Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

254 results about "Absorption edge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

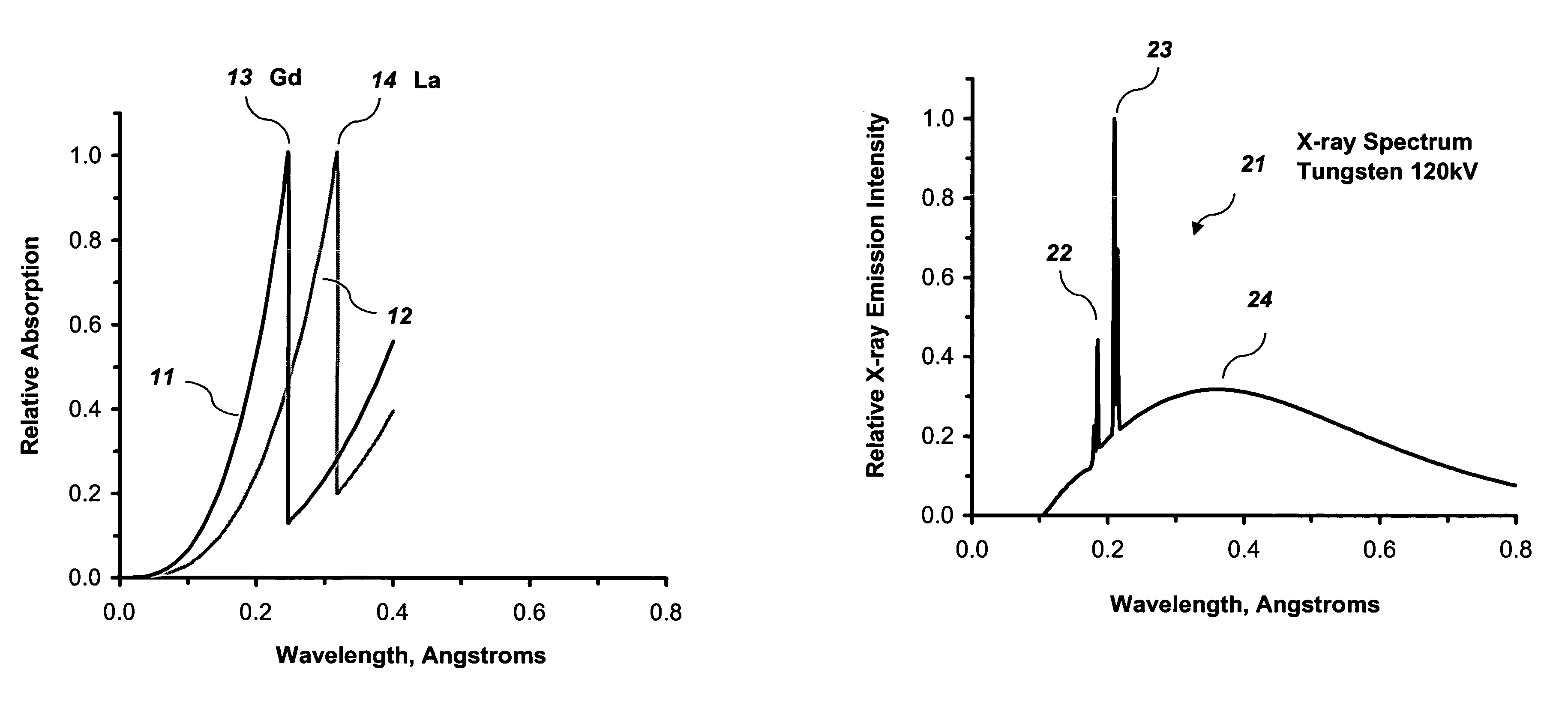

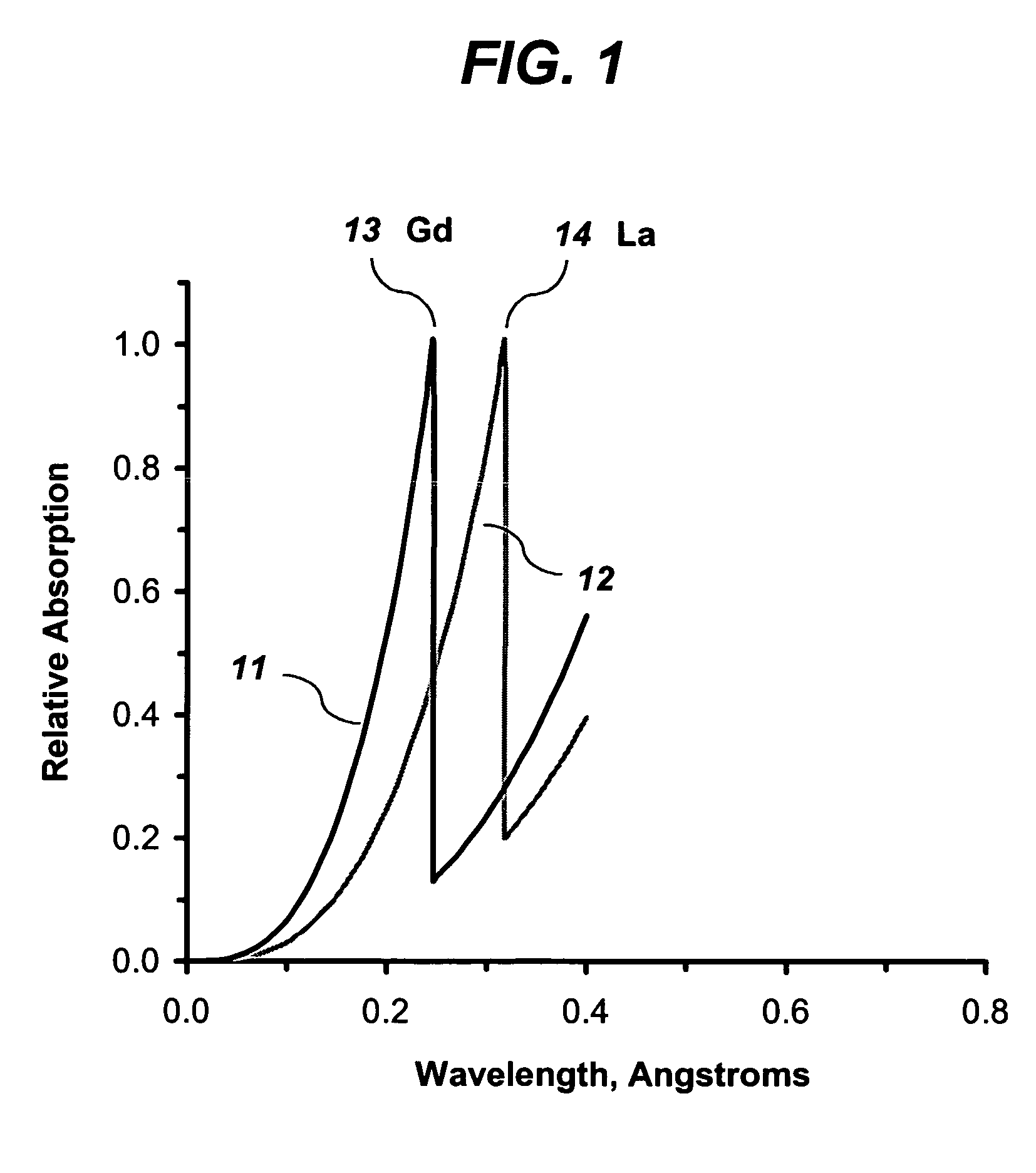

Inventor

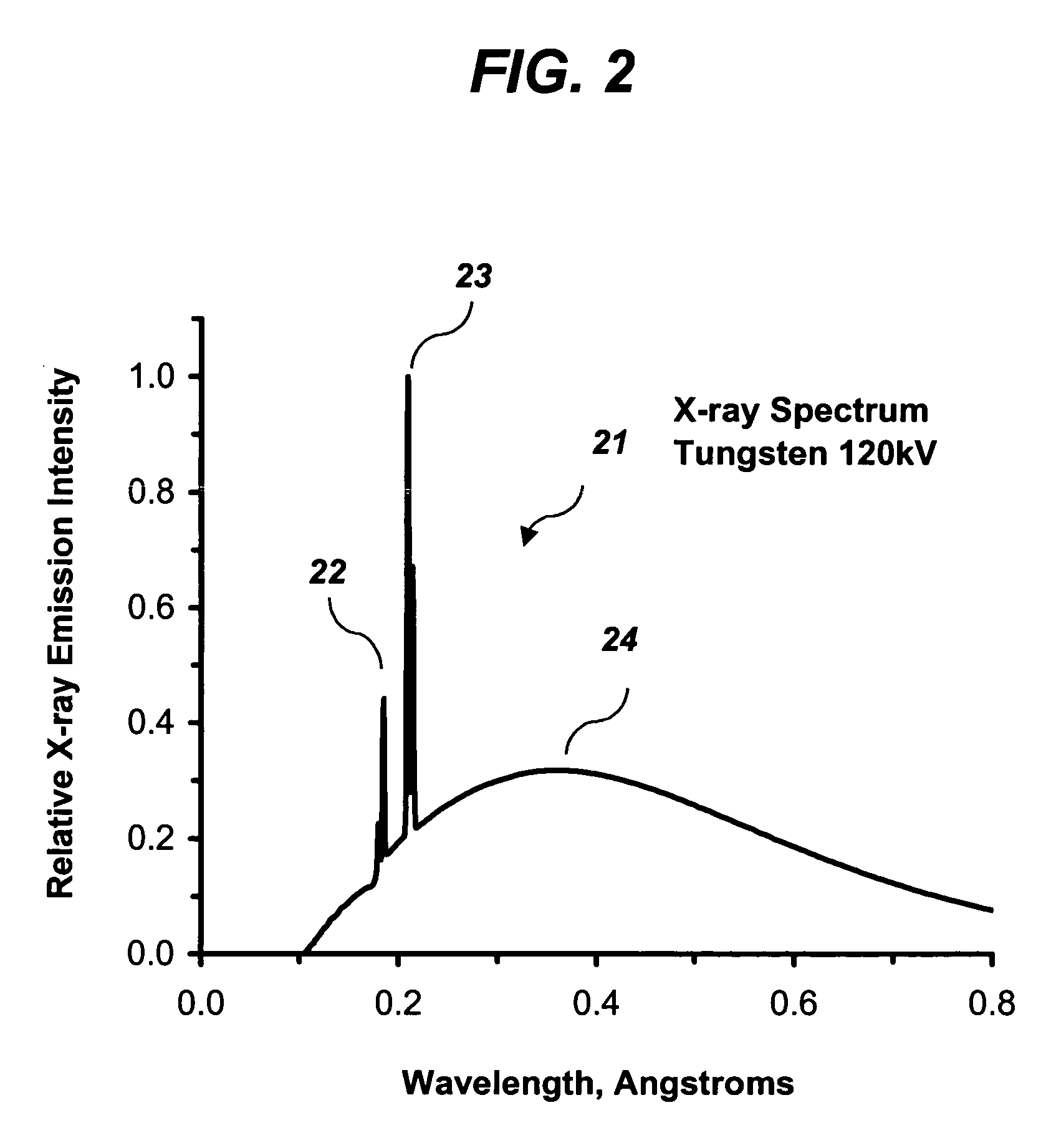

An absorption edge, absorption discontinuity or absorption limit is a sharp discontinuity in the absorption spectrum of a substance. These discontinuities occur at wavelengths where the energy of an absorbed photon corresponds to an electronic transition or ionization potential. When the quantum energy of the incident radiation becomes smaller than the work required to eject an electron from one or other quantum states in the constituent absorbing atom, the incident radiation ceases to be absorbed by that state. For example, incident radiation on an atom of a wavelength that has a corresponding energy just below the binding energy of the K-shell electron in that atom cannot eject the K-shell electron.

Laser-based method and system for memory link processing with picosecond lasers

InactiveUS20040134896A1Quality improvementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserNanosecond

A laser-based method of removing a target link structure of a circuit fabricated on a substrate includes generating a pulsed laser output at a pre-determined wavelength less than an absorption edge of the substrate. The laser output includes at least one pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond, the pulse duration being within a thermal laser processing range. The method also includes delivering and focusing the laser output onto the target link structure. The focused laser output has sufficient power density at a location within the target structure to reduce the reflectivity of the target structure and efficiently couple the focused laser output into the target structure to remove the link without damaging the substrate.

Owner:ELECTRO SCI IND INC

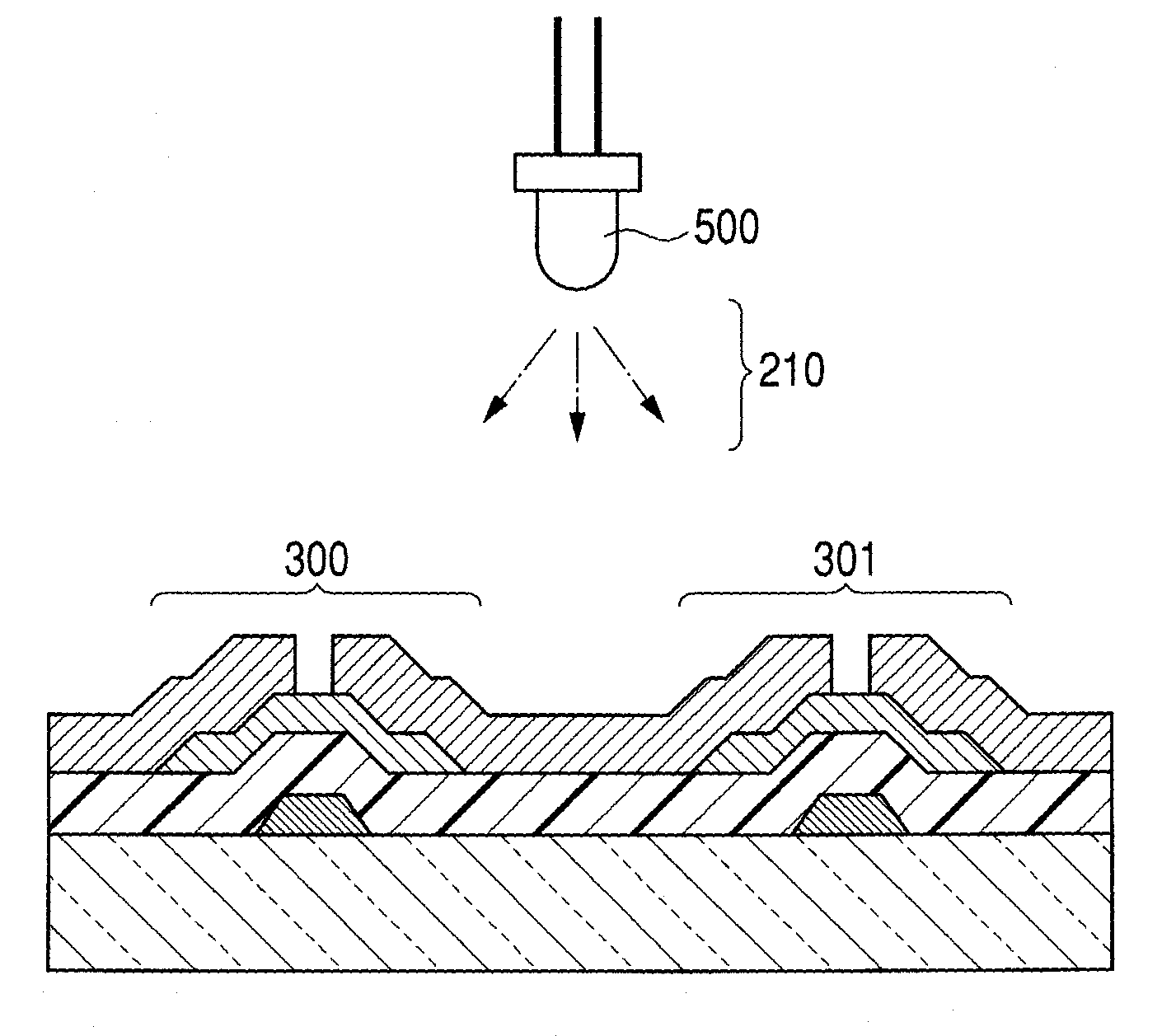

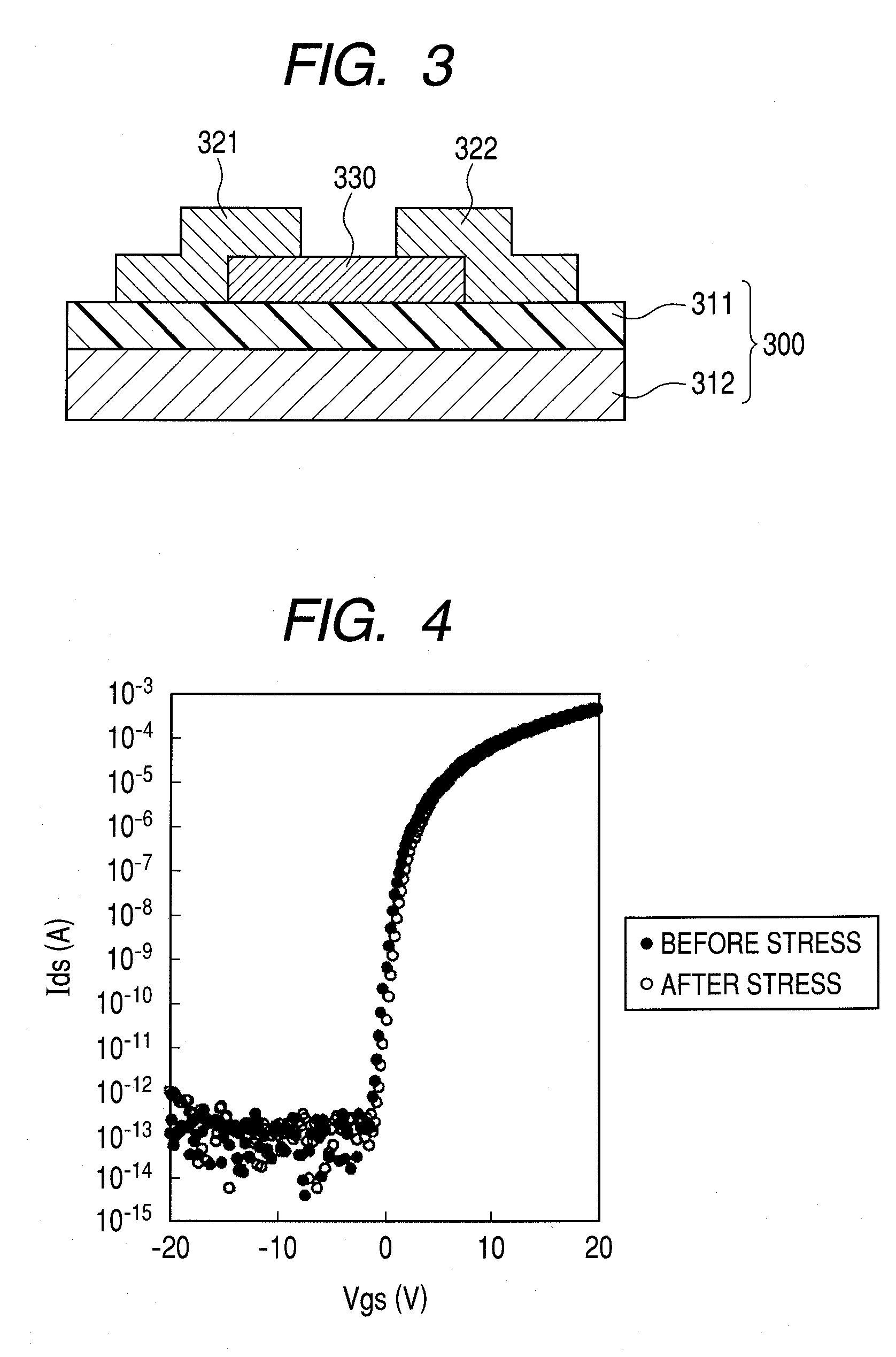

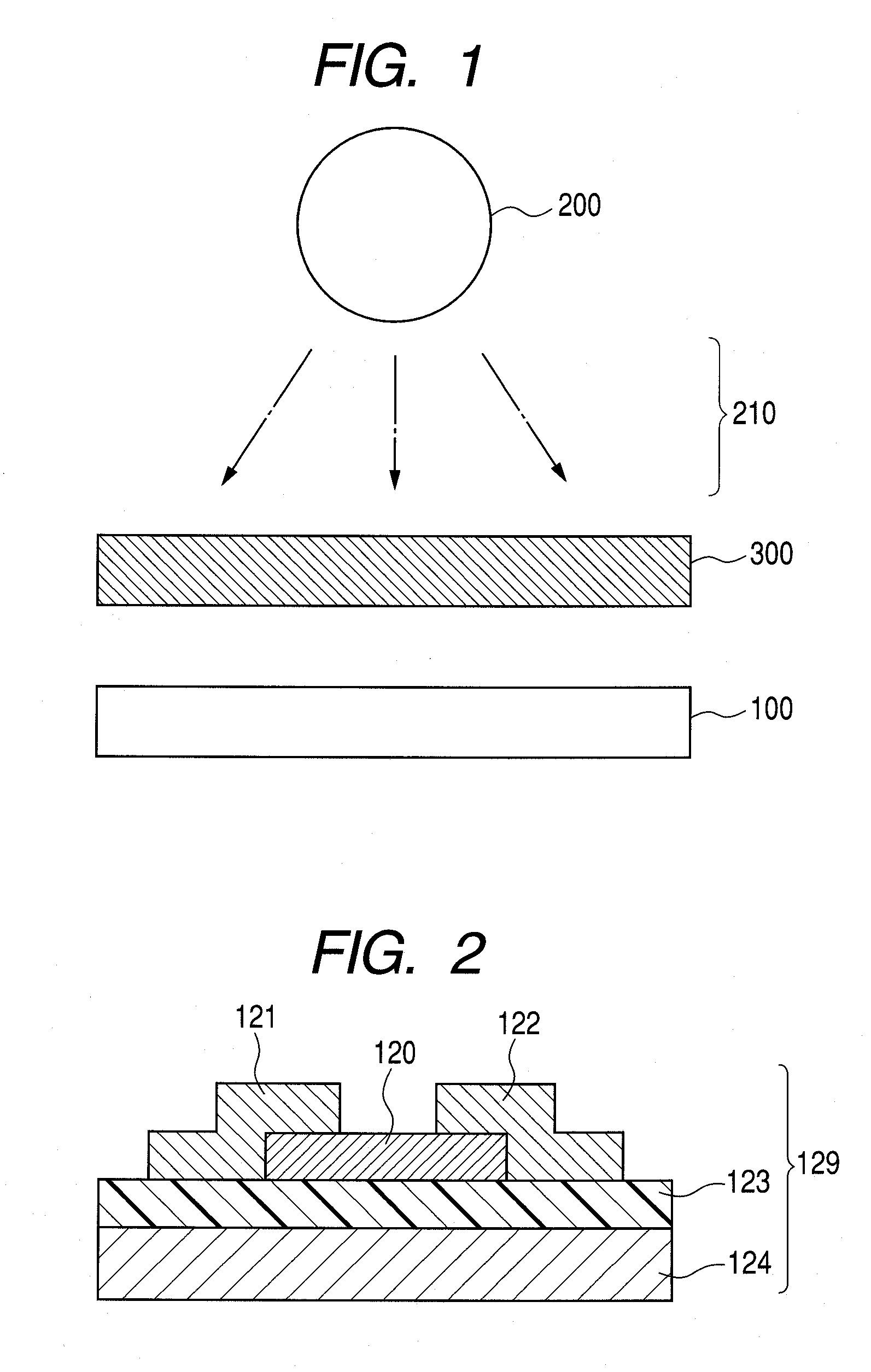

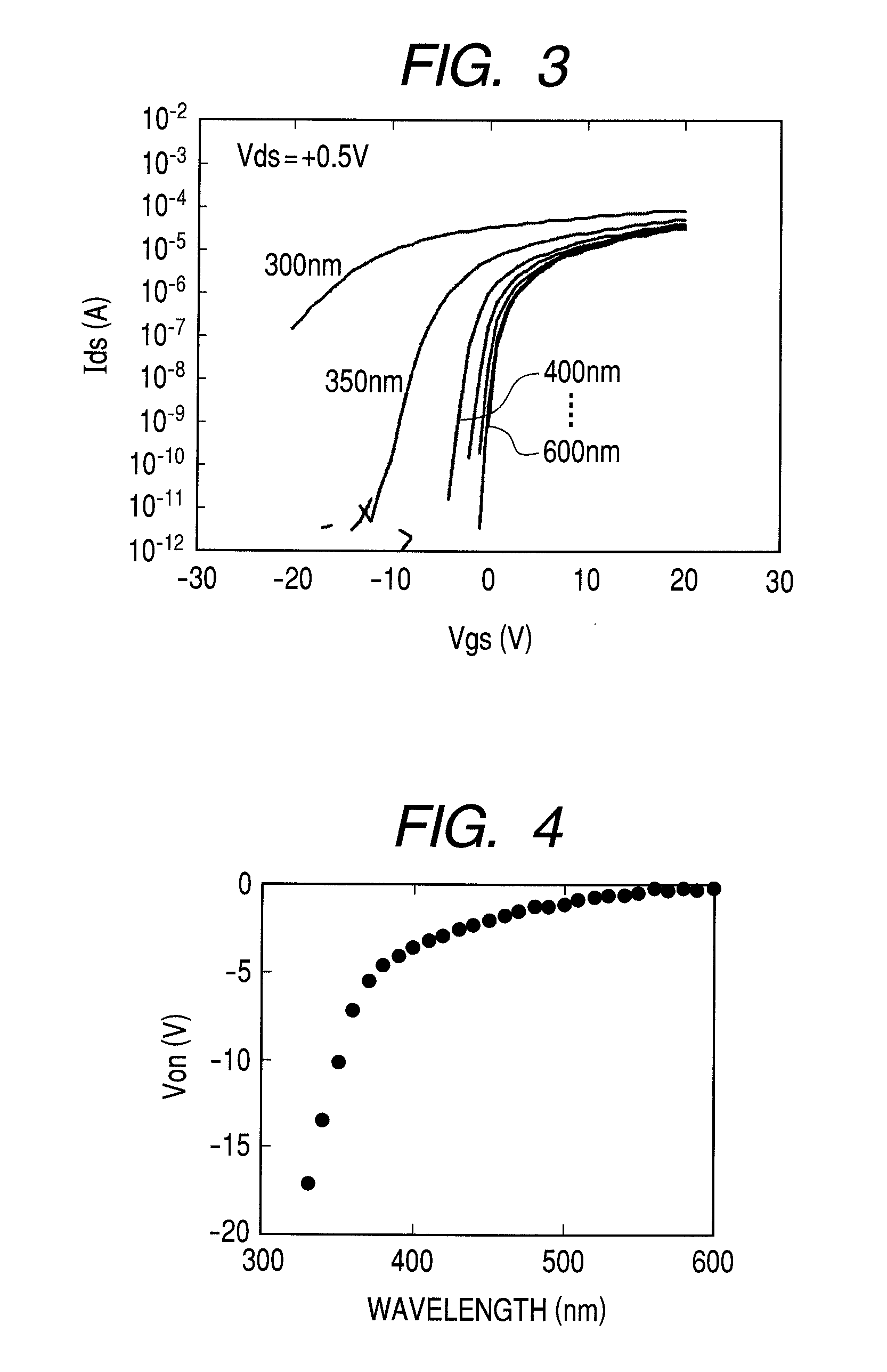

Method of treating semiconductor element

InactiveUS8084331B2Little influenceSemiconductor/solid-state device manufacturingSemiconductor devicesLight irradiationLength wave

