Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111 results about "Beryllium-Copper Alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A white colored, crystalline, inorganic compound composed of beryllium and copper in which beryllium increases the alloys thermal and electrical conductivity. This alloy emits toxic fumes of beryllium oxides upon heating. Beryllium-copper alloy is used in the electronics industry for numerous applications. Inhalation exposure to its dust and fumes irritates the nose, throat and lungs and can cause pneumonitis. Prolonged exposure can result in a chronic beryllium disease called berylliosis causing granuloma and fibrosis formation in the lungs. Beryllium is associated with an increased risk of developing lung cancer. (NCI05)

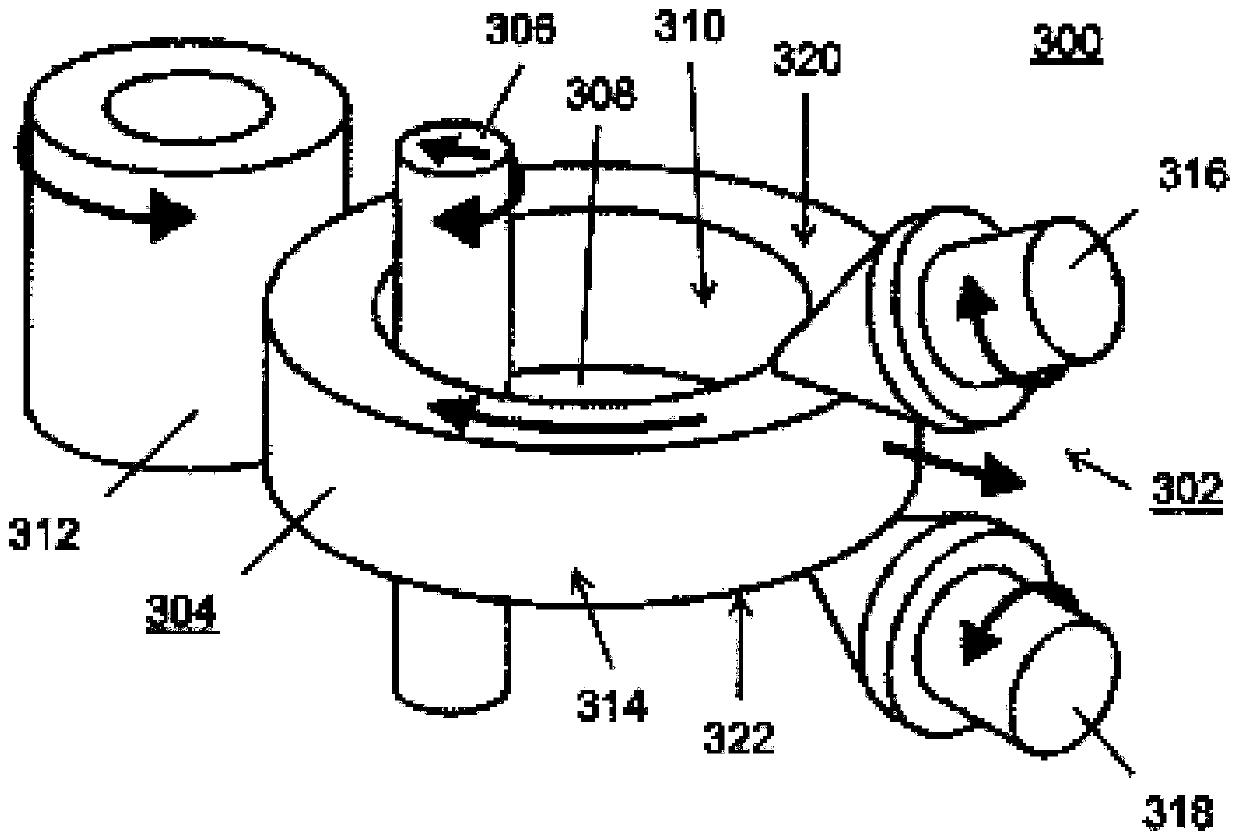

Copper or copper alloy target/copper alloy backing plate assembly

Owner:JX NIPPON MINING& METALS CORP

Preparation method of high-strength and high-conductivity beryllium copper alloy

ActiveCN102383078AConductivity has little effectLittle tensile strengthNiobium alloyComposite structure

The invention relates to a preparation method of a high-strength and high-conductivity beryllium copper alloy. In the method, the high-strength and high-conductivity beryllium copper alloy is obtained through hot working, high-working rate cold working, solution treatment, finish rolling or product drawing and aging treatment after smelting the low-beryllium alloy and copper-niobium composite materials together and casting into an ingot. The dispersively distributed copper-niobium composite materials are added into the high-conductivity low-beryllium alloy, the dispersively distributed niobium particles form an ordered composite structure in the low-beryllium alloy after one-time hot working and multiple high-working rate cold working, so that the strength and hardness of the low-beryllium alloy are greatly improved, the conductivity of the low-beryllium alloy is not influenced, and the beryllium copper alloy with the tensile strength sigma b equal to 1200-1400Mpa, hardness HB equal to 334-374 and conductivity g equal to 45-60% IAC is finally obtained. The beryllium niobium alloy prepared by the invention has high strength, high hardness, high elasticity and high wear resistance of the high-beryllium alloy and high conductivity and thermal conductivity of the low-beryllium alloy at the same time, and the comprehensive property of the beryllium copper alloy is greatly improved.

Owner:CNMC NINGXIA ORIENT GRP

Tellurium berylco alloy and preparation method thereof

The invention discloses a tellurium berylco alloy; the tellurium berylco alloy is prepared from 0.2-2.1 wt.% of Be, 0.1-0.7 wt.% of Te, and others including Co, Ni, Ti, rare-earth elements and impurity elements of which total is not more than 4% wt; the rest is Cu; the preparation method includes steps of a, dosing, feeding, smelting and casting raw materials to acquire an ingot blank according to weight percent; b, orderly performing homogenizing heat treatment, heat processing technique, cold processing technique and annealing, solid dissolving, and aging heat treatment on the ingot blank acquired in step a orderly; and preparing the tellurium berylco alloy. Through adding tellurium in the berylco alloy, tellurium and a copper base can form Cu2Te; the tellurium berylco alloy is good in high-temperature stability, remains the excellent physical performance and corrosive resistance of tellurium beryllium copper, and greatly improves the material cutting performance on the basis of environmental protection, and also performs the plasticity performance.

