Organic zinc compound comprising polyolefin-polystyrene block copolymer, and method for preparing same

A compound, organic zinc technology, applied in the direction of silicon organic compounds, zinc organic compounds, organic chemistry, etc., can solve problems that require multi-stage engineering, cannot be applied to commercial engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Process for the preparation of organozinc compounds comprising block copolymers

[0071] Another example of the present invention relates to the preparation method of the organozinc compound of the chemical formula 1.

[0072] The method for preparing an organozinc compound comprising a polyolefin-polystyrene block copolymer of the present invention prepares the organozinc compound of Chemical Formula 1 by using olefin monomers and styrene monomers as reactants. The organozinc compound of 1 prepared by this method can be easily converted into an industrially useful polyolefin-polystyrene block copolymer having a structure represented by the following chemical formula 7 by reacting with water, oxygen, or an organic acid.

[0073] Also, the method for preparing an organozinc compound of the present invention has the advantage that it is easy to obtain polyolefin-polystyrene block copolymerization only by a simple process of continuously feeding water, oxygen, or organic a...

Embodiment 1

[0129] Example 1: Preparation of organozinc compounds containing polystyrene groups [chemical formula 1 (a=0, A=hexyl (hexyl), Ar=phenyl (Ph))]

[0130] After dihexylzinc compound (11.3mg, 0.048mmol) was dissolved in methylcyclohexane (2.5g) and put into a 1-necked flask, at the same time, n- Butyl lithium (6.2 mg, 0.096 mmol, [Li] / [Zn]=0.20) and tetramethylethylenediamine (11.2 mg, 0.096 mmol) as a compound of Chemical Formula 5. After stirring for 10 minutes, dissolved styrene monomer (2.5 g, 24 mmol, [styrene] / [zinc]=500) was added to methylcyclohexane (2.5 g), followed by anionic polymerization at 90 for 2 hours. The conversion of styrene to polystyrene was confirmed by nuclear magnetic resonance (NMR) spectroscopy.

