Heat pipe type solid-liquid phase transition heat accumulator

A solid-liquid phase change, phase change heat storage technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of slow heat storage and heat release process, insufficient reliability, and insufficient heat transfer area and other problems, to achieve the effect of rapid heat storage and heat release process, improve work reliability, and improve the distribution of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Carry out further detailed description below in conjunction with accompanying drawing:

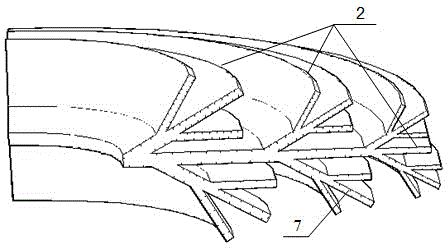

[0025] For easy observation, figure 1 A 1 / 4 perspective view of the fork-shaped heat pipe heat accumulator of the present invention is given. A heat pipe heat accumulator with a fork-like structure is composed of a box body 1, fins 2, and a phase-change heat storage material 3. The box body 1 includes two parts, the main channel 4 and the shell 5, and the cold / hot fluid 11 flows through the main channel to exchange heat with the heat accumulator. A thermal insulation material 6 is placed on the surface of the shell 5; a phase-change thermal storage material 3 is filled in the gap between the box body 1 and the fins 2. The fins 2 are arranged around the main passage 4, and multi-layer fins are arranged along the axial direction of the main passage. The fins 2 extend radially and form branch fins.

[0026] figure 2 A schematic diagram of the structure of the fork-shaped heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com