Methanesulfonic acid tin-plating solution

A technology of methanesulfonic acid and tin plating solution, which is applied in the field of methanesulfonic acid tin plating solution, can solve problems such as unintroduced product quality, and achieve the effect of good coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

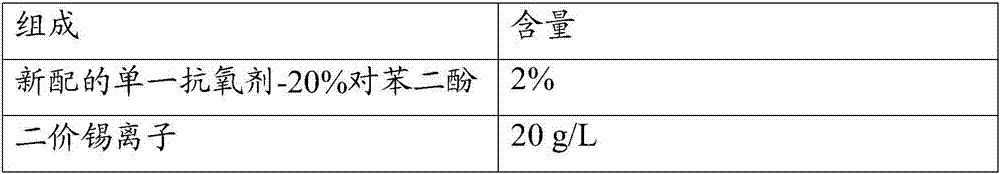

Embodiment 1

[0045] Prepare the electroplating solution with the composition and content shown in the table below. First add water to the plating tank, then add methanesulfonic acid, antioxidant, divalent tin ions and grain refiner accordingly, and finally circulate for half an hour to obtain a uniform electroplating solution.

[0046]

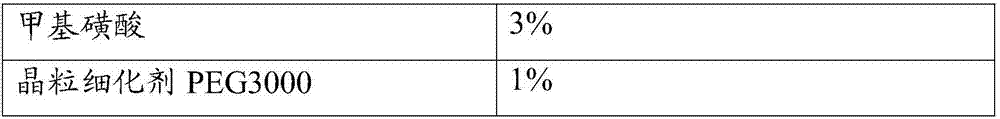

Embodiment 2

[0048] Prepare the electroplating solution with the composition and content shown in the table below. First add water to the plating tank, then add methanesulfonic acid, antioxidant, divalent tin ions and grain refiner accordingly, and finally circulate for half an hour to obtain a uniform electroplating solution.

[0049]

[0050]

Embodiment 3-7

[0065] Using the same tin plating solution formula as in Example 1, the tin plating solution of Example 3-7 was prepared, the difference is only in the auxiliary antioxidant (2R, 3S)-2-(3,4-dihydroxyphenyl)-3 , The content of 4-dihydro-2H-chromene-3,5,7-triol in the compound antioxidant is shown in the table below, and the sum of the content of hydroquinone and auxiliary antioxidant Still at 20%.

[0066]

[0067] Similarly, the amount of tin sludge produced in the tin plating solution of Examples 3-7 was tested, and it was found that the produced tin sludge was at a similar level to that of Example 1, both of which were lower than those of Comparative Examples 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com