Owner:KINKOU SUZHOU COPPER IND CO LTD

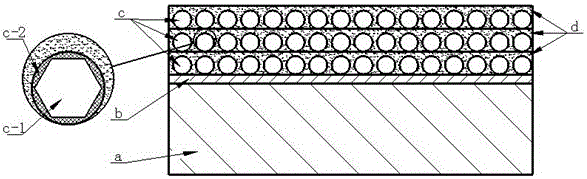

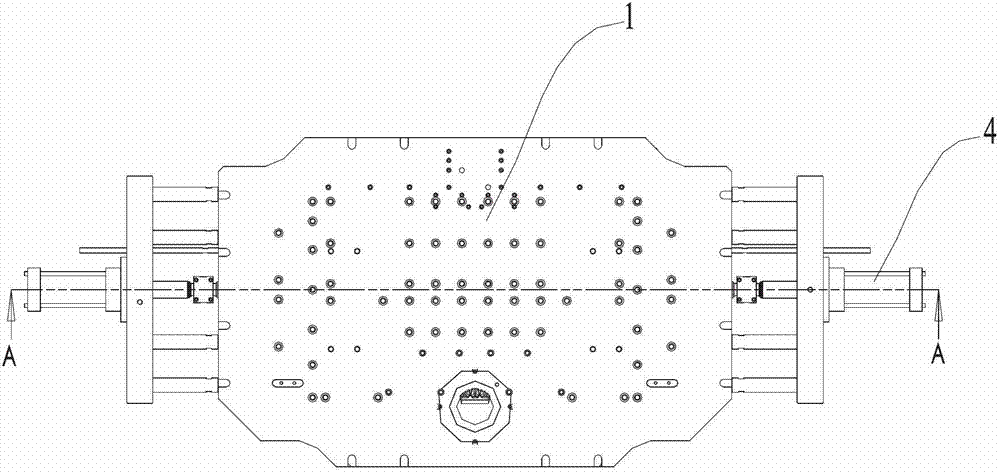

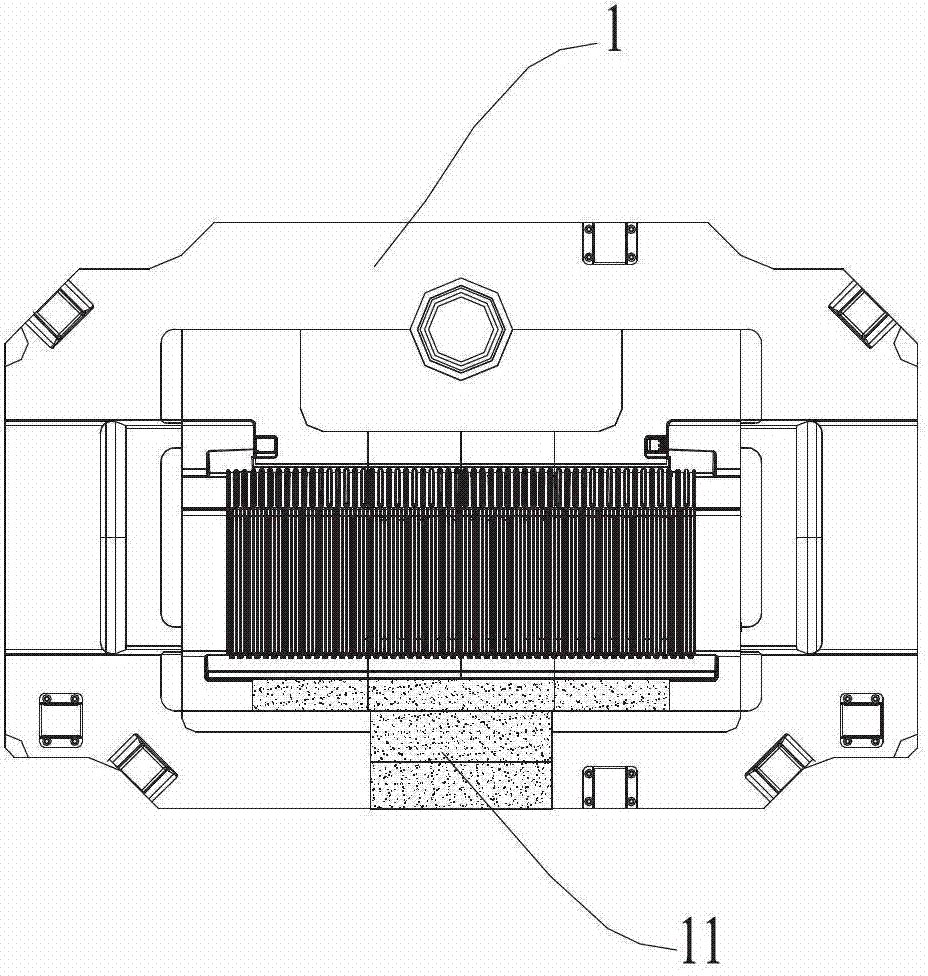

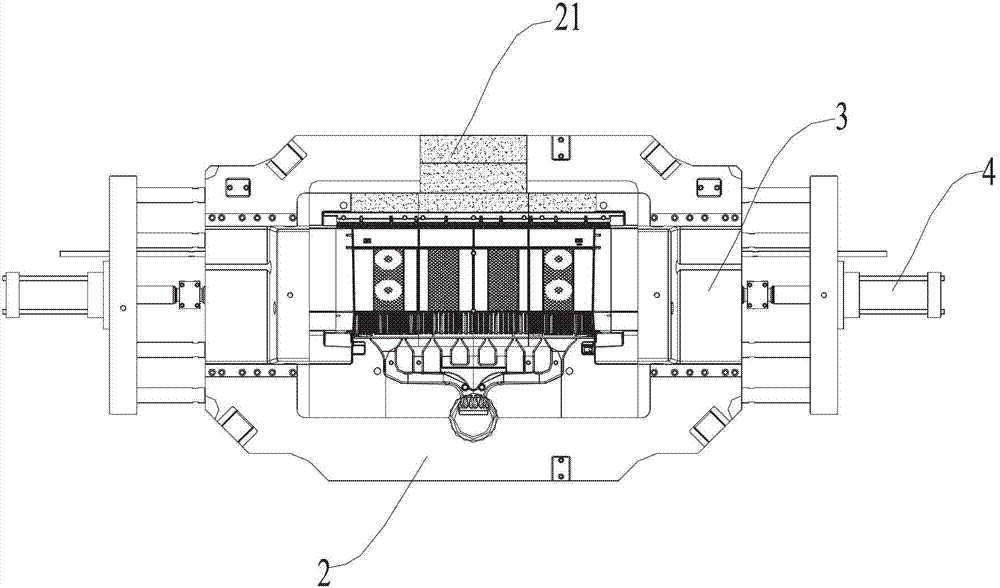

Beryllium copper alloy, copper bush for amorphous and/or nano crystal strip production equipment and preparation method

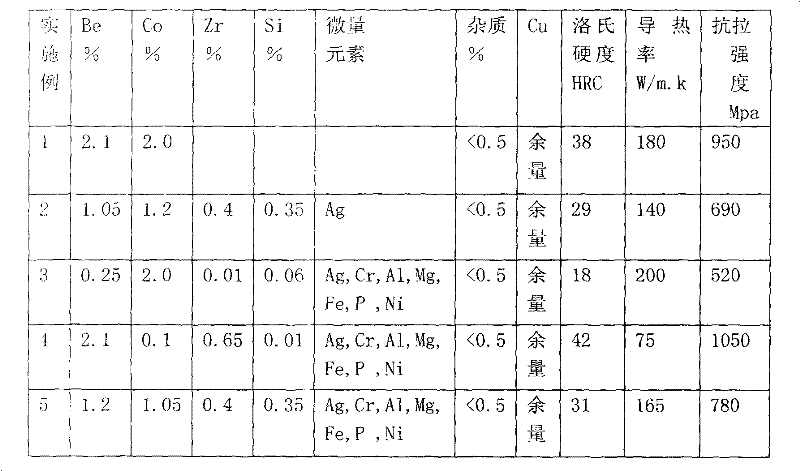

The invention discloses a beryllium copper alloy, a copper bush for amorphous and / or nano crystal strip production equipment and a preparation method. The copper contains the following elements in percentage by mass: 0.25 to 2.1 percent of Be, and 0.1 to 2.0 percent of Co. By adding the elements such as Co and the like into the beryllium copper alloy, the advantage of interaction of the alloy elements is exerted; and the smelted alloy is cast into a cast ingot or a cast blank, and the cast blank is subjected to the processes of hot forging, heat preservation, ageing treatment and the like to prepare the beryllium copper alloy with high strength and high thermal conductivity and in accordance with the copper bush for the amorphous or nano crystal strip production equipment. When the beryllium copper bush is applied in the strip production link, the appearance quality and the actual performance of amorphous or nano crystal strips can be effectively promoted.

Owner:李希涛

High-performance beryllium-copper alloy and preparation method thereof

The invention discloses a high-performance beryllium-copper alloy and a preparation method thereof. The high-performance beryllium copper comprises 1.6-2.2% of beryllium, 0.35-0.65% of cobalt and nickel, 0.03-0.1% of yttrium, 0.03-0.1% of titanium, 0.1-0.3% of boron, 0.1-0.3% of magnesium and the balance of copper in percentage by weight, wherein the beryllium is added in the form of a beryllium-copper immediate alloy and accounts for 3.8-4.2% of the beryllium-copper alloy; the cobalt and the nickel are also respectively added in the form of immediate alloys of a cobalt-copper alloy and a nickel-copper alloy and respectively account for 8-12% of the alloy; the titanium is added in the form of a titanium-copper immediate alloy and accounts for 4-6% of the alloy; and the yttrium is added in the form of a yttrium-copper immediate alloy and accounts for 8-12% of the alloy. By using the invention, the mechanical comprehensive performance is improved, the service life of the material is largely prolonged, and the service life of a beryllium-copper injection plunger head applied to a die casting machine is increased to more than 20000 mold times from the original 8000-12000 mold times.

Owner:DONGGUAN JIASHENG COPPER

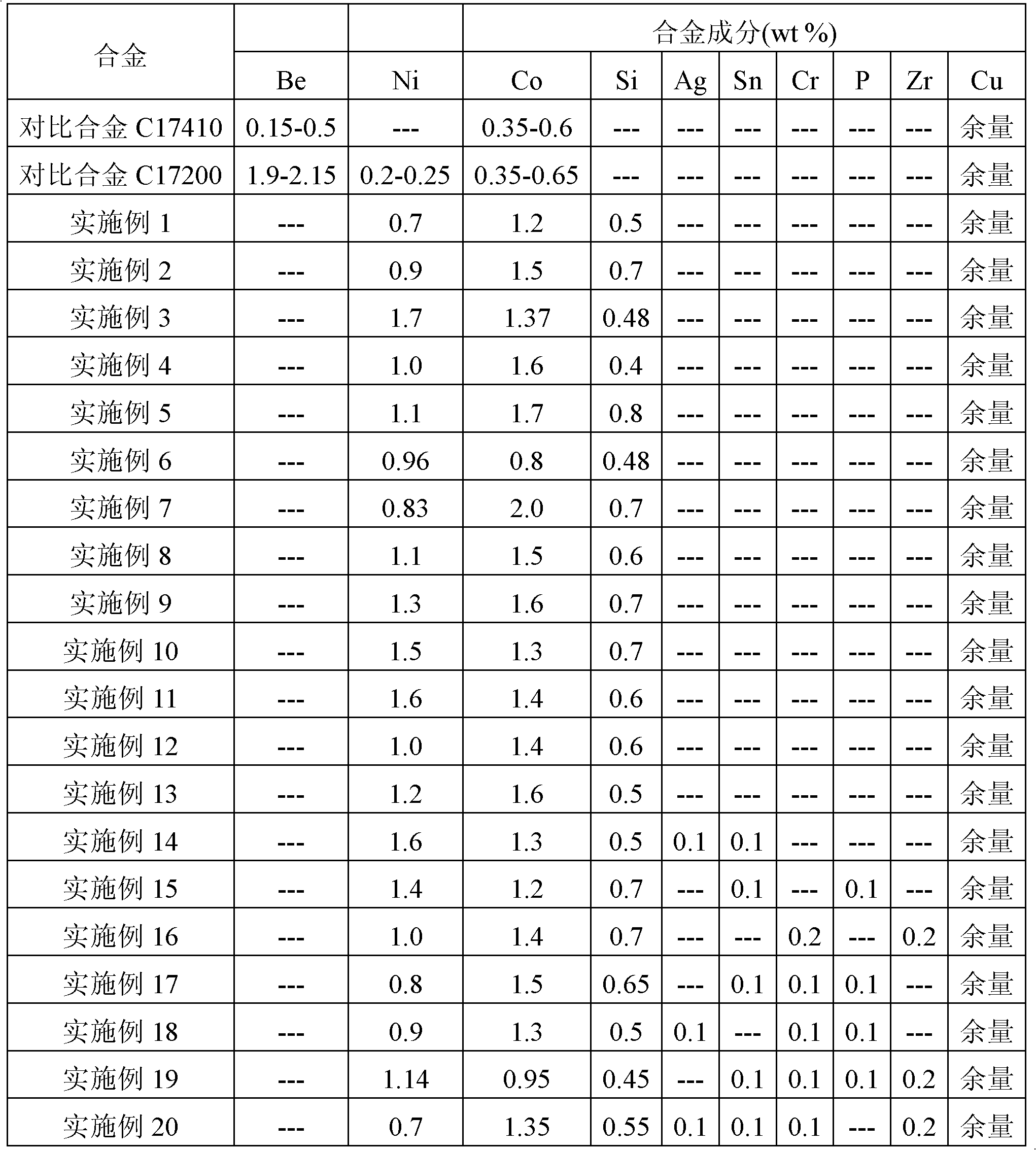

Anti-stress relaxation beryllium free copper alloy with high strength and high elasticity as well as preparation and processing methods thereof

The invention relates to an anti-stress relaxation beryllium free copper alloy with high strength and high elasticity as well as preparation and processing methods thereof, and belongs to the field of processing of nonferrous metals. The alloy comprises the components in percentage by weight as follows: 0.7-1.7% of Ni, 0.4-0.8% of Si, 0.8-2.0% of Co and the balance of Cu. The components of the alloy meet the conditions: (a) (Ni+Co) / Si is greater than or equal to 3.4 but less than or equal to 6.5; (b) (Ni+Co) is greater than or equal to 1.0% but less than or equal to 3.5%; (c) Ni / Co is greater than or equal to 0.4% but less than or equal to 1.3%; (d) (Ni+Co+Si) is greater than or equal to 2.0% but less than or equal to 3.6%; and (e) Ni / Si is greater than or equal to 1.0% but less than or equal to 3.6%. The copper alloy provided by the invention has high elasticity, high strength, high fatigability and good heat resistance, and meanwhile has good conductivity, and can be widely applied to occasions such as various elastic reeds, electric contacts, spot welding poles, anti-explosion tools, electric contact components, connecting components and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Copper-nickel-tin alloy and preparation method for wires thereof

