Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Good abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

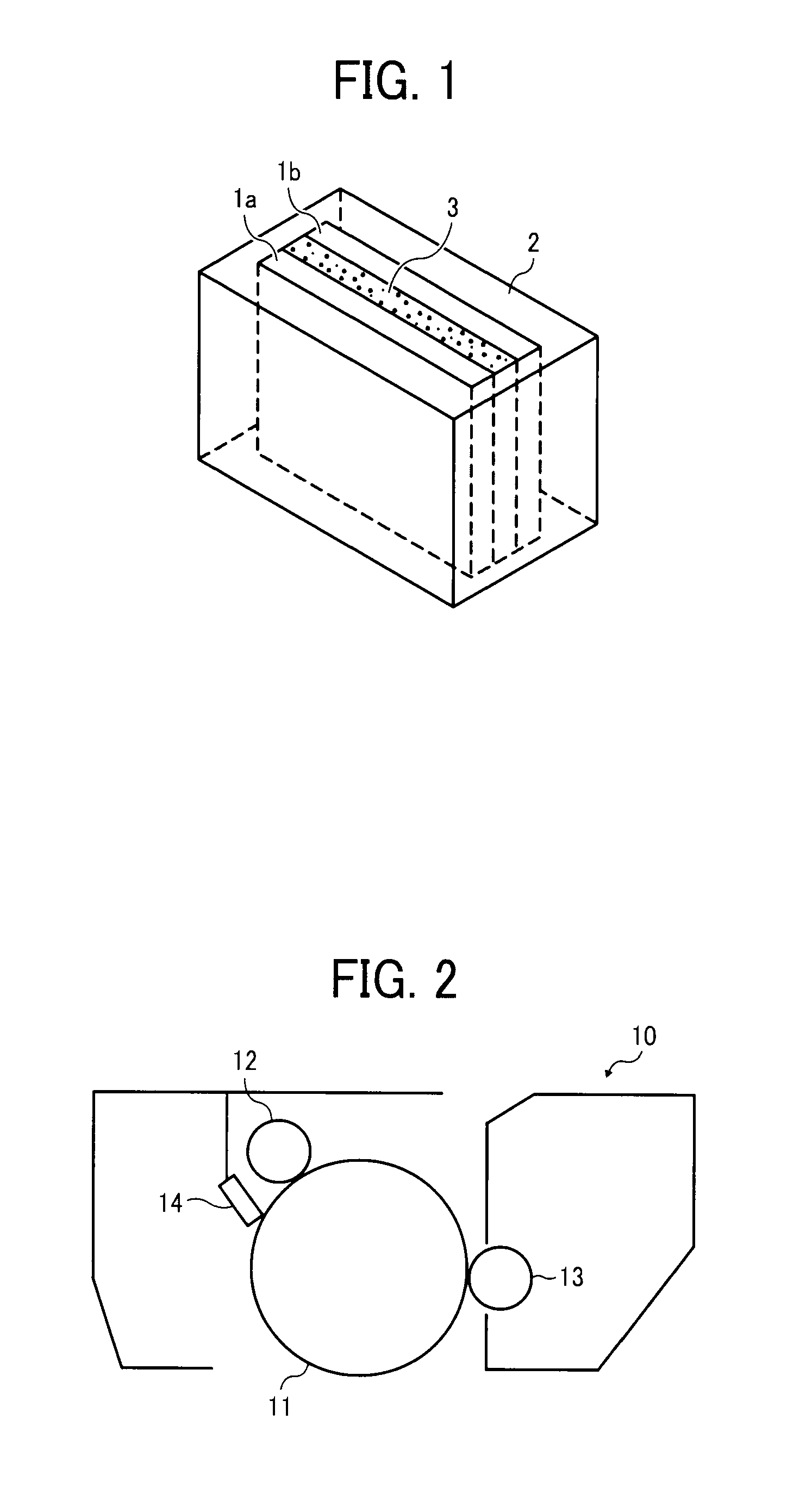

Multi-layer sheet comprising a protective polyurethane layer

InactiveUS6383644B2Good abrasion and scratch resistanceReadily convertFilm/foil adhesivesSynthetic resin layered productsAcid groupPolycarbonate

The present invention provides a multilayer sheet comprising a polymeric film having on a first major side a cross-linked polyurethane layer, the major part of said cross-linked polyurethane layer comprising a polycarbonate based polyurethane containing acid groups and cross-linked with a cross-linker, the polycarbonate-based polyurethane comprising the reaction product of a polycarbonate polyol or a polycarbonate polyamine and an aliphatic polyisocyanate and the uncross-linked polycarbonate-based polyurethane having a Koenig hardness of at least 150 seconds.

Owner:3M INNOVATIVE PROPERTIES CO

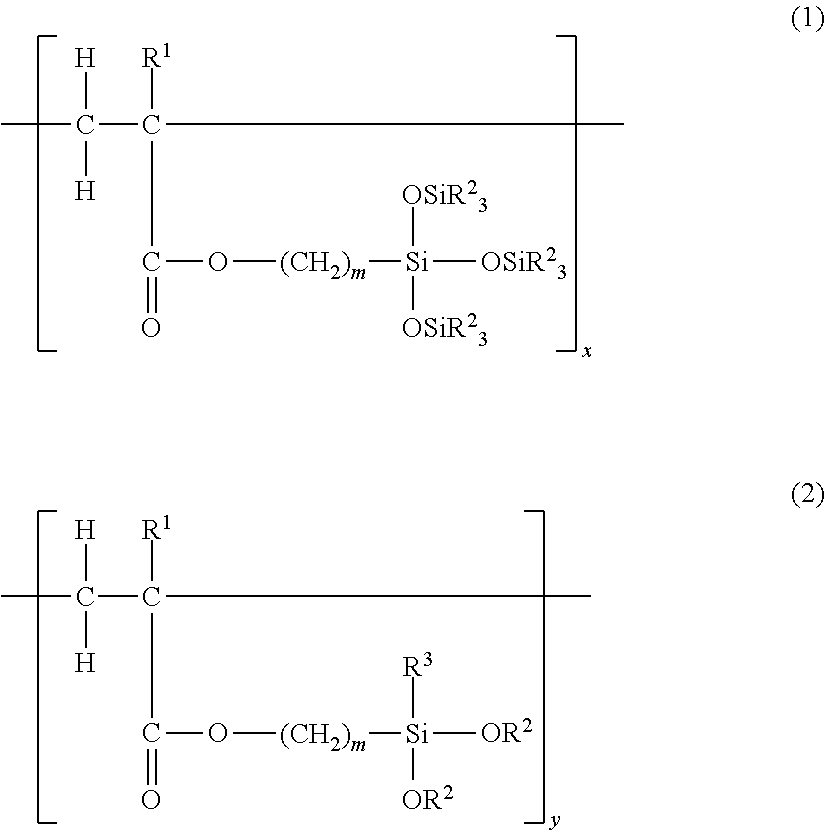

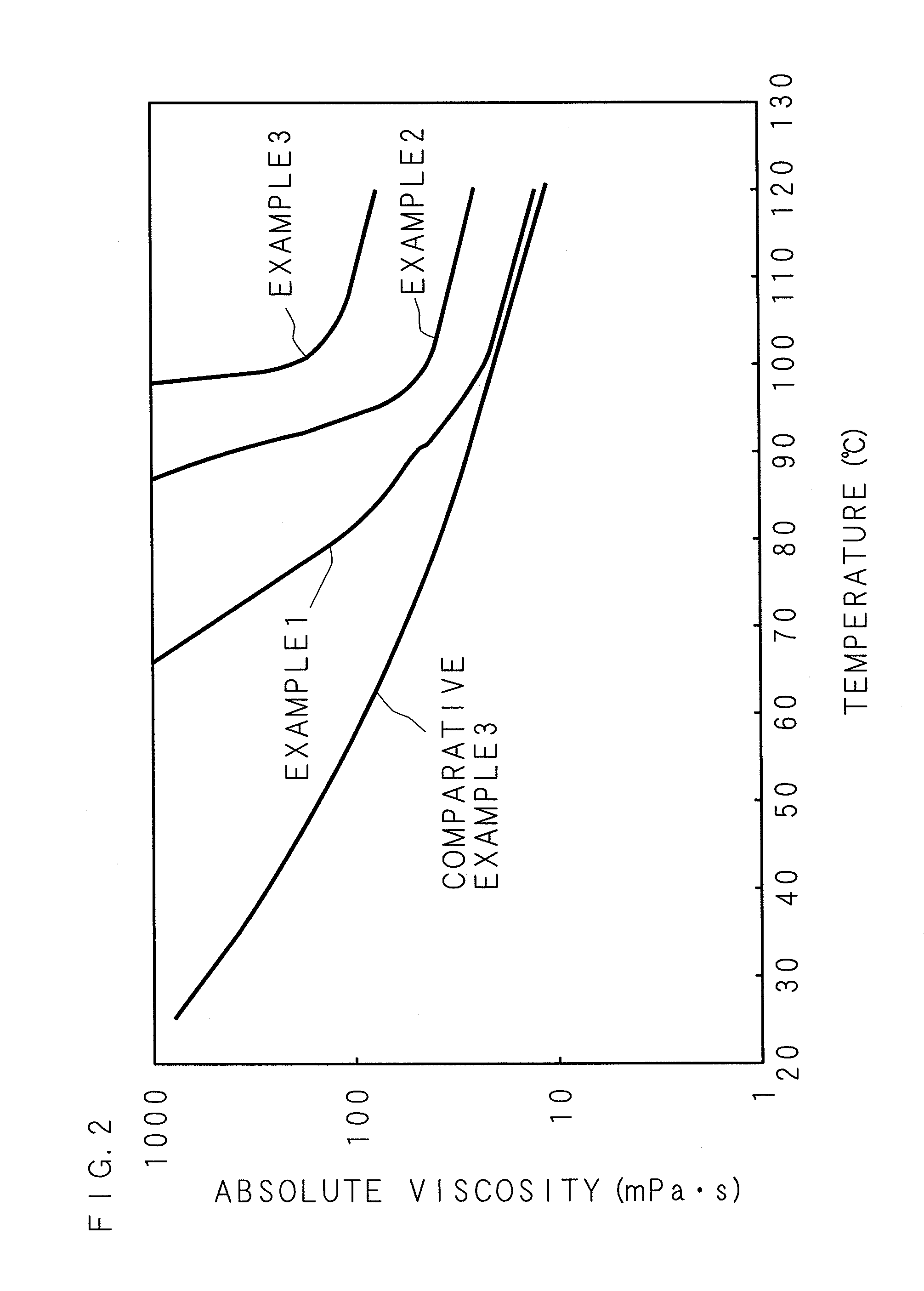

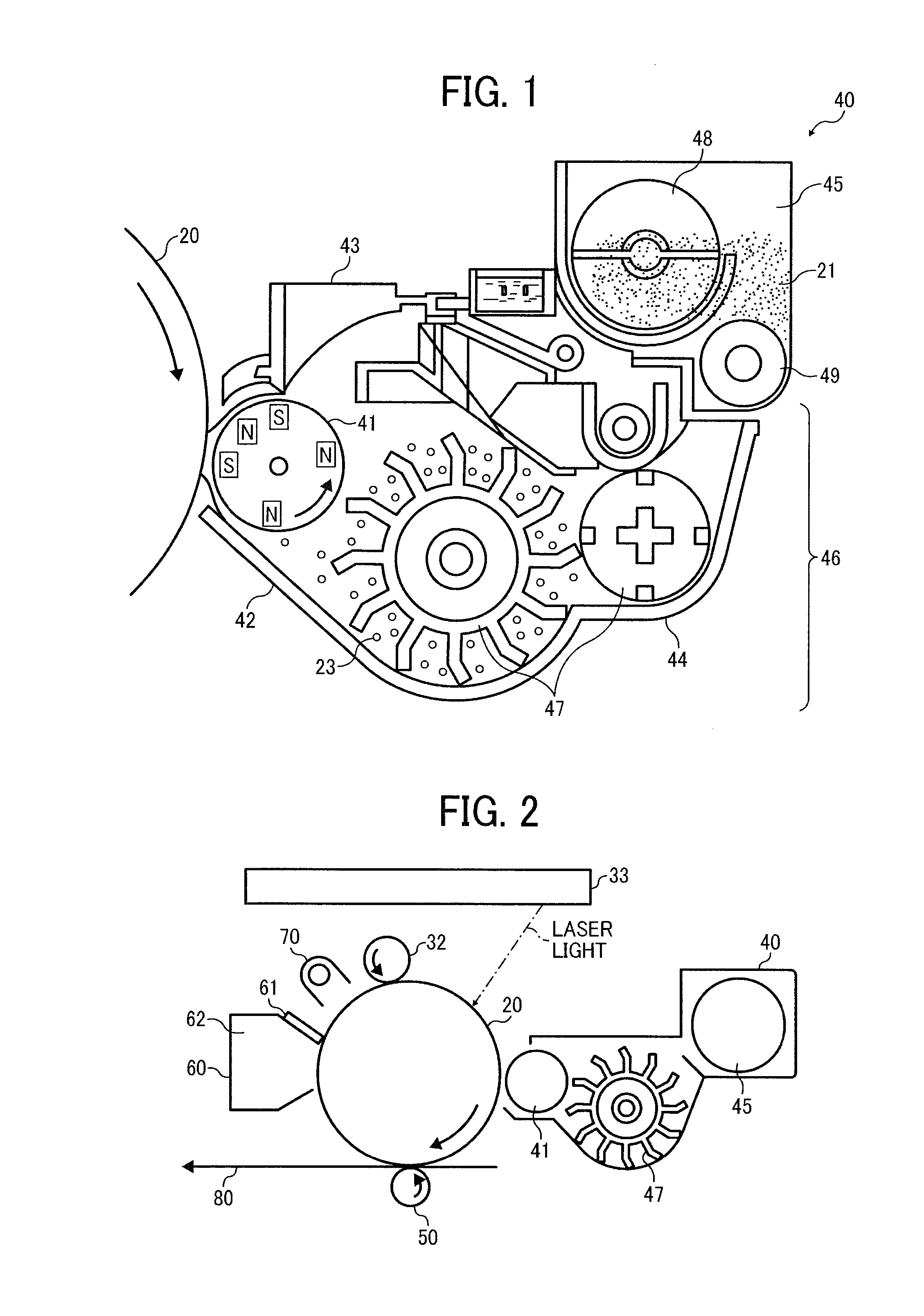

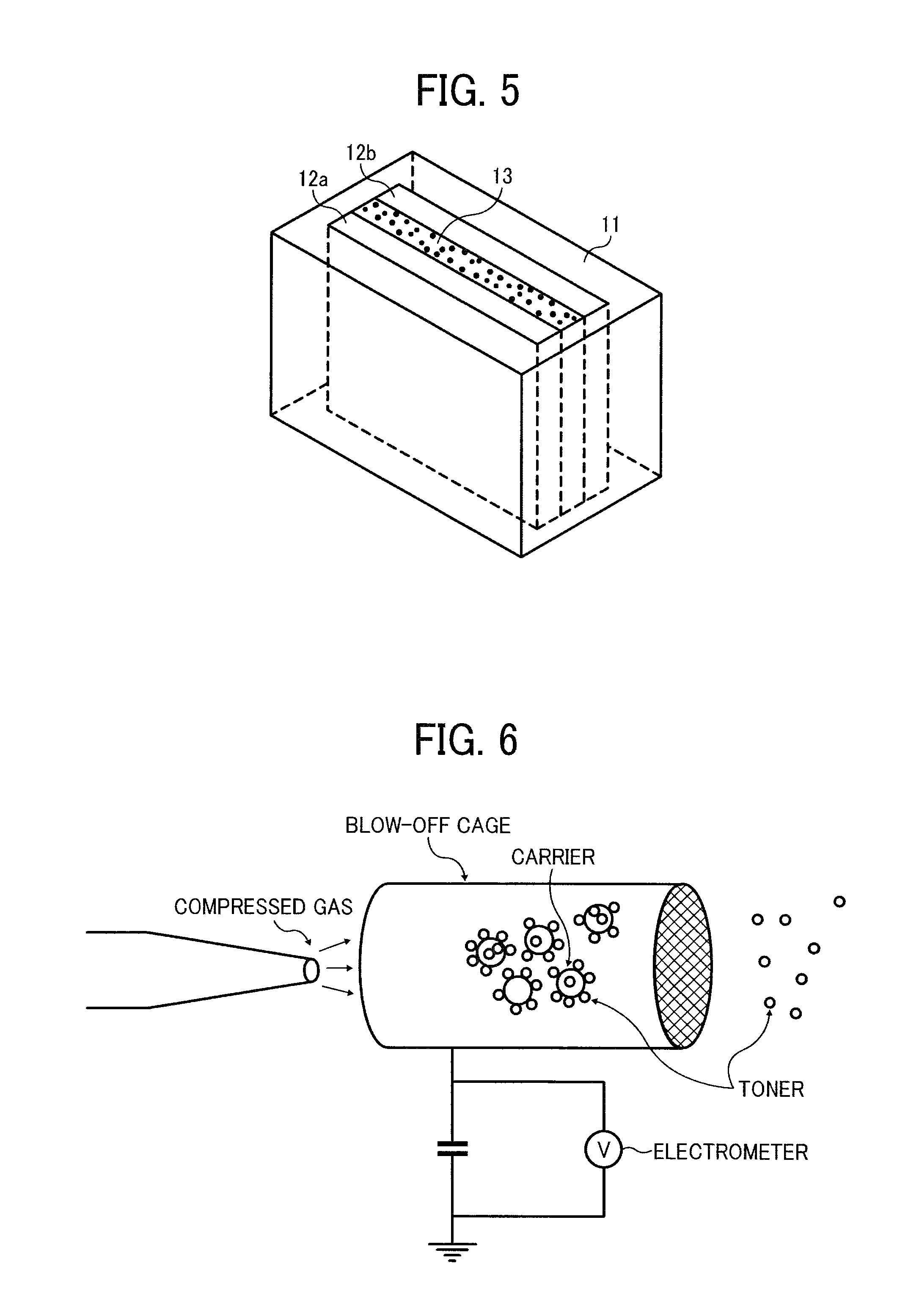

Carrier for two-component developer

ActiveUS20110086307A1Good abrasionIncrease resistanceElectrographic process apparatusDevelopersCross-linkParticulates

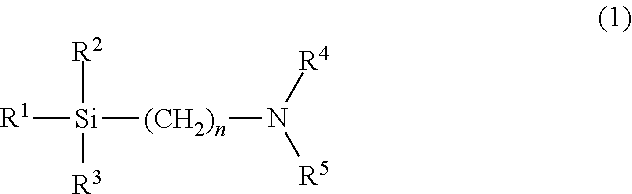

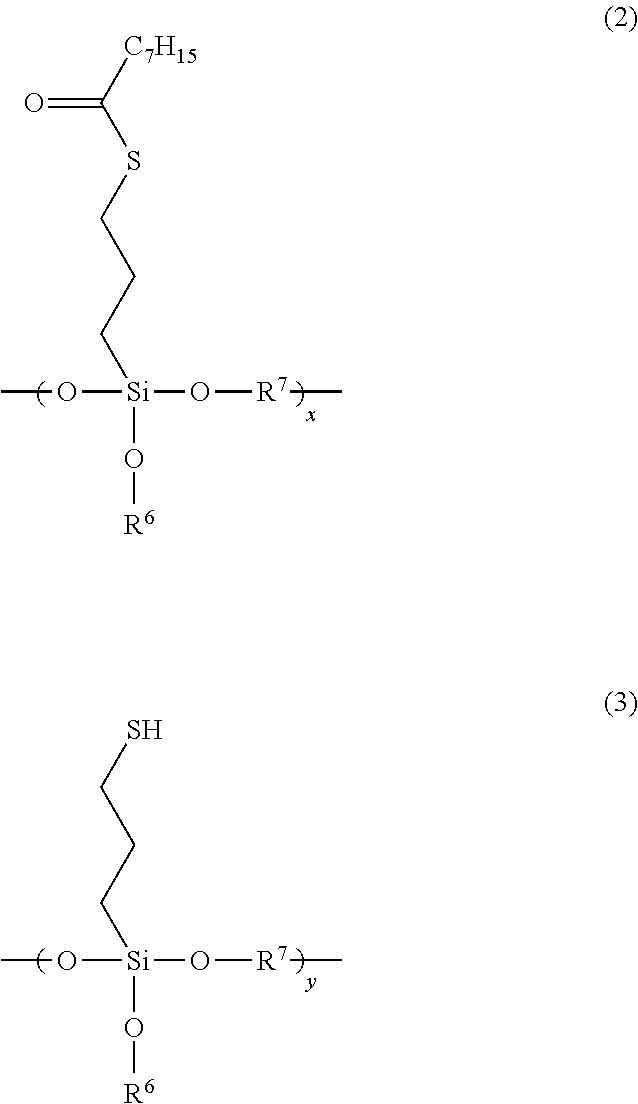

A carrier, including a magnetic particulate core material and a resin layer on the core material, wherein the resin layer includes a resin obtained by heat treatment of a copolymer including a site derived from a monomer component having the following formula (1) and a site derived from a monomer component having the following formula (2), and includes a cross-linked material obtained by hydrolysis of the copolymer to produce a silanol group and condensation using an organotitanium compound:wherein R1 represents a hydrogen atom or a methyl group; m represents an alkylene group having 1 to 8 carbon atoms; R2 represents an alkyl group having 1 to 4 carbon atoms; R3 represents an alkyl group having 1 to 8 carbon atoms, or an alkoxy group having 1 to 4 carbon atoms; X represents 10 to 90 mol %; and Y represents 10 to 90 mol %.

