Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

638 results about "Fluorocarbon Resins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorocarbon resin. Polymeric material made up of carbon and fluorine with or without other halogens (such as chlorine) or hydrogen; the resin is extremely inert and more dense than corresponding fluorocarbons such as Teflon.

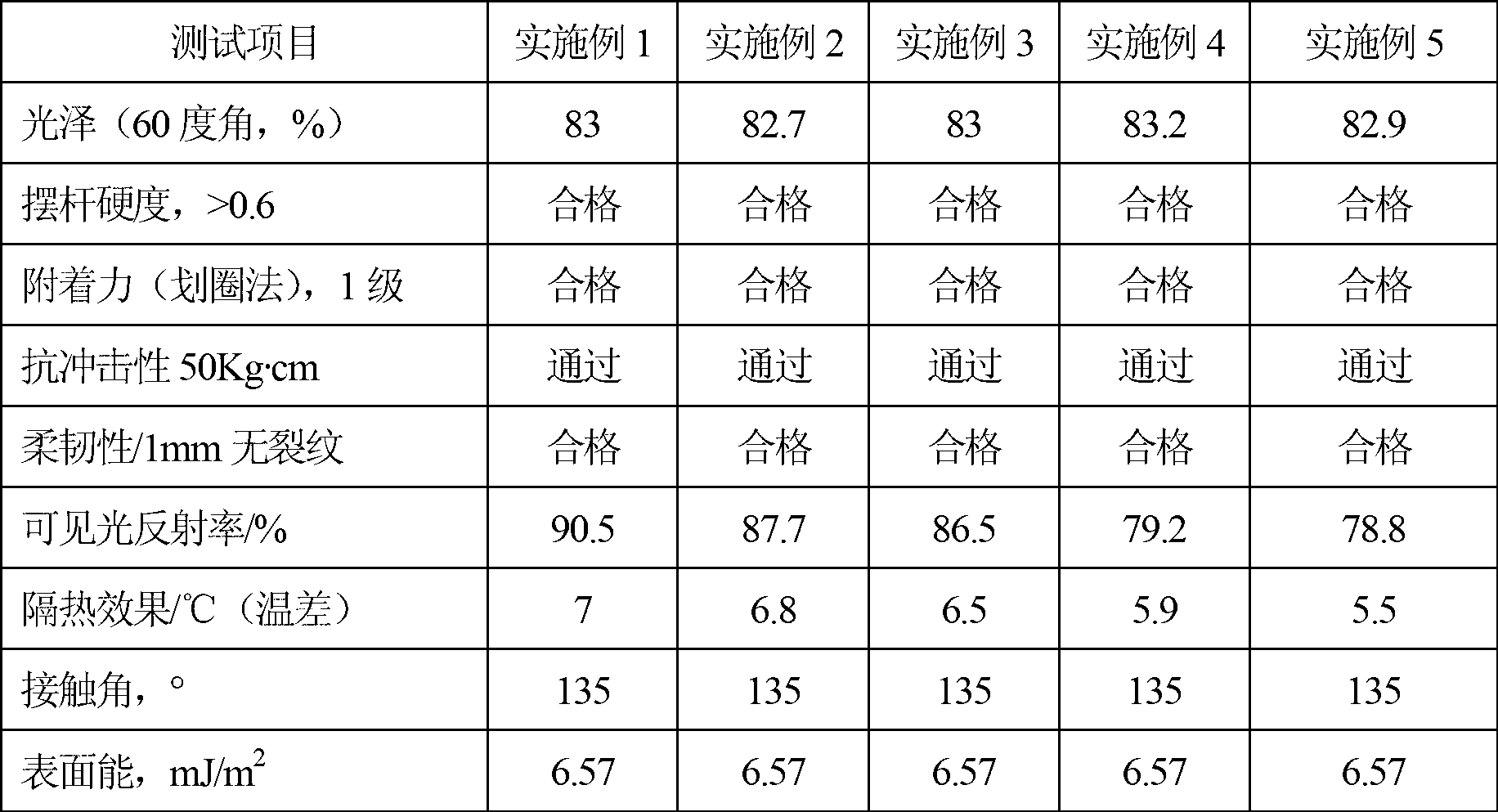

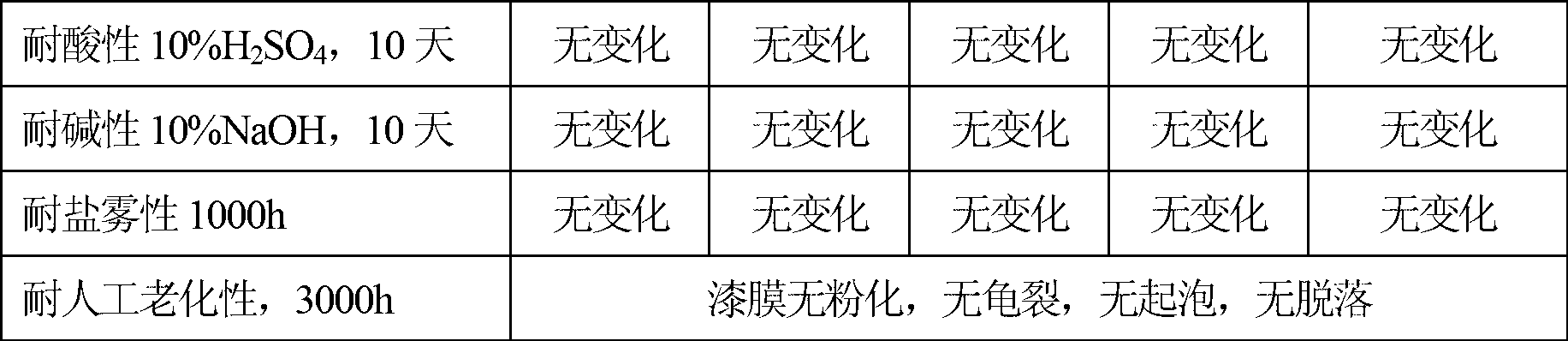

Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

ActiveCN103013241AImprove reflectivityImprove anti-corrosion performanceReflecting/signal paintsCross-linkInfrared

The invention relates to a fluorocarbon nanometer solar heat-insulation reflective paint, a preparation method thereof and a using method thereof. The paint can be used for roofs and glass curtain walls of the building industry, offshore drilling platforms, oil tanks and petroleum pipelines of the petroleum industry, the surfaces of cars and trains of the transportation industry, hulls and decks of the ship-building industry, and the tanks and warships of the weapon and aerospace industry. The fluorocarbon nanometer solar heat-insulation reflective paint comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 40%-70% of fluorocarbon resin, 1%-10% of nanometer TiO2 concentrated slurry, 10%-30% of infrared-ray reflective pigment, 3%-10% of hollow micro beads, 1%-5% of auxiliaries and 10%-20% of organic solvent; and the component B is cross-linking agent. The preparation method for the fluorocarbon nanometer solar heat-insulation reflective paint comprises the following steps: 1) preparing, dispersing and grinding the materials of the component A in proportion until the fineness is lower than 30 microns; and 2) mixing and curing the component A and the component B to prepare the fluorocarbon nanometer solar heat-insulation reflective paint. The fluorocarbon nanometer solar heat-insulation reflective paint provided by the invention is suitable for normal-temperature drying or low-temperature baking and drying; moreover, a coating film formed by the paint has the characteristics such as high reflectivity, a good heat-insulation effect, high corrosion prevention, high weather resistance, high self-cleanness, low friction and the like.

Owner:大连佳秀百隆新材料股份有限公司

Fluorosilicone rubber nano composite alloy three-proof paint and production method thereof

InactiveCN101230224AImprove anti-corrosion performanceExcellent anti-fouling flashEpoxy resin coatingsCross-linkPolymer science

The invention discloses a fluorosilicone rubber nano-composite alloy triplicate-prevention paint and the production method. The organic silicon provided with hydroxyl is introduced into the carbon resin, and is dispersed into resin polymerize and cross-linked by a variety of polymer resin via nano-particle which is processed by nano-dispersion solution; and then the fluorosilicone rubber nano-composite alloy triplicate-prevention paint which can resist salt spray, acid, alkali and impact; has strong adhesive attraction, strong resistance to elements, and heavy corrosion resistance; can prevent pollution flashover , and can drain for anti-icing is produced by modifying the obtained resin. The invention has high reaction energy and ultra-low surface energy, can resist chemical corrosion and electrochemical corrosion, has ability for resisting strong corrosion medium, has strong adhesive attraction and high reliability between paint film layers, can prevent water, oxygen and other corrosion mediums from destructing, can resist ultraviolet radiation, can resist temperature change, has super resistance to elements, has long coating maintenance usage duration, and is applicable to bad weather conditions and all kinds of strong corrosive environments.

Owner:孟中

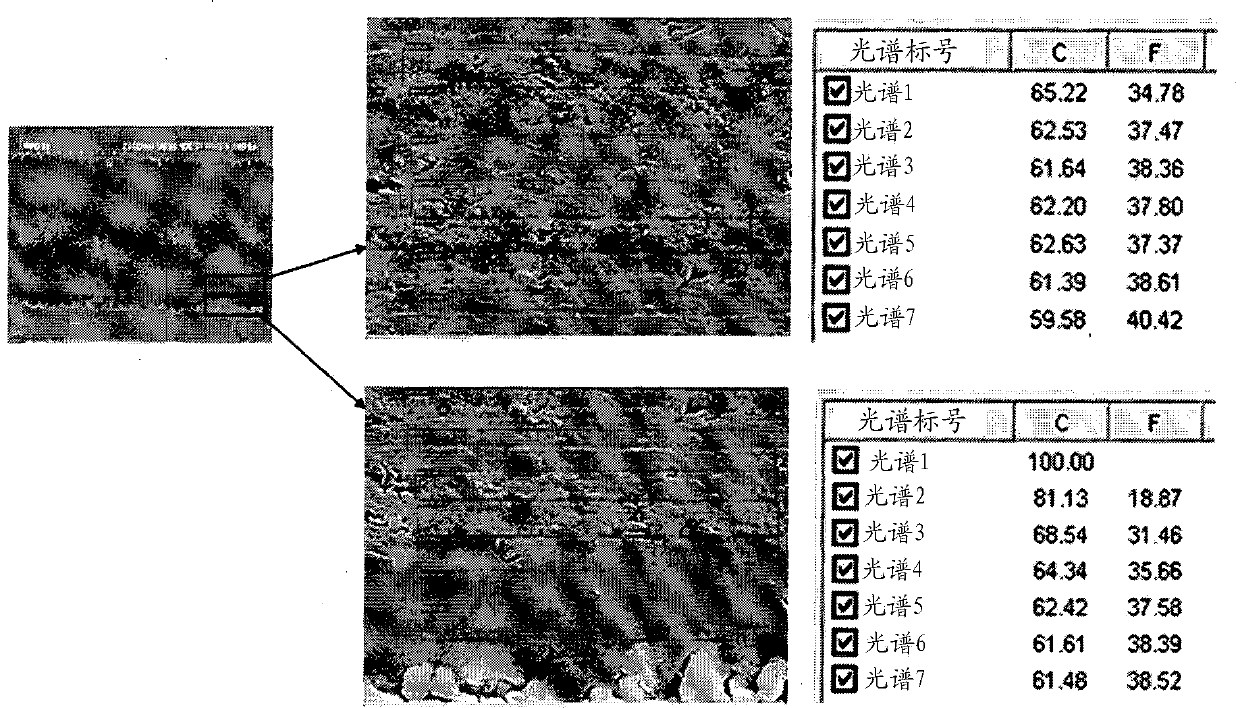

Thermosetting fluorine-carbon resin for metal coiled material and coating thereof

The invention relates to a thermosetting fluorocarbon resin and the coating thereof. The copolymerization chain segment of the resin comprises chlorotrifluoroethylene of 45.0-55.0mol percent, vinyl-acetic ester of 28.0-37.0mol percent, vinyl versatate of 4.0-10.0mol percent, hydroxyl vinyl ether of 10.0-14.0mol percent and aliphatic olefine acid of 0-0.6mol percent. The fluorocarbon coating mainly comprises the following components with certain weight percentage, thermosetting fluorocarbon resin of 20.0-40.0 percent, cross-linking agent of 0-15.0 percent, paint of 0-35.0 percent, promoter of 0.15-1.5 percent and mixed solvent of 30.0-60.0 percent. The fluorocarbon coating adopts no acid catalyst, has stable properties in storage, has excellent softness, methyl ethyl ketone wiping resistance and aging resistance, etc., and is applicable for rolling coating of metal rolling material.

Owner:万博新材料科技(南通)有限公司

Titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint and preparation method thereof

InactiveCN103242718ASolve the problem of pollution flashoverImprove hydrophobicityCoatingsPolymer sciencePolymer chemistry

The invention discloses titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint which comprises the following components in parts by weight: 30-50 parts of fluorocarbon resin, 10-30 parts of filler, 1-10 parts of pigment, 3.5-10 parts of curing agent, 2-10 parts of coupling agent, 0.03-3 parts of assistant, 35-45 parts of solvent and 0.001-0.1 part of drying agent. The invention also discloses a preparation method of the fluorocarbon resin paint. The static contact angle theta of the fluorocarbon resin paint can be up to 118 degrees; and the fluorocarbon resin paint has favorable hydrophobicity and hydrophobic migration performance and high pollution flashover preventing performance, thus ensuring that the physical / chemical properties and electric properties of a prepared coating can meet pollution flashover preventing conditions. The invention is used for insulator pollution flashover prevention, and solves the problem of insulator pollution flashover of a high-voltage transmission line.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Aqueous self-cleaning transparent heat-insulated nano-dope capable of fully shielding infrared ray and ultraviolet ray

InactiveCN102732108AStrong hardnessHardness can reach 2H level, strong adhesionRadiation-absorbing paintsReflecting/signal paintsPhotochemistryFluorocarbon Resins

The invention relates to an aqueous self-cleaning transparent heat-insulated nano-dope capable of fully shielding infrared ray and ultraviolet ray and a preparation method. The dope comprises the following components in percentage by weight: 30%-70% of film-forming resin, 5%-30% of nano-ATO dispersion, 1%-10% of nano-LaB6 dispersion, 1%-15% of nano-WO3 dispersion, 5%-15% of co-solvent, 2%-10% of film-forming assistant, 0.5%-5.0% of assistant and 5%-25% of deionized water. The preparation method comprises the following steps of: dropping the nano-ATO dispersion, the nano-LaB6 dispersion and the nano-WO3 dispersion into aqueous fluorocarbon resin while stirring, stirring for 30-40 min, orderly adding antifoaming agent, wetting agent, the film-forming assistant, thickening agent and accelerating agent, stirring the solution to obtain the self-cleaning transparent thermal-insulation nano-dope. The dope is applied to the surfaces of cement, an automotive glass and a building glass, has self-cleaning function, can fully shield the infrared ray and ultraviolet ray and has obvious thermal-insulation performance.

Owner:惠州市彩田化工实业有限公司

Curing nanometer building paint from fluoride carbon resin at normal temperature and production thereof

InactiveCN1712470AUnique performanceUnique excellent performanceCoatingsUltravioletFluorocarbon Resins

A cured nanometer resin fluorinated carbon building coating at normal temperature and its production are disclosed. The process is carried out by using tin catalyst, and adding into wetting disperser, anti-bubbling agent, curing agent, anti-settling agent, ultraviolet absorber and coloring pigment. It achieves long anti-aging time, better water-proof and anti-fouling ability, and higher hardness of coating.