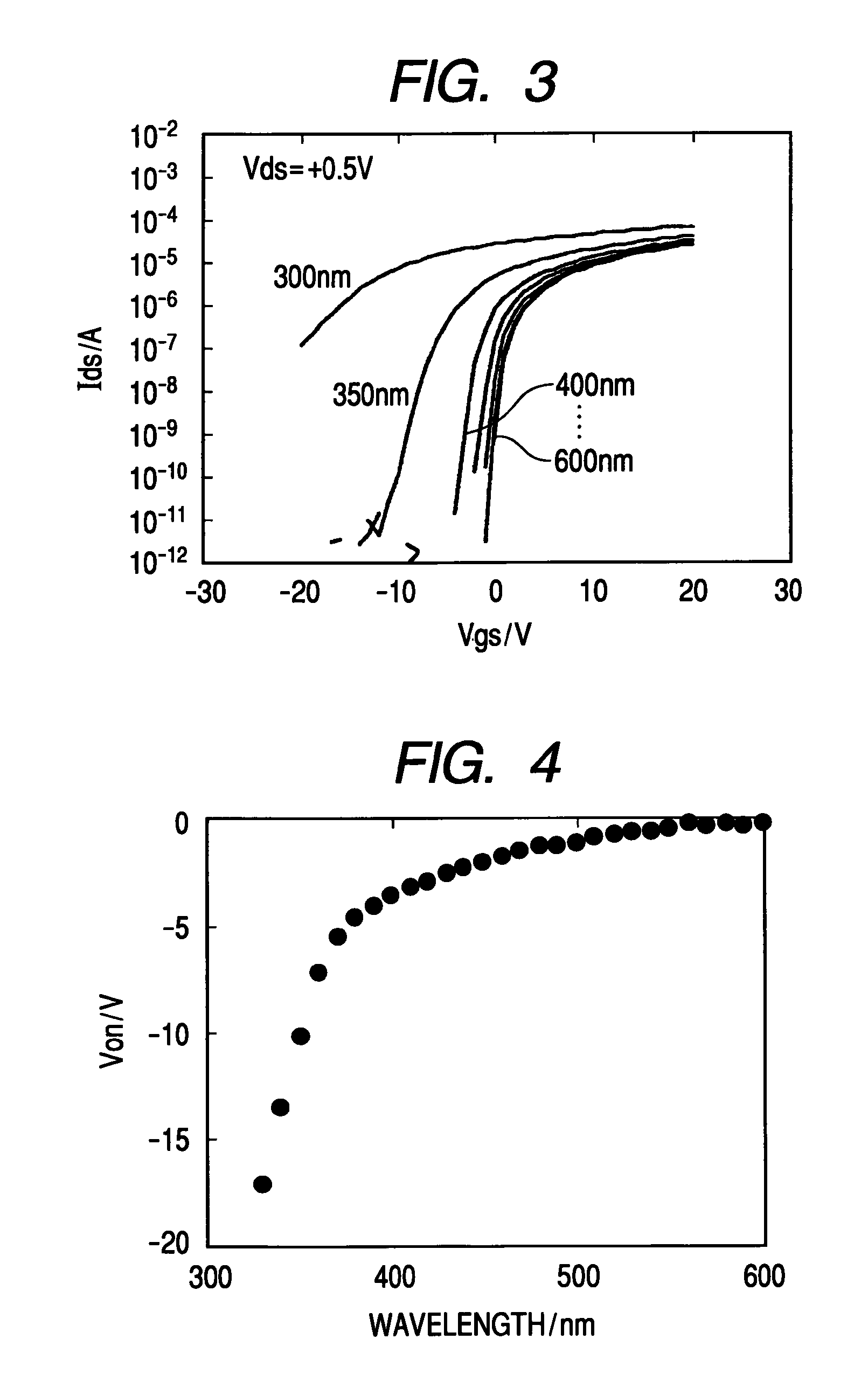

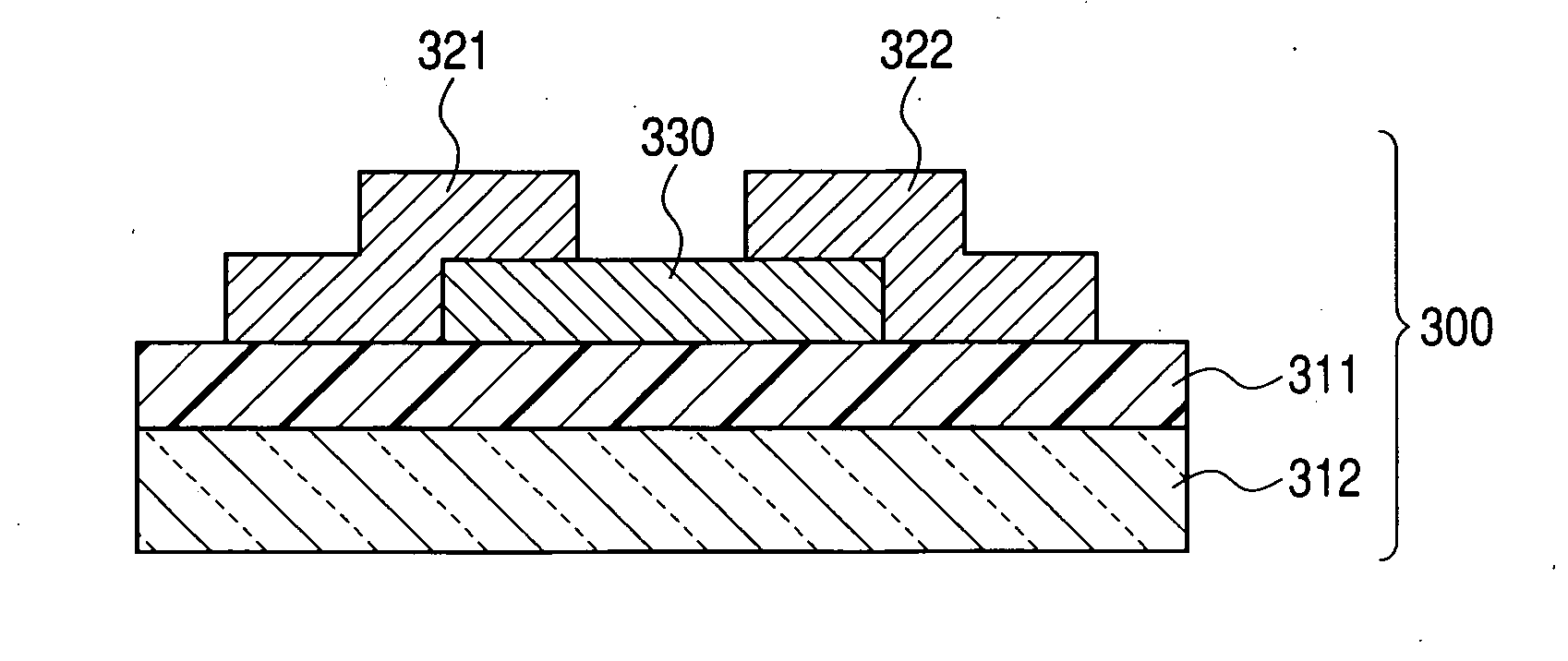

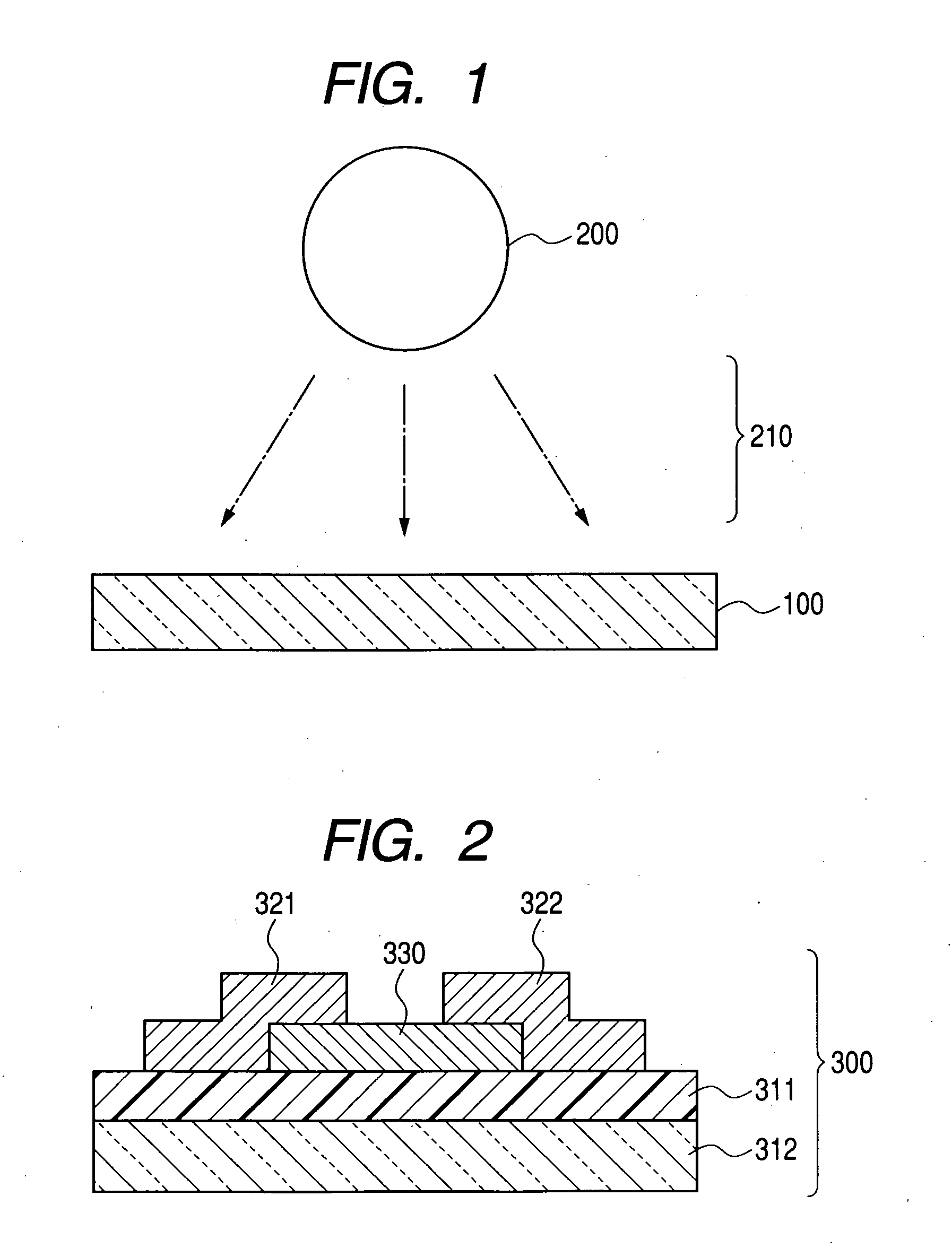

In a method of treating a semiconductor element which at least includes a semiconductor, a threshold voltage of the semiconductor element is changed by irradiating the semiconductor with light with a wavelength longer than an absorption edge wavelength of the semiconductor. The areal density of in-gap states in the semiconductor is 1013 cm−2eV−1 or less. The band gap may be 2 eV or greater. The semiconductor may include at least one selected from the group consisting of In, Ga, Zn and Sn. The semiconductor may be one selected from the group consisting of amorphous In—Ga—Zn—O (IGZO), amorphous In—Zn—O (IZO) and amorphous Zn—Sn—O (ZTO). The light irradiation may induce the threshold voltage shift in the semiconductor element, the shift being of the opposite sign to the threshold voltage shift caused by manufacturing process history, time-dependent change, electrical stress or thermal stress.

Owner:CANON KK

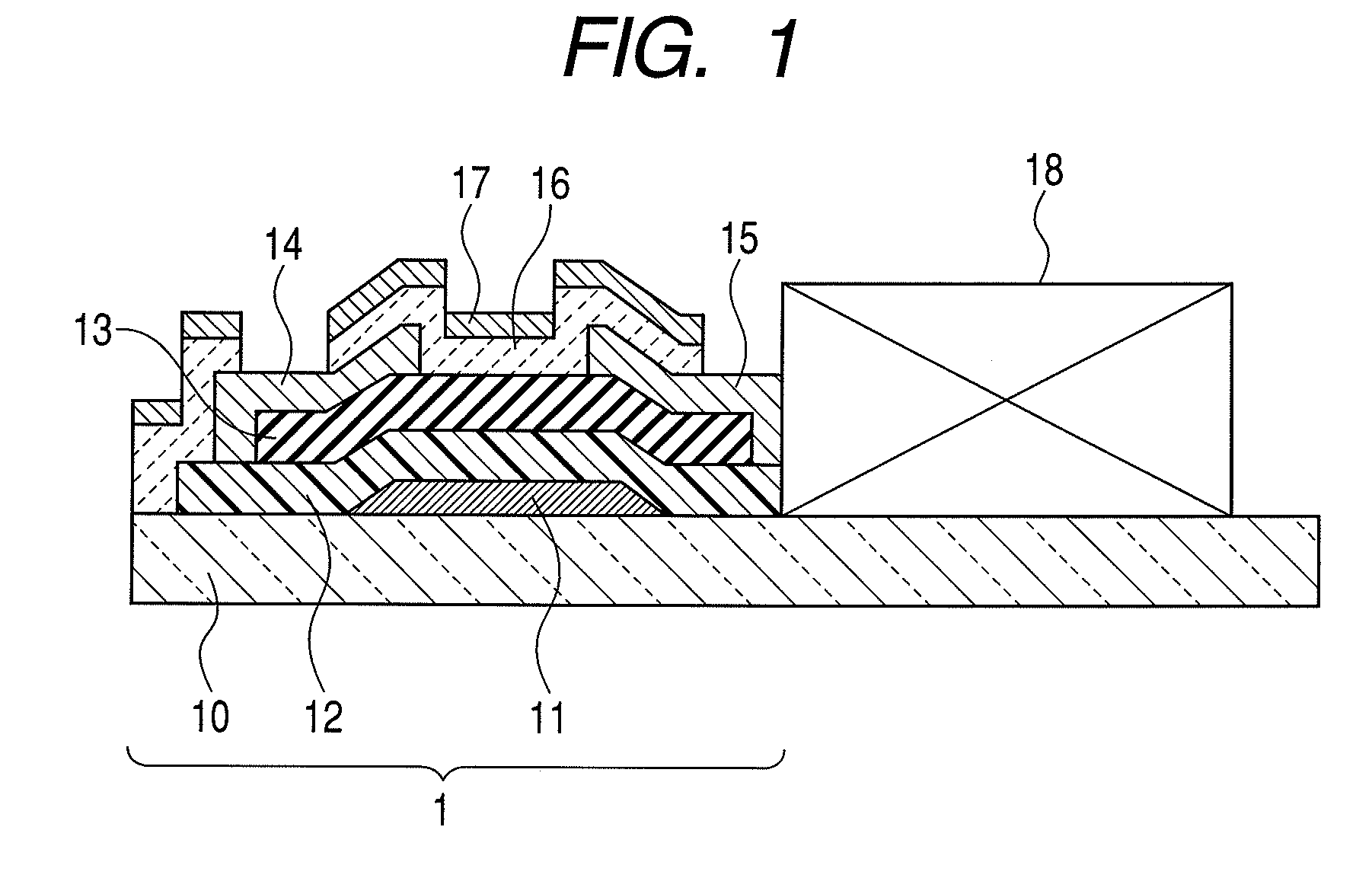

Method for controlling threshold voltage of semiconductor element

ActiveUS8530246B2Accurate operationComplicates the entire circuitSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingThreshold voltageVoltage

A method for controlling the threshold voltage of a semiconductor element having at least a semiconductor as a component is characterized in including a process to measure one of a threshold voltage and a characteristic value serving as an index for the threshold voltage; a process to determine one of the irradiation intensity, irradiation time, and wavelength of the light for irradiating the semiconductor based on one of the measured threshold voltage and the measured characteristic value serving as the index for the threshold voltage; and a process to irradiate light whose one of the irradiation intensity, irradiation time, and wavelength has been determined onto the semiconductor; wherein the light irradiating the semiconductor is a light having a longer wavelength than the wavelength of the absorption edge of the semiconductor, and the threshold voltage is changed by the irradiation of the light.

Owner:CANON KK

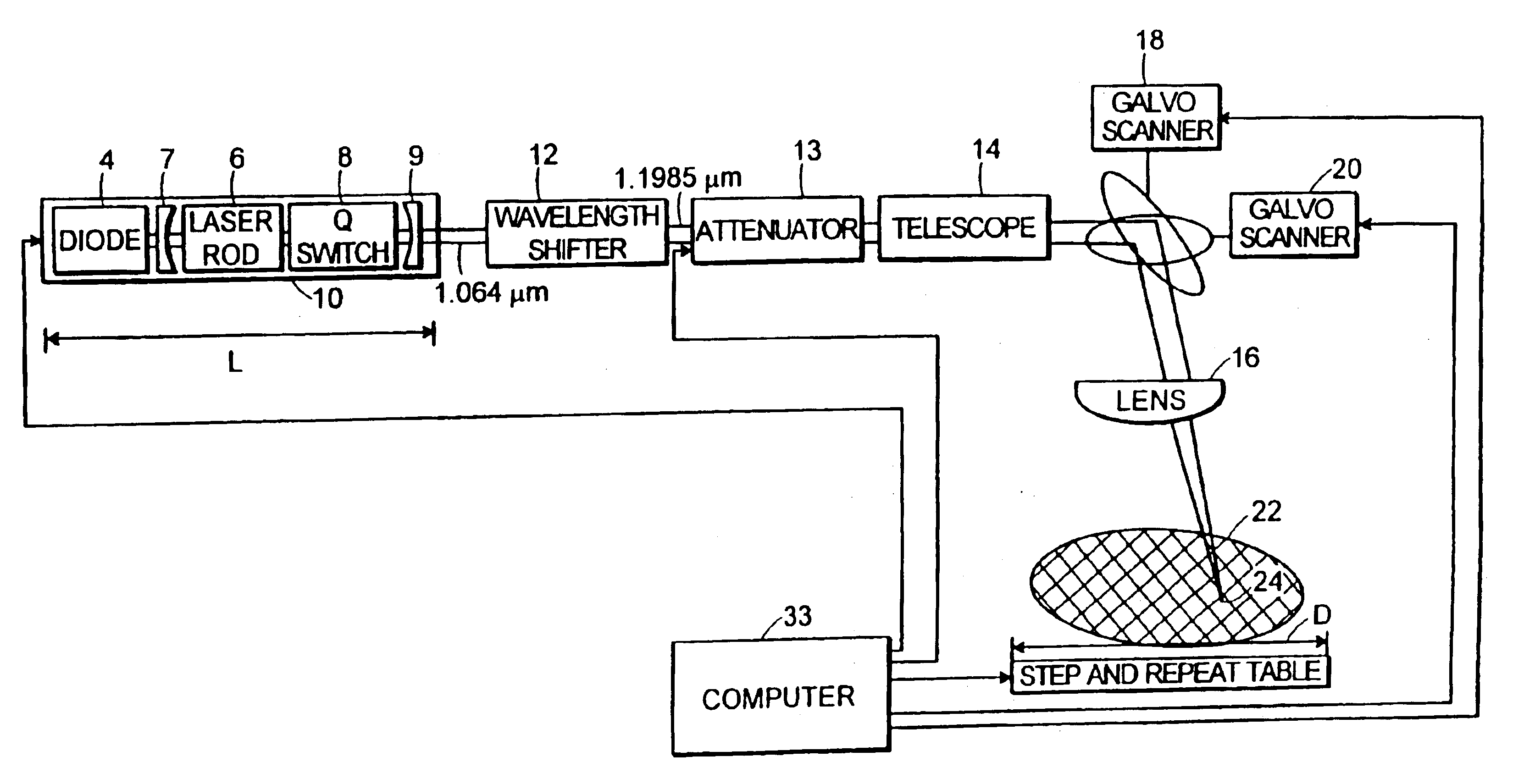

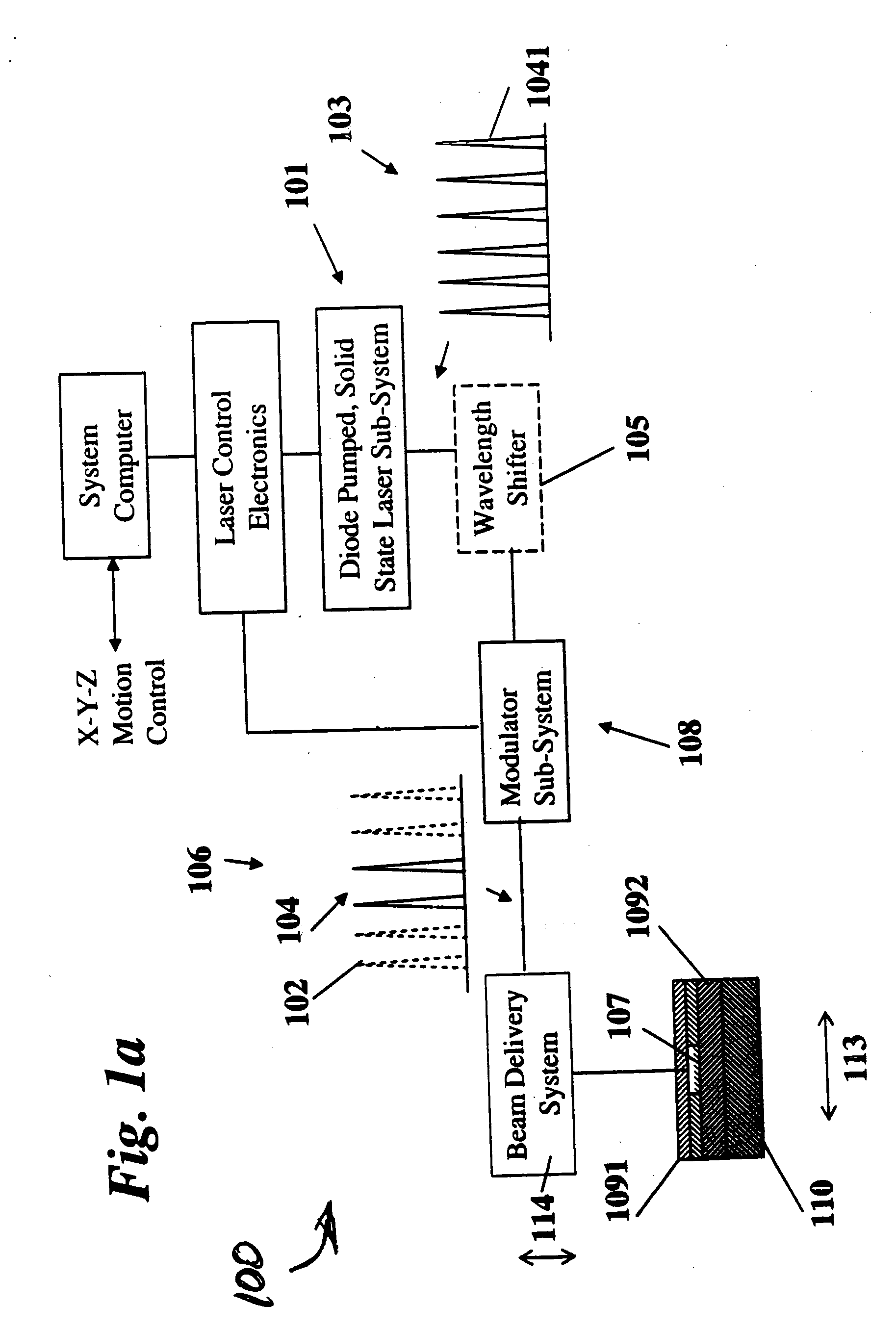

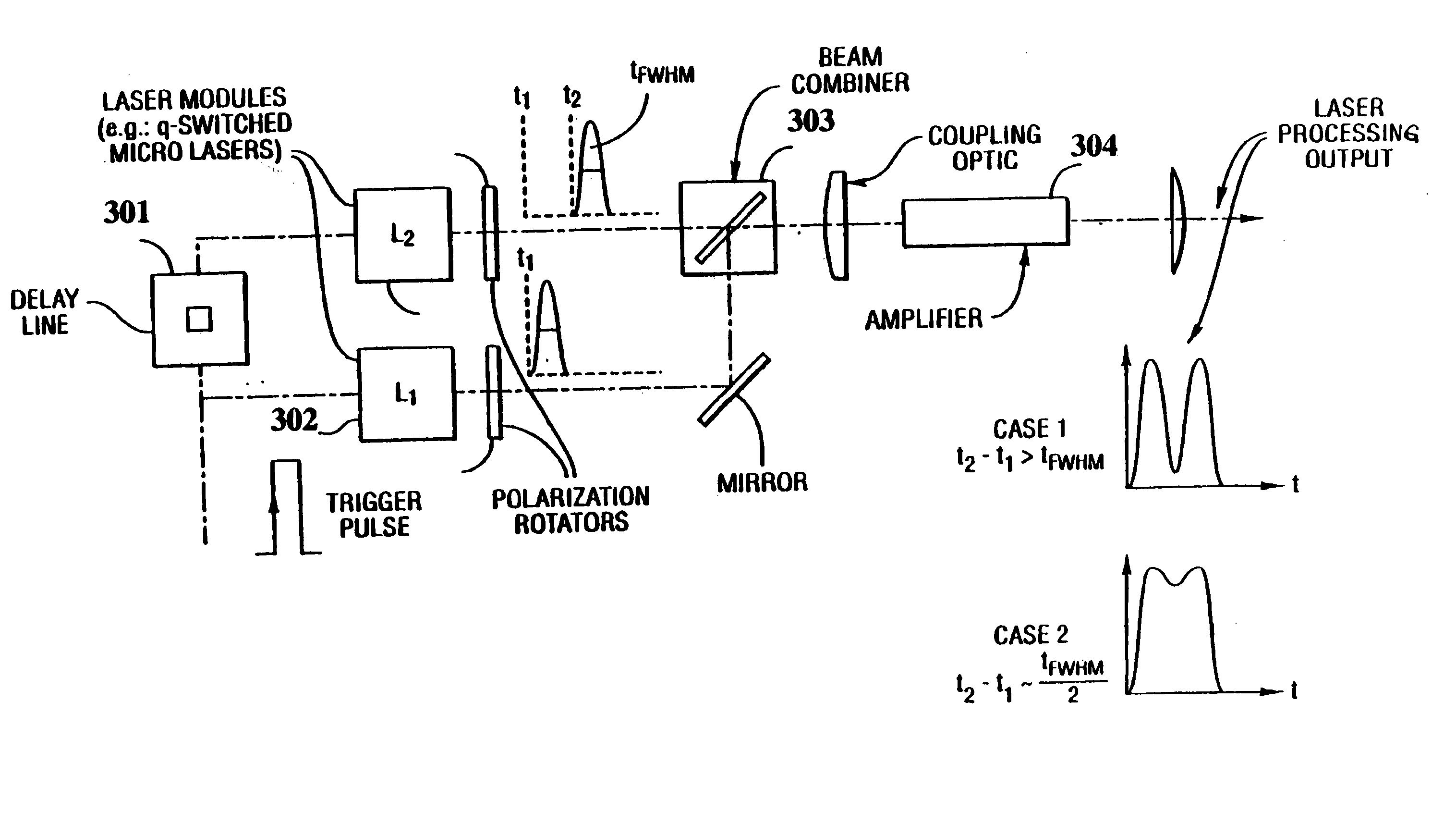

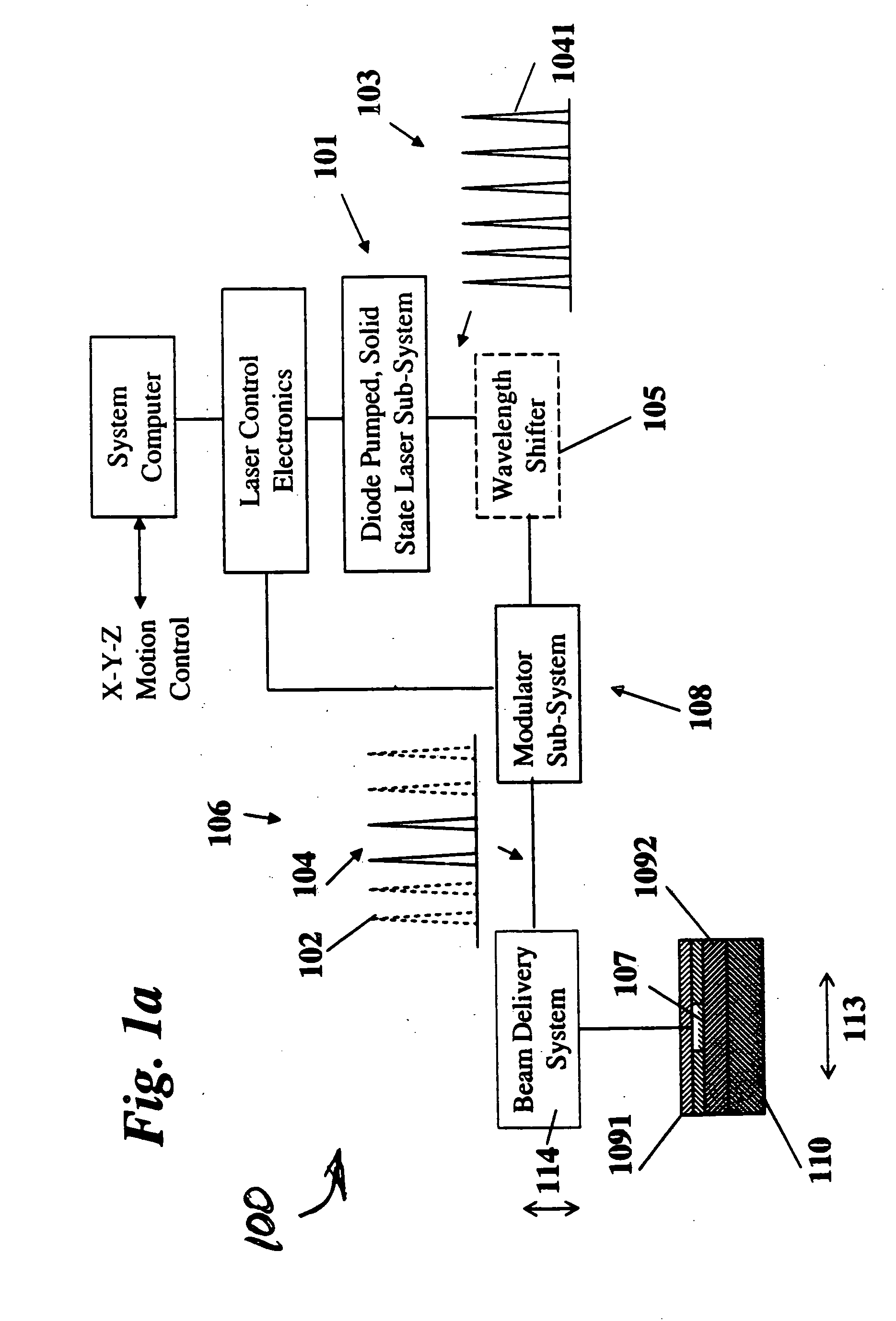

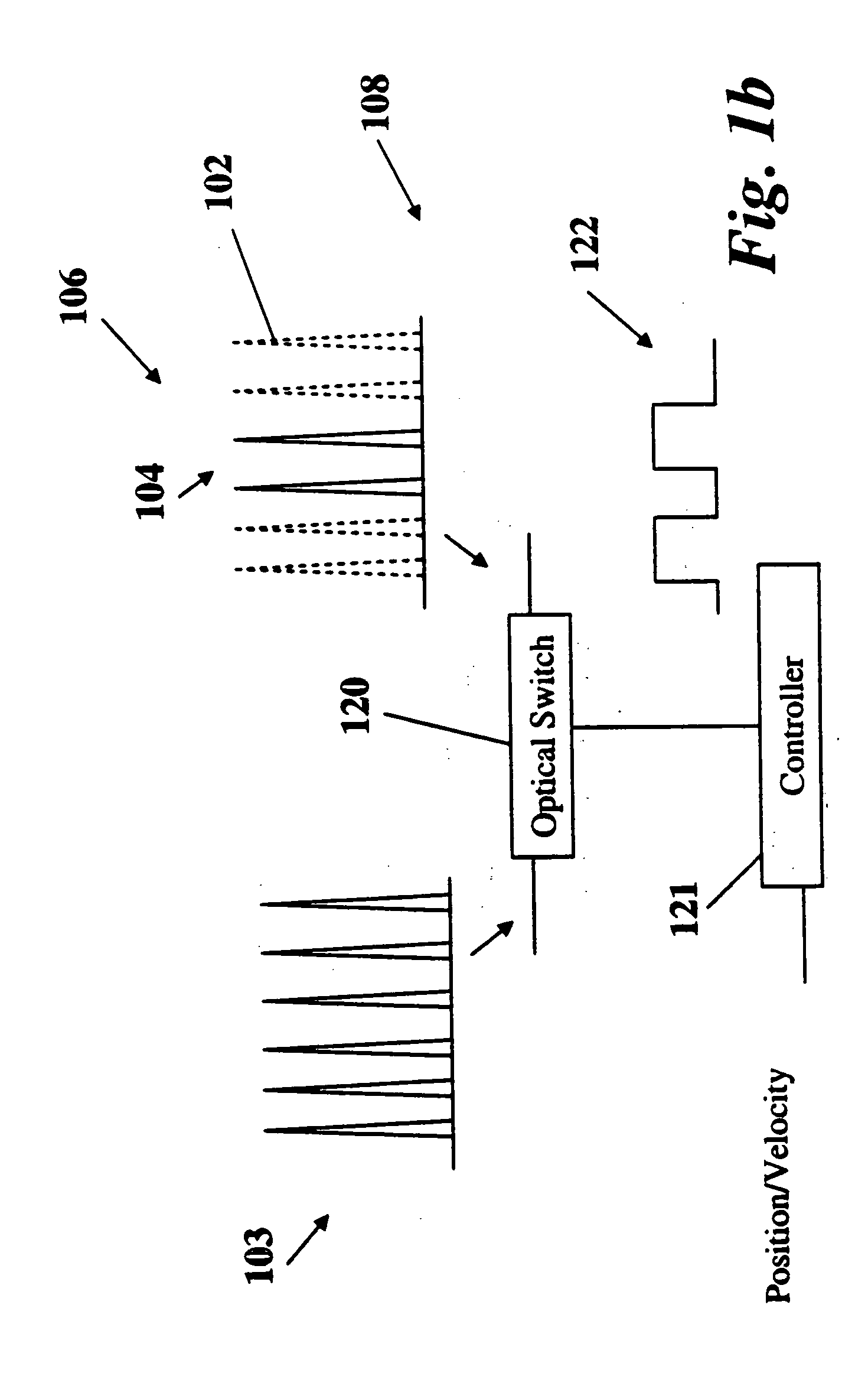

Laser processing

InactiveUS6878899B2Limit temperature riseAvoid damageSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingLength wave

