Composite graphene infrared radiation and heat conduction film and manufacturing method thereof

A graphene composite, infrared radiation technology, applied in the direction of semiconductor devices, conjugated diene coatings, semiconductor/solid-state device parts, etc. Device function failure and other problems, to achieve the effect of good infrared heat radiation ability, improve heat conduction efficiency, and good heat conduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

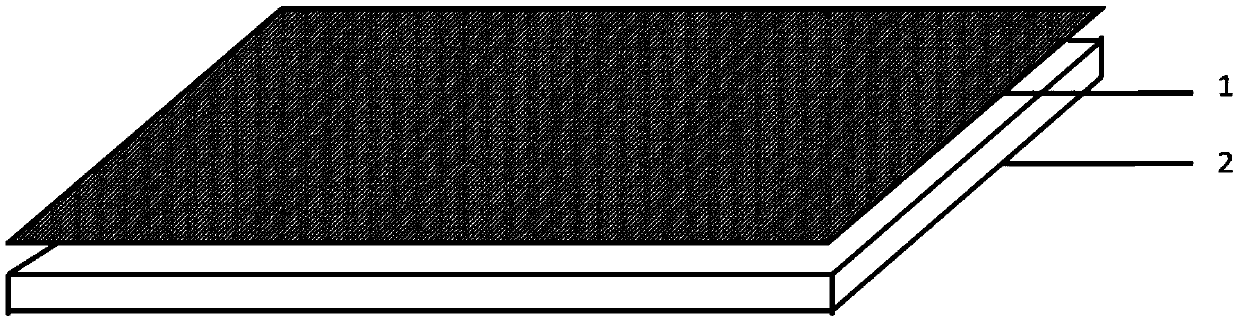

Image

Examples

Embodiment 1

[0029] The present embodiment makes graphene composite infrared radiation heat conduction film according to the following steps:

[0030] (1) Mix 10 parts of graphene, 5 parts of diamond powder, 2 parts of sodium dodecylbenzenesulfonate, 10 parts of epoxy resin and 73 parts of water, and carry out ultrasonic dispersion for 2 hours to obtain a mixed slurry; then use high shear Emulsify the mixed slurry at room temperature for the first time, the emulsification speed is 16000rpm, and the emulsification time is 6h; then put the slurry after the first emulsification into a ball mill for wet grinding for 24h, and pass the ground slurry through a 200-mesh sieve; finally use high-shear Carry out secondary normal temperature emulsification on the sieved slurry, the emulsification speed is 16000rpm, and the time is 3h, that is, the graphene composite infrared radiation coating is obtained;

[0031] (2) Coating the graphene composite infrared radiation coating obtained in step (1) onto ...

Embodiment 2

[0034] The present embodiment makes graphene composite infrared radiation heat conduction film according to the following steps:

[0035] (1) Mix 20 parts of graphene, 8 parts of alumina, 5 parts of sodium dodecylbenzenesulfonate, 15 parts of epoxy resin and 52 parts of water, and carry out ultrasonic dispersion for 2 hours to obtain a mixed slurry; then use high shear Emulsify the mixed slurry at room temperature for the first time, the emulsification speed is 16000rpm, and the emulsification time is 8h; then put the slurry after the first emulsification into the ball mill for wet grinding for 24h, and pass the ground slurry through a 200-mesh sieve; finally use high-shear Carry out secondary room temperature emulsification on the sieved slurry, the emulsification speed is 16000rpm, and the time is 4h, that is, the graphene composite infrared radiation coating is obtained;

[0036] (2) Coating the graphene composite infrared radiation coating obtained in step (1) onto a 20 μm...

Embodiment 3

[0039] The present embodiment makes graphene composite infrared radiation heat conduction film according to the following steps:

[0040] (1) Mix 10 parts of graphene, 5 parts of silicon carbide, 3 parts of sodium dodecylbenzenesulfonate, 10 parts of epoxy resin and 72 parts of water, and perform ultrasonic dispersion for 2 hours to obtain a mixed slurry; then use high shear Emulsify the mixed slurry at room temperature for the first time, the emulsification speed is 16000rpm, and the emulsification time is 6h; then put the slurry after the first emulsification into a ball mill for wet grinding for 24h, and pass the ground slurry through a 200-mesh sieve; finally use high-shear Carry out secondary normal temperature emulsification on the sieved slurry, the emulsification speed is 16000rpm, and the time is 3h, that is, the graphene composite infrared radiation coating is obtained;

[0041] (2) Apply the graphene composite infrared radiation coating obtained in step (1) to a 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com