Isocyanate modified graphene containing heat-dissipating coating material and preparation method

A heat-dissipating coating and isocyanate technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of inapplicability of fast-volatile coatings, slow volatilization speed, and poor heat-dissipating effect of coatings. The effect of conduction, excellent thermal conductivity, high infrared emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

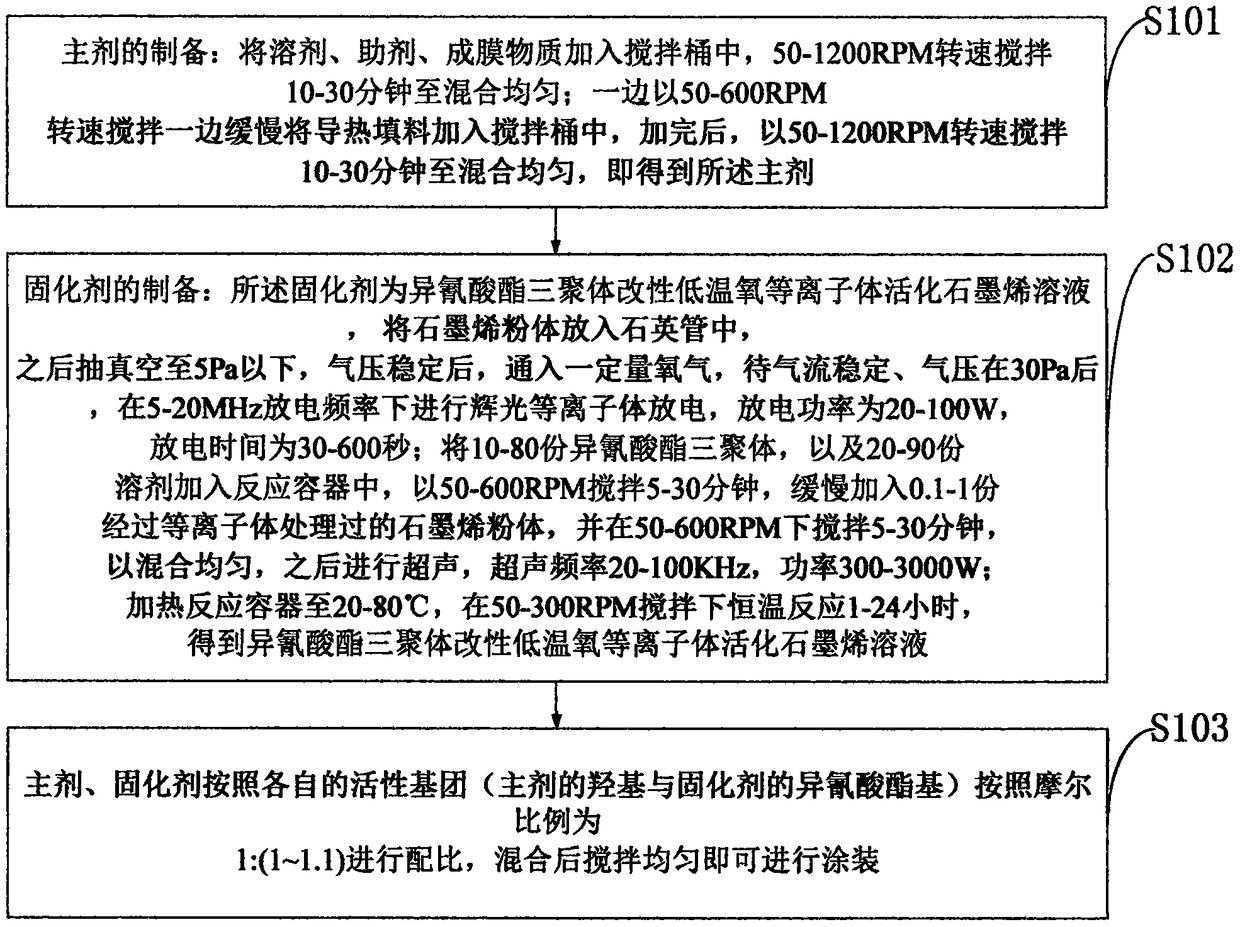

[0057] figure 1 It is the preparation method of the heat dissipation coating containing isocyanate modified graphene provided by the embodiment of the present invention, comprising:

[0058] S101: Preparation of the main ingredient: Add solvent, additives, and film-forming substances into the mixing bucket, and stir at 50-1200RPM for 10-30 minutes until the mixture is uniform; while stirring at 50-600RPM, slowly add the thermally conductive filler into the mixing bucket , after the addition is complete, stir at a speed of 50-1200 RPM for 10-30 minutes until the mixture is evenly mixed to obtain the main ingredient.

