Surface-treated zinc oxide powder, anti-bacterial agent, and anti-bacterial composition

A technology of surface treatment and zinc oxide powder, which is applied in the field of antibacterial agents and antibacterial compositions, and surface treatment of zinc oxide powder, which can solve the problems of no antibacterial effect and achieve good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

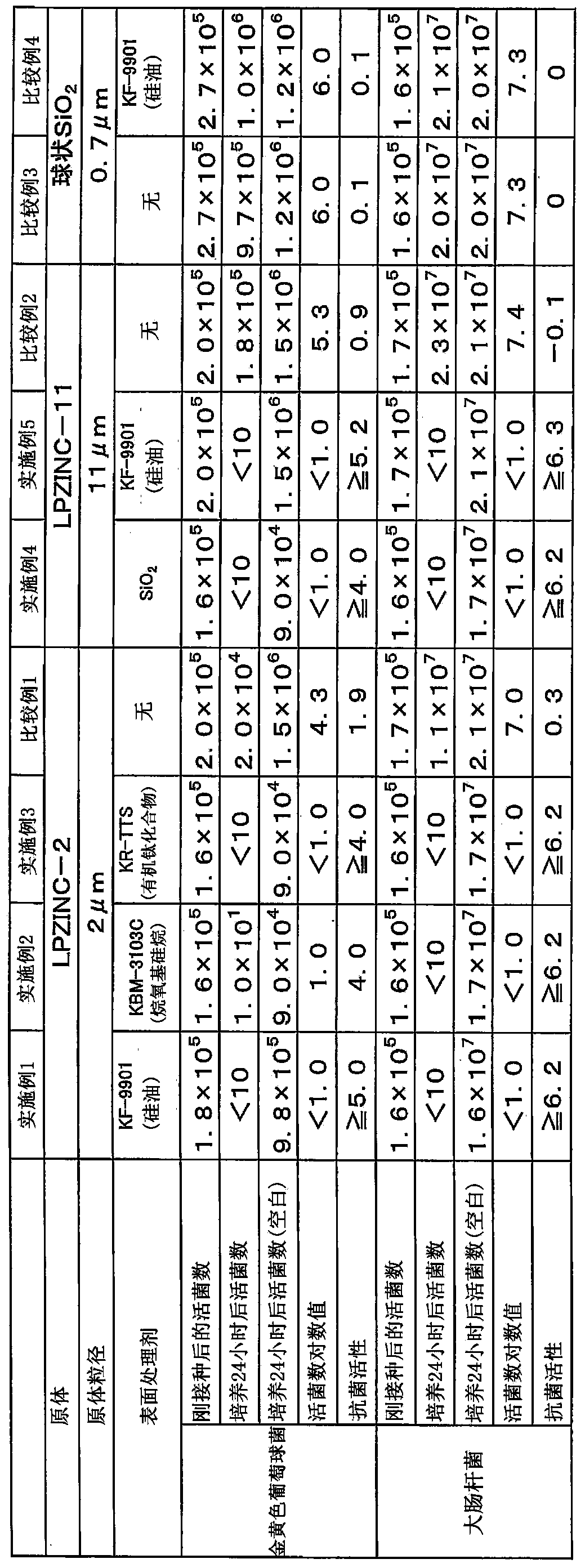

[0068] Take 100 g of large particle zinc oxide LPZINC-2 (manufactured by Sakai Chemical Industry Co., Ltd., with an average particle size of 2 μm) and 1 g of silicone oil (KF-9901 manufactured by Shin-Etsu Chemical Co., Ltd.) in a 300 ml mayonnaise bottle, and shake with a paint conditioner (Paint Conditioner). After 20 minutes of uniform coating, heat treatment was performed at 105° C. for 12 hours to obtain surface-treated zinc oxide particles. The obtained surface-treated zinc oxide particles were prepared as test pieces for antibacterial property tests according to the above procedure. The results of the antibacterial test are listed in Table 1.

Embodiment 2

[0070] In a 300 ml mayonnaise bottle, 100 g of large-particle zinc oxide LPZINC-2 (manufactured by Sakai Chemical Industry Co., Ltd., with an average particle size of 2 μm) and 1 g of decyltrimethoxysilane (KBM-3103C, manufactured by Shin-Etsu Chemical Co., Ltd.) were prepared with paint. After 20 minutes of machine vibration and uniform coating, heat treatment was performed at 105° C. for 12 hours, thereby obtaining surface-treated zinc oxide particles. The obtained surface-treated zinc oxide particles were prepared as test pieces for antibacterial property tests according to the above procedure. The results of the antibacterial test are listed in Table 1.

Embodiment 3

[0072] In a 300ml mayonnaise bottle, take 100 g of large-particle zinc oxide LPZINC-2 (manufactured by Sakai Chemical Industry Co., Ltd., with an average particle size of 2 μm) and 1 g of a titanium coupling agent (KR-TTS, manufactured by AJINOMOTO FINE TECHNO Co., Ltd.), and use a paint preparation machine After shaking for 20 minutes, the coating was uniform, and then heat treatment was performed at 105° C. for 12 hours to obtain surface-treated zinc oxide particles. The obtained surface-treated zinc oxide particles were prepared as test pieces for antibacterial property tests according to the above procedure. The results of the antibacterial test are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com