Owner:RICOH KK

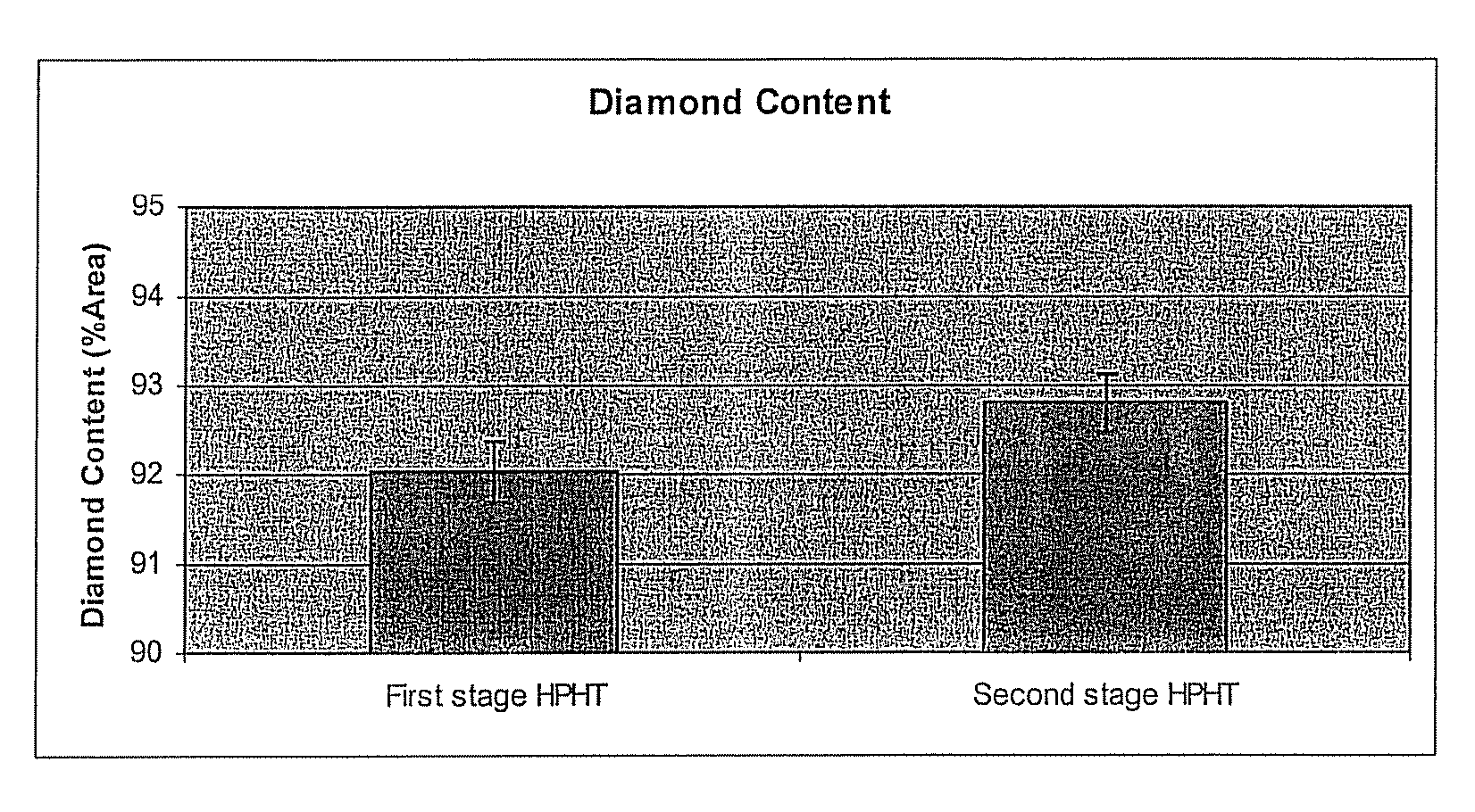

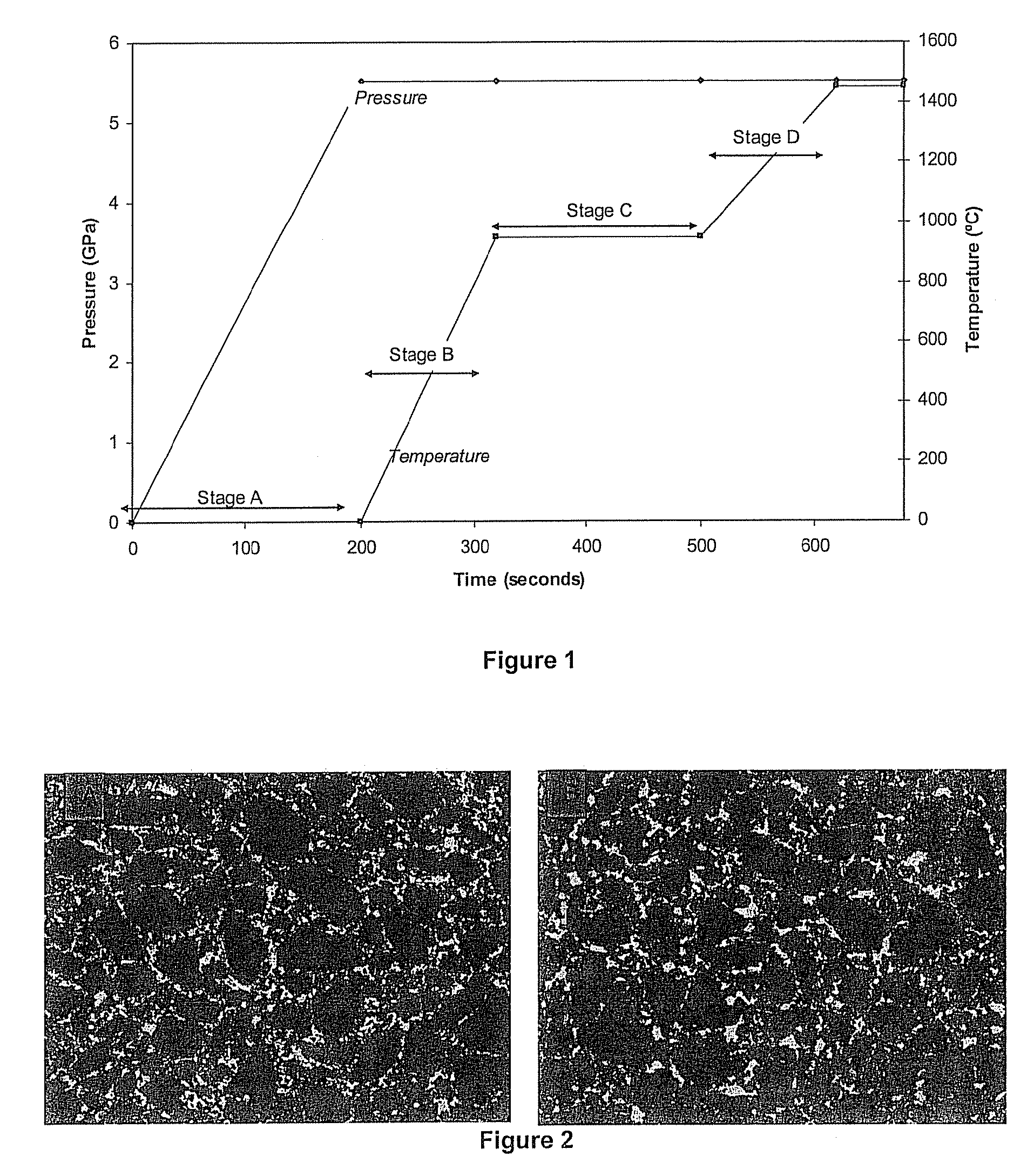

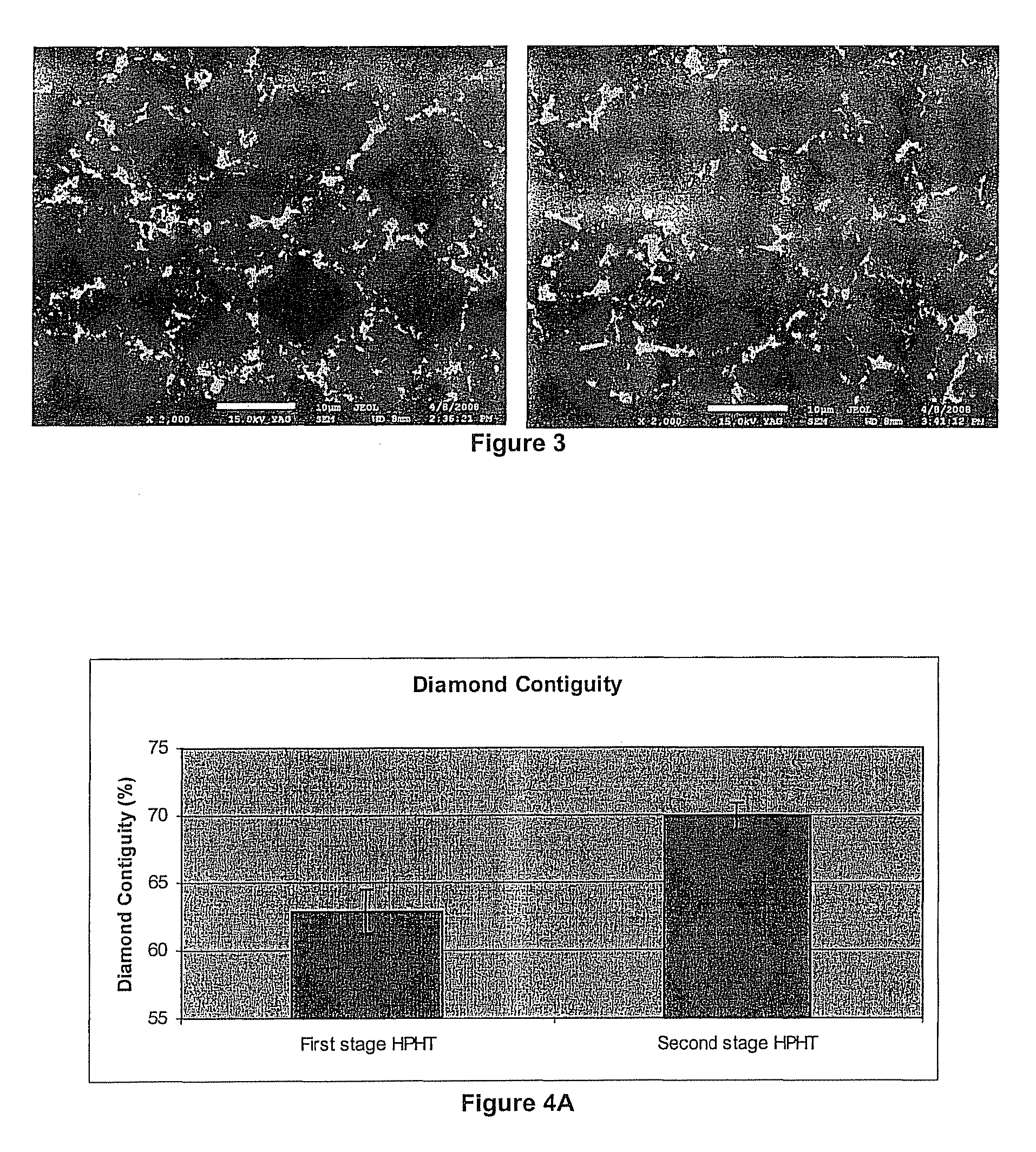

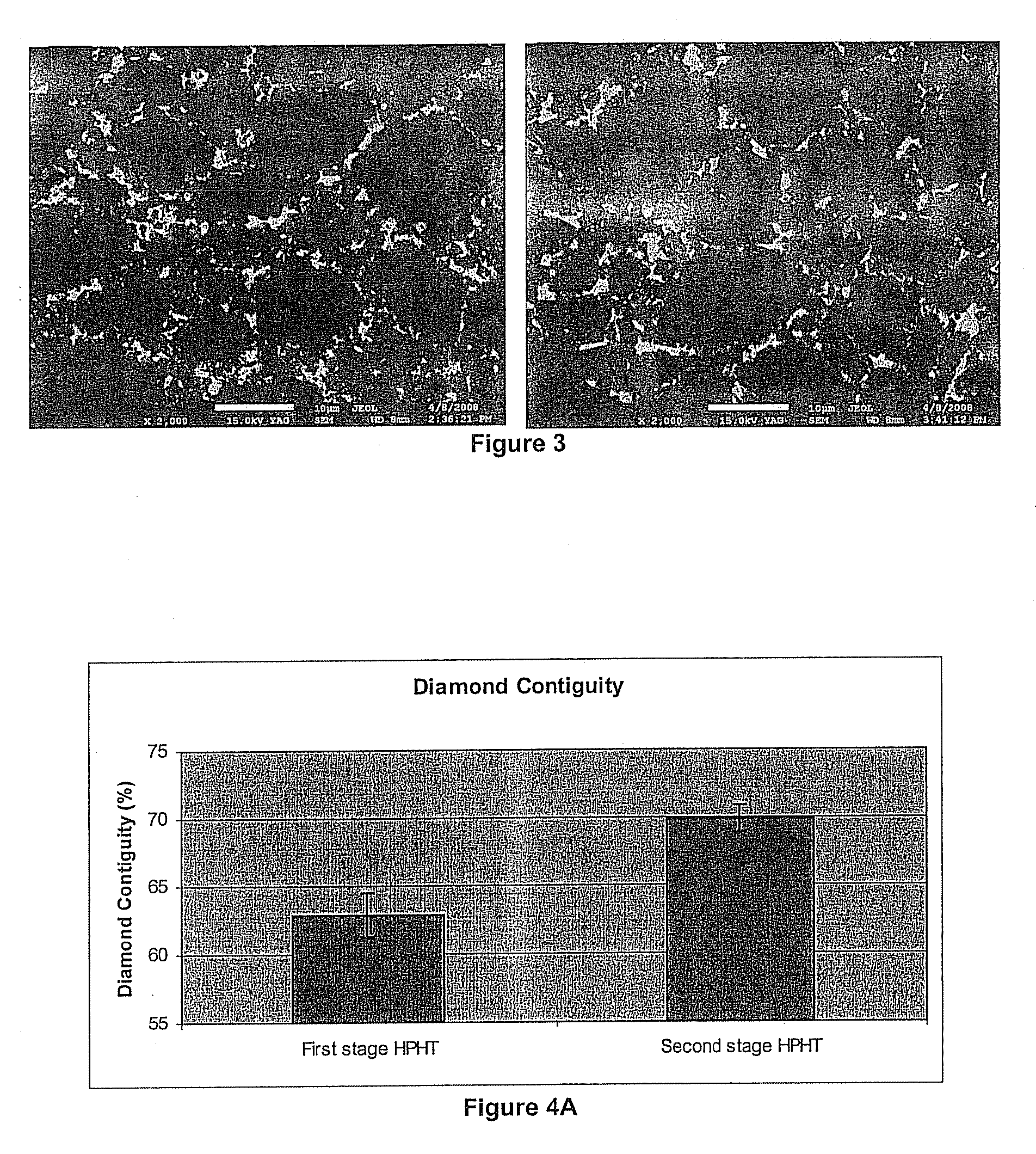

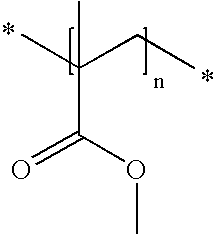

Method for producing a PCD compact

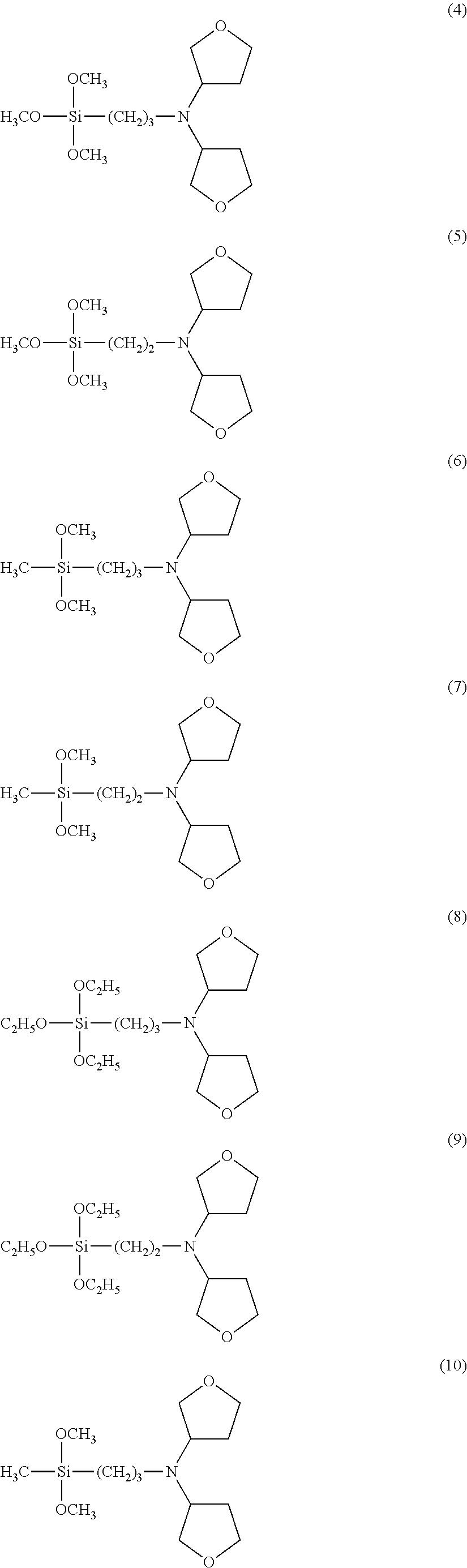

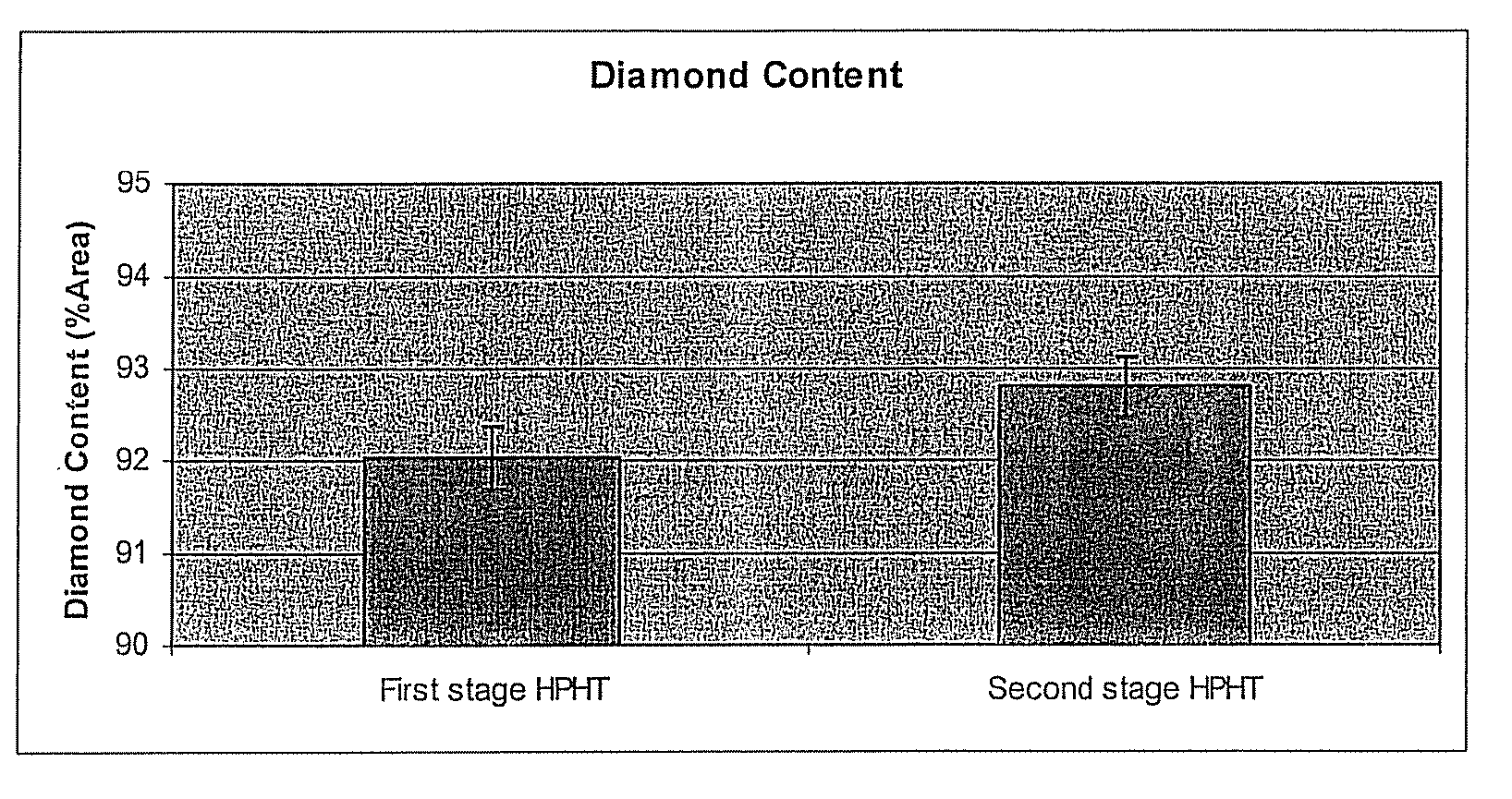

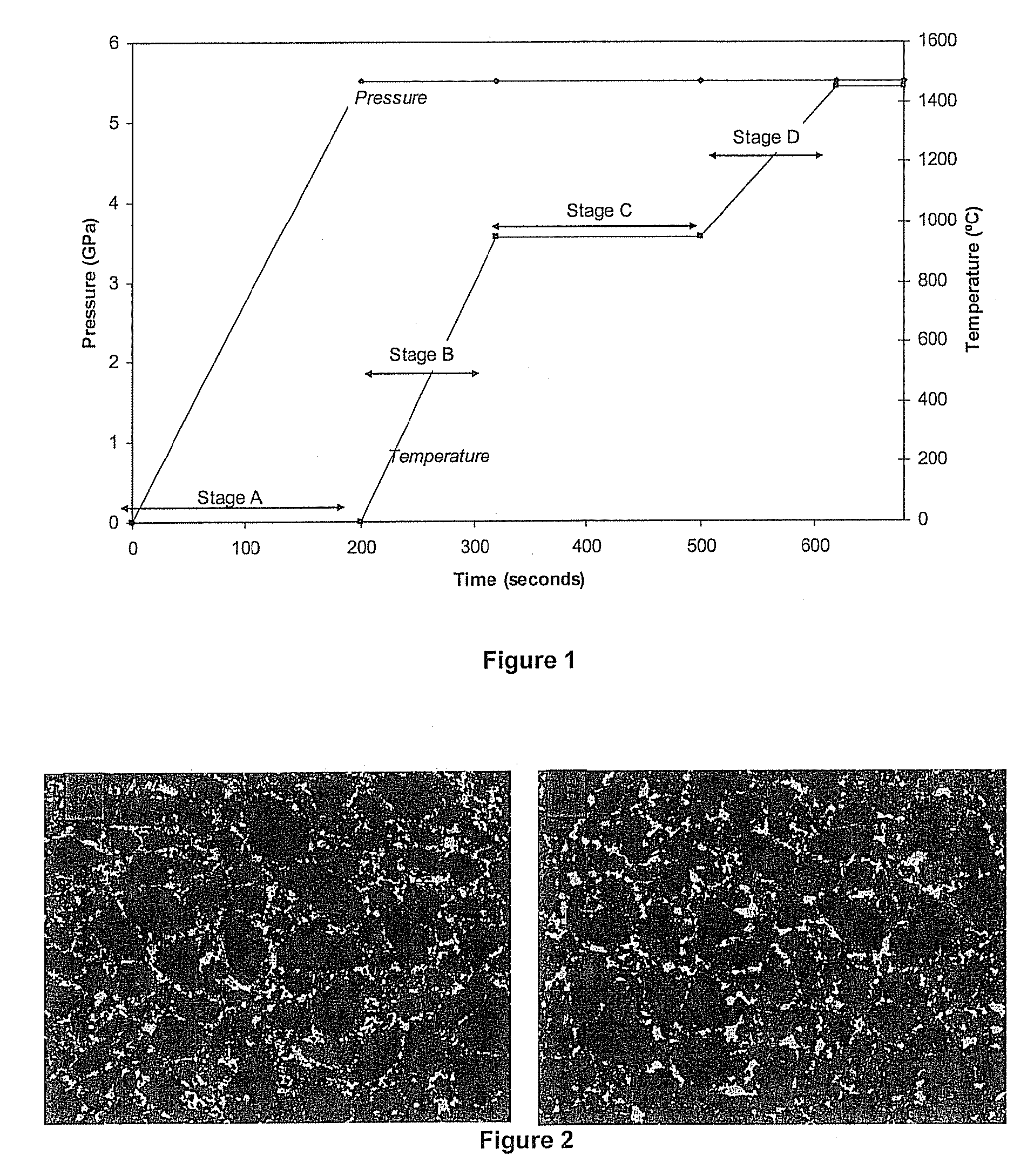

ActiveUS8485284B2High diamond contiguity and densityGood abrasionPigmenting treatmentPressurized chemical processPolycrystalline diamondAlloy

A method of producing a composite diamond compact comprising a polycrystalline diamond (PCD) compact bonded to a cemented carbide substrate is provided. The method includes the steps of: providing a PCD table, preferably a PCD table with diamond-to-diamond bonding and a porous microstructure in which the pores are empty of second phase material bringing together the PCD table and a cemented carbide substrate in the presence of a bonding agent to form an unbonded assembly; subjecting the unbonded assembly to an initial compaction at a pressure of at least 4.5 GPa and a temperature below the melting point of the bonding agent for a period of at least 150 seconds; and thereafter subjecting the unbonded assembly to a temperature above the melting point of the bonding agent and a pressure of at least 4.5 GPa for a time sufficient for the bonding agent to become molten and bond the PCD table to the substrate to form a composite diamond compact.

Owner:ELEMENT SIX ABRASIVES

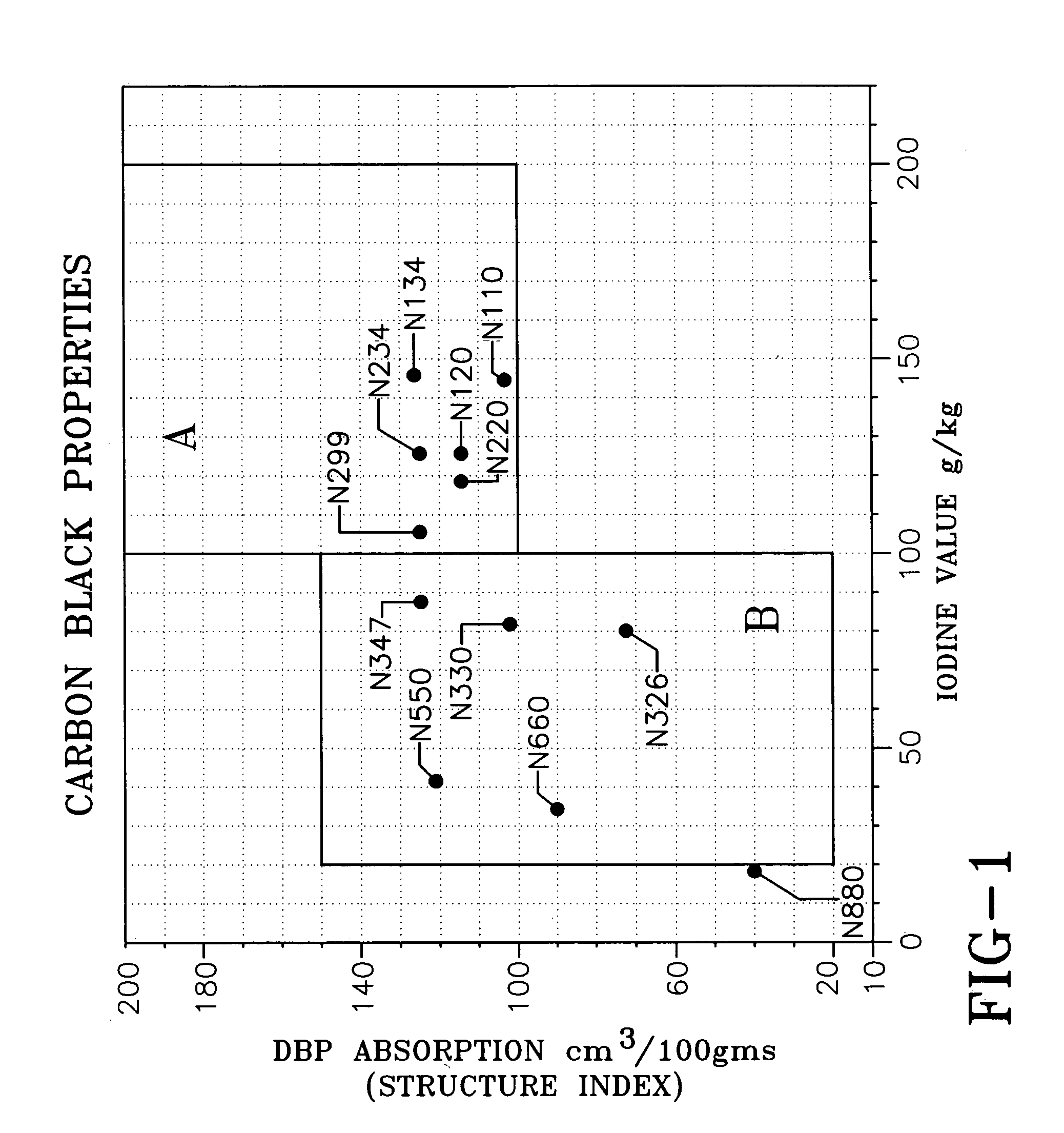

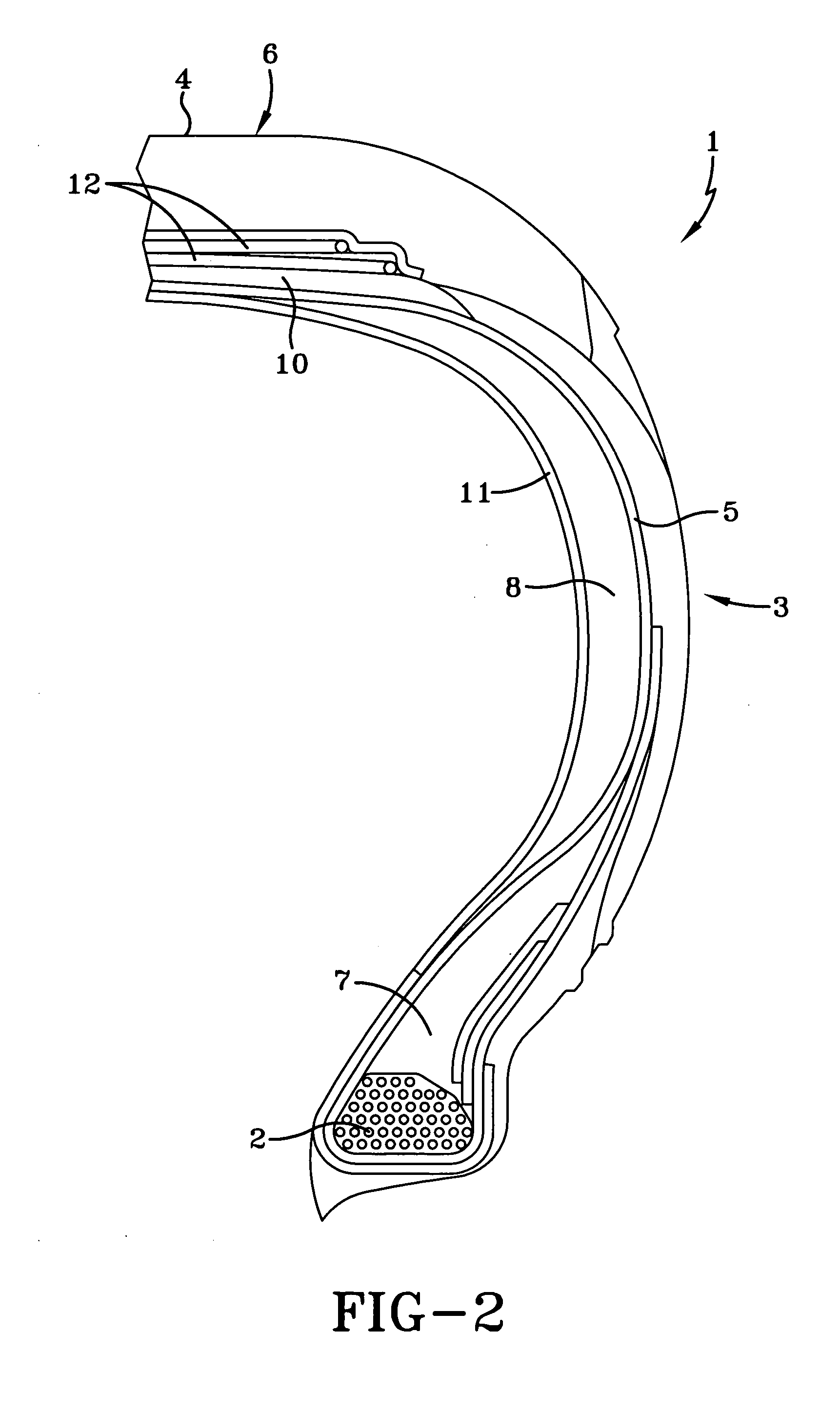

Tire with natural rubber rich tread and at least two additional rubber components with high reinforcing carbon blacks

The invention relates to pneumatic tires with a focus on pneumatic tires primarily intended for use in off-the-road service at relatively slow vehicular speeds, and to large truck tires, aircraft tires and agricultural tires and therefor not primarily focused on, and in one aspect intended to be exclusive of, passenger tires and particularly smaller passenger tires, wherein the elastomer composition of the treads, and at least two additional components, of such tires are of natural rubber rich rubber compositions composed, based upon the elastomers of the rubber compositions, of at least 45, alternately at least 75 weight percent cis 1,4-polyisoprene natural rubber. For this invention, the natural rubber rich treads and at least two additional natural rubber rich rubber components of such tires contain rubber reinforcing carbon blacks comprised primarily of high reinforcing, small particle size, carbon blacks. Silica reinforcement can also be used in combination with the high reinforcing carbon black for the natural rubber rich tire components.