[0059] S102: Preparation of a curing agent: the curing agent is an isocyanate trimer modified low-temperature oxygen plasma activated graphene solution, the graphene powder is put into a quartz tube, and then vacuumed to below 5Pa. After the air pressure is stabilized, pass Inject a certain amount of oxygen, after the gas flow is stable and the air pressure is 3...

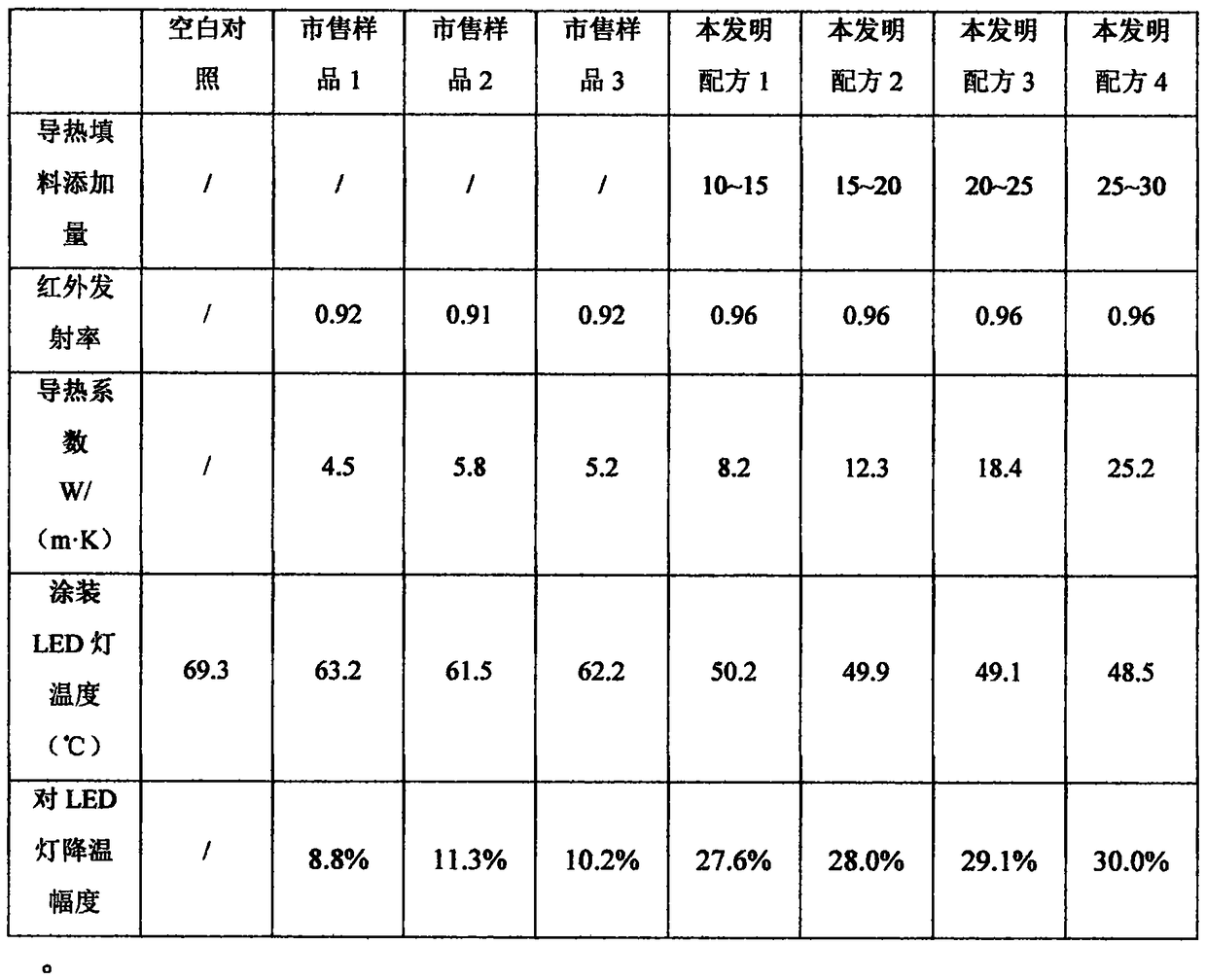

Embodiment 1

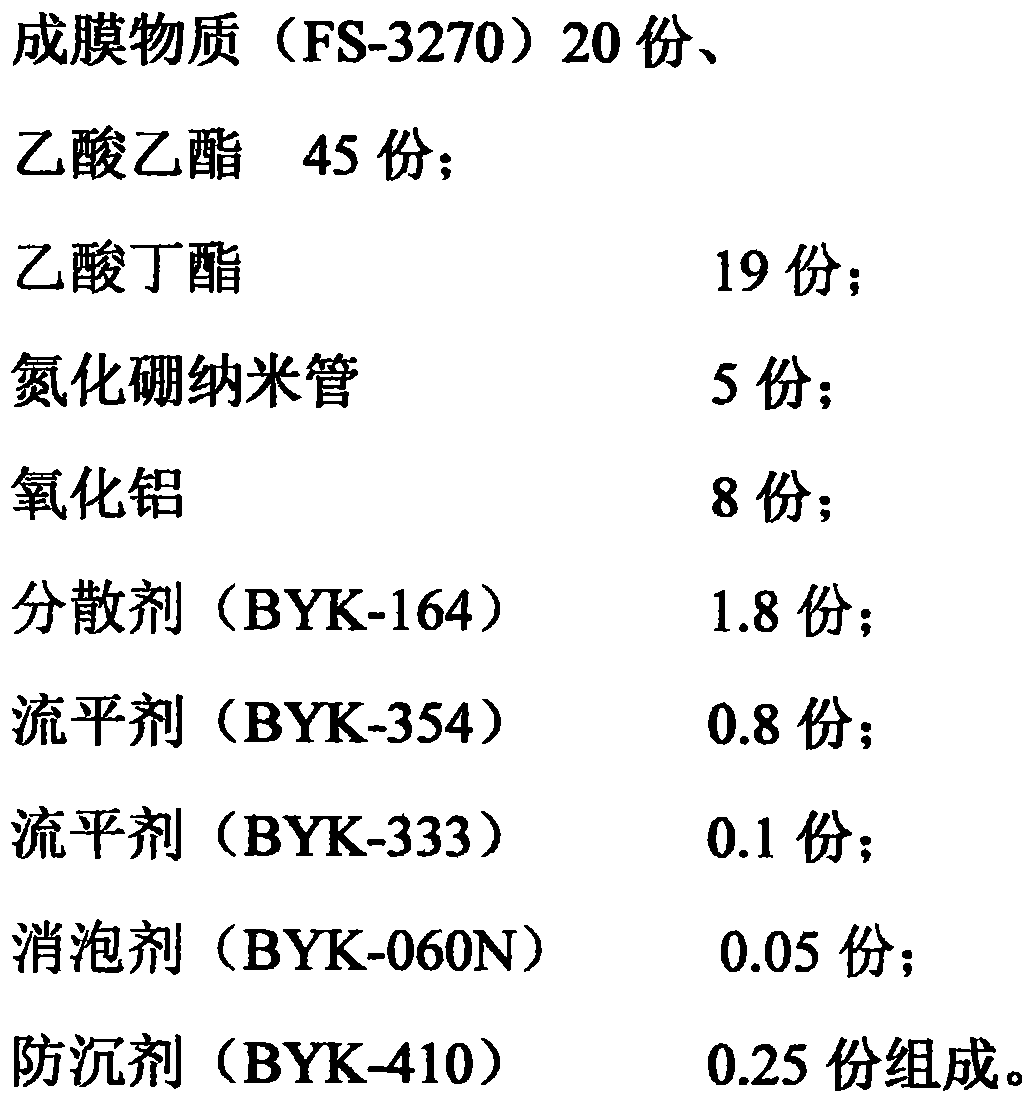

[0073] The main agent of the heat-dissipating coating containing isocyanate-modified graphene provided by the embodiments of the present invention is composed of:

[0074]

[0075] Deploy as follows:

[0076] Step 1: Add the solvent, additives, and film-forming substances into the mixing tank, and stir at 600 RPM for 20 minutes until the mixture is uniform.

[0077] Step 2: While stirring at 300 RPM, slowly add boron nitride nanotubes and aluminum oxide into the mixing tank. After the addition, stir at 900 RPM for 30 minutes until uniformly mixed to obtain the main ingredient.

[0078] The curing agent of the heat-dissipating coating containing isocyanate-modified graphene provided by the embodiments of the present invention is composed of:

[0079] 1 part of monolayer graphene;

[0080] 40 parts of hexamethylene diisocyanate trimer;

[0081] 59 parts of butyl acetate;

[0082] Deploy as follows:

[0083] Step 1, put the single-layer graphene powder into the quartz tub...

Embodiment 2

[0088] The main agent of the heat-dissipating coating containing isocyanate-modified graphene provided by the embodiments of the present invention is composed of:

[0089]

[0090] The deployment method is the same as in Example 1.

[0091] The curing agent of the heat-dissipating coating containing isocyanate-modified graphene provided by the embodiments of the present invention is composed of:

[0092] 1 part of monolayer graphene;

[0093] Toluene diisocyanate trimer 40 parts

[0094] Butyl acetate 59 parts composition.

[0095] The deployment method is the same as in Example 1.

[0096] Calculate the blending ratio of the main agent and the curing agent, and prepare according to the molar ratio of hydroxyl group and isocyanate group as 1:1.1, and spray to control the dry film thickness of the coating within 10-20 microns, and the spraying is completed within 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com