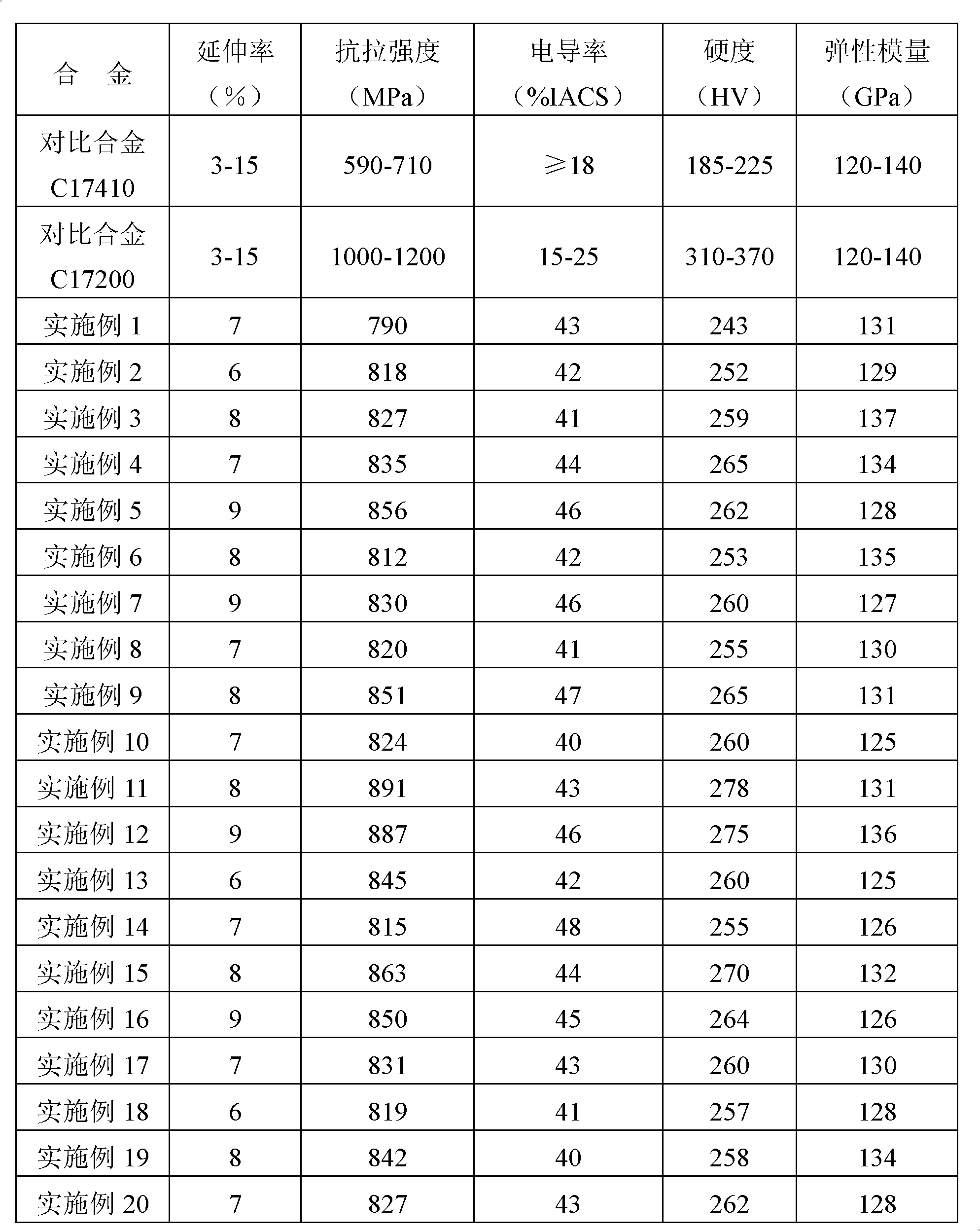

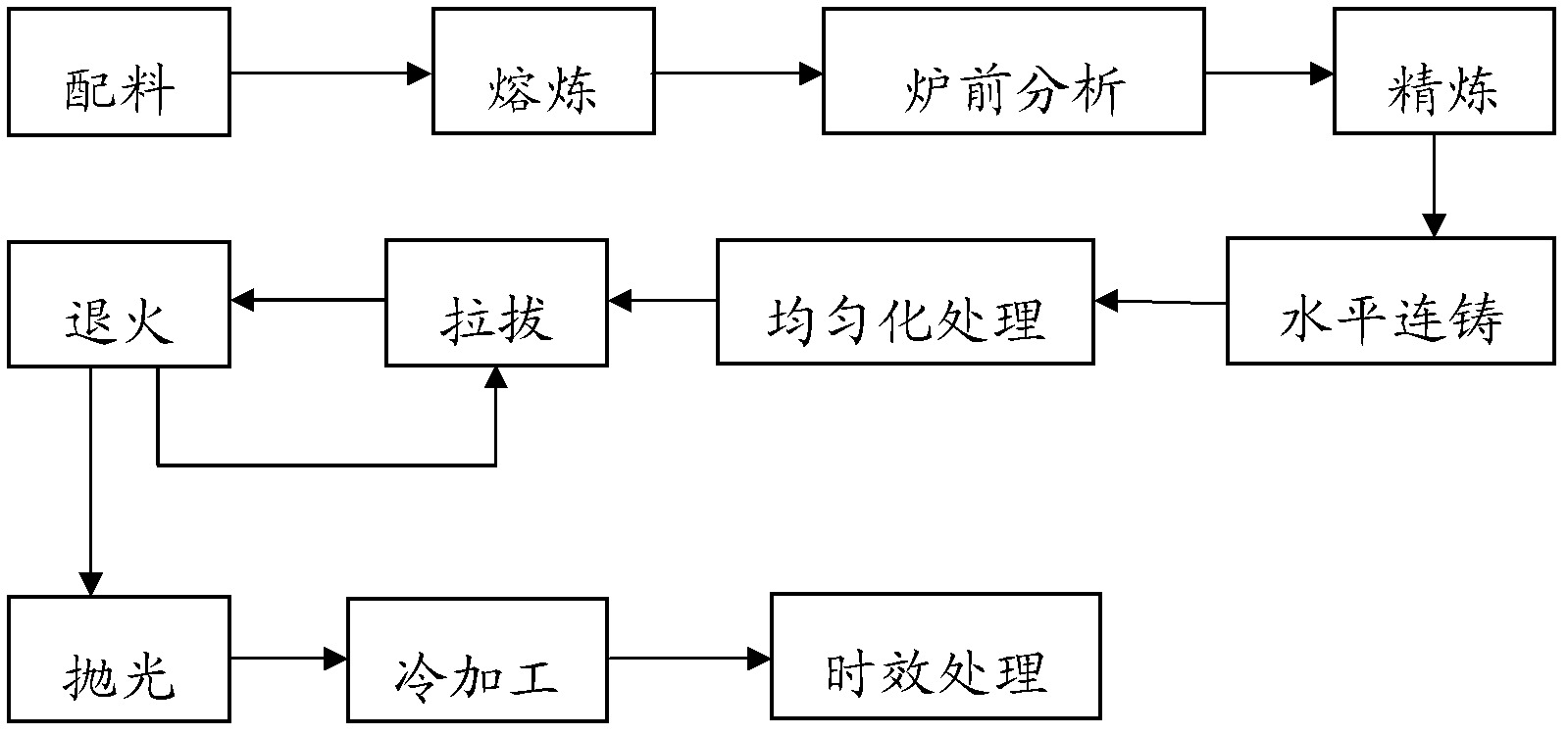

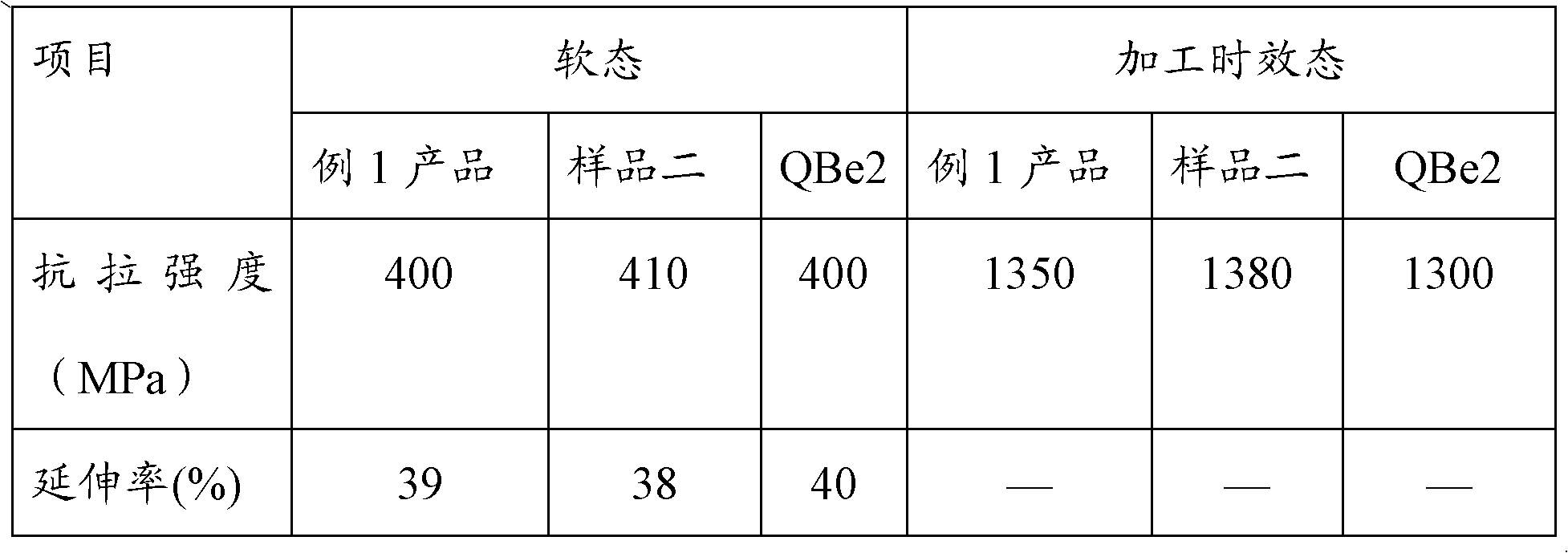

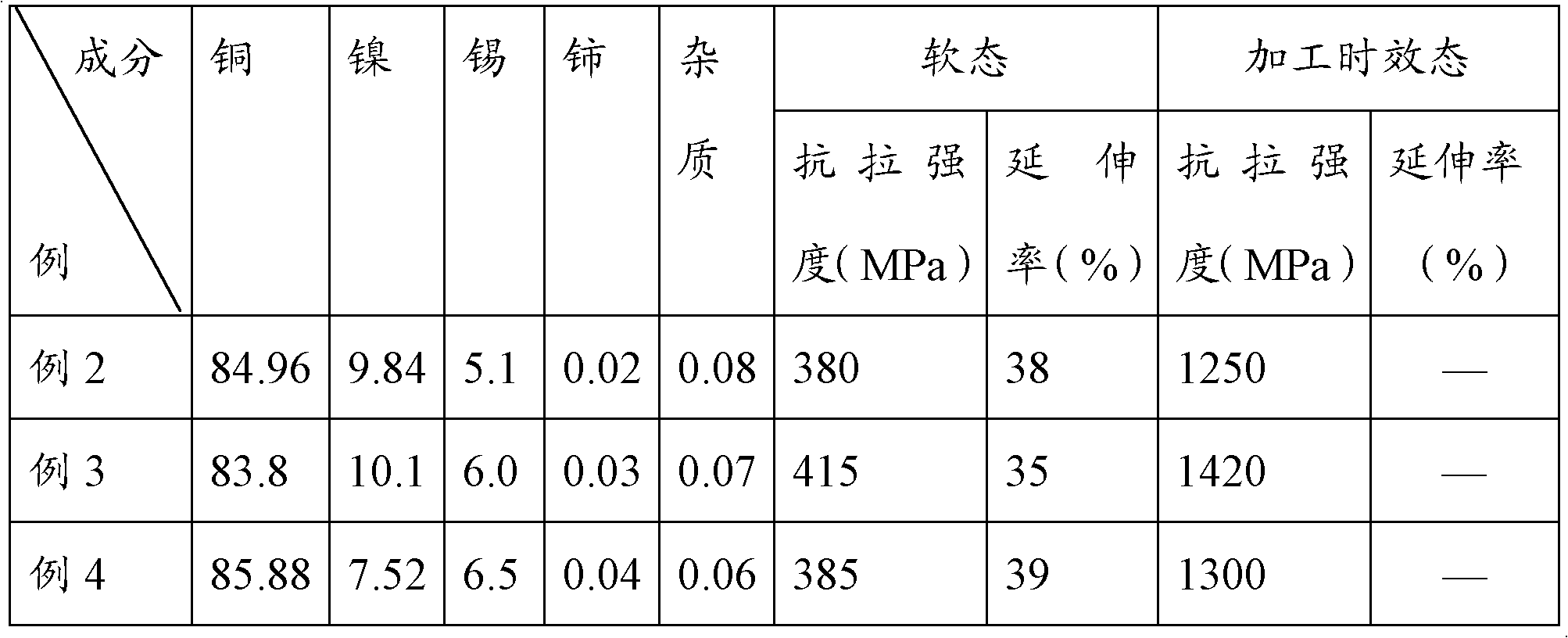

The invention discloses copper-nickel-tin alloy and a preparation method for wires thereof. The copper-nickel-tin alloy comprises, by weight, 7 to 11% of nickel, 4 to 8% of tin and 0.02 to 0.04% of cerium, with the balance being copper and unavoidable impurities; the alloy has same performance as beryllium-copper alloy does. Horizontal continuous casting is used in the preparation method for wires of the copper-nickel-tin alloy; compared to vacuum melting commonly used at home and abroad, the method provided in the invention has the advantages of high rolling yield, simple processing equipment, small investment, short process flow and capacity of obtaining wire products with same excellent performance.

Owner:厦门火炬特种金属材料有限公司

Low-beryllium elastic copper alloy and preparation and manufacture method thereof

InactiveCN102676878AReduce the difficulty of productionSimple preparation processSolution treatmentStress relaxation

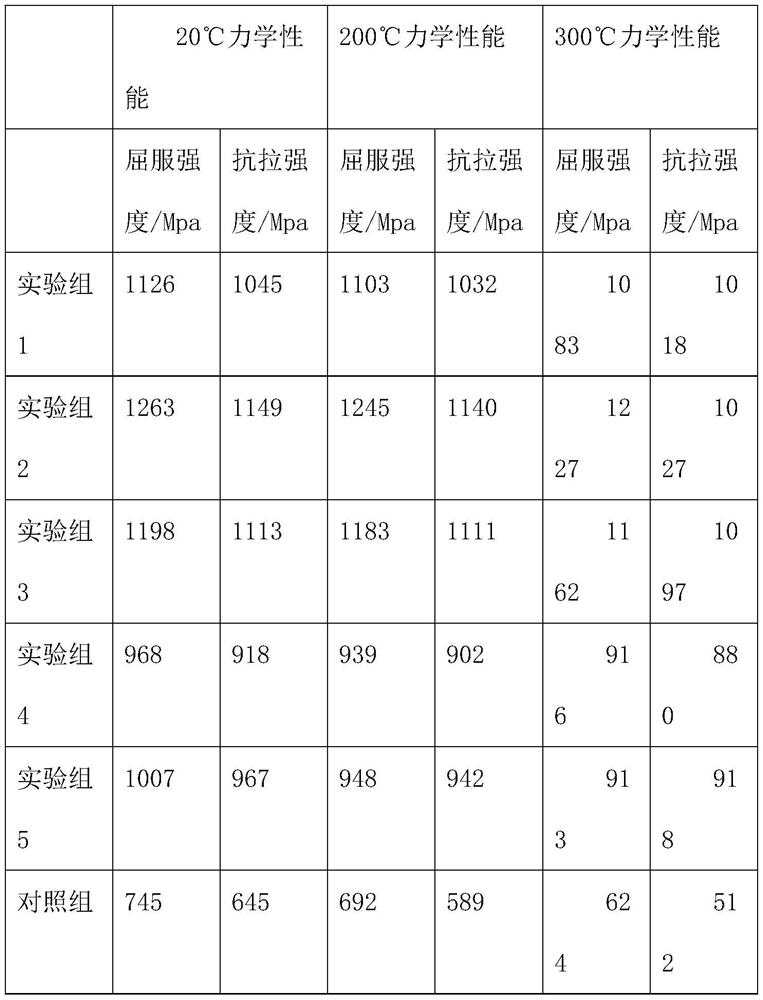

The invention relates to low-beryllium elastic copper alloy and a preparation and manufacture method thereof. The low-beryllium elastic copper alloy comprises by mass: 0.2-0.4% of Be, 1.3-2.6 % of Ni and the balance Cu, wherein the mass ratio of the Ni to the Be in the beryllium copper alloy is larger than or equal to 5.5 and smaller than or equal to 6.5. The alloy can further contain Cr and Zr. The preparation method of the low-beryllium elastic copper alloy comprises alloy component design, casting, hot rolling, solution treatment, rolling deformation and ageing treatment. The alloy is low in Be content (smaller than 0.5%) and can effectively save metal beryllium, the tensile strength of the alloy after deformation ageing treatment can reach 968MPa, conductivity is larger than 55% according to the international annealed copper standard (IACS), and the rate of resistance to stress relaxation is larger than 85%. Therefore, the low-beryllium elastic copper alloy can serve as a conductive elastic material which has high elasticity, high strength and excellent resistance to stress relaxation, can be applied to electrical contact components, connectors, relays and the like, and has wide application prospects.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

High-strength beryllium-copper alloy bar and preparation process thereof