Owner:SANDSTROM PAUL HARRY +2

Multilayer sheet comprising a protective polyurethane layer

InactiveUS20060127666A1Excellent abrasion resistanceImprove scratch resistanceFilm/foil adhesivesCeramic layered productsIonomerCross-link

The invention relates to a multi-layer sheet for use as a decorative protective film on a door or window post of a vehicle. The multi-layer sheet comprises (i) a polymeric film having a thickness of not more than 150μ and that is formed from an ionomer of an olefin-vinyl carboxylic acid copolymer, (ii) on a first side of the polymeric film a cross-linked polyurethane layer comprising the crosslinking reaction product of a polyurethane containing acid groups and a crosslinker and (iii) on a second side of the polymeric film opposite to the first side, an adhesive layer.

Owner:3M INNOVATIVE PROPERTIES CO

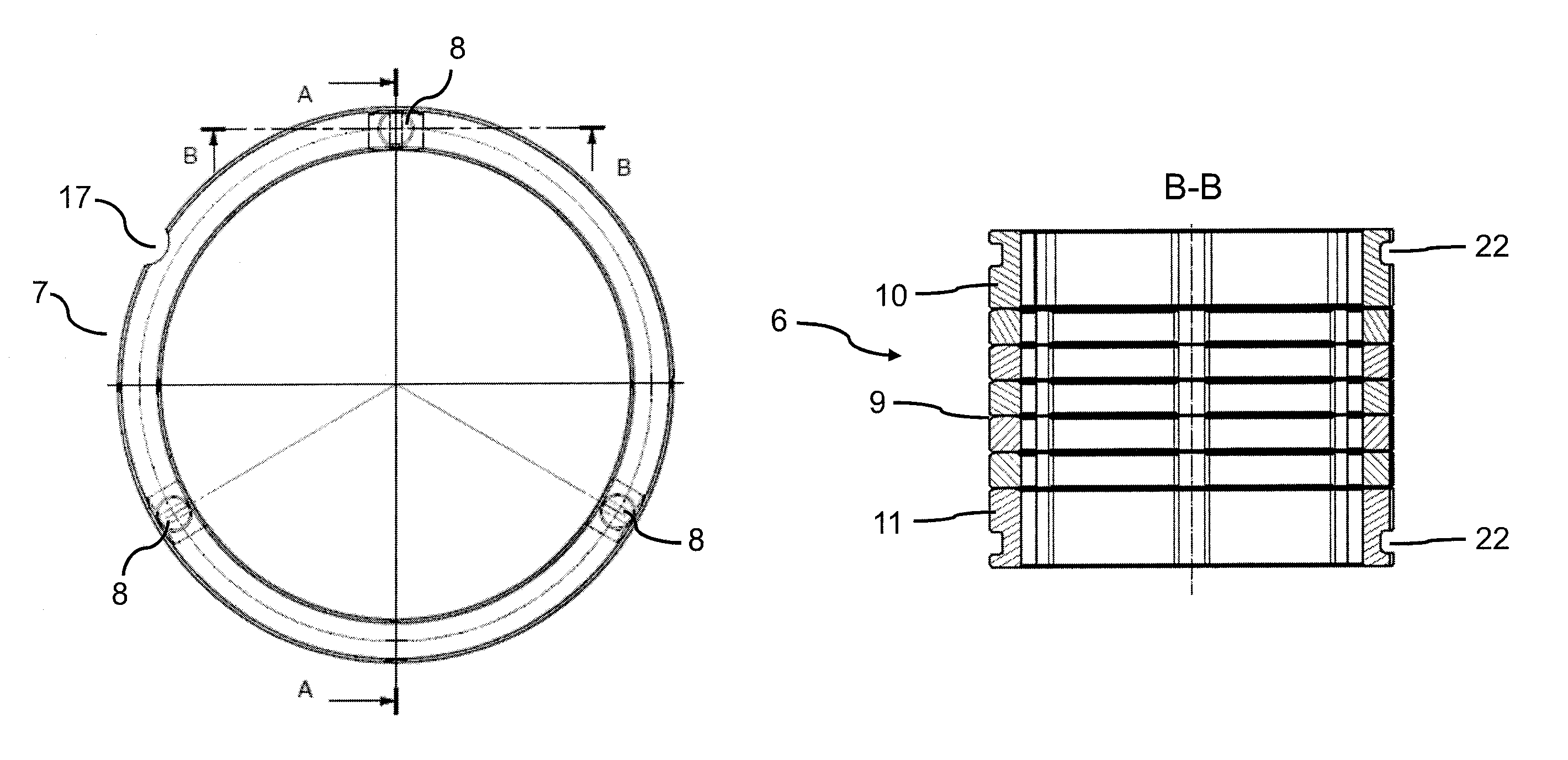

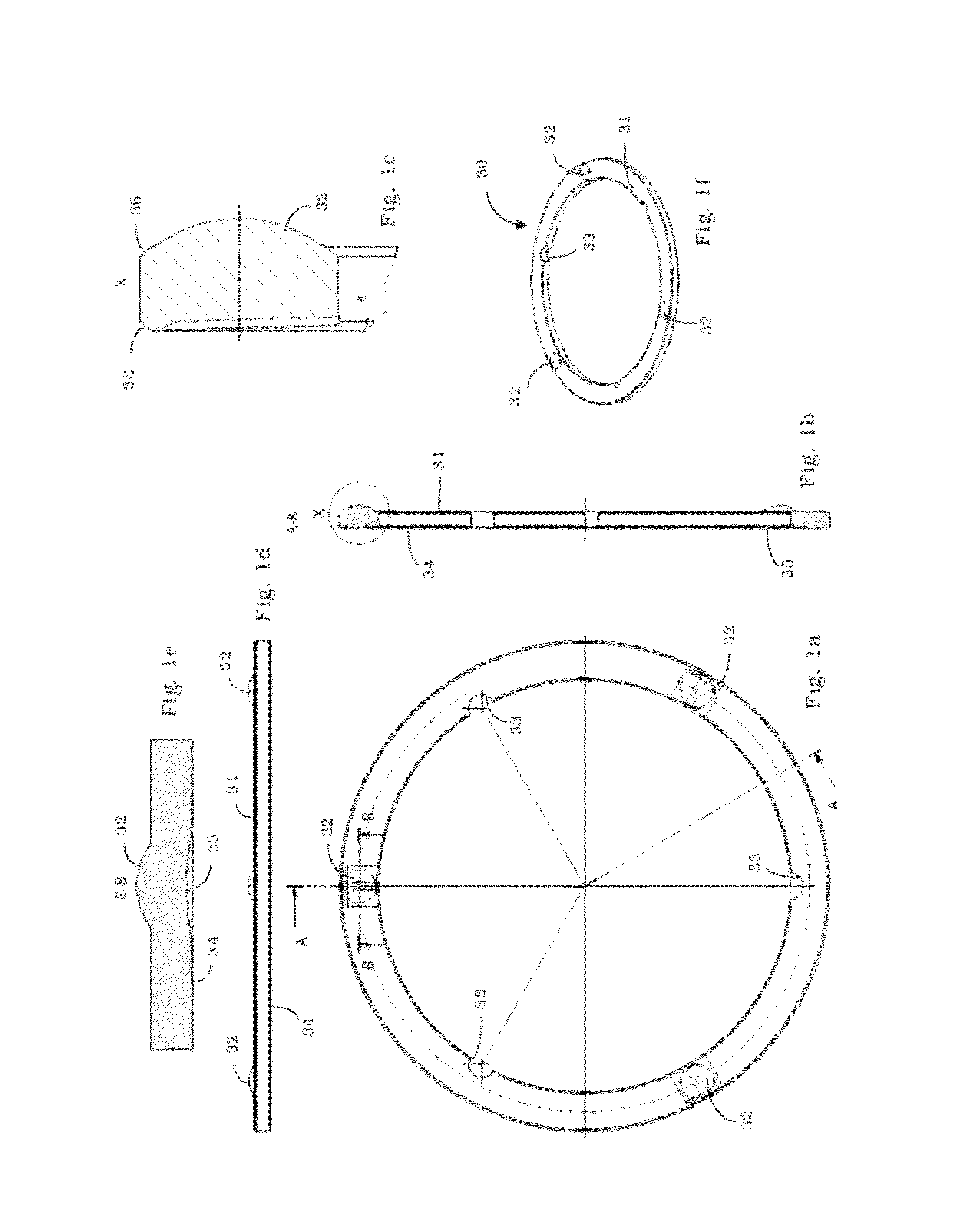

Wear-resistant separating device for removing sand and rock particles

ActiveUS8662167B2Tendency to fractureEasy to useFluid removalDrinking water installationCircular discWear resistant

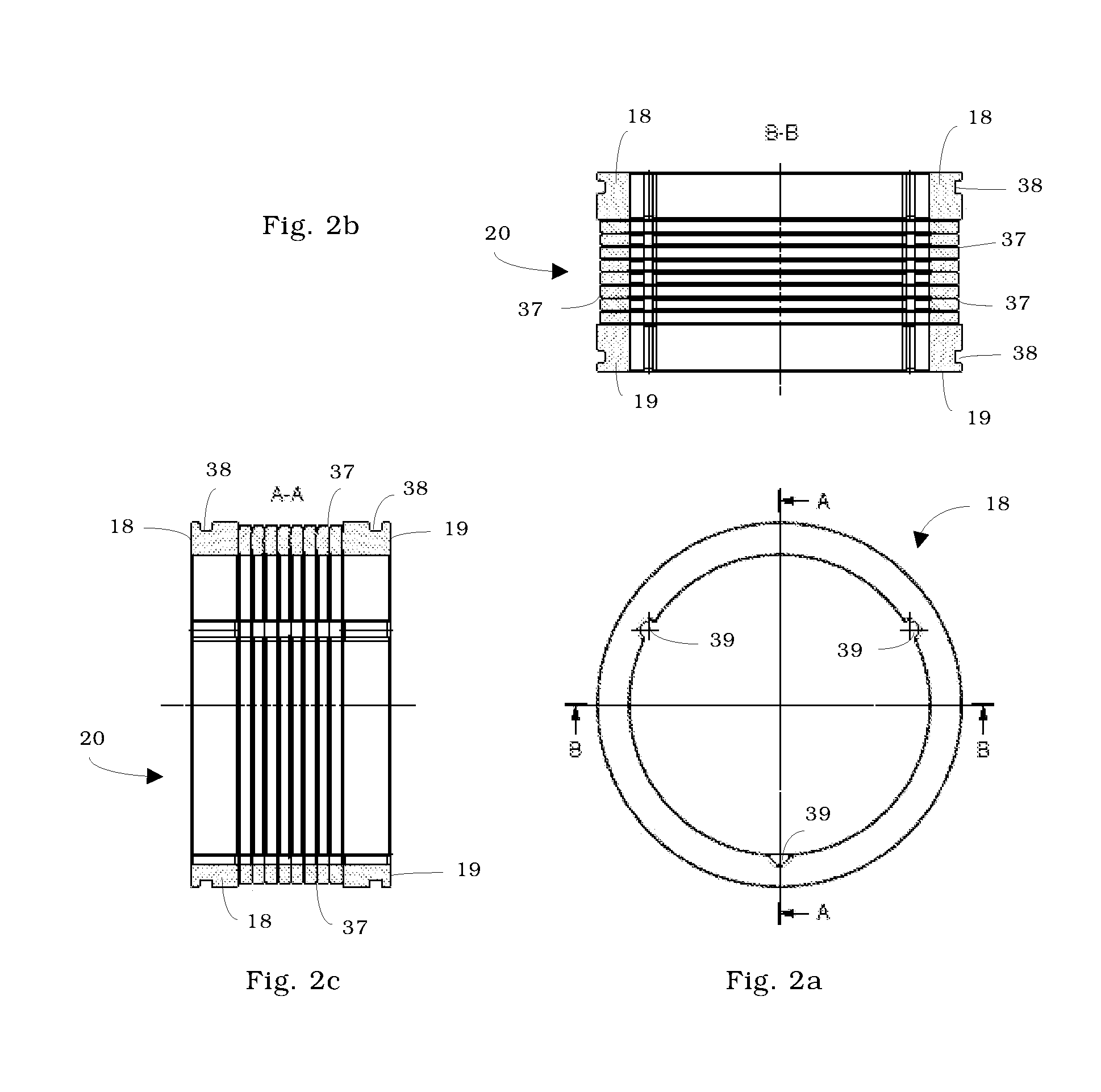

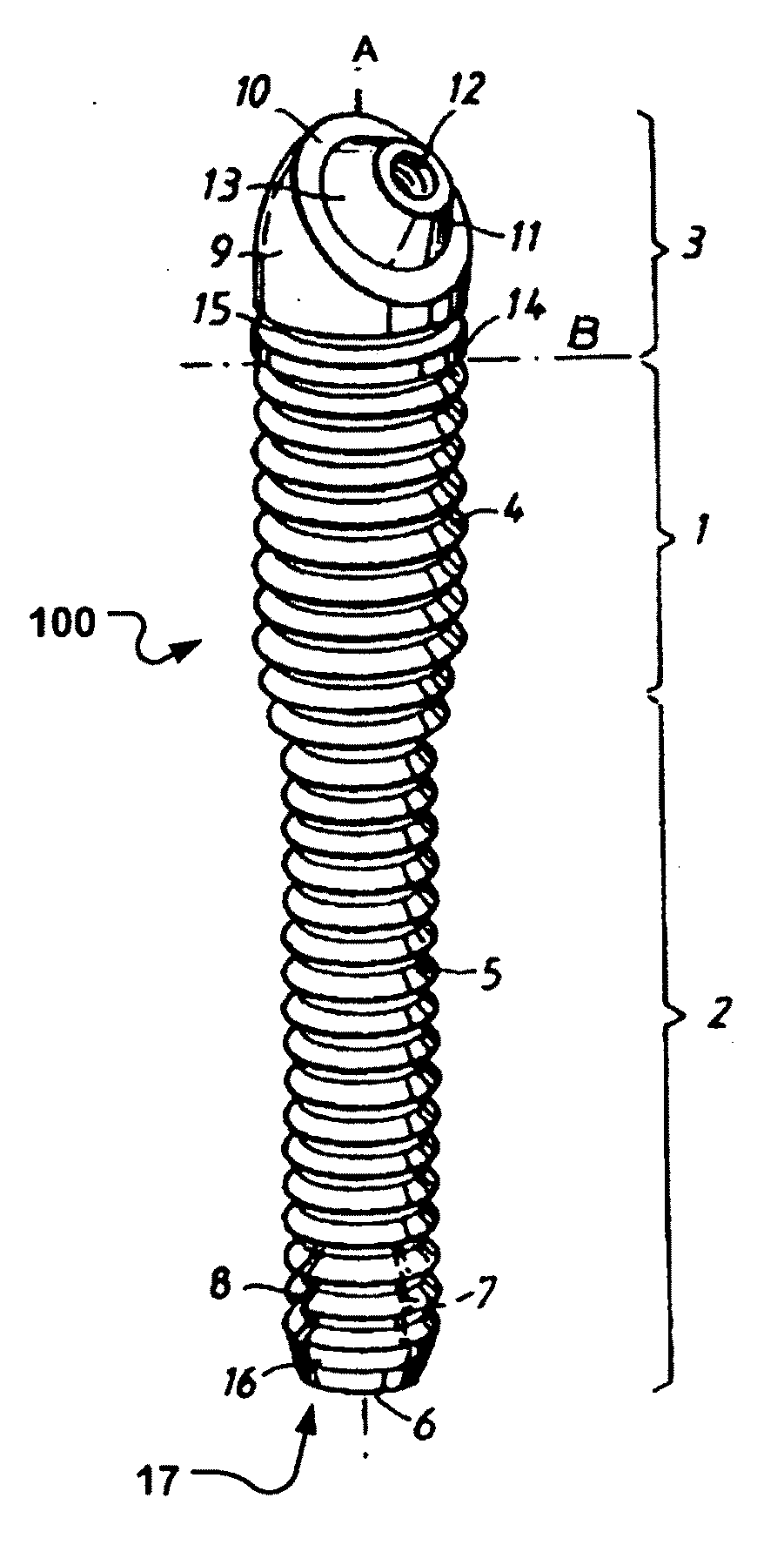

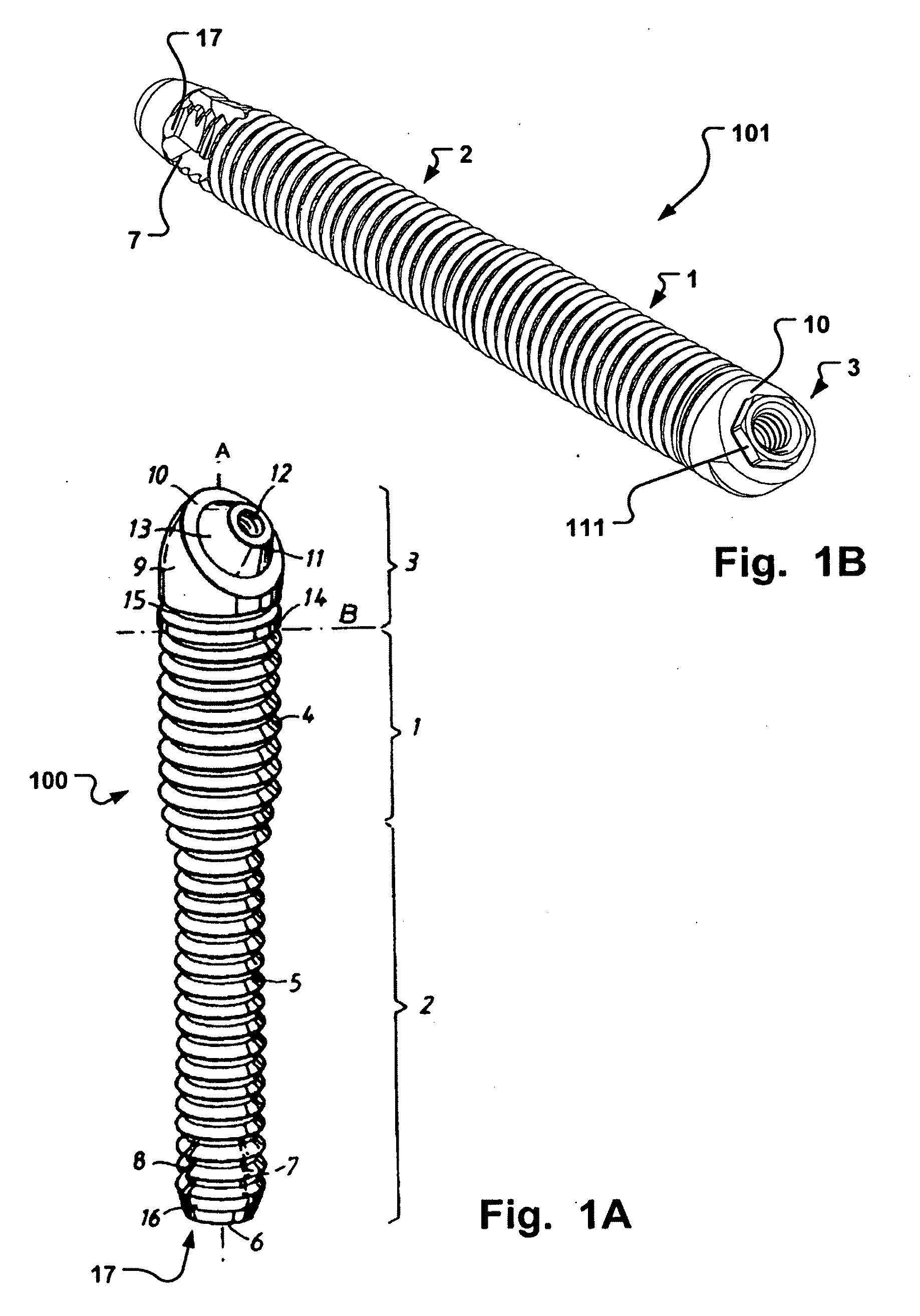

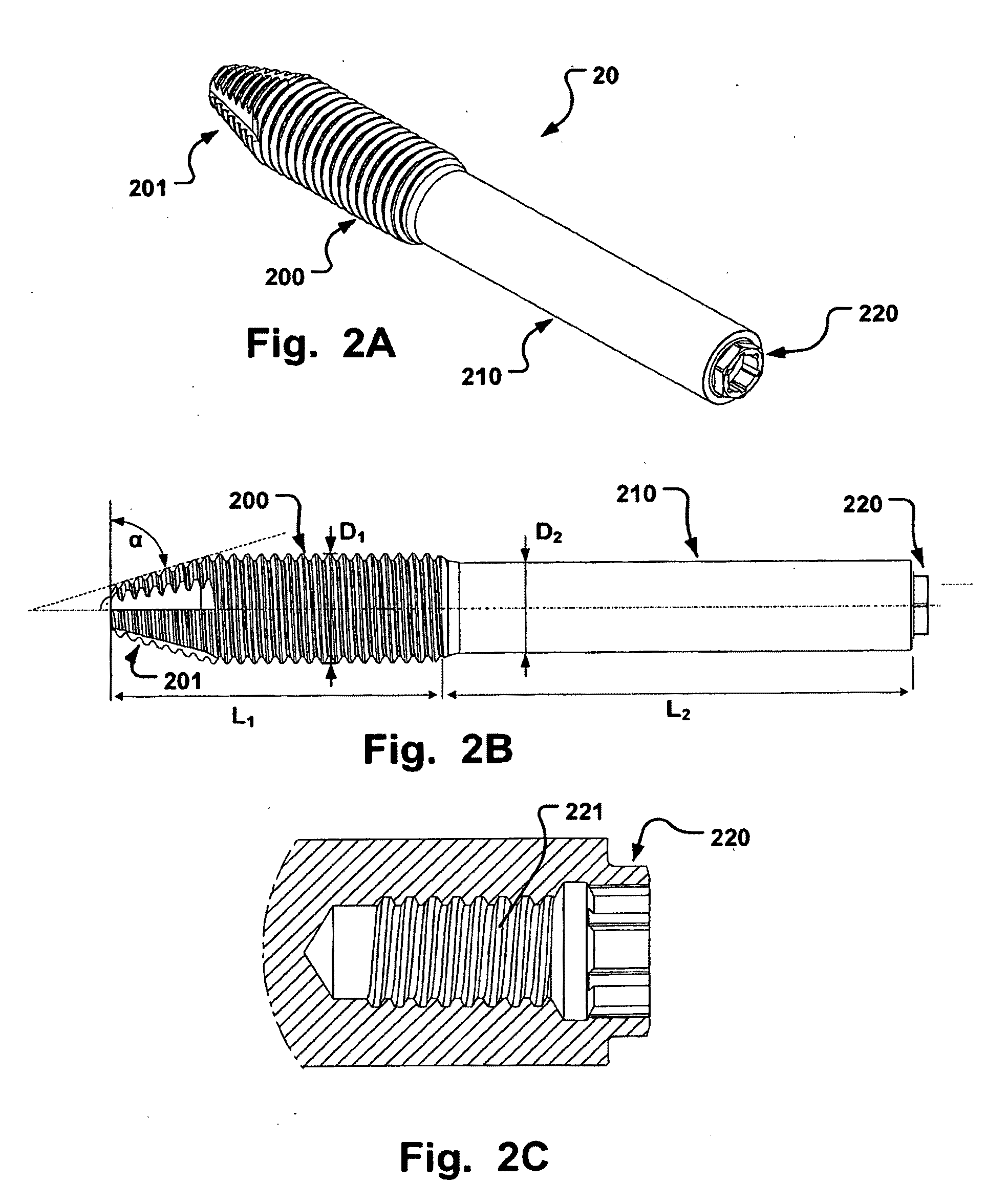

A separating device for removing sand and rock particles, and is an integral component of extraction equipment for extraction of liquids or gases from deep wells, having at least one ceramic filter module comprising: an annular stack of annular discs, the upper side of which has at least three elevations uniformly distributed over the circumference of the discs, the discs are stacked such that a separating gap for the removal of sand and rock particles is present between the individual discs, a coupling-on element at the upper end and a coupling-on element at the lower end of the annular stack, a clamping device bracing the annular stack, an outer cage, a coupling element at the upper end and a coupling element at the lower end of the filter module connecting the filter module to further components of the extraction equipment.

