Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve electrical corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

Novel anti-pollution flashover coating for ultra and super high voltage insulator

ActiveCN105086820AReduce the temperaturePrevent escapeFireproof paintsAntifouling/underwater paintsSolventSurface-active agents

The invention belongs to the technical field of functional coatings and particularly relates to a novel anti-pollution flashover coating for an ultra and super high voltage insulator. The novel anti-pollution flashover coating comprises, by mass, 40%-50% of room temperature vulcanized silicone rubber, 5%-10% of titanate coupling agent, 2%-6% of composite fire retardant, 5%-12% of modified composite reinforcing agent, 2%-4% of nano TiO2, 0.5%-1% of surface active agent, 1%-5% ofhexamethyldisilazane, 0.2%-0.5% of antifoaming agent, 0.3%-0.6% of catalyst, 0.3%-0.6% of cross-linking agent and the balance solvent. The prepared anti-pollution flashover coating is sprayed on the surface of the cleaned ceramic insulator, and the coating can be used after being naturally cured for 96 hours under the condition of 25 DEG C+ / -2 DEG C and 40%-70% of RH. According to the anti-pollution flashover coating, after the sprayed anti-pollution flashover coating is completely cured, the contact angle is not smaller than 135 degrees.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

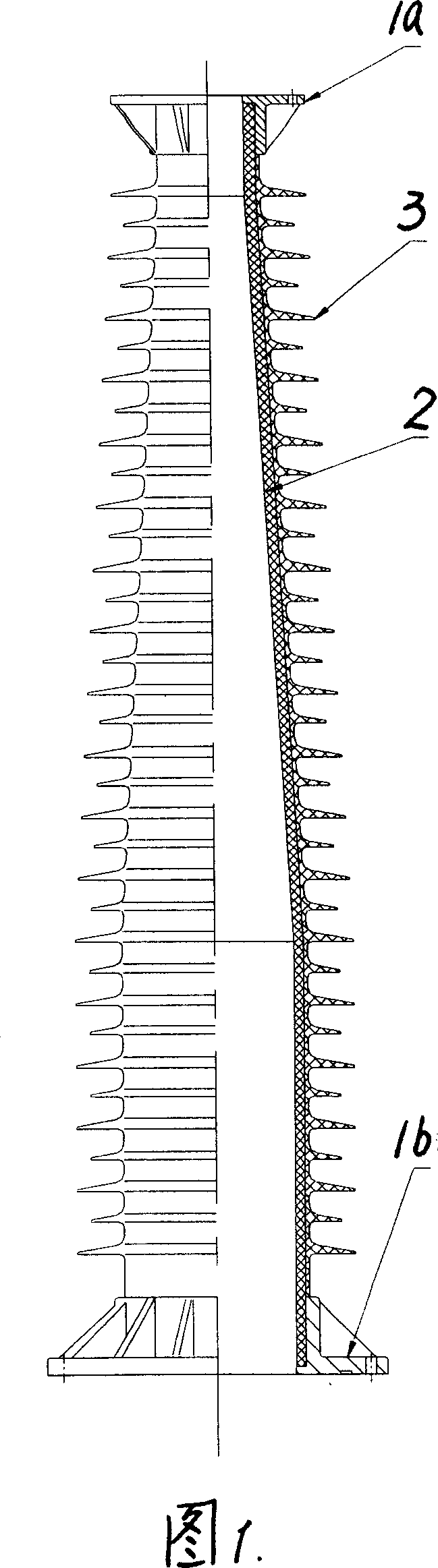

Reducing diameter high voltage hollow composite insulator and its manufacturing method

InactiveCN101000816ALower center of gravity and frontal areaIncreased bending load requirementsInsulatorsEngineeringSilicon disulfide

A high voltage hollow composite insulator of diameter variable type is prepared as sticking end connection pieces firmly at two ends of winding tube, setting a unified structure of umbrella body at external of winding tube, setting said winding tube to be tube body in variable diameter, using high temperature silicon sulfide rubber to form a unified structure of umbrella body by injection forming process.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