Owner:宁波艾利特科技发展有限公司

Fire and thermal insulative wrap

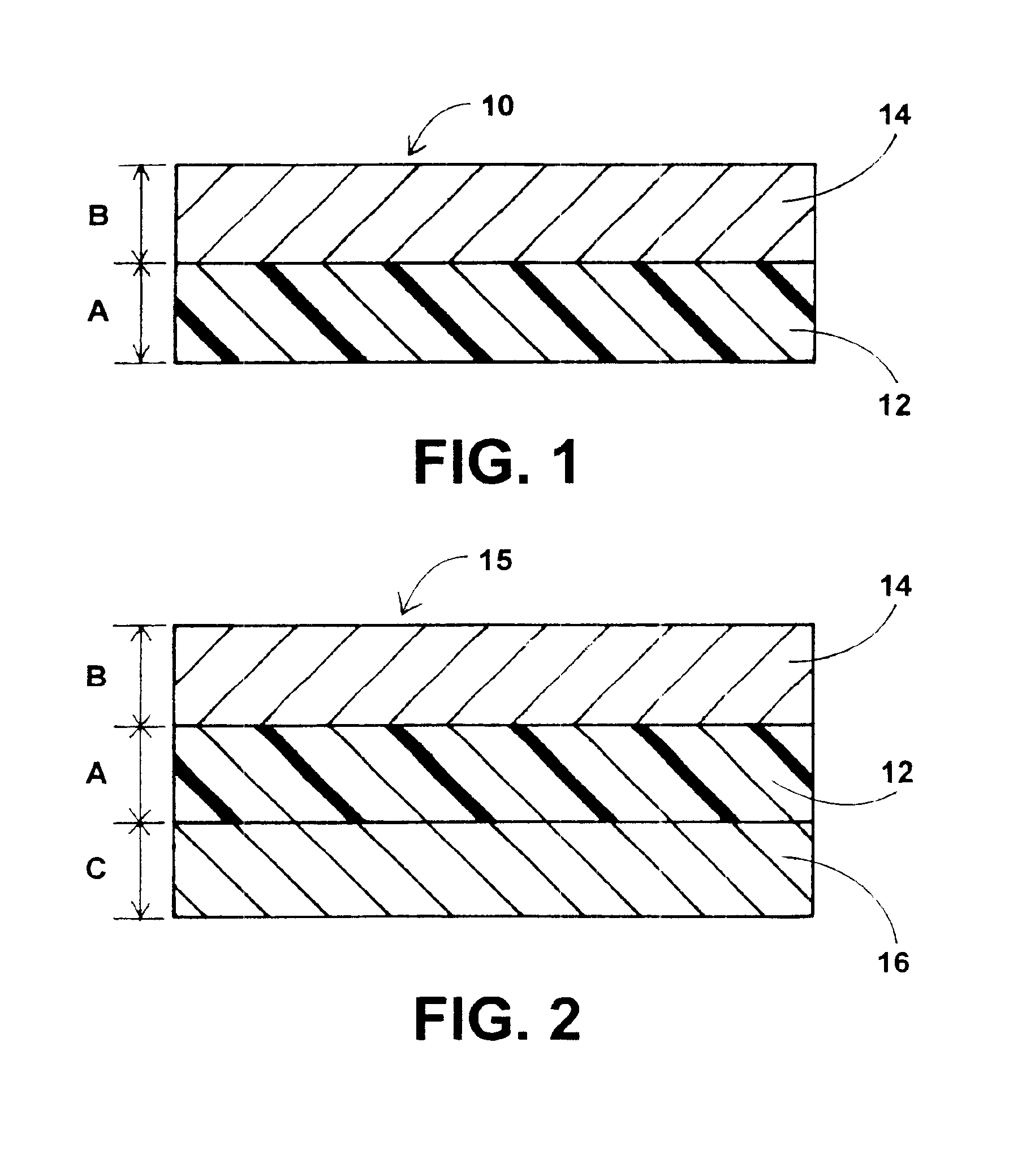

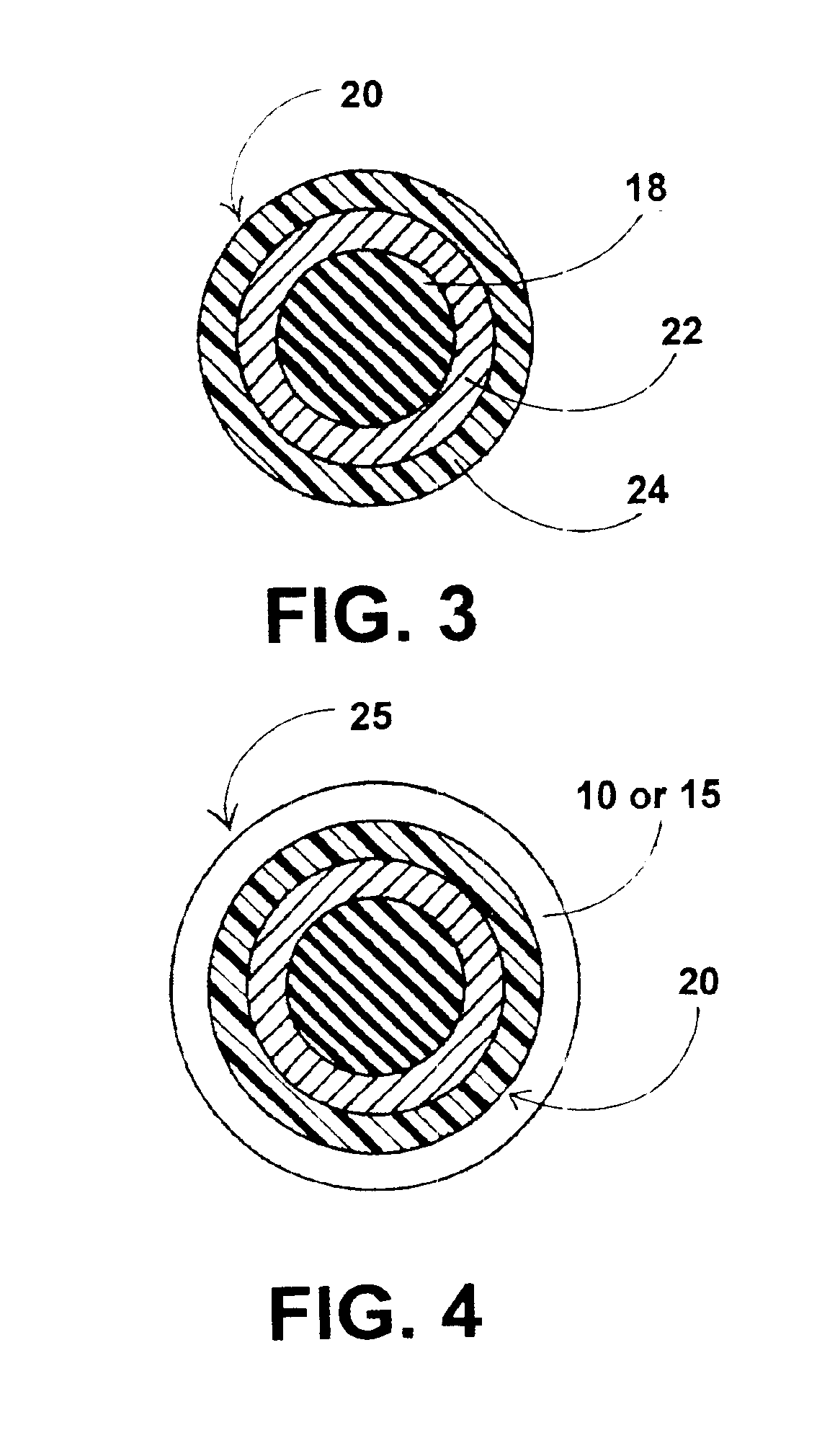

InactiveUS6852412B2Prevent the spread of flamesLow costPlastic/resin/waxes insulatorsSynthetic resin layered productsElectricityPolyolefin

A fire and thermal insulative wrap for protecting building wires and cables is provided comprising a layered construction of a support substrate and a coating, thereon, of an intumescent material. Optionally, a third ceramic layer is provided for added fire protection and electrical properties. Wires and cables constructed to include the wraps are cost effective because construction can include the substitution of low cost polyolefin resins and compounds for fluorocarbon resins and smoke suppressed PVC compounds. The new constructions based on polyolefin components advantageously produce lower levels of smoke and toxic and corrosive gases during a fire event when compared with the halogen based PVC and fluorocarbon systems. Moreover, the superior fire and thermal protection provided adds safety gained from increased circuit integrity. Finally, the wrap thickness being slight does not add significantly to cable size and therefore promotes an installation advantage.

Owner:KEOGH MICHAEL JOHN

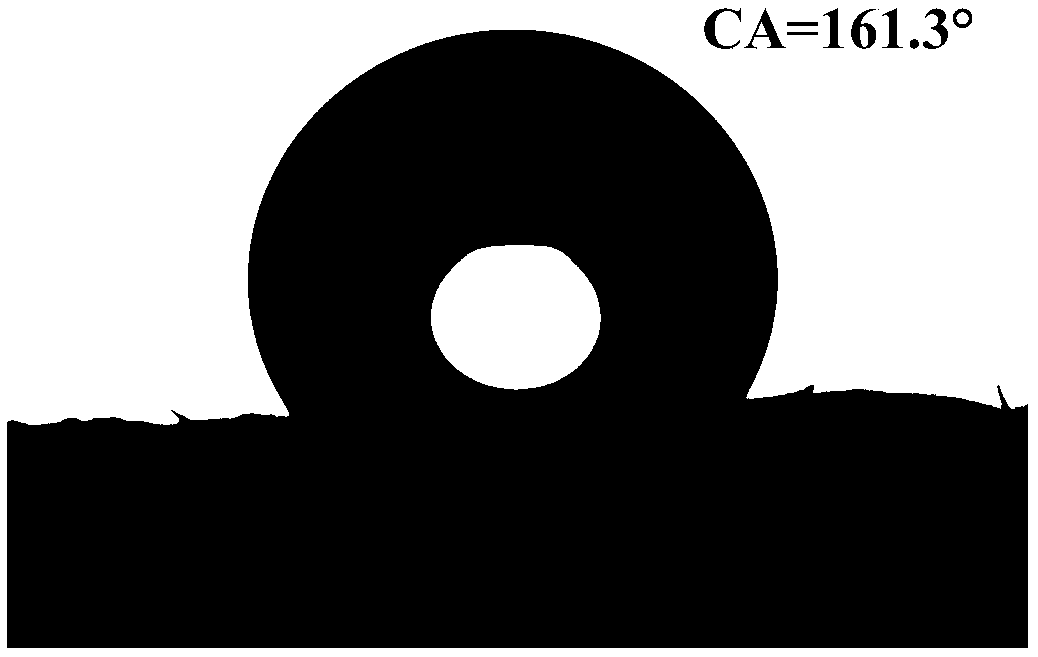

Preparation method of highly-hydrophobic fluorocarbon coating for photovoltaic component back plate

ActiveCN104530852AAvoid stickingReduce transmittancePolyurea/polyurethane coatingsCarbon coatingPtru catalyst

The invention provides a preparation method of a highly-hydrophobic fluorocarbon coating for a photovoltaic component back plate. The preparation method is suitable for outdoor coatings and in particular suitable for coated type photovoltaic back plates. The fluorocarbon coating consists of a component A and a component B in a mass ratio of (1-5):1, wherein the component A comprises fluorocarbon resin, hydrophobic modified nano-particles, a tin type catalyst and an anhydrous diluent A; and the component B comprises an isocyanate curing agent and an anhydrous diluent B. The nano-particles can be uniformly dispersed in main body resin after being subjected to coupling agent hydrophobic modification, is good in compatibility, and can form a micro-nano rough grain structure after being coated on a substrate; and by combining low surface energy of the fluorocarbon resin, the surface of the fluorocarbon coating has high hydrophobicity of a 'lotus leaf effect', has a good antifouling effect, and can greatly reduce influence of water drops on components. Meanwhile, the prepared fluorocarbon coating is excellent in weathering resistance, chemical resistance and salt spray resistance, so that the fluorocarbon coating is suitable for coated type photovoltaic component back plates and is good in performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Transparent hydrophobic and oleophobic functional coating material and transparent hydrophobic and oleophobic functional coating layer formed thereby

InactiveCN106905807AWith super hydrophobic functionRealize hydrophobic and oleophobic treatmentPolyurea/polyurethane coatingsCyclohexanoneAcrylic resin

The invention provides a transparent hydrophobic and oleophobic functional coating material. The transparent hydrophobic and oleophobic functional coating material is prepared from fluorine-containing resin, silicon dioxide particles and a solvent, wherein the mass concentration of the fluorine-containing resin is 5 to 15%; the mass of the silicon dioxide particles accounts for 1 to 5% of the mass of the fluorine-containing resin; the fluorine-containing resin contains at least one of fluorine-containing acrylic resin, fluorocarbon resin, fluorine-containing acrylic modified polyurethane resin and fluorine-containing acrylic modified organic silicon resin; the fluorine content of the fluorine-containing resin is 10 to 50wt%, the particle size of the silicon dioxide particles is 10 to 40 nanometers, and a modifying solvent uses a fluoroalkyl silane coupling agent to modify; the solvent is prepared from ethyl acetate, butyl acetate, isoamyl acetate, ethyl butyrate, acetone, butanone, cyclohexanone, methylbenzene, xylene or nonafluorobutyl ether. The invention also provides a transparent hydrophobic and oleophobic functional coating layer which is made of the transparent hydrophobic and oleophobic functional material.

Owner:北京奥润联创微电子科技开发有限公司

Fluorocarbon finish paint for corrosion protection of wind power equipment and preparation method thereof

InactiveCN101538434AReduce the number of construction passesReduce construction costsAnti-corrosive paintsFluorocarbon ResinsEpoxide

The invention relates to fluorocarbon finish paint for the corrosion protection of wind power equipment and a preparation method thereof, belonging to the technical field of the coating. The fluorocarbon finish paint for the corrosion protection of the wind power equipment comprises coating and solidified agents, wherein the using amount of the solidified agents is 7-12 percent of the weight of the coating, the coating is prepared from the following raw materials by weight percent: 55-75 of fluorocarbon resins, 0-10 of epoxide resins, 10-30 of pigment fillers, 0.01-2 of dispersing agents, 0.01-0.5 of flatting agents, 0.01-0.3 of siccatives, 0-5 of other auxiliary agents and 10-30 of mixed organic solvents. The fluorocarbon finish paint for the corrosion protection of the wind power equipment can replace acrylic polyurethane coating universally used in the market and obviously enhance the corrosion protection effect of the wind power equipment on the basis of no change of an original coating technique, thereby having markedly prolonged service life.

Owner:JINAN HUALIN CHEM

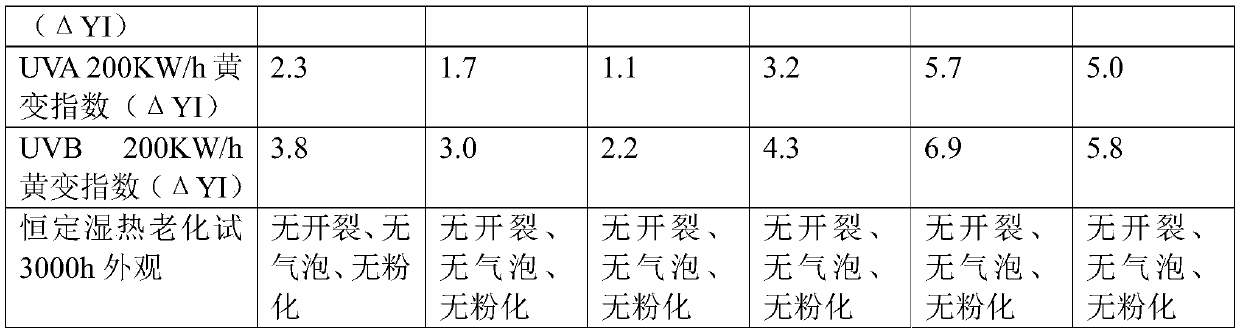

Weatherability fluorocarbon paint and preparation method thereof

The invention discloses a weatherability fluorocarbon paint and a preparation method thereof. The paint is composed of a component A and a component B, wherein the component A comprises an isocyanate curing agent and a waterless diluent A, and the component B comprises fluorocarbon resin, saturated polyester, low molecular compound containing special reactive groups, a catalyst, and a waterless diluent B. The component A and the component B are mixed according to a substance amount ratio of NCO / OH of 0.6-1.5:1.0 so as to obtain the fluorocarbon paint. Saturated polyester is added into the paint so as to soften the coating formed by the paint. At the same time, the added low molecular compound containing special reactive groups effectively increases the crosslinking density of coating, so that the coating is hard and flexible, has a strong weatherability and excellent wear resistant property, and can be used to prepare a solar battery backplane which can be used under severe climate conditions.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Electronic device housing

An electronic device housing is provided. The electronic device housing includes a substrate, a metallic-appearing coating formed on the substrate, and a top coating formed on the metallic-appearing coating. The top coating contains nano-titanium dioxide powder and fluorocarbon resin. The electronic device housing has self-cleaning and anti-fingerprint properties.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Water-based superhydrophobic coating and preparation method thereof

The invention provides a water-based superhydrophobic coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by mass: 1-20 percent of hydrophobic resin, 10-90 percent of good solvent of hydrophobic resin, 0.01-1 percent of an additive, 0.1-10 percent of nano-particles and the balance of water, wherein the additive is a curing agent or adhesive resin; the hydrophobic resin is one or more of organic silicon resin, fluorocarbon resin, fluorinated modified epoxy resin and fluorinated modified polyurethane; and the nano-particles are one ormore of fumed silica, nano-titanium dioxide, nano-alumina, fluorine-modified nano-silicon dioxide and alkyl modified nano-silicon dioxide. The water-based superhydrophobic coating is easily availablein raw materials and simple in preparation condition, and can be used for treating various substrates by a simple dip-coating or spraying process so as to obtain a superhydrophobic surface by curing.

