Tellurium berylco alloy and preparation method thereof

A technology of beryllium-copper alloy and master alloy, which is applied in the field of free-cutting tellurium-beryllium-copper alloy and its preparation, can solve the problems of large influence of plasticity of copper alloy, poor thermal processing performance of lead-containing beryllium-copper alloy, cracking of beryllium-copper alloy, etc., to achieve Good stability in plastic thermal processing, high temperature softening temperature point, and the effect of improving electrical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Fabrication of beryllium tellurium copper tubes by extrusion

[0045] (1) Dosing is carried out according to the weight percentage of Table 1, and the feeding order is successively cathode copper CATH-1, copper-beryllium master alloy (containing beryllium 4%), pure tellurium, copper-nickel master alloy (containing nickel 10%), copper-cobalt master alloy (Containing 10% cobalt), using a 750Kg power frequency cored furnace for melting and non-vacuum induction furnace, the melting temperature is 1170 ° C, until the melt melts, keep it warm for 15 minutes, pass in argon gas to remove impurities and gases, after degassing and removing impurities , stand still for 15 minutes, and then cast a Φ155 round ingot with a hydraulic semi-continuous casting machine, casting temperature 1100 ° C, argon protection, casting speed 150-250mm / min, cooling water pressure 0.3MPa, sawing cut length Φ155×330;

[0046] (2) The round ingot is hot-extruded at a temperature of 910°C, the extrusion ...

Embodiment 2

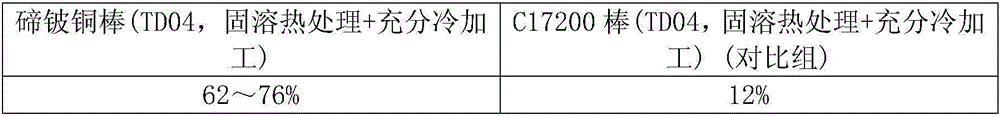

[0057] Embodiment 2: Continuous casting method prepares beryllium tellurium copper bar

[0058] (1) carry out batching according to table 4 weight percent, raw material is cathode copper CATH-1, copper-beryllium master alloy (containing beryllium 10%), copper-tellurium master alloy (containing tellurium 10%), copper-nickel master alloy (containing nickel 10%) ), copper-cobalt master alloy (containing 10% of cobalt), using vacuum induction furnace for smelting, firstly adding cathode copper CATH-1, copper-tellurium master alloy (containing 10% of tellurium), copper-nickel master alloy (containing 10% of nickel), Copper-cobalt master alloy (containing 10% cobalt), after melting, use a vacuum feeding device to add copper-tellurium master alloy (containing 10% tellurium), copper-beryllium master alloy (containing 10% beryllium), after melting, heat up to 1270 ° C, and remove slag at high temperature , then lower the temperature to 1120°C with low power, and keep it warm for 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com