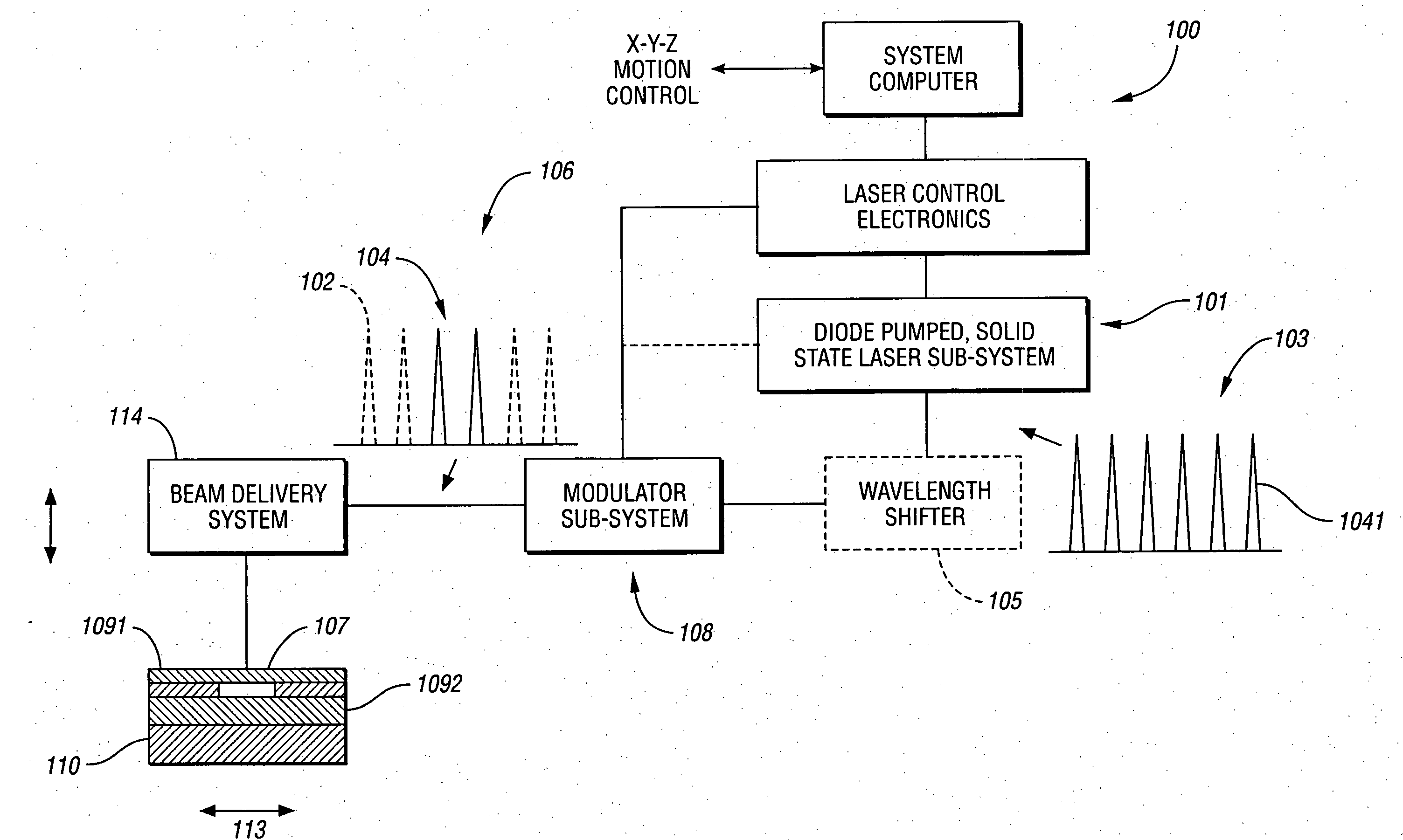

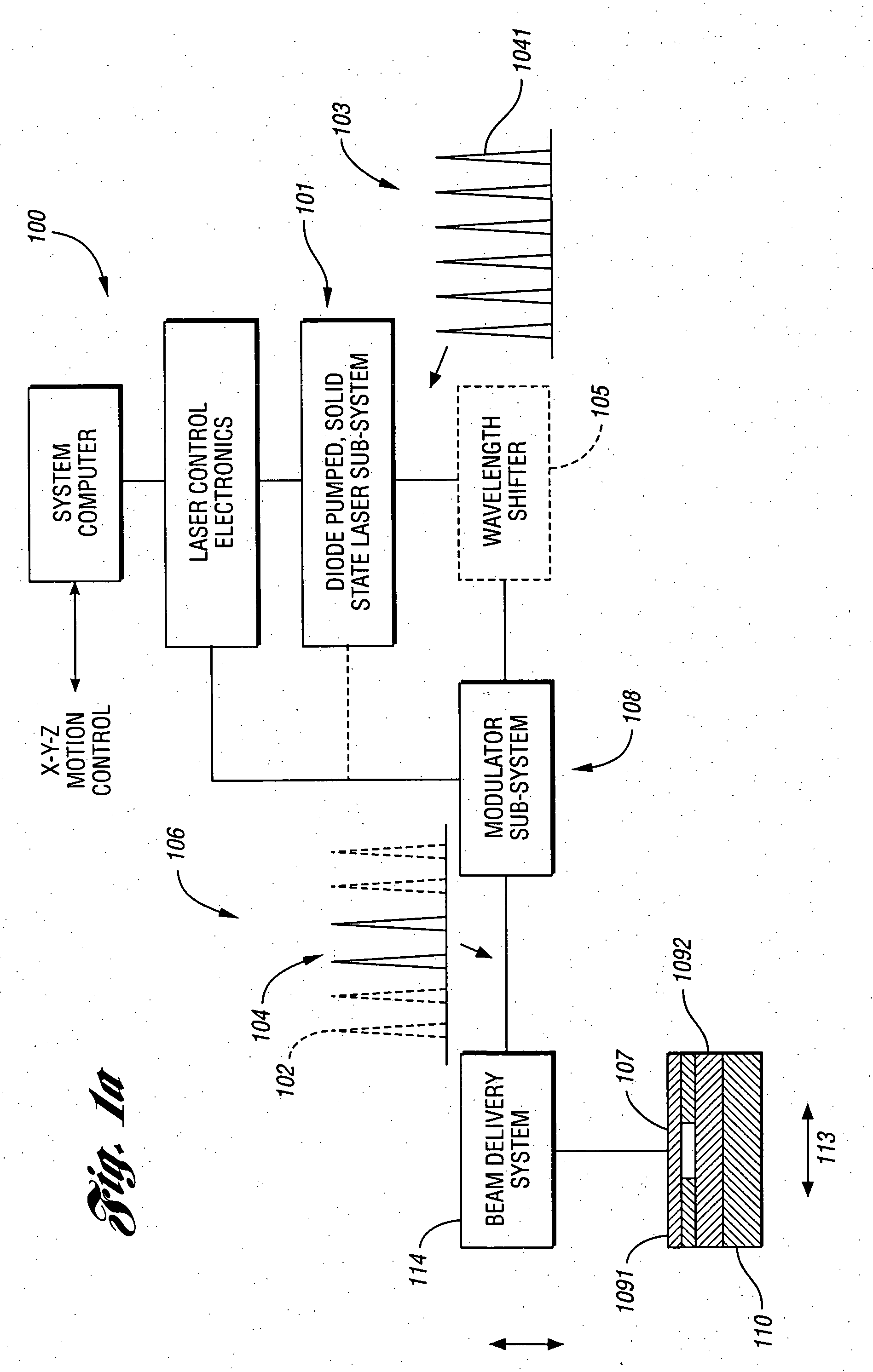

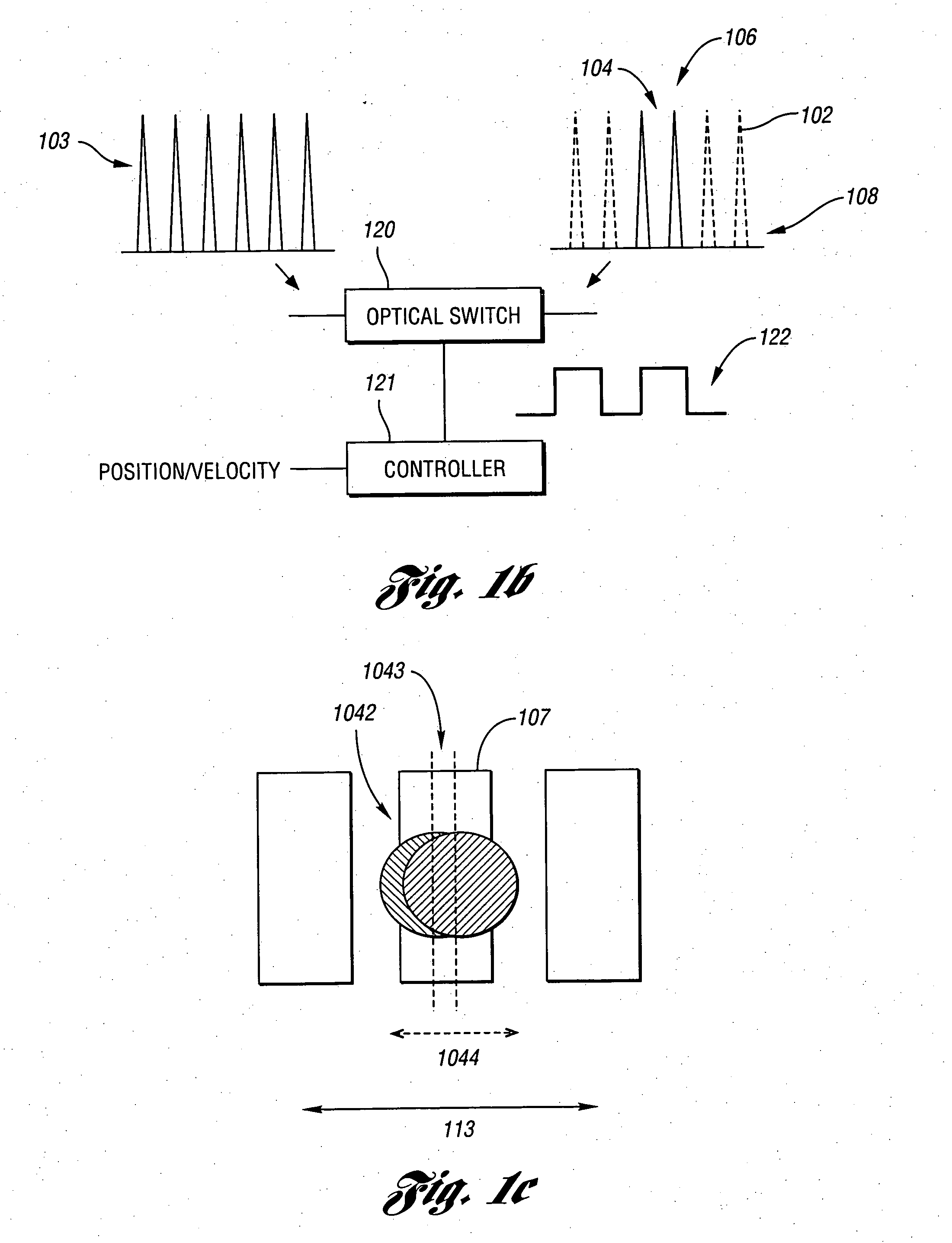

A controlled, switched laser system for vaporizing a target structure on a substrate includes a diode-pumped, solid-state laser for producing a laser output, a controllable switch for controlling the on / off state and power level of the laser, and a wavelength shifter. The wavelength shifter shifts the wavelength of the laser output from a conventional wavelength to a wavelength beyond the absorption edge of the substrate but shorter than 1.2 μm in order to obtain a decrease in absorption of the laser output by the substrate due to the shift in the wavelength of the laser output. The wavelength shifter is removably insertable into the switched laser system so as to enable the switched laser system to operate at the conventional wavelength and at the wavelength beyond the absorption edge of the substrate. Heating of the substrate and hence damage to the substrate is limited due to the wavelength being beyond the absorption edge of the substrate. Good depth of focus of the laser beam output is maintained relative to spot size of the laser beam output due to the wavelength being less than about 1.2 μm.

Owner:ELECTRO SCI IND INC

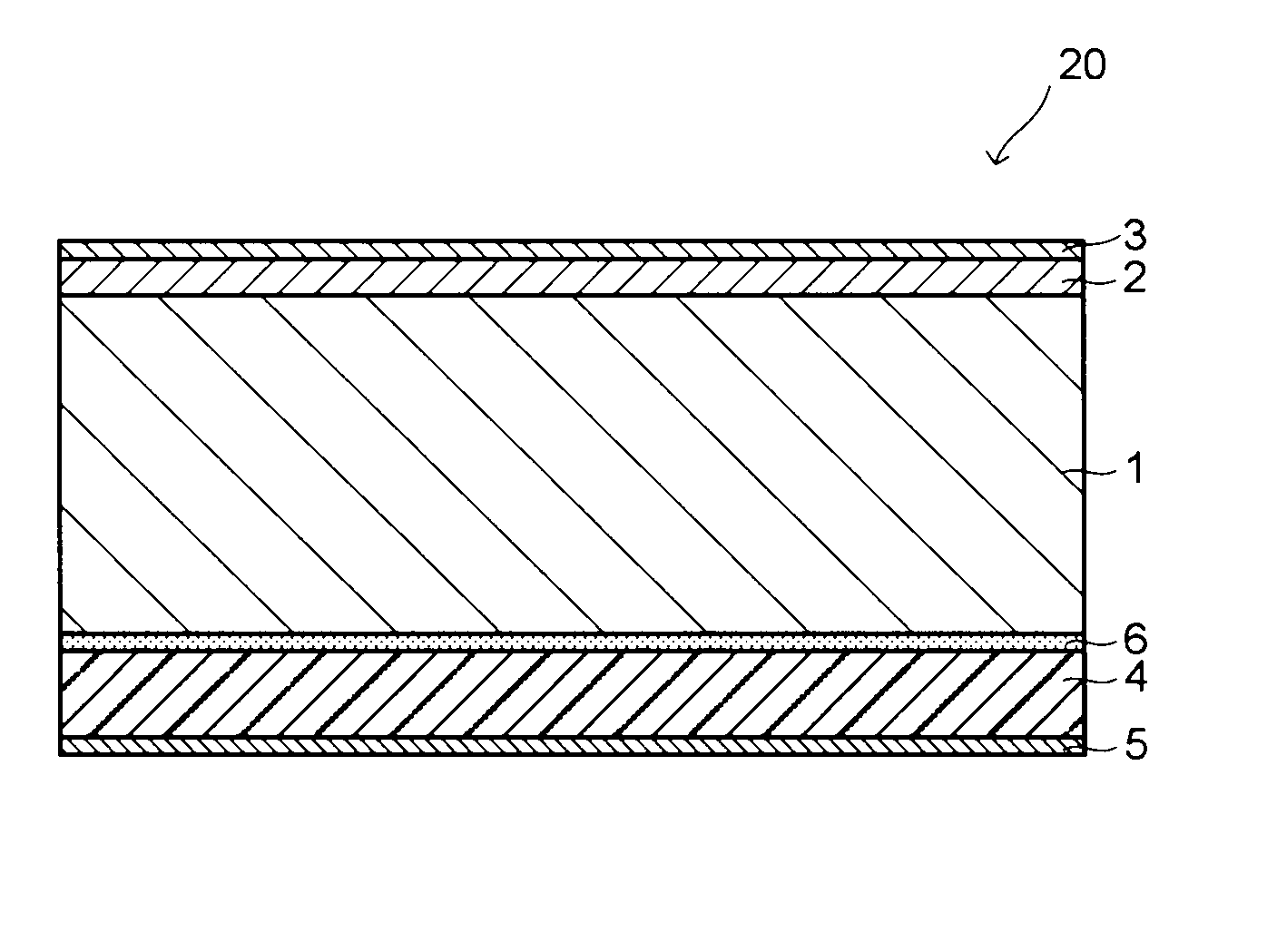

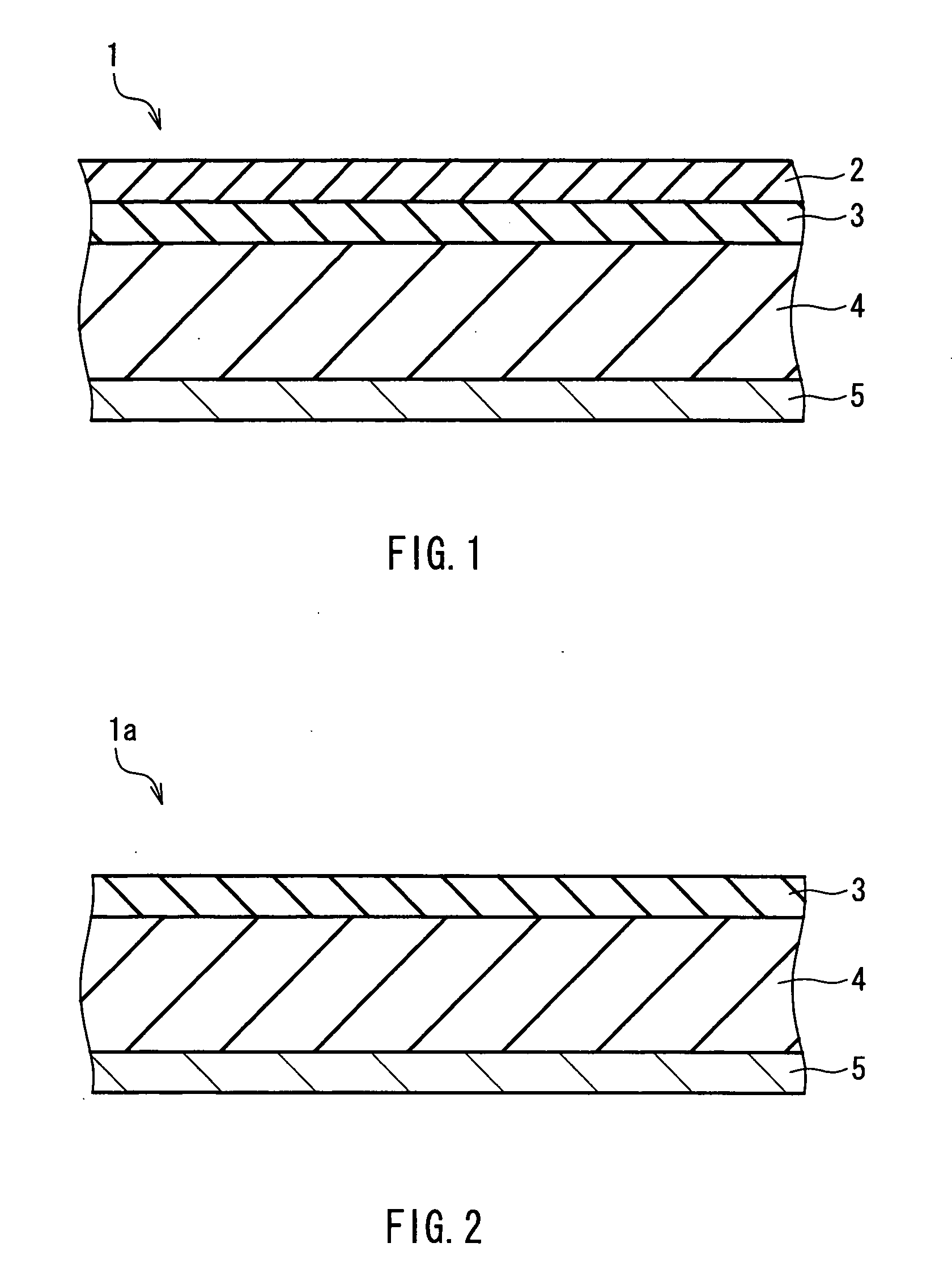

Infrared transmission filter and imaging device

ActiveUS20120145901A1Excellent permselectivityMade small and thinnerMirrorsOptical filtersLength waveInfrared transmission

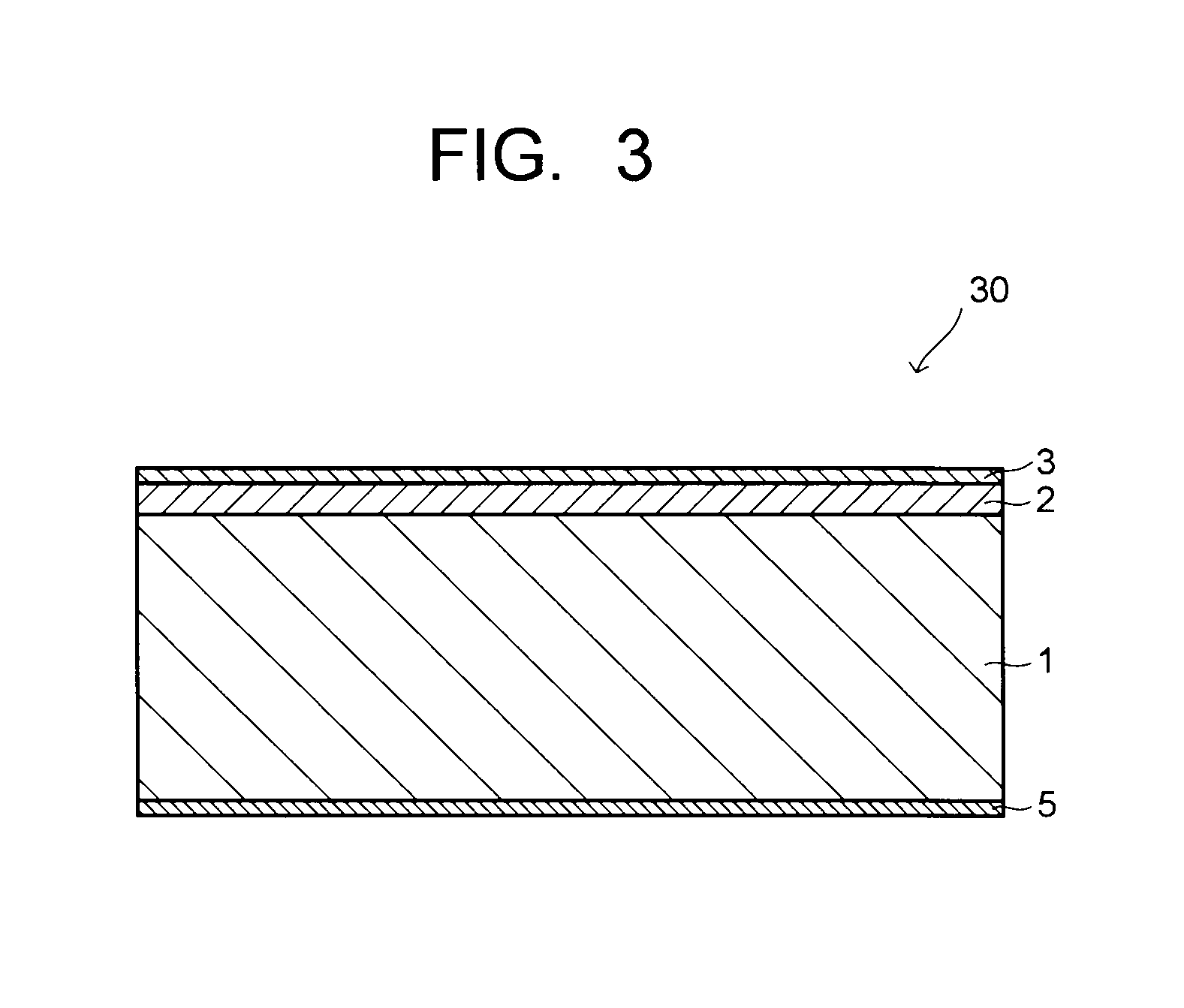

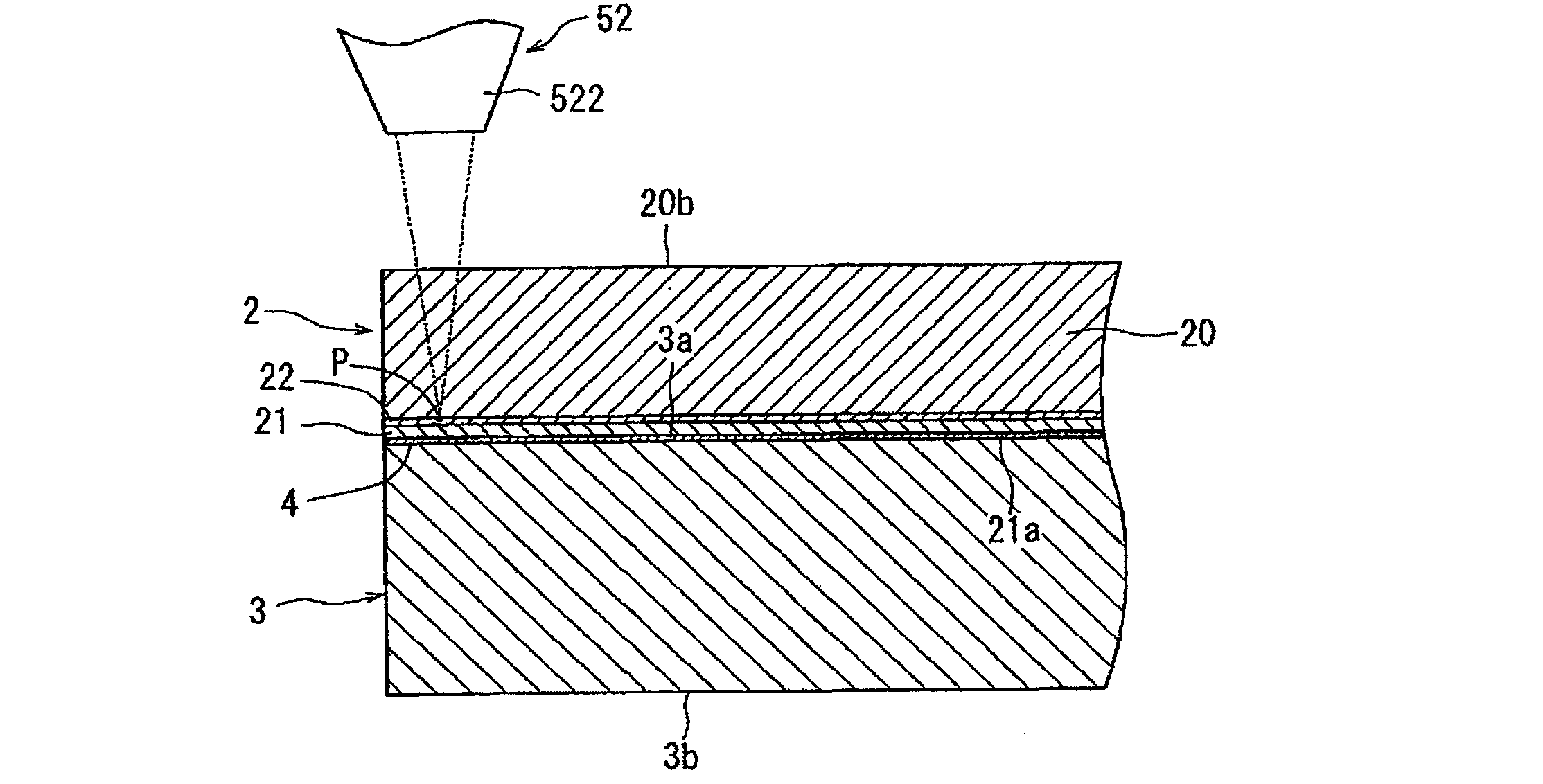

There are provided an infrared transmission filter, which is inexpensive, is capable of being sufficiently made lighter and thinner, has no incident angle dependency, and is excellent in permselectivity for infrared light, and an imaging device, which employs such an infrared transmission filter.An infrared transmission filter 10 includes an infrared transmission base material 1 selectively transmitting light in an infrared wavelength range; and a short wavelength side infrared absorbing film 2 formed on one side of the infrared transmission base material 1 and containing a near-infrared absorbent having an optical absorption edge on a short wavelength side of a transmission wavelength band of the infrared transmission base material. An imaging device includes the infrared transmission filter 10.

