Combined titanium anode for hexavalent chromium electroplating and preparation method thereof

A technology of hexavalent chromium and titanium anodes, applied in the direction of electrodes, can solve the problems of plating solution pollution, poor anode stability, accelerated dissolution, etc., and achieve the effect of good plating solution stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

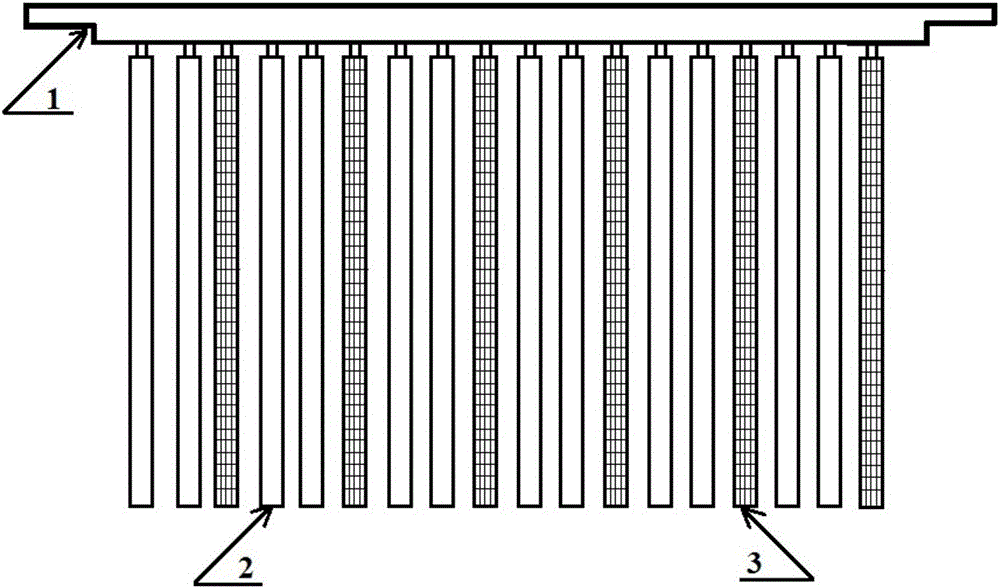

[0039] A method for preparing a combined titanium anode for hexavalent chromium electroplating, comprising the following steps;

[0040] Step 1. After the pretreatment of the titanium substrate, Ta 2 o 5 , IrO 2 -Ta 2 o 5 , IrO 2 -Ta 2 o 5 -SnO 2 and IrO 2 -SnO 2 A titanium-based noble metal oxide anode 2 containing a coating is made, and the other titanium substrate is pre-treated, and SnO is first burnt 2 -Sb 2 o 5 , then plated PANI-doped PbO 2 Layer made of titanium-based base metal oxide anode 3 containing coating;

[0041] The titanium-based noble metal oxide anode 2 containing the coating made in step 1 is specifically;

[0042] Step 1.1. After the titanium substrate is sandblasted, put it into 10wt% NaOH solution and boil it to remove oil, then pickle it in boiling oxalic acid solution for at least 1 hour to remove scale, and finally wash it with tap water, deionized water and alcohol in sequence. After washing, dry for later use;

[0043] Step 1.2, mix...

Embodiment 1

[0058] A method for preparing a combined titanium anode for hexavalent chromium electroplating, comprising the following steps;

[0059] Step 1, making a titanium-based noble metal oxide anode 2 containing a coating is specifically;

[0060] Step 1.1. After the titanium substrate is sandblasted, put it into 10wt% NaOH solution and boil it to remove oil, then pickle it in boiling oxalic acid solution for at least 1 hour to remove scale, and finally wash it with tap water, deionized water and alcohol in sequence. After washing, dry for later use;

[0061] Step 1.2, mix n-butanol and isopropanol at a volume ratio of 1:1 to make n-butanol-isopropanol mixed solvent, which is used to dissolve the precious metal precursor and configure it as a coating solution;

[0062] Step 1.3, 20g / L TaCl 5 The n-butanol-isopropanol coating liquid is coated on the dried titanium substrate, dried at 120°C for 10 minutes, and then fired at 500°C for 15 minutes, and the above coating-drying-calcinat...

Embodiment 2

[0073] Example 2 is the same as Example 1, except that the combination ratio of A1 and B1 is 3:1 to obtain a combined titanium anode P2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com