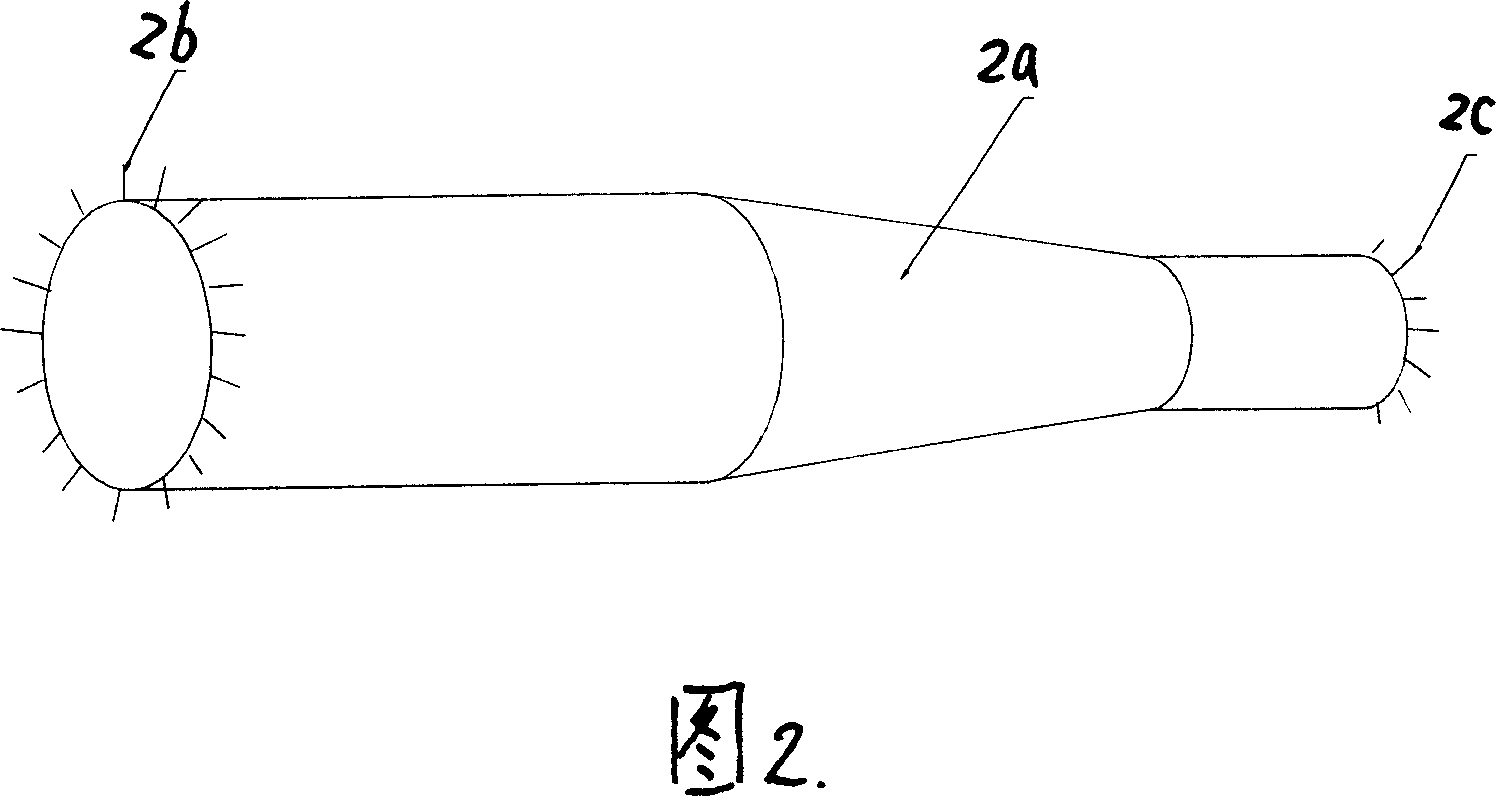

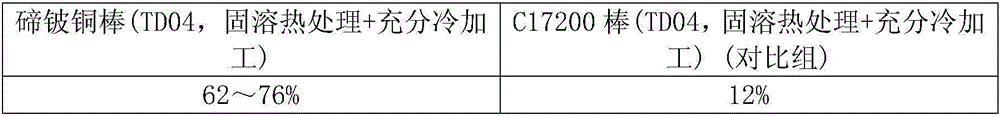

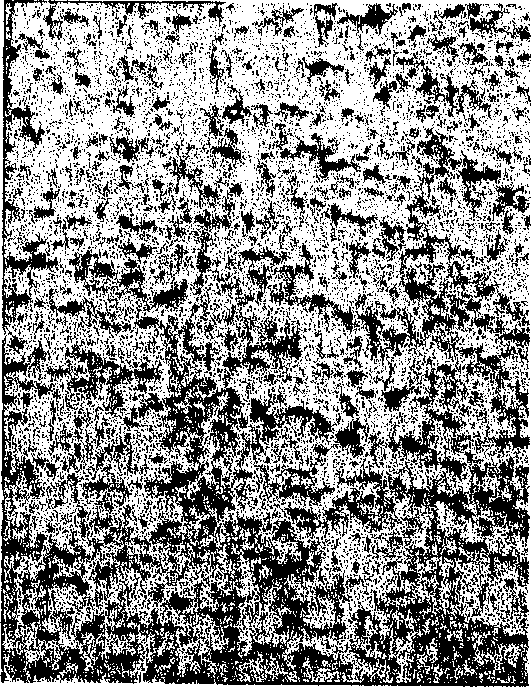

Tellurium berylco alloy and preparation method thereof

The invention discloses a tellurium berylco alloy; the tellurium berylco alloy is prepared from 0.2-2.1 wt.% of Be, 0.1-0.7 wt.% of Te, and others including Co, Ni, Ti, rare-earth elements and impurity elements of which total is not more than 4% wt; the rest is Cu; the preparation method includes steps of a, dosing, feeding, smelting and casting raw materials to acquire an ingot blank according to weight percent; b, orderly performing homogenizing heat treatment, heat processing technique, cold processing technique and annealing, solid dissolving, and aging heat treatment on the ingot blank acquired in step a orderly; and preparing the tellurium berylco alloy. Through adding tellurium in the berylco alloy, tellurium and a copper base can form Cu2Te; the tellurium berylco alloy is good in high-temperature stability, remains the excellent physical performance and corrosive resistance of tellurium beryllium copper, and greatly improves the material cutting performance on the basis of environmental protection, and also performs the plasticity performance.