Owner:ASAHI GLASS CO LTD

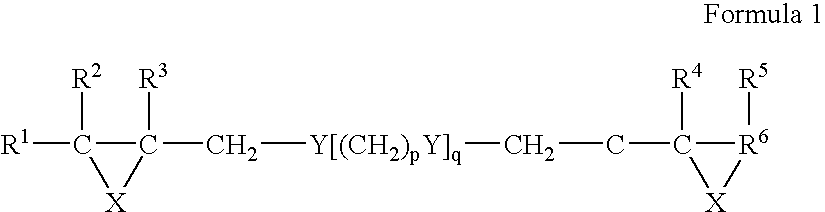

Organic electroluminescence device and method of manufacture

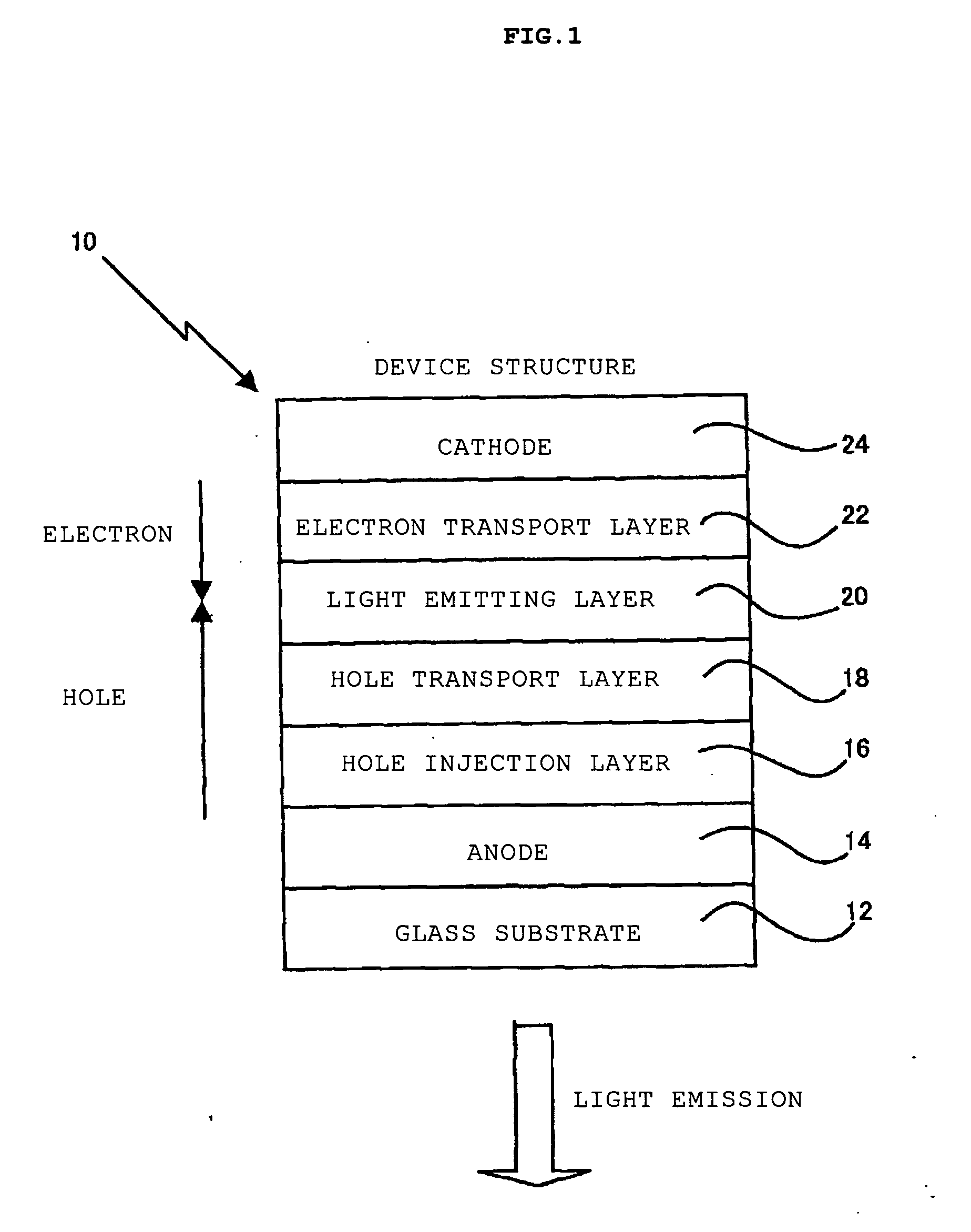

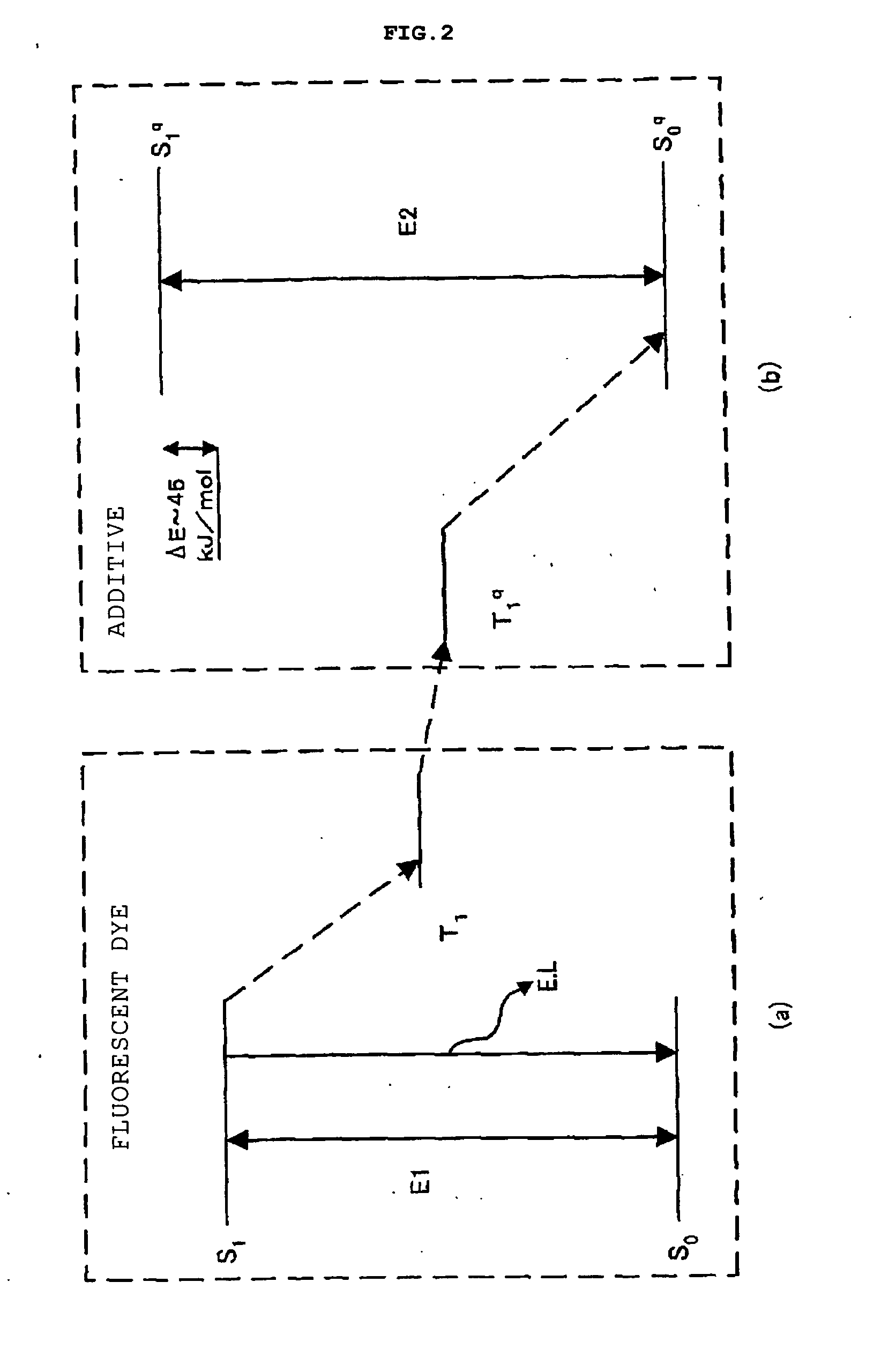

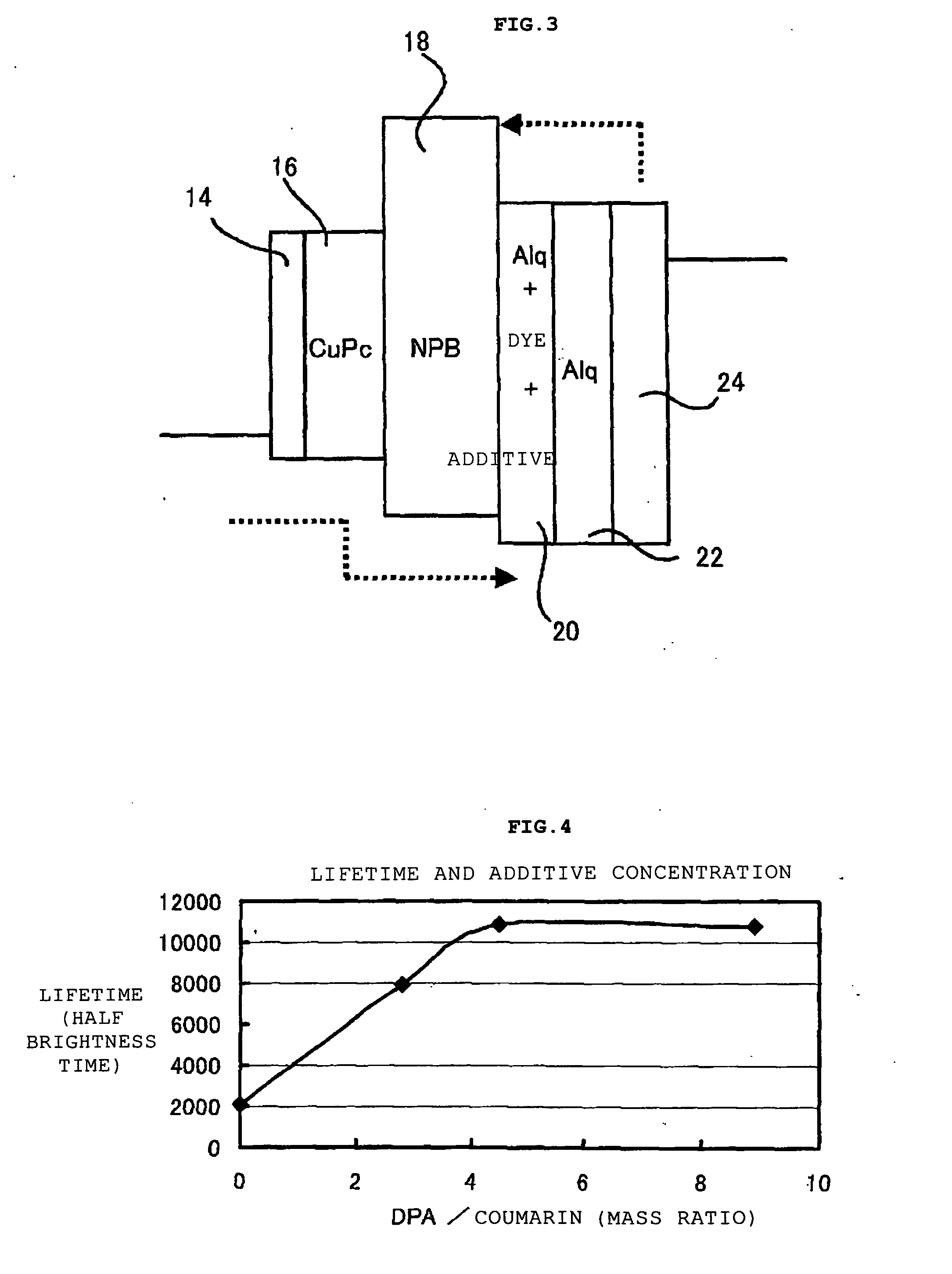

InactiveUS20050095456A1Long luminescence life-timeProlong lifeDischarge tube luminescnet screensElectroluminescent light sourcesPhenyl groupPyrene

An organic electroluminescence device of the present invention comprises a light emitting layer held between electrodes, the light emitting layer containing at least a host material and a dye or pigment. The light emitting layer further comprises an additive exhibiting an absorption edge of which energy level is higher than that of an absorption edge of the dye or pigment, but the difference of the energy levels being less than 120 kJ / mol, having no lone pair, and including at least two aromatic rings. The additive of the present invention is selected from a group consisting of phenyl-substituted anthracenes, naphthyl-substituted anthracenes, naphthyl-substituted naphthalenes, pyrenes, and a naphthacene derivatives.

Owner:IBM CORP

Method for controlling threshold voltage of semiconductor element

ActiveUS20110076790A1Fluctuation of threshold voltageSuppress fluctuationsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringLength wave

A method for controlling the threshold voltage of a semiconductor element having at least a semiconductor as a component is characterized in including a process to measure one of a threshold voltage and a characteristic value serving as an index for the threshold voltage; a process to determine one of the irradiation intensity, irradiation time, and wavelength of the light for irradiating the semiconductor based on one of the measured threshold voltage and the measured characteristic value serving as the index for the threshold voltage; and a process to irradiate light whose one of the irradiation intensity, irradiation time, and wavelength has been determined onto the semiconductor; wherein the light irradiating the semiconductor is a light having a longer wavelength than the wavelength of the absorption edge of the semiconductor, and the threshold voltage is changed by the irradiation of the light.

Owner:CANON KK

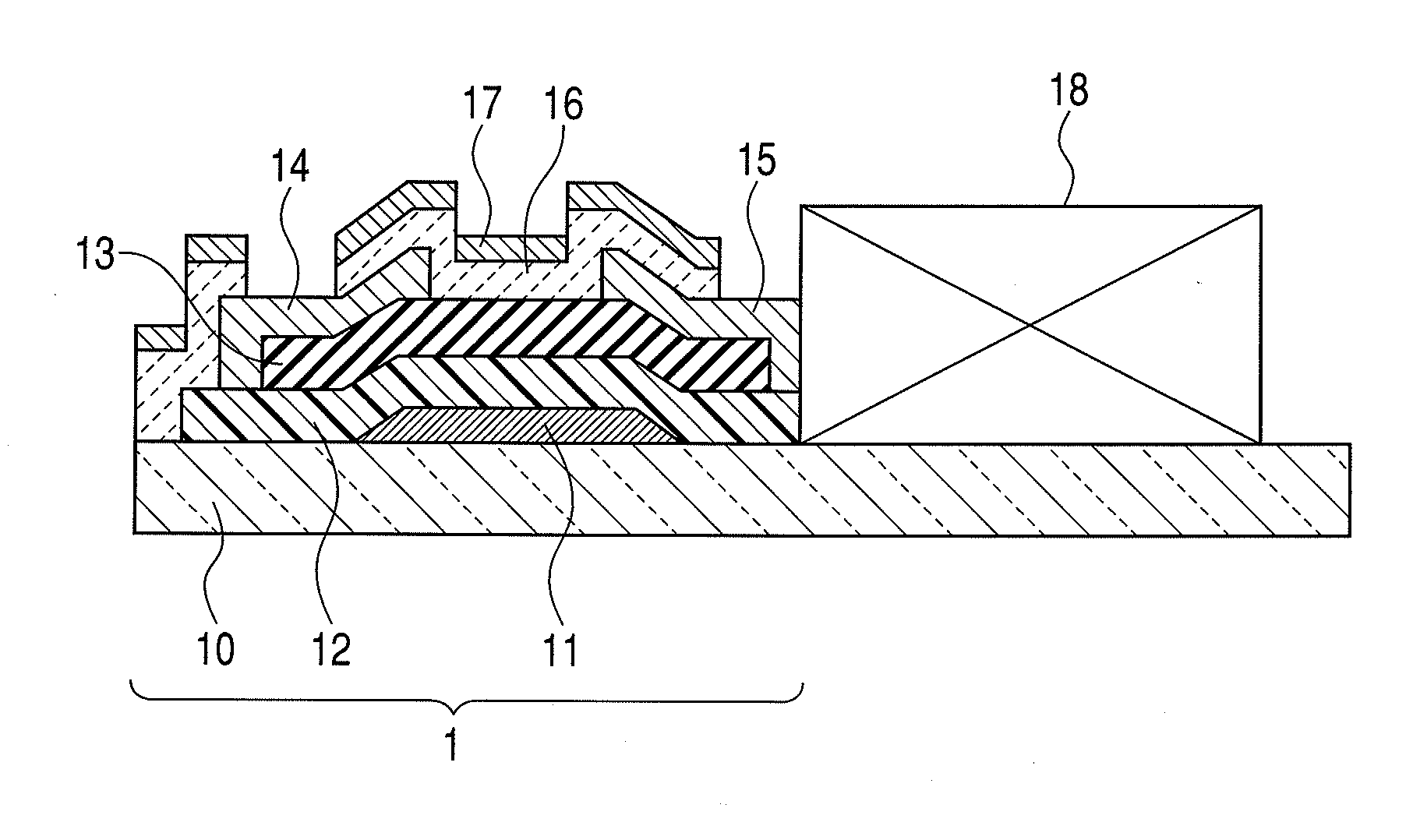

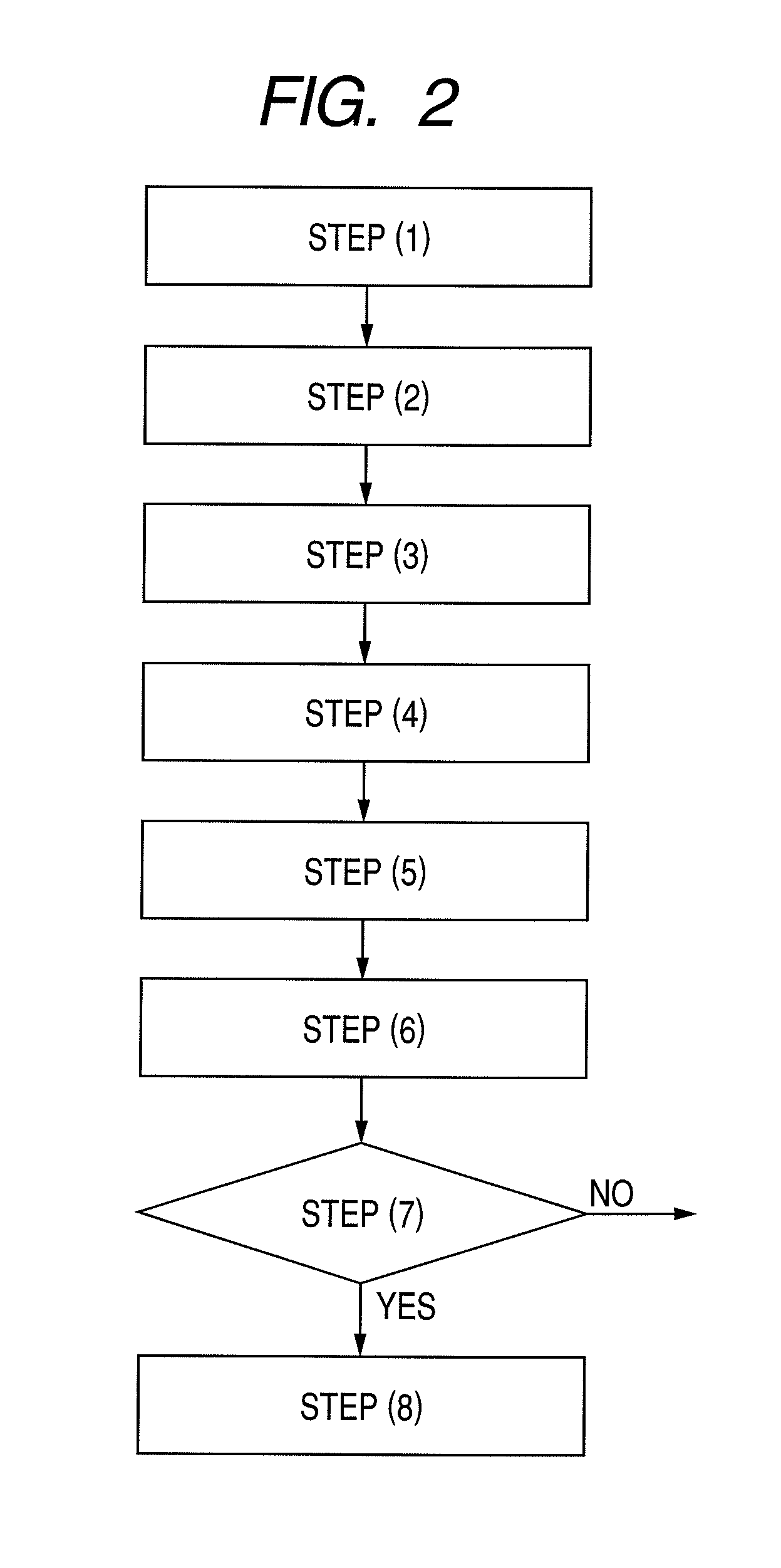

Method for manufacturing semiconductor device or apparatus, and apparatus for manufacturing the same

InactiveUS20110065216A1Manufacturing is longOptimize timingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringLength wave

A method for manufacturing a semiconductor device or apparatus having at least a semiconductor as a component, characterized by including irradiating the semiconductor with light having a longer wavelength than the absorption edge wavelength of the semiconductor to change the threshold voltage of the semiconductor device or apparatus, and checking the threshold voltage of the semiconductor device or apparatus, after or during irradiation with the light, to determine whether the threshold voltage is in a predetermined range, during manufacturing the semiconductor device or apparatus.

Owner:CANON KK

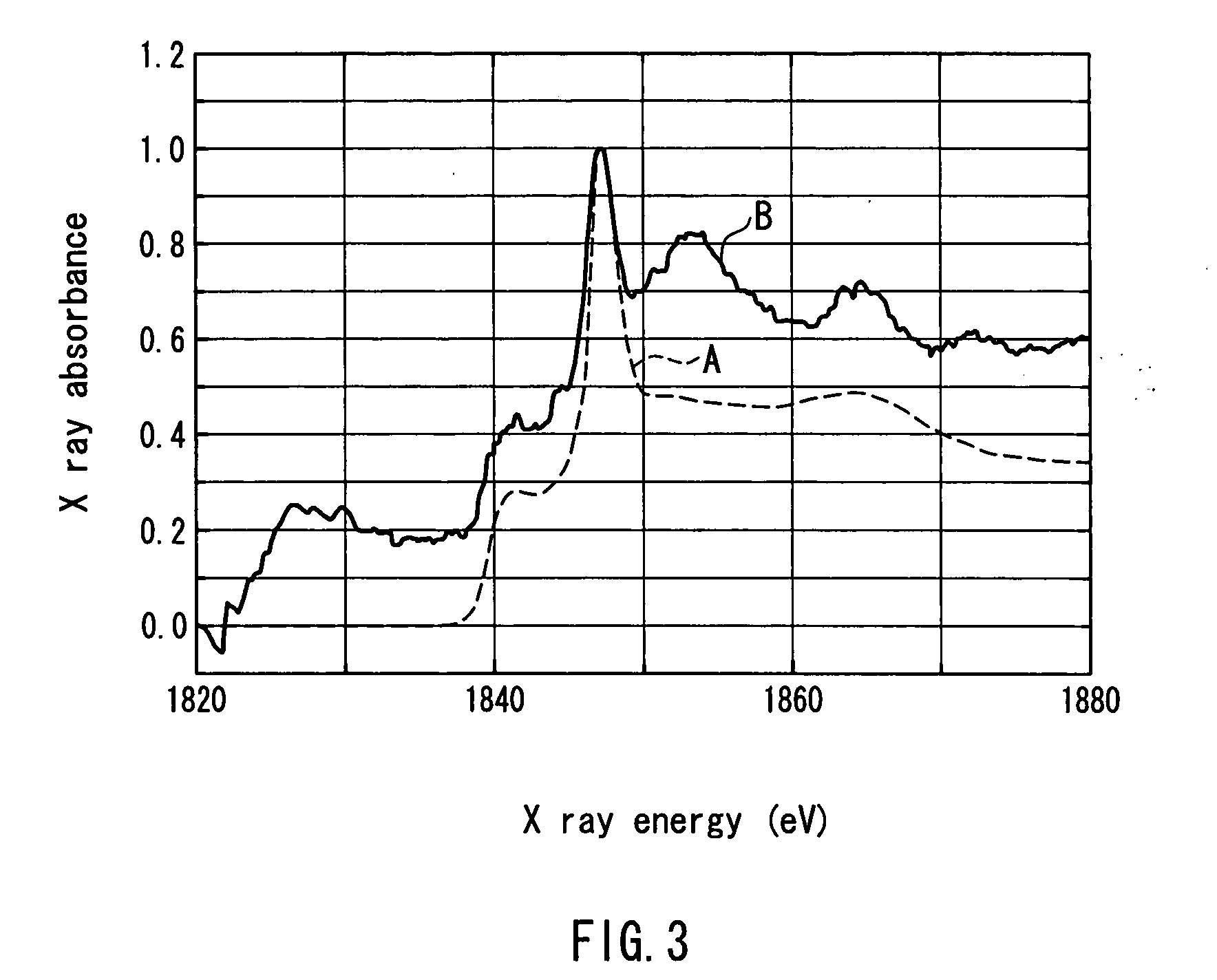

Non-aqueous secondary battery and method for producing the same

ActiveUS20070190416A1Large capacityExcellent battery characteristicsFinal product manufacturePrimary cellsPeak valueOxygen

A non-aqueous secondary battery of the present invention includes a positive electrode, a negative electrode and a non-aqueous electrolyte. The positive electrode includes a positive electrode material mixture layer containing a lithium-containing transition metal oxide. The negative electrode includes a negative electrode material mixture layer and a porous layer containing an insulating material unreactive with lithium formed thereon. The negative electrode material mixture layer includes a negative electrode material including a core and a carbon covering layer covering a surface of the core. The core includes a material containing silicon and oxygen at an atomic ratio x of the oxygen to the silicon of 0.5≦×≦1.5. The material containing silicon and oxygen has a peak at least in a range of 1850 to 1860 eV in an X-ray absorption near edge structure spectrum at the K absorption edge of Si in a state in which discharge of the battery is finished.

Owner:MAXELL HLDG LTD

Laser-based method and system for memory link processing with picosecond lasers

InactiveUS20050092720A1Quality improvementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserLaser processing

A laser-based method of removing a target link structure of a circuit fabricated on a substrate includes generating a pulsed laser output at a pre-determined wavelength less than an absorption edge of the substrate. The laser output includes at least one pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond, the pulse duration being within a thermal laser processing range. The method also includes delivering and focusing the laser output onto the target link structure. The focused laser output has sufficient power density at a location within the target structure to reduce the reflectivity of the target structure and efficiently couple the focused laser output into the target structure to remove the link without damaging the substrate.

Owner:GSI LUMONICS CORP

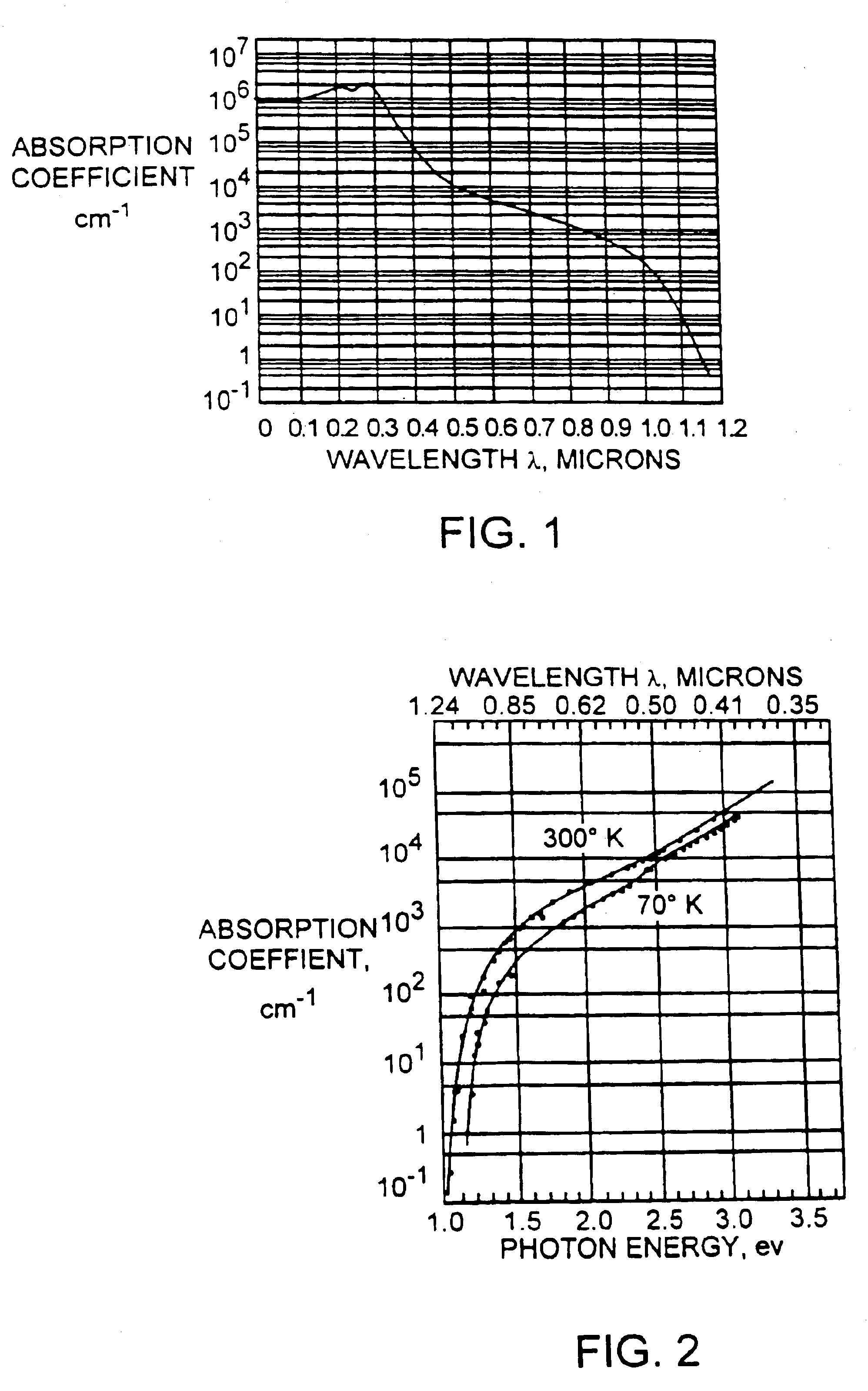

Method for determining the temperature of semiconductor substrates from bandgap spectra

InactiveUS6116779AThermometer detailsThermometers using physical/chemical changesAbsorptanceLength wave