Owner:3M INNOVATIVE PROPERTIES CO +1

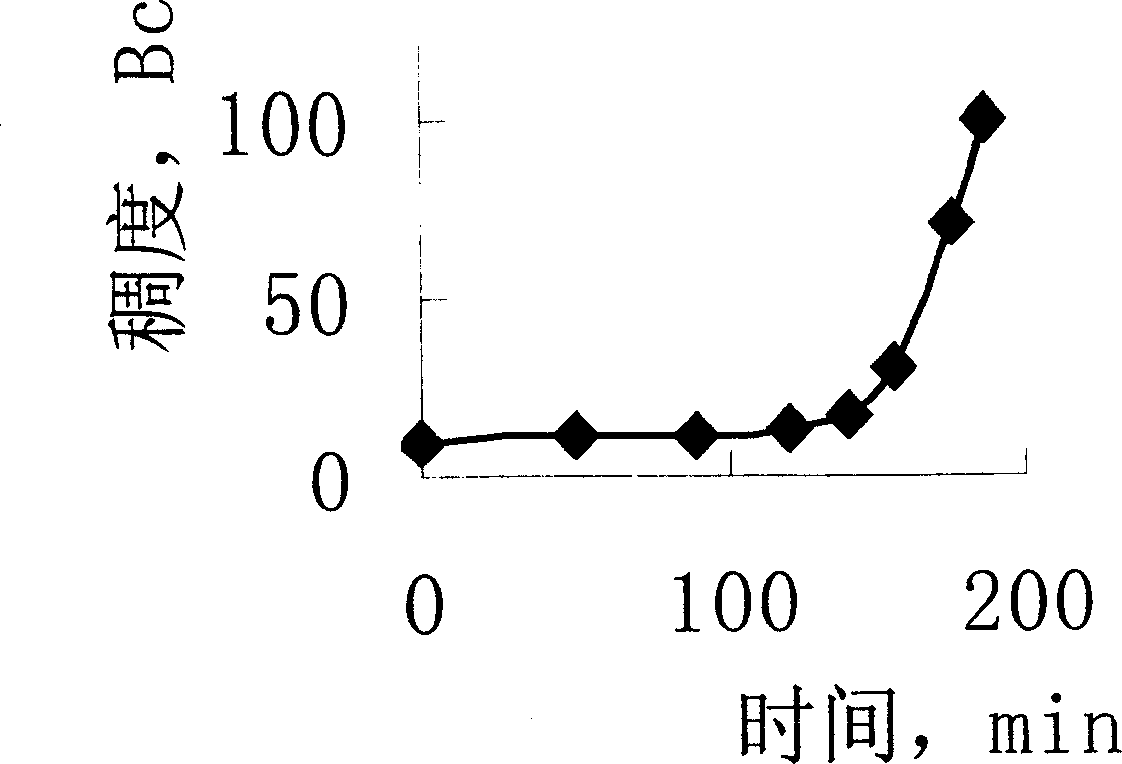

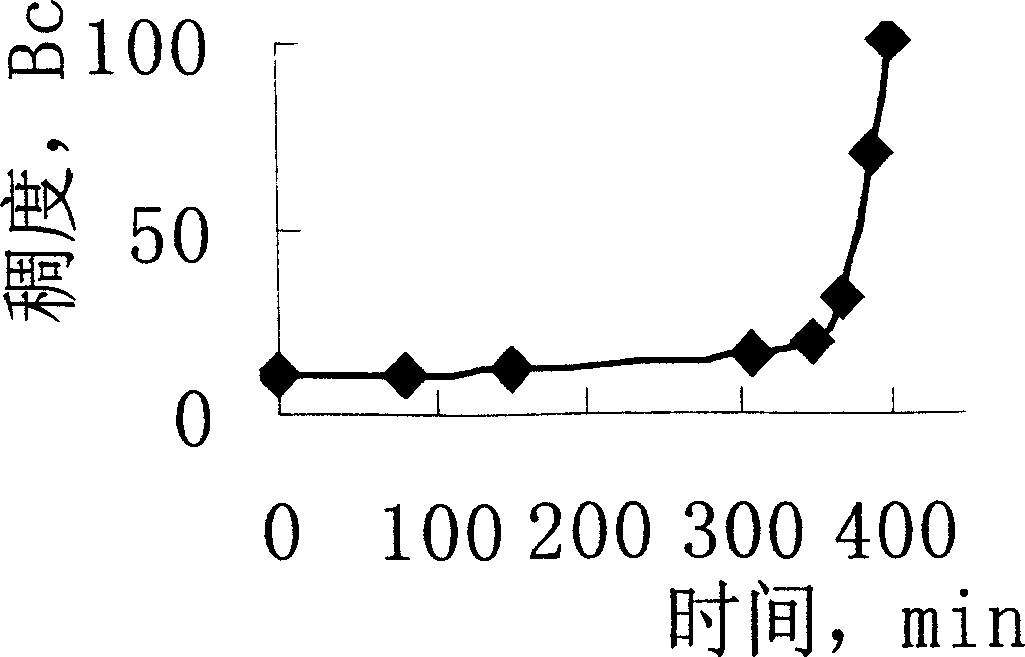

Anti-pollution high efficiency isolation liquid and preparing method

The present invention relates to anti-pollution high efficiency isolating liquid for shaft wall cementing operation and its preparation process. The isolating liquid is compounded through adding suspension stabilizer, water reducing agent, tackifier, diluent, viscosity and shearing force increasing agent, weight additive and pH regulator in certain weight proportion into water. One compounding process is a water base process through throwing the said components successively into water in a slurry tank apparatus. One other compounding process is one dry mixture process in a cementing tank apparatus. The isolating liquid has flexible compounding process, high anti-pollution capacity and effective eliminating effect on well wall interface pollutant.

Owner:SOUTHWEST PETROLEUM UNIV

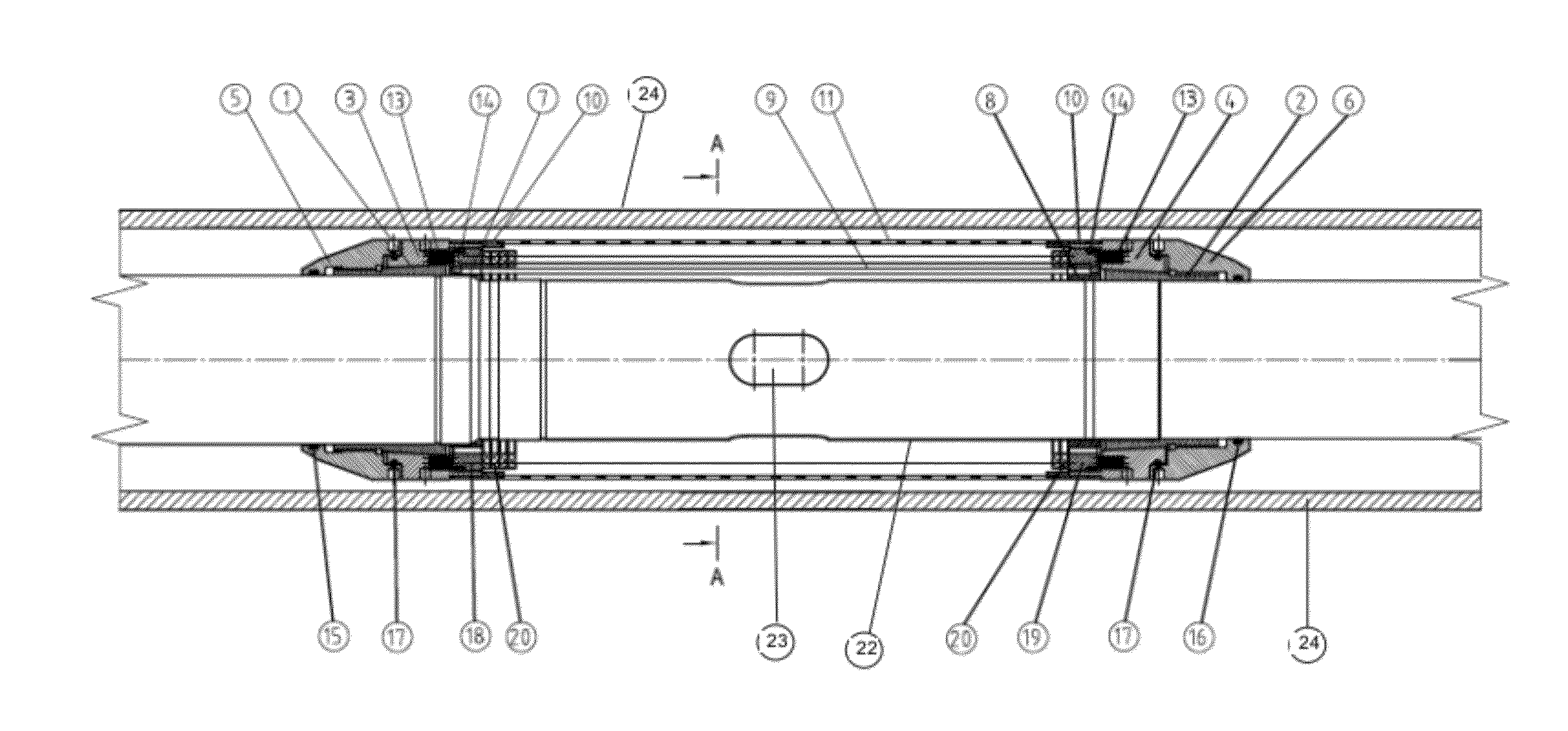

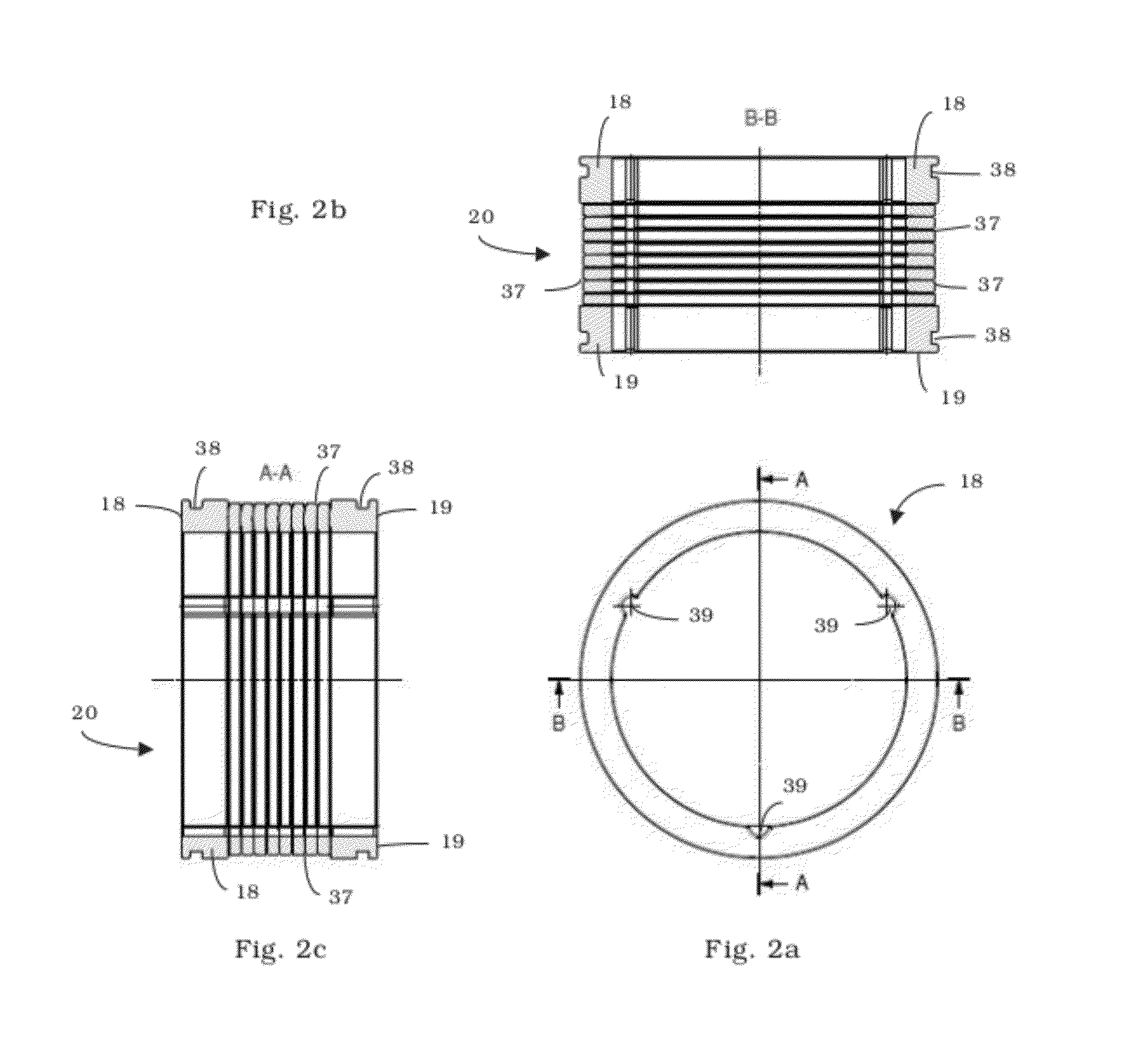

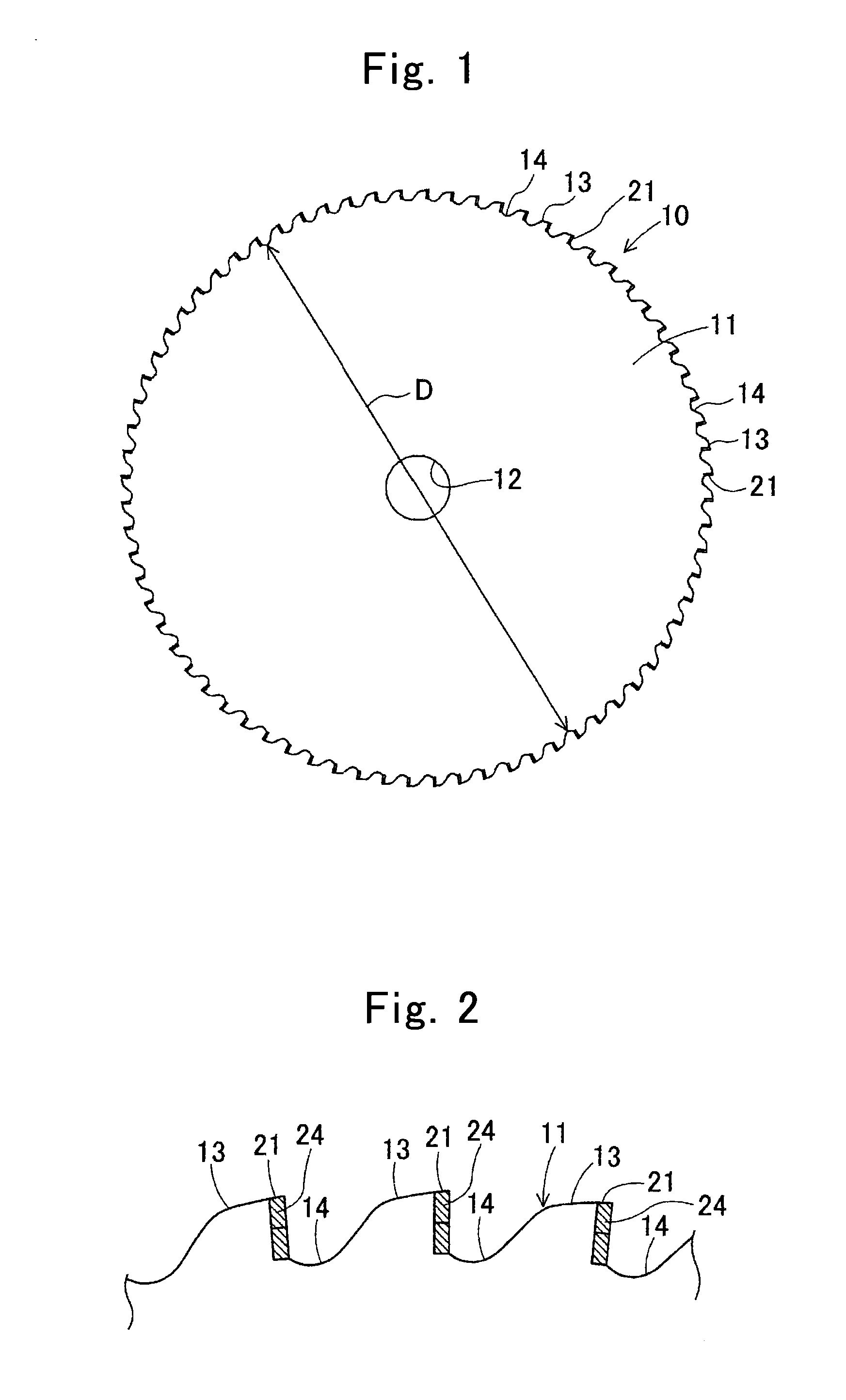

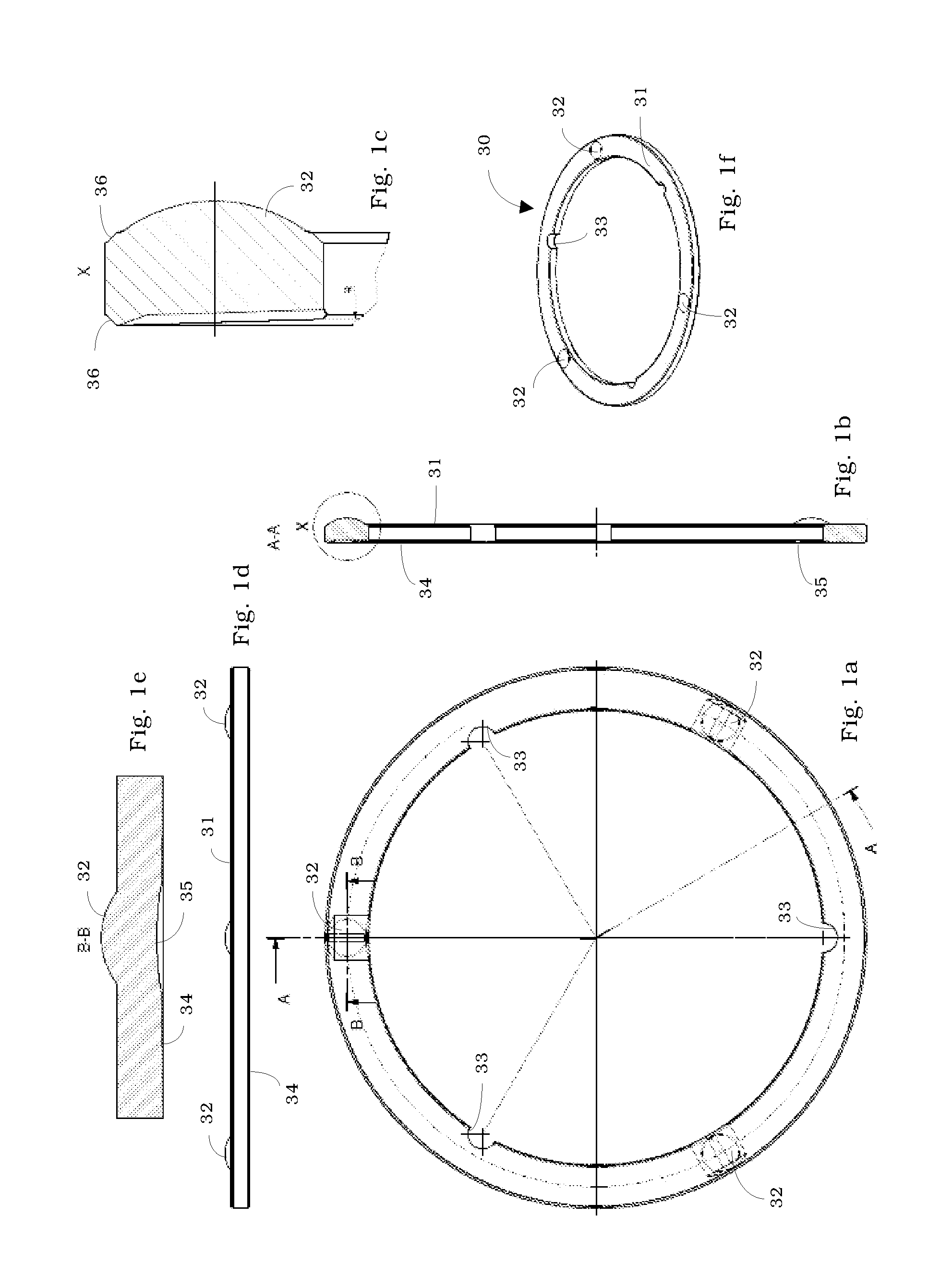

Separating device for tubular flow-through devices

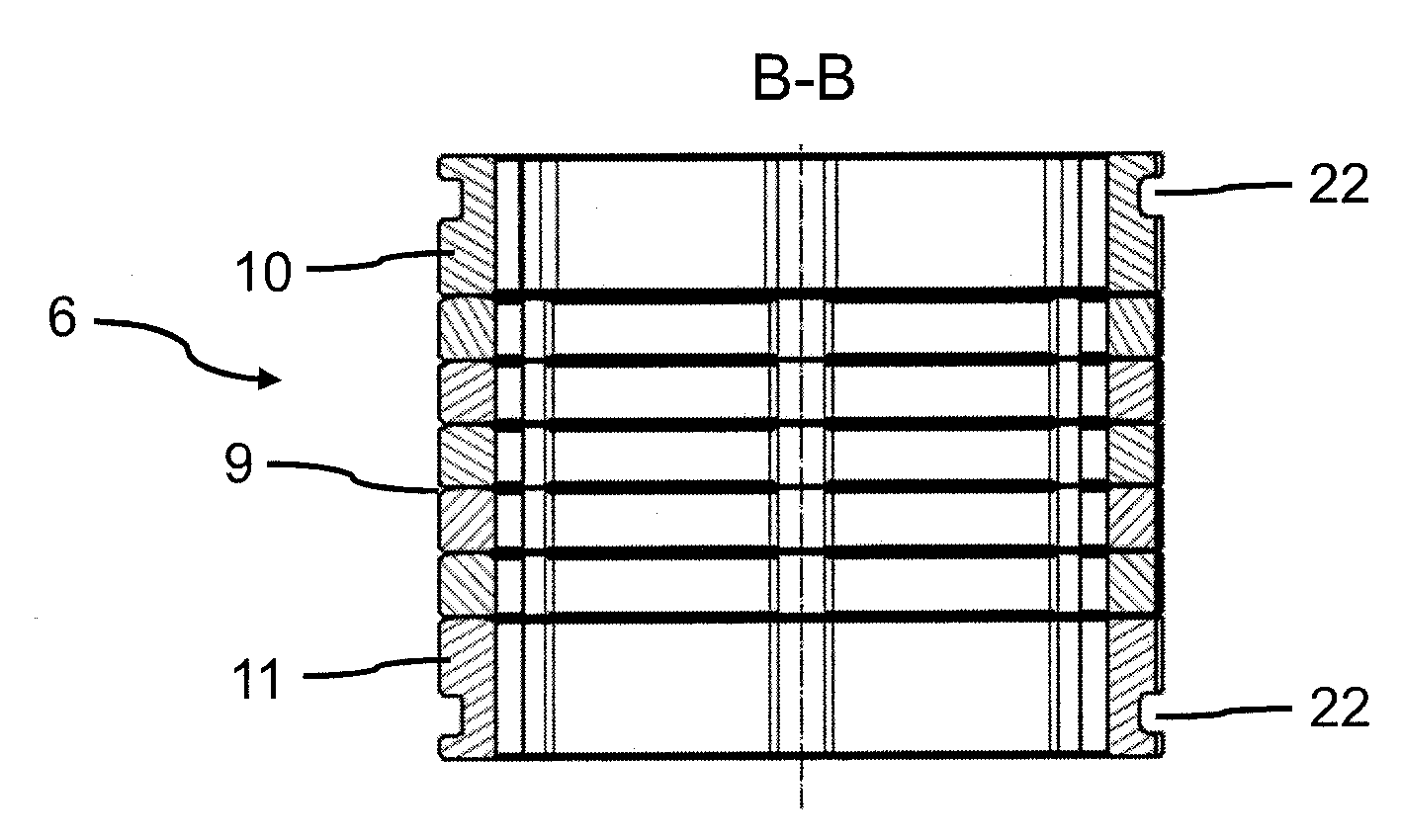

ActiveUS8833447B2Good abrasionIncrease resistanceDispersed particle filtrationFluid removalWell drillingGeophysics

The invention relates to a separating device for tubular flow-through devices (22) which serve for the extraction of liquids or gases from wells drilled in rock or deep wells, the separating device being suitable for the removal of sand and rock particles and comprisingan annular stack (20) of brittle-hard annular disks, the disks (30) being stacked and braced in such a way that a separating gap (37) for the removal of sand and rock particles is present in each case between the individual disks (30),a coupling-on element (18, 19) at one or both ends of the annular stack (20),a clamping device at one or both ends of the annular stack (20), making it possible on the one hand to flexibly brace the brittle-hard disks (30) and on the other hand to variably fasten the annular stack (20) on the tubular flow-through device (22).

