Etching solution for processing N-type silicon microchannel array by photon-assisted electrochemical etching method

A silicon microchannel, electrochemical technology, applied in the field of etching solution, can solve the problems of silicon microchannel pore size becoming larger, difficult to control, difficult to obtain a large aspect ratio silicon microchannel structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

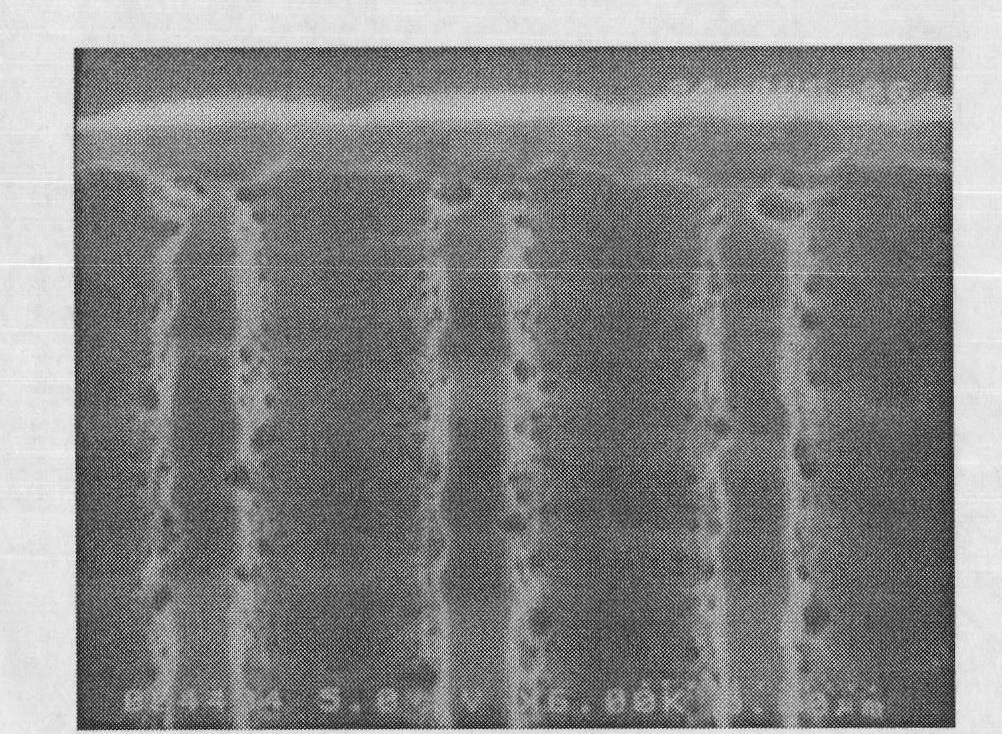

[0009] The preparation raw material of corrosion solution: take 200ml 40wt% hydrofluoric acid, 180ml absolute ethanol, 1800ml deionized water, mix to obtain hydrofluoric acid, ethanol aqueous solution, in this aqueous solution, the concentration of hydrofluoric acid is 4.30wt%, and the concentration of ethanol is 6.53 % by weight; additionally add 10ml of AOS, ie sodium α-olefin sulfonate, as anionic surfactant, the addition amount is 0.46% of the volume of the hydrofluoric acid and ethanol aqueous solution.