Owner:HEBEI UNIV OF TECH

Novel nano TiO2/PTFE hybrid fluorocarbon paint applied for resisting pollution flashover of insulators, and preparation method thereof

ActiveCN103224741AEnhanced interface bindingGet hydrophobicCoatingsFluorocarbon ResinsWeather resistance

The invention discloses a novel nano TiO2 / PTFE hybrid fluorocarbon paint applied for resisting pollution flashover of insulators. The paint is composed of a component 1 and a component 2, wherein the component 1 comprises the following components by weight parts: 10-65 parts of fluorocarbon resin, 3-20 parts of rutile-type nanometer TiO2, 0.75-5 parts of a silicon fluoride modifier, 10-25 parts of polytetrafluoroethylene nanometer powder, 0.5-5 parts of an auxiliary agent, 20-45 parts of a mixed solvent, 0.01-0.5 parts of a catalyst; and the component 2 comprises the following components by weight parts: 50-100 parts of a curing agent, and 0-50 parts of a mixed solvent. The invention further discloses a preparation method of the fluorocarbon paint. The fluorocarbon paint is quite good in weatherability, soiling resistance, aging resistance and chemical resistance, good in surface energy, and good in bonding capability of a surface and a base material, and can effectively improve safe and reliable operation level of electrical devices.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

