Application of charcoal-based magnetic adsorption material or product thereof in adsorption of liquid chemicals

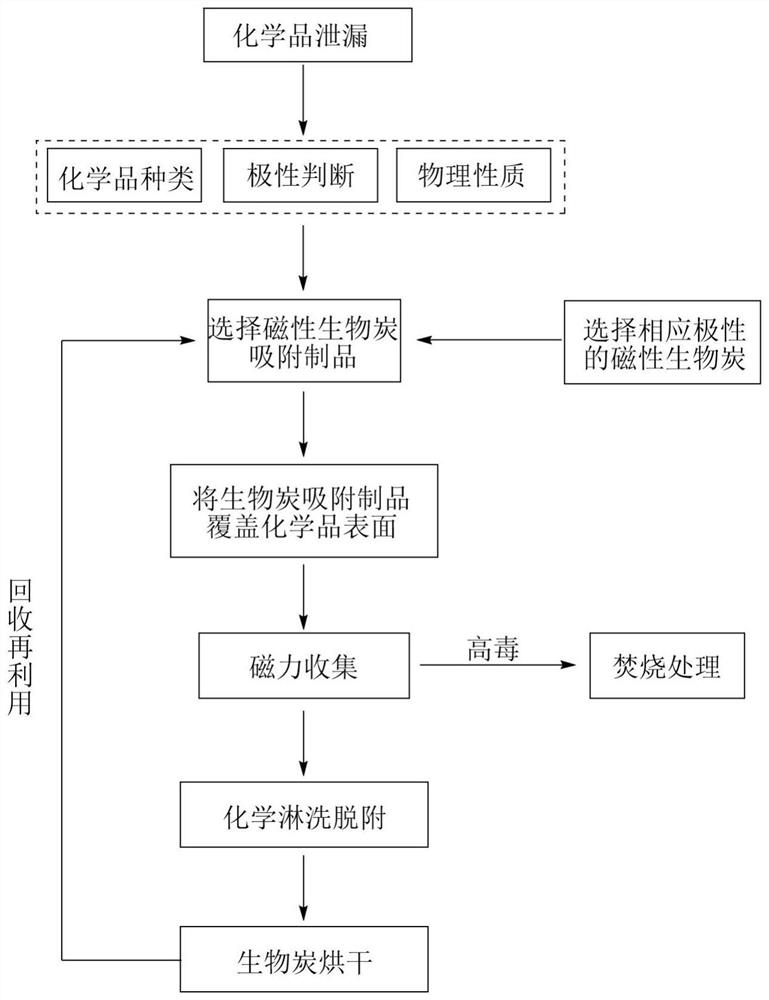

A magnetic adsorption material, biochar technology, applied in other chemical processes, inorganic chemistry, selective adsorption, etc., can solve the problems of inability to effectively block continuous pollution, unsuitable for large-scale use, slow response time, etc. Adjustable, easy-to-get, quick-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

