Etching device and etching method for reducing side erosion angle of circuit board

An etching device and circuit board technology, which is applied in chemical/electrolytic methods to remove conductive materials, printed circuits, printed circuit manufacturing, etc., can solve problems affecting the precise wiring of circuit boards, achieve high integration, improve wiring accuracy and Density, the effect of reducing the degree of side erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

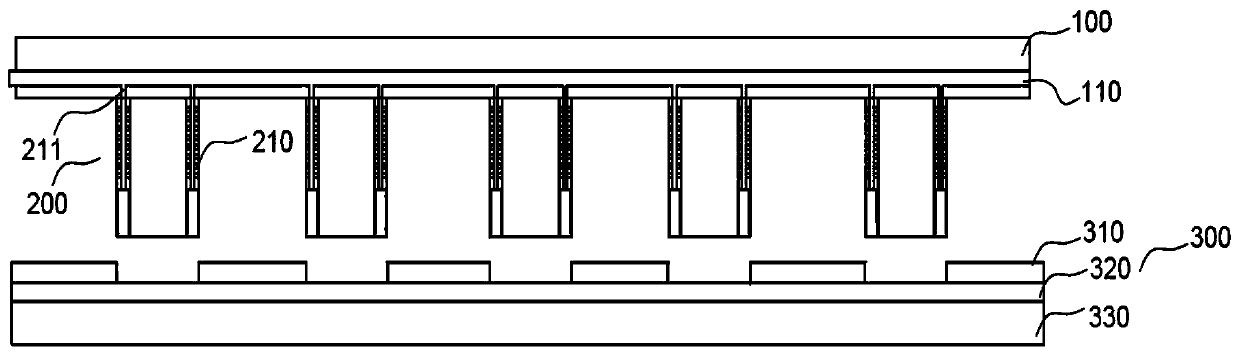

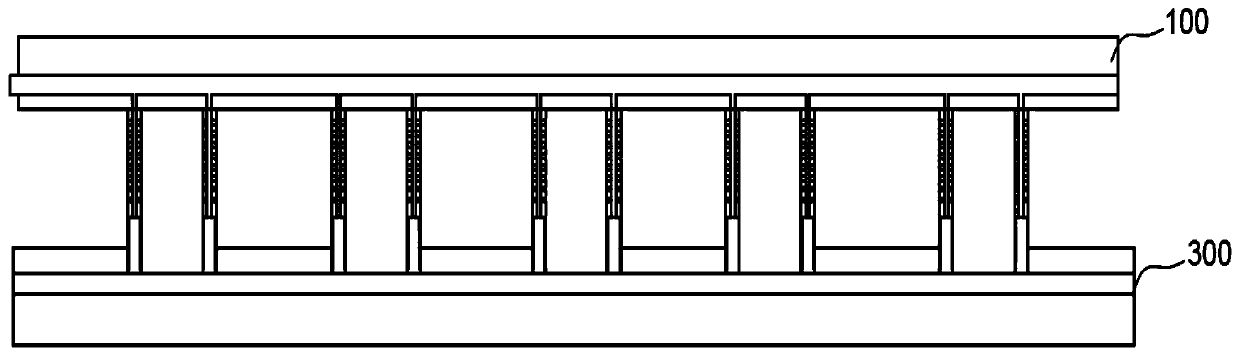

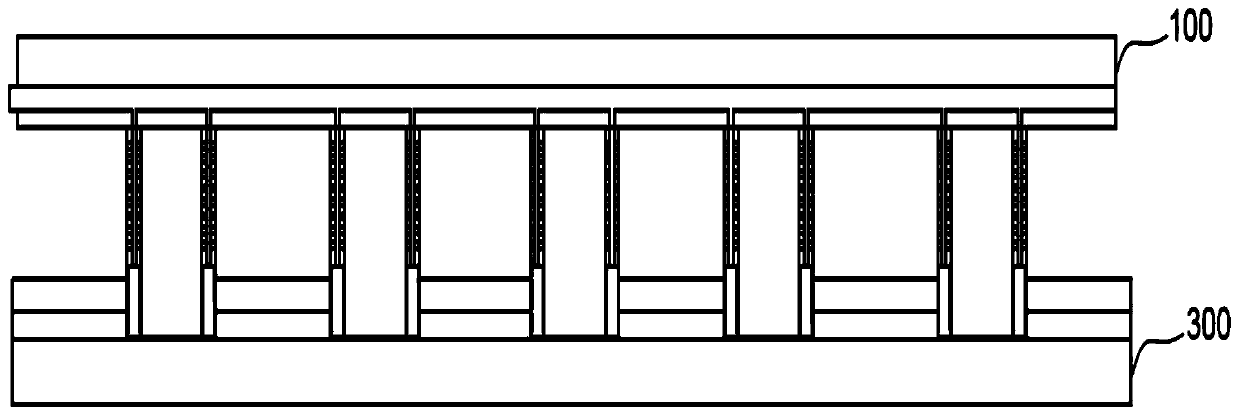

[0036] The invention provides an etching device for reducing the inclination angle of side erosion of a circuit board, such as Figure 1-4 As shown, it includes a mask plate, a press plate 100 and a protective sleeve 200, wherein the mask plate is movably arranged on the upper end of the circuit board 300 to be etched, and is used to mask the photoresist on the circuit board 300, and the mask plate The stencil is provided with a number of through holes. After masking, exposure, and development, the photoresist 310 in the corresponding area of the through holes is removed to expose the part of the conductor to be etched, and then the exposed conductor is etched, and the remaining conductor That is the conductive line.

[0037] The pressing plate 100 is movably arranged on the upper end of the mask plate. After the masking is completed, the mask plate can be removed, and the mask plate can be kept in place. A first channel 110 is arranged laterally in the pressing plate 100 . ...

Embodiment 2

[0045] An etching method of an etching device for reducing the side erosion inclination of a circuit board 300, comprising the following steps:

[0046] Step 1, apply photoresist on the conductive layer of the circuit board 300 to be etched, dry, mask, expose, develop, and show the channel of the photoresist, that is, expose the conductive layer to be etched;

[0047] Step 2: According to the shape and position of the through hole of the mask plate, assemble each side plate 210 at the bottom of the platen 100, so that the shape and position of each protective sleeve 200 are consistent with the shape and position of the through hole of the mask plate, and one through hole corresponds to A protective sleeve 200 with the same shape and location;

[0048] Step 3. The mask can be removed or kept in place, and the platen 100 can be moved laterally to align each of the protective sleeves 200 with the through holes on the mask and the holes on the photoresist. The channels are aligne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com