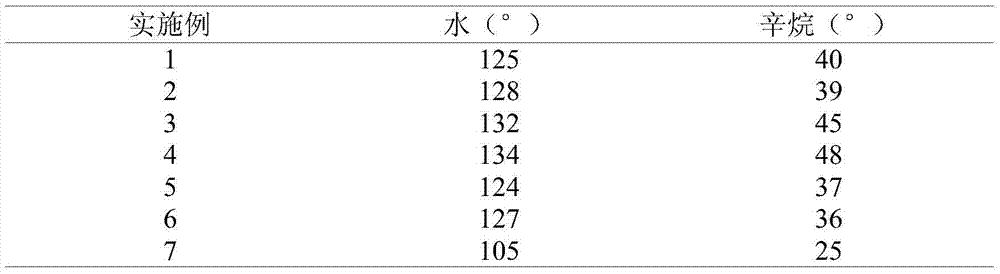

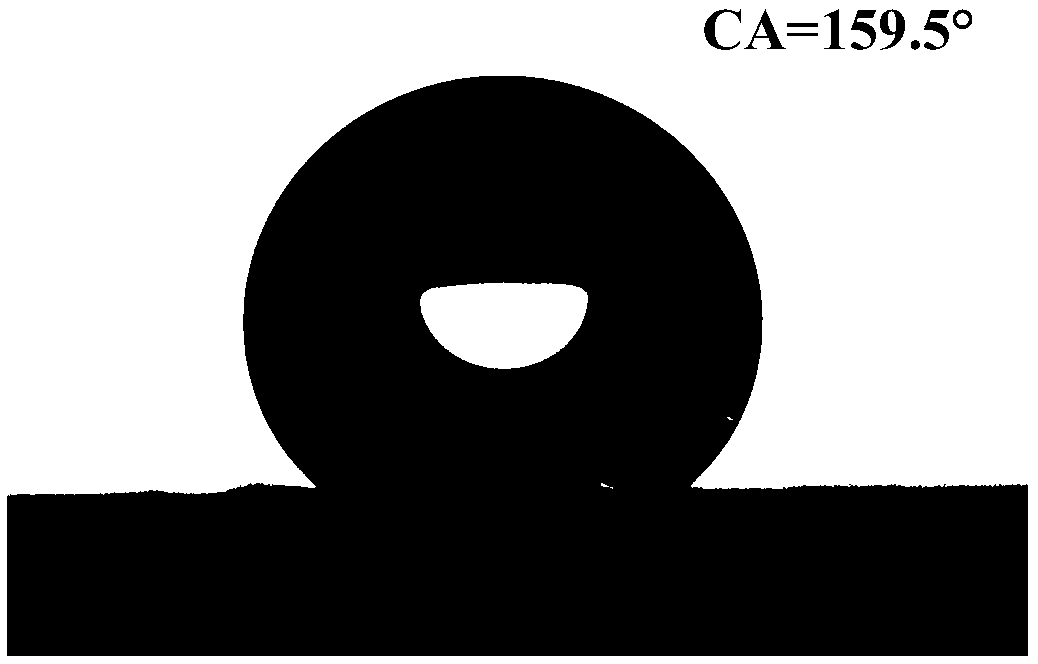

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

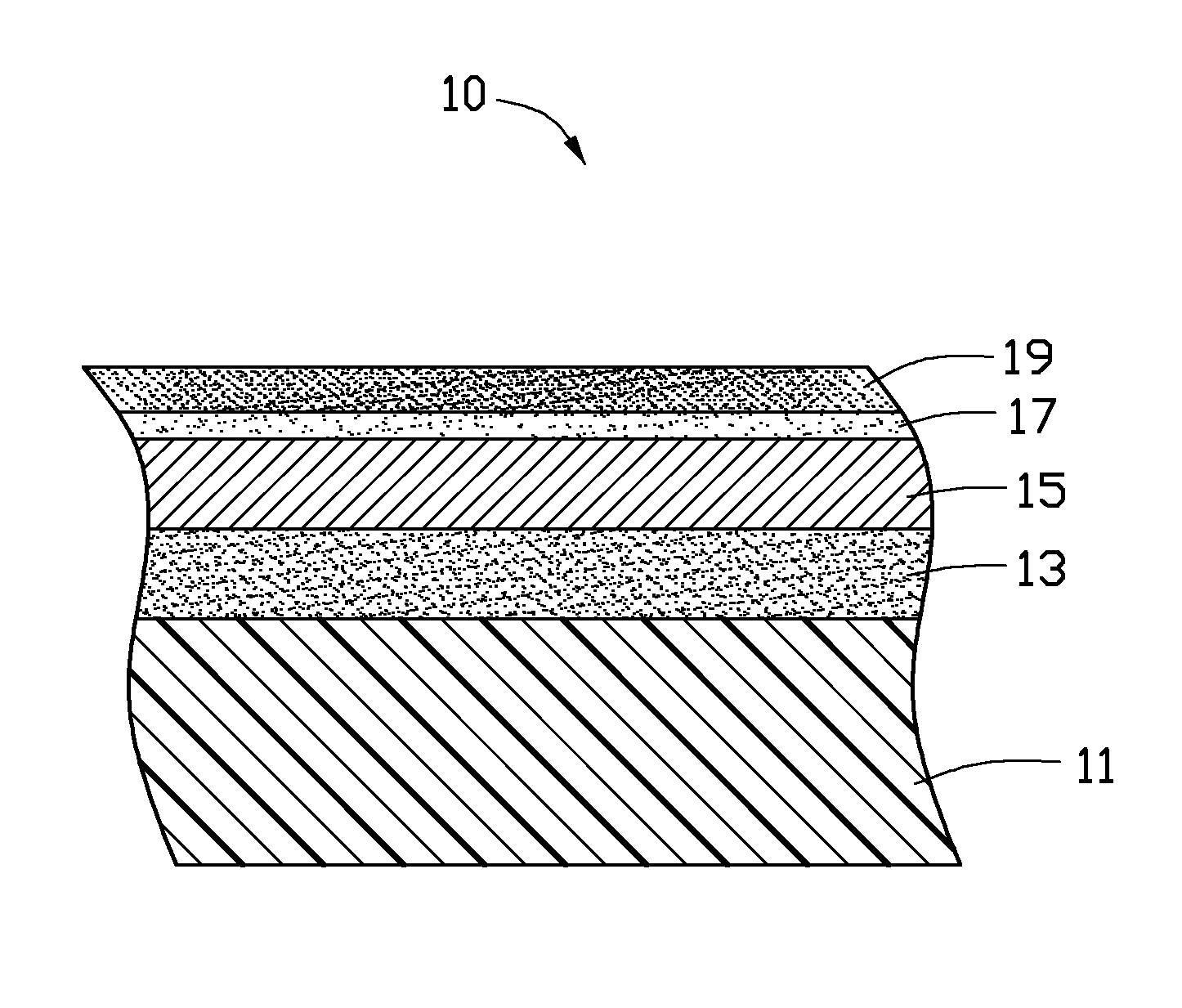

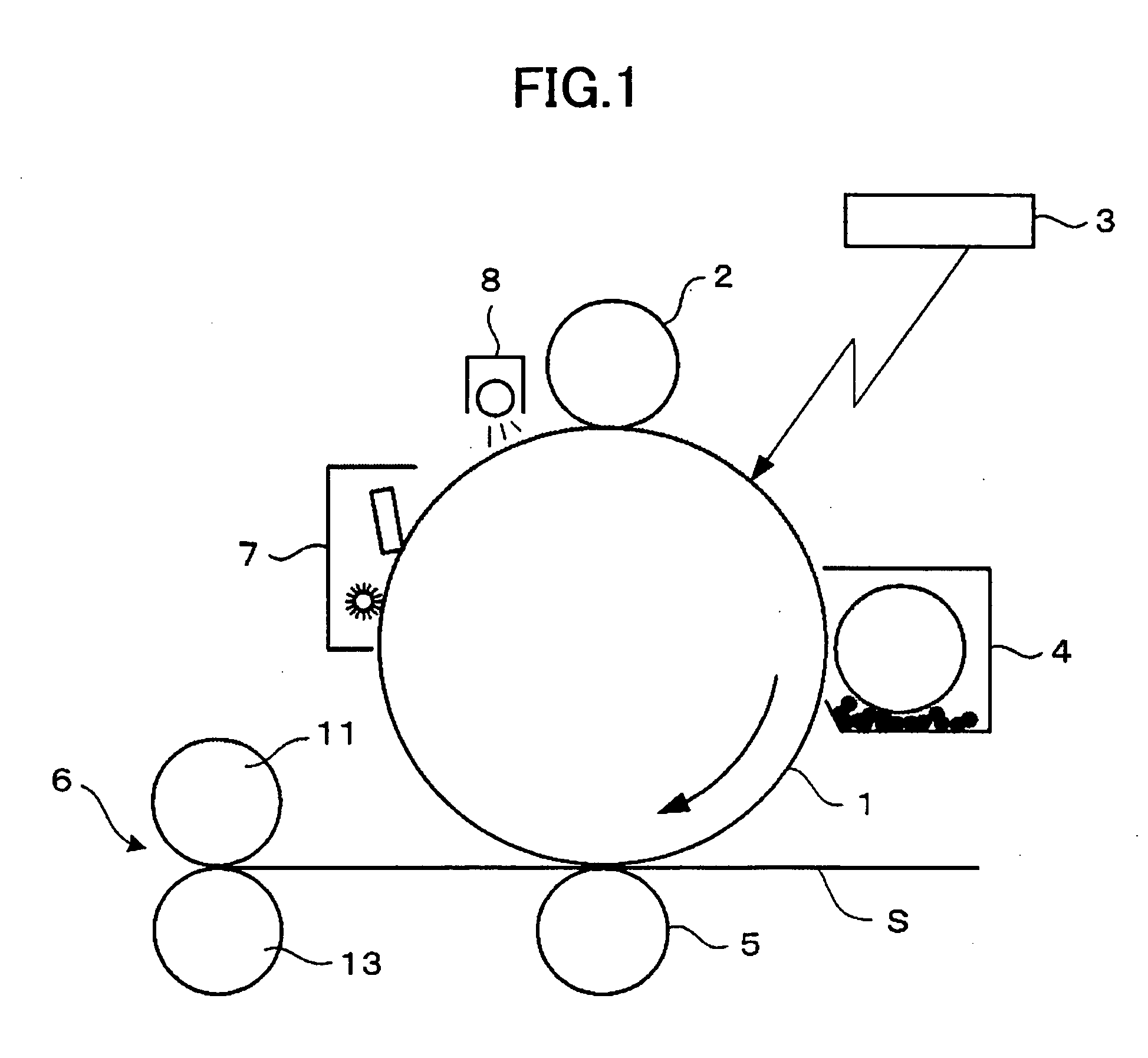

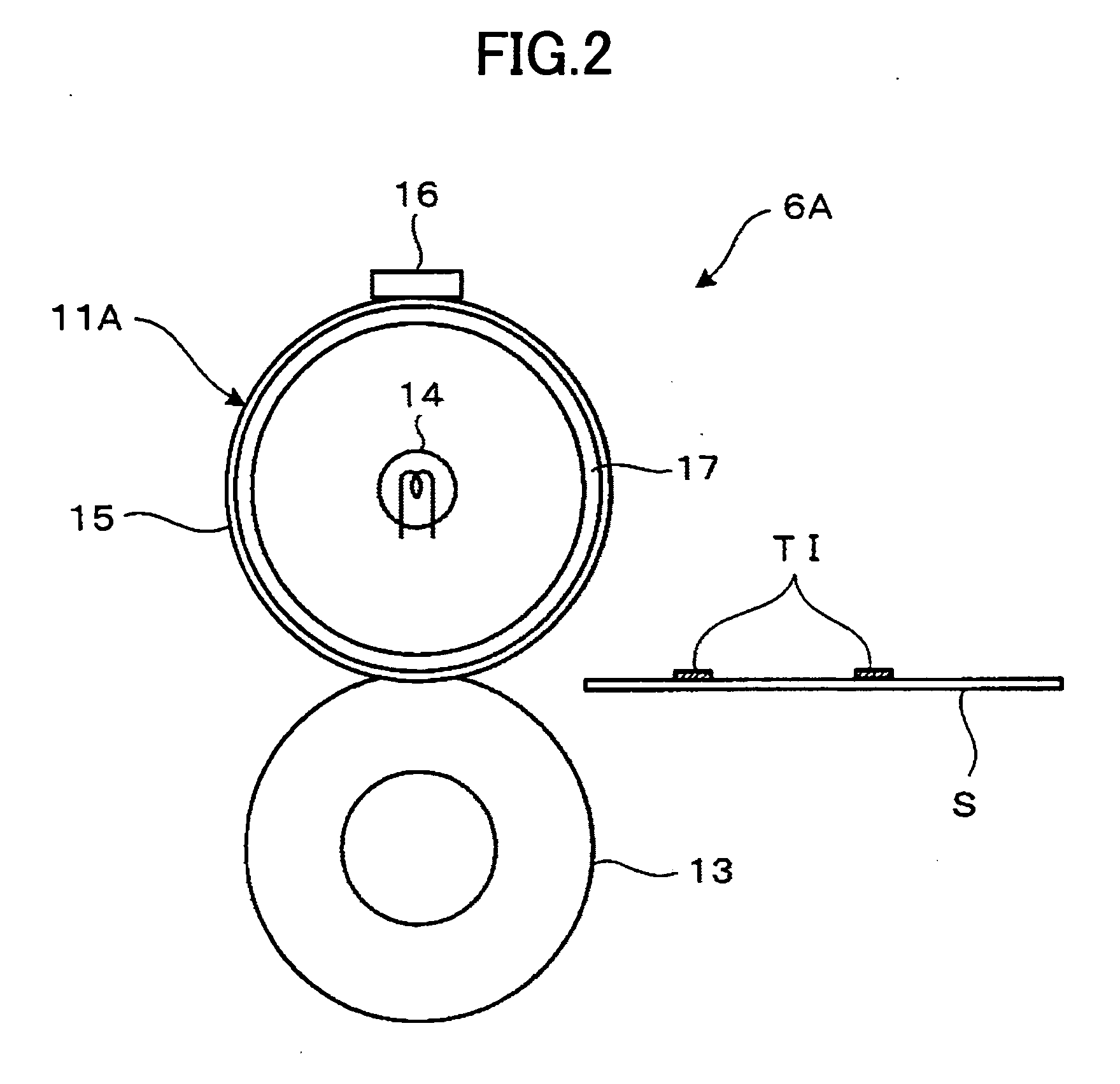

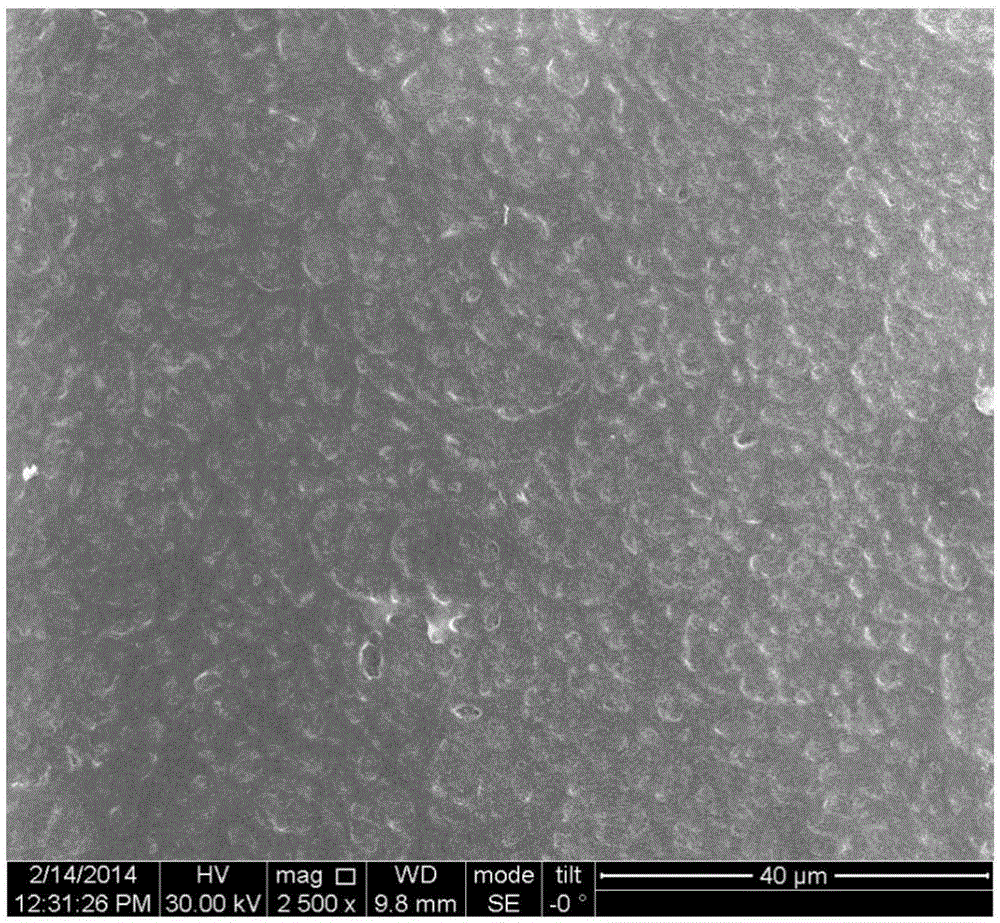

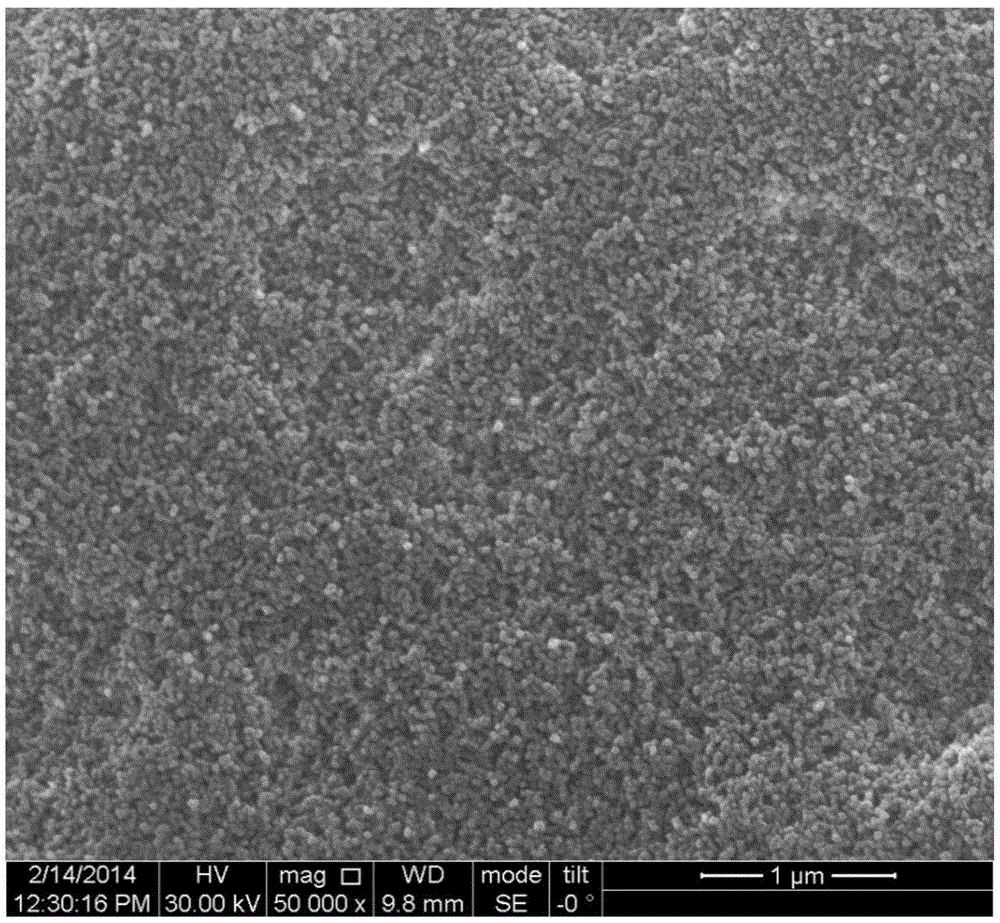

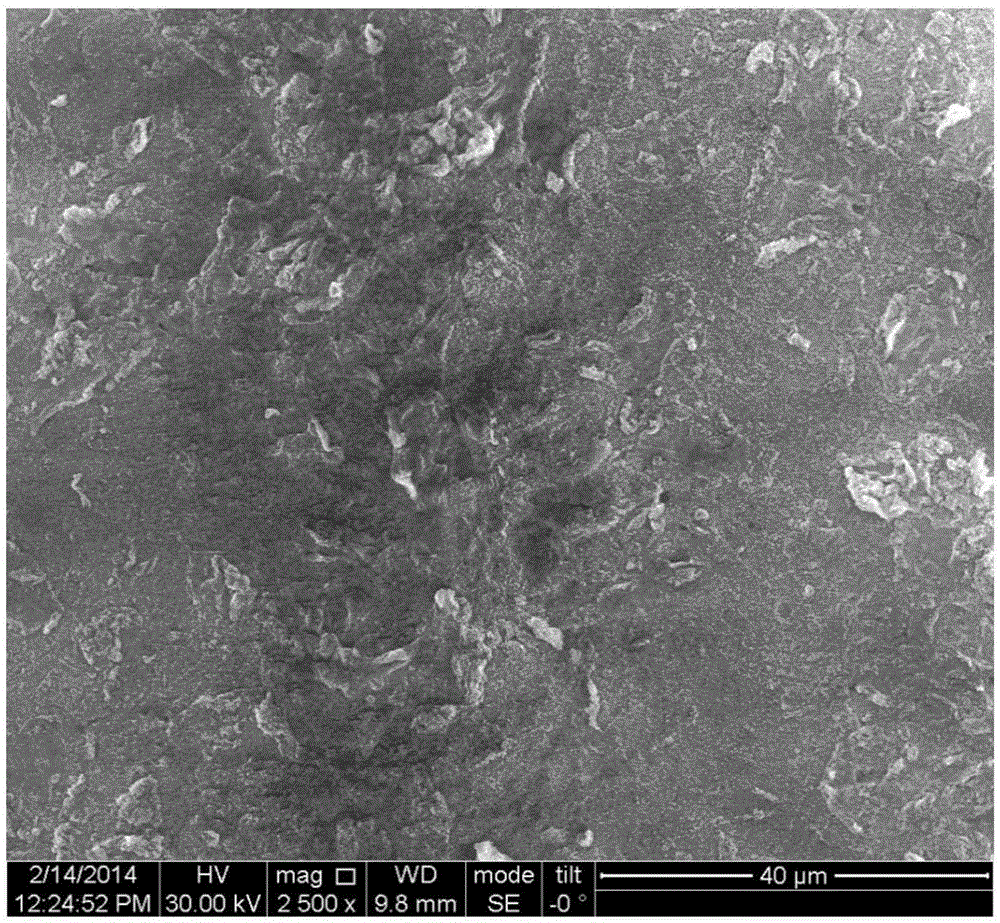

Heating member, heating member surface layer producing method, fixing member, heating device, fixing method, fixing device and image forming apparatus

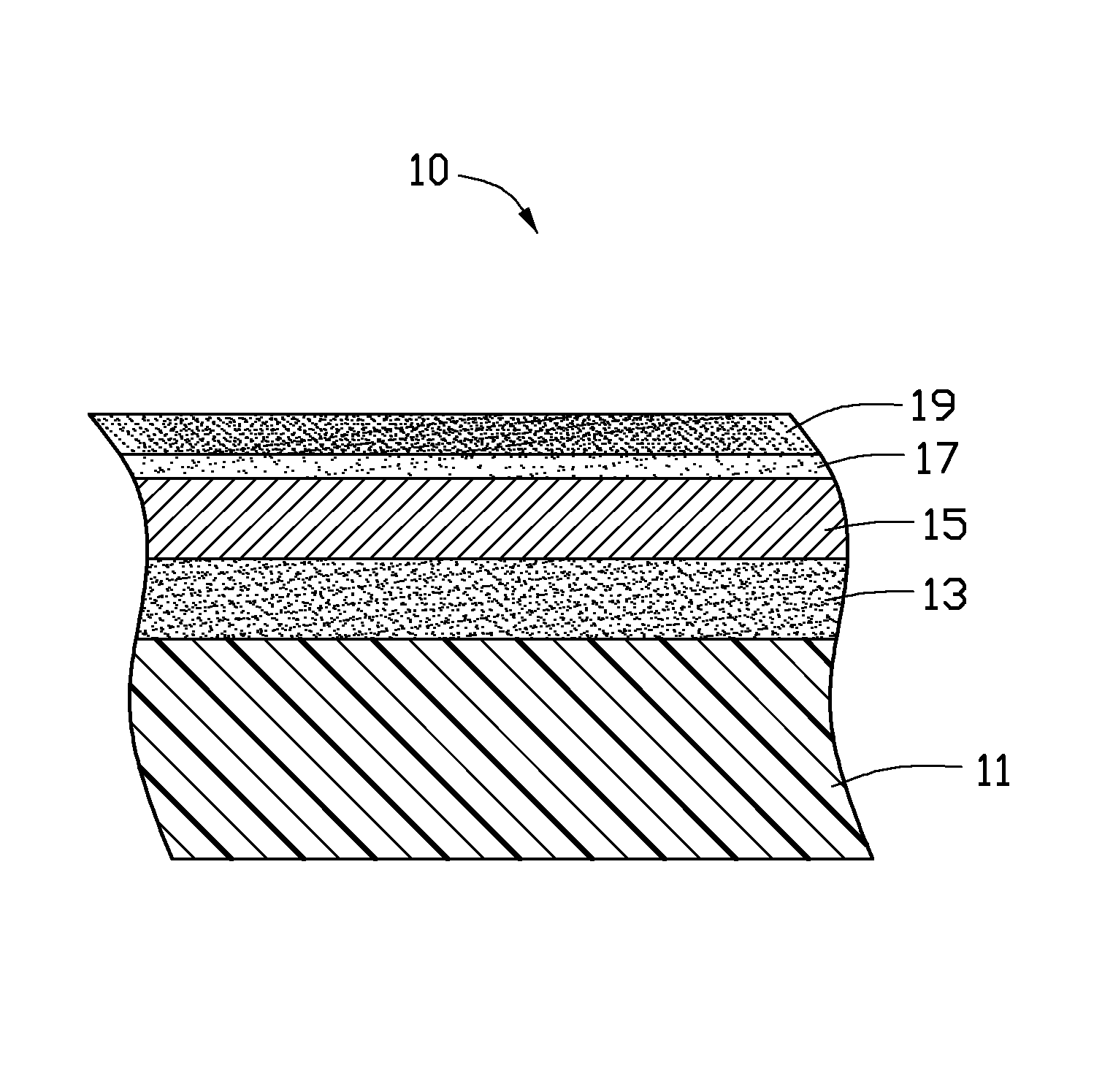

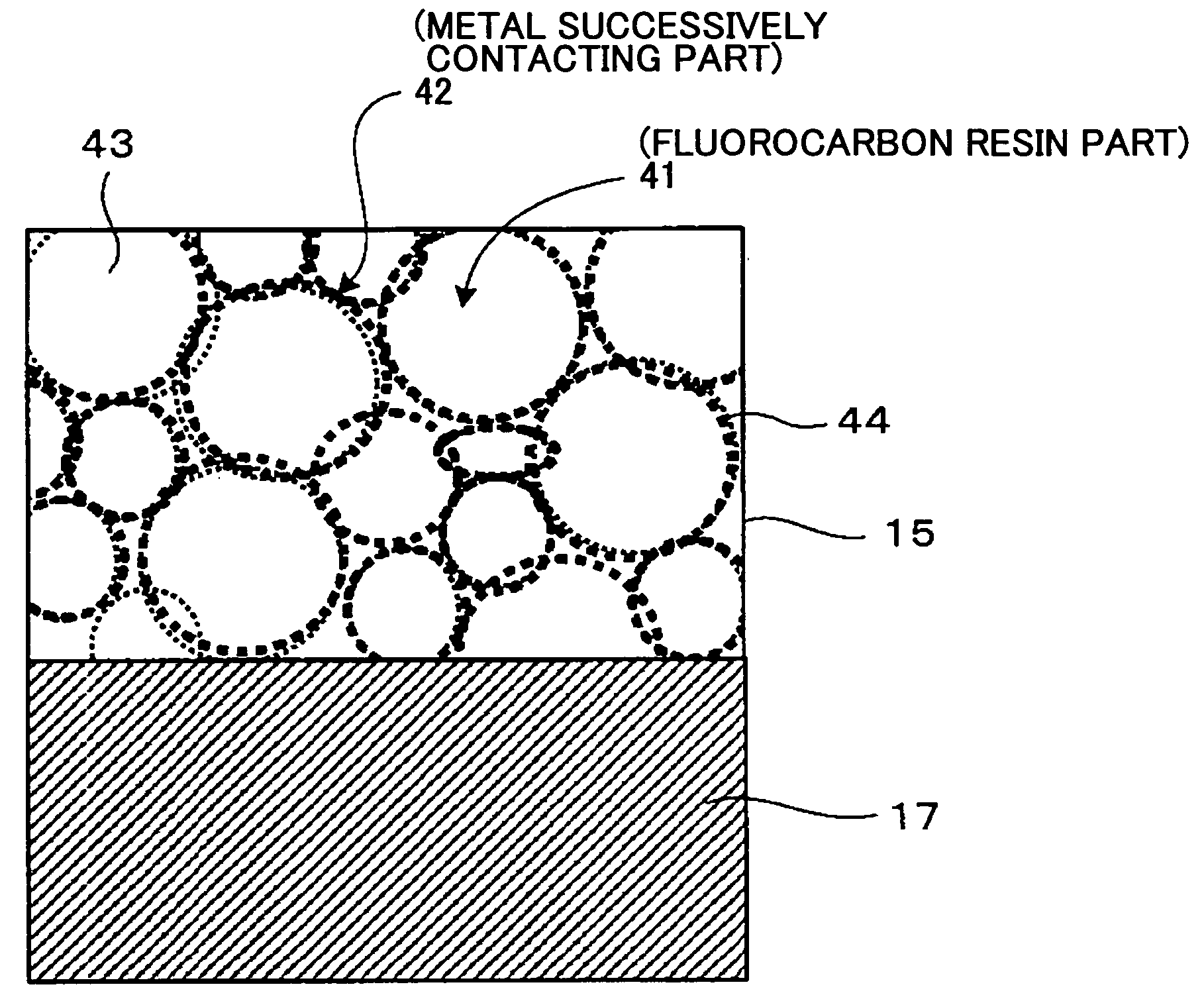

InactiveUS20060014021A1Reduce material usageImprove heating efficiencySynthetic resin layered productsOhmic-resistance heatingSurface layerFluorocarbon

The present invention is characterized in that, for the purpose of achieving a heating member (fixing member) in which thermal conductivity or electrical conductivity is given to a resin surface layer without loss of releasability, and heating efficiently is improved, the heating member contacting a to-be-heated member and heating the same has a surface layer 15 in which, in a resin material 43 having releasability, a material (for example, metal) 44 having either one or both thermal conductivity and electrical conductivity is mixed, and the material contact successively. Specifically, the heating member (fixing member) according to the present invention has the surface layer 15 in which the metal 44 is mixed into the fluorocarbon resin 43, and the metal 44 forms metal successively contacting part 42 in which the metal 44 successively contacts in such a manner as to surround the fluorocarbon resin part 41. Thereby, it is possible to improve thermal conductivity or electrical conductivity while maintaining releasability.