Owner:KINKOU SUZHOU COPPER IND CO LTD

Silver-copper-carbon-rare earth alloy material and production thereof

One kind of alloy that composed by Ag-Cu-C-RE has a good material electricity property. Add Cu and rare-earth element in Ag-C material to form one kind of Ag-Cu-C-RE alloy that synthesized by the method of mechanical composition. Its advantages: a good property; a lower cost by using Cu and RE; obvious technology advantage and marker competitive; and fit for the national policy of saving Ag; can yield good economic returns and social returns.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

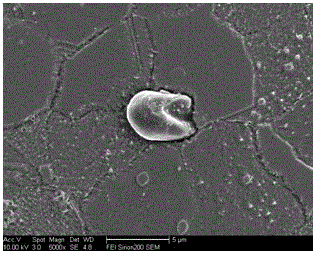

Composite material tool electrode for electrolytic deposition and electric spark and preparation method thereof

ActiveCN103878455AHigh specific heat capacityHigh hardnessElectrical-based machining electrodesMachined surfaceHardness

The invention discloses a composite material tool electrode for electrolytic deposition and electric spark and a preparation method of the composite material tool electrode, and belongs to the technical field of electrical discharge machining of electric spark. The composite material tool electrode for electrolytic deposition and electric spark is characterized by comprising, by weight, 16-18% of SiC particles, 14-16% of TiB2 particles, and the balance copper as a base body, and the SiC particles and the TiB2 particles are embedded in the base body. Due to the fact that the SiC particles and the TiB2 particles are added to the copper base body, compared with the method that only the SiC particles are added in the initial research stage, on the premise of not changing the total adding amount, the specific heat capacity of the tool electrode is improved by 10%, the coefficient of thermal expansion is lowered by 3%, the hardness is improved by 5%, and therefore the loss of the electrode under same electrical discharge machining parameters is lowered by 7%, and the roughness of a machined surface is lowered by 2%.

Owner:SHANDONG UNIV OF TECH

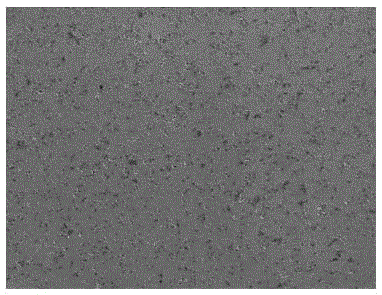

High-conductivity abrasion-resistant coating for guide rail and preparation technology thereof

ActiveCN106282884AImprove thermohardnessHigh hardnessMolten spray coatingFailure rateChemical composition

The invention relates to a high-conductivity abrasion-resistant coating for a guide rail and a preparation technology thereof. The coating comprises the following chemical components by content: 45 to 55% of Mo, 15 to 25% of Cu, 6 to 10% of Cr, 1 to 3% of B and 2 to 4% of Si, and the balance being Ni. The preparation technology comprises the steps like surface down cutting of the to-be-coated guide rail, surface cleaning of the guide rail, shield protection, sand-blasting roughening, coating preparation and coating grinding processing. The preparation technology is characterized in that a high-speed plasma spraying technology is adopted, a uniform and compact large-thickness, high-conductivity and abrasion-resistance coating can be prepared on the surface of an electromagnetic railgun launching guide rail, the thickness of the grinded coating is 1.0 to 1.1 mm, the bonding strength of the coating and the guide rail is 20 to 35 MPa, the microhardness of the coating is 450 to 600 HV, and the electric conductivity is 5 to 12% IACS. The obtained high-conductivity abrasion-resistant coating is mainly used in special parts like the electromagnetic railgun launching guide rail, the surface hardness, abrasion resistance and electrical erosion resistance of the guide rail can be effectively improved, the service life is prolonged, the thermal hardness of the surface of the guide rail is improved, the failure rate of grinding is decreased, and the coating has important engineering application value.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

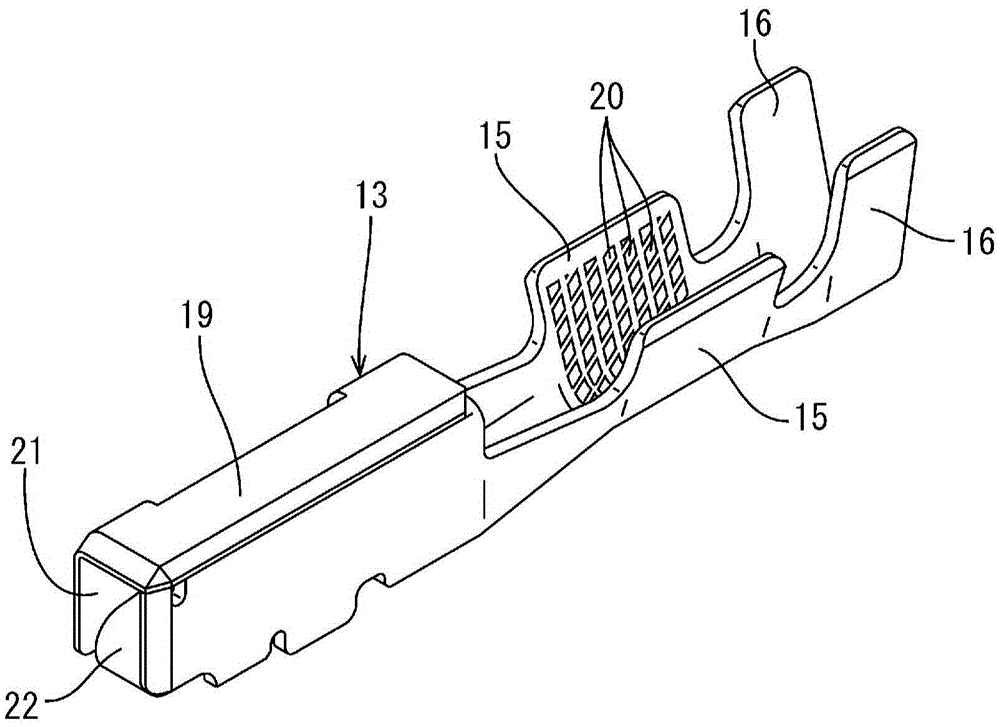

Terminal-equipped wire and method of producing terminal-equipped wire

ActiveCN105379018AImprove electrical corrosion resistanceLine/current collector detailsConductive materialIonizationMetal

