Far infrared radiation nano material and preparation thereof

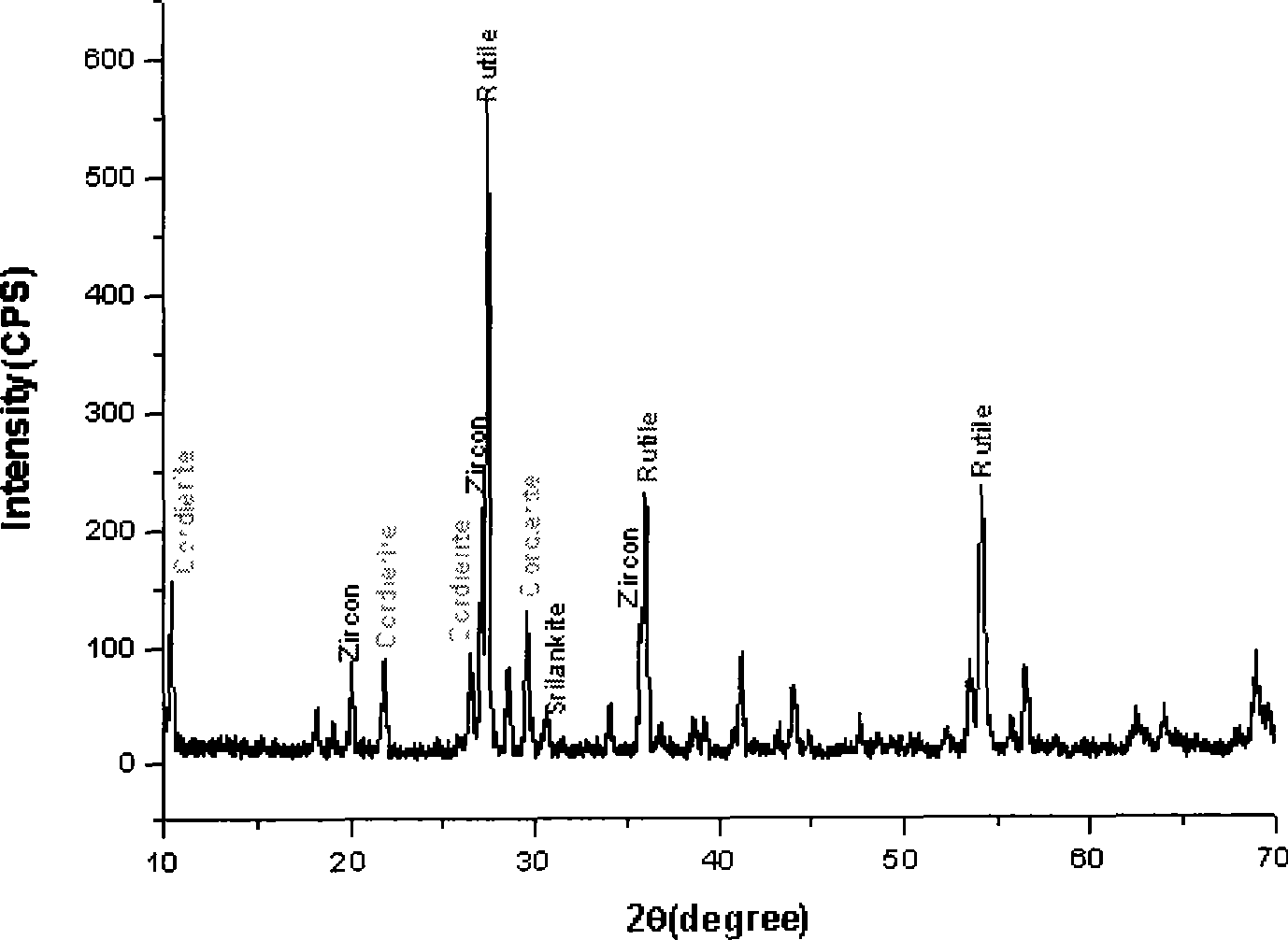

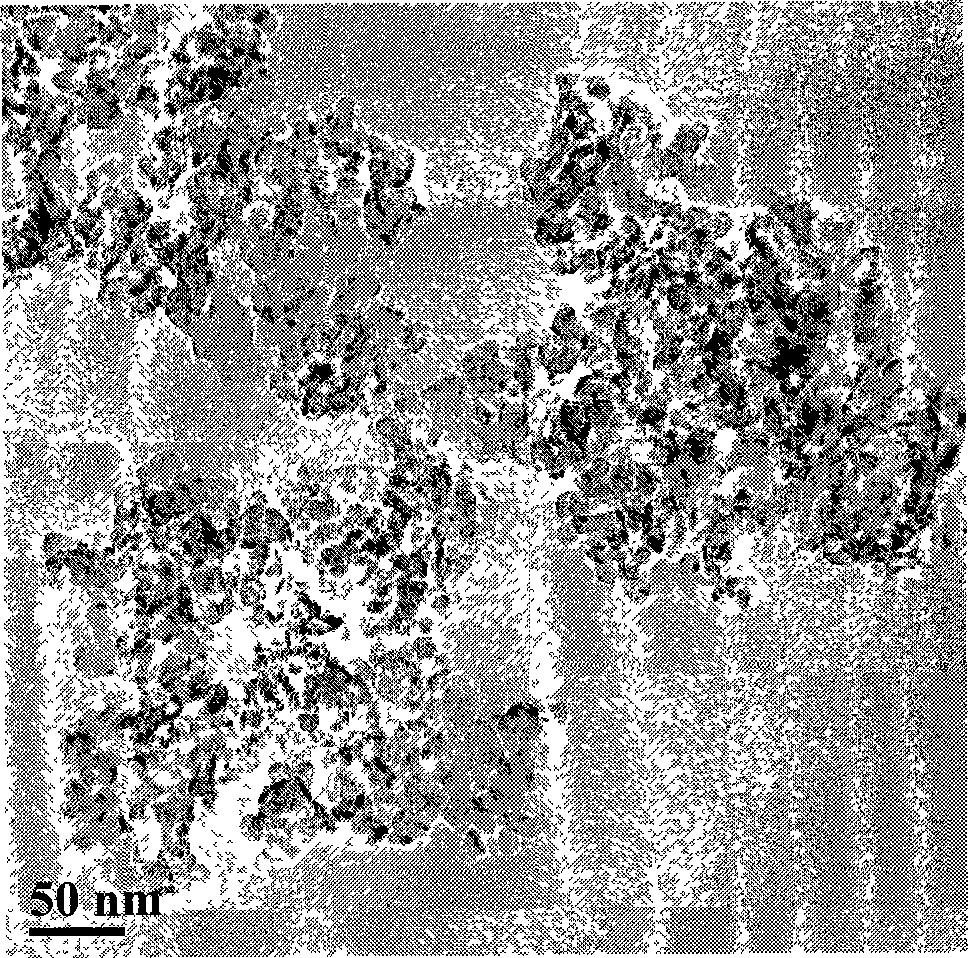

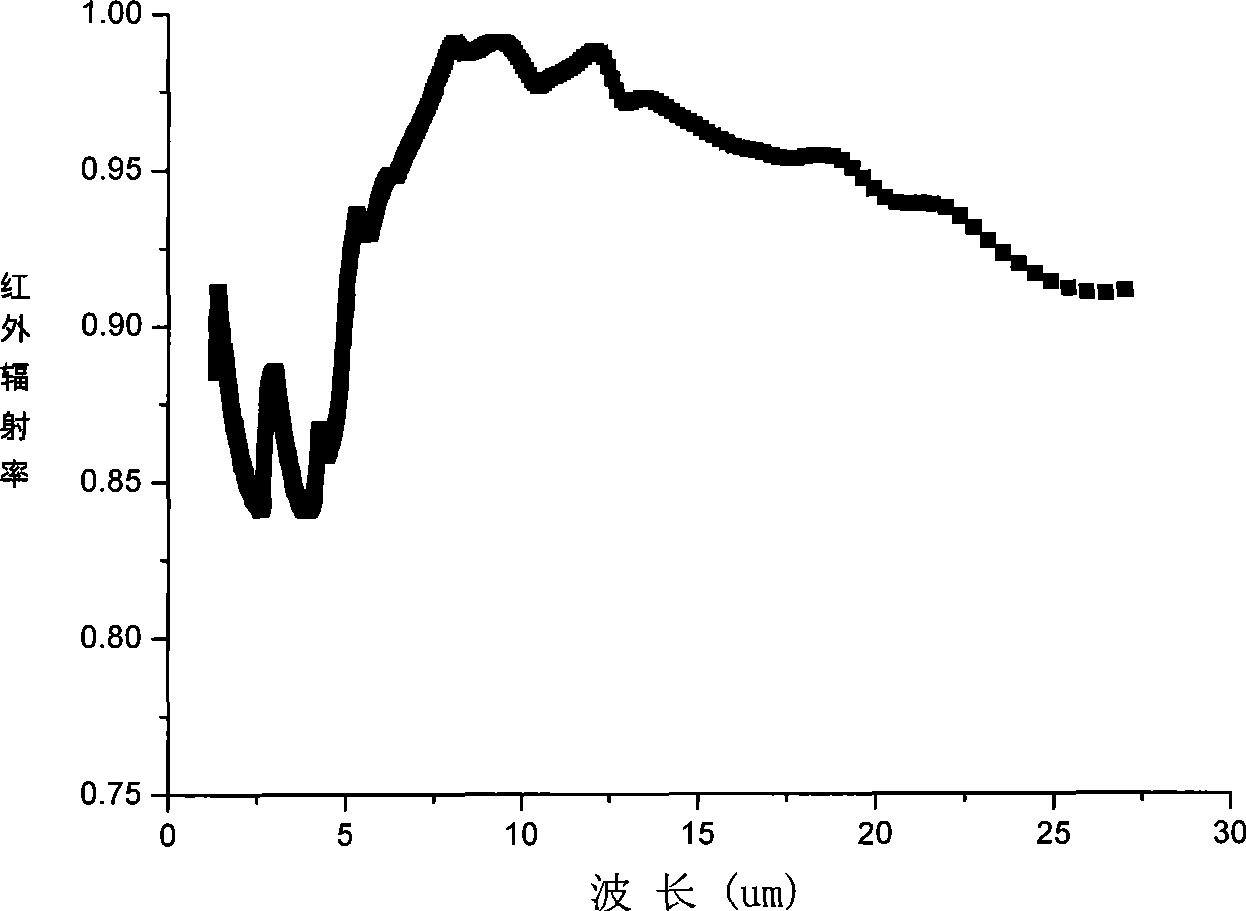

A technology of far-infrared radiation and nanomaterials, applied in the field of far-infrared radiation nanomaterials and their preparation, can solve the problems of narrow half-width of energy distribution, poor uniformity of powder composition, large particle size, etc. The effect of increasing infrared emissivity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 2.048g magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 O), 7.5g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 3.22g zirconium oxychloride (ZrOCl 2 ·6H 2 O), 0.476g nickel chloride (NiCl 2 2H 2 O) be dissolved in the mixed solvent of 5ml deionized water and 15ml absolute ethanol, get the Y(NO of 10ml0.01mol / L 3 ) 3 The solution was added thereto, and 20 g of dispersant polyethylene glycol (PEG) was added at the same time, the pH was adjusted to 2-3 with ammonia water, and heated and stirred at a temperature of 70° C. until a clear solution was obtained. Weigh 13.6g of tetrabutyl titanate and dissolve in 20ml of absolute ethanol, add 2g of citric acid as a complexing agent, and 5ml of ethylene glycol as a polymerization aid. At the same time, 8.32 g of tetraethyl orthosilicate was dissolved in 15 ml of absolute ethanol, 2 g of citric acid was added as a complexing agent, and 5 ml of ethylene glycol was used as a polymerization aid and dispersant. Add the above-mentioned et...

Embodiment 2

[0025] Weigh 1.830g magnesium chloride (MgCl 2 ·6H 2 O), 0.270g ferric chloride (FeCl 3 ·6H 2 O), 9.486g titanium chloride, 8.495g silicon tetrachloride, no nickel chloride added. Finally, the powder is calcined at 1250°C, and the composition is (Mg 0.9 Fe 0.1 ) O·Al 2 o 3 ·5SiO2 2 ·5TiO 2 · ZrO 2 0.01Y 2 o 3 . Other conditions are with embodiment 1.

Embodiment 3

[0027] Weigh 0.238g nickel chloride (NiCl 2 2H 2 O), 0.404g ferric nitrate (FeCl 3 9H 2 O). Other conditions are with embodiment 1, obtain infrared radiation powder material, and its component is (Mg 0.8 Ni 0.1 Fe 0.1 ) O·Al 2 o 3 4SiO2 2 4TiO 2 · ZrO 2 0.01Y 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com