Owner:RICOH KK

Method for preparing high-performance fluoro-carbon anticorrosive coating through grafting of conducting polymer onto carbon nanotube

The invention provides a method for preparing a high-performance fluoro-carbon anticorrosive coating. According to the method, a polyaniline conducting polymer grows on the surface of a carbon nanotube in situ, and a modified carbon nanotube grafting a polymer compatible with a fluoro-carbon resin onto the conducting polymer is used as an additive. Highly basic mechanical ball milling technology is employed for surface functionalization of the carbon nanotube so as to introduce a hydroxyl group onto the surface of the carbon nanotube; then under the action of a catalyst, the carbon nanotube and liquid ammonia undergo an ammonolysis reaction in a high pressure reactor, so an amino group is introduced onto the surface of the carbon nanotube; the surface aminated carbon nanotube is placed in a polymerization system of aniline, and a chemical oxidation method is employed for in-situ grafting of the polyaniline copolymer onto the surface of the carbon nanotube; and active groups on the polyaniline copolymer are used for grafting of short chains compatible with a coating and dispersed in the coating, so the high-performance fluoro-carbon anticorrosive coating is prepared. The prepared high-performance fluoro-carbon anticorrosive coating has good stability and conductive performance and has wide application prospects in the field of preparation of materials with conductive, antistatic, electromagnetic shielding and wave absorbing performance.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +2

Composition for leak stopper and sealer

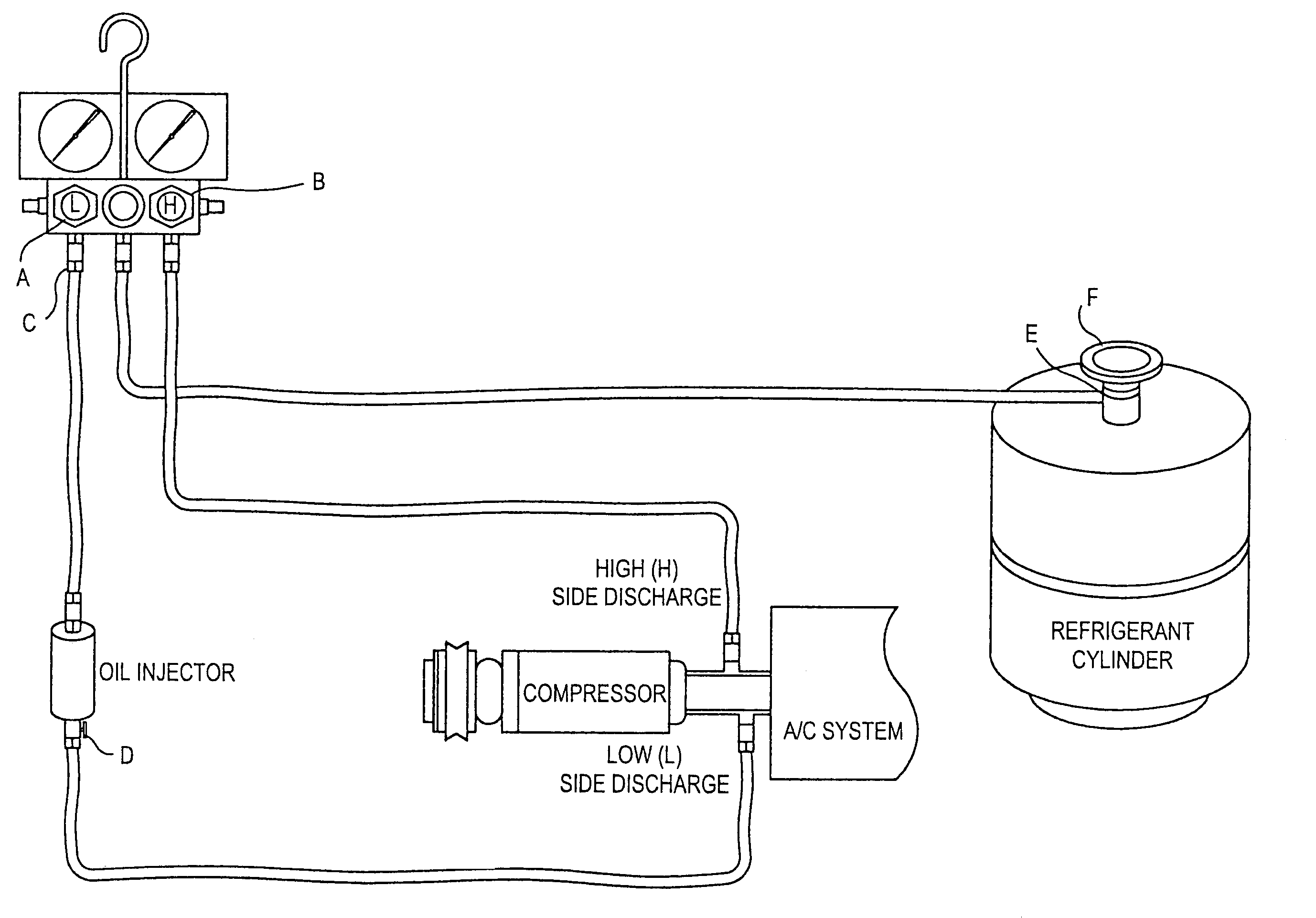

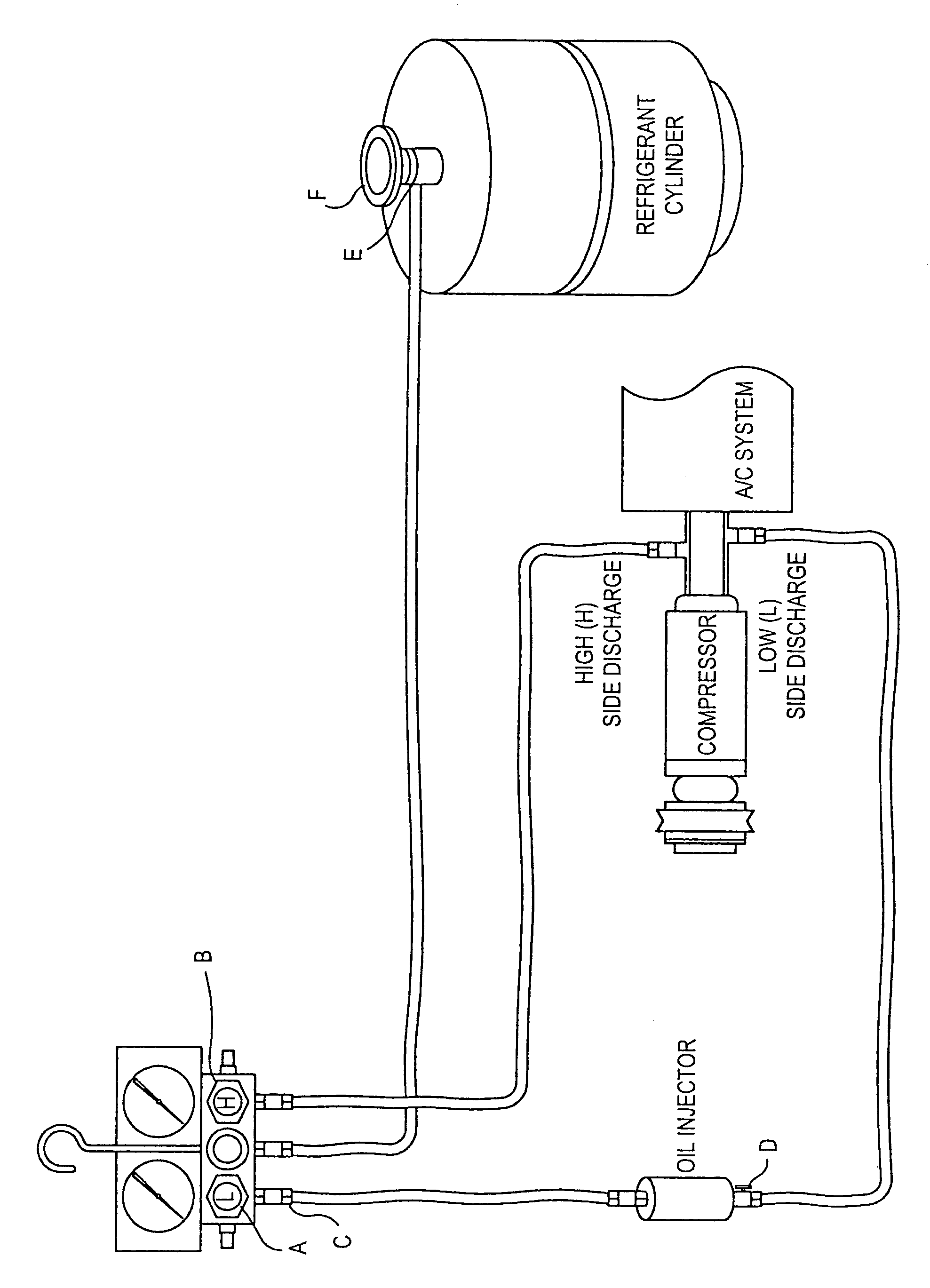

InactiveUS7127902B1Simple to useEasily manufactureOther chemical processesPipe elementsRefrigerantInjector

A composition is disclosed for preventing and repairing leaks, and lubricating gaskets and o-rings, preferably for use in a motor vehicle air conditioning system. The composition preferably includes a fluorocarbon resin mixed a dye. Mineral oil for R-12 refrigerant systems or ester oil for R-134a refrigerant systems can also be added to the mixture. The composition is preferably installed with an air conditioning oil injector through the low pressure side service port of the air conditioning system. When using the product, it is not required to evacuate the air conditioning system. The oil injector containing the composition is connected to the low pressure side service port, the motor vehicle engine is started, the air conditioning system is set to maximum cooling and the system recharged with either R-12 or R-134a refrigerant. The relevant leaks are sealed by composition which also lubricates rubber parts of the air conditioning system.

Owner:LEVY AHRON

Weather-resistant epoxy polyurethane anticorrosive paint and preparation thereof

InactiveCN101298535AGood weather resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsGas phaseSiloxane

The invention relates to a weather resistant epoxy-polyurethane anti-corrosion coating and a manufacturing method thereof, which adds phenol-A epoxy resin, bisphenol-F epoxy resin, hydroxyl contained saturated polyester resin and fluorocarbon resin into the mixed solvent of dimethylbenzene, n-butyl acetate, methyl isobutyl ketone and butanone; then adds rutile type titanium pigment, saponite, sericite in powder, polyacrylate co-polymer, polymethyl alkyl siloxane, benzotriazole, gas phase silica and iso-caprylic acid znic to make the fluid A of the weather resistant epoxy-polyurethane anti-corrosion coating while adds fatty group polyisocyanate into the mixed liquor of anhydro-dimethylbenzene and the n-butyl acetate to make fluid B, and mix the two components during application. The invention can be applied to the preservation of the surfaces of outdoor steel structures, pipes and concrete requiring weather resistance, light aging resistance and acid, alkali and salt corrosion resistance.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