Owner:AUTONETWORKS TECH LTD +3

Wind self-cleaning type composite insulator

InactiveCN103151121AEnhance anti-pollution flashover capabilityAvoid deformationInsulatorsComposite insulatorsErosion

The invention relates to a wind self-cleaning type composite insulator, which consists of a fitting ball head, a fitting ball socket, a rod core and a composite outer sleeve. The composite insulator is characterized in that the upper surface of an umbrella skirt of the composite insulator is an arc rotary surface, and is provided with a wind cleaning ring (5), and each cleaning ring can clean to the edge of each umbrella skirt of the insulator under a general wind attitude (8), to the most of part of the upper surface of each umbrella skirt under a weak wind attitude (9), to the highest part of the upper surface and the center part of the lower surface of each umbrella skirt under a high wind attitude (10), and to the lower surface (4) of each umbrella skirt under a strong wind attitude (11). Compared with the wind cleaning ring of the existing composite insulator, the composite insulator has the advantages that the wind cleaning area is greatly increased, the anti-pollution flashover capability of the insulator is improved, the aging-resistant performance, the breakdown-resistant performance and the electrical erosion-resistant performance are higher, and the deformation of the umbrella skirts difficultly occurs.

Owner:SHANGHAI GENDOW ELECTRIC POWER TECH

Fluorocarbon coating with high flame retardance, tracking resistance and electrical erosion resistance as well as preparation method and application of fluorocarbon coating

InactiveCN112029346AImprove flame retardant performanceHigh bond energyFireproof paintsCarbon coatingElectric power equipment

The invention relates to a fluorocarbon coating with high flame retardance, tracking resistance and electrical erosion resistance as well as a preparation method and an application of the fluorocarboncoating, and belongs to the field of electrical insulation materials. The fluorocarbon coating comprises a component A and a curing agent, the component A comprises the following raw materials by weight: 100 parts of fluorocarbon resin; 100 parts of butyl acetate; 30 to 80 parts of a composite flame retardant; 20 to 80 parts of an anti-creeping tracking agent; and 0.2-1 part of dispersing agent.The application of the fluorocarbon coating in the field of external insulation of power equipment is expanded, and the fluorocarbon coating has excellent tracking resistance and flame retardance, canresist tracking damage and provides safety guarantee. The coating is a fluorocarbon coating with good flame-retardant effect, tracking resistance and electric corrosion resistance, can resist electric corrosion and high-temperature damage caused by the electric corrosion, and opens up the application field of the fluorocarbon coating in the aspect of external insulation of power equipment.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Anti-pollution flashover coating and preparation method thereof

PendingCN112011227AUniform colorImprove electrical corrosion resistanceAntifouling/underwater paintsPaints with biocidesFluorocarbon ResinsAntifoam agent

The invention relates to the field of anti-pollution flashover coatings, and particularly provides an anti-pollution flashover coating and a preparation method thereof. The anti-pollution flashover coating comprises the following raw materials in parts by weight: 90-120 parts of fluorocarbon resin, 90 to 120 parts of butyl acetate, 5-20 parts of a reinforcing filler, 40 to 80 parts of an inorganicflame retardant, 10 to 20 parts of pigment, 0.2-1 part of a dispersing agent, 0.1 to 0.5 part of an antifoaming agent, 0.1 to 0.5 part of leveling agent, 8-16 parts of curing agent. The preparation method of the anti-pollution flashover coating comprises the following steps: adding the dispersing agent into butyl acetate, stirring, adding the reinforcing filler, the inorganic flame retardant andthe pigment filler, carrying out high-power ultrasonic dispersion to obtain pigment filler dispersion liquid, pouring the pigment and filler dispersion liquid into a grinding machine, blending and grinding with fluorocarbon resin, adding an antifoaming agent and a leveling agent into the grinding system, sieving the obtained mixed liquid through a screen to obtain a coating component A, and beforeuse, mixing and stirring the component A and the curing agent to obtain the product. The coating is good in comprehensive performance and simple to prepare.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Method for manufacturing gradient composite electrode for electrical spark rough machining and electrical spark finish machining for laser solid forming

ActiveCN104972186AImprove equalization performanceImprove processing qualityElectrical-based machining electrodesElectricityElectric discharge

The invention discloses a method for manufacturing a gradient composite electrode for electrical spark rough machining and electrical spark finish machining for laser solid forming and belongs to the technical field of electric discharge machining. The method comprises the steps that a three-dimensional solid model is generated by means of software, the model is sliced and layered, and the parameters of all slice layers are obtained; then, Cu-based SiC composite micro powder is sintered on a vibrating substrate by means of laser according to the shape parameter of the slice layer on the inner side; finally, Cu powder and graphite powder are sintered on a Cu-based SiC composite sediment layer in a mixing mode by means of laser according to the shape parameter of the slice layer on the outer side. The electrode manufactured through the method is provided with a gradient structure, and electricity is discharged firstly by the Cu-based graphite sediment layer located on the outer layer of the electrode so as to achieve rough machining of a workpiece; then finish machining of the workpiece is achieved by means of the Cu-based SiC composite sediment layer of the electrode. Meanwhile, the Cu-based SiC composite micro powder is formed by blowing SiC particles in molten Cu in a dispersed mode by means of nitrogen and then conducting atomization and cooling, in this way, the distribution uniformity of the SiC particles is improved, and the equilibrium of the electric corrosion resistance of the electrode is improved.