ActiveCN113174509AHigh strengthGrain refinementFurnace typesHeat treatment furnacesRare-earth elementVanadium atom

The invention discloses a high-strength beryllium-copper alloy bar, and particularly relates to the technical field of beryllium-copper alloys. The high-strength beryllium-copper alloy bar comprises the following elements: Be, Si, Ni, Co, Zr, Ti, V, rare earth elements, and the balance of Cu and inevitable impurities. According to the produced high-strength beryllium-copper alloy bar, nickel, cobalt, zirconium, titanium, vanadium and rare earth elements are added, the addition of nickel and cobalt can refine crystal grains in an alloy material and improve the uniformity of an internal structure, so that the beryllium-copper alloy material has good mechanical properties, zirconium can improve the softening temperature of the beryllium-copper alloy and refine recrystallized crystal grains, and titanium can effectively enhance the strength of the beryllium-copper alloy, the vanadium can purify, deteriorate and refine crystal grains and can improve the wear resistance of the beryllium-copper alloy bar, and the rare earth elements can refine the crystal grains to make the crystal grains uniform and can effectively improve the strength and corrosion resistance of the beryllium-copper alloy bar. The practicability of the beryllium-copper alloy bar can be improved, and the beryllium-copper alloy bar can meet the use requirements of people.

Owner:江阴金湾合金材料有限公司

Alloy material for aerospace field and manufacturing method thereof

The invention provides an alloy material for the aerospace field and a manufacturing method thereof. The alloy material comprises the components by weight percent as follows: 6-10% of nickel, 6-9% of tin, 3-6% of aluminum, 0.1-0.5% of manganese, 0.02-0.1% of iron and 74.4-84.88% of copper. According to the invention, the beryllium element of a beryllium-copper alloy is replaced through complete fusion of a copper-nickel alloy material and an aluminum-tin alloy, and excellent properties of the alloy material are realized under the action of a plurality of trace elements; the yield strength of the material is greater than 980 MPa; and as a result, the alloy material provided by the invention completely takes the place of beryllium bronze and achieves the goal of environmental protection and health standards.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