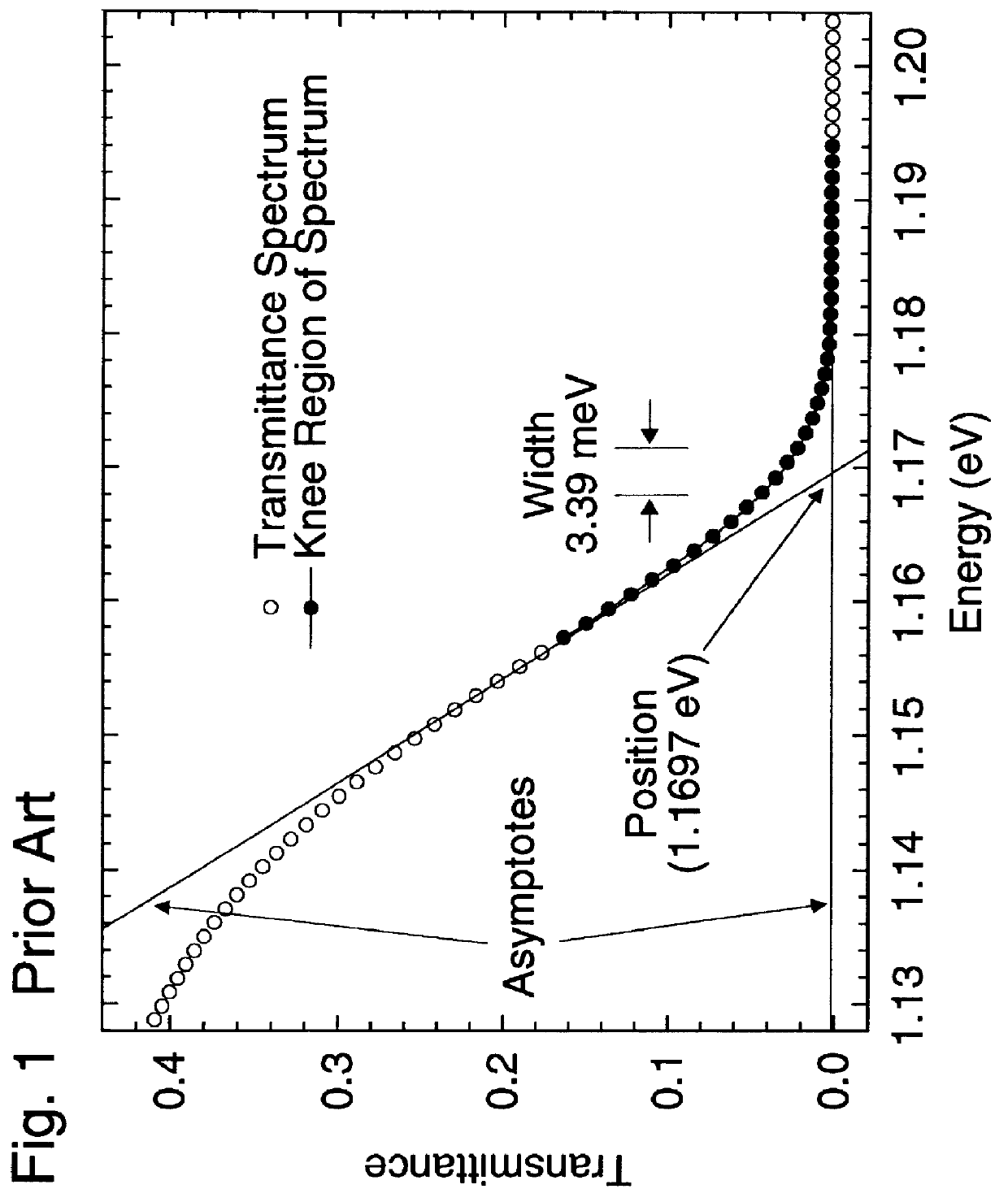

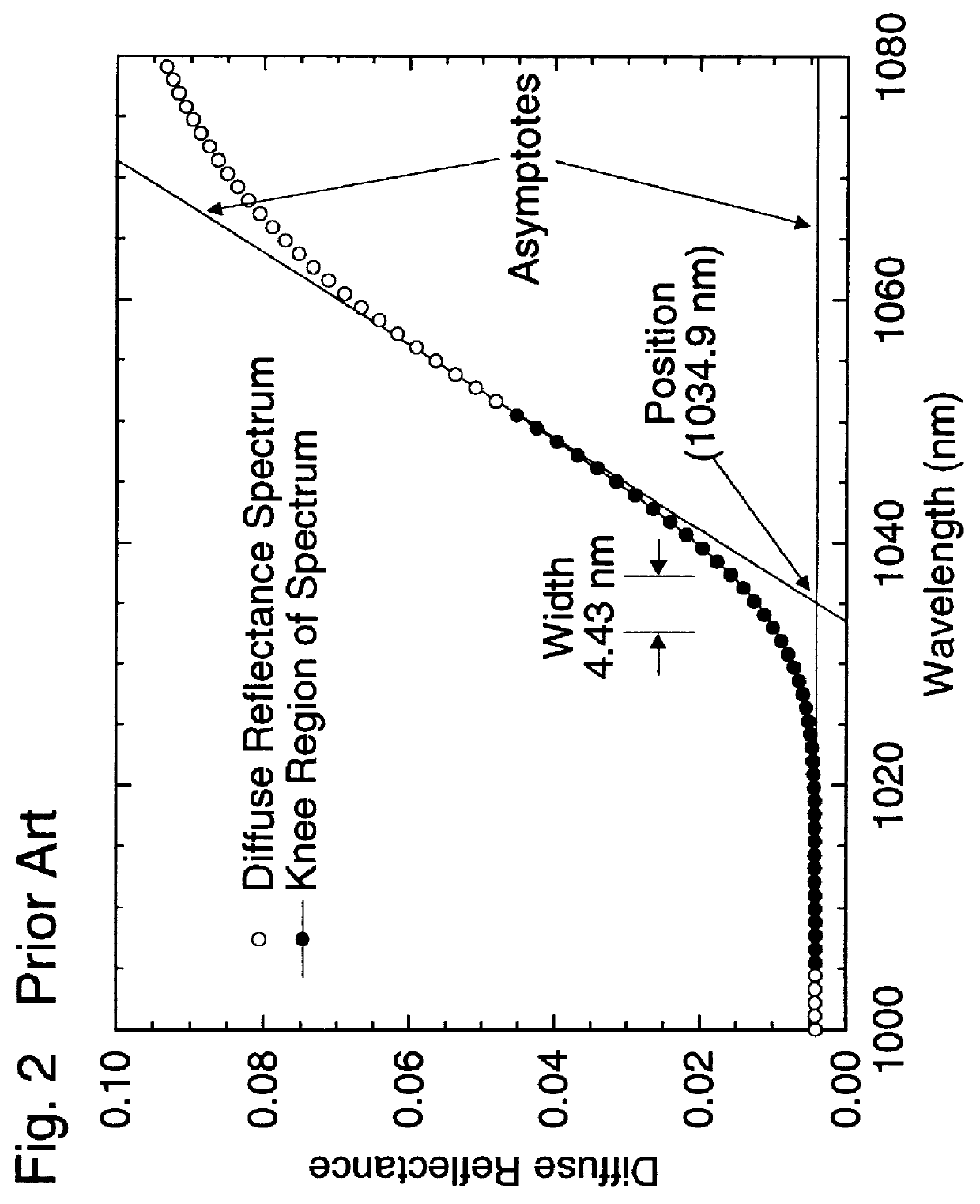

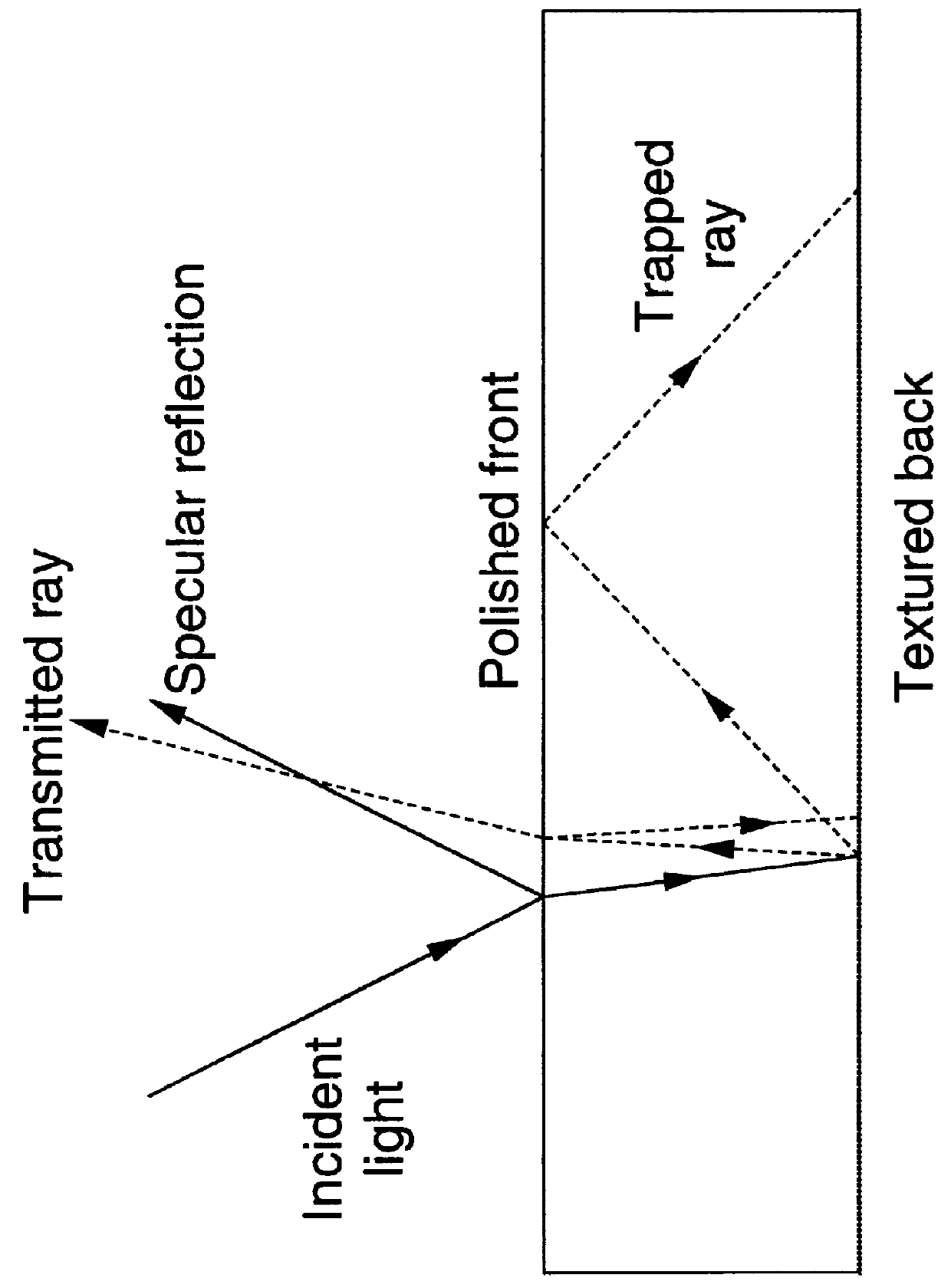

An optical method for measuring the temperature of a substrate material with a temperature dependent band edge. In this method both the position and the width of the knee of the band edge spectrum of the substrate are used to determine temperature. The width of the knee is used to correct for the spurious shifts in the position of the knee caused by: (i) thin film interference in a deposited layer on the substrate; (ii) anisotropic scattering at the back of the substrate; (iii) the spectral variation in the absorptance of deposited layers that absorb in the vicinity of the band edge of the substrate; and (iv) the spectral dependence in the optical response of the wavelength selective detection system used to obtain the band edge spectrum of the substrate. The adjusted position of the knee is used to calculate the substrate temperature from a predetermined calibration curve. This algorithm is suitable for real-time applications as the information needed to correct the knee position is obtained from the spectrum itself. Using a model for the temperature dependent shape of the absorption edge in GaAs and InP, the effect of substrate thickness and the optical geometry of the method used to determine the band edge spectrum, are incorporated into the calibration curve.

Owner:JOHNSON SHANE R +1

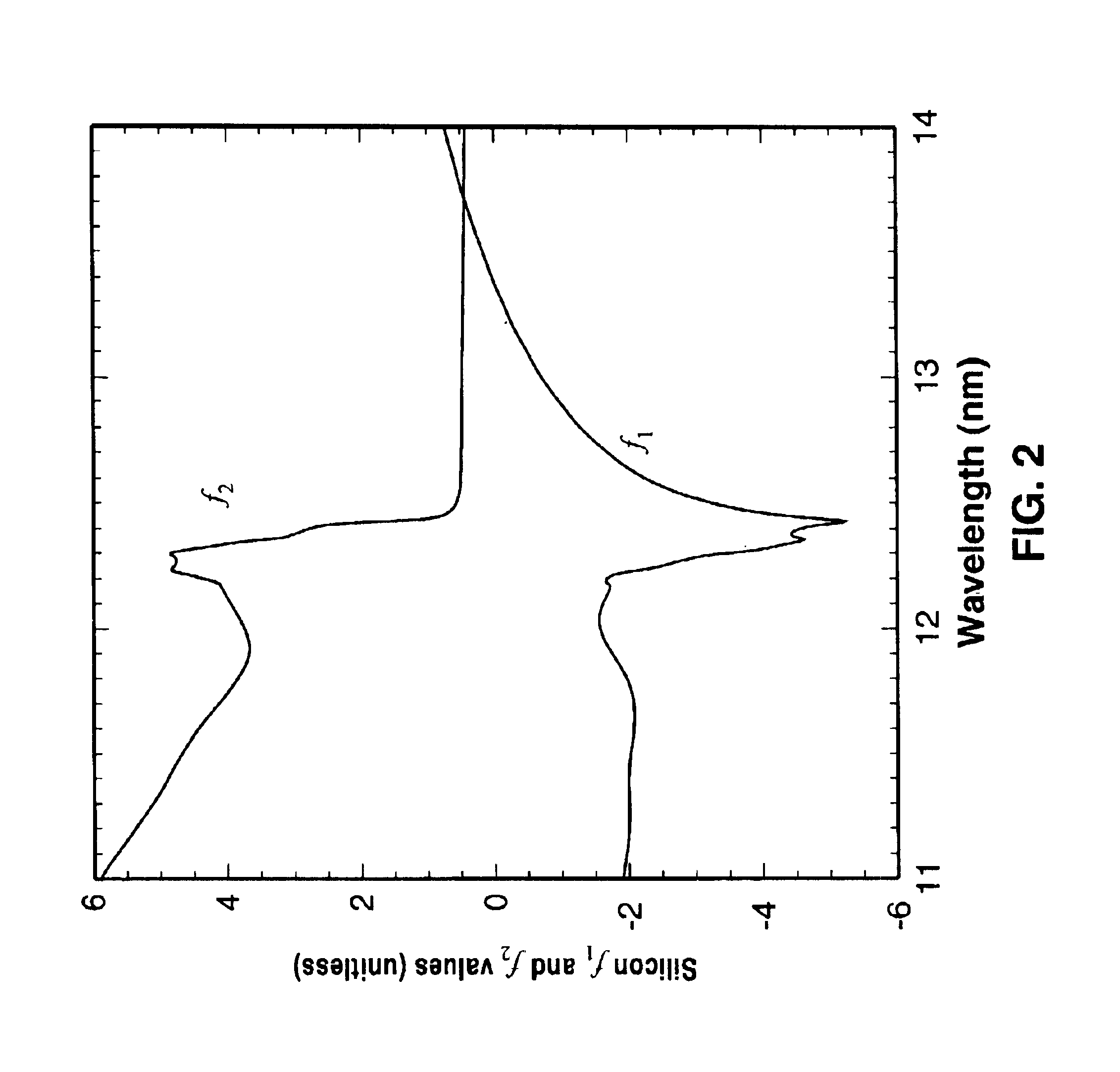

Achromatic fresnel optics for ultraviolet and x-ray radiation

InactiveUS6917472B1Relatively large bandwidthIncrease amplitudeOptical filtersDiffraction gratingsRefractive indexX-ray

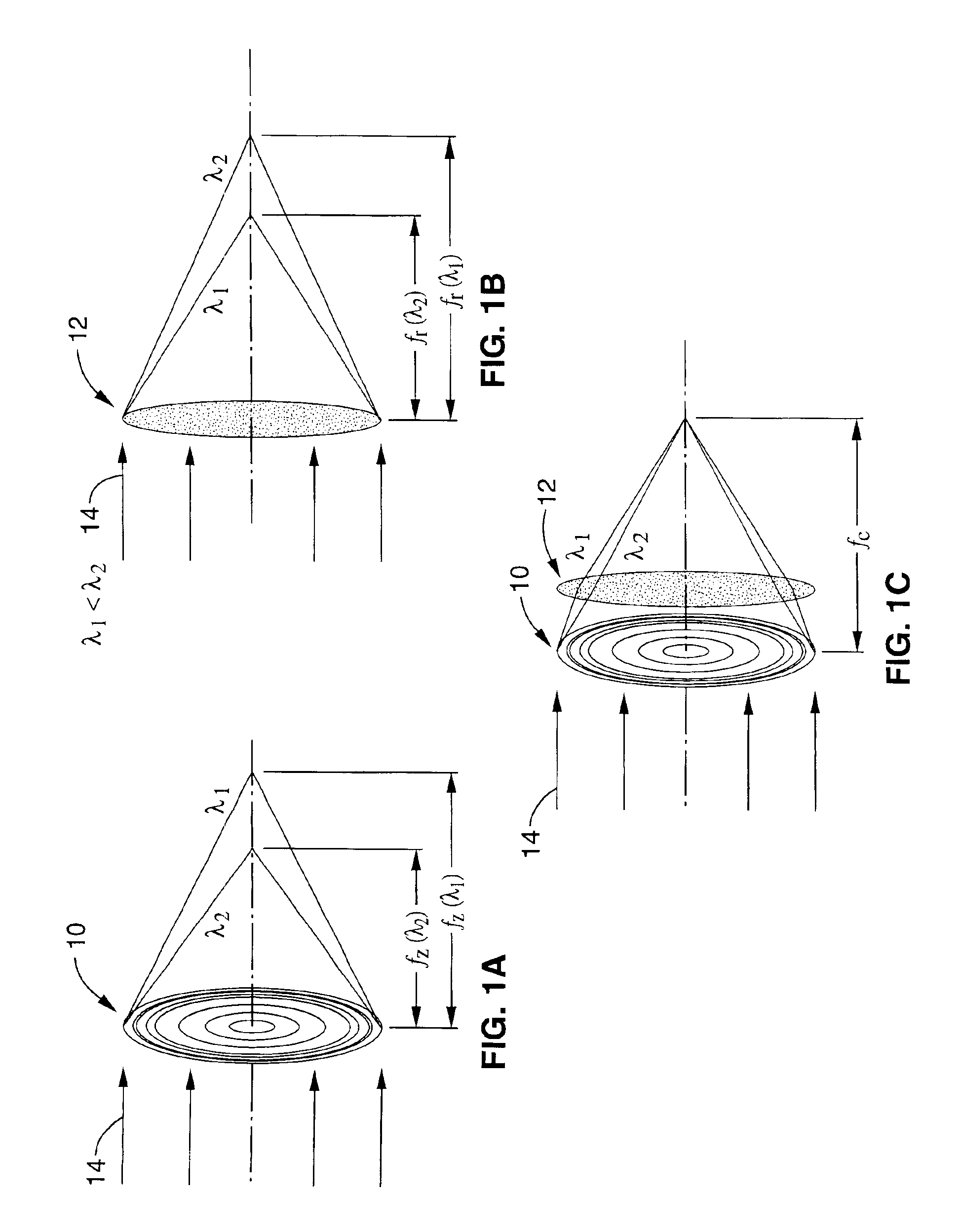

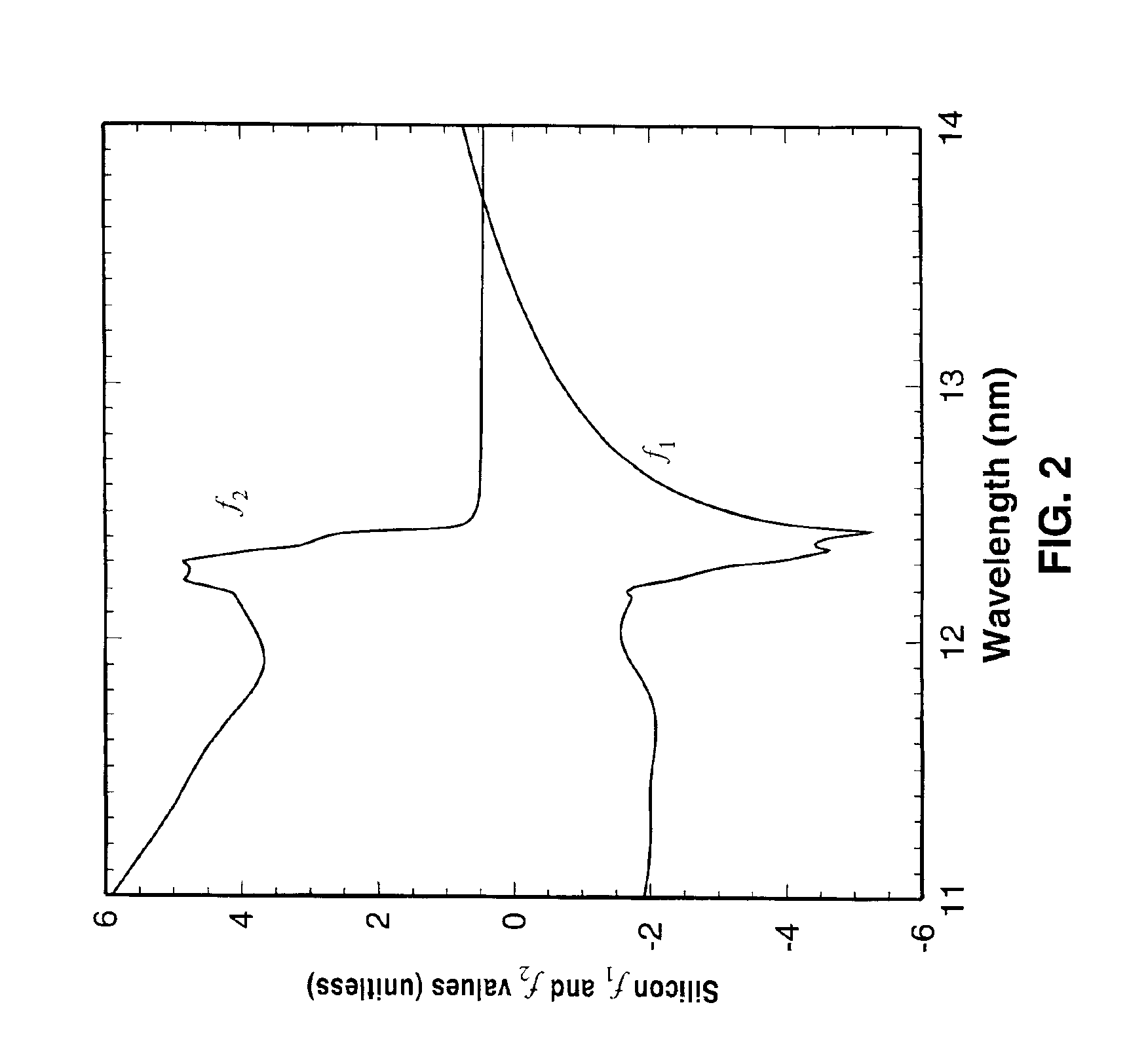

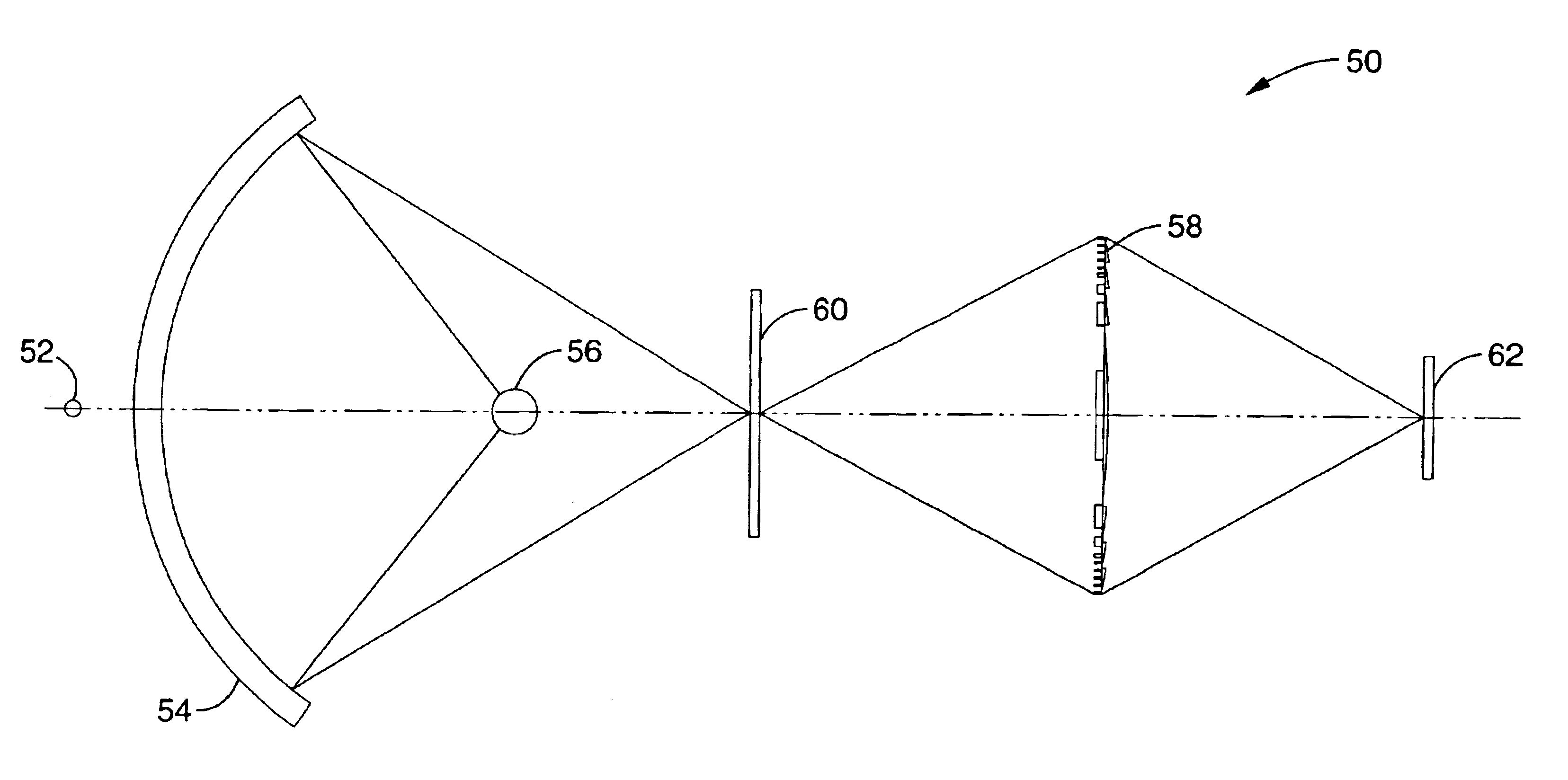

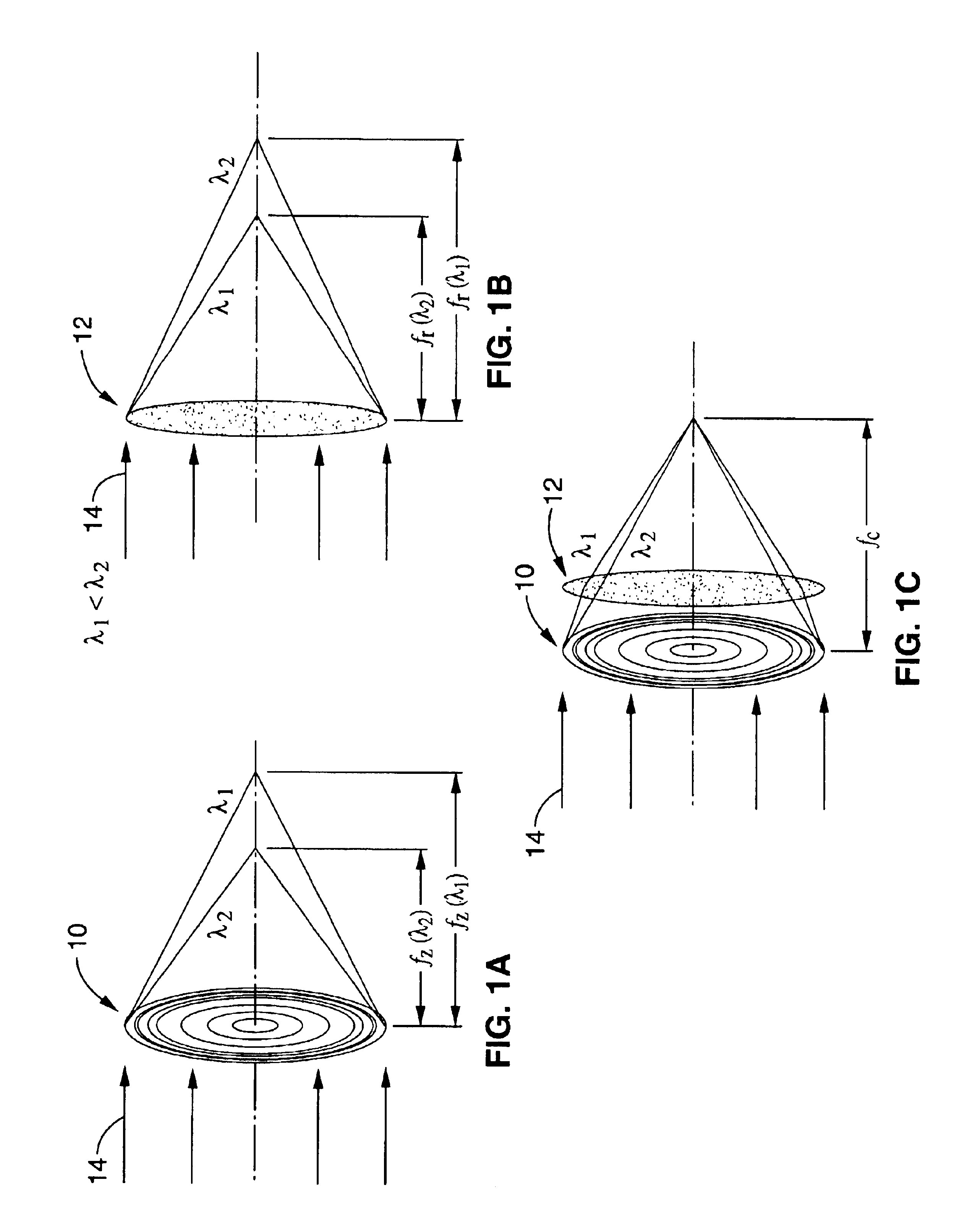

An achromatic Fresnel optic that combines a Fresnel zone plate and a refractive Fresnel lens. The zone plate provides high resolution for imaging and focusing, while the refractive lens takes advantage of the refraction index change properties of appropriate elements near absorption edges to recombine the electromagnetic radiation of different energies dispersed by the zone plate. This compound lens effectively solves the high chromatic aberration problem of zone plates. The AFO has a wide range of potential applications in lithography, microimaging with various contrast mechanisms and measurement techniques.

Owner:CARL ZEISS X RAY MICROSCOPY

Achromatic fresnel optics based lithography for short wavelength electromagnetic radiations

InactiveUS6885503B2Simplify System DesignImprove system throughputMirrorsDiffraction gratingsRefractive indexElectromagnetic radiation

A lithography apparatus having achromatic Fresnel objective (AFO) that combines a Fresnel zone plate and a refractive Fresnel lens. The zone plate provides high resolution for imaging and focusing, while the refractive lens takes advantage of the refraction index change properties of appropriate elements near absorption edges to recombine the electromagnetic radiation of different energies dispersed by the zone plate. This compound lens effectively solves the high chromatic aberration problem of zone plates. The lithography apparatus allows the use of short wavelength radiation in the 1-15 nm spectral range to print high resolution features as small as 20 nm.

Owner:XRADIA

Laser-based method and system for memory link processing with picosecond lasers

InactiveUS20050115936A1Quality improvementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserLaser processing

A laser-based method of removing a target link structure of a circuit fabricated on a substrate includes generating a pulsed laser output at a pre-determined wavelength less than an absorption edge of the substrate. The laser output includes at least one pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond, the pulse duration being within a thermal laser processing range. The method also includes delivering and focusing the laser output onto the target link structure. The focused laser output has sufficient power density at a location within the target structure to reduce the reflectivity of the target structure and efficiently couple the focused laser output into the target structure to remove the link without damaging the substrate.