Owner:3M INNOVATIVE PROPERTIES CO +1

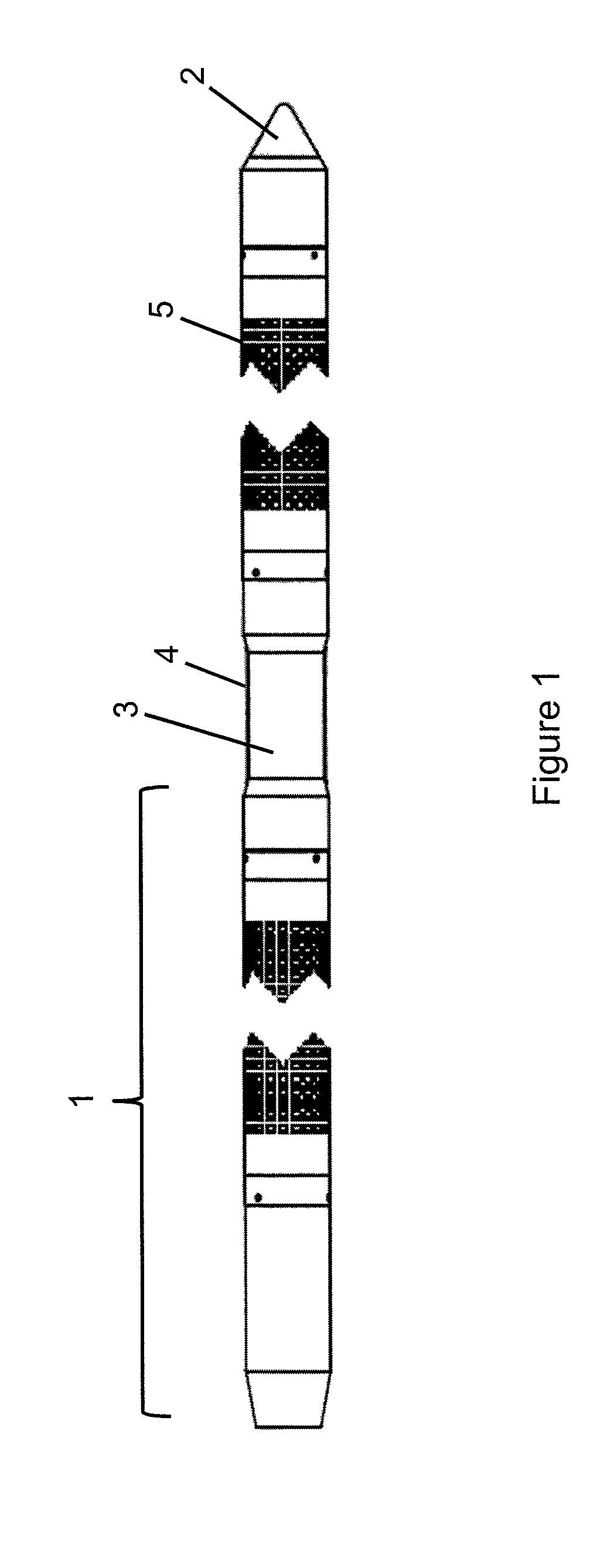

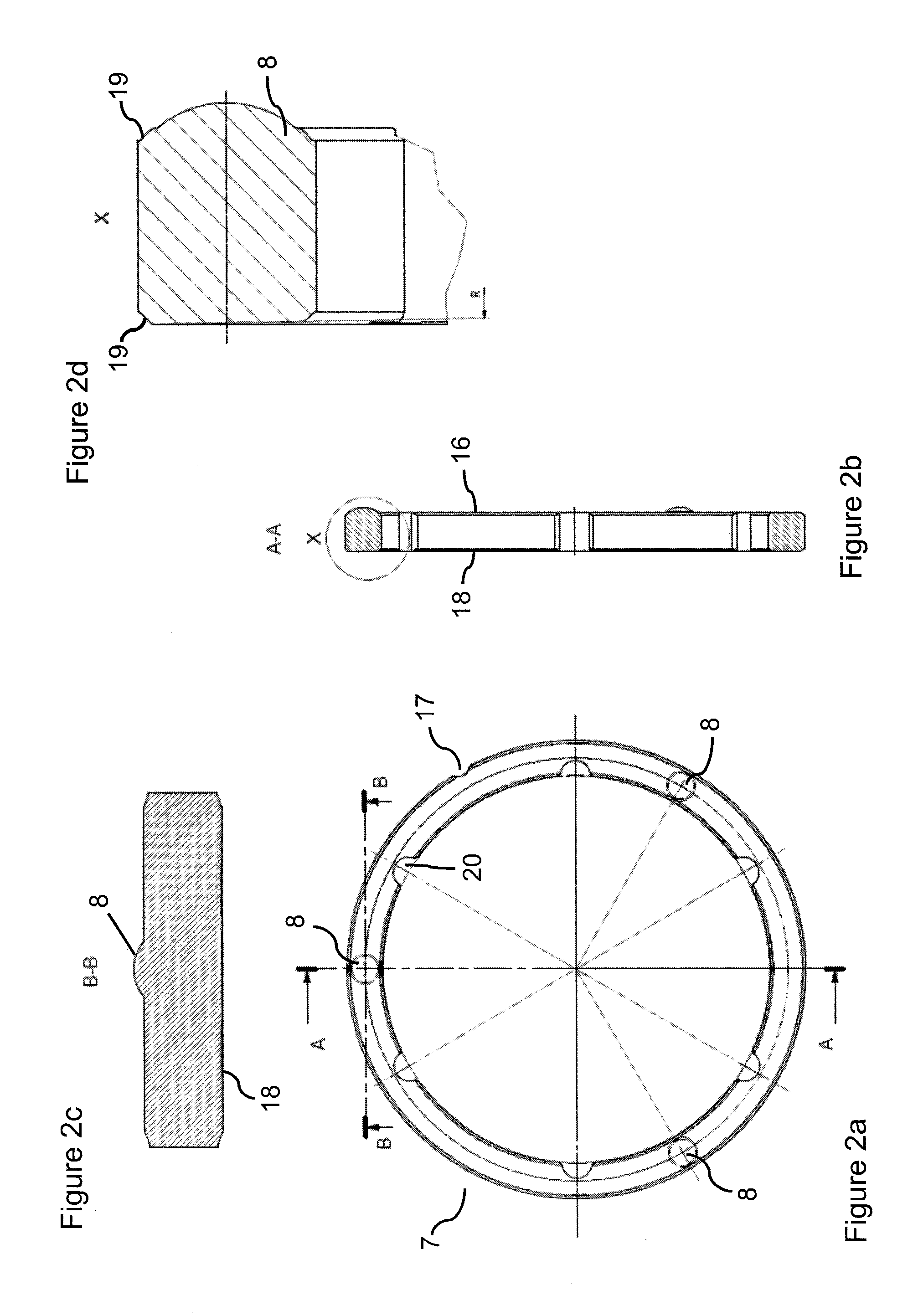

Wear-resistant separating device for removing sand and rock particles

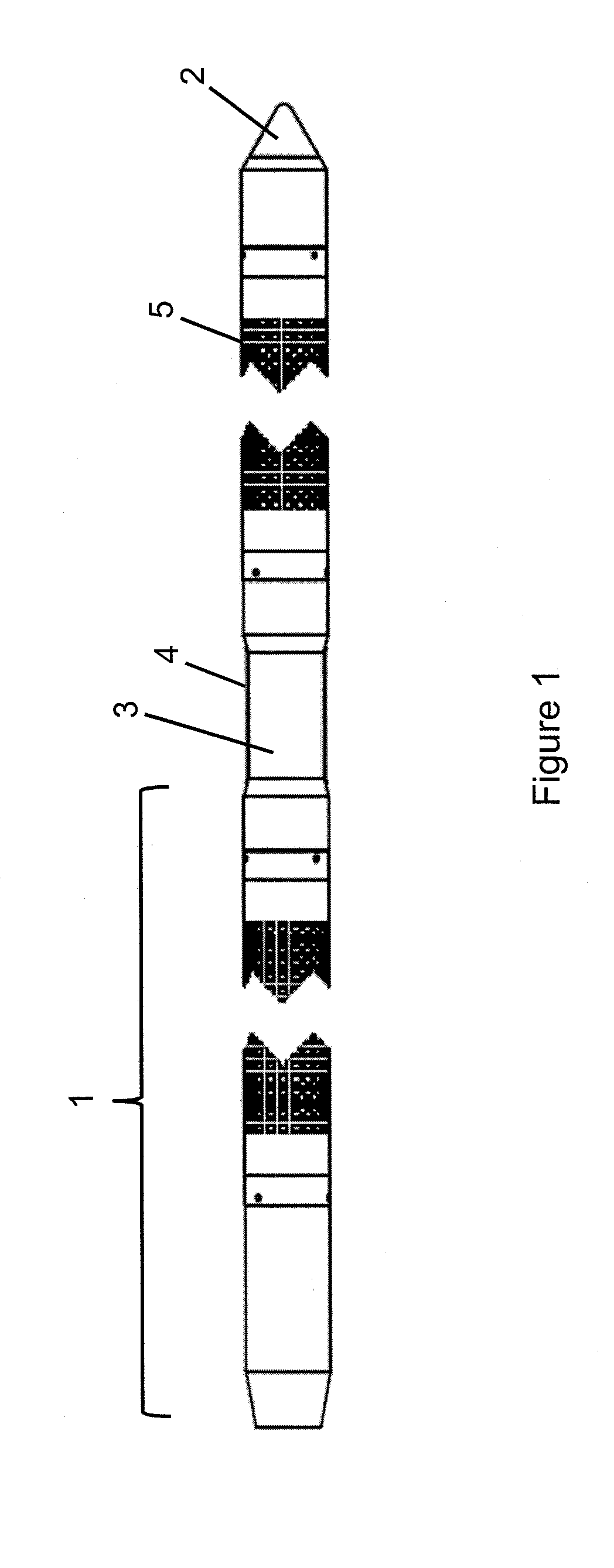

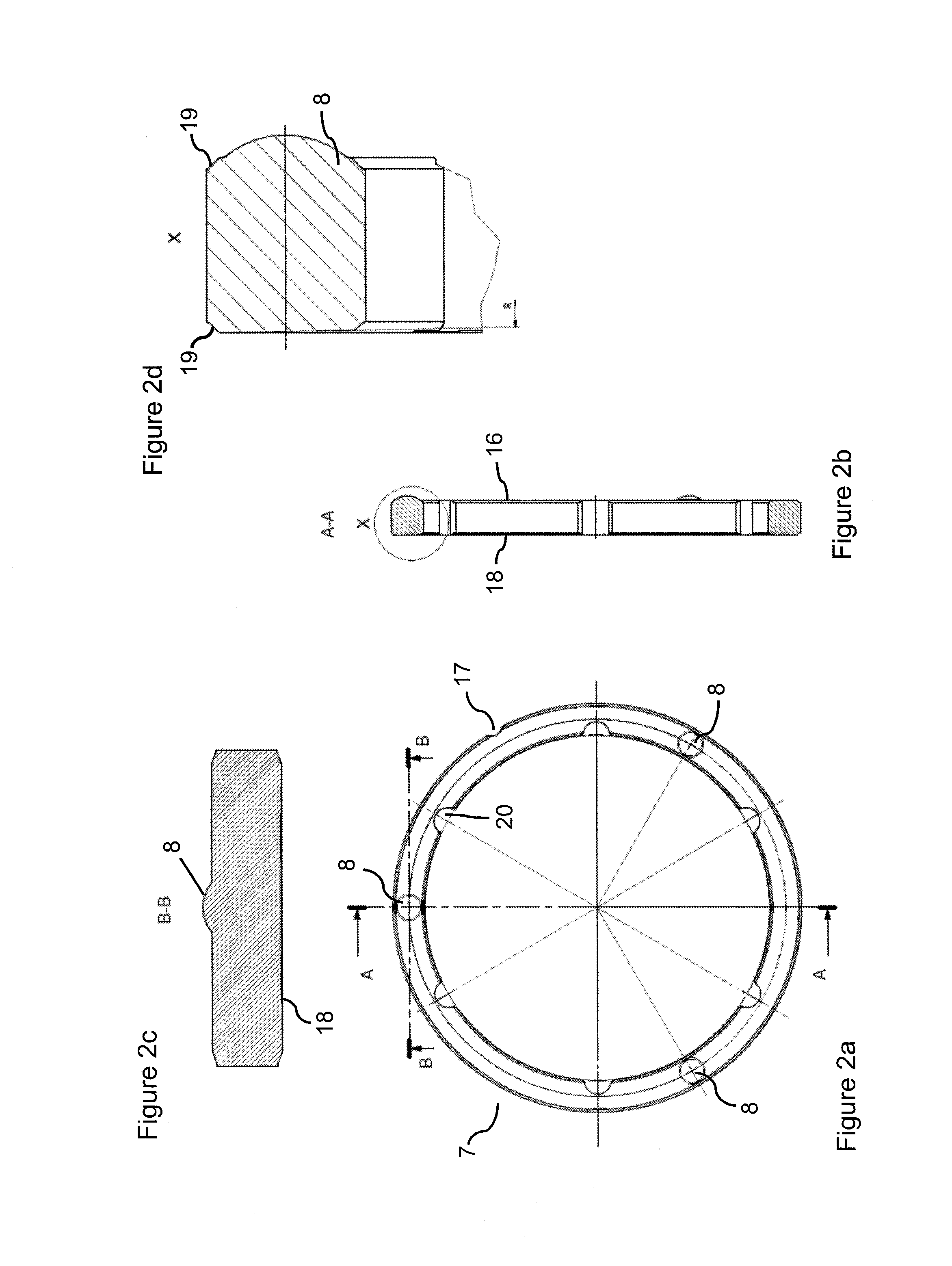

ActiveUS20120018146A1Tendency to fractureEasy to useFluid removalDrinking water installationCouplingWear resistant

The subject matter of the invention is a separating device for removing sand and rock particles which is suitable as an integral component part of extraction equipment for the extraction of liquids or gases from deep wells, the separating device comprising at least one ceramic filter module (1), the filter module (1) comprisinga) an annular stack (6) of brittle-hard annular discs (7), the upper side (16) of which has at least three elevations (8) uniformly distributed over the circular circumference of the discs, the discs (7) being stacked and braced in such a way that a separating gap (9) for the removal of sand and rock particles is present in each case between the individual discs (7),b) a coupling-on element (10) at the upper end and a coupling-on element (11) at the lower end of the annular stack (6),c) a clamping device (14, 15) for the axial bracing of the annular stack (6),d) an outer cage (5) for the mechanical protection of the filter module (1),e) a coupling element (12) at the upper end and a coupling element (13) at the lower end of the filter module (1) for connecting the filter module (1) to further components of the extraction equipment.The subject matter of the invention likewise covers the use of a separating device according to the invention for removing sand and rock particles in a process for extracting liquids or gases from wells drilled in rock or deep wells.

Owner:3M INNOVATIVE PROPERTIES CO +1

Tire rubber composition and heavy-load tire

The present invention provides: a rubber composition for a tire that achieves both good fuel economy and abrasion resistance, and also achieves good degradation resistance and processability; and a heavy-load tire having a tread produced therefrom. The present invention relates to a rubber composition for a tire, comprising a rubber component that contains a modified natural rubber having a phosphorus content of 200 ppm or less and a butadiene rubber, wherein the amount of the modified natural rubber is 60 to 95% by mass and the amount of the butadiene rubber is 5 to 40% by mass, based on 100% by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

Method for Producing a PCD Compact

ActiveUS20110072730A1High diamond contiguity and densityGood abrasionPigmenting treatmentPressurized chemical processPolycrystalline diamondAlloy

A method of producing a composite diamond compact comprising a polycrystalline diamond (PCD) compact bonded to a cemented carbide substrate is provided. The method includes the steps of: providing a PCD table, preferably a PCD table with diamond-to-diamond bonding and a porous microstructure in which the pores are empty of second phase material bringing together the PCD table and a cemented carbide substrate in the presence of a bonding agent to form an unbonded assembly; subjecting the unbonded assembly to an initial compaction at a pressure of at least 4.5 GPa and a temperature below the melting point of the bonding agent for a period of at least 150 seconds; and thereafter subjecting the unbonded assembly to a temperature above the melting point of the bonding agent and a pressure of at least 4.5 GPa for a time sufficient for the bonding agent to become molten and bond the PCD table to the substrate to form a composite diamond compact.

Owner:ELEMENT SIX ABRASIVES

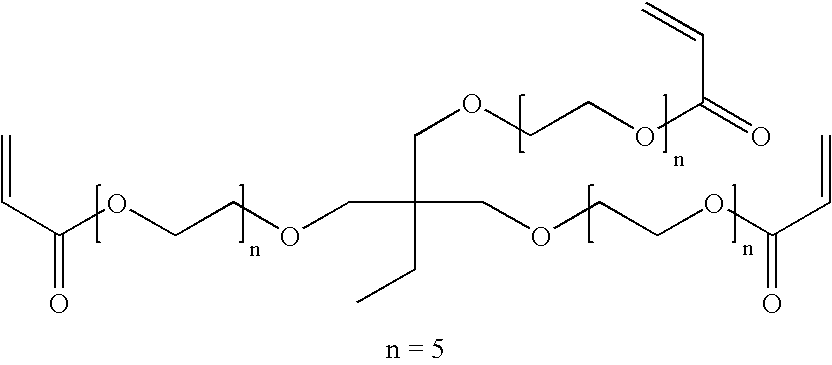

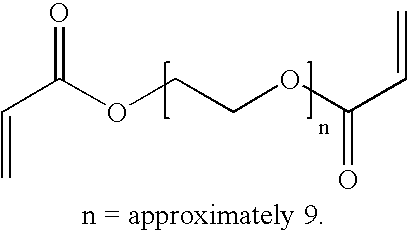

Topcoat layers for phosphor or scintillator screens or panels

InactiveUS20080026334A1Increase flexibilityExcellent abrasion resistancePhotosensitive materialsPretreated surfacesMeth-Polymer science

A photo-curable composition comprising a polymer or copolymer and a (meth)acrylate type monomer with more than one (meth)acrylate group per monomer molecule and two or more ethyleneoxy groups per (meth)acrylate group in said monomer is particularly suitable for use as a topcoat layer for phosphor or scintillator screens or panels, when said polymer is polymethyl methacrylate or a copolymer thereof.

Owner:T2PHARMA GMBH

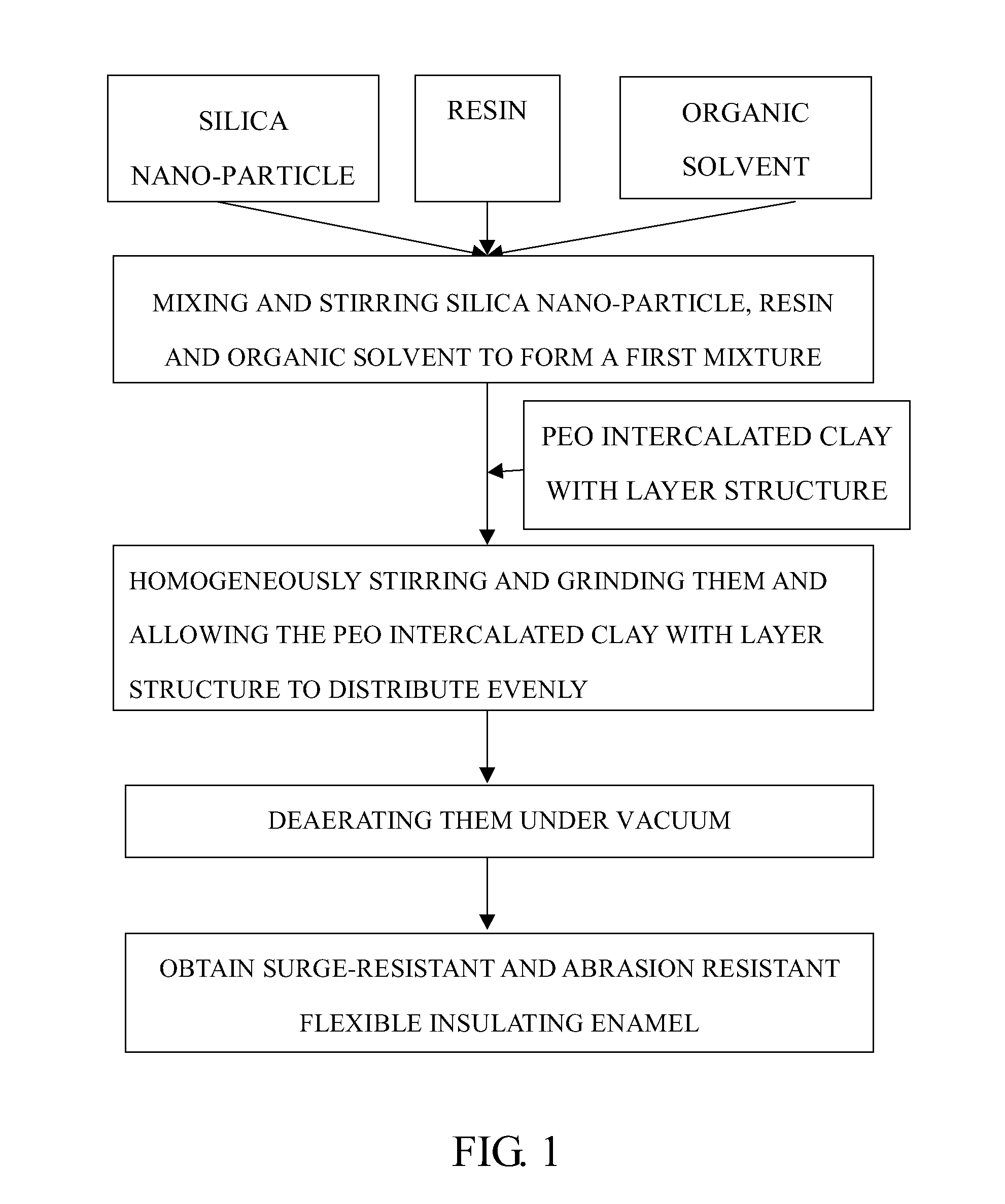

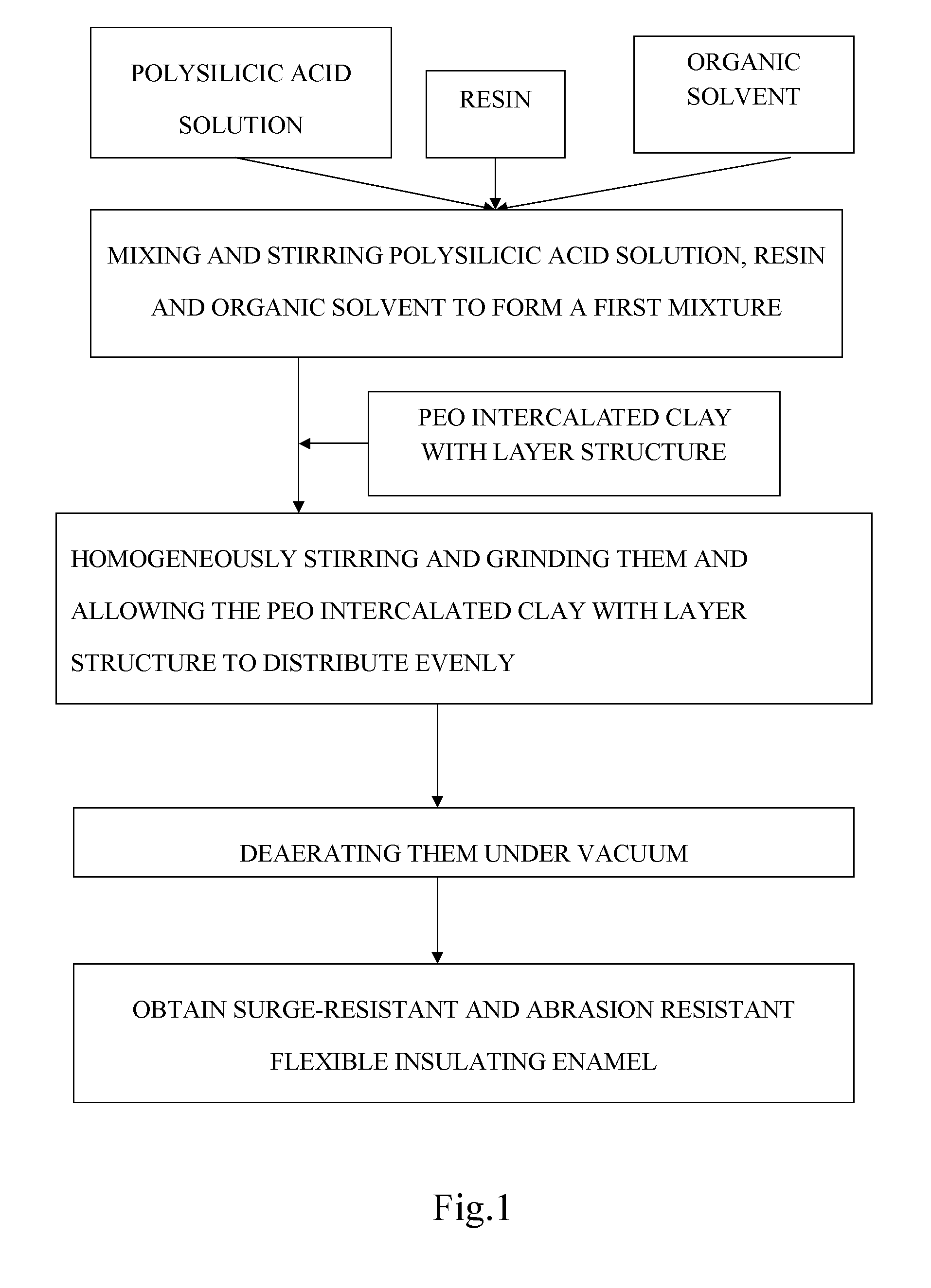

Surge-resistant and abrasion-resistant flexible insulating enamel

InactiveUS20110118393A1Increase flexibilityIncrease resistancePigmenting treatmentMaterial nanotechnologyDielectricOrganic solvent

A surge-resistant and abrasion resistant flexible insulating enamel has resin in an amount of 12 wt % to 76 wt % per 100 wt % by weight of the enamel, an organic solvent in an amount of 20 wt % to 80 wt % per 100 wt % by weight of the enamel, polyethylene oxide (PEO) intercalated clay in an amount of 0.005 wt % to 16 wt % per 100 wt % by weight of the enamel, and organic dispersible silica nano-particles in an amount of 0.995 wt % to 16 wt % per 100 wt % by weight of the enamel. The clay and silica nano-particles have high dielectric constant to absorb, disperse evenly and evacuate surge, which prevents an insulating layer made by the insulating enamel from being damaged from the surge. PEO provides the insulating layer has good flexibility, adhesion and abrasion resistance.