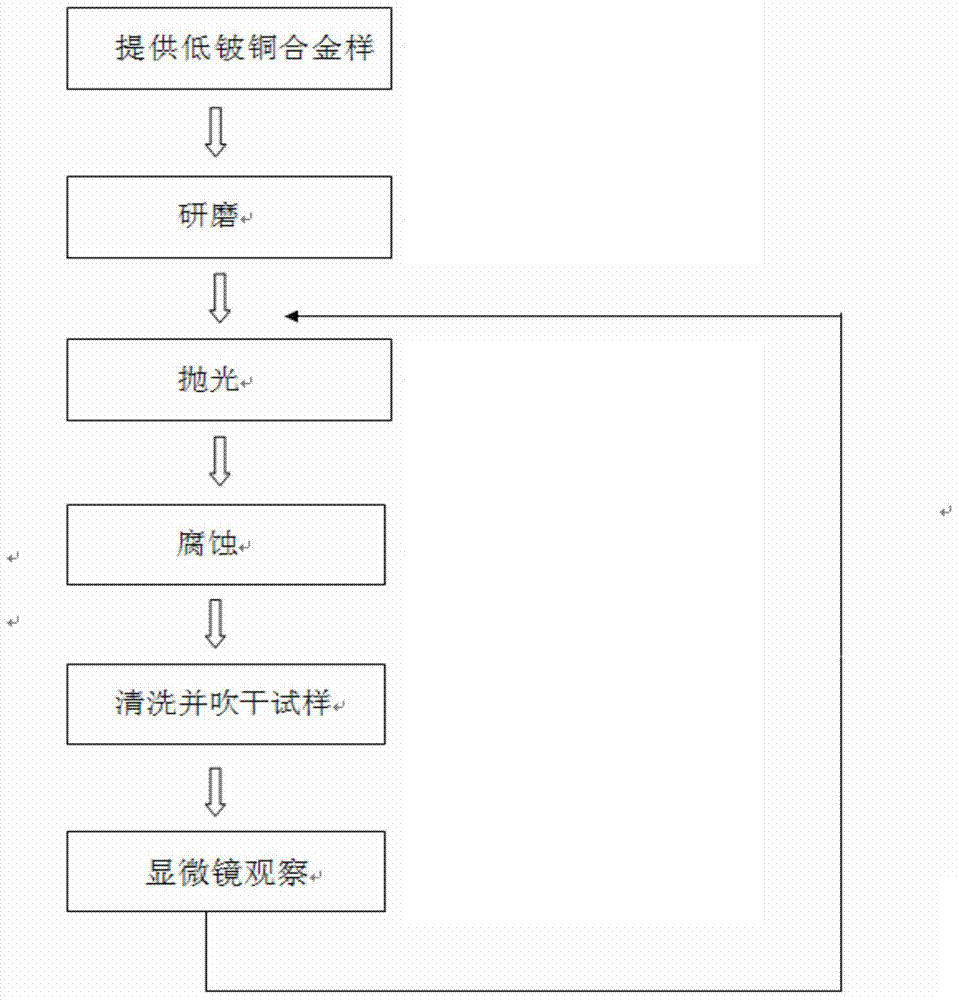

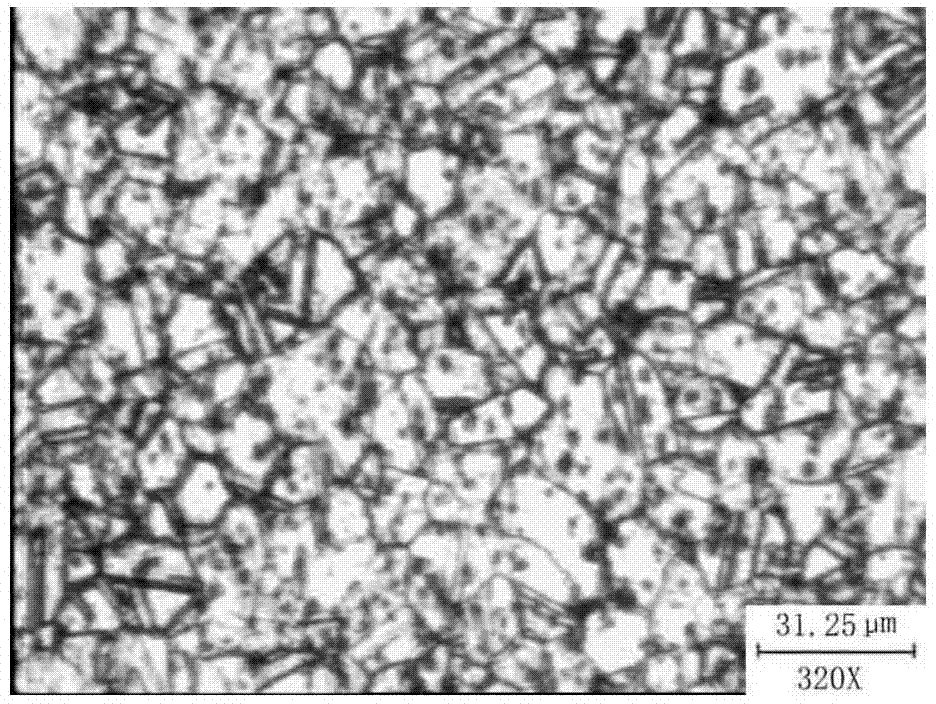

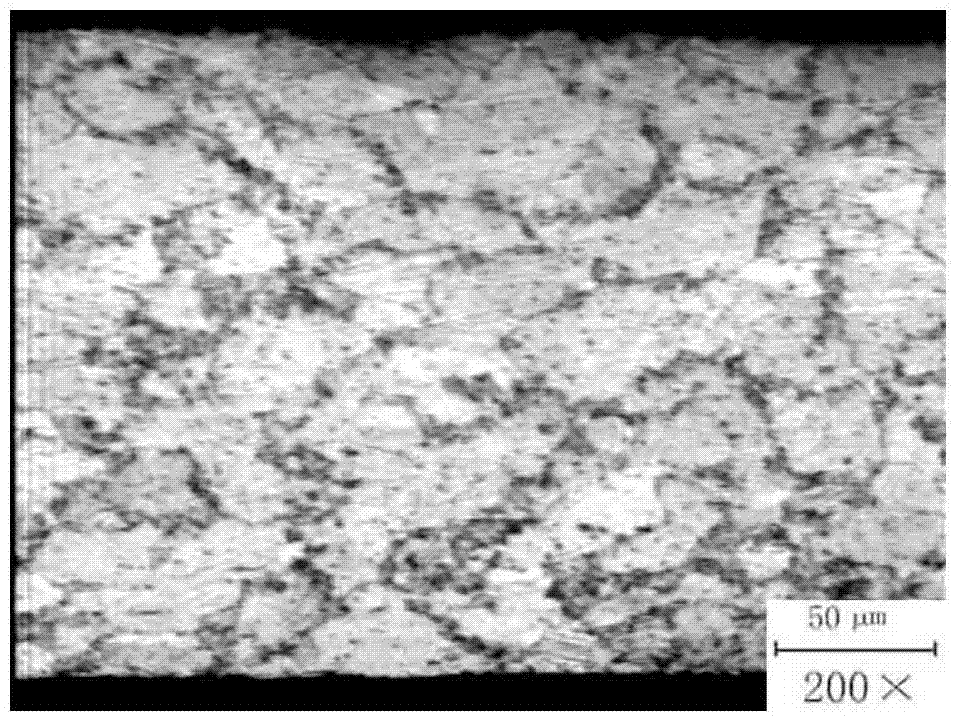

Low-beryllium copper alloy metallographic corrosive agent and display method of metallographic structure of low-beryllium copper alloy

ActiveCN103575585AImplement testSimple processPreparing sample for investigationBeryllium-Copper AlloyBeryllium copper

The invention relates to a low-beryllium copper alloy metallographic corrosive agent and a display method of metallographic structure of low-beryllium copper alloy. The method comprises the following steps of: orderly burnishing a low-beryllium copper alloy sample with 180-mesh, 400-mesh, 800-mesh and 1500-mesh silicon carbide waterproof abrasive papers or aluminum oxide waterproof abrasive paper by virtue of using water as a wetting agent, then, polishing the alloy with aluminum oxide polishing solutions of different particle sizes, finally, performing corrosion treatment by using one or any combination of three types of low-beryllium copper alloy metallographic corrosive agents prepared by the invention, and further washing and observing the sample. According to the invention, with the prepared corrosive agent effective to the metallographic structure of the low-beryllium copper alloy, the metallographic structure of the low-beryllium copper alloy can be displayed clearly, so that inspection on the low-beryllium copper alloy is realized. The technology is simple, and is simple and convenient to operate.

Owner:西北稀有金属材料研究院宁夏有限公司

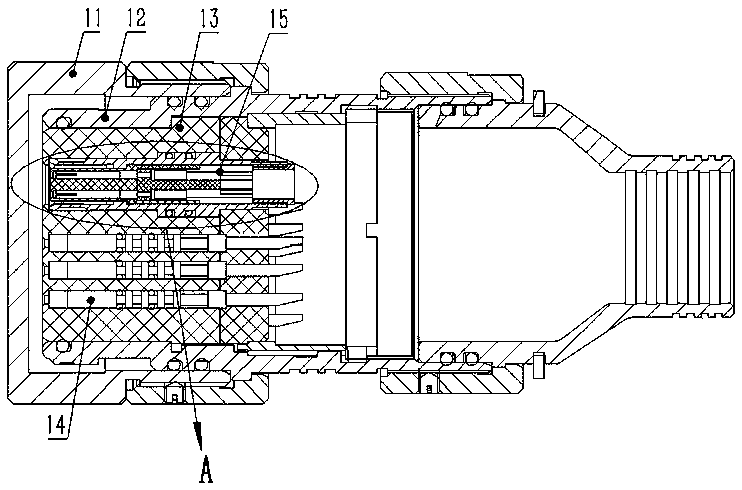

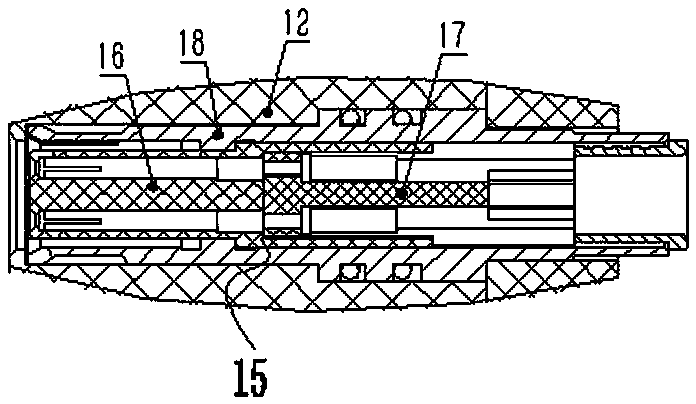

Connector and contact component thereof

ActiveCN105375159AImprove sealingSecuring/insulating coupling contact membersCoupling contact membersMetallic materialsEngineering

The invention discloses a connector and a contact component thereof. The front contact member of the contact component is assembled in a front sleeve by adopting an insulator spacing and fixing mode, and the rear contact member is fixed in a rear sleeve in a spacing way by adopting a glass sintering sealing mode. Meanwhile, butt plugging of the front contact member and the contact member of another connector is realized, and conductive connection of a rear insulator and a conductive wire is realized so that a beryllium copper alloy or a tin bronze alloy can be adopted to act as the front contact member. Metal material suitable for glass sintering sealing is adopted to act as the rear contact member and the rear sleeve so that flowing and burning-resistant capacity of the plugging contact part of the contact members in the plugging process of the plug and the socket of the whole contact component can be guaranteed by the front contact member, and sealing performance between the contact members and the fixing sleeves of the contact component can be enhanced by glass sintering sealing as for the rear contact member. Therefore, sealing performance between the contact members and the fixing sleeves can be enhanced in the contact component under the premise of guaranteeing basic plugging and flowing performance.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Production of beryllium copper pipe

A technology for manufacturing the beryllium-copper pipe includes such steps as providing a beryllium-copper alloy ingot prepared from Be, P and Cu and with 50-90 mm for diameter, 30-50 mm for internal hole diameter and 210-300 mm for length, extruding at 750-800 deg.C by (600-800)-ton press, annealing in H2 at 500-600 deg.C, forced cooling to 0-50 deg.C, and rolling.

Owner:上海威嘉金属材料有限公司

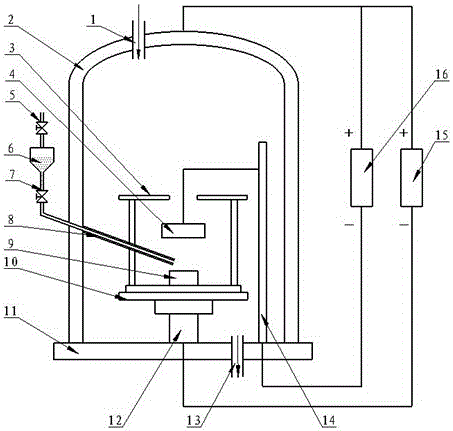

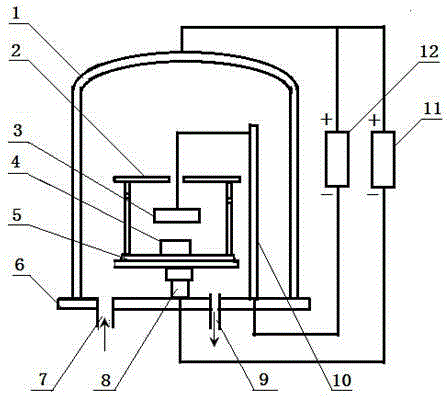

Method for preparing beryllium-copper alloy sheet by adopting continuous magnetron sputtering physical-vapor deposition method

ActiveCN102965634AContinuous beryllium treatmentControlled beryllium treatmentVacuum evaporation coatingSputtering coatingSputteringGas phase

The invention relates to a method for preparing a beryllium-copper alloy sheet, and particularly relates to a method for preparing the beryllium-copper alloy sheet by adopting a continuous magnetron sputtering physical-vapor deposition method. The method for preparing the beryllium-copper alloy sheet by adopting the continuous magnetron sputtering physical-vapor deposition method comprises the following steps: depositing a pure Be or Be-rich membrane with good combination on the single surface or both surfaces of a pure copper strip by taking a pure Be metal target or a beryllium-copper alloy target with high beryllium content as a cathode and the pure copper strip as an anode and adopting the magnetron sputtering physical-vapor deposition method; and then carrying out diffusion treatment at high temperature to enable Be atoms to be diffused inwards and permeated into a pure copper base body till the content of Be contained in the pure copper strip reaches 1-3 percent by weight so as to obtain a Cu-Be alloy strip, which is excellent in mechanical property and conductive property, with the Be content of 1-3 percent by weight. The method disclosed by the invention has the advantages of simplicity, easiness for operation, high work efficiency, energy-saving and environment-friendly preparation process, controllable quality and great suitability for industrialized application.