Owner:GSI LUMONICS CORP

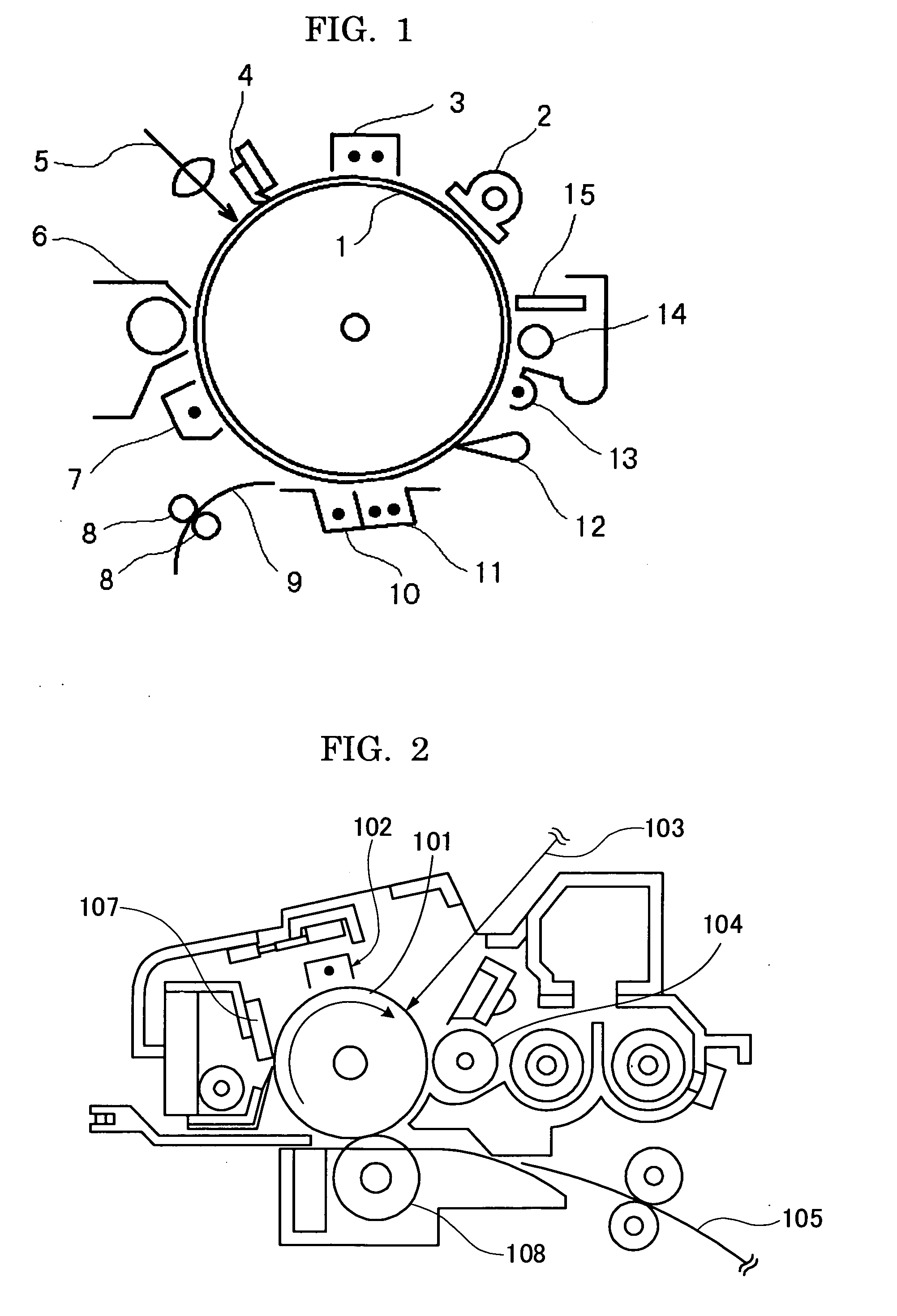

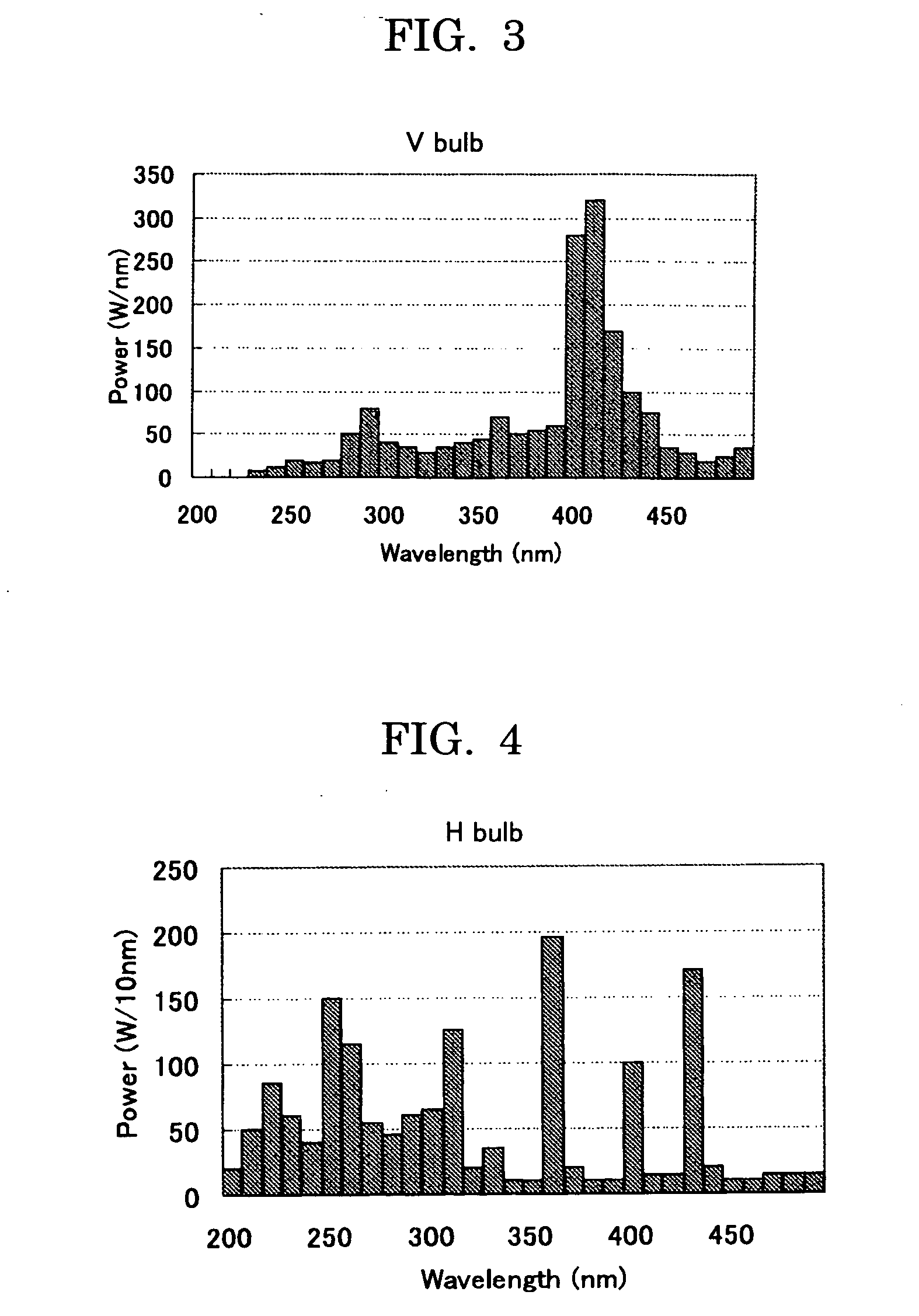

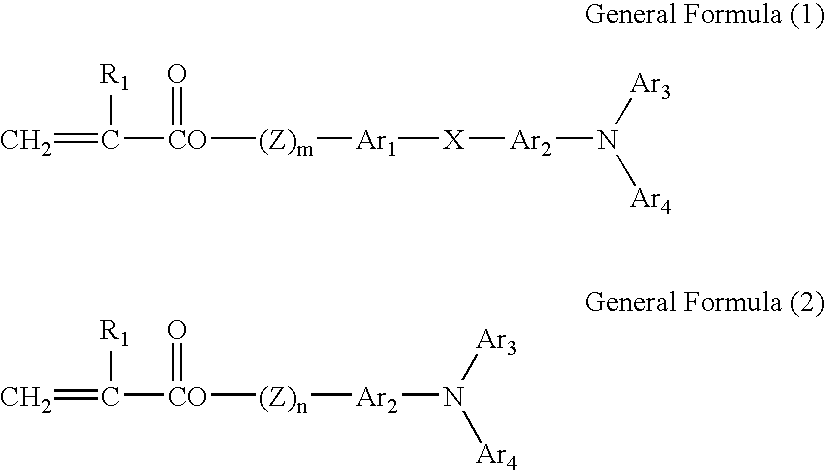

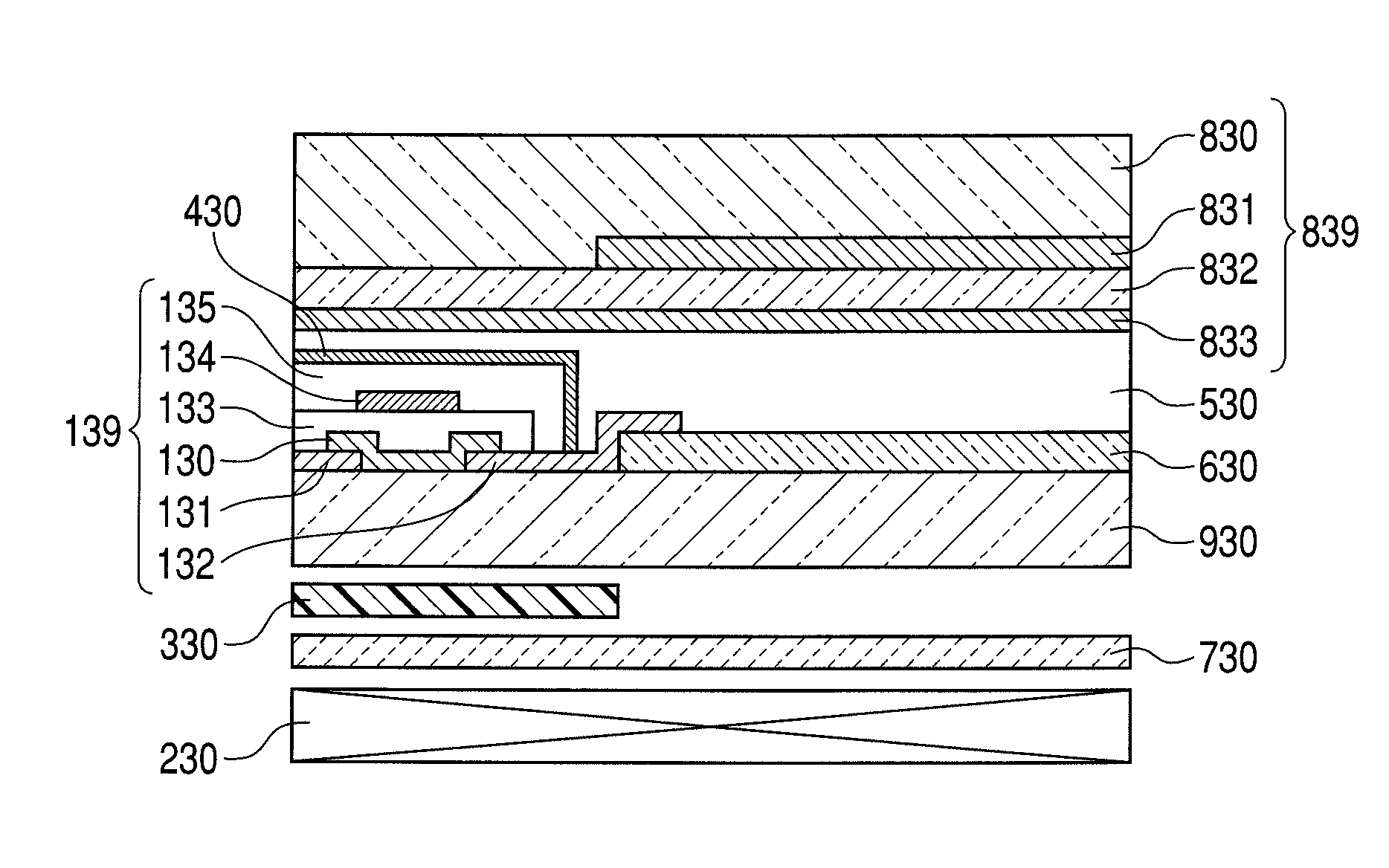

Electrophotographic photoconductor, process cartridge, and image forming method

InactiveUS20070031746A1Efficient curingMinimize the differenceElectrographic process apparatusElectrographic processes using charge patternPhoto irradiationOrganic chemistry

The present invention provides an electrophotographic photoconductor which contains a substrate, at least a photosensitive layer and a surface layer being formed on the substrate in this order; the surface layer contains a cured material which is cured by irradiating with light a trifunctional or more radical polymerizable monomer having no electric charge transportable structure, a radical polymerizable monomer having an electric charge transportable structure, and a photo-radical polymerization initiator; the photo-radical polymerization initiator contains a titanocene derivative; and the relation between the absorption edge wavelength HA (nm) in the light absorption spectrum of the radical polymerization initiator and the absorption edge wavelength HB (nm) in the light absorption spectrum of the radical polymerizable monomer having an electric charge transportable structure is represented by HA>HB and satisfies HA−HB>40 nm.

Owner:RICOH KK

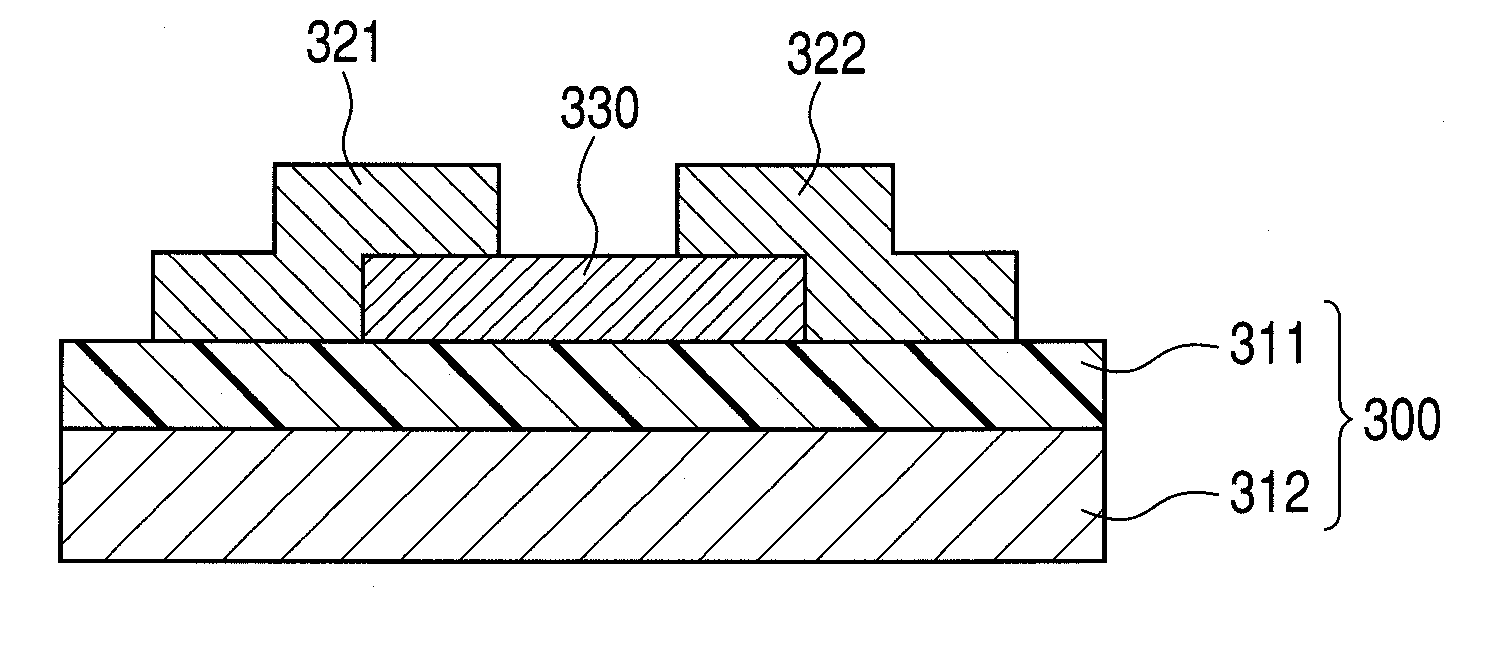

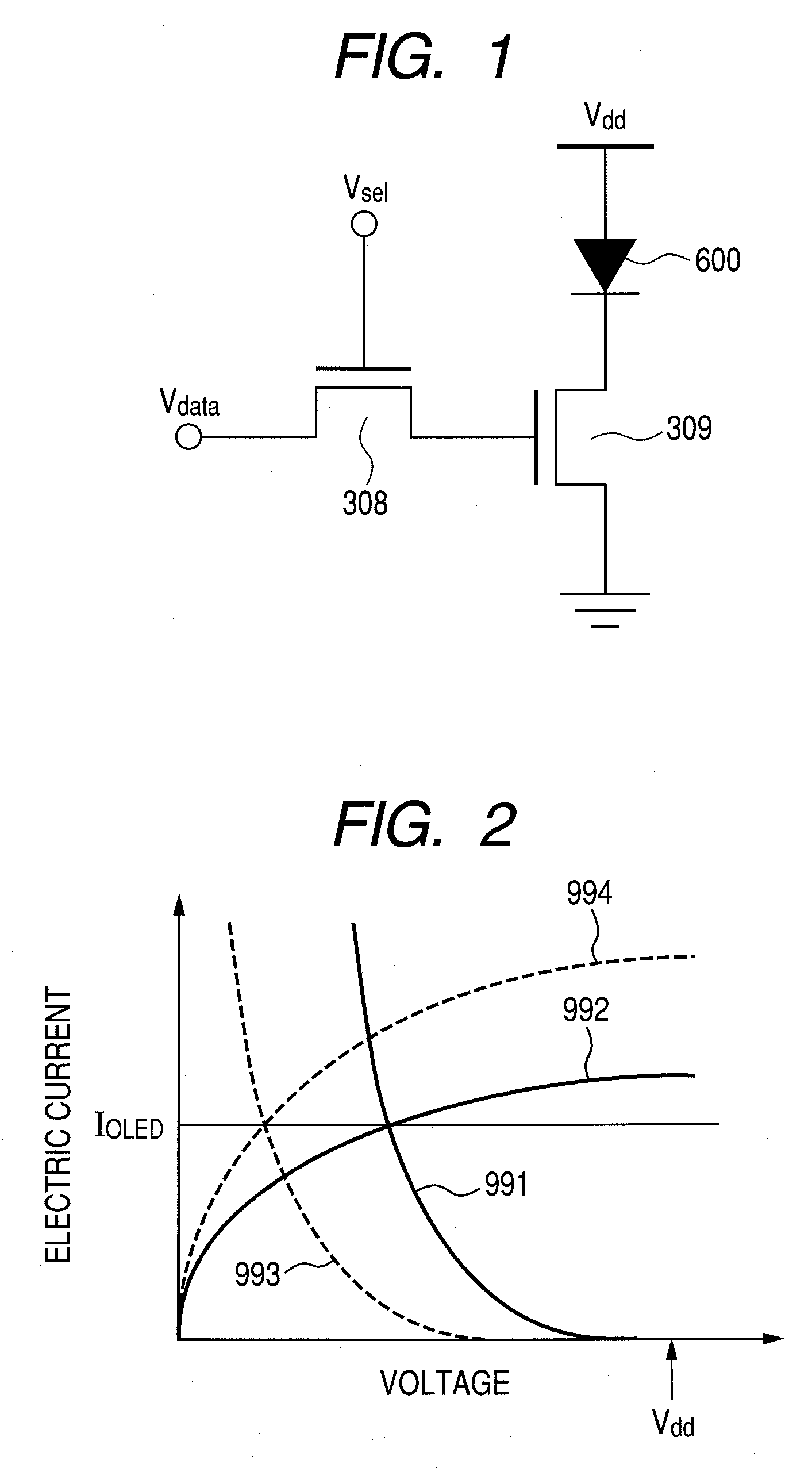

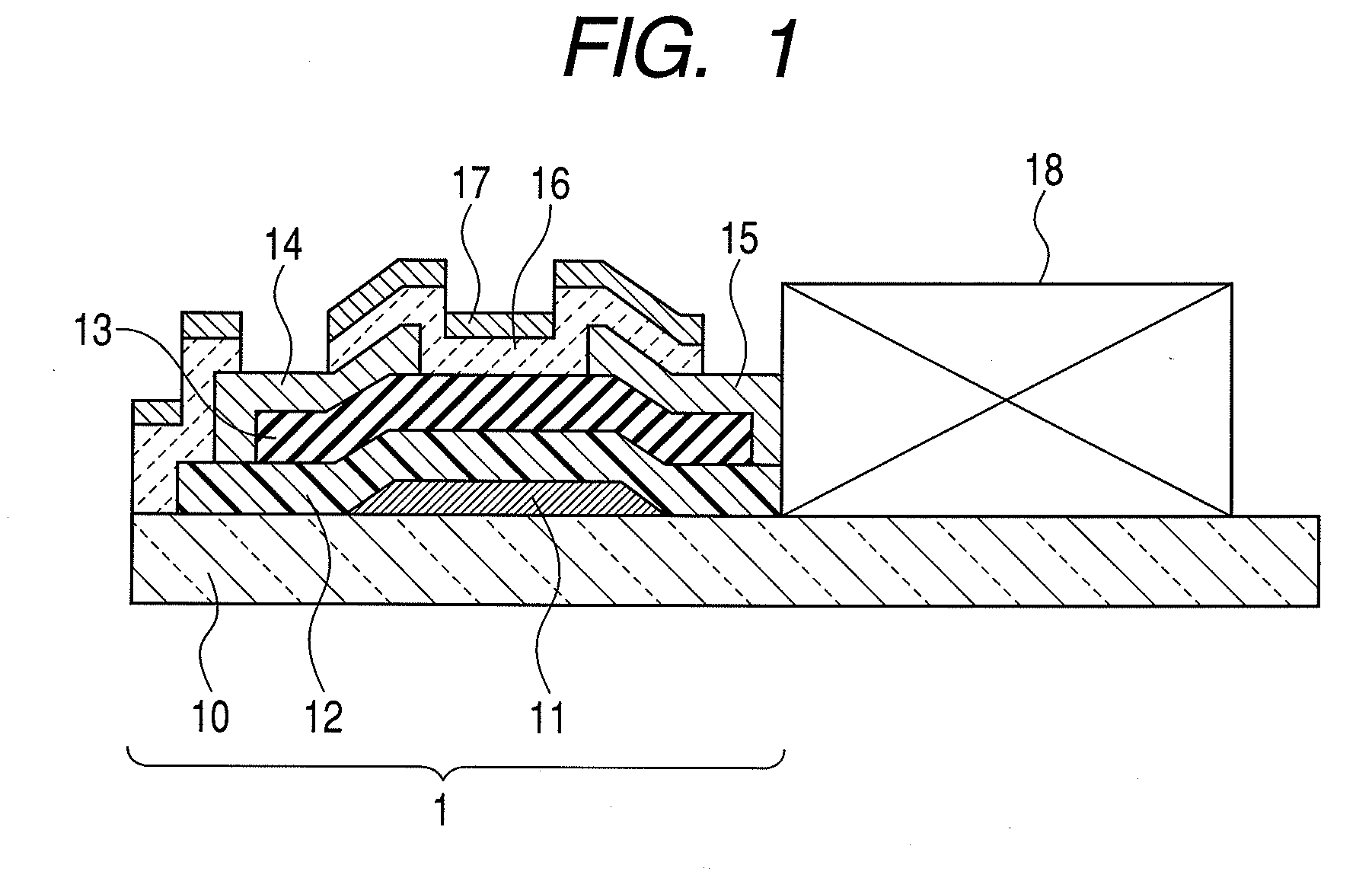

Semiconductor device and display apparatus

Provided is a semiconductor device including a semiconductor element including at least a semiconductor as a component characterized by including: a mechanism for irradiating the semiconductor with light having a wavelength longer than an absorption edge wavelength of the semiconductor; and a dimming mechanism, provided in a part of an optical path through which the light passes, for adjusting at least one factor selected from an intensity, irradiation time and the wavelength of the light, wherein a threshold voltage of the semiconductor element is varied by the light adjusted by the dimming mechanism.

Owner:CANON KK

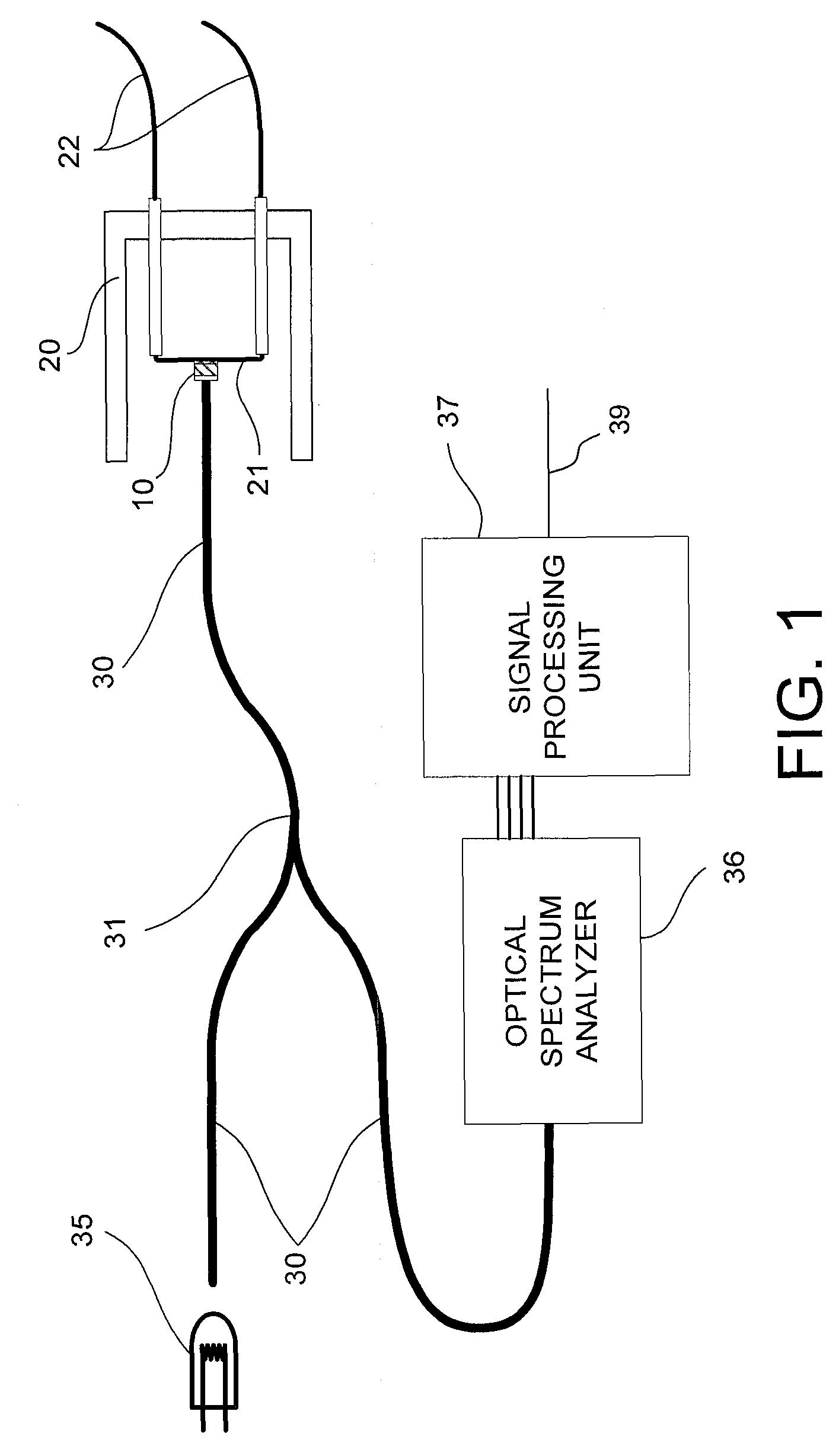

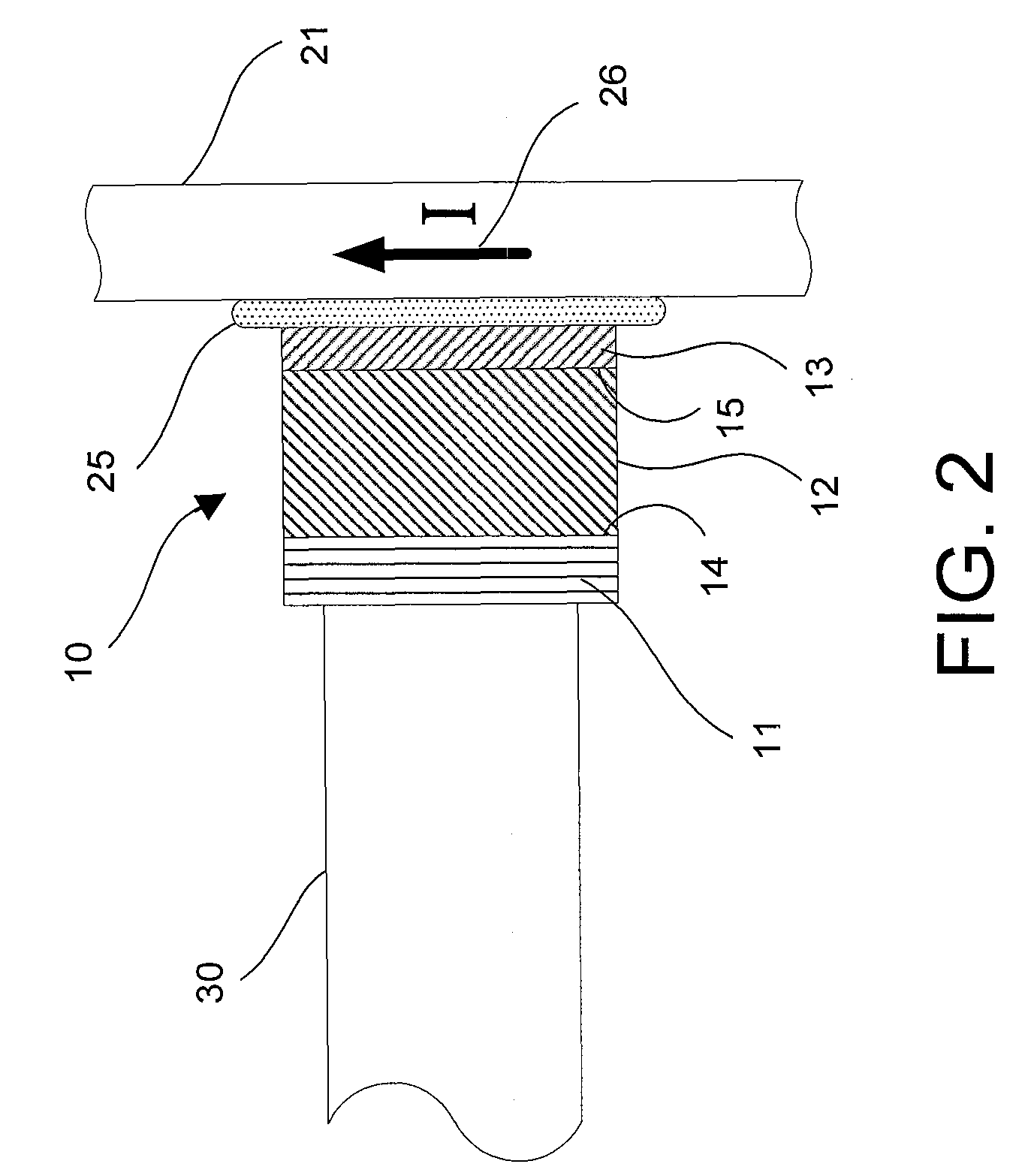

Optical sensor for monitoring electrical current or power

The present invention provides an optical sensor for monitoring current or power in a monitored element of a device such as a bridge-wire or hot-wire of electro-explosive devices. The optical sensor comprises an optical sensor made of semiconductor material. The semiconductor material comprises an absorption edge which is sensitive to a temperature variation. The semiconductor material is for placing in thermal contact with the monitored element of the device, whereby, when the current or power varies in the monitored element, it causes a variation in temperature in the semiconductor element and hence a spectral shift of the absorption edge which can be measured and which is representative of current and power variation.

Owner:OPSENS SOLUTIONS

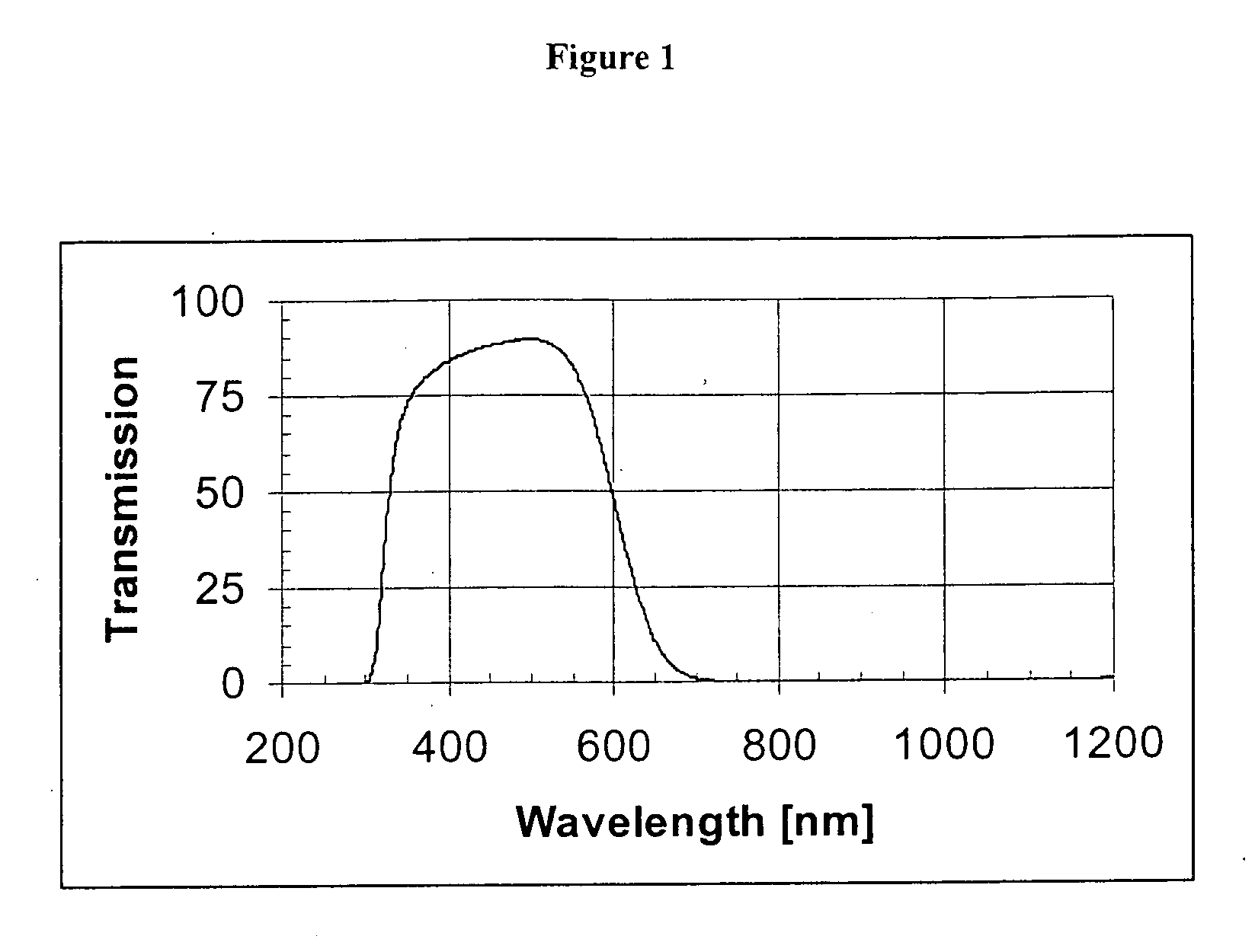

Aluminophosphate glass containing copper (II) oxide and uses thereof for light filtering

InactiveUS20070099787A1Reduce transmissionSteep absorption edgeCamera filtersSpectrometry/spectrophotometry/monochromatorsAlkaline earth metalCopper oxide

Aluminophosphate glasses containing copper(II) oxide having a low transmission in the near infrared range with a steep absorption edge, as well as a very uniform high transparency in the visible range and excellent chemical durability under conditions of exposure to elevated temperature and high relative humidity, are particularly suitable as filter glasses for use in CCD and CMOS camera and detector applications and as filter glass, e.g., for goggles and color displays. The glass comprising, in % by weight on an oxide basis: 65-80 of P2O5; 4-20 of Al2O3; 0-<5.5 of B2O3, 0-2.1 of La2O3; 0-2.1 of Y2O3, 0-3 of SiO2; >2-12.5 of Li2O; 0-6 of Na2O; 0-4 of K2O; 0-2.5 of Rb2O; 0-2.5 of Cs2O; 0-7.9 of MgO; 0-5 of CaO; 0-5 of SrO; 0-10 of BaO; 0-8 of ZnO; 0-5 ZrO2, 5-15 of CuO; and 0-0.5 of V2O5, wherein the sum of alkaline-earth metal oxides+ZnO (ΣR′O) is <18; and the sum of CuO+V2O5 is 5-15.