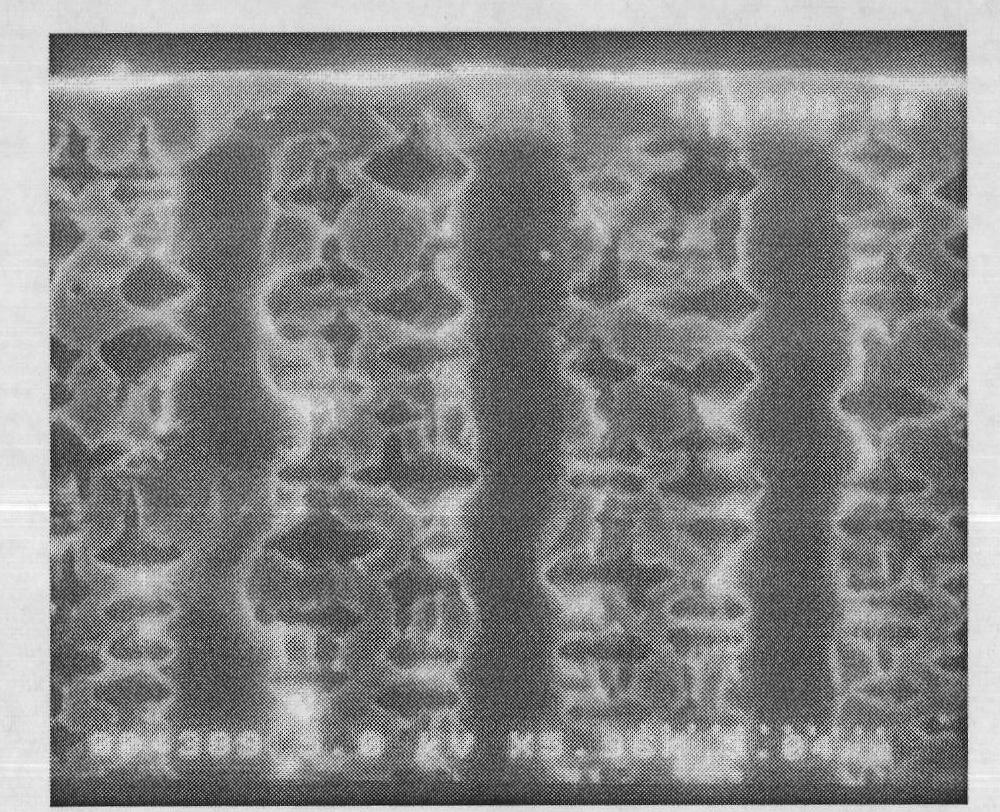

[0010] Processing of the silicon microchannel array: the light source adopts an area array of light-emitting diodes with a wavelength of 850nm and a size of 18×18, and the total power is 32.4W. The silicon wafer is an N-type crystalline silicon wafer with a resistivity of 2-4Ωcm. Under the irradiation of the light source, the holes required for the corrosion reaction are excited, anodized for 10 hours, and the average etching rate is 32 μm / hour, and a silicon microchann...

Embodiment 2

[0012] The preparation raw material of corrosion solution: take 220ml 40wt% hydrofluoric acid, 180ml absolute ethanol, 1800ml deionized water, mix to obtain hydrofluoric acid, ethanol aqueous solution, in this aqueous solution, the concentration of hydrofluoric acid is 4.68wt%, and the concentration of ethanol is 6.46 wt%; Add 20ml of AES in addition, i.e. fatty alcohol polyoxyethylene ether sodium sulfate, as anionic surfactant, the addition amount is 0.91% of the volume of the hydrofluoric acid and ethanol aqueous solution.

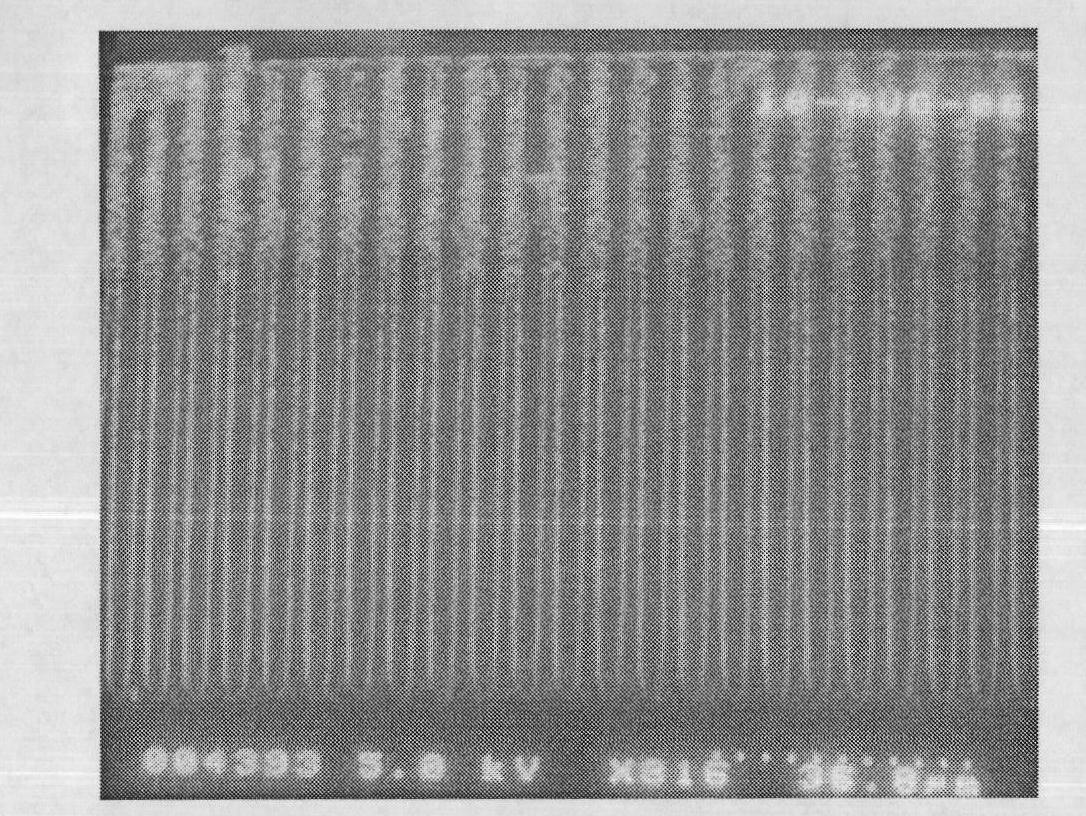

[0013] Processing of the silicon microchannel array: the light source adopts an area array of light-emitting diodes with a wavelength of 850nm and a size of 18×18, and the total power is 32.4W. The silicon wafer is an N-type crystalline silicon wafer with a resistivity of 2-4Ωcm. Under the irradiation of the light source, the holes required for the corrosion reaction are excited, anodized for 10 hours, and the etching rate is 34.5 μm / hour, and a macrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com