Owner:兰州大成科技股份有限公司 +1

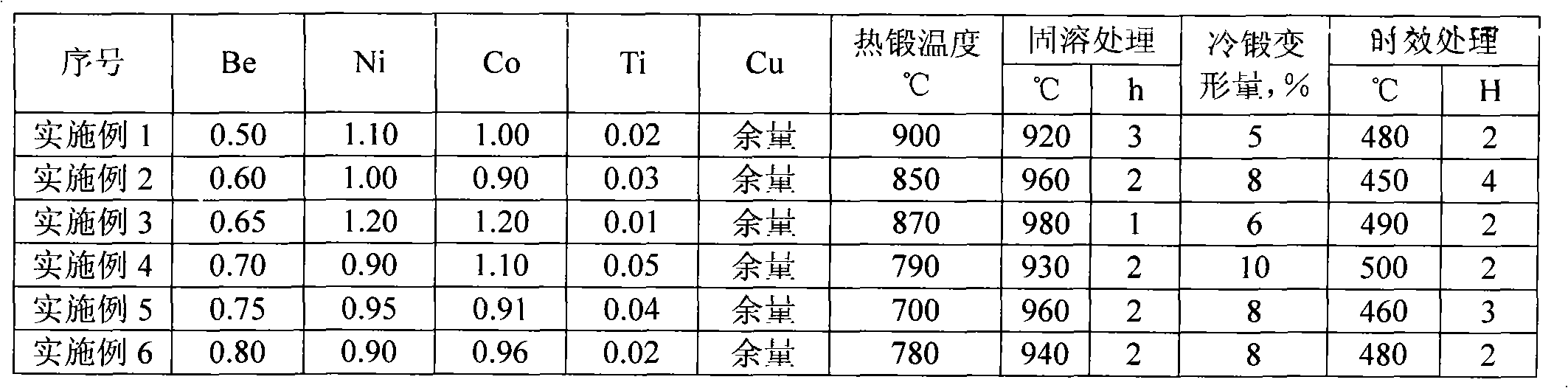

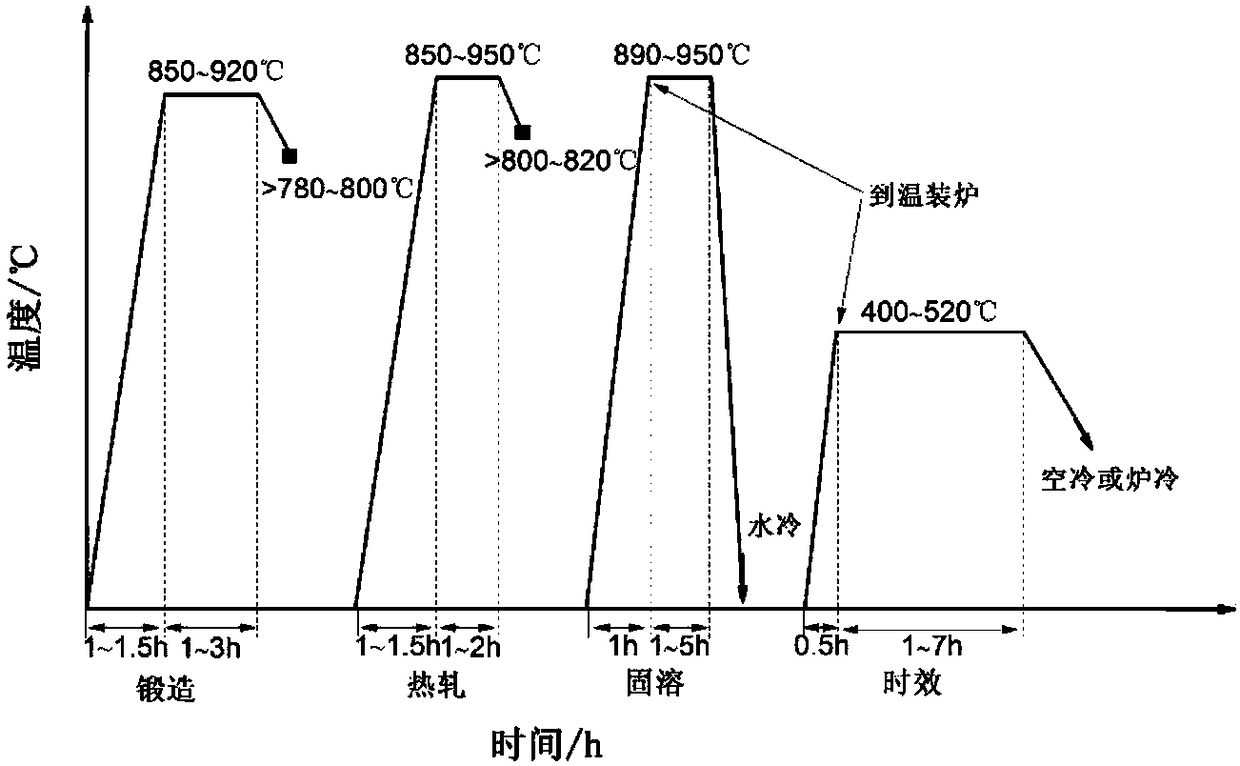

Low copper beryllium mold material for gravitation and low-pressure casting and production process thereof

The invention provides a low beryllium copper alloy mold material used for gravity and low pressure casting as well as a production process, comprising: adding Ni, Co and Ti elements on the basis of a low beryllium copper alloy, giving full play to advantages of the interaction of alloying elements, carrying out processing steps of cold deformation and time effect treatment after the hot forging, solution treatment and water quenching to a cast ingot, and obtaining the special low beryllium copper alloy mold material used in the gravity and low pressure casting industry and having high strength, good toughness and high heat conductivity, and products of the invention are equivalent to ASTM B534 C17500 materials and can fully replace imported goods.

Owner:周水军

Preparation method of high beryllium copper alloy strip material short process for dynode of photomultiplier

The invention relates to a preparation method of a high beryllium copper alloy strip material short process for a dynode of a photomultiplier, and relates to a preparation method of the beryllium copper alloy strip. The problems that the mass fraction of beryllium in an existing beryllium copper strip is low, the porosity of a beryllium copper strip is large, the compactness of a structure is poor, macroscopic segregation is generated and production efficiency is low are solved; the method comprises the following steps that 1, semi-continuous preparation is carried out to prepare a blank; 2, extrusion is carried out; 3, rolling and acid pickling are carried out; and 4, finish rolling, annealing and winding are carried out to obtain the high beryllium copper alloy strip for the dynode of the photomultiplier. According to the method, a peak secondary electron emission coefficient of the high beryllium copper alloy strip for the dynode of the photomultiplier prepared by the method is 8.4-10.8, the tensile strength is 645.4 MPa-670.2 MPa, the yield strength ranges from 314.8 MPa-360.9 MPa, and the percentage elongation after fracture is 15%-19%; and the high beryllium copper alloy strip for the dynode of the photomultiplier can be obtained.

Owner:XIANGTAN UNIV

Beryllium copper alloy

The Be-Cu alloy contains Be 0.2-0.6 wt%, Cr 0-0.5 wt%, Mn 1.8-3.0 wt%, Fe 1.8-3.0 wt% and Al 12.5-14.5 wt%, except Cu and inevitable small amount of impurity. It has hardness of HRC 42-52 deg, high heat conductivity, small friction coefficient, high wear resistance, high anticorrosion, smoothness and long service life.

Owner:宋协福

Method for preparing high beryllium-copper alloy used for photomultiplier tube dynodes

ActiveCN106498226ASuppress generationImprove toughnessMultiplier dynodesPorosityMaterials preparation

The invention discloses a method for preparing high beryllium-copper alloy used for photomultiplier tube dynodes. The method includes the steps of material preparation, smelting, hearth cleaning, strip manufacturing and finish rolling. By the adoption of the method, the condition of hard and brittle phase generation in preparation of high beryllium-copper alloy strips through a traditional semi-continuous rolling machining method is avoided, the toughness of the beryllium-copper alloy strips prepared through a strip-spinning method is improved, the strip porosity is lowered, working efficiency is improved, and input cost is reduced.

Owner:KINKOU SUZHOU COPPER IND CO LTD

Preparation method of compound wear-resistant coating on surface of beryllium-copper alloy

ActiveCN105734485ALow resistivityHigh bonding strengthVacuum evaporation coatingSputtering coatingBi layerGlow plasma

The invention discloses a preparation method for a compound wear-resistant coating on the surface of a beryllium-copper alloy. The preparation method comprises the following steps: by adopting a double-layered glow plasma diffusion metallizing technology, preparing a diffusion coating layer on the surface of a beryllium-copper workpiece by taking a target material manufactured by any one wire of W, Mo and Nb or a W-Mo alloy, a Mo-Nb alloy, a W-Nb alloy and a W-Mo-Nb alloy and a beryllium-copper alloy panel as a source electrode, wherein before preparation, diamond particles subjected to Cu surface metallized treatment are uniformly sprayed to the surface of the beryllium-copper workpiece, so that the diamond particles are dispersively distributed; in the preparation process of the diffusion coating layer, uniformly spraying the diamond particles subjected to Cu surface metallized treatment to the surface of the workpiece once if the thickness of the coating is increased by 2-5[mu]m; after preparation of the diffusion coating layer is finished, introducing hydrogen for quick cooling; and then polishing the surface of the coating, and exposing the surfaces of the diamond particles. The coating prepared by the method has high electric conductivity, heat conductivity and wear resistance, the bonding strength of the coating with a matrix is high, and the preparation technology is simple in process.

Owner:TAIYUAN UNIV OF TECH

High-temperature-resistant, high-strength and beryllium-copper-free wire and preparation method thereof

ActiveCN107400796AImprove performanceLow costConductive materialMetal/alloy conductorsRare-earth elementIndium

The invention discloses a high-temperature-resistant, high-strength and beryllium-copper-free wire and a preparation method thereof. The preparation method comprises steps: S1, high-purity copper, pure iron and a block-shaped covering agent are mixed, molten, kept at the constant temperature and stirred, a copper-nickel alloy, a copper-strontium alloy, a copper-indium alloy, magnesium rods and rare earth element lanthanum are added, the mixture is heated to 1,230-1,260 DEG C, stirred and molten, and copper alloy melt is obtained; S2, component detection is performed on the copper alloy melt; S3, the copper alloy melt obtained in S2 is introduced into a high-vacuum single-roll rotary quenching and spray casting system and heated to 950-970 DEG C for spray casting, air is introduced after cooling, and a thin strip is obtained after balance of atmospheric pressure; S4, the thin strip is subjected to continuous annealing and homogenization in a magnetic field under the condition of 590-630 DEG C, and the high-temperature-resistant, high-strength and beryllium-copper-free wire is obtained through cold rolling and ageing treatment. With the iron-copper alloy as a basis, multiple alloy elements are added in a matched manner to replace conventional beryllium copper alloy materials, the cost is reduced, a reasonable preparation process is matched, and the comprehensive performance of the material is improved.