Owner:SCHOTT CORP

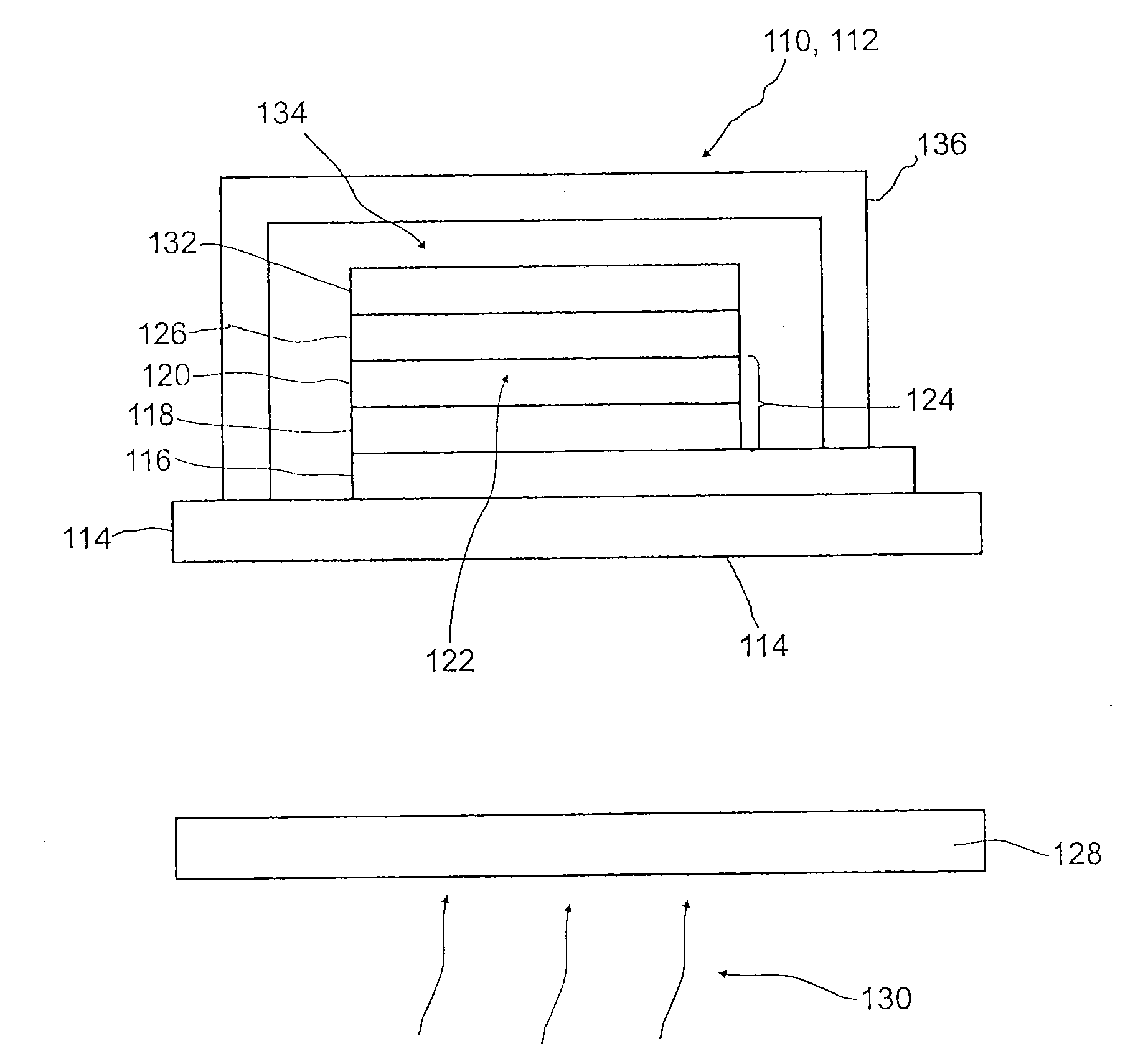

Photovoltaic element with increased long-term stability

InactiveUS20120279566A1Improve applicabilityPromote regenerationElectrolytic capacitorsSolid-state devicesElectrical conductorTransmittance

A photovoltaic element for conversion of electromagnetic radiation to electrical energy, having at least one first electrode, at least one n-semiconductive metal oxide, at least one dye for absorption of electromagnetic radiation, at least one organic hole conductor material, and at least one second electrode. The organic hole conductor material has an absorption spectrum which has a maximum in the ultraviolet or blue spectral region and, toward higher wavelengths, an absorption edge declining with wavelength and having a characteristic wavelength λHTL. A decadic absorbance of the hole conductor material at a wavelength λHTL within the declining absorption edge is 0.3. The photovoltaic element includes a longpass filter, which has a transmission edge rising with wavelength and having a characteristic wavelength λLP. A transmission of the longpass filter at λLP is 50% of a maximum transmission of the longpass filter, where λHTL−30 nm≦λLP≦λHTL+30 nm.

Owner:BASF AG

Method for manufacturing semiconductor device or apparatus, and apparatus for manufacturing the same

InactiveUS8216879B2Manufacturing is longOptimize timingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringLength wave

A method for manufacturing a semiconductor device or apparatus having at least a semiconductor as a component, characterized by including irradiating the semiconductor with light having a longer wavelength than the absorption edge wavelength of the semiconductor to change the threshold voltage of the semiconductor device or apparatus, and checking the threshold voltage of the semiconductor device or apparatus, after or during irradiation with the light, to determine whether the threshold voltage is in a predetermined range, during manufacturing the semiconductor device or apparatus.

Owner:CANON KK

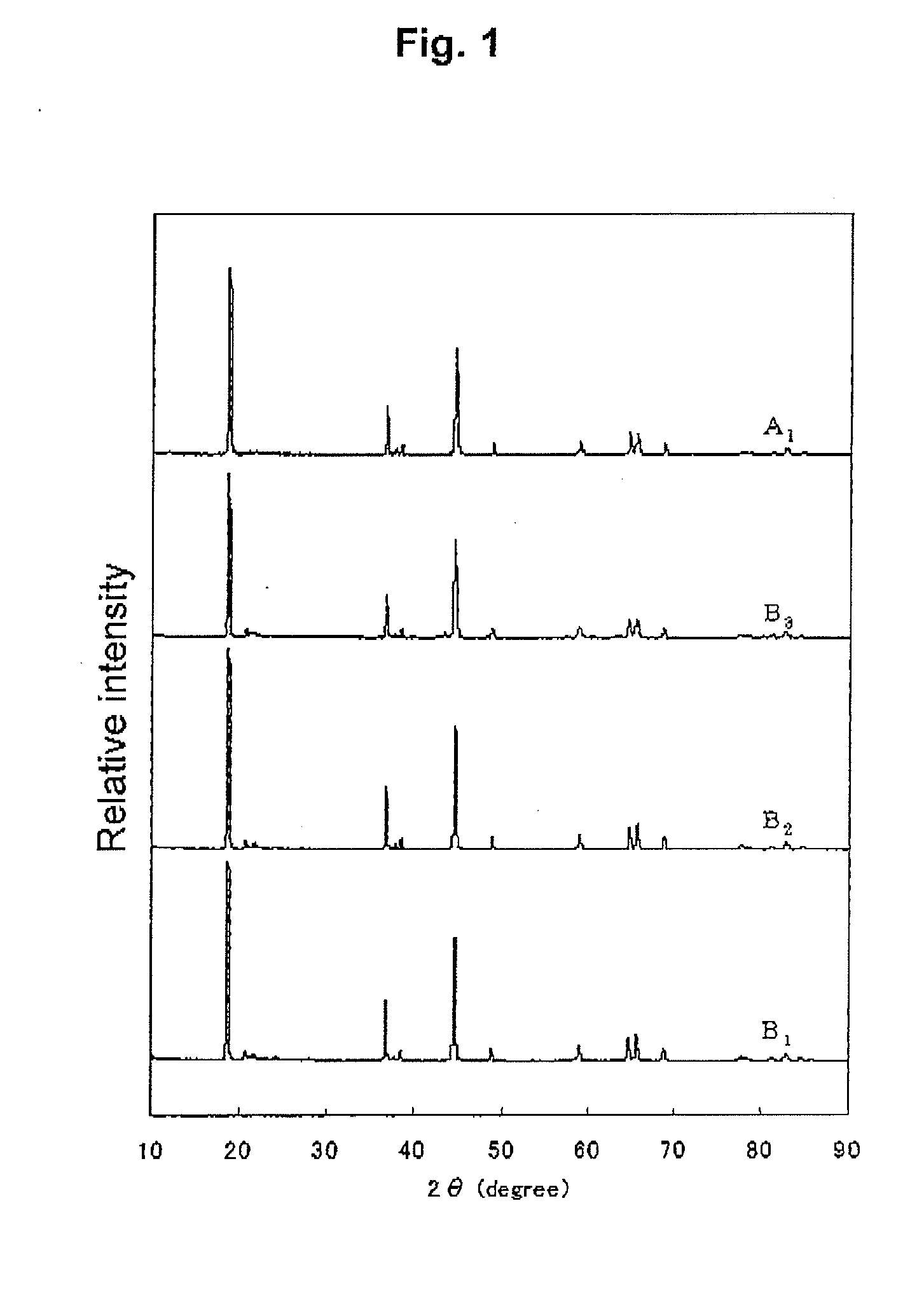

Lithium mixed metal oxide

ActiveUS20110059363A1Material analysis using wave/particle radiationAlkali metal oxidesLithiumXANES Spectroscopy

A lithium mixed metal oxide containing Li, Mn and M (M represents at least one metal element, and is free from Li or Mn), and having a peak around 1.5 Å (peak A), a peak around 2.5 Å (peak B), and the value of IB / IA is not less than 0.15 and not more than 0.9 in a radial distribution function obtained by subjecting an extended X-ray absorption fine structure (EXAFS) spectrum at K absorption edge of Mn in the oxide to the Fourier transformation, wherein IA is the intensity of peak A and IB is the intensity of peak B.

Owner:SUMITOMO CHEM CO LTD

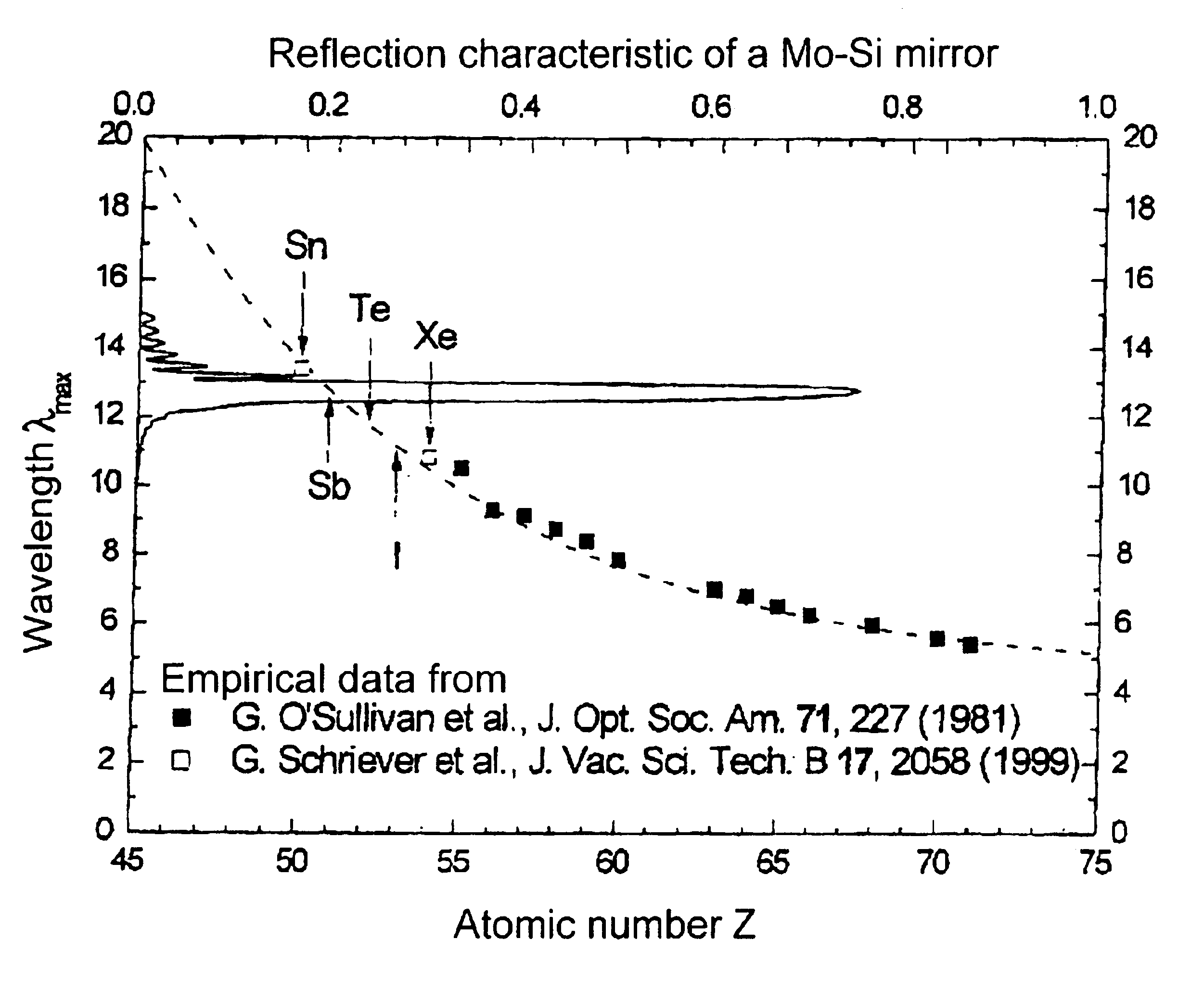

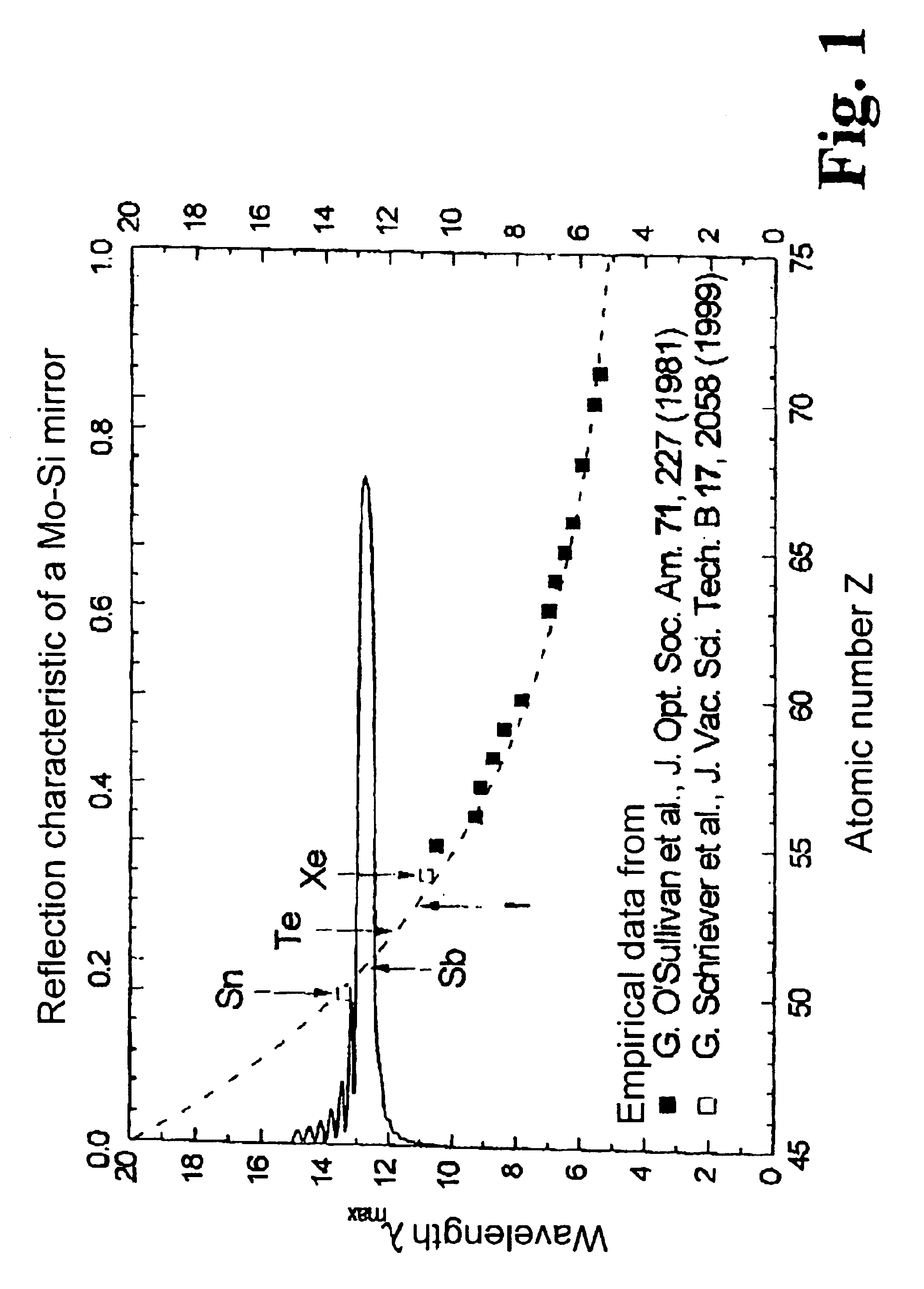

Method for generating extreme ultraviolet radiation based on a radiation-emitting plasma

InactiveUS6770896B2Increasing technical and monetary expenditure for plasma generationReduce material costsRadiation pyrometryNanoinformaticsSemiconductor chipTe element

The invention is directed to a method for generating extreme ultraviolet (EUV) radiation based on a radiation-emitting plasma, particularly for generating EUV radiation with a wavelength around 13 nm. The object of the invention, to find a novel possibility for generating extreme ultraviolet radiation based on a radiation-emitting plasma in which the emission output of the EUV source is increased to the wavelength range above the L-absorption edge of silicon without substantially increasing the technical and monetary expenditure for plasma generation, is met in a method for generating extreme ultraviolet radiation through emission of broadband radiation from a plasma under vacuum conditions in that the plasma is generated using at least one element from V to VII in the p-block of the fifth period of the periodic table of elements. Iodine, tellurium, antimony or materials containing these elements or chemical compounds formed with these elements are preferably used. The invention is advantageously applied in EUV lithography for semiconductor chip fabrication.

Owner:USHIO DENKI KK

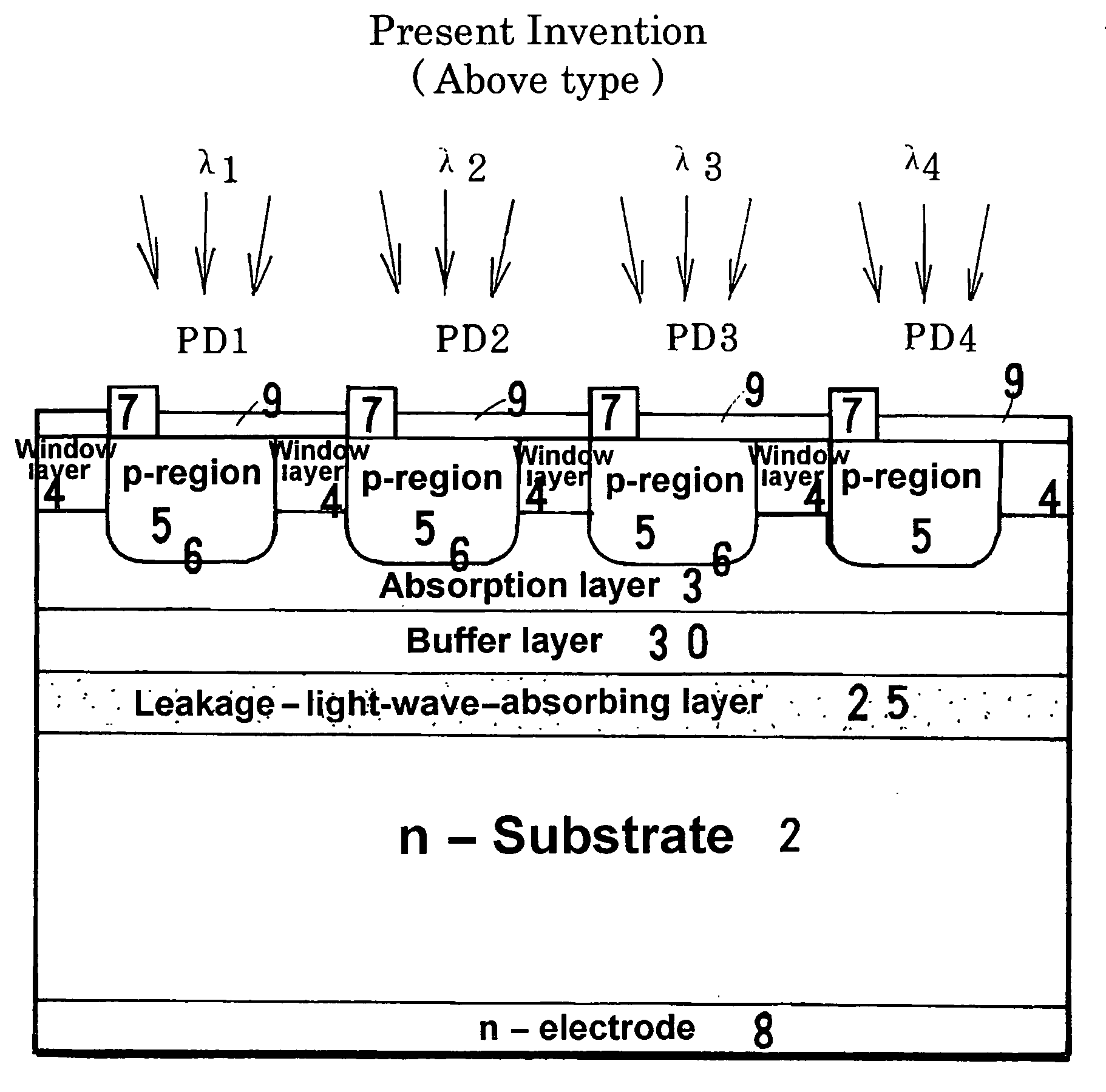

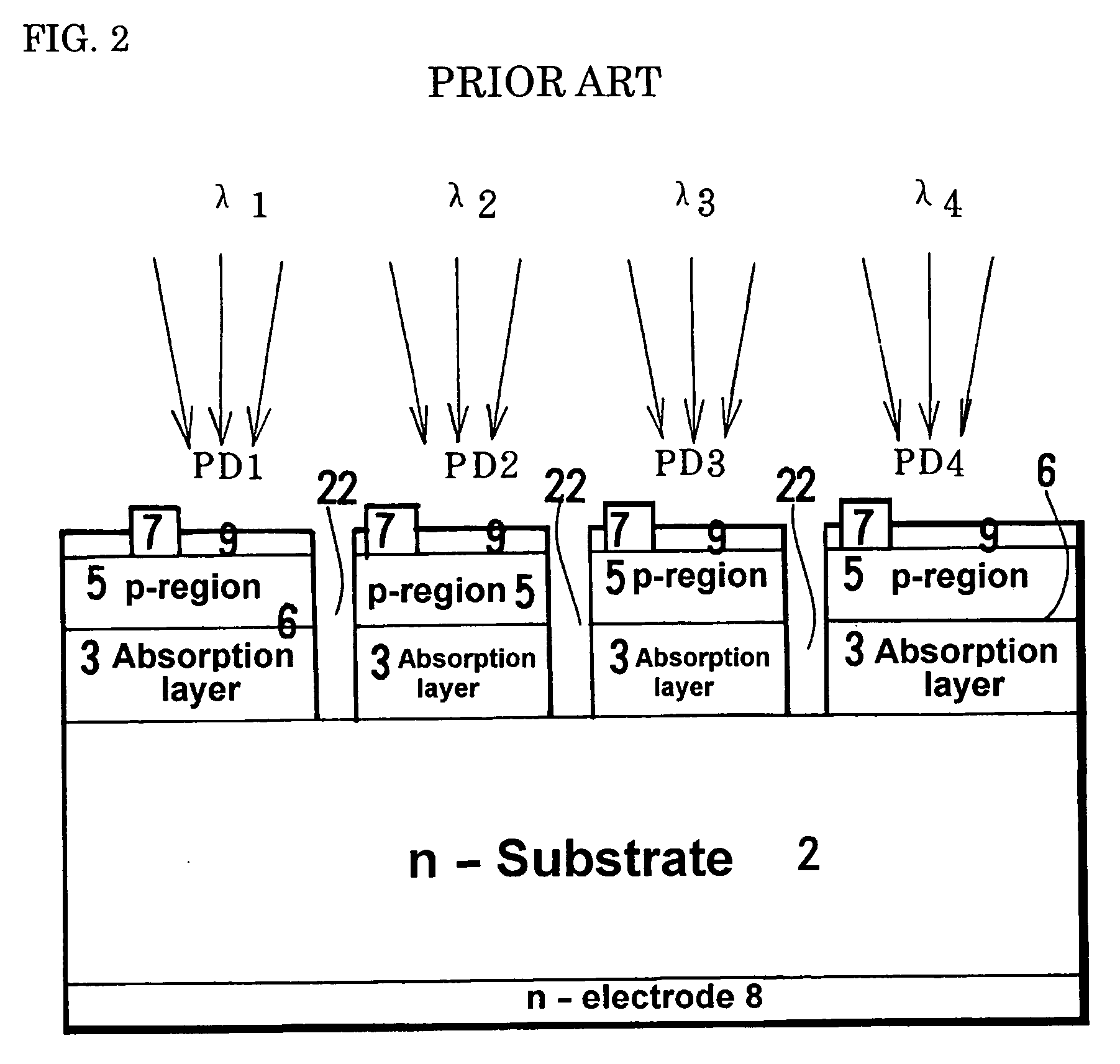

Front-illuminated-type photodiode array

ActiveUS20050194654A1Prevent optical crosstalkAvoid reflectionsSolid-state devicesRadiation controlled devicesLength wavePhotodiode

A front-illuminated-type photodiode array comprises (a) a first-electroconductive-type semiconductor substrate, (b) a first-electroconductive-type electrode placed at the rear-face side of the semi-conductor substrate, (c) a first-electroconductive-type absorption layer formed at the front-face side of the semiconductor substrate, (d) a plurality of second-electroconductive-type regions formed from the surface of the absorption layer to a certain distance into the absorption layer such that the regions are arranged one- or two-dimensionally, (e) a second-electroconductive-type electrode provided at part of each of the second-electroconductive-type regions, (f) an antireflective coating that covers the top surface other than the individual second-electroconductive-type electrodes and that is for preventing reflection of an incoming lightwave, and (g) at least one leakage-lightwave-absorbing layer that is provided between the first-electroconductive-type electrode and the absorption layer and that has an absorption edge wavelength, λga, equal to or longer than the absorption edge wavelength, λgr, of the absorption layer (λga≧λgr).

Owner:SUMITOMO ELECTRIC IND LTD

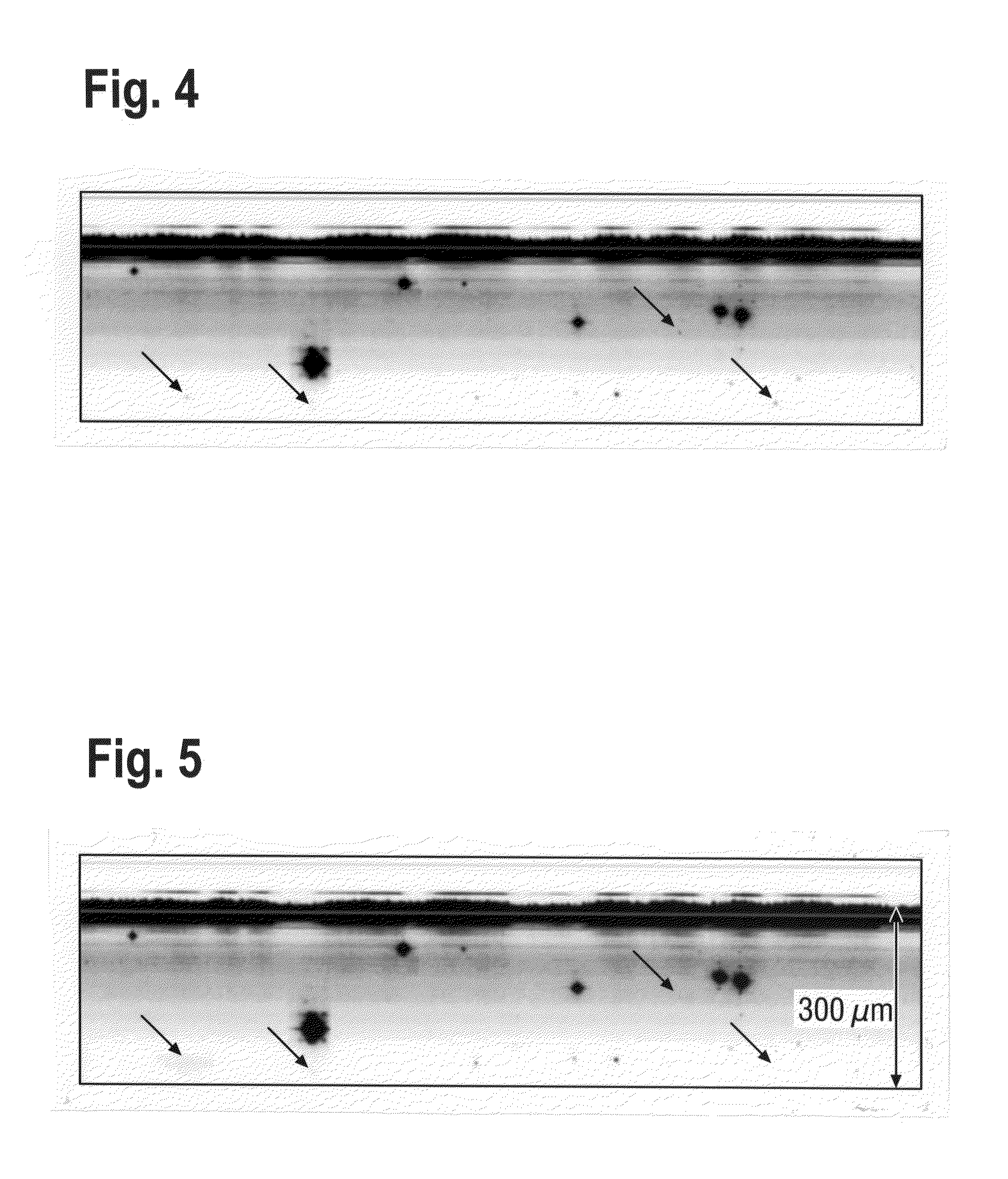

Monocrystalline semiconductor wafer comprising defect-reduced regions and method for producing it

Monocrystalline semiconductor wafers have defect-reduced regions, the defect-reduced regions having a density of GOI-relevant defects within the range of 0 / cm2 to 0.1 / cm2 and occupy overall an areal proportion of 10% to 100% of the planar area of the semiconductor wafer, wherein the remaining regions of the semiconductor wafer have a significantly higher defect density than the defect-reduced regions. The wafers may be produced by a method for annealing GOI relevant defects in the wafer, by irradiating defined regions of a side of the semiconductor wafer by laser wherein each location is irradiated with a power density of 1 GW / m2 to 10 GW / m2 for at least 25 ms, wherein the laser emits radiation of a wavelength above the absorption edge of the wafer semiconductor material and wherein the temperature of the wafer rises by less than 20 K as a result of irradiation.

