Preparation method of high-performance fluorocarbon coating

A fluorocarbon coating and high-performance technology, applied in the field of preparation of fluorocarbon coatings, can solve the problems of low strength, cracking of the coating, complicated production process, etc., and achieve good low temperature flexibility, hydrolysis resistance, and excellent weather resistance. With the effect of corrosion resistance, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

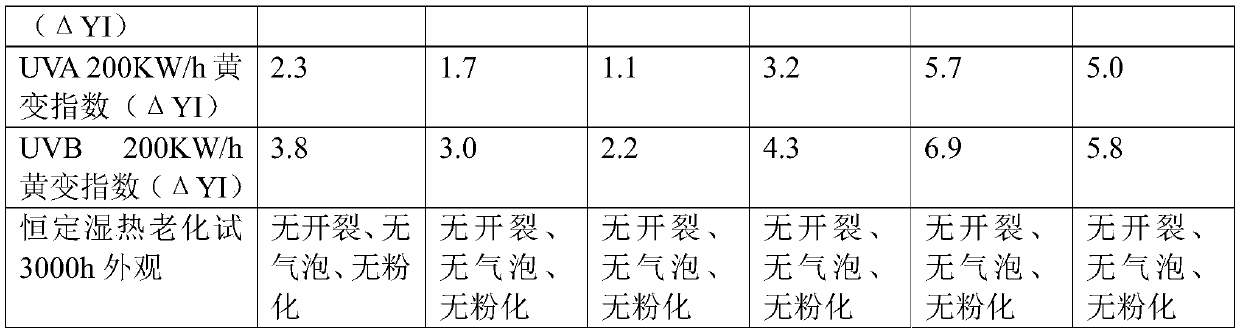

Examples

Embodiment 1

[0025] A high-performance fluorocarbon coating, composed of two components, A and B.

[0026] Preparation of component A: Add 1000g (3.04molOH group) polytetrahydrofuran ether-oxypropylene copolymer glycol (Shanghai Yiqing Trading Co., Ltd.) at 150°C, and add 15g of hindered phenolic antioxidant 1076 (Dongguan City Huiyi Chemical Materials Co., Ltd.), add 5g p-toluenesulfonic acid (McLean’s reagent) for dehydration for 2.5 hours; then the reaction temperature drops to 95°C, and 2932g (9.12mol NCO-based Group) hexamethylene diisocyanate trimer solidifying agent HT-90BS (Wanhua Chemical Group Co., Ltd.), 2932g anhydrous butyl acetate (Zhejiang Chemical Industry Company) join in the reactor successively, insulation reaction 8 hours, then Vacuum was maintained for 1 hour to prepare isocyanate-terminated polytetrahydrofuran ether-propylene oxide copolymer prepolymer to obtain component A, which was sealed after cooling down for later use;

[0027] Preparation of Component B:

[0...

Embodiment 2

[0031]Preparation of component A: Add 1000g (9.6molOH group) polycaprolactone polyol PCL303 (Dacel, Japan) at 100°C, and add 5g of hindered phenolic antioxidant 1076 (Dongguan Huiyi Chemical Materials Co., Ltd. Co., Ltd.), dehydration for 3.5 hours; then the reaction temperature dropped to 75°C, and 3717g (19.2mol NCO group) hexamethylene diisocyanate trimer curing agent TKA100 (Asahi Kasei Chemical Co., Ltd.), 18g dibutyltin dilaurate, and 3717g anhydrous n-butyl ketone (Zhejiang Chemical Industry Co., Ltd.) were successively added to the reactor to insulate and react for 6 hours, and then kept in vacuum for 2 hours to obtain the isocyanate-terminated polycaprolactone polyol Prepolymer, get component A, seal it for later use after cooling down;

[0032] Preparation of Component B:

[0033] Put 230g of anhydrous methyl ethyl ketone (Hangzhou Chemical Reagent Co., Ltd.) in a container, and add 400g (0.46molOH group) of fluorocarbon resin L101 (Wanbo Paint Chemical Co., Ltd.) s...

Embodiment 3

[0036] A high-performance fluorocarbon coating, composed of two components, A and B.

[0037] Preparation of component A: Dehydrate 1000g of polycarbonate diol T5651 (1.96molOH group) (Guangzhou Haoyi Chemical Technology Co., Ltd.) at 130°C for 4.5 hours; Polycarbonate polyol T5651 added 1557g (4.41molNCO group) isophorone diisocyanate trimer Z4470BA (Bayer, Germany), 854g (4.41molNCO group) hexamethylene diisocyanate trimer curing agent TKA100 (Asahi Kasei Chemical Co., Ltd.), 2411g anhydrous ethyl acetate (Zhejiang Chemical Industry Co., Ltd.) were added to the reactor successively, kept for 5 hours insulated and kept in vacuum for 3 hours to obtain the isocyanate-terminated polycarbonate diol prepolymer , to obtain component A, and seal it for later use after cooling down;

[0038] Preparation of Component B:

[0039] 350g of anhydrous xylene (Hangzhou Chemical Reagent Co., Ltd.) was placed in a container, and 650g (1.7molOH group) of fluorocarbon resin GK570 (Dakin in Ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com