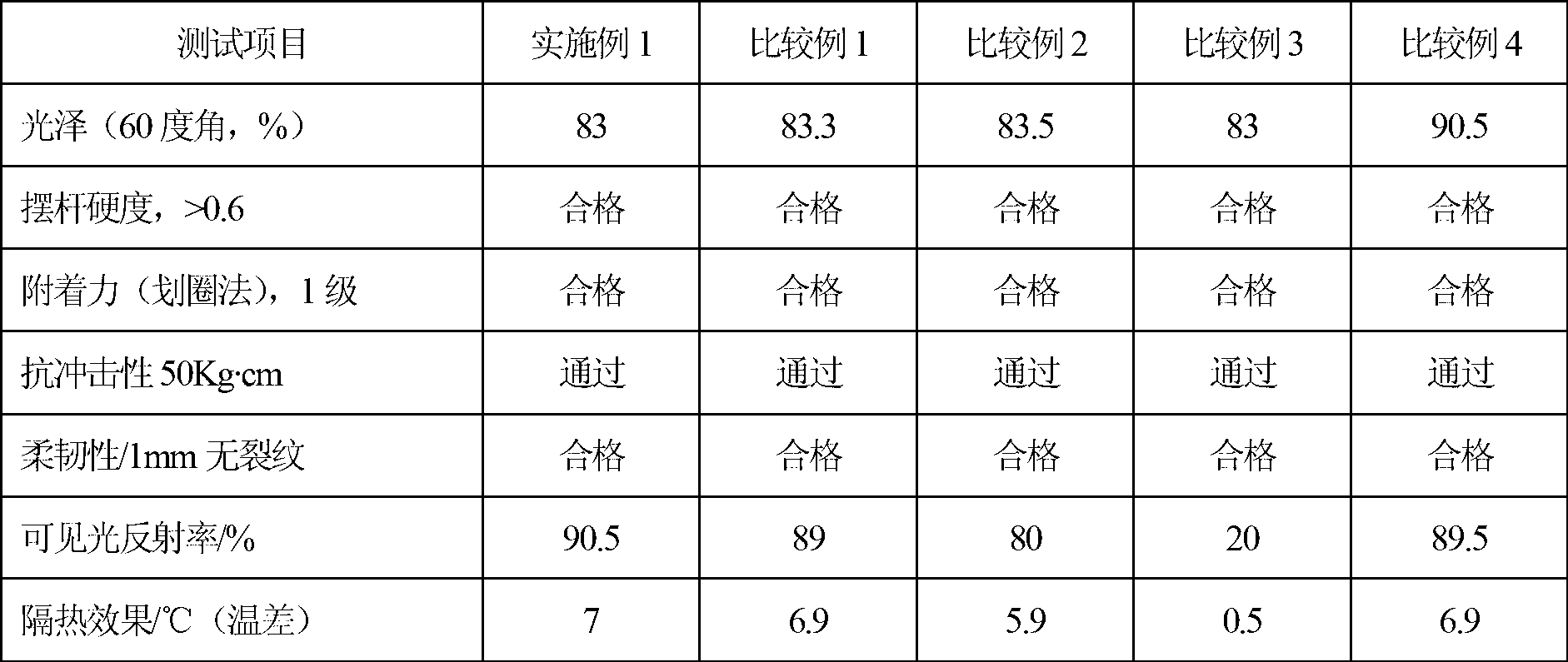

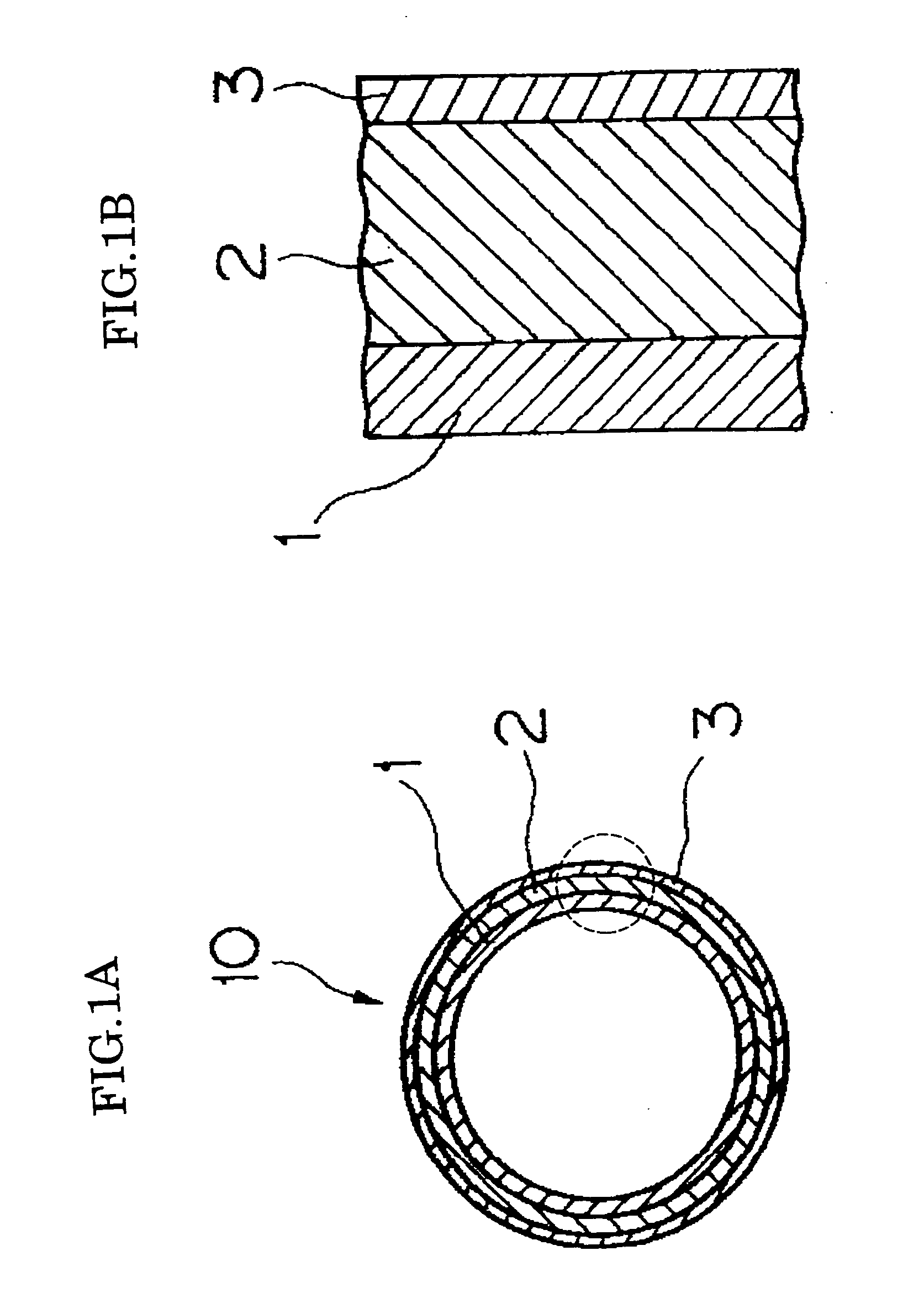

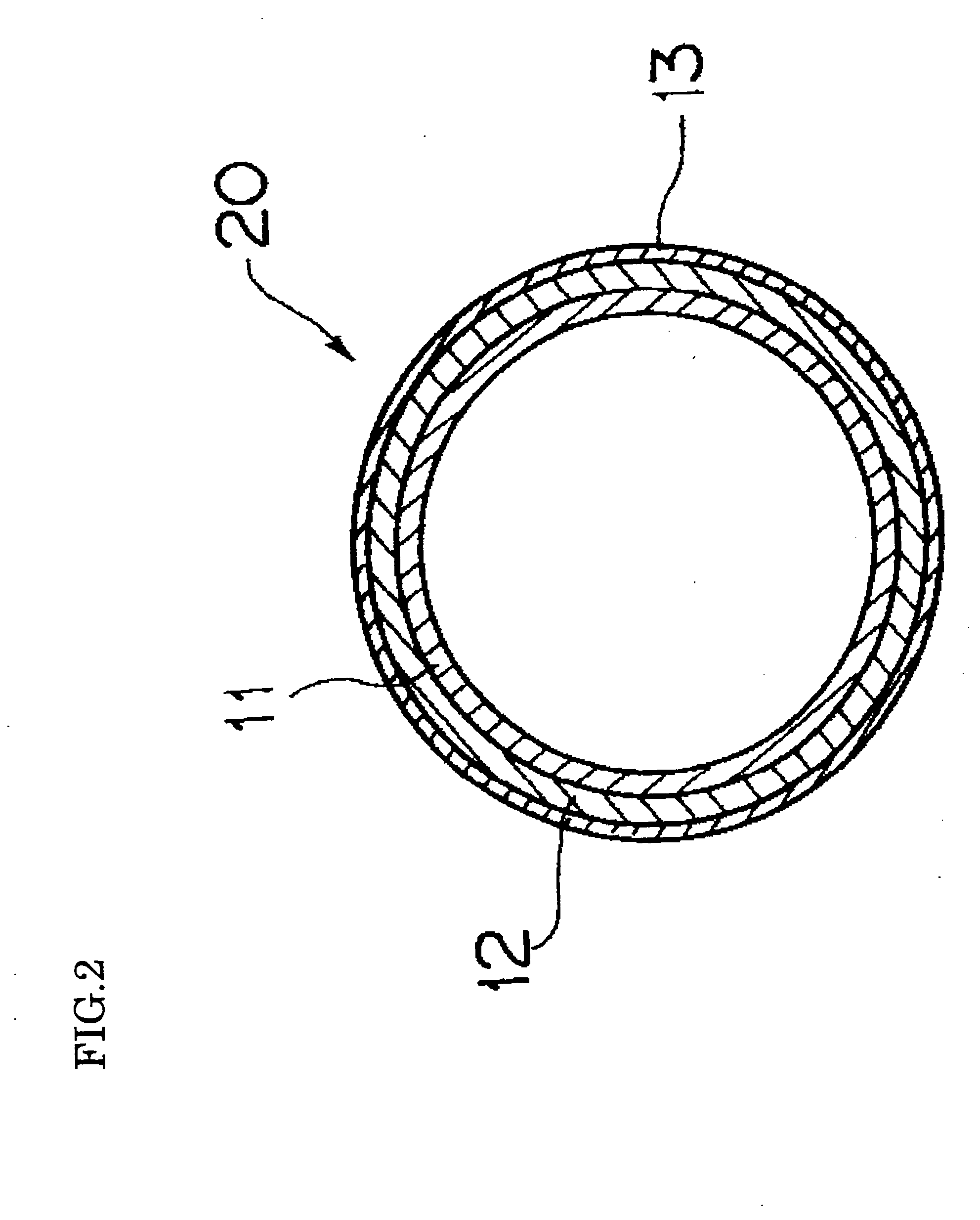

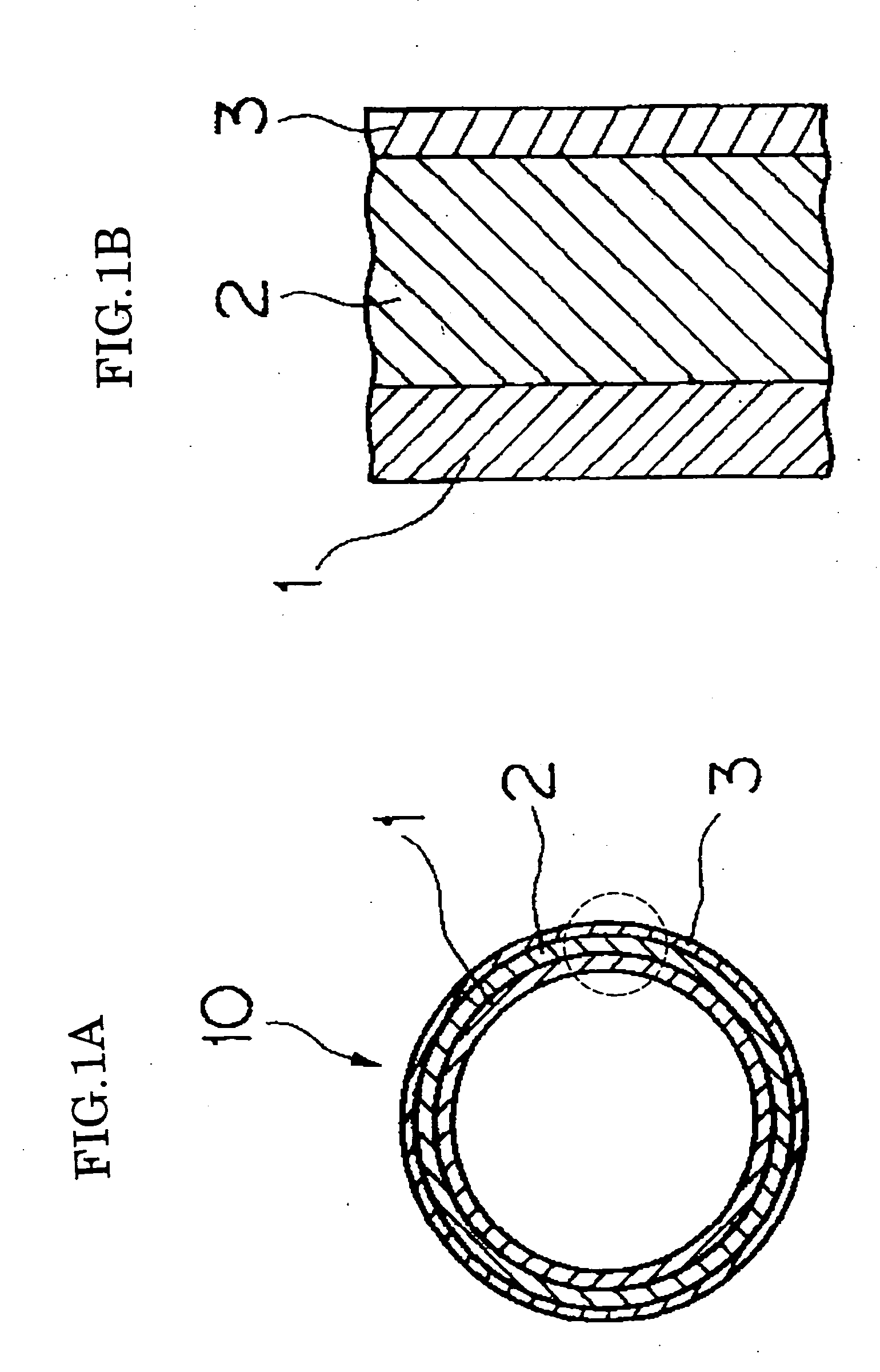

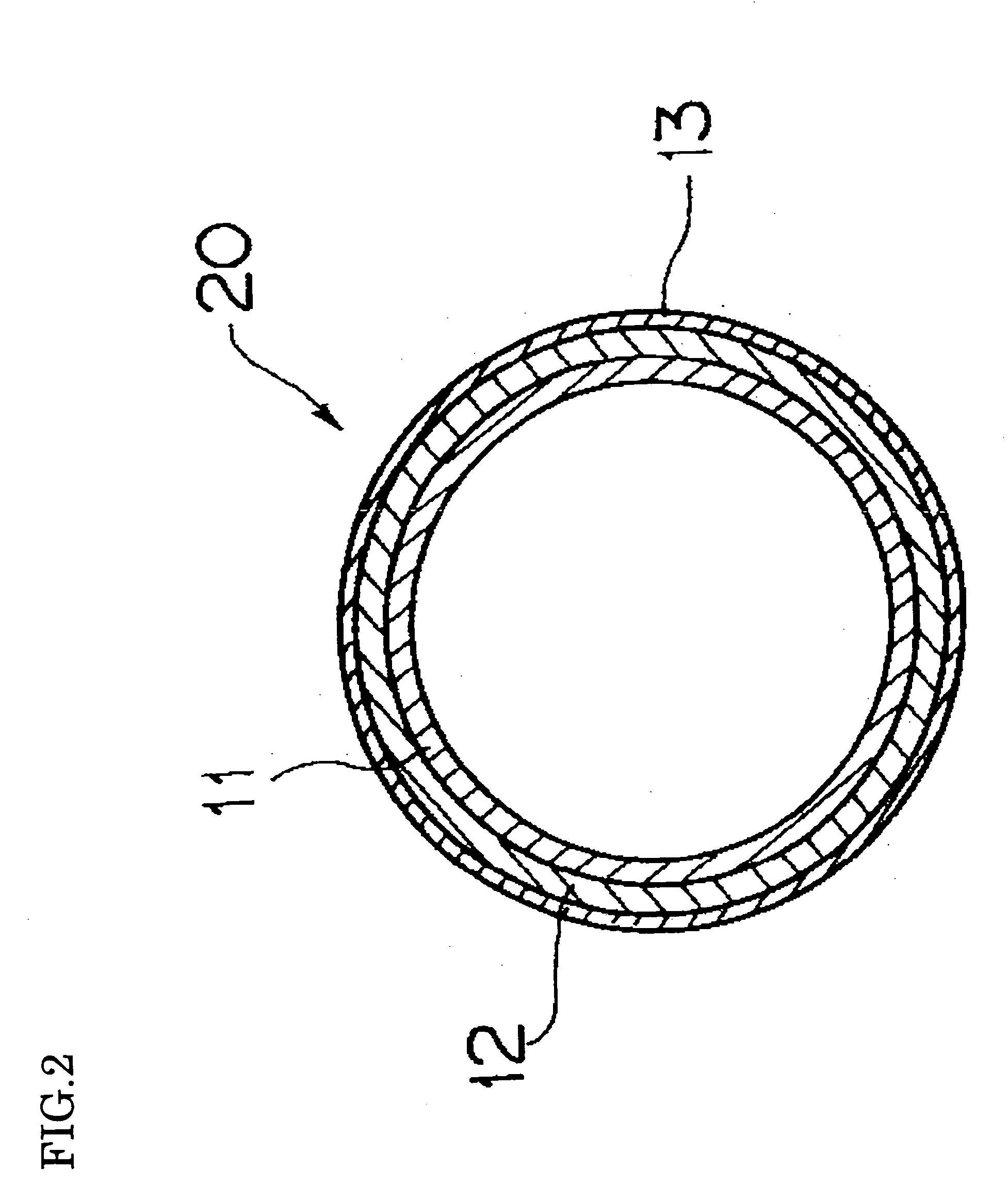

Fixing member, method for producing it, and image forming apparatus comprising the fixing member

In a fixing member (10) in which an elastic layer made of heat-resistance synthetic rubber and a releasing layer made of fluorocarbon resin are sequentially provided on a substrate, a melting point of the fluorocarbon resin constituting the releasing layer (3) is set to be at least 20° C. lower than a temperature for starting an oxidation of the heat-resistance synthetic rubber constituting the elastic layer (2), and the releasing layer (3) is burned by a temperature which is higher than the melting point of the fluorocarbon resin constituting the releasing layer (3), and a burning temperature which does not exceed the starting temperature for the oxidation of the heat-resistance rubber constituting the elastic layer (2).