Owner:SHANDONG UNIV OF TECH

High-fatigue-resistance alloy steel material for automobile crankshafts

The invention discloses a high-fatigue-resistance alloy steel material for automobile crankshafts. The high-fatigue-resistance alloy steel material is composed of, by weight, 0.5%-0.8% of carbon, 1.4%-1.7% of silicon, 0.9%-1.5% of manganese, 0.6%-0.8% of zinc, 0.05%-0.07% of titanium, 0.5%-0.8% of nickel, 0.003%-0.05% of aluminum, 0.1%-0.2% of boron, 0.02%-0.05% of niobium, less than or equal to 0.015% of sulfur, less than or equal to 0.015% of phosphorus, and the balance iron and inevitable impurities. The prepared alloy steel material is excellent in comprehensive performance, and has high tensile strength and good fatigue resistance. A process method is simple, convenient to operate and suitable for industrial application and reduces cost.

Owner:ANHUI HEKUANG MACHINERY

Silver-based multicomponent alloy composite solution and method for preparing functional coating through silver-based multicomponent alloy composite solution

The invention provides a silver-based multicomponent alloy composite solution and a method for preparing a functional coating through the silver-based multicomponent alloy composite solution. The silver-based multicomponent alloy composite solution comprises components with the following concentrations: 40-80 g / L of KAg(CN)2, 45-75 g / L of KCN, 5-50 g / L of K4P2O7.3H2O, 0.2-1.0 g / L of nickel salt (by Ni), 15-25 g / L of sodium potassium tartrate, 0.1-0.8 g / L of antimonic salt (by Sb), 0.2-2 g / L of rare earth oxide and 5-50 ml / L of cationic dispersion activator, wherein H2O serves as a solvent. The pH value of the silver-based multicomponent alloy composite solution is adjusted to range from 9 to 11. The silver consumption of the functional coating is reduced, and the cost performance of a product is improved.

