Active carbon fiber containing nano titanium dioxide particles and its preparation method and uses

A nano-titanium dioxide, activated carbon fiber technology, applied in chemical instruments and methods, chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of secondary pollution, difficult recycling, easy coagulation, etc. Solve the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

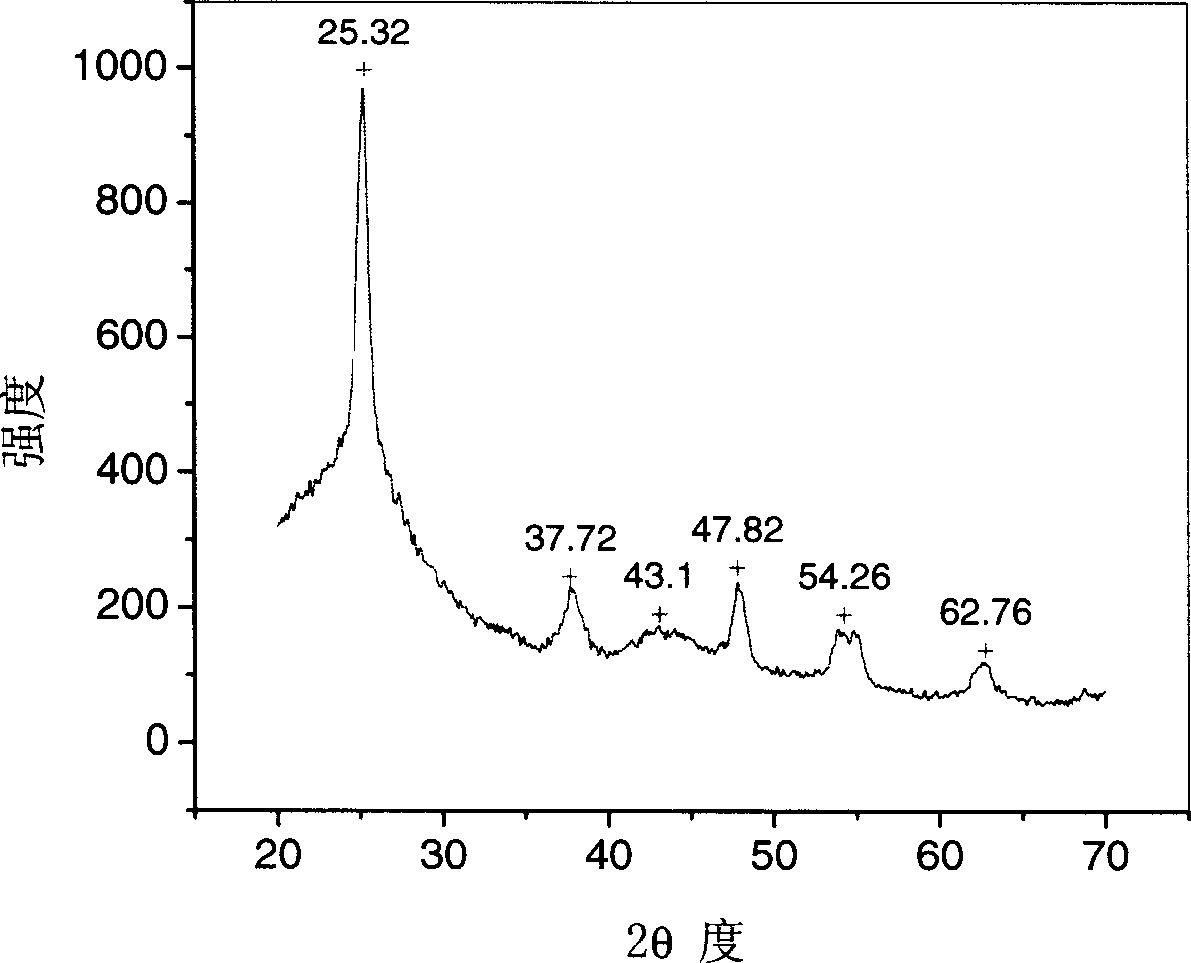

[0020] Mix butyl titanate and n-propanol in a mass ratio of 1:3, and after fully mixing, add 0.5 parts by mass of sisal-based activated carbon fiber, soak for 0.5 hours, add 10 parts by mass of water, and dissolve the solvent after complete hydrolysis and water are removed by evaporation, the fibers are taken out, dried at 90° C., and then sintered at 500° C. to obtain activated carbon fibers loaded with titanium dioxide, wherein nanometer titanium dioxide particles account for 5% of the total mass. The product is analyzed by the scanning electron microscope, and the carbon layer on the surface is inlaid with uniform spherical particles, and the particle size is about 10nm. The particles were analyzed by X-ray diffraction and proved to be anatase titanium dioxide crystals.

Embodiment 2

[0022] Mix butyl titanate with n-propanol and viscose-based activated carbon fiber in a mass ratio of 1:6:0.1. After mixing thoroughly, add 10 parts of water to hydrolyze butyl titanate, and then evaporate the solvent and water under low pressure. Remove, take out the fibers, dry at 90°C, and then sinter at 850°C to obtain activated carbon fibers loaded with titanium dioxide, in which nanometer titanium dioxide particles account for 25% of the total mass. The product is analyzed by a scanning electron microscope, and its surface carbon layer is inlaid with dense particles, and the particle size is about 200nm. The particles were analyzed by X-ray diffraction and proved to be anatase titanium dioxide crystals.

Embodiment 3

[0024] Mix butyl titanate with n-propanol and pitch-based activated carbon fibers at a mass ratio of 1:7:0.1, and mix them evenly by ultrasonic oscillation, then add 2 parts of water to hydrolyze butyl titanate, and dry the fibers at 100°C, then After sintering at 500 DEG C, activated carbon fibers loaded with titanium dioxide are obtained, wherein nanometer titanium dioxide particles account for 20% of the total mass. The product is analyzed by a scanning electron microscope, and its surface carbon layer is inlaid with dense particles, and the particle size is about 10nm. The particles were analyzed by X-ray diffraction and proved to be anatase titanium dioxide crystals. Activated carbon fibers without titanium dioxide and TiO 2 The comparison of the pore structure of the loaded activated carbon fibers shows that the specific surface area, total pore volume, and average diameter of micropores of the activated carbon fibers after loading are slightly smaller than those before...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com