High-performance beryllium-copper alloy and preparation method thereof

A beryllium-copper alloy, high-performance technology, applied in the field of high-performance beryllium-copper alloy and its preparation, can solve the problems that restrict the application of beryllium-copper castings and forgings, and achieve the effect of improving yield rate, improving mechanical comprehensive performance, and increasing unit weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

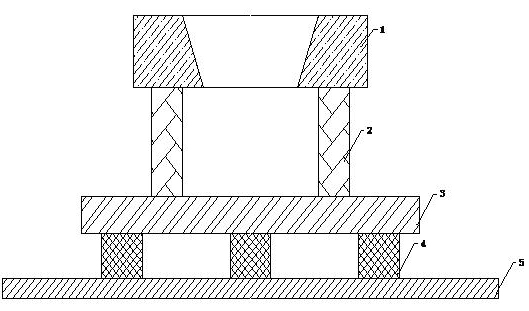

Image

Examples

Embodiment 1

[0018] The high-performance beryllium-copper alloy of the present invention comprises 2 beryllium, 0.45 total of cobalt and nickel, 0.08 of yttrium, 0.06 of titanium, 0.1 of boron, 0.1 of magnesium, and copper of the balance by weight percentage; wherein, beryllium is added in the form of a beryllium-copper master alloy, Beryllium accounts for the percentage weight of beryllium-copper alloy 4, cobalt and nickel are also added in the form of master alloys of cobalt-copper alloy and nickel-copper alloy respectively, cobalt and nickel account for the percentage weight of alloy 10 respectively, titanium is added in the form of titanium-copper master alloy, and titanium % by weight of Alloy 5, yttrium is added as a yttrium-copper master alloy, and yttrium is added by weight % of Alloy 10.

[0019] As the preparation method of above-mentioned high-performance beryllium-copper alloy, comprising the following steps:

[0020] (1) Smelting: First put the electrolytic copper Co-Cu master...

Embodiment 2

[0028] Embodiment two: the high-performance beryllium-copper alloy of the present invention comprises beryllium 1.6 by weight percentage, cobalt and nickel total 0.35, yttrium 0.03-0.1, titanium 0.03, boron 0.1, magnesium 0.1, the copper of balance; Wherein, beryllium is copper beryllium Add in the form of master alloy, beryllium accounts for 3.8% of beryllium-copper alloy, cobalt and nickel are also added in the form of master alloy of cobalt-copper alloy and nickel-copper alloy, cobalt and nickel account for 8% of the alloy respectively, and titanium takes titanium Copper master alloy is added, titanium accounts for 4% by weight of the alloy, and yttrium is added in the form of yttrium-copper master alloy, and yttrium accounts for 8% by weight of the alloy.

[0029] As the preparation method of above-mentioned high-performance beryllium-copper alloy, comprising the following steps:

[0030] (1) Smelting: add cobalt-copper master alloy, nickel-copper master alloy, and 60% ber...

Embodiment 3

[0036] Embodiment three: the high-performance beryllium-copper alloy of the present invention comprises beryllium 2.2 by weight percentage, cobalt and nickel total 0.65, yttrium 0.03-0.1, titanium 0.1, boron 0.3, magnesium 0.3, the copper of balance; Wherein, beryllium is copper beryllium Add in the form of master alloy, beryllium accounts for 4.2% of beryllium-copper alloy, cobalt and nickel are also added in the form of master alloy of cobalt-copper alloy and nickel-copper alloy, cobalt and nickel account for 12% of the alloy respectively, and titanium takes titanium Copper master alloy is added, titanium accounts for 6% by weight of the alloy, and yttrium is added in the form of yttrium-copper master alloy, and yttrium accounts for 12% by weight of the alloy.

[0037] The preparation method of the above-mentioned high-performance beryllium-copper alloy is characterized in that, comprising the following steps:

[0038] (1) Melting: add cobalt-copper master alloy, nickel-copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com