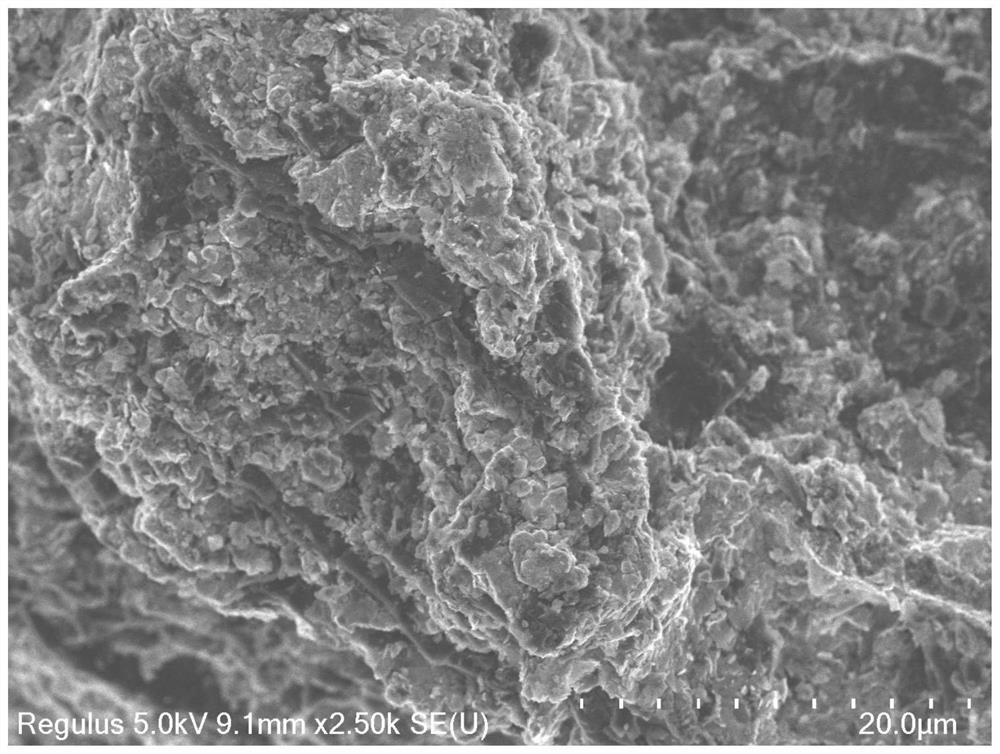

[0053] A biochar emergency adsorption material capable of magnetically recovering non-polar chemicals is prepared by the following steps:

[0054] (1) The collected straw was washed with deionized water to remove dirt, and then dried in an oven at 80°C for 24 hours; subsequently, these samples were pulverized into powder with a pulverizer, and passed through a 20-mesh mechanical sieve.

[0055] (2) Add 2g K 2 FeO 4 Add it into a beaker with 50mL of deionized water, stir to dissolve; pour 10.0g of straw powder into the above K 2 FeO 4 solution, mechanically stirred for 10 h; then the mixed solution was placed in a water bath and continuously stirred at 80°C to obtain a paste; subsequently, it was transferred to an oven and dried at 100°C for 12 hours.

[0056] (3) The obtained solid mixture was pulverized and passed through a 20-mesh sieve, and pyrolyzed in a tube furnace at a specified temperature of 700°C for 2 hours, with a heating rate of 5°C min -1 , both heating and p...

Embodiment 2

[0059] A biochar emergency adsorption material capable of magnetically recovering non-polar chemicals is prepared by the following steps:

[0060] (1) The collected straw was washed with deionized water to remove dirt, and then dried in an oven at 80°C for 24 hours; subsequently, these samples were pulverized into powder with a pulverizer, and passed through a 20-mesh mechanical sieve.

[0061] (2) Add 2g K 2 FeO 4 Add it into a beaker with 50mL of deionized water, stir to dissolve; pour 10.0g of straw powder into the above K 2 FeO 4 solution, mechanically stirred for 10 h; then the mixed solution was placed in a water bath and continuously stirred at 80°C to obtain a paste; subsequently, it was transferred to an oven and dried at 100°C for 12 hours.

[0062] (3) The obtained solid mixture was pulverized and passed through a 20-mesh sieve, and pyrolyzed in a tube furnace at a specified temperature of 600 ° C for 2 hours, and the heating rate was 5 ° C min -1 , both heating...

Embodiment 3

[0071] A biochar emergency adsorption material capable of magnetically recovering polar chemicals is prepared by the following steps:

[0072] (1) The collected straw was washed with deionized water to remove dirt, and then dried in an oven at 80°C for 24 hours; subsequently, these samples were pulverized into powder with a pulverizer, and passed through a 20-mesh mechanical sieve.

[0073] (2) Add 2g K 2 FeO 4 Add it into a beaker with 50mL of deionized water, stir to dissolve; pour 10.0g of straw powder into the above K 2 FeO 4 solution, mechanically stirred for 10 h; then the mixed solution was placed in a water bath and continuously stirred at 80°C to obtain a paste; subsequently, it was transferred to an oven and dried at 100°C for 12 hours.

[0074] (3) The obtained solid mixture was pulverized and passed through a 20-mesh sieve, and pyrolyzed in a tube furnace at a specified temperature of 300°C for 2 hours, with a heating rate of 5°C min -1 , both heating and pyrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com