Owner:RICOH KK

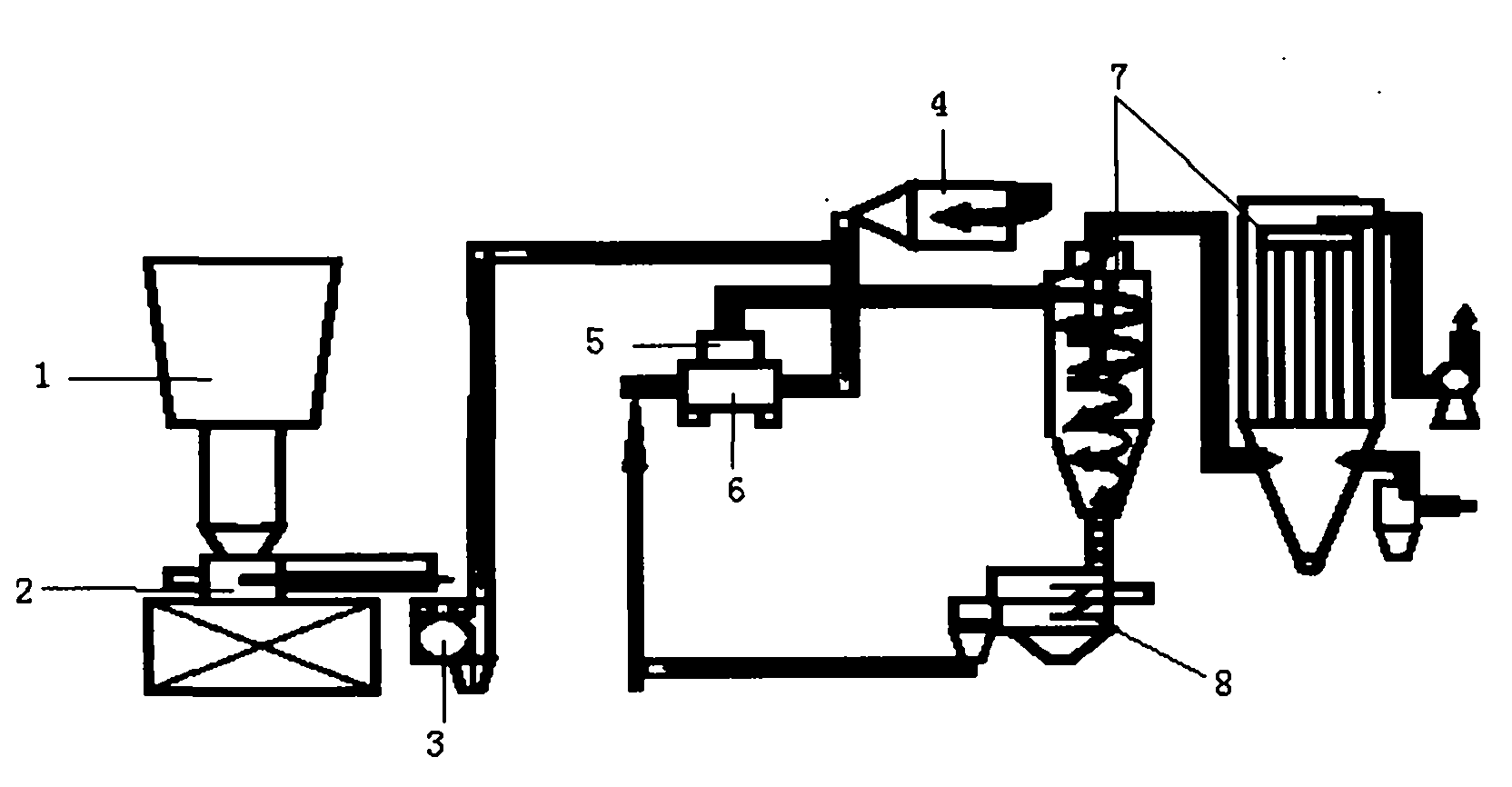

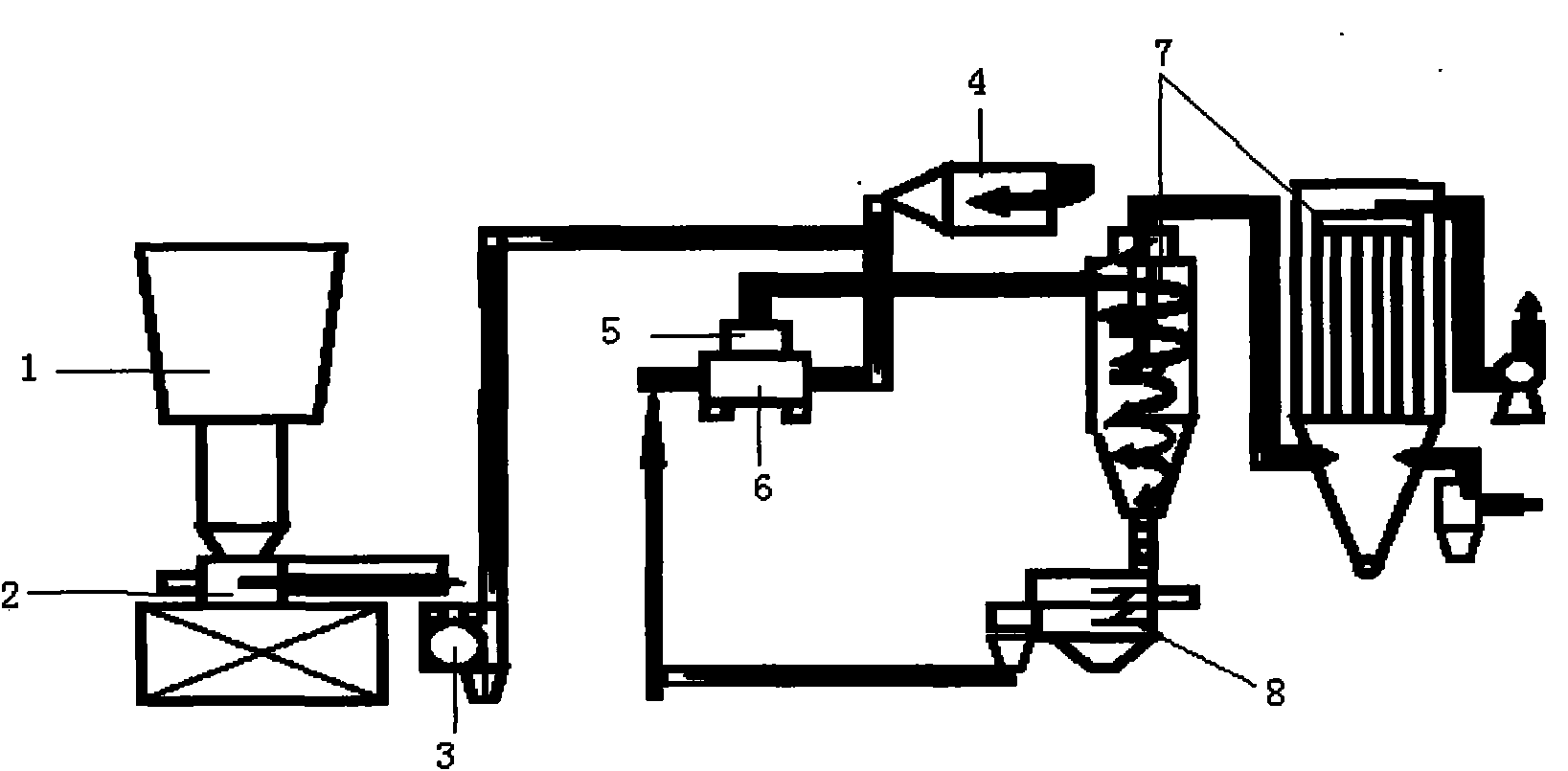

Anticorrosive pipeline paint and its prepn

InactiveCN1887993AShort curing timeImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsChemistryFluorocarbon

The anticorrosive pipeline paint consists of epoxy resin 100 weight portions, fluorocarbon resin 5-15 weight portions, nylon resin 5-15 weight portions, inorganic filler 10-40 weight portions and compound curing agent 10-25 weight portions. The preparation process includes the following steps: treating the inorganic filler with titanate coupler; mixing epoxy resin, fluorocarbon resin, nylon resin and compound curing agent and smelting and extruding in a double screw extruder; freezing and crushing to 100-300 mesh, adding the inorganic filler through stirring. The anticorrosive pipeline paint has the advantages of short curing period, high corrosion resistance, high strength, low friction coefficient, hydrophobicity and lipophobicity.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Water-based transparent super-amphiphobic nano-paint and preparation method and application thereof

The invention relates to water-based transparent super-amphiphobic nano-paint and a preparation method and application thereof. Under the room temperature condition, hydrophilic silica nanoparticles and tetraethoxysilane or carbon tetrachloride serve as raw materials to synthesize oily nanoparticles with the concentration of 1-10 mg / mL; the oily nanoparticles and fluorocarbon resin are compounded according to the volume ratio of 1:1, a rotary evaporator is utilized for rotary evaporation for 30-60 min under the condition of a water bath at the temperature of 60-90 DEG C, and high-solid-content oily nano-paint concentrated liquor with the concentration of 20-40 mg / mL is obtained; water and surfactant are added, and the water-based transparent nano-paint with the super-amphiphobic surface is obtained. The prepared paint is soluble in water, the preparation process is simple, and the paint is suitable for large-area spraying, is high in adaptability to a base material and transparency, good in protective performance, environmentally friendly and capable of improving the working environment, and saves energy.

Owner:SOUTHEAST UNIV

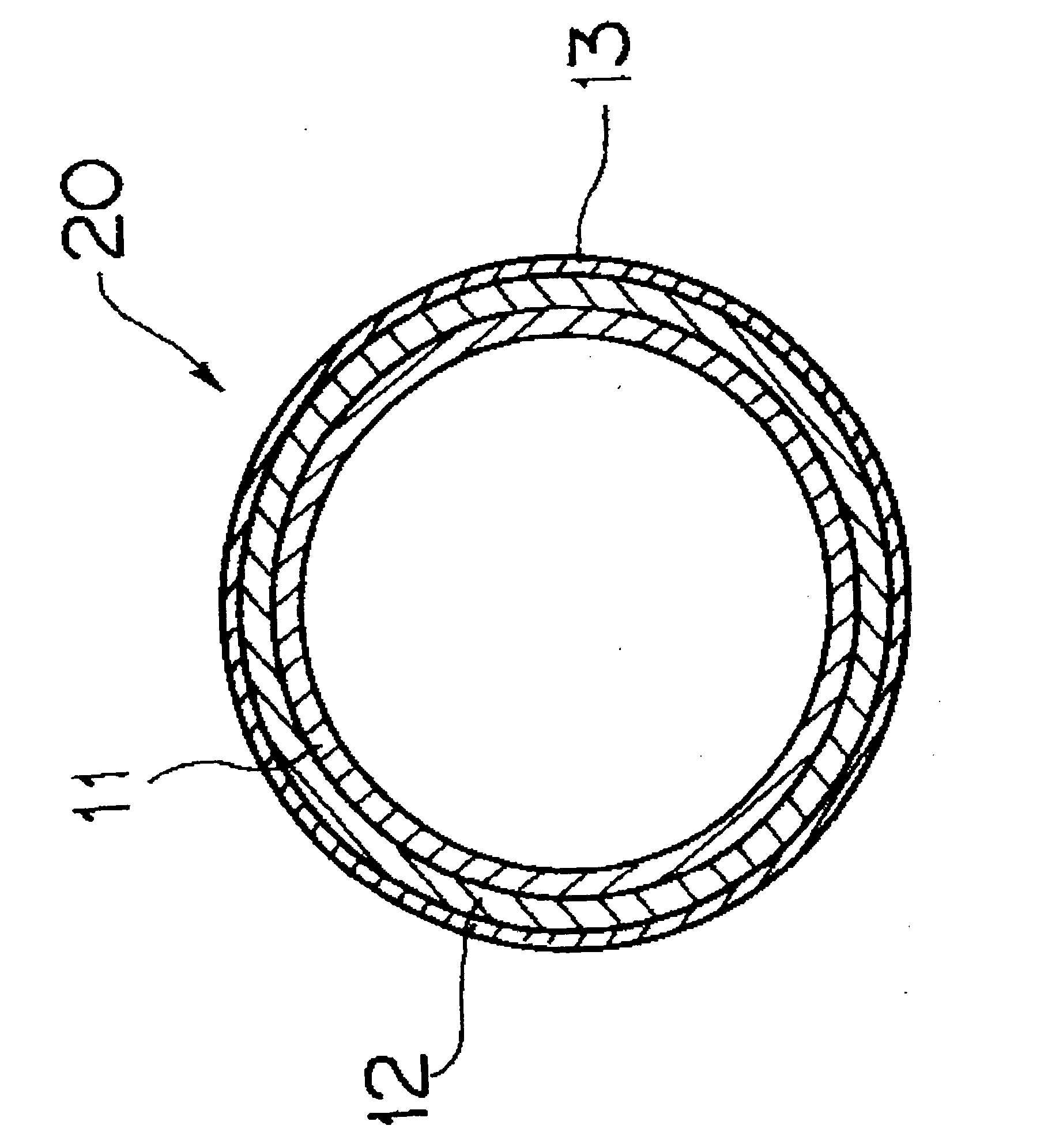

Fixing member, method for producing it, and image forming apparatus comprising the fixing member

InactiveUS20050095381A1Low costShaft and bearingsSynthetic resin layered productsHeat resistanceImage formation

In a fixing member (10) in which an elastic layer made of heat-resistance synthetic rubber and a releasing layer made of fluorocarbon resin are sequentially provided on a substrate, a melting point of the fluorocarbon resin constituting the releasing layer (3) is set to be at least 20° C. lower than a temperature for starting an oxidation of the heat-resistance synthetic rubber constituting the elastic layer (2), and the releasing layer (3) is burned by a temperature which is higher than the melting point of the fluorocarbon resin constituting the releasing layer (3), and a burning temperature which does not exceed the starting temperature for the oxidation of the heat-resistance rubber constituting the elastic layer (2).

Owner:KONDOH TSUNEAKI

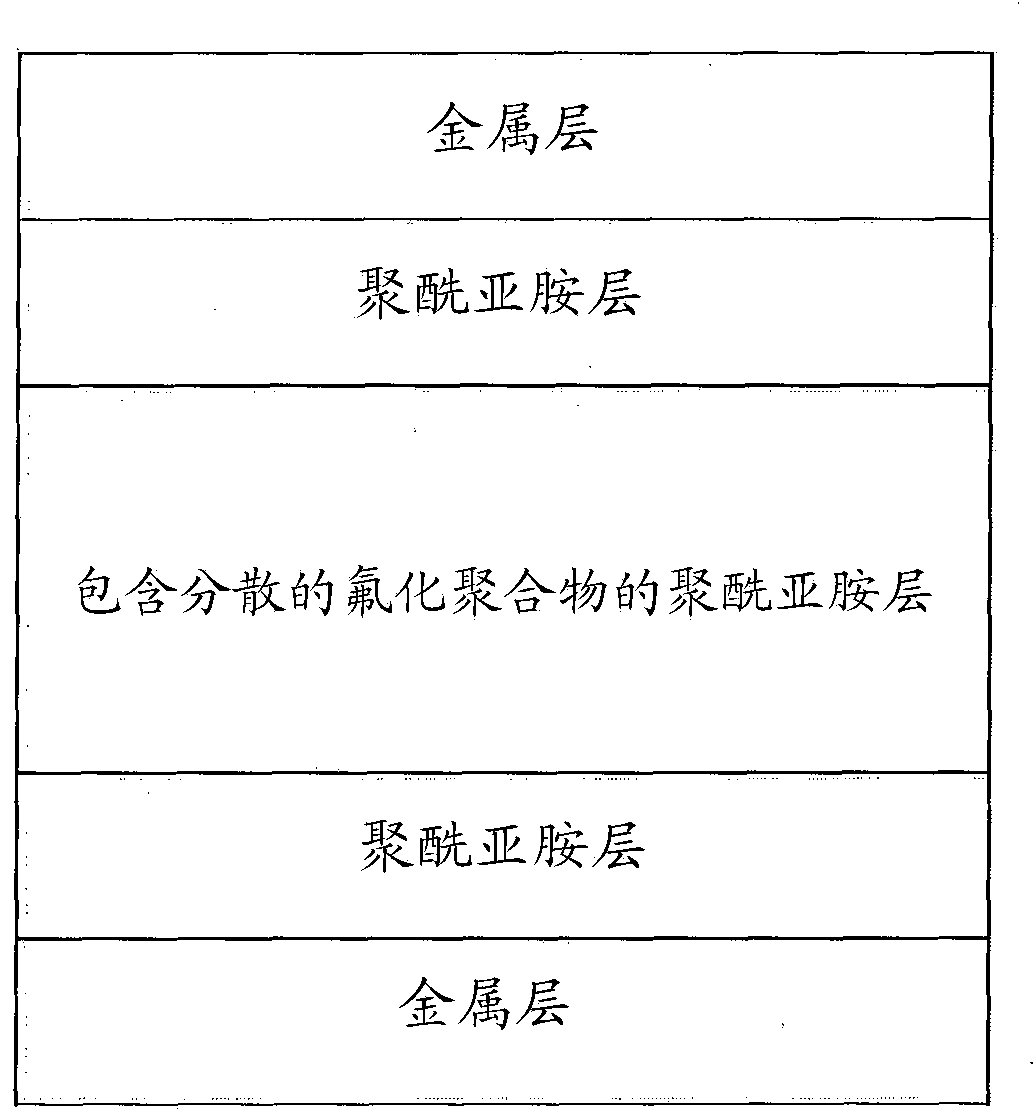

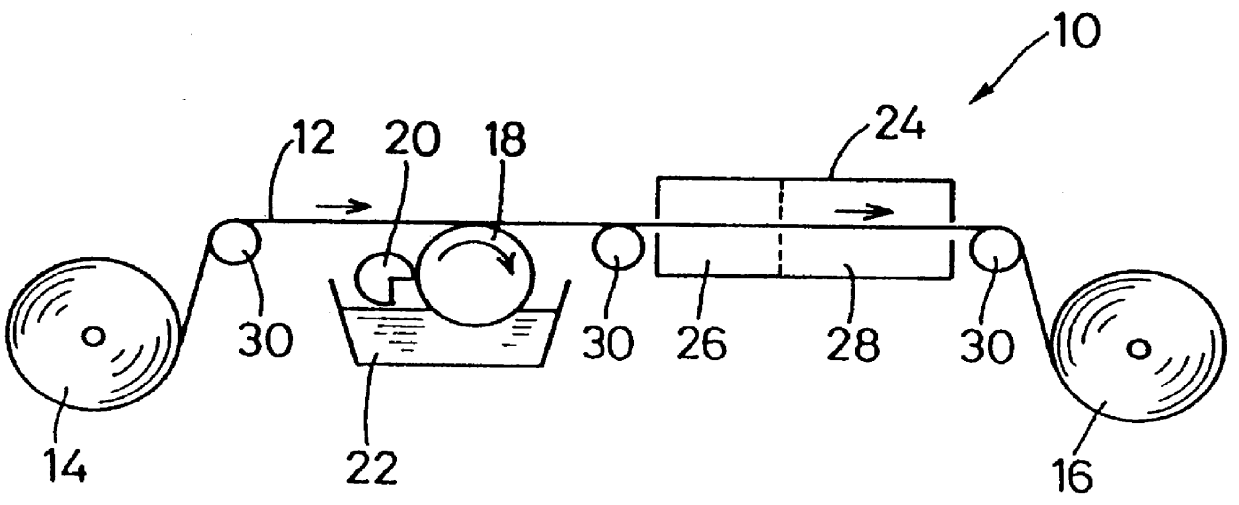

Flexible metal laminate containing fluorocarbon resin

ActiveCN103958188AEvenly dispersedImprove heat resistanceLiquid surface applicatorsSynthetic resin layered productsPermittivityTotal thickness

The present invention relates to a flexible metal laminate having low permittivity, capable of being applied to a soft printed circuit board. According to one aspect of the present invention, the flexible metal laminate comprises: a first metal layer; a first polyimide layer; a polyimide layer in which a fluorocarbon resin, which is formed on the first polyimide layer, is dispersed; and a second polyimide layer formed on the polyimide layer in which a fluorocarbon resin is dispersed, wherein the content per unit volume of the fluorocarbon resin is greater in a depth of 40-60% than in a depth of 5-10% of the total thickness from the surface of the polyimide layer in which a fluorocarbon resin is dispersed.