Owner:FU PAO CHEM CO LTD

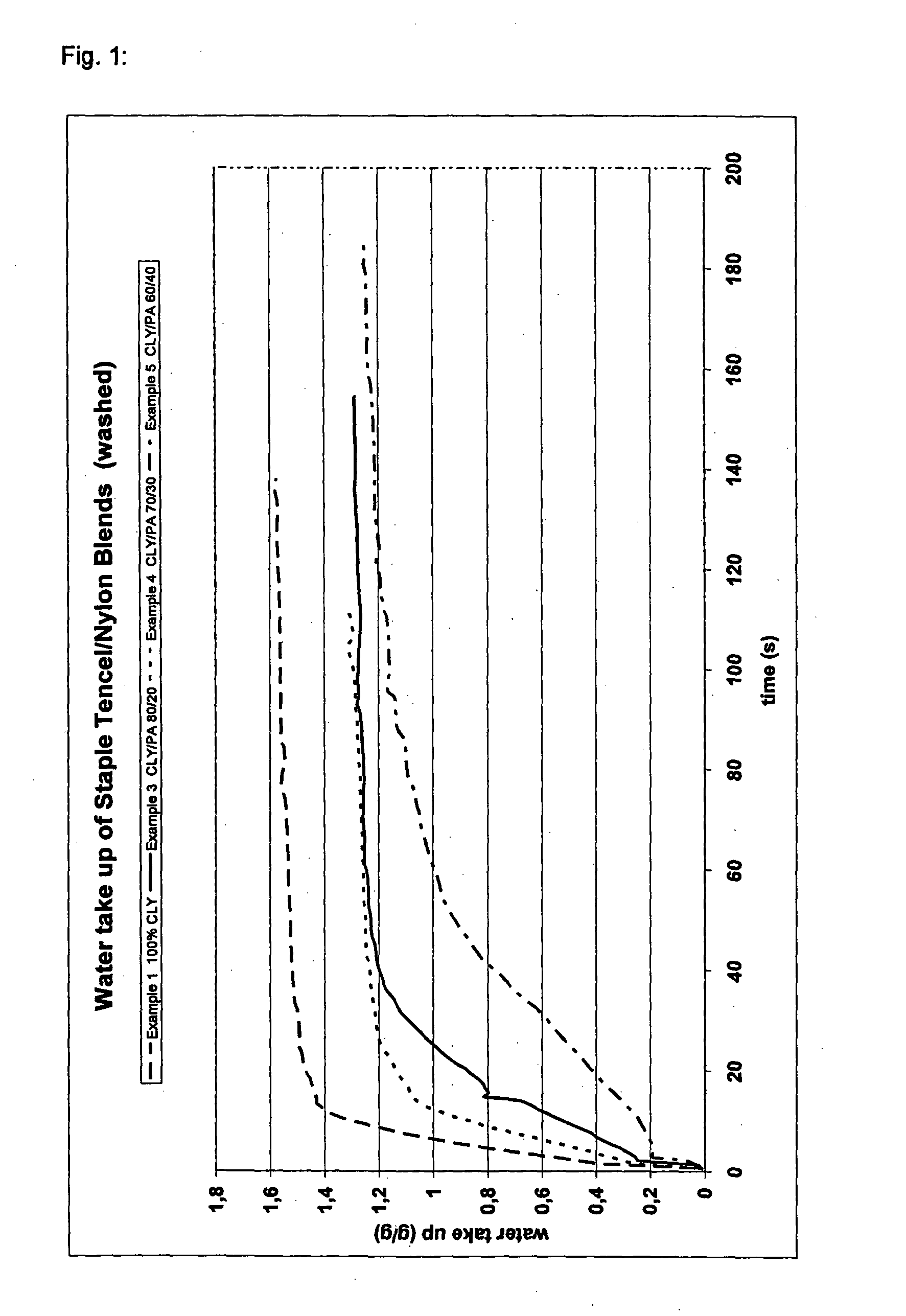

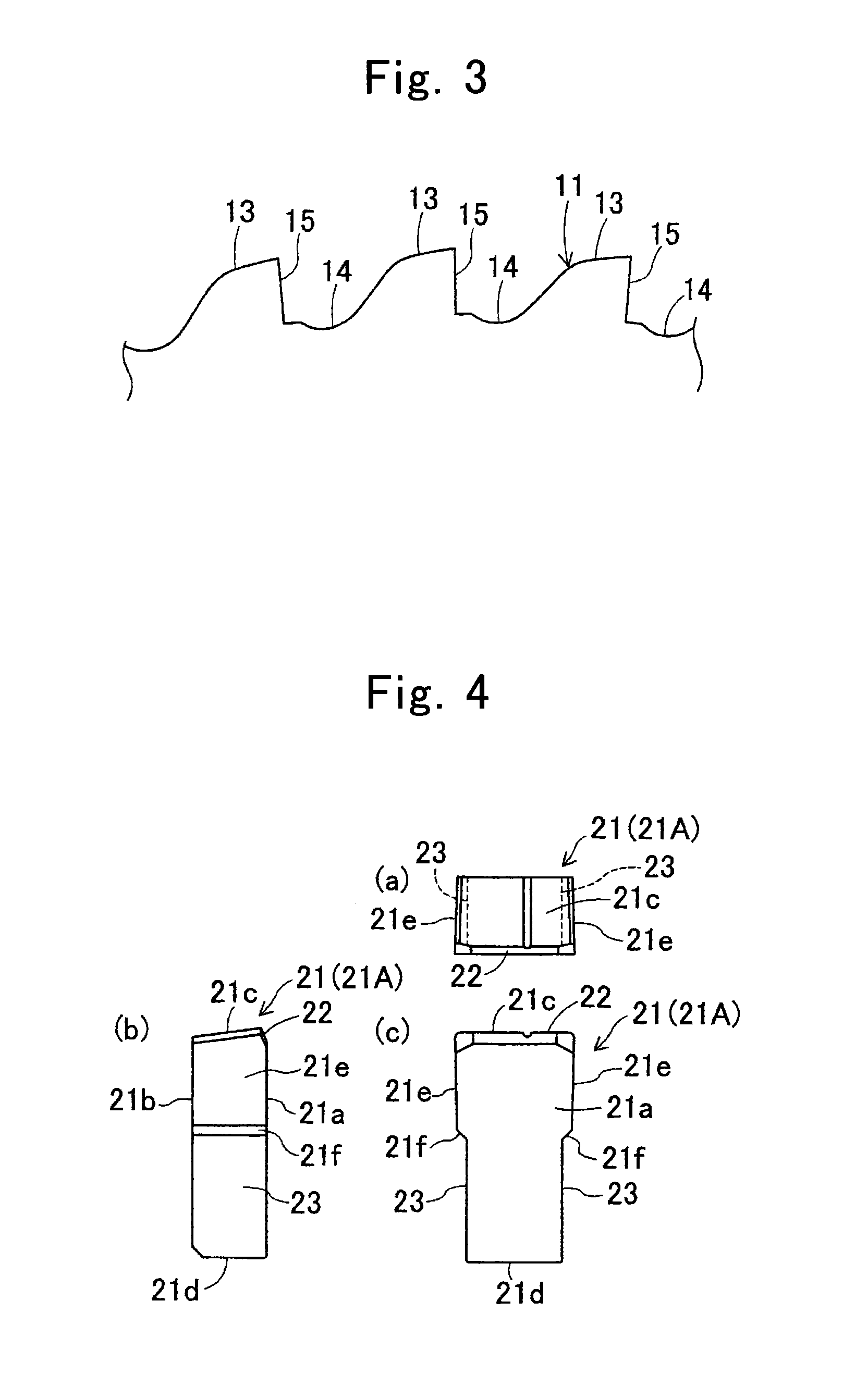

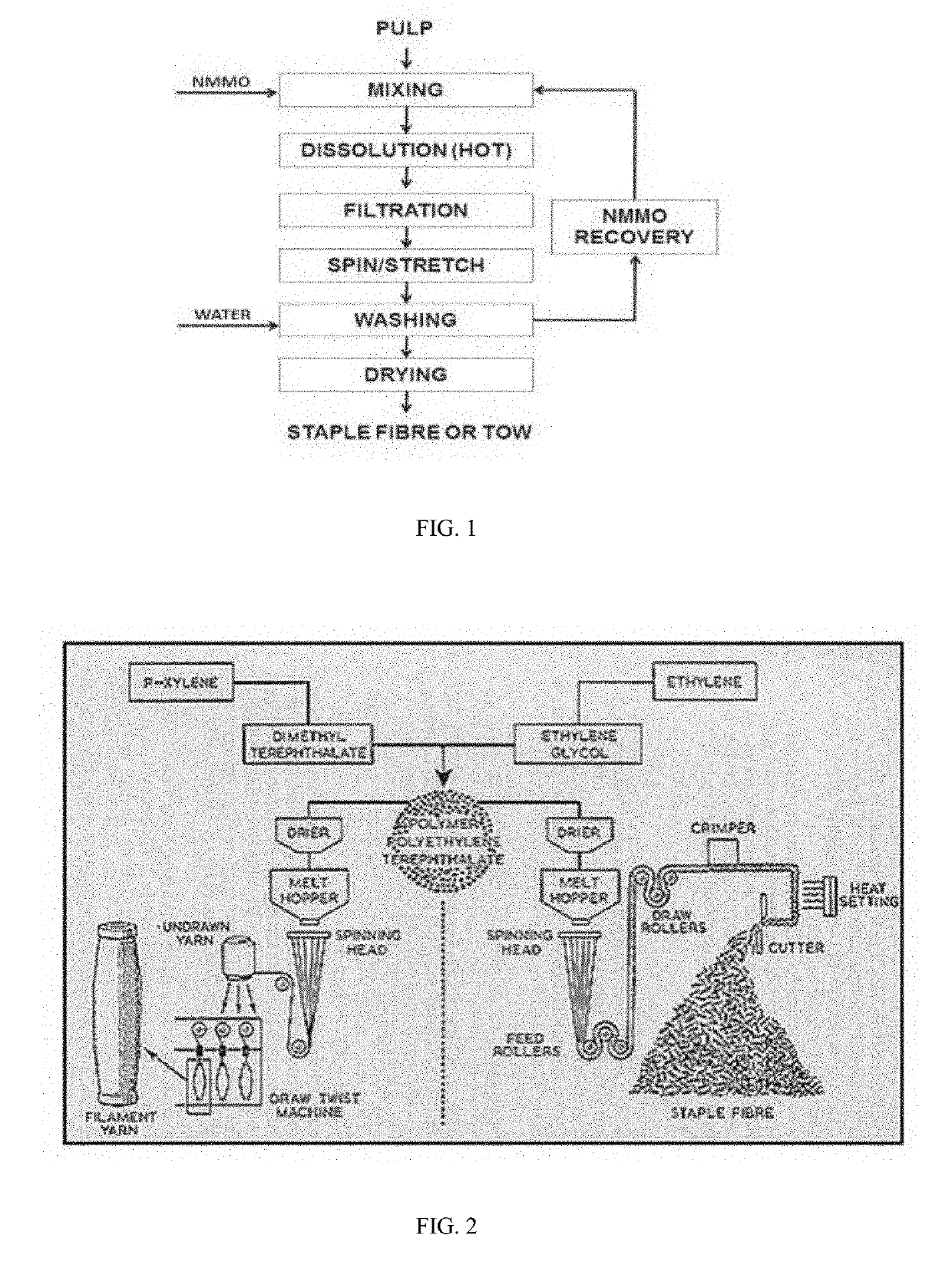

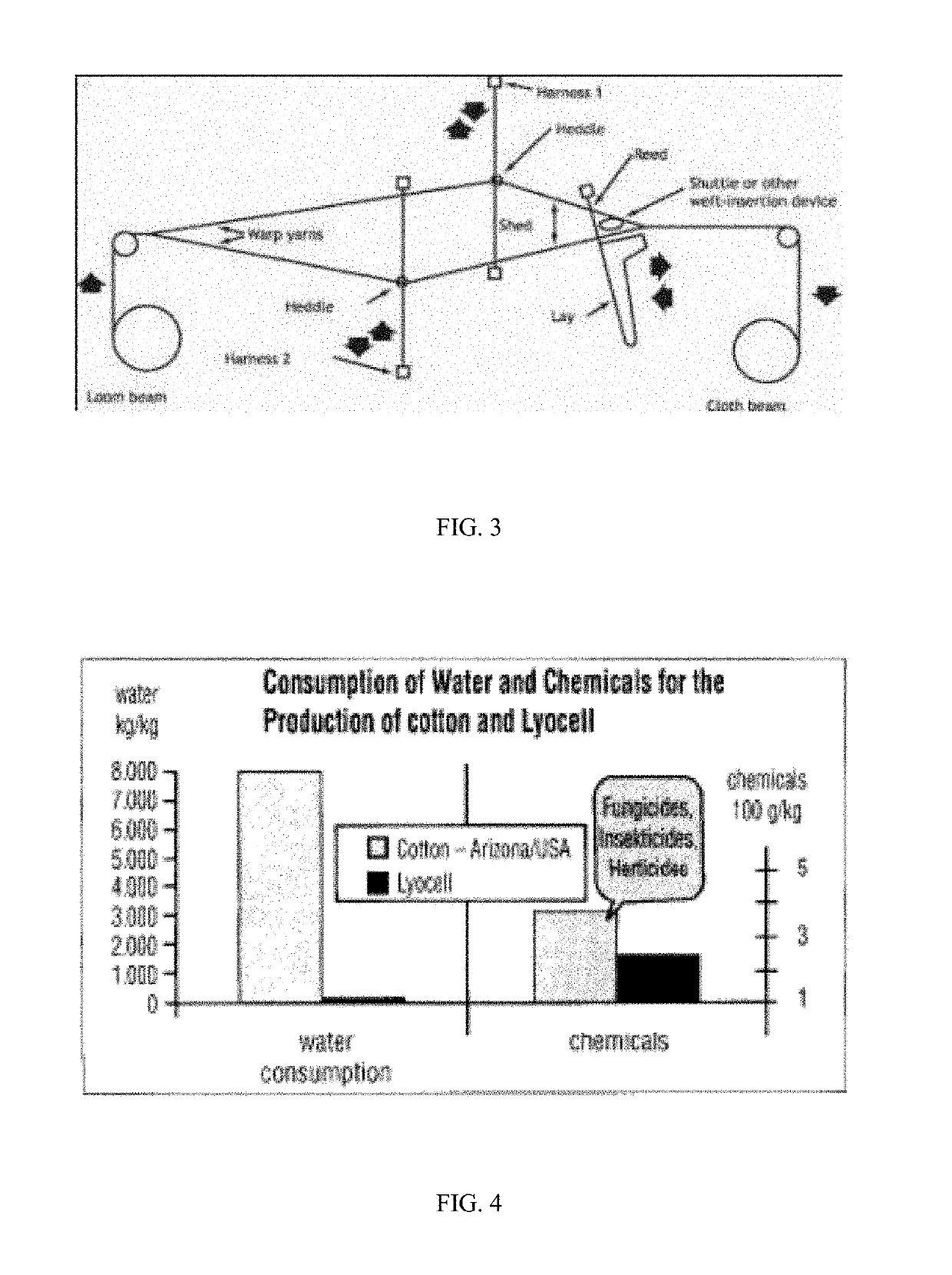

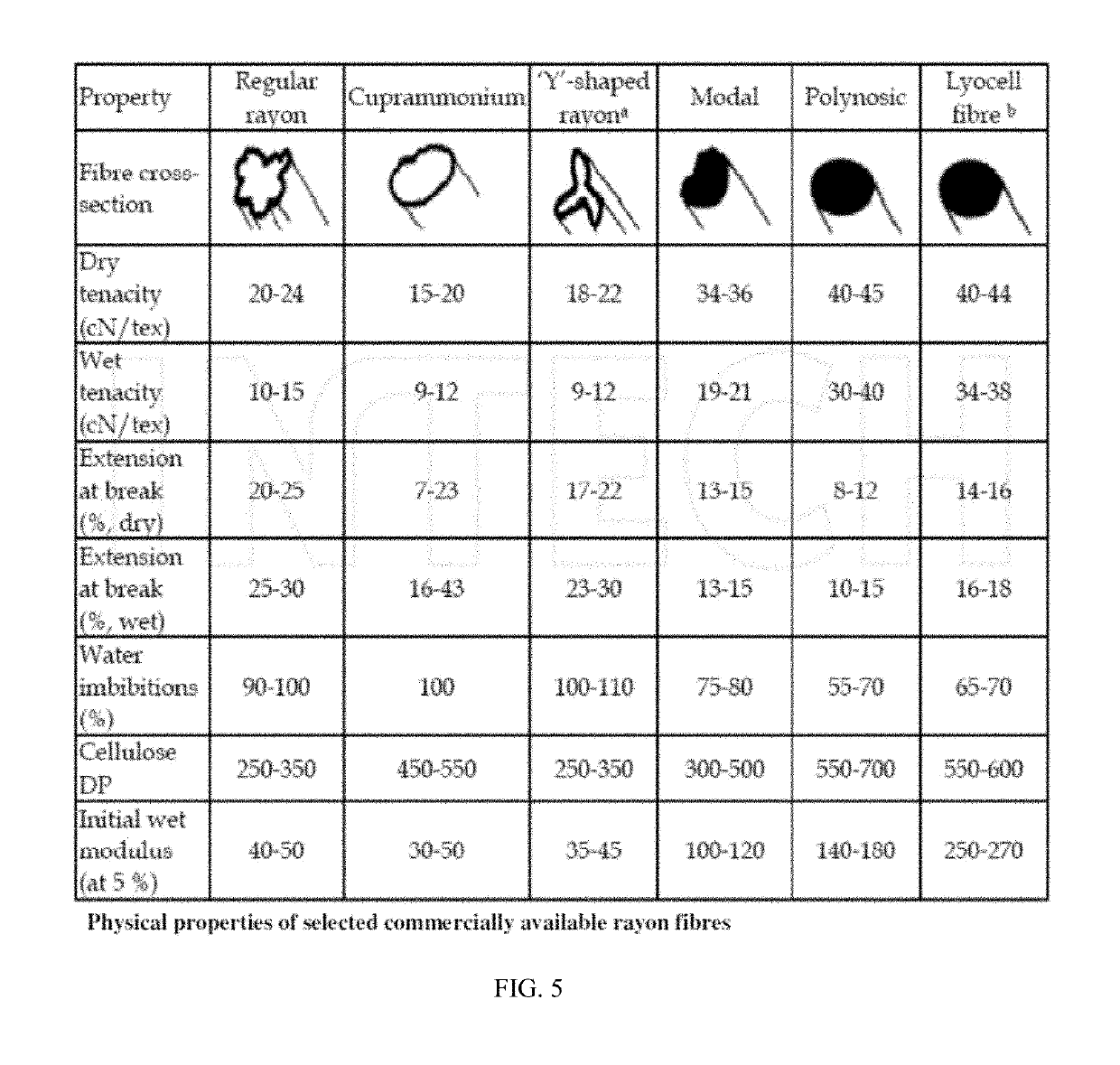

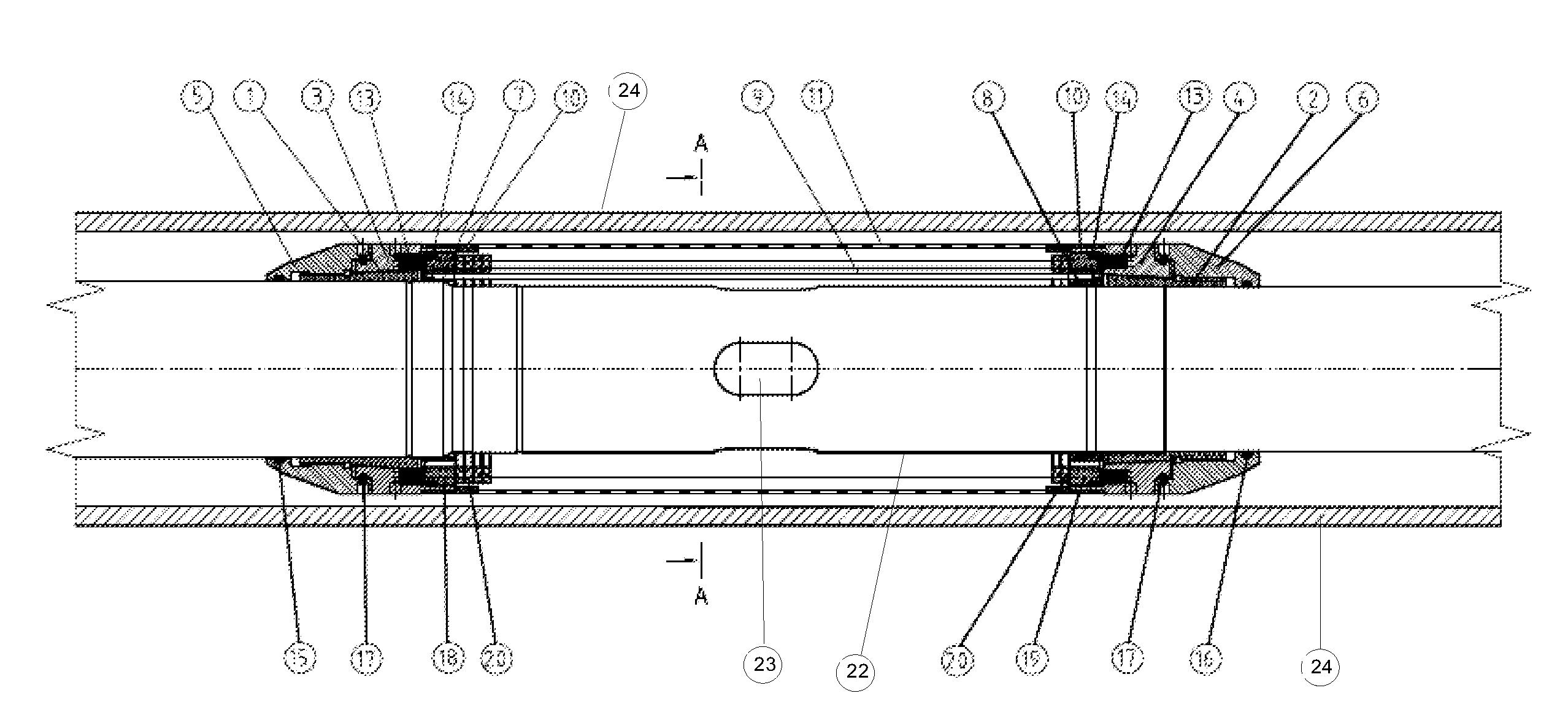

Yarns, high wear resistance fabrics and objects made therefrom

InactiveUS20100330351A1Improve balanceGood abrasionProtective fabricsWarp knittingHigh resistanceFiber

The invention relates to yarns and fabrics containing nylon staple fiber and high-tenacity man-made cellulosic staple fiber, and garments made therefrom, and has particular reference to fabrics having a high resistance to wear whilst retaining a high comfort level.