Owner:佛山市宇光电气有限公司

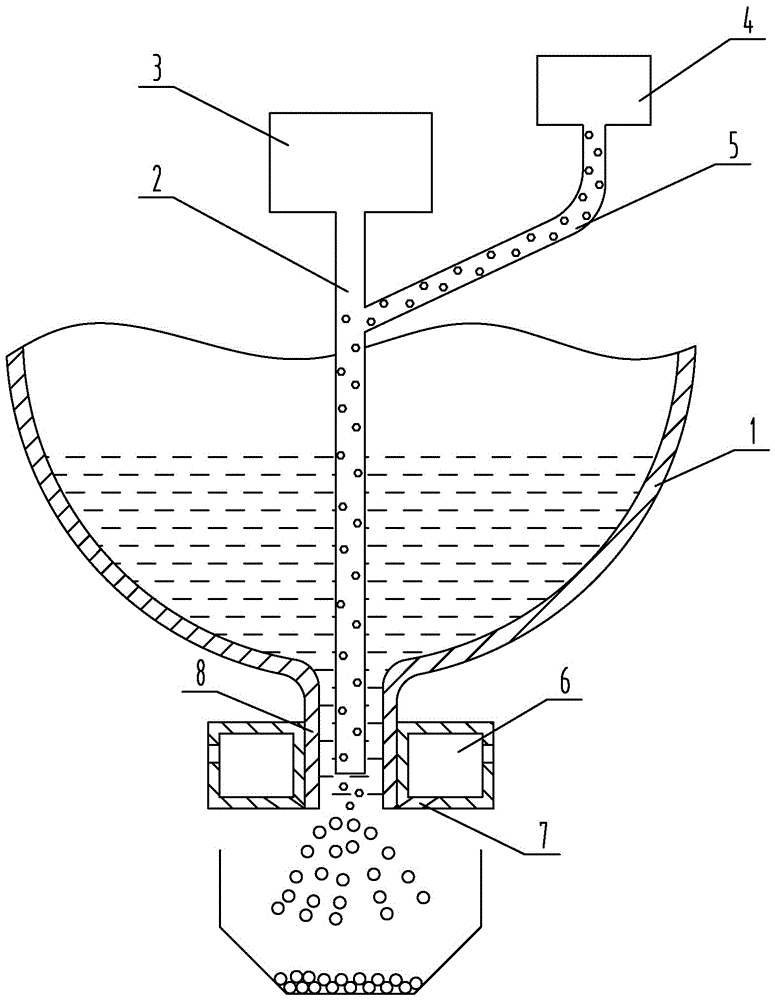

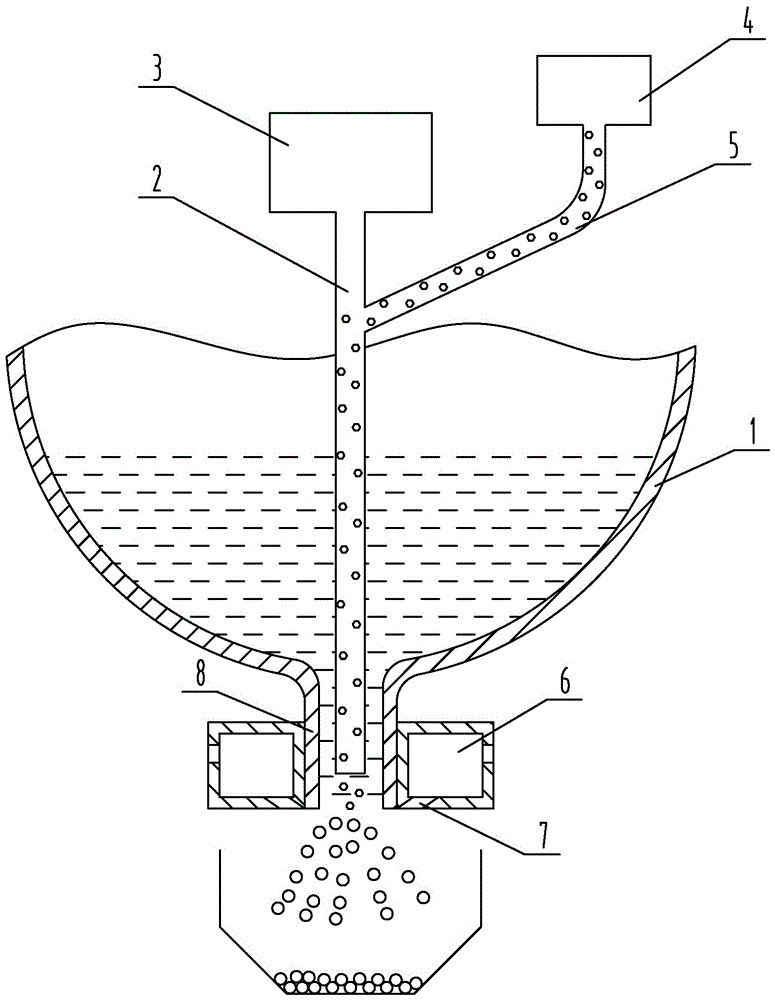

Method for preparing Cu-based SiC composite micro powder for electrode of electric spark tool

ActiveCN104972133AImprove uniformityIncrease contentLiquid/solution decomposition chemical coatingElectric dischargeCopper plating

The invention discloses a method for preparing Cu-based SiC composite micro powder for an electrode of an electric spark tool and belongs to the technical field of electric discharge machining. The method relates to a funnel. The method is characterized in that electroless copper plating and drying are conducted on the surface of SiC particles, so that SiC copper-plated particles are obtained; molten Cu is poured into the funnel, the SiC copper-plated particles are added into a uniform feeder, the SiC copper-plated particles enter a guide pipe evenly by means of a feeding pipe and are blown out of the guide pipe under the constant-speed wind force of a high-pressure nitrogen source, the peripheries of the SiC copper-plated particles are wrapped in the molten Cu, the SiC copper-plated particles drip down from a discharge spout together with the molten Cu, and the SiC copper-plated particles wrapped by the molten Cu are atomized into composite micro powder by means of gas. According to the method, the SiC particles are blown into the molten Cu in a dispersed mode by means of nitrogen, and thus the distribution uniformity of the SiC particles is improved; meanwhile, by increasing the feeding speed of the SiC copper-plated particles, the content of the SiC particles can be flexibly increased, and the electric corrosion resistance can be improved easily.

Owner:SHANDONG UNIV OF TECH

Silver copper based metal oxide electrical contact material containing adding elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

Low-temperature-resistant anti-crack alloy steel material for automobiles

The invention discloses a low-temperature-resistant anti-crack alloy steel material for automobiles. The alloy steel material is composed of, by weight, 0.4%-0.7% of carbon, 1.9%-2.3% of silicon, 0.5%-0.8% of manganese, 0.6%-0.8% of molybdenum, 0.007%-0.05% of bismuth, 1.2%-1.4% of nickel, 0.003%-0.05% of aluminum, 0.01%-0.02% of vanadium, 0.003%-0.01% of tin, less than or equal to 0.015% of sulfur, less than or equal to 0.015% of phosphorus, and the balance iron and inevitable impurities. The alloy steel material has the characteristics of being high in strength, resistant to impact, abrasion and brittle fracture under low temperature and good in welding performance, and the quality of products is stable and uniform. The alloy steel material applied to automobile parts is low in cost and long in service life.

Owner:ANHUI HEKUANG MACHINERY

Zirconium element doped alloy steel material

InactiveCN105970103APrevent oxidationGood dispersionTransportation and packagingMetal-working apparatusIridiumSulfur

The invention discloses a zirconium element doped alloy steel material. The zirconium element doped alloy steel material is prepared from, by weight percent, 0.2%-0.6% of carbon, 1.6%-2.5% of silicon, 1.0%-1.5% of manganese, 2.6%-2.8% of molybdenum, 0.3%-0.5% of boron, 0.04%-0.06% of zirconium, 0.003%-0.05% of aluminum, 0.01%-0.02% of iridium, not larger than 0.015% of sulfur, not larger than 0.015% of phosphorus and the balance iron and inevitable impurities. The prepared alloy steel material is attractive in appearance, large in rigidity, high in wear and corrosion resistance and low in cost; the preparation process is simple, and high operability is achieved; and the alloy steel material has few product defects and is worthy of popularization.

Owner:ANHUI HEKUANG MACHINERY

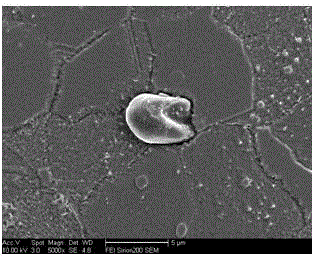

A kind of preparation method of photocatalytic thin film foam body for electrocatalytic reaction

ActiveCN107051417BImprove electrical corrosion resistanceExtended service lifeCatalyst activation/preparationThin membranePhoto catalysis

The invention discloses a method for preparing a photocatalytic film foam for electrocatalytic reaction. A photocatalytic film is formed on the surface of the foam by dipping and pulling, and then the photocatalytic film is processed under the voltage and current conditions of the electrocatalytic device. The organic matter in the film is degraded and decomposed to form a stable film material. At the same time, the degradation removes the easy-to-shed chemical bonds on the surface, reducing the generation of impurities and reducing the impurity pollution caused by the electrical corrosion process.