Owner:安徽晋源铜业有限公司

Laser beam welding technique of berylliumcopper alloy mold

InactiveCN101462203ADoes not affect statusReduce distortionFurnace typesHeat treatment process controlLength waveBeryllium-Copper Alloy

The invention provides a process for carrying out laser welding on a beryllium copper alloy mould. The process comprises the following operation steps: firstly, carbon tetrachloride is used to clean the mould and the surface of a beryllium copper welding wire with phi of between 0.30 and 0.50 mm; a Nd:YAG pulse laser welder with power of between 75 and 300 W, laser wavelength of 1.06um and an X, Y and Z-axis processing machine is used to carry out wire filling and welding to the needed dimension under protection of argon gas; the welder is used to carry out local heat treatment on a welding part of the mould; and finally, the surface of the mould is subjected to final finishing to the needed precision. The laser facula is very small; the diameter of the local part of the weldable mould can reach about 1mm; the mould has small deformation; one welder simultaneously carries out wire filling and welding and heat treatment; the process is simple and saves investment; a weld bead of the mould has no disadvantages of cracks, pores and the like; and a weldless part of the mould is not influenced and has high rigidity, thereby ensuring the service life of the mould. The process is mainly used for rehabilitating the abrasion and local damage of the beryllium copper alloy mould.

Owner:成都敏捷制造工程有限公司

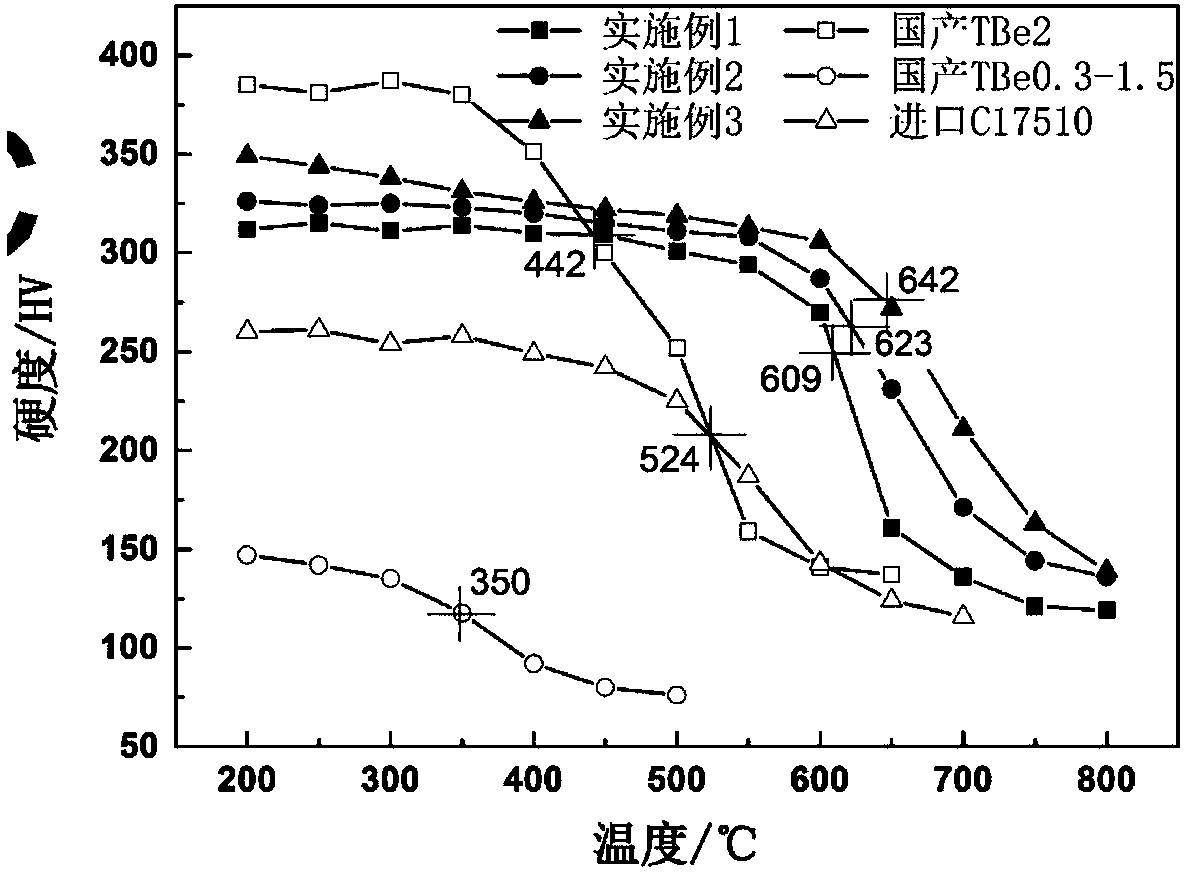

High-strength and high softening temperature low beryllium-copper alloy and preparation method thereof

ActiveCN108315581AHigh dimensional accuracyImprove mechanical propertiesElectro conductivityWear resistance

The invention relates to a high-strength and high softening temperature low beryllium-copper alloy and a preparation method thereof. The low beryllium-copper alloy is prepared from the components of,by mass, 0.2-0.5% of Be, 1.0-1.8% of Ni, 0.15-0.4% of Co, 0.5-0.8% of Ag, 0.05-0.1% of Zr, 0.02-0.05% of Mg, less than or equal to 0.1% of unavoidable impurities and the balance of Cu. The tensile strength of the prepared beryllium-copper alloy can reach 850-1000 MPa, the specific conductivity is 50-60% IACS (international annealed copper standard), the softening temperature can reach 600 DEG C orabove, and meanwhile, the alloy has the comprehensive performance of excellent high elastic stability, the low elastic aftereffect, non magnetism, abrasive resistance, corrosion resistance, plasticity and the like, and can be applied to the industries such as rail traffic, aviation, automobile, electric power, electronic engineering, and precise instrument and apparatus.

Owner:CHONGQING MATERIALS RES INST

Continuous casting alloy pipe in aerospace field and manufacturing method thereof

ActiveCN103540794AEasy to processImprove performanceElongated constructional elementsManganeseCobalt

The invention provides a continuous casting alloy pipe in the aerospace field and a manufacturing method thereof. The alloy pipe comprises components in percentage by weight: 20-25% of nickel, 8-12% of tin, 9-11% of aluminum, 1-3% of manganese, 1.5-3% of iron, 0.05-0.3% of phosphorus, 0.01-0.1% of chromium, 0.01-0.1% of cobalt and the balance of copper. According to the continuous casting alloy pipe in aerospace field, the multi-element alloy formed by completing fusing copper-nickel alloy and aluminum-tin alloy can achieve the needed strength so as to replace the toxic beryllium in beryllium-copper alloy, and the performance of the alloy material can be improved.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

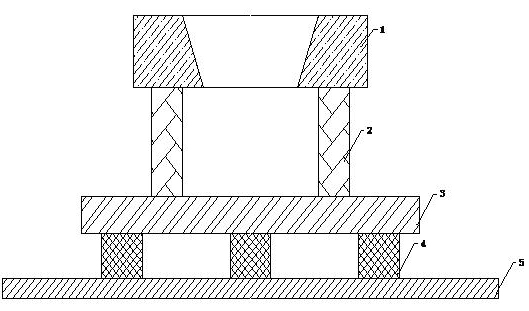

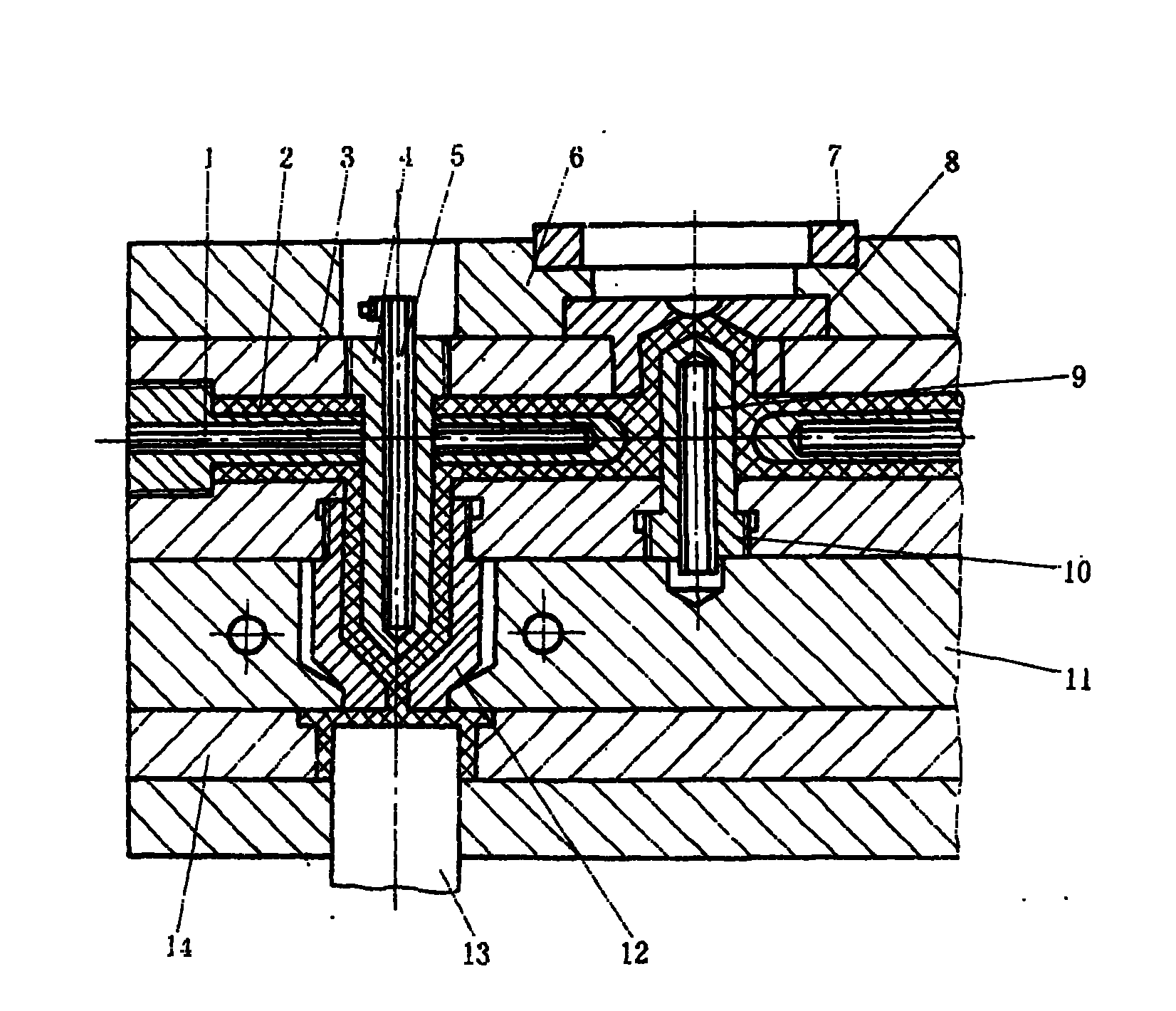

Internal heating type multi-cavity hot runner mold

The invention relates to an internal heating type multi-cavity hot runner injection mold, comprising the following parts: a pipe type heater, a runner torpedo body, a hot runner plate, a nozzle torpedo body, a fixed mold seat plate, a locating ring, a main runner bushing, a main runner torpedo body, a sprue plate, a secondary nozzle, a mold core, a fixed mold cavity plate and the like (a connection mode is shown in a specification figure). The mechanism has small heat loss and high thermal efficiency and simultaneously can be used for the multiple feed of large-sized products. When the internal heating type multi-cavity hot runner injection mold is in heating, because a heating hole is arranged in the hot runner plate and the pipe type heater is inserted into the hole, plastics in the runner are kept to be in the melting state all along. The secondary nozzle is made of beryllium copper alloy with good thermal conductivity and high strength so that heat can be easy to transfer to the front end. Because the secondary nozzle and the outer wall of a cavity are not insulated in an annular area, the secondary nozzle is called as a semi-insulation nozzle. The secondary nozzle and the hot runner plate are in sliding fit and are sealed by using a packing. During injection moulding, the secondary nozzle and the sprue bushing can be well fit due to the pressure of the plastics so that flash is not generated.