Owner:LENZING AG

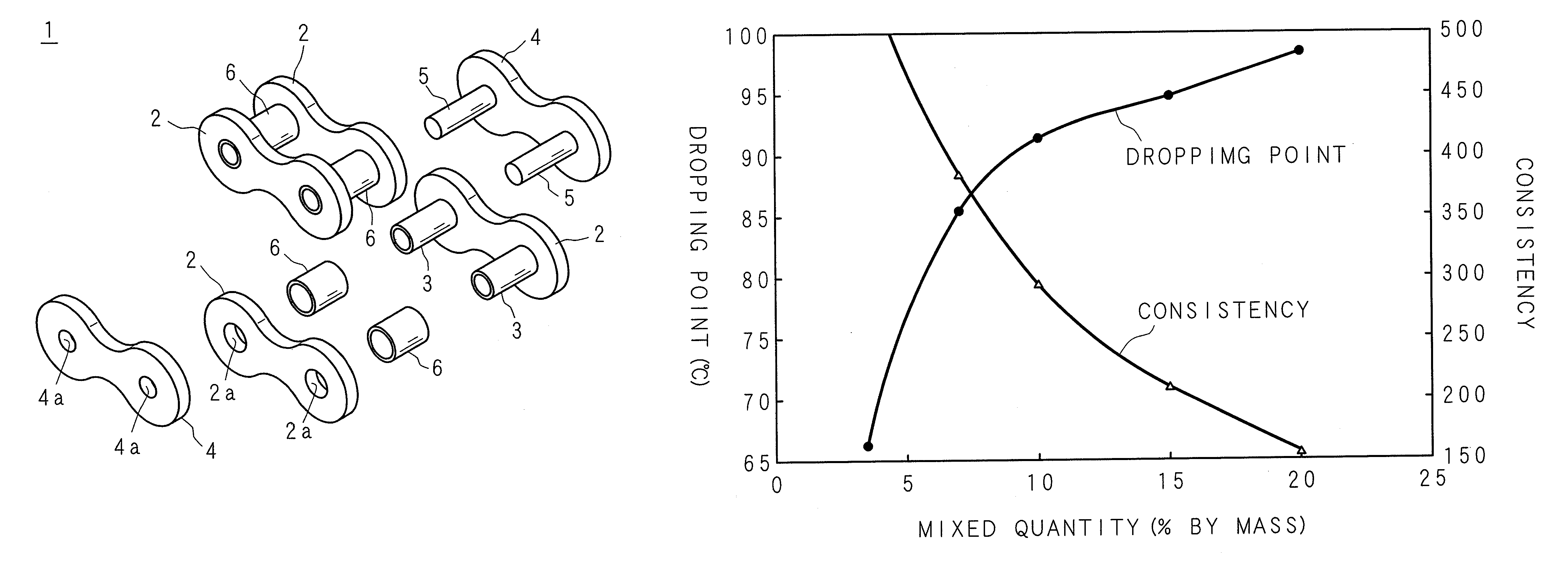

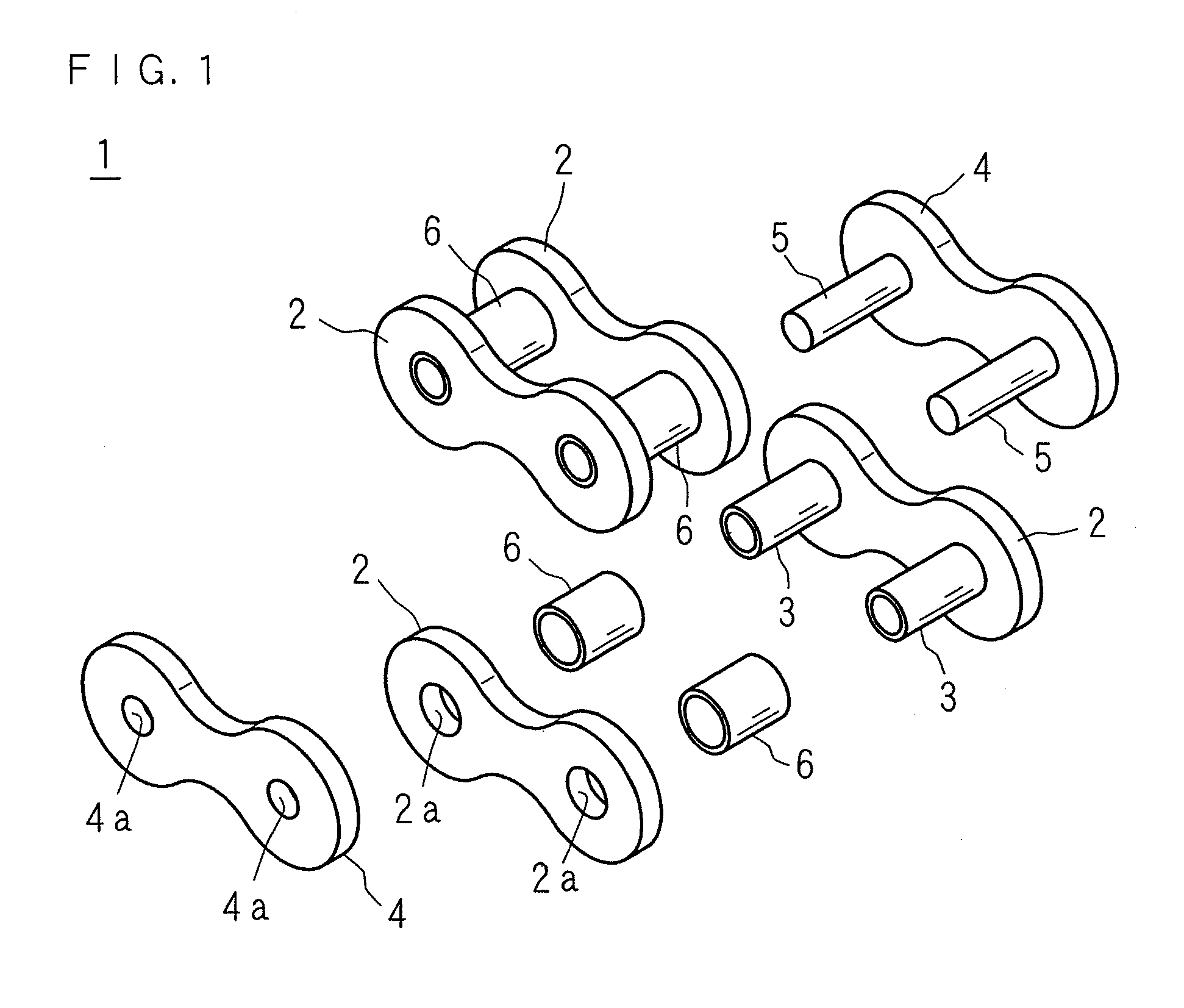

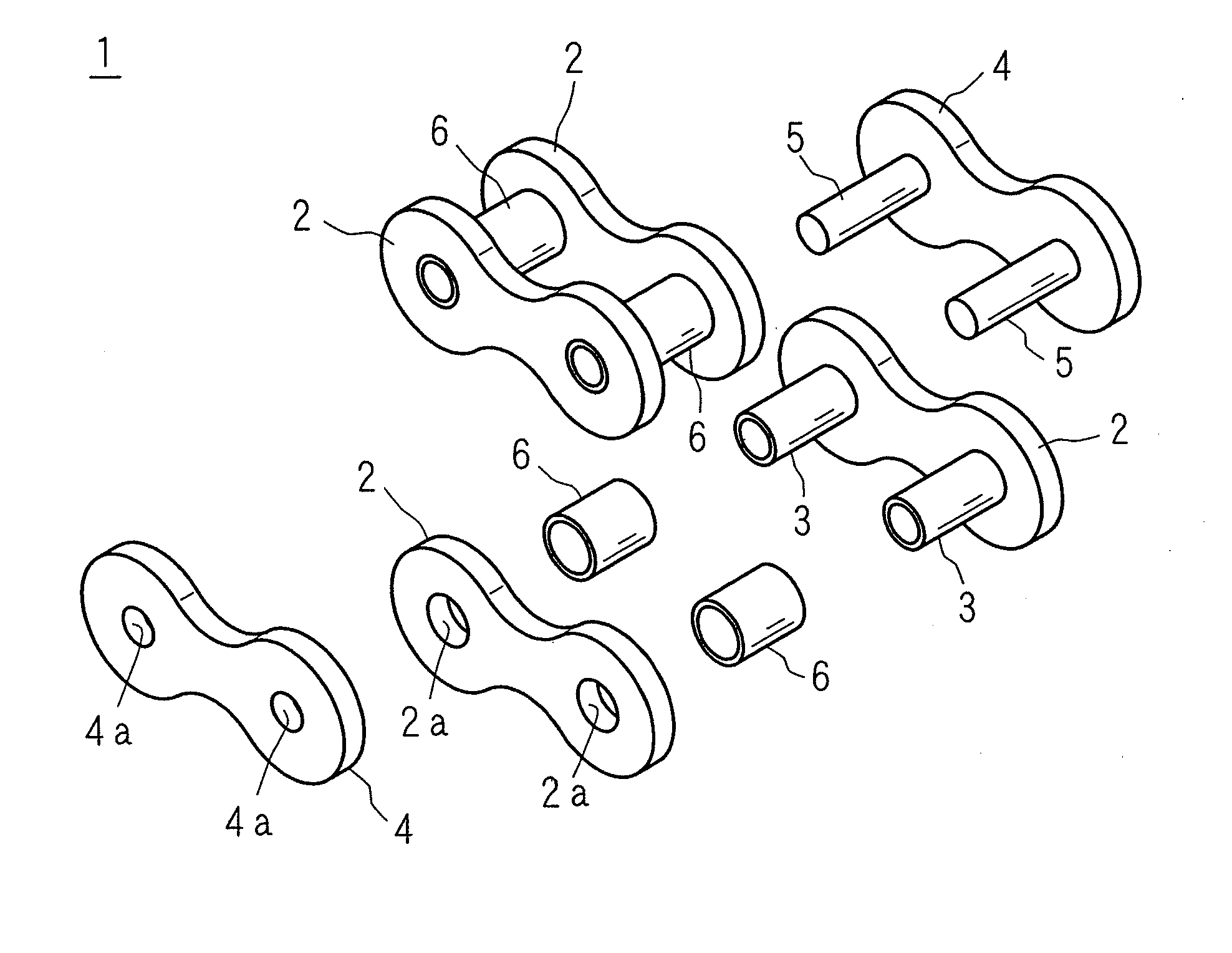

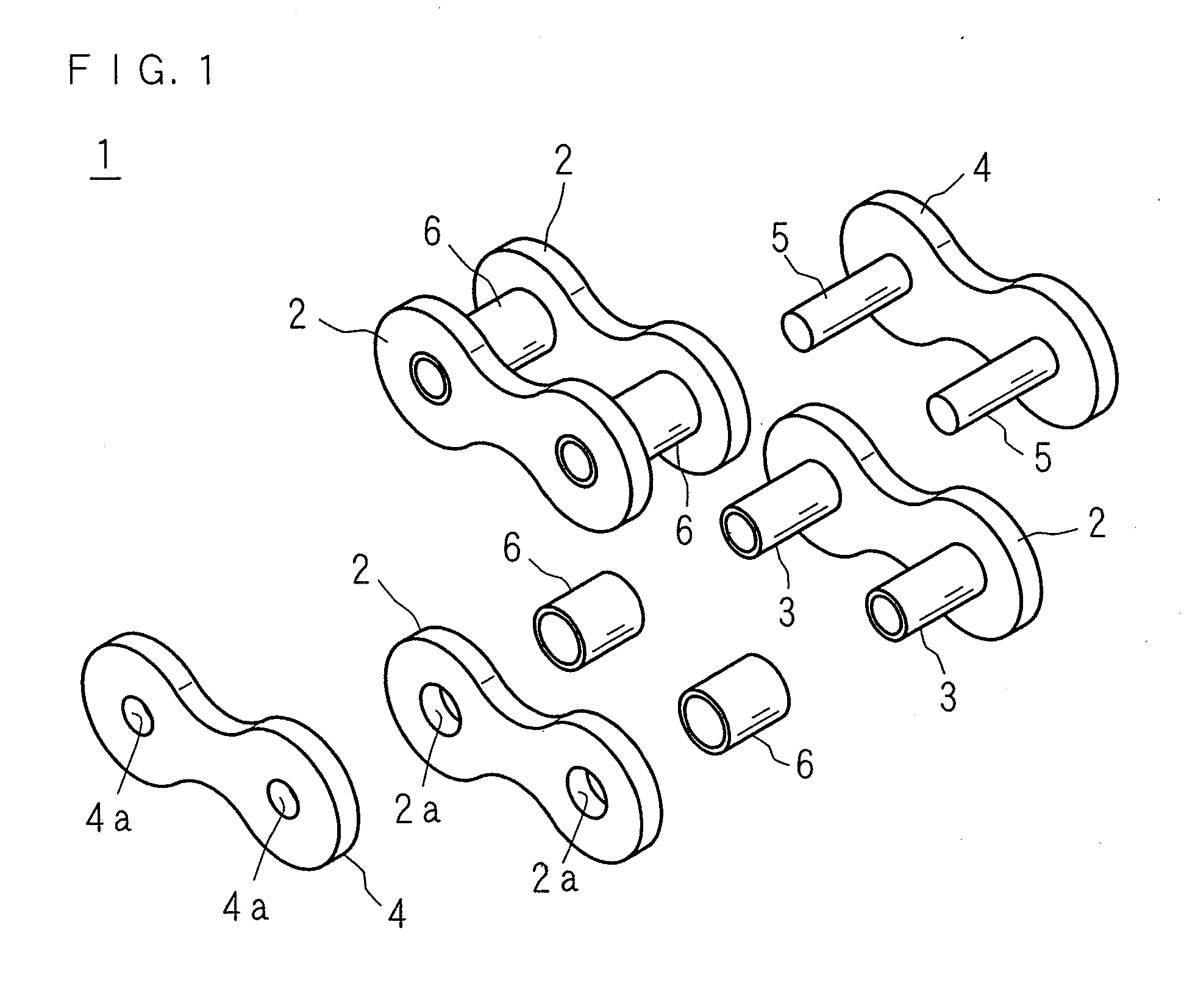

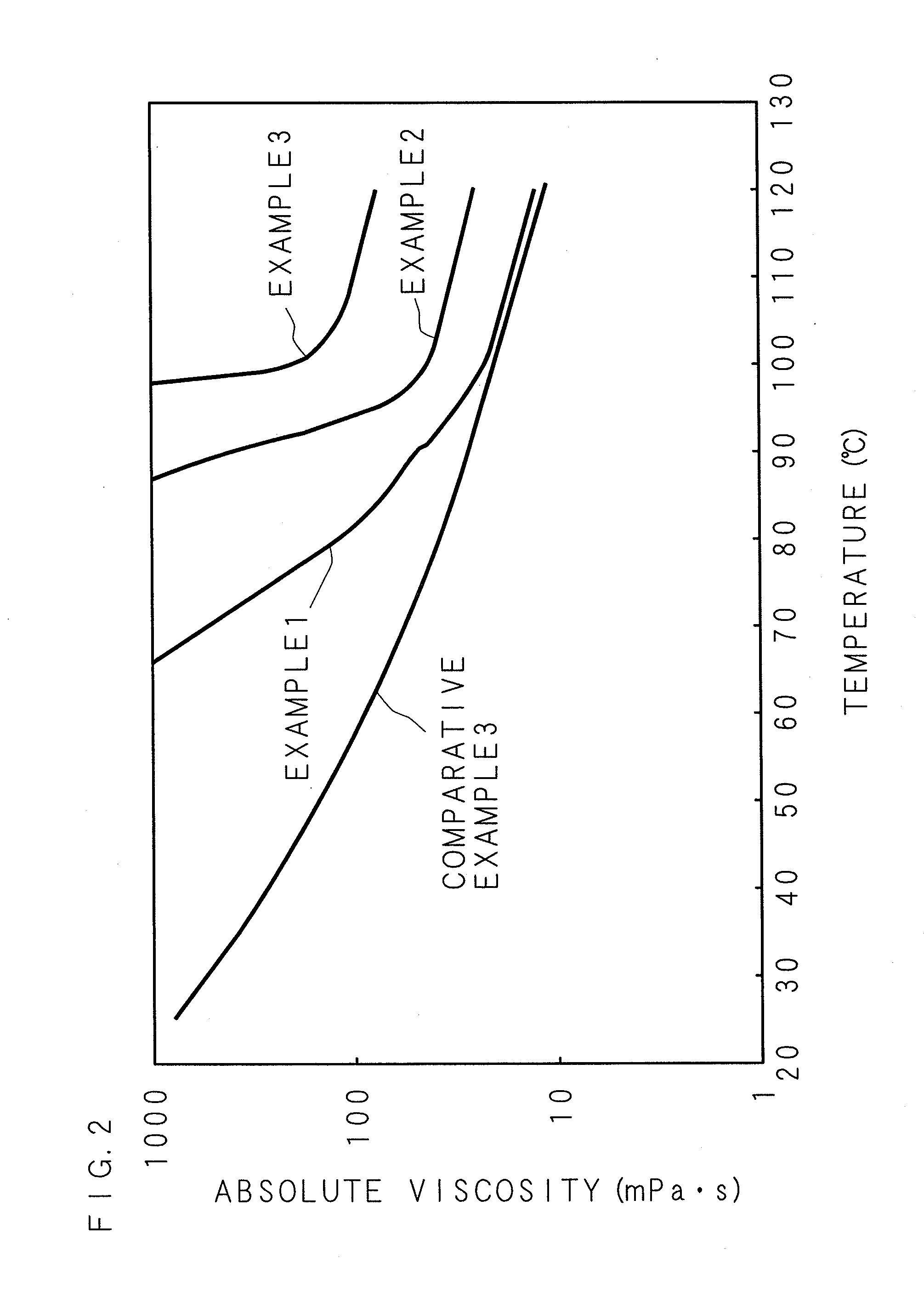

Lubricant composition for chains, and chain

InactiveUS8771119B2Excellent abrasionImprove the lubrication effectSolid fuelsLiquid carbonaceous fuelsWaxRoom temperature

Owner:TSUBAKIMOTO CHAIN CO

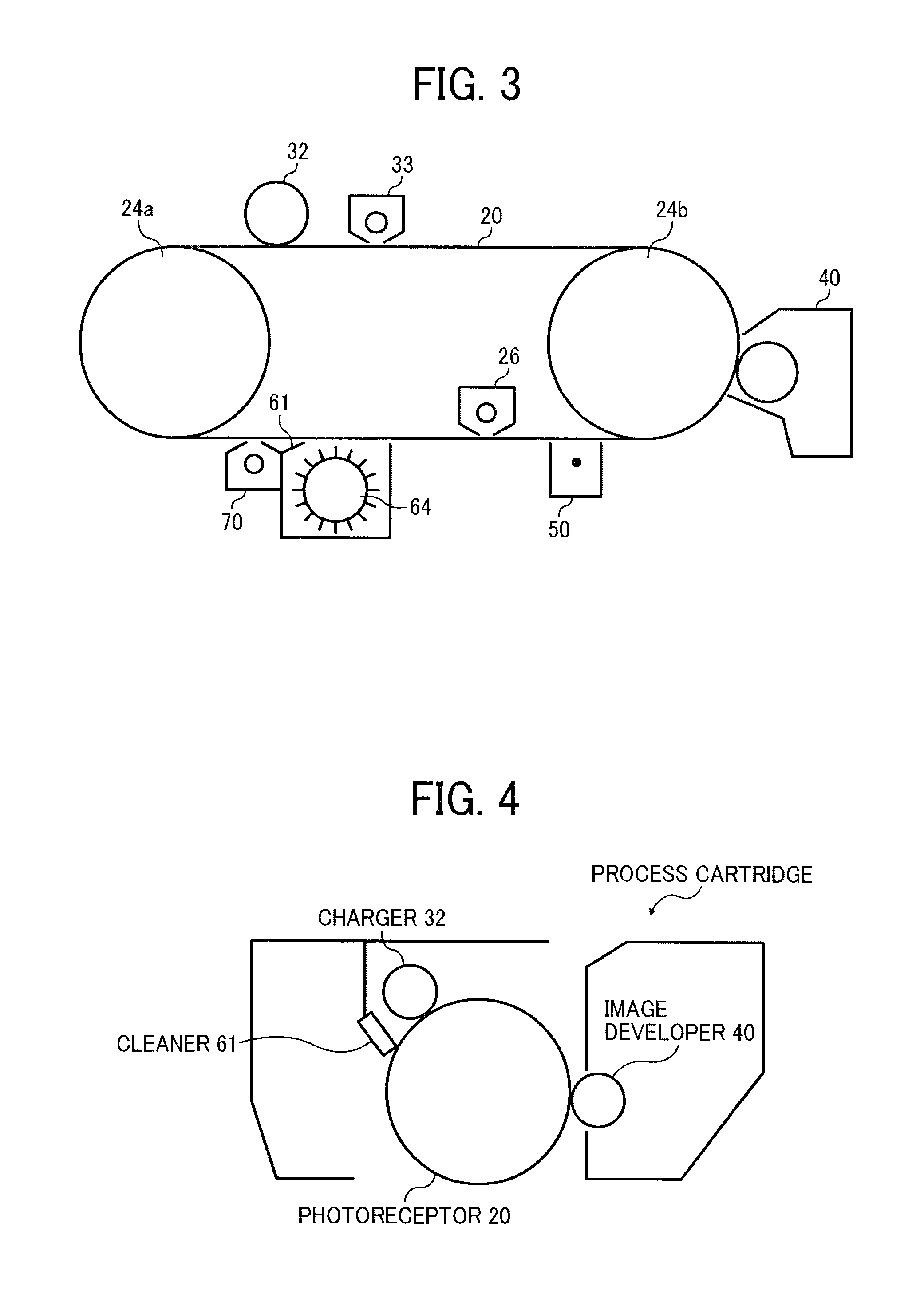

Carrier for two-component developer, electrostatic latent image developer, and image forming method

InactiveUS20140080052A1High color reproductionImprove charging effectElectrographic process apparatusDevelopersParticulatesLatent image

A carrier for developing electrostatic latent images produced in an image developer includes a magnetic particulate core material and a covering layer covering the surface of the core material. The image developer includes an image bearer, a developer bearer including comprising a magnetic field generator inside and a developer regulation member facing the surface of the image developer with a predetermined gap. The carrier has a bulk density of from 1.6 to 2.25 g / cm3, a BET specific surface area of from 0.5 to 2.0 m3 / g, a saturated magnetization (σ5000) not less than 70 emu / g at 5 kOe, and a residual magnetization (σr) not greater than 2 emu / g.

Owner:RICOH KK

Self-Primed Coating Formulation and Universal, Printable, Plastic Media Coated with the Formulation

InactiveUS20110200803A1Universal printabilityImprove performancePigmenting treatmentDuplicating/marking methodsUltravioletSolvent

Self-primed, printable formulations comprise:A. A polyurethane binder,B. An absorptive pigment,C. A crosslinker,D. An ultraviolet (UV) absorber,E. A light stabilizer, andF. Solvent.These formulations are coated to plastic substrates without the substrate first receiving a primer coating or other surface treatment to enhance print receptivity. These coatings provide a high performance, single layer, matte-finish, universal printable plastic media for use with a wide variety of printers and photocopiers. In one embodiment the single layer matte finish universal printable media is converted to a satin finish universal printable media by applying a gloss-promoting coating formulation over the single layer matte finish base layer.

Owner:BRADY WORLDWIDE INC

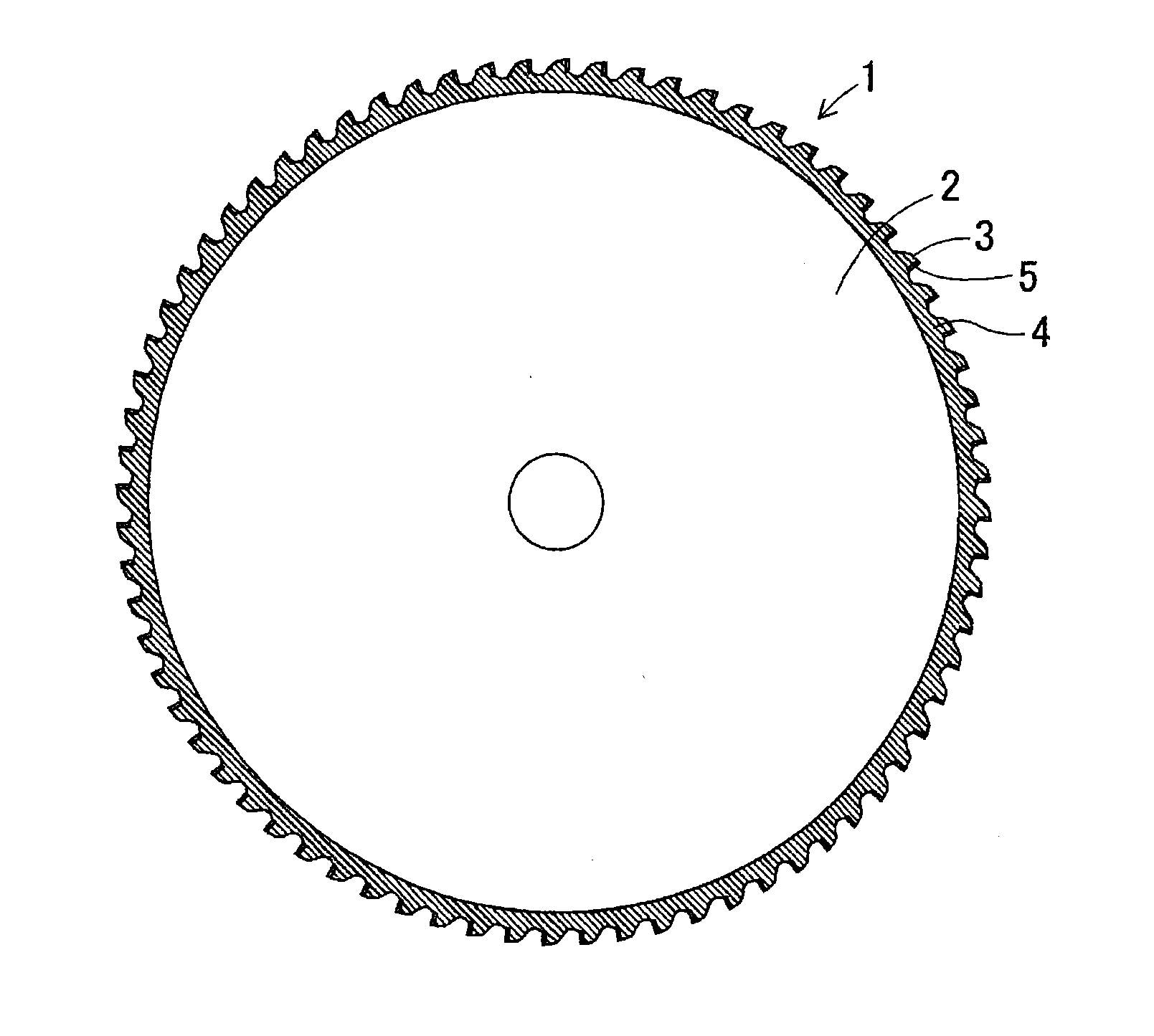

Method for manufacturing a tipped circular saw blade

InactiveUS20160082534A1High positioning accuracyImprove accuracyMetal sawing tool makingMetal sawing toolsCircular sawNitride

A method for manufacturing a tipped circular saw blade includes forming a disk-shaped metal base producing cutting edge tips by grinding cutting edges, coating the cutting edge tips with hard coating film, fixing the cutting edge tips coated with the hard coating film to teeth of the metal base by brazing. The hard coating film is of one material selected from a first material including one of nitrides, oxides or oxynitrides containing at least one of Al, Ti, and Cr, a second material including the first material containing at least one of Si, V, Ni, Y, Zr, Nb, Mo, Ta and W, a third material including the first material including at least one of B and C, and a fourth material including the second material containing at least one of B and C.

Owner:KANEFUSA HAMONO KOUGIYOU KK

Ultra soft fabric and process of manufacturing same

InactiveUS20190323152A1Improve balanceExcellent abrasion resistanceBed linenWoven fabricsHigh resistanceFiber

An ultra-soft fabric and a process of manufacturing the ultra-soft fabric is described. The ultra-soft fabric is made from polyester staple fiber and high-tenacity, man-made cellulosic staple fiber, and fabrics made therefrom, and has particular reference to fabrics having a high resistance to wear while retaining a high comfort level. Another embodiment improves the durability of the ultra-soft fabric.