Owner:SILTRONIC AG

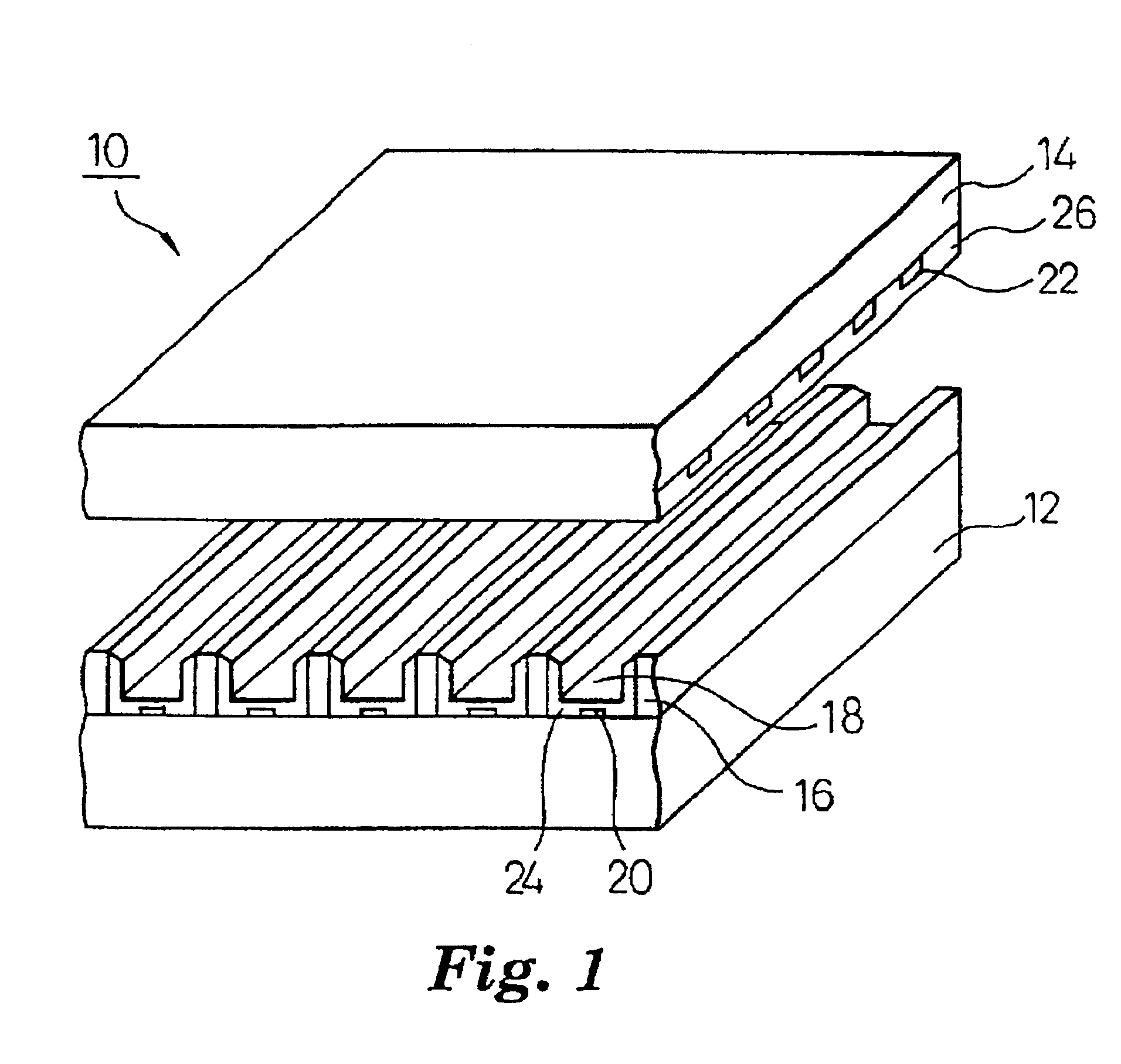

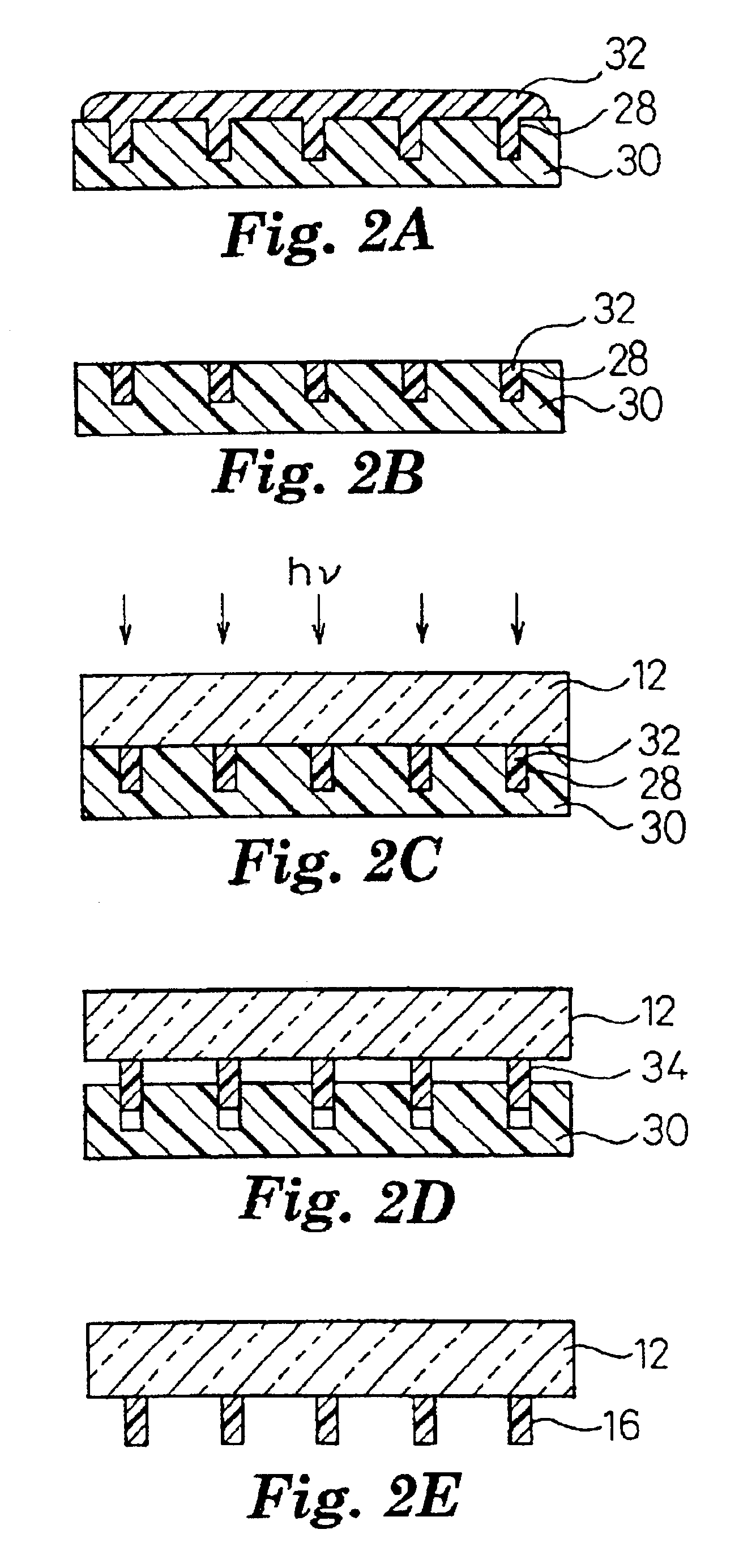

Barrier rib formation on substrate for plasma display panels and mold therefor

InactiveUS6878333B1Avoid breakingRepeat usageElectric discharge tubesVessels or leading-in conductors manufactureEngineeringLength wave

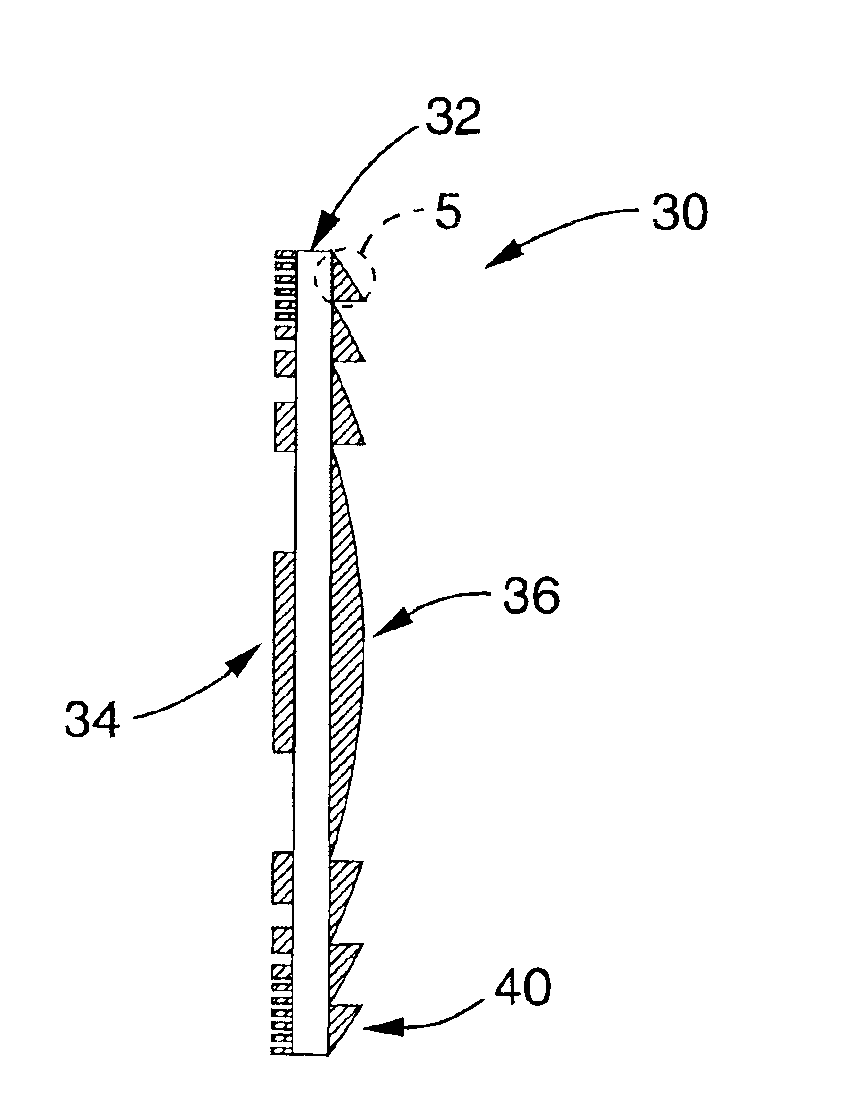

A method of producing a substrate (12) for a plasma display panel, which comprises the steps of: contacting a rib precursor composition (32) containing a first photo-setting initiator having a first absorption edge and a first photo-setting component, closely with a base (12); filling a mold (30), obtained by photo-setting of a second photo-setting component in a presence of a second photo-setting initiator having a second absorption edge whose wavelength is shorter than that corresponding to the first absorption edge of the first photo-setting initiator, with the rib precursor composition (32); irradiating the rib precursor composition (32) with light having a wavelength longer than that corresponding to the second absorption edge to set the rib precursor composition (32), thereby forming a rib (34) on the base (12); and removing the mold (30) from the resulting base (12) on which the rib (34) is formed.

Owner:3M INNOVATIVE PROPERTIES CO

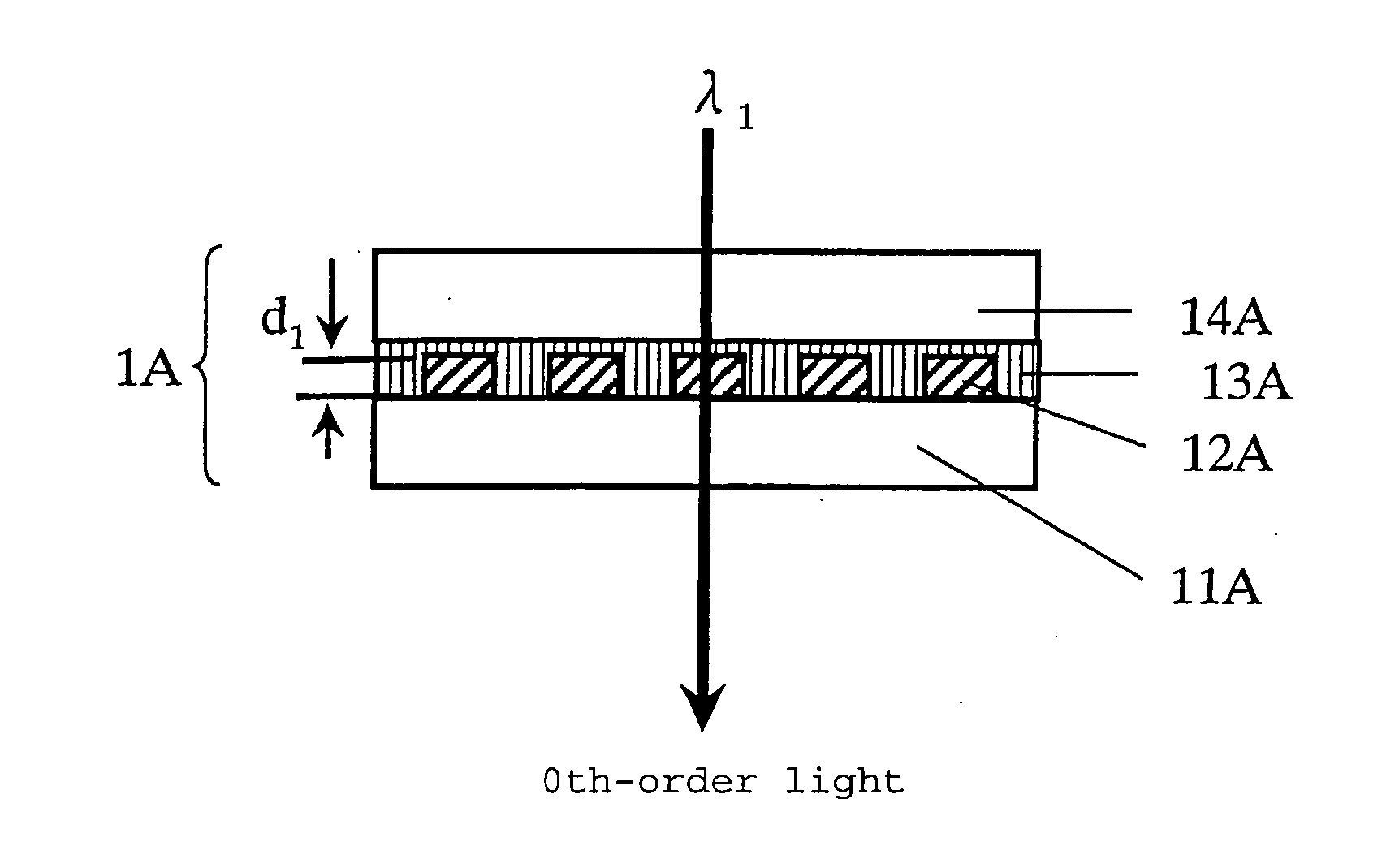

Wavelength-selective diffraction element and an optical head device

InactiveUS20040094699A1Increased durabilityBeam/ray focussing/reflecting arrangementsOptical filtersOptical pickupGrating

An optical head device having an optical element capable of transmitting without diffracting light having a wavelength emitted from a two-wavelength semiconductor laser and capable of diffracting light having another wavelength, to provide high utilization efficiency of light in a stable manner. For this purpose, a wavelength-selective diffraction element 1A comprising a transparent substrate having a front surface on which a grating having a periodically recessed and projected shape in cross section is formed and a filling member 13A filled in the concavo-convex portion 12A of the grating wherein the concavo-convex portion of the grating is provided with an organic pigment having the absorption edge of light in a region having a shorter wavelength than the wavelength lambda1, and the concavo-convex member and the filling member have the same refractive index with respect to either one of light having a wavelength lambda1 and light having a wavelength lambda2, and they have different refractive indices with respect to the other light having a wavelength, is disposed between the light source and the objective lens of the optical head device.

Owner:ASAHI GLASS CO LTD

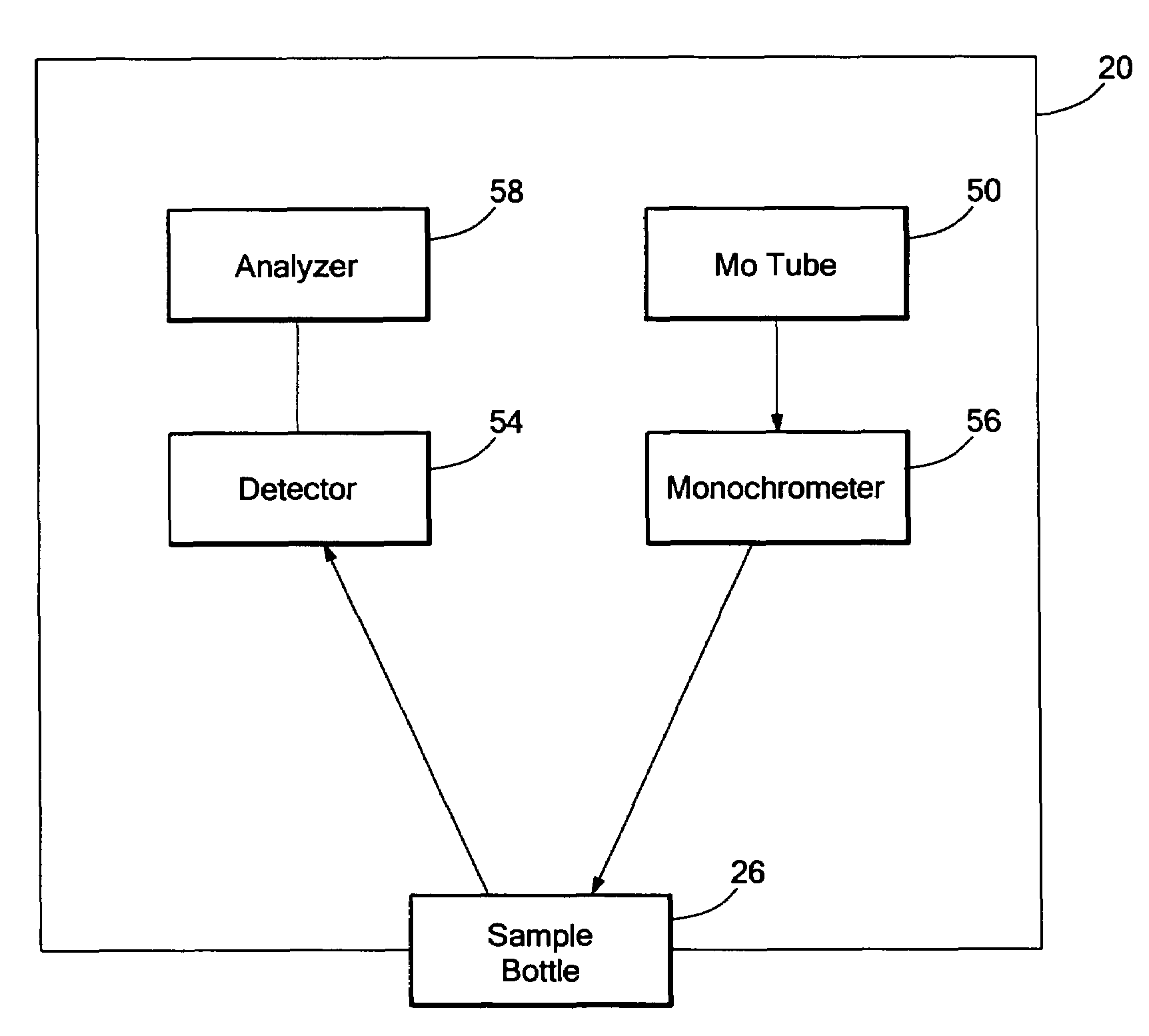

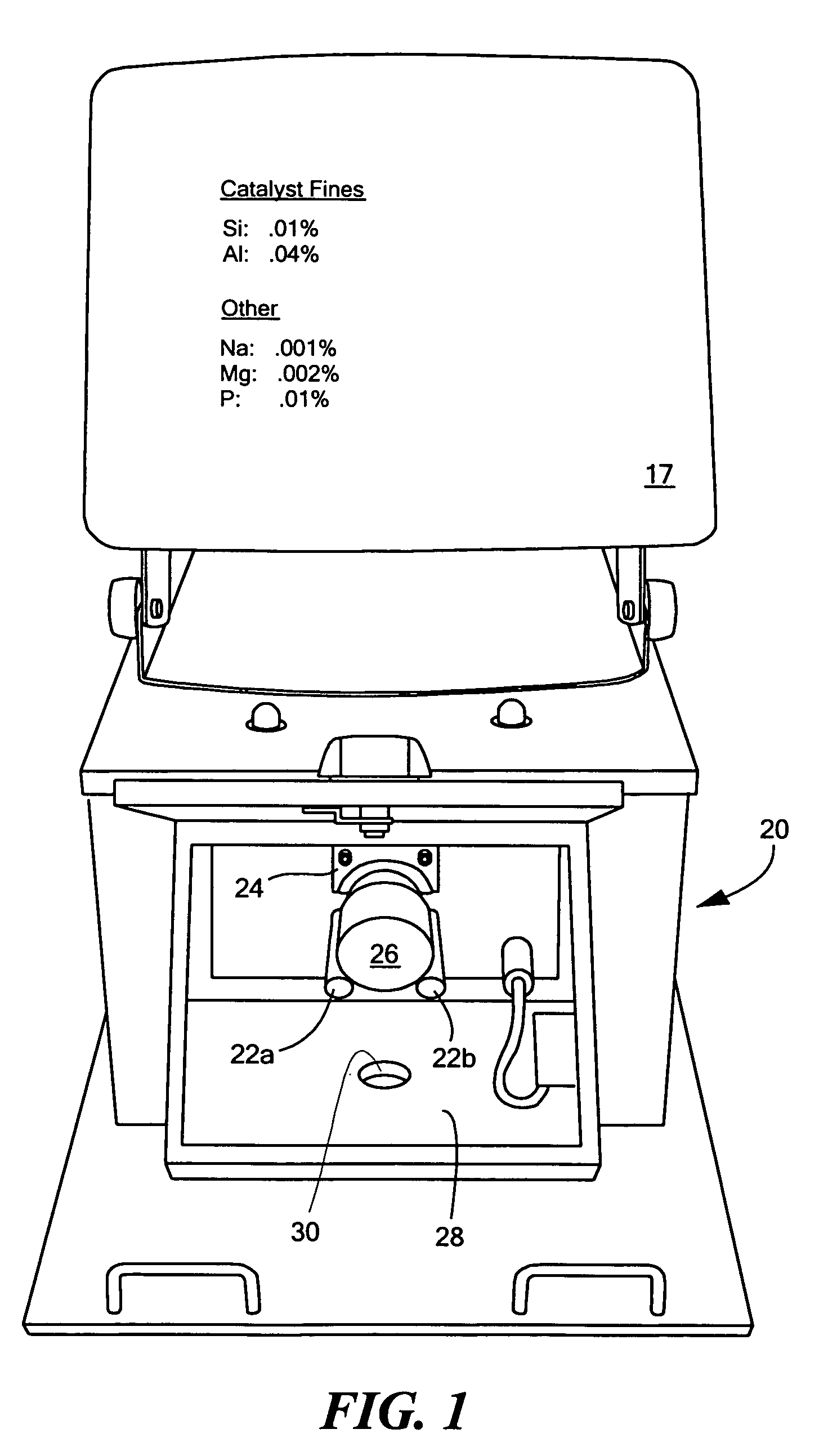

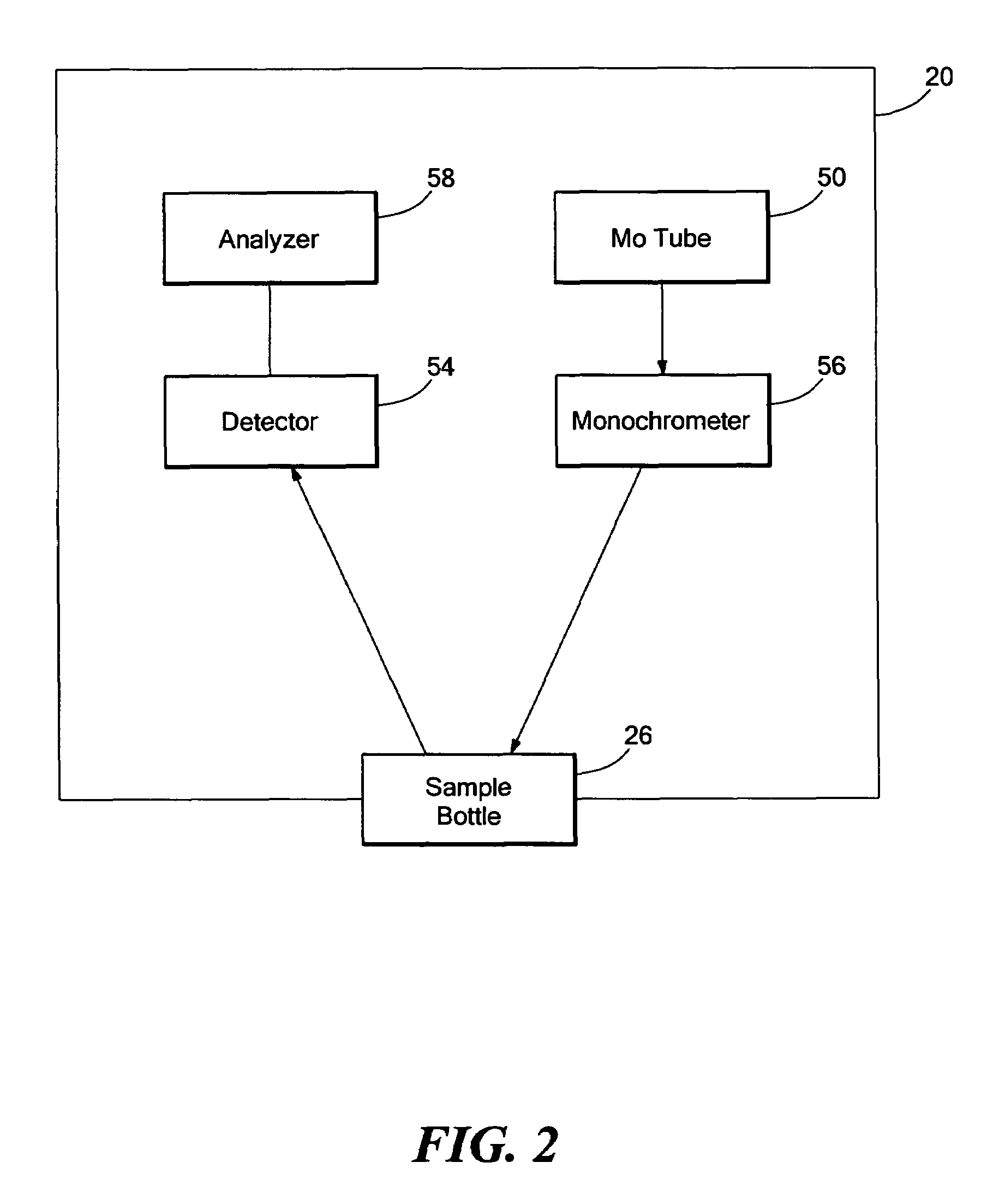

Fuel analysis system

ActiveUS7286633B1Reduce background signalRobust designMaterial analysis using wave/particle radiationX-ray spectral distribution measurementSulfurMonochromator

A fuel analysis system and method wherein an x-ray source emits x-rays at an energy level below but proximate the absorption edge of sulfur. A monochromator is in the optical path between the source and a fuel sample for directing x-rays at a single energy level at the fuel sample to limit excitation of any sulfur in the fuel sample. A detector is responsive to x-rays emitted by the sample and an analyzer is responsive to the detector and configured to determine the amount of silicon and aluminum in the sample.

Owner:OLYMPUS AMERICA

Ionizing radiation imaging system and method with decreased radiation dose

Owner:PEDIATRIC IMAGING TECH

Method of processing optical device wafer

InactiveUS20130017640A1Long wavelengthShort wavelengthSemiconductor/solid-state device detailsSolid-state devicesLight beamOptoelectronics

A method of processing an optical device wafer having an optical device layer including an n-type semiconductor layer and a p-type semiconductor layer stacked over a sapphire substrate, a buffer layer therebetween, allowing peeling of the sapphire substrate. The method includes joining a transfer substrate to the optical device layer, breaking the buffer layer by irradiation with a pulsed laser beam from the sapphire substrate side of the wafer with the transfer substrate joined to the optical device layer, and peeling the sapphire substrate from the optical device wafer with the buffer layer broken, transferring the optical device layer onto the transfer substrate. The pulsed laser beam has a wavelength longer than an absorption edge of the sapphire substrate and shorter than an absorption edge of the buffer layer, and a pulse width set so that a thermal diffusion length will be not more than 200 nm.

Owner:DISCO CORP

Method of treating semiconductor element

InactiveUS20110092016A1Little influenceSemiconductor/solid-state device manufacturingSemiconductor devicesLight irradiationLength wave

In a method of treating a semiconductor element which at least includes a semiconductor, a threshold voltage of the semiconductor element is changed by irradiating the semiconductor with light with a wavelength longer than an absorption edge wavelength of the semiconductor. The areal density of in-gap states in the semiconductor is 1013 cm−2eV−1 or less. The band gap may be 2 eV or greater. The semiconductor may include at least one selected from the group consisting of In, Ga, Zn and Sn. The semiconductor may be one selected from the group consisting of amorphous In—Ga—Zn—O (IGZO), amorphous In—Zn—O (IZO) and amorphous Zn—Sn—O (ZTO). The light irradiation may induce the threshold voltage shift in the semiconductor element, the shift being of the opposite sign to the threshold voltage shift caused by manufacturing process history, time-dependent change, electrical stress or thermal stress.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com