Owner:牟维军

Pressure casting die

The invention provides a pressure casting die, which comprises a fixing die provided with a fixing die cavity, and a movable die provided with a movable die cavity and arranged below the fixing die, wherein the fixing die cavity is matched with the movable die cavity; a fixing die insert is arranged on the fixing die; a movable die insert is arranged on the movable die; the fixing die insert is matched with movable die insert; a sliding block capable of sliding on the movable die is arranged on the movable die; and the fixing die insert and the movable die insert are made of a beryllium copper alloy material. The beryllium copper alloy material has good characteristics of high strength, good heat dissipation performance and the like, so that the heat dissipation performances of the inserts of the pressure casting die are very good; and during the course of product processing, the forming cycle of the product can be shortened, the working efficiency can be improved, and the production cost can lowered.

Owner:东泰精密模具(苏州)有限公司

Method for preparing beryllium-copper alloy sheet by adopting continuous multi-arc ion plating physical vapour deposition

ActiveCN103014634AEasy to operateContinuous beryllium treatmentVacuum evaporation coatingSputtering coatingGas phaseBeryllium-Copper Alloy

The invention relates to a method for preparing a beryllium-copper alloy sheet, in particular to a method for preparing a high-quality beryllium-copper alloy sheet by adopting continuous multi-arc ion plating physical vapour deposition. The method for preparing the beryllium-copper alloy sheet by adopting the continuous multi-arc ion plating physical vapour deposition comprises the following steps: by using a pure Be metal target or a beryllium-copper alloy target with high beryllium content as a cathode, using a pure copper strip as an anode and adopting the multi-arc ion plating physical vapour deposition, depositing a pure Be or Be-rich film which is well combined on the single surface or on double surfaces of the pure copper strip; and then carrying out high temperature diffusion treatment to enable Be atoms to be diffused to permeate a pure copper matrix until the Be content in the copper strip reaches 1 to 3 weight percent, so that a Be alloy strip with excellent mechanical performance and electrical conductivity and Cu content of minus 1 to 3 weight percent is obtained. The method disclosed by the invention is simple and easy to operate, has high working efficiency, is energy-saving and environmental-friendly in the preparing process, has controllable quality and is very suitable for industrial application.

Owner:兰州大成科技股份有限公司 +1

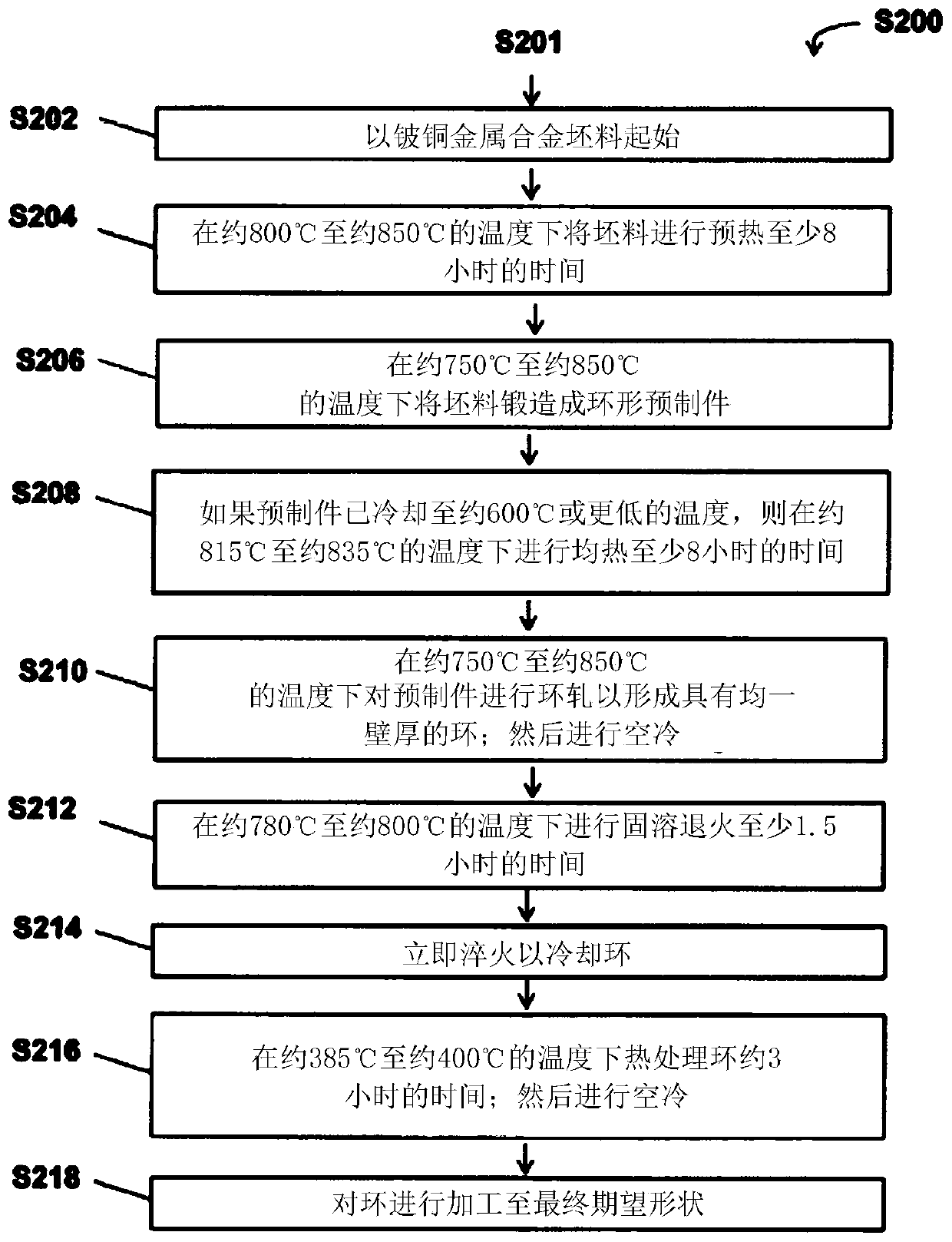

Metal rings formed from beryllium-copper alloys

Owner:MATERION

Tellurium-copper alloy for electric vehicle charging pile connector and production process thereof

The invention relates to tellurium copper alloy for an electric vehicle charging pile connector and a production technology of the tellurium copper alloy. Smelting and casting are conducted by using high-purity cathode copper, copper tellurium intermediate alloy, copper chromium intermediate alloy, copper cobalt intermediate alloy, copper indium intermediate alloy, copper yttrium intermediate alloy, copper antimony intermediate alloy and copper selenium intermediate alloy as raw materials, processing is conducted by the use of a continuous extrusion or hot extrusion method, and then the steps of solid solution treatment, cold rolling, ageing, drawing and the like are adopted, so that the tellurium copper alloy for the electric vehicle charging pile connector is prepared, wherein the tellurium copper alloy is high in strength and electrical conductivity.

Owner:中山市诺乐盟电子有限公司

High-strength high-heat-conductivity beryllium copper alloy

The invention discloses high-strength high-heat-conductivity beryllium copper alloy. The high-strength high-heat-conductivity beryllium copper alloy comprises, by weight, 2.3%-3.7% of beryllium, 0.2%-0.9% of ytterbium, 3.6%-6% of manganese, 8.2%-12.5% of aluminum, 1.2%-2.5% of rare earth elements, 0.8%-1.4% of titanium and the balance copper. According to the high-strength high-heat-conductivity beryllium copper alloy, the vacuum self-consumable electrode electric arc melting technology is adopted, and double annealing, artificial aging treatment and other operations are conducted later, so that the heat conductivity of the beryllium copper alloy is improved, and meanwhile, the high strength and stability of the beryllium copper alloy are also maintained.

Owner:ANHUI YINLONG PUMP VALVE

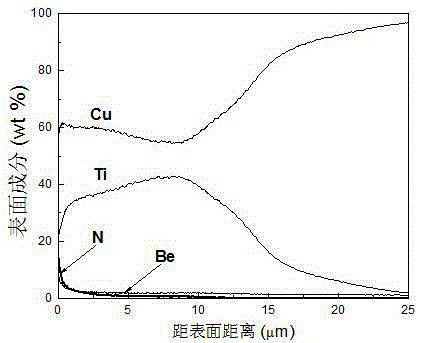

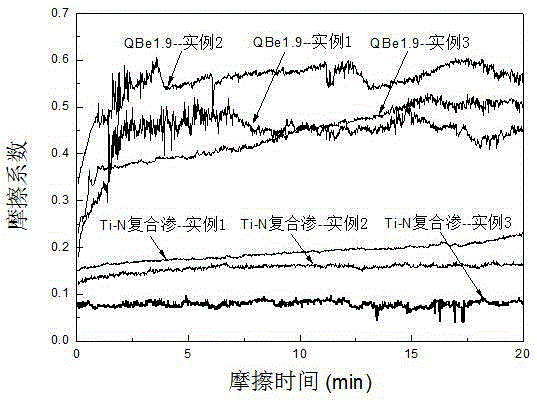

Preparation method for TiN/Ti composite permeable layer on surface of beryllium-copper alloy

ActiveCN105386001AImprove wear resistanceImprove carrying capacityVacuum evaporation coatingSputtering coatingMetallic materialsBeryllium-Copper Alloy

The invention discloses a preparation method for a TiN / Ti composite permeable layer on the surface of beryllium-copper alloy and belongs to the technical field of metallic material surface modification. The preparation method comprises the steps that (1) a beryllium-copper alloy workpiece is pretreated; (2) a plasma titanizing process is conducted in a plasma metal cementation furnace; and (3) the titanized beryllium-copper alloy workpiece is placed in a conventional ion nitriding furnace to be subjected to nitridation, and finally the TiN / Ti composite permeable layer of the beryllium-copper alloy is obtained. According to the preparation method, the plasma surface alloying technique and the ion nitriding technique are combined, the TiN / Ti composite permeable layer is formed on the surface of the soft beryllium-copper alloy, and the obtained composite permeable layer is good in abrasion resistance.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com