Owner:RANGANATHAN VIJAYARAGAVAN

Low drag coating containing boron nitride powder

ActiveUS20140373965A1Excellent abrasion resistanceImprove corrosion resistanceOther chemical processesCorrosion preventionBoron nitrideWear resistance

The present invention relates to coatings having improved resistance to corrosion and / or abrasion. In one embodiment, the compositions disclosed herein comprise at least one resin material in combination with at least one type of boron nitride powder. In another embodiment, the compositions disclosed herein comprise at least one resin in combination with at least one type of boron nitride powder, wherein the amount of boron nitride powder in the coating material is in the range of about 1 weight percent to about 25 weight percent.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

Separating device for tubular flow-through devices

ActiveUS20120125601A1Excellent abrasion resistanceImprove erosion resistanceDispersed particle filtrationFluid removalWell drillingGeophysics

The invention relates to a separating device for tubular flow-through devices (22) which serve for the extraction of liquids or gases from wells drilled in rock or deep wells, the separating device being suitable for the removal of sand and rock particles and comprisingan annular stack (20) of brittle-hard annular disks, the disks (30) being stacked and braced in such a way that a separating gap (37) for the removal of sand and rock particles is present in each case between the individual disks (30),a coupling-on element (18, 19) at one or both ends of the annular stack (20),a clamping device at one or both ends of the annular stack (20), making it possible on the one hand to flexibly brace the brittle-hard disks (30) and on the other hand to variably fasten the annular stack (20) on the tubular flow-through device (22).

Owner:3M INNOVATIVE PROPERTIES CO +1

Curable Coating Compositions Providing Antistatic Abrasion Resistant Coated Articles

ActiveUS20110020604A1Avoid disadvantagesImparting antistatic and abrasion resistant propertiesMaterial nanotechnologySynthetic resin layered productsConductive polymerHydrolysis

Curable composition providing, upon curing, an abrasion resistant, transparent, antistatic coating comprising: —a) at least one conductive polymer, —b) colloidal particles of at least one non-conductive oxide, —c) at least one binder comprising at least one epoxysilane having at least two hydrolysable groups directly linked to the Si atom of the epoxysilane, and / or its hydrolysis product, said at least one conductive polymer and said colloidal particles of at least one non-conductive oxide being substantially not agglomerated, the content of said conductive polymer in the dry extract of said curable composition ranging from 0.1 to 10% by weight, preferably from 0.2 to 10% by weight and the content of the dry extract of said at least one epoxysilane in the dry extract of said curable composition ranging from 20 to 80%, preferably 25 to 60% by weight based on the total weight of the dry extract.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Inkjet ink composition and ink/receiver combination

InactiveUS7381755B2Good abrasionGood lightfastnessDuplicating/marking methodsFibre treatmentSURFACTANT BLENDPolymer chemistry

Owner:EASTMAN KODAK CO

Lubricant composition for chains, and chain

InactiveUS20100248879A1Excellent abrasion resistanceImprove the lubrication effectSolid fuelsLiquid carbonaceous fuelsWaxRoom temperature

A chain is constructed by alternately connecting a pair of outer link plates connected together with pins and a pair of inner link plates connected together with bushings into which adjacent pins of adjacent pairs of outer link plates are inserted. On the outer and inner surfaces of component parts of the chain, a lubricant composition for chains containing 95% to 80% by mass of a lubricant which is liquid at room temperature and 5% to 20% by mass of a wax which is solid at room temperature and having a consistency of from 60 to 475 and a dropping point of from 60° C. to 120° C., is adhered.

Owner:TSUBAKIMOTO CHAIN CO

Improved Asphaltic Concrete Compositions That Contain Anhydrite As Anti-Stripping Asphalt Agents

The present invention describes improved asphaltic concrete compositions resistant to the stripping, as well as their methods of obtaining. Also compositions that contain anhydrite are described that result to be useful like anti-stripping agents of asphaltic concretes. The described anti-stripping compositions allow to improve the properties of union of the asphaltic concrete compositions after their application, increasing with it the useful lifetime of coverings elaborated with these materials.

Owner:GCC TECH & PROCESSES

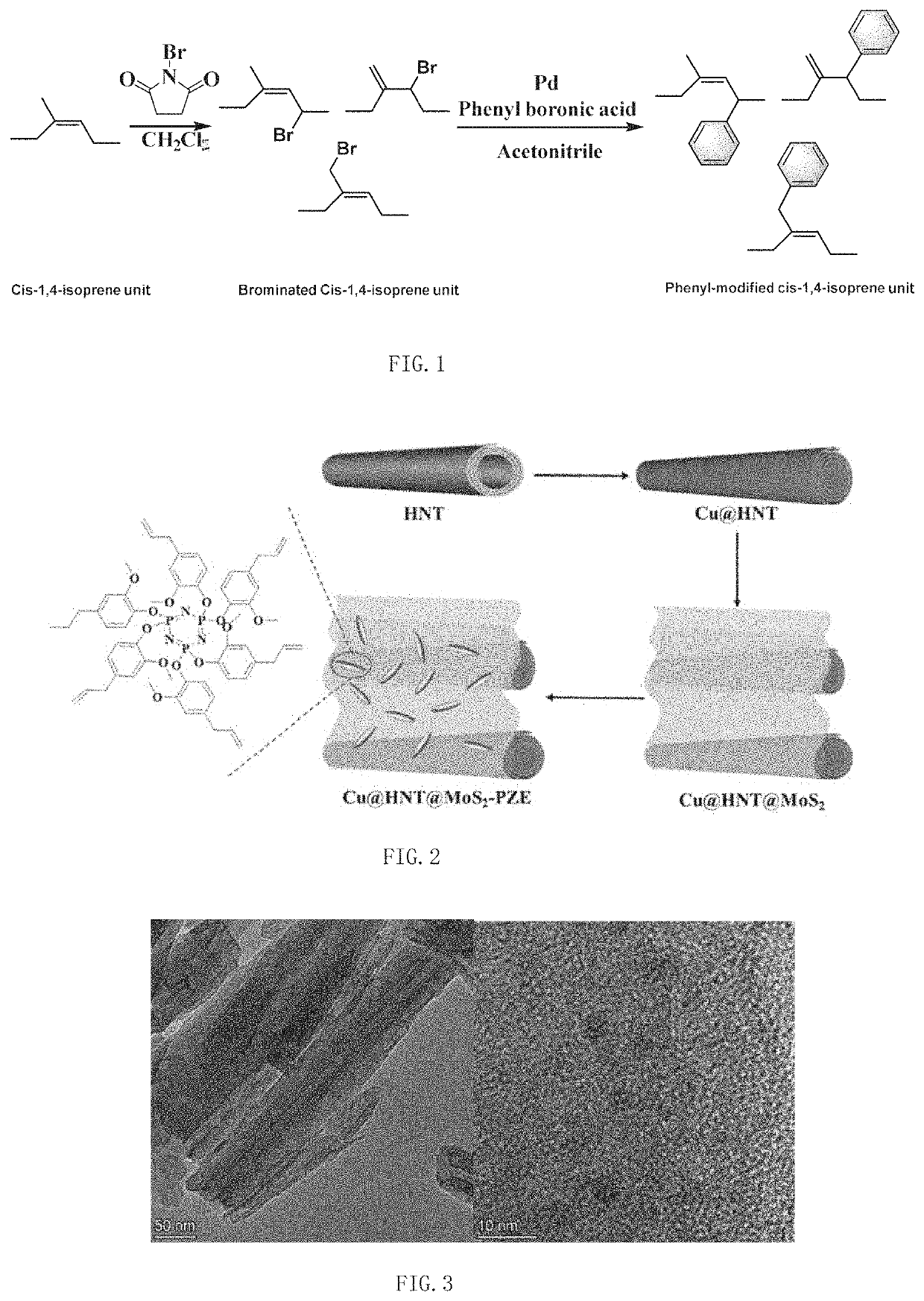

Vehicle tire rubber composite material

A vehicle tire rubber composite material, raw materials of the vehicle tire rubber composite material comprise the following components by weight: 30-40 weight distributions of solution-polymerized styrene-butadiene rubber, 35-55 weight distributions of rare earth butadiene rubber, 10-30 weight distributions of phenyl modified natural rubber, 5-14 weight distributions of polyurethane elastomer, 3-9 weight distributions of acetylene carbon black, 2-5 weight distributions of multifunctional abrasion-resistant flame retardant Cu@HNT@MoS2-PZE, 3-6 weight distributions of elastic fiber, 1-3 weight distributions of heat stabilizer, 2-3 weight distributions of silane coupling agent, 1-2.5 weight distributions of anti-scorching agent, 1-2.5 weight distributions of turpentine oil, and 4-6 weight distributions of accelerator.

Owner:XIAMEN UNIV +1

Surge-resistant and abrasion-resistant flexible insulating enamel

ActiveUS20110263772A1Excellent abrasion resistanceIncrease flexibilityPlastic/resin/waxes insulatorsPaper coatingDielectricOrganic solvent

A surge-resistant and abrasion resistant flexible insulating enamel has resin in an amount of 12 wt % to 76 wt % per 100 wt % by weight of the enamel, an organic solvent in an amount of 20 wt % to 80 wt % per 100 wt % by weight of the enamel, polyethylene oxide (PEO) intercalated clay in an amount of 0.005 wt % to 16 wt % per 100 wt % by weight of the enamel, and polysilicic acid in an amount of 0.995 wt % to 16 wt % per 100 wt % by weight of the enamel. The clay and polysilicic acid have high dielectric constant to absorb, evenly disperse and evacuate surges, preventing an insulating layer made by the insulating enamel from being damaged from the surge. PEO provides the insulating layer having good flexibility and adhesion.

Owner:FU PAO CHEM

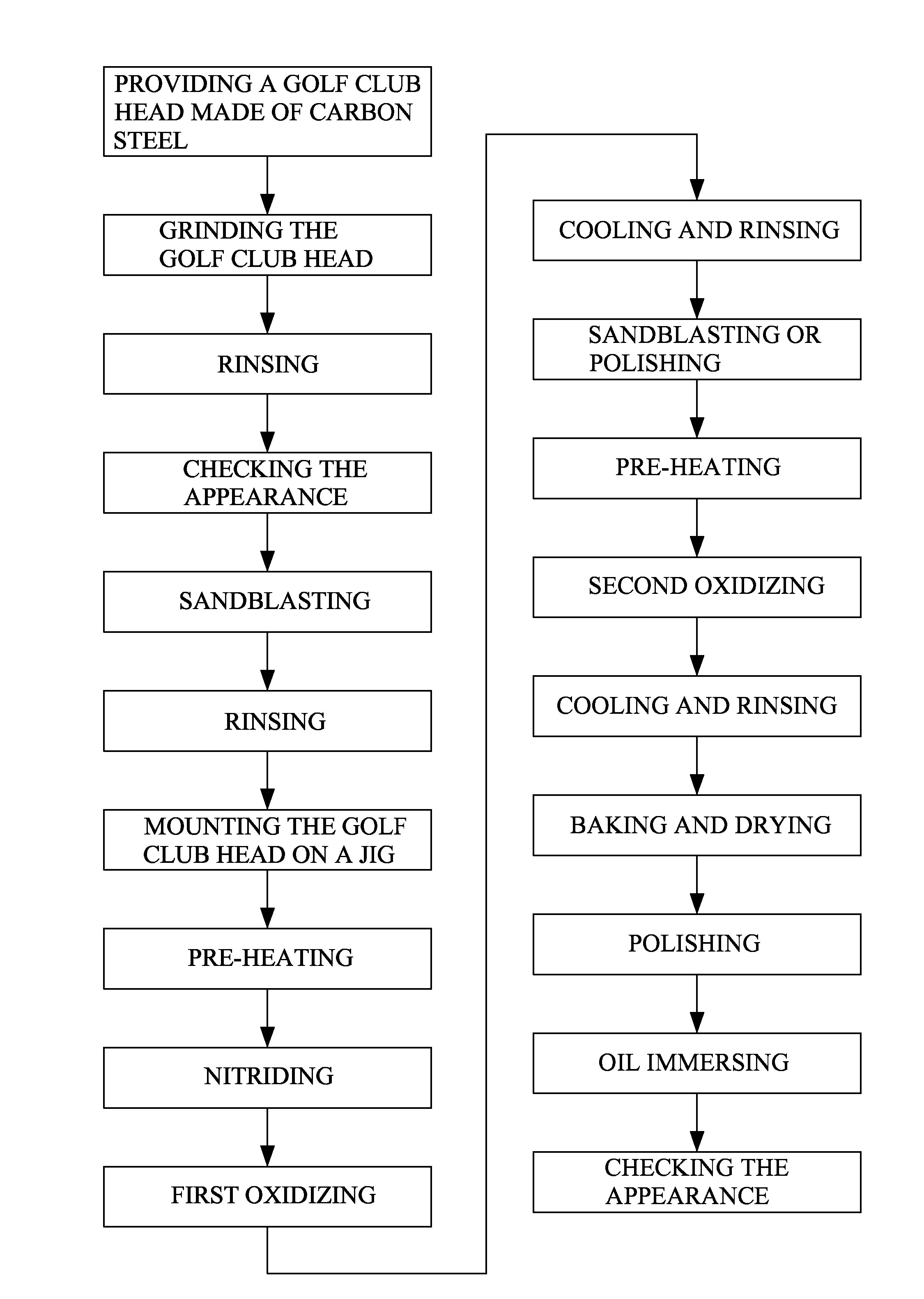

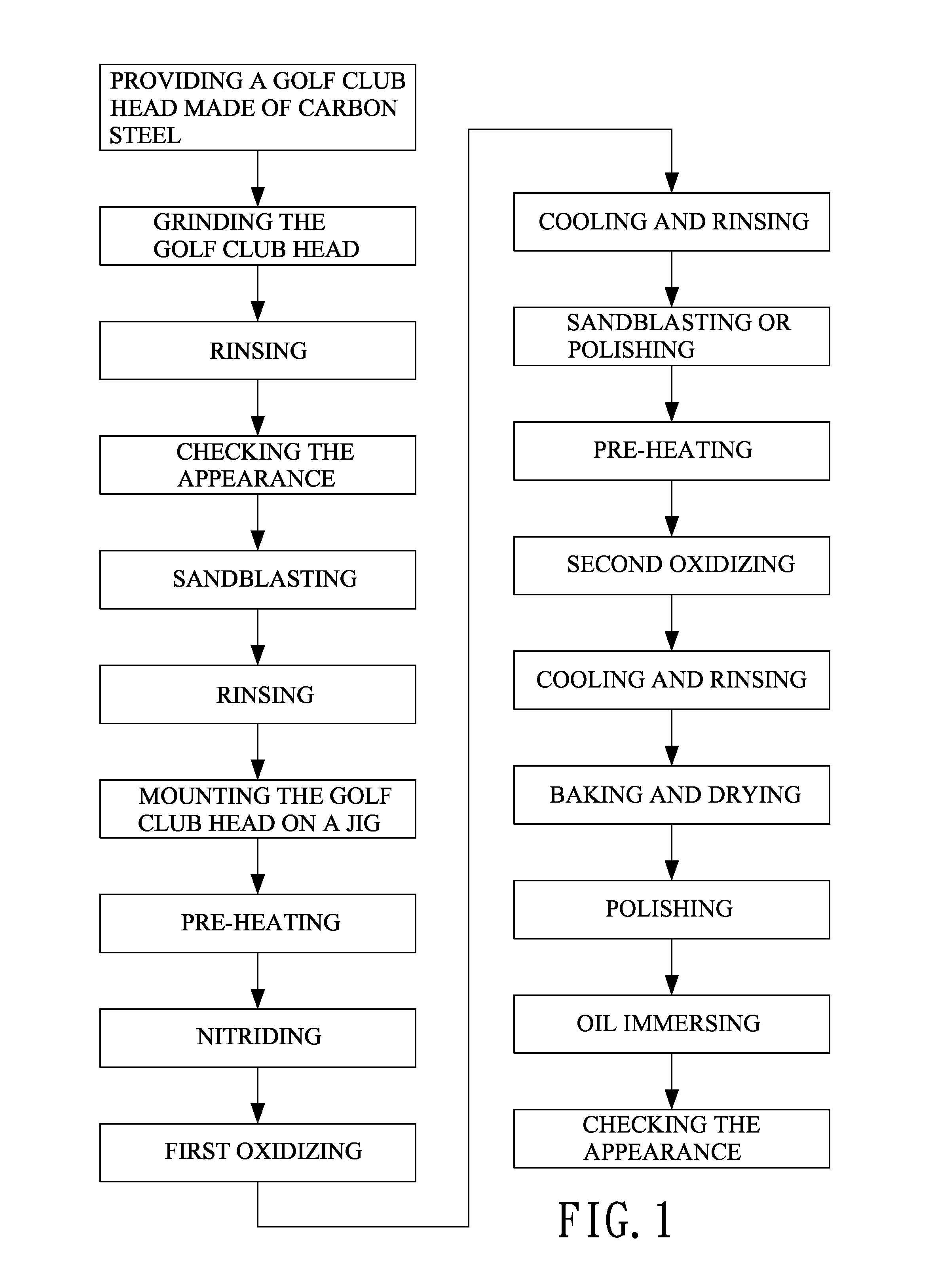

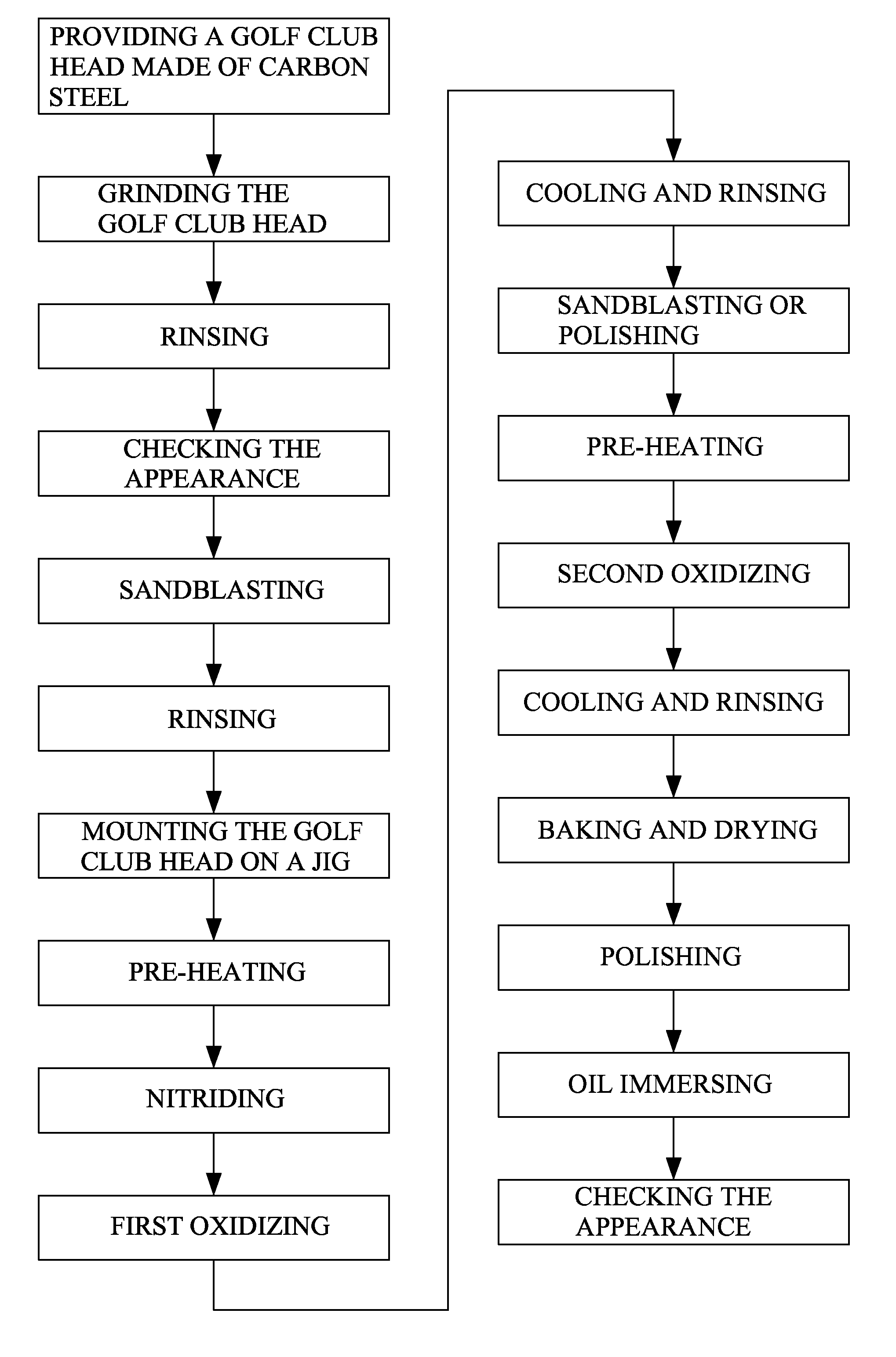

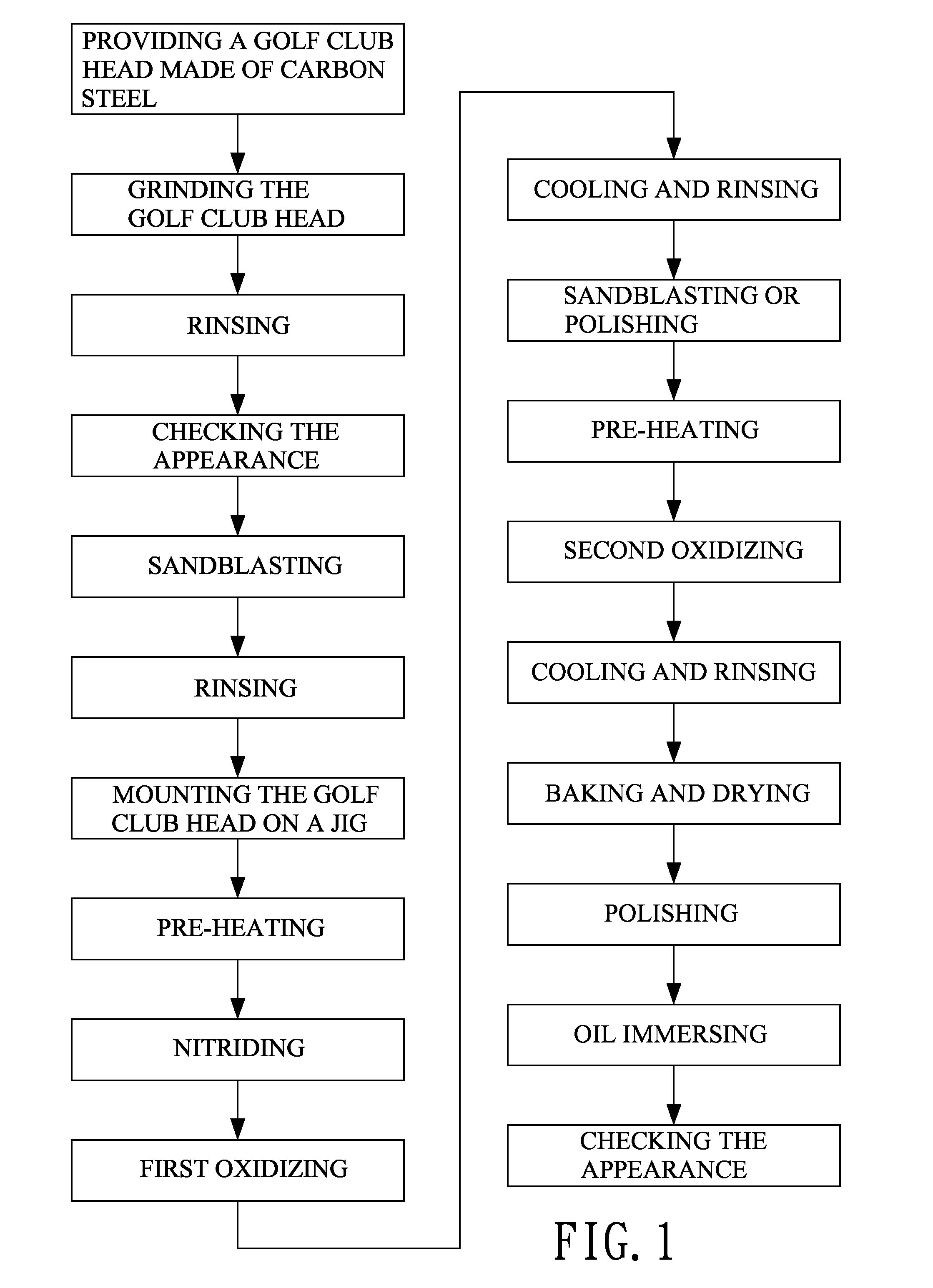

Surface treating method for a golf club head

ActiveUS20150047747A1Good abrasionIncrease resistanceSolid state diffusion coatingAbrasive machine appurtenancesAbrasive blastingEngineering

A surface treating method for a golf club head made of carbon steel basically has one nitriding step and two oxidizing steps. The method further has polishing, sandblasting and rinsing steps and so on processed prior to or between the basic steps, and then has polishing and oil immersing steps and so on processed after the basic steps. The finished golf club head has uniform dark appearance and also has good corrosion resistance and abrasion resistance. Furthermore, the surface of the finished golf club head does not peel off. Moreover, the method also has advantages including low pollution and low cost.

Owner:SU CHI HUNG

Surface treating method for a golf club head

InactiveUS20140141698A1Excellent abrasion resistanceImprove corrosion resistanceGolf clubsRacket sportsSand blastingEngineering

A surface treating method for a golf club head made of carbon steel basically has one nitriding step and two oxidizing steps. The method further has polishing, sandblasting and rinsing steps and so on processed prior to or between the basic steps, and then has polishing and oil immersing steps and so on processed after the basic steps. The finished golf club head has uniform dark appearance and also has good corrosion resistance and abrasion resistance. Furthermore, the surface of the finished golf club head does not peel off. Moreover, the method also has advantages including low pollution and low cost.

Owner:SU CHI HUNG

Low drag coating containing boron nitride powder

ActiveUS9689074B2Maintain good propertiesImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationBoron nitrideWear resistance

The present invention relates to coatings having improved resistance to corrosion and / or abrasion. In one embodiment, the compositions disclosed herein comprise at least one resin material in combination with at least one type of boron nitride powder. In another embodiment, the compositions disclosed herein comprise at least one resin in combination with at least one type of boron nitride powder, wherein the amount of boron nitride powder in the coating material is in the range of about 1 weight percent to about 25 weight percent.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com