Owner:GUANGDONG SHENGYI SCI TECH

Fluoro-carbon resinous laminate having a crack-resistant surface and method of producing said laminate

InactiveUS6060158AShort timeEasy to produceSynthetic resin layered productsPretreated surfacesOrganic solventAtmospheric air

A fluoro-carbon resinous laminate has a crack-resistant surface on a fluoro-carbon resinous layer thereof produced by coating a single surface or both surfaces of a plastic film with a single layer of a fluoro-carbon resinous dispersion, and a method of producing the laminate. To produce the fluoro-carbon resinous laminate, which is a minimum of 10 mu m in thickness, a single surface or both surfaces of a plastic film are coating with a single layer of concentration-adjusted fluoro-carbon resinous dispersion and then dried, followed by curing the resinous dispersion in a thermal treating furnace with heated atmospheric air or by adding organic solvent to the resinous dispersion, the enabling production of a fluoro-carbon resinous laminate having a surface appearance in which cracks cannot visually be identified.

Owner:KANEKA CORP

Preparation method of high-performance fluorocarbon coating

ActiveCN105505183ASimple preparation processGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterOligomer

The invention relates to a preparation method of a high-performance fluorocarbon coating. The fluorocarbon coating is composed of a component A and a component B. The component A is composed of an isocyanate-capped polyol oligomer and an anhydrous diluent A, and the component B consists of fluorocarbon resin, dispersant, inorganic filler, catalysts and anhydrous diluents. The component A and the component B are mixed in accordance with the molar ratio of isocyanate to hydroxyl value being (0.6-1.5): 1 to obtain the fluorocarbon coating. The polyol oligomer contains polyester polyol and polyether polyol, endows the coating with outstanding mechanical performance, good low-temperature flexibility and hydrolysis resistance and is capped by isocyanate to be reacted with fluorocarbon resin, and soft segments formed by the polyol oligomer and the fluorocarbon resin and isocyanate hard segments are distributed regularly in the coating to form a three-dimensional network interpenetration structure. The prepared fluorocarbon coating has the advantages of ageing resistant and wind and sand resistant performance and is applicable in preparation of coating type solar cell back plates used in areas with adverse environments.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Oil-repellent thermosetting powder coating and preparation method and application thereof

ActiveCN101955712AExcellent oil repellencyGood chemical resistanceAntifouling/underwater paintsPaints with biocidesAcrylic resinPolyester resin

The invention discloses an oil-repellent thermosetting powder coating and a preparation method and application thereof. The powder coating consists of the following raw materials in part by weight: 20 to 90 parts of acrylic resin, 5 to 20 parts of organic silicon resin, 4 to 50 parts of curing agent, 0.1 to 1.5 parts of flatting agent, 0.2 to 0.8 part of degassing agent, 5 to 45 parts of pigment filler, 0 to 20 parts of thermosetting fluorocarbon resin, 0 to 50 parts of hydroxyl polyester resin and 0 to 2 parts of other aids. The provided oil-repellent thermosetting powder coating has the advantages of scientific and reasonable ratio of components of each raw material and raw materials, and synergy of the components. A high-density film can be formed on the surface of a coating film sprayed by the provided powder coating, the polarity which repels oil dirt can be formed on the surface of the coating film, oil substances cannot attach to the surface of the coating film for a long time, and the oil dirt is easily removed. The coating film has the advantages of excellent oil repellency, economical efficiency, environmental protection and wide use.

Owner:ZHEJIANG ZHENGTE CO LTD

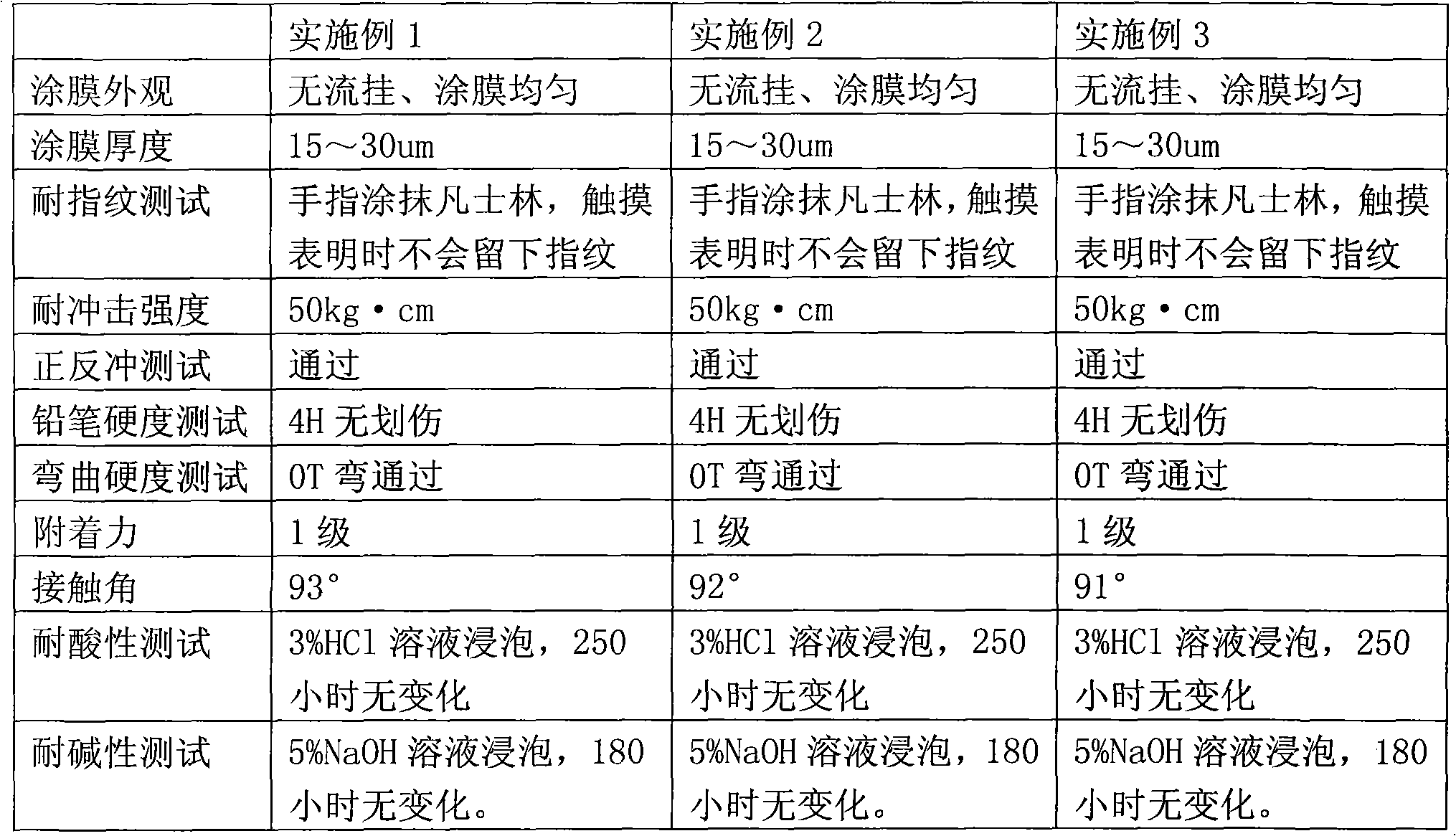

High-hardness fingerprint-resistant coating and preparation method thereof

The invention discloses a high-hardness fingerprint-resistant coating and a preparation method thereof. The high-hardness fingerprint-resistant coating comprises the following components in percentage by weight: 10 to 30 percent of solvent, 40 to 60 percent of fluorocarbon resin, 10 to 20 percent of amino resin, 1 to 30 percent of nano granules, 5 to 10 percent of polytetrafluoroethylene, 2 to 5 percent of polyethylene wax and 1 to 2 percent of auxiliary agent, wherein the nano granules are at least one of nano silicon dioxide, nano titanium dioxide, nano zirconium dioxide and nano zinc oxide. Compared with the prior art, the high-hardness fingerprint-resistant coating does not contain metal ions with environmental pollution, has strong adhesion, and can be coated on the surface of a steel plate by adopting modes of dip coating, spray coating, roll coating and the like; and the coated steel plate has the characteristics of high hardness, fingerprint resistance, pollution resistance, high toughness, acid resistance, alkaline resistance and the like, and can be widely applied to home appliances and other living goods.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

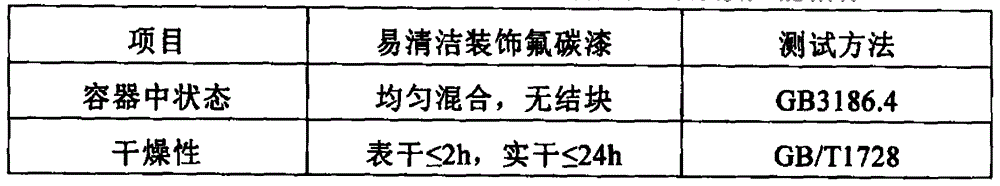

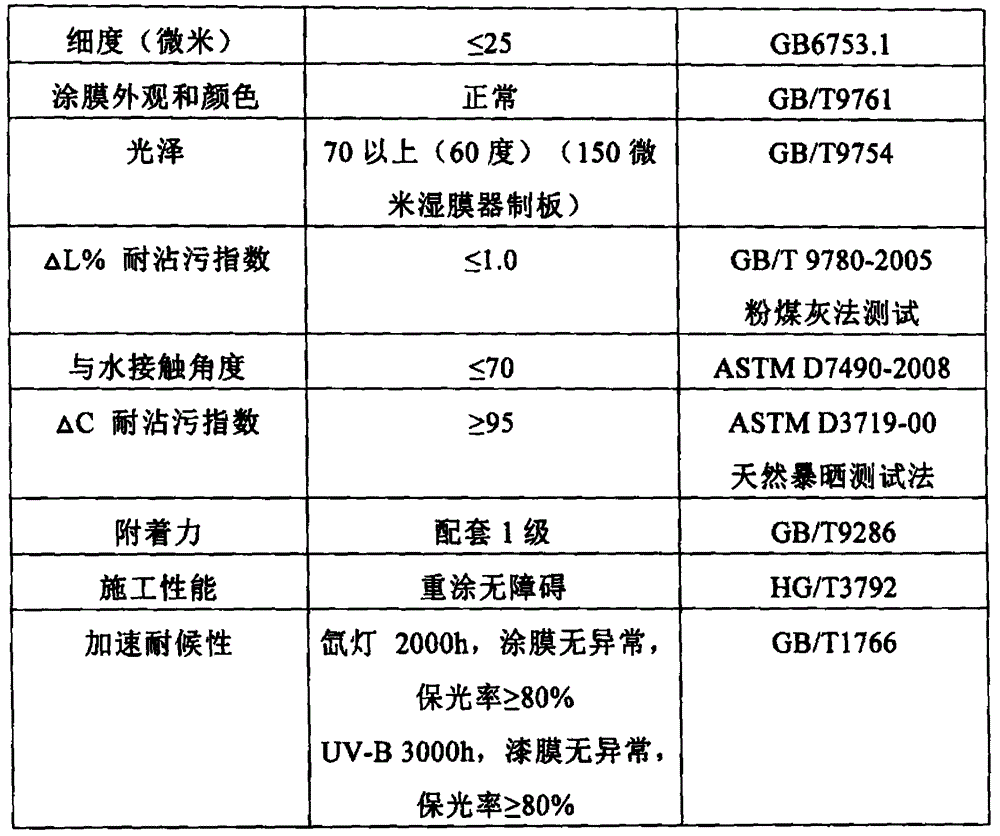

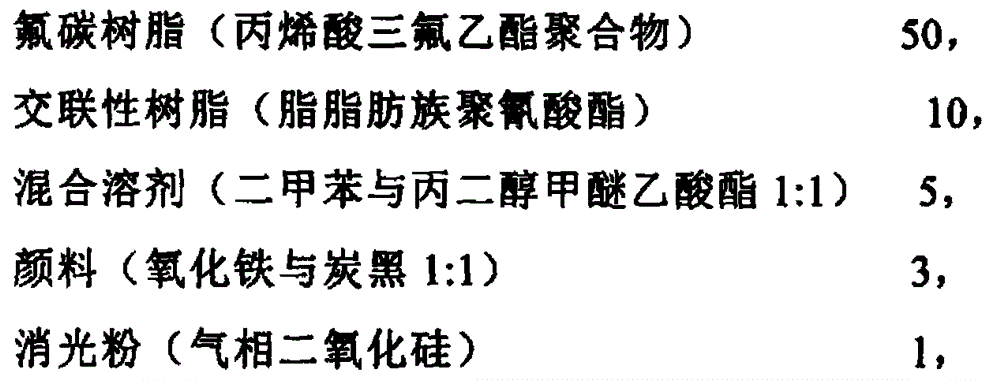

Easy-to-clean fluorocarbon paint and preparation method thereof

The invention relates to easy-to-clean fluorocarbon paint and a preparation method thereof. The fluorocarbon paint comprises the following components in parts by weight: 40-60 parts of fluorocarbon resin, 10-20 parts of crosslinking resin, 5-20 parts of a mixed solvent, 3-30 parts of a pigment, 0-5 parts of extinction powder, 0-1 part of a flatting agent, 0-1 part of a foam killer and 0-1 part of a dispersant. The fluorocarbon resin with low interface energy is mainly adopted for crosslinking and solidifying with the crosslinking resin, and the characteristic that fluorine-containing side chains can be centralized on a coating surface after film forming is utilized to give the role of fluorine atoms into play to the utmost extent, so that the surface performance of a copolymer is effectively changed to form a hydrophobic-oleophobic group, and accordingly, the effects of water resistance, oil repellency, rust prevention and the like are achieved. Compared with the prior art, the fluorocarbon paint provided by the invention is excellent in easy-to-clean performance, the paint film is smooth and even in appearance and sound in color, and the light and color maintenance properties are good.

Owner:DONGLAI COATING TECH SHANGHAI

Thermo-setting transfer mould release agent and method for preparing and using same

InactiveCN102492358AGood solvent resistanceImprove friction resistanceDuplicating/marking methodsPolyurea/polyurethane coatingsAlkaneTetrafluoroethylene

The invention provides a thermo-setting transfer mould release agent. The thermo-setting transfer mould release agent comprises polyisocyanates and an ingredient, wherein the ingredient comprises the following components in part by weight: 15 to 45 parts of fluorocarbon resin, 2 to10 parts of polytetrafluoroethylene micro powder, 40 to 62 parts of C4-C8 alkane, 0.2 to 0.5 part of antifoaming agent, 1 to 3 parts of flatting agent, 1 to 5 parts of release auxiliaries, and 1 to 4 parts of flatting silica, wherein the weight ratio of the polyisocyanates to the fluorocarbon resin is 1 to 8. and the method for preparing and using the mould release agent is as follows: adding the fluorocarbon resin while agitating the C4-C8 alkane and the polytetrafluoroethylene; adding the antifoaming agent, the flatting agent, the release auxiliaries and the flatting silica, and then agitating the mixture; and, regulating the weight ratio of the fluorocarbon resin to the polyisocyanates in the product to be 8 to 1. The acquired mould release agent is coated on a PET (Polymer) film by a mesh plate and then dried for the use. The mould release agent is not transferred after being transfer-printed, so that the performances of the printing oil are not affected; the bottom film has no change after transfer-printing, and the friction resistant and solvent resistant performances are very good.

Owner:XIAMEN HOWER MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com