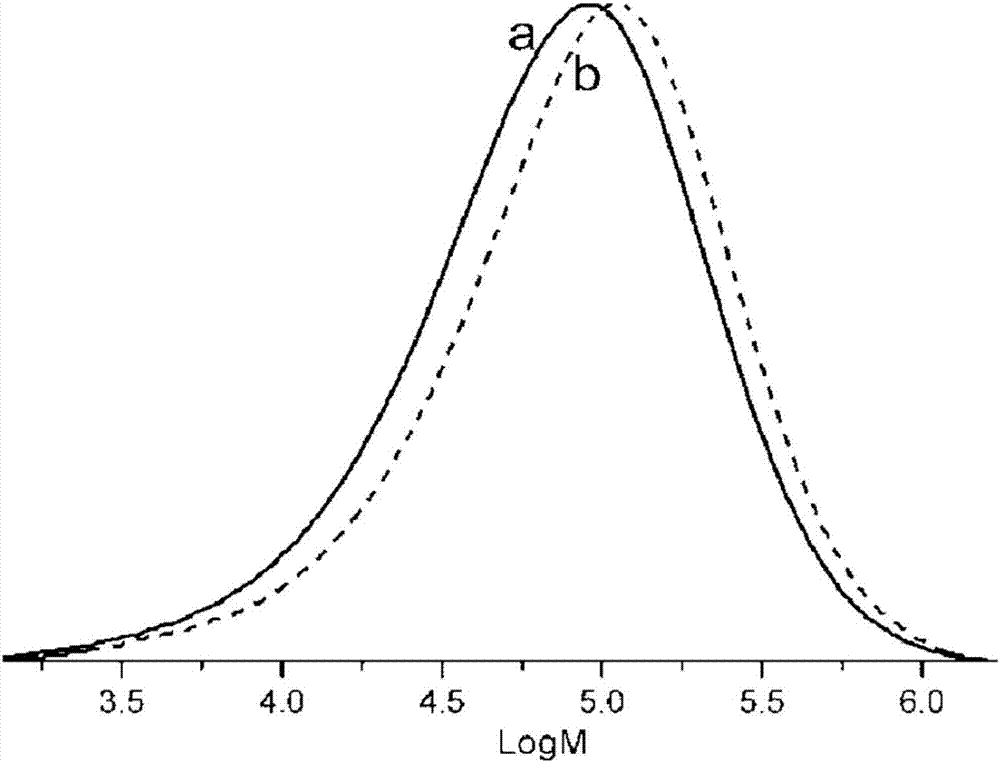

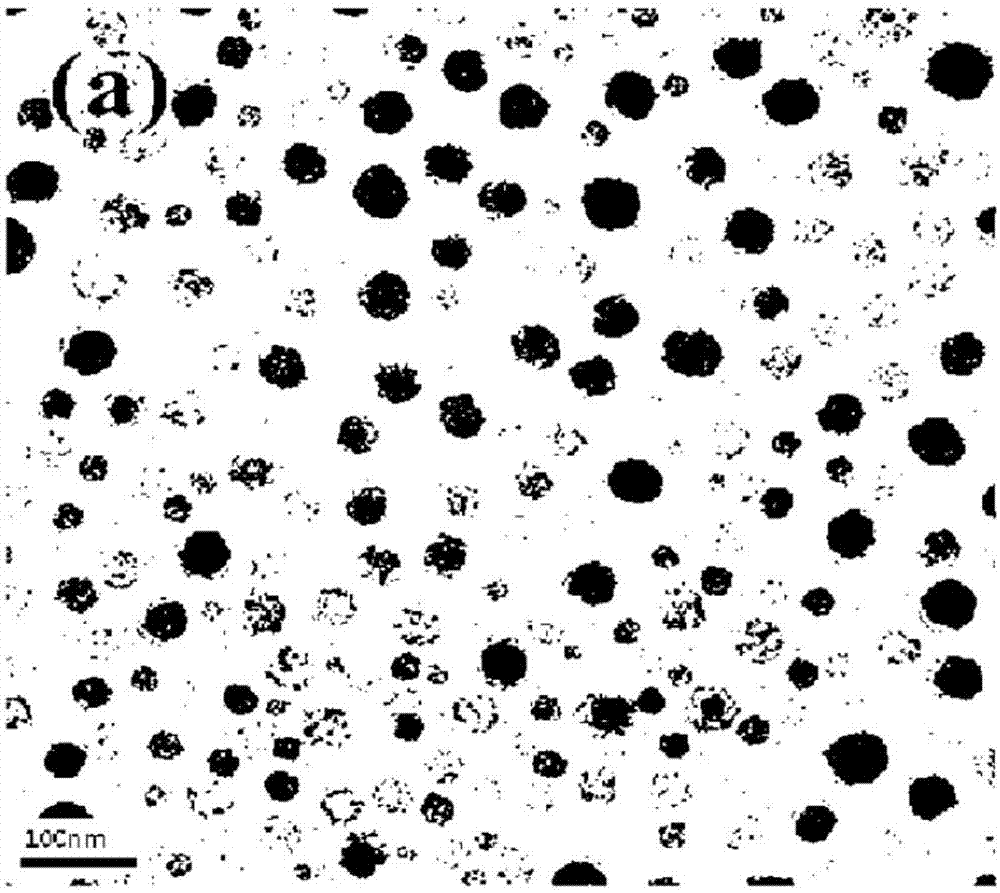

[0131] After decomposing an organozinc compound and an organolithium compound including polystyrene produced by adding ethanol (1 mL), it was dissolved in methylcyclohexane and passed through a silica gel pad to obtain pure polystyrene. The quality of pure ...

Embodiment 2

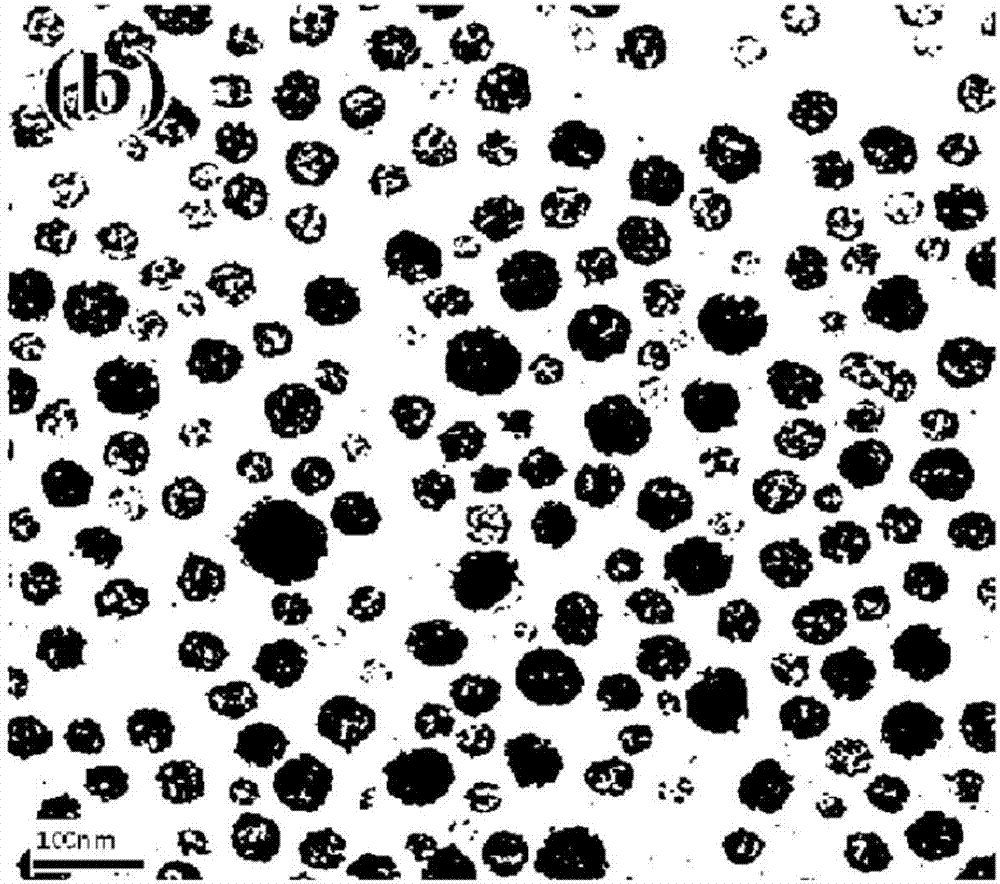

[0137] An experiment was performed in the same manner as in Example 1, except that the amount of n-butyllithium·(tetramethylethylenediamine) was increased by 5 times (ie, [Li] / [Zn]=1.0). It was confirmed that the number of polystyrene polymer chains generated from the organozinc compound was (ie, {[PS-chain]-[Li]} / [Zn]) 1.97, and the polymer chains were efficiently grown bidirectionally from the zinc compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com