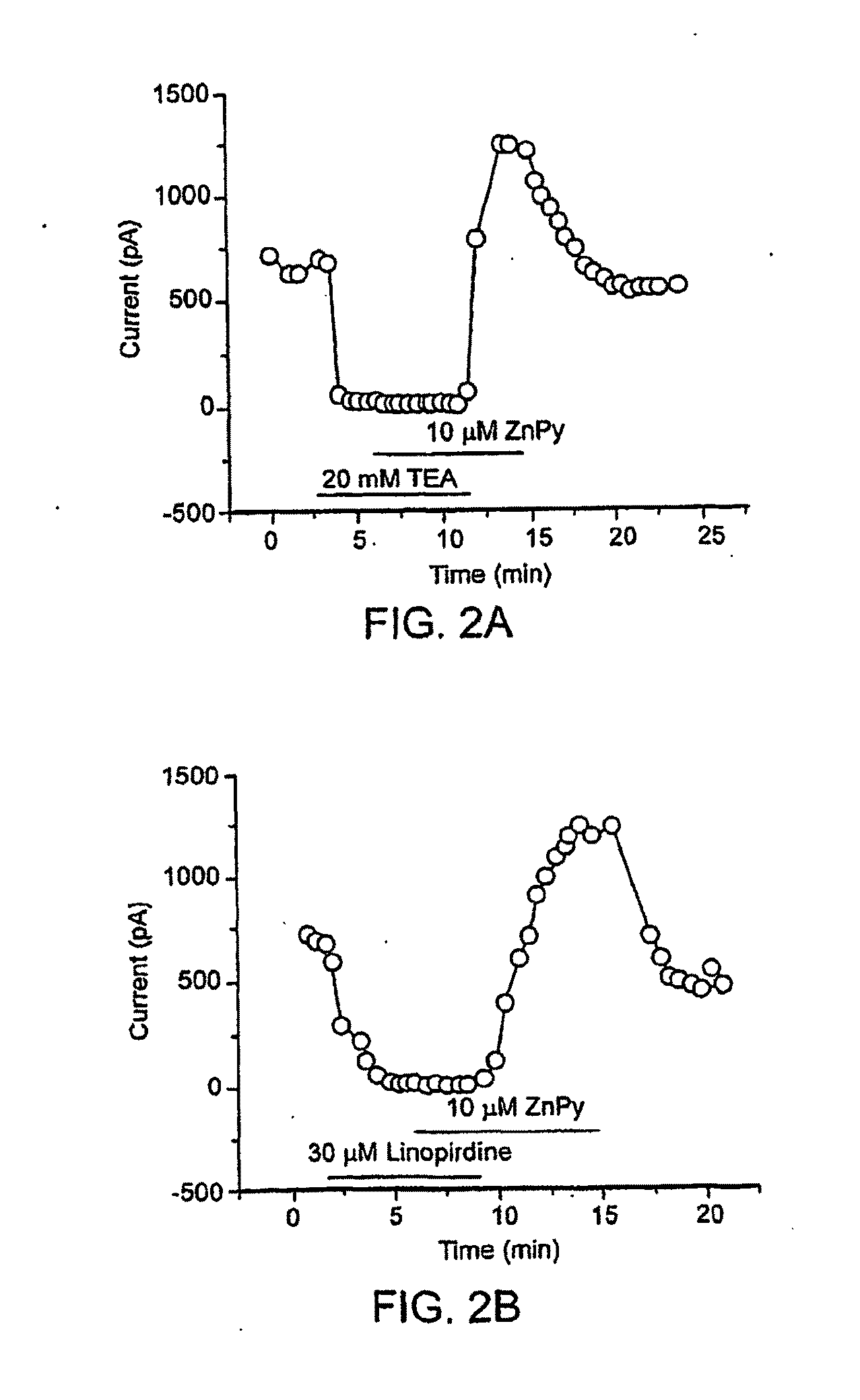

Method of Treating Kcnq Related Disorders Using Organozinc Compounds

InactiveUS20110257146A1Increase flow of ionAvoid inactivationBiocideBiological testingOrganozinc compoundSodium Pyrithione

The instant invention describes methods of treating KCNQ related diseases and disorders using organozinc compounds. In certain embodiments, pain is treated using Zinc Pyrithione.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Lubricant for metallic material working and a method of press working a metallic material

ActiveUS20090011965A1Reduce frictionImprove working precisionWork treatment devicesAdditivesOrganozinc compoundZinc compounds

[Object] To provide a lubricant for metallic material working and a method of press working a metallic material that makes it possible to improve the working accuracy of a press worked product and prolong the life of the die assembly beyond prior levels of life. [Solution] A lubricant for metallic material working comprises a mixture of a sulfur-based extreme pressure agent, an organic zinc compound, a calcium-based additive, and an ester compound, with lubricant base oil. The sulfur-based extreme pressure agent has a sulfur content of 5% by weight or higher based on the total weight of the lubricant. The organic zinc compound has a zinc content of 0.5% by weight or higher based on the total weight of the lubricant. The calcium-based additive has a calcium content of 0.5% by weight or higher based on the total weight of the lubricant. And the ester compound occupies a content of 1.0% by weight or higher based on the total weight of the lubricant. Additionally, the solution includes a method of press working a metallic material that employs such a lubricant.

Owner:TOYOTA BOSHOKU KK

Method for Producing Block Copolymer Composition

PendingUS20210002303A1Excellent chemical durabilityImprove thermal stabilityZinc organic compoundsOrganozinc compoundOrganic acid

A method for producing a block copolymer composition including a diblock copolymer and a triblock copolymer each containing a polyolefin-based block and a polystyrene-based block is disclosed herein. In some embodiments, the method includes reacting an organic zinc compound with one or more kinds of olefin-based monomers in the presence of a transition metal catalyst to form an intermediate having an olefin-based polymer block, reacting the intermediate styrene-based monomer in the presence of an alkyllithium compound to form a product having a styrene-based polymer block, and reacting the product with water, oxygen, or an organic acid to form a block copolymer wherein the number of moles of the alkyllithium compound used to form the product is larger than the number of moles of the organic zinc compound used to form the intermediate.

Owner:LG CHEM LTD

Lubricant for use in press working of a metal material and a press working method of a metal material using the same

ActiveCN101255370AHigh viscosityImproved cleaning propertiesAdditivesOrganozinc compoundZinc compounds

Owner:TOYOTA BOSHOKU KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com