Owner:绍兴市梓昂新材料有限公司

A kind of pt-ru-ir alloy spark plug electrode material and its preparation method and applied spark plug

The present invention disclosed a spark plug that PT 公Ru IR alloy spark plugs and their preparation methods and applications. The spark plug electrode material includes: RU 1 to 20 %, IR 1 to 10 %, metal element A 0.05‑55555%, Rare earth element B 0.05‑1.5 %, the balance is PT and inevitable impurities. The metal element A is selected from one or more in one or more in the metal element A from RE, Al, W, NB, Th, Ti, ZR, CR.The present invention can reduce the amount of precious metals, reduce costs, enhance the combination of the crystal world in the alloy organization, improve the toughness and intensity of alloy materials, and improve the resistance of the alloy material's high temperature and ablation;The growth of such shaft crystals has improved the high temperature persistence and conductivity of the alloy.At the same time, the present invention adopts electrical pulse treatment and fast -cooled casting technology during the preparation process, reducing the analysis of components in the process of preparation alloy, reducing the resistivity, and improving the anti -electrical erosion capacity.

Owner:昆明富尔诺林科技发展有限公司

Electronic voltage transformer

ActiveCN102024555BImprove stabilityReduce crackingTransformersVoltage/current isolationCapacitive voltage dividerEngineering

The invention relates to an electronic voltage transformer, which is used in the power industry. The electronic voltage transformer consists of a connection terminal, a lifting ring, a capacitive voltage divider, a supporting seat, a grounding terminal, a connecting piece, a pull box and a collector, wherein the capacitive voltage divider is fixed on the supporting seat and provided with the lifting ring and the connection terminal; the grounding terminal is connected with the capacitive voltage divider and arranged below the supporting seat; the connecting piece is fixed on the supporting seat and connected with the pull box; and the collector is arranged in the pull box. An umbrella skirt of an insulated sleeve of the capacitive voltage divider adopts a structural form which is formed by one-step overall injection molding of high-temperature vulcanizing silicone rubber, so that the phenomenon of easy cracking at the joint of the umbrella skirt is avoided, and pollution flashover resistance and galvanic corrosion resistance are enhanced; an optical fiber is used for transmitting, so that a transmission frequency band is wide; a lower connecting end is provided with a reinforcing rib, so that the capacitive voltage divider has high stability; and the supporting seat has a splayed-shape structure, so that the wind resistance and stabilizing capability of equipment are enhanced.

Owner:JIANGSU SIYUAN HERTZ TRANSFORMER

Preparation method of graded composite electrode for laser three-dimensional forming electric discharge rough and fine machining

ActiveCN104972186BImprove equalization performanceImprove processing qualityElectrical-based machining electrodesElectric dischargeNitrogen gas

The invention discloses a preparation method of a gradient composite electrode for laser three-dimensional forming electric discharge rough and fine machining, which belongs to the technical field of electric discharge machining, and uses software to generate a three-dimensional solid model, slices and layers the model, and obtains the parameters of each slice layer ; Then use laser to sinter Cu-based SiC composite micro-powder on the vibrating substrate according to the shape parameters of inner slice layers; finally use laser to mix and sinter Cu powder and graphite powder on Cu-based SiC composite deposition according to the shape parameters of outer slice layers layer. The electrode prepared by this method has a gradient structure, and the Cu-based graphite deposition layer located on the outer layer of the electrode is discharged first to realize the rough machining of the workpiece; then the Cu-based SiC deposition layer of the electrode is used to complete the finishing of the workpiece; The composite micropowder is formed by spraying and cooling SiC particles in Cu melt with nitrogen gas, which improves the uniformity of SiC particle distribution and improves the balance of electrode corrosion resistance.

Owner:SHANDONG UNIV OF TECH

A composite material tool electrode for electrodeposition electric discharge and its preparation method

ActiveCN103878455BHigh specific heat capacityHigh hardnessElectrical-based machining electrodesMachined surfaceThermal expansion

The invention discloses a composite material tool electrode for electrolytic deposition and electric spark and a preparation method of the composite material tool electrode, and belongs to the technical field of electrical discharge machining of electric spark. The composite material tool electrode for electrolytic deposition and electric spark is characterized by comprising, by weight, 16-18% of SiC particles, 14-16% of TiB2 particles, and the balance copper as a base body, and the SiC particles and the TiB2 particles are embedded in the base body. Due to the fact that the SiC particles and the TiB2 particles are added to the copper base body, compared with the method that only the SiC particles are added in the initial research stage, on the premise of not changing the total adding amount, the specific heat capacity of the tool electrode is improved by 10%, the coefficient of thermal expansion is lowered by 3%, the hardness is improved by 5%, and therefore the loss of the electrode under same electrical discharge machining parameters is lowered by 7%, and the roughness of a machined surface is lowered by 2%.

Owner:SHANDONG UNIV OF TECH

A new type of anti-pollution flashover coating for special and ultra-high voltage insulators

ActiveCN105086820BHigh strengthHigh tensile strengthFireproof paintsAntifouling/underwater paintsUltra high voltageSurface-active agents

The invention belongs to the technical field of functional coatings, and specifically relates to a novel anti-fouling flashover coating for special and ultra-high voltage insulators. The mass percentages of the components are as follows: room temperature vulcanized silicone rubber 40%-50%; titanate coupling agent 5%-10% %; composite flame retardant 2‑6%; modified composite reinforcing agent 5‑12%; nano-TiO22‑4%; surfactant 0.5%‑1%; hexamethyldisilazane 1%‑5%; Defoamer 0.2%-0.5%; catalyst 0.3%-0.6%; cross-linking agent 0.3%-0.6%; the rest is solvent. Spray the prepared anti-fouling flashover coating on the surface of the cleaned ceramic insulator, and use it after natural curing for 96 hours at 25°C±2°C, 40%-70%RH. For the antifouling flashover coating, after the antifouling flashover coating is sprayed and cured completely, the contact angle is not less than 135°.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Preparation method of diamond-nickel composite coating electrosparking electrode

PendingCN114525560AImprove electrical corrosion resistanceLower work functionComposite electrodeElectrical discharge machining

The preparation method of the diamond-nickel composite coating electric spark machining electrode is specifically implemented according to the following steps that 1, diamond micro powder is pretreated; step 2, pretreating the metal-based electrode; 3, the diamond micro-powder nickel pre-sulfate solution pretreated in the step 1 is mixed to prepare a plating solution, the metal-based electrode pretreated in the step 2 is placed in the plating solution for chemical composite plating, and a composite electrode is obtained; and step 4, drying the composite electrode to obtain the composite electrode. Diamond and nickel metal with high electric corrosion resistance are plated on a metal base electrode in a chemical composite plating mode, the electric spark machining composite electrode with high electric corrosion resistance is prepared, and the electrode can effectively reduce length loss and side surface loss and improve machining precision.

Owner:SHAANXI RAILWAY INST

Silver-copper-carbon-rare earth alloy material and production thereof

One kind of alloy that composed by Ag-Cu-C-RE has a good material electricity property. Add Cu and rare-earth element in Ag-C material to form one kind of Ag-Cu-C-RE alloy that synthesized by the method of mechanical composition. Its advantages: a good property; a lower cost by using Cu and RE; obvious technology advantage and marker competitive; and fit for the national policy of saving Ag; can yield good economic returns and social returns.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

A kind of high conductive wear-resistant coating for guide rail and preparation process thereof

ActiveCN106282884BImprove thermohardnessHigh hardnessMolten spray coatingFailure rateSurface cleaning

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A kind of preparation method of Cu-based SIC composite micropowder for electric discharge tool electrode

ActiveCN104972133BImprove uniformityIncrease contentLiquid/solution decomposition chemical coatingElectric dischargeCopper plating

The invention discloses a preparation method of Cu-based SiC composite micropowder for electric spark tool electrodes, which belongs to the technical field of electric spark discharge machining, and includes a funnel, and is characterized in that the surface of SiC particle is chemically copper-plated and dried to obtain SiC copper-plated particle ;Pour the Cu melt into the funnel, and add the SiC copper-plated particles into the uniform feeder, and the SiC copper-plated particles enter the conduit evenly through the feeding tube, and are blown out of the conduit under the uniform wind force of the high-pressure nitrogen source, and the Cu melt is coated On the periphery of the SiC copper-plated particles and leaked from the nozzle together, they are atomized into composite fine powder by gas. This method uses nitrogen to blow SiC particles into Cu melt, which improves the uniformity of SiC particle distribution; at the same time, by increasing the feeding speed of SiC copper-plated particles, the content of SiC particles can be flexibly increased, which is beneficial to improve the anti-corrosion performance.

Owner:SHANDONG UNIV OF TECH

An anti-pollution flashover insulating coating with added micro-nano composite particles and its preparation process

ActiveCN105086826BSolve the problem of easy pollution flashLower surface energyFireproof paintsAntifouling/underwater paintsContamination zoneSolvent

The invention discloses an anti-fouling flashover insulating coating added with micro-nano composite particles and a preparation process thereof. The weight percentage of each raw material is such as: fluorosilicone resin 36%-52%; micron-sized (10μm-200μm) composite particles: mainly fumed white carbon black 3%-5% CaCO3 0.5%-1.5%, CeO2 0.3%-1% and 0.5%-1.5% cerium fluoride composite particles and 2%-6% composite cross-linking agent for modification of micron-sized particles, 3%-8% composite reinforcing agent, nano-scale (25nm-75nm) composite particles: mainly There are nano-SiO2 0.3%-1%, nano-TiO2 2%-4%, nano-lanthanum oxide 0.2%-0.5%, and composite cross-linking agent for micron particle modification 2%-4%, surfactant 0.5% ‑1.5%, hexamethyldisilazane 3.5%‑7.5%, fluorosilicone resin defoamer 0.2%‑0.5%, catalyst 0.3%‑0.6%, composite titanate coupling agent 4%‑11%, composite Flame retardant 2%-6%, the rest is solvent. The preparation process of the anti-pollution flashover insulating coating in heavily polluted areas with the addition of micro-nano composite particles provided by the present invention adopts the method of segmented preparation and module combination, which can be industrialized and has excellent anti-pollution flashover performance, and can be widely used in heavily polluted areas. Power equipment for UHV transmission lines.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Hollow compound insulator for 1100kV combined electrical appliance and its making method

ActiveCN101123132BImprove anti-corrosion performanceImprove performanceLead-in/lead-through insulatorsEpoxyGlass fiber

The invention relates to a hollow composite insulator used in 1100kV composite apparatus in power industry, and a producing method of the insulator. The insulator comprises an end connecting part, an insulation tube and an umbrella. The end connecting parts are stuck on the two ends of the winding tube. The invention is characterized in that: an integrated umbrella is stuck at the out side of an insulation tube; the insulation tube is a wound tube with an inner liner; the umbrella is an injecting-formed part made of high-temperature vulcanization silicon rubber, and because the inner liner of the insulation tube is an epoxy resin adhesive and SF6 decomposition mixing and solidifying structure, the anti-corrosion performance of the product is greatly increased; the umbrella is hot-solidified on the surface of the insulation tube at high vacuum and high temperature, so the connecting strength between the umbrella and the insulation tube is high, and the product performance is more stable and reliable. When winding the insulation tube, a track is first simulated on a computer, and then pins are fixed on both shaft ends of the mold core. When winding, a mechanism with even and constant tension force is used for control, thus realizing even paving of the glass fiber.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com