Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

536 results about "Fluorocarbon coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorocarbon Coating is an organic coating consisting of solid lubricant dispersed in an organic binder and dissolved in a specially formulated mixture of solvents. It is also corrosion-resistant due to the use of a thermally cured thermosetting synthetic binding material. ... Fluorocarbon Coating has the following characteristics: - It is a lustrous coating.

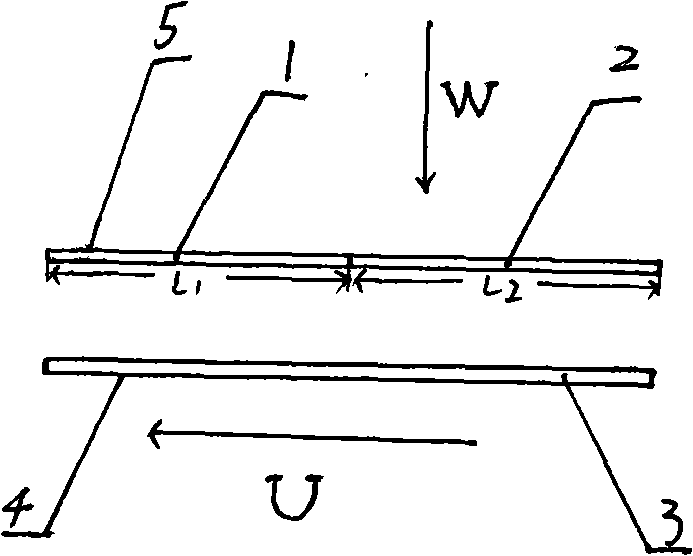

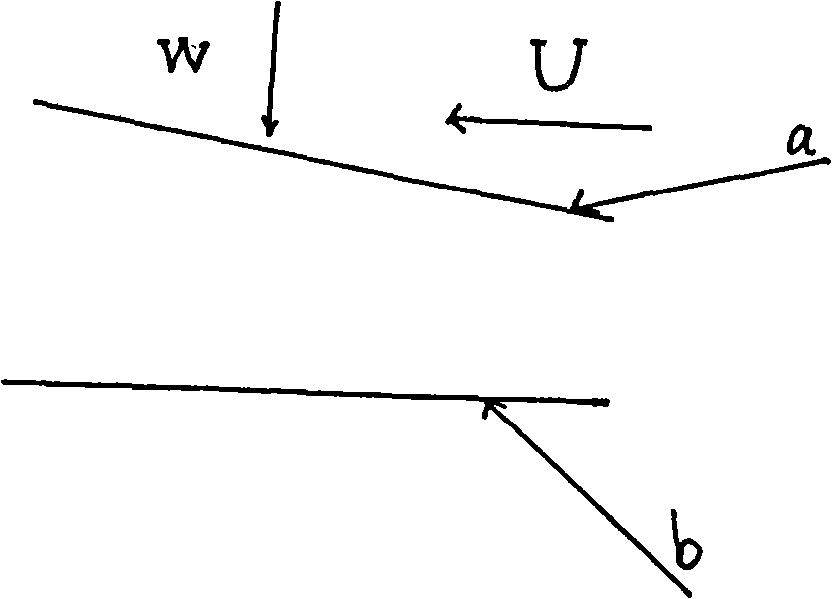

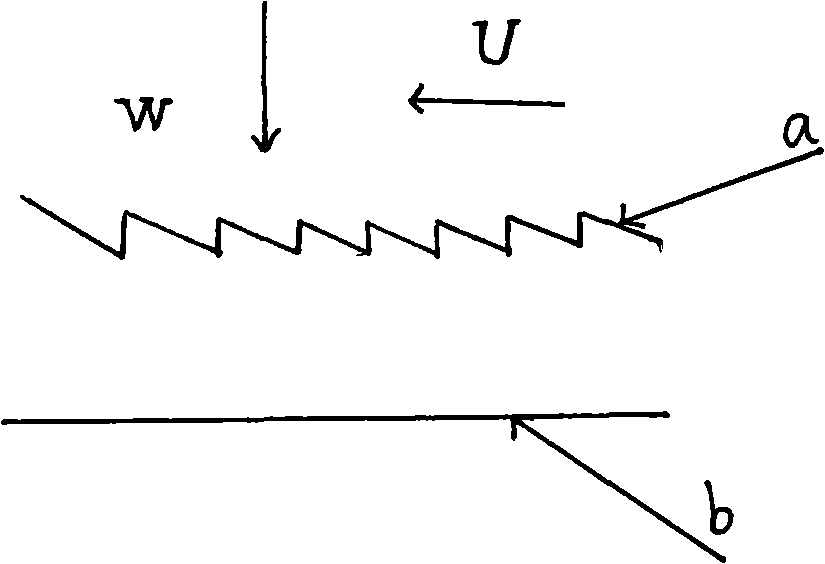

Surface coating method for hydrophobic and superhydrophobic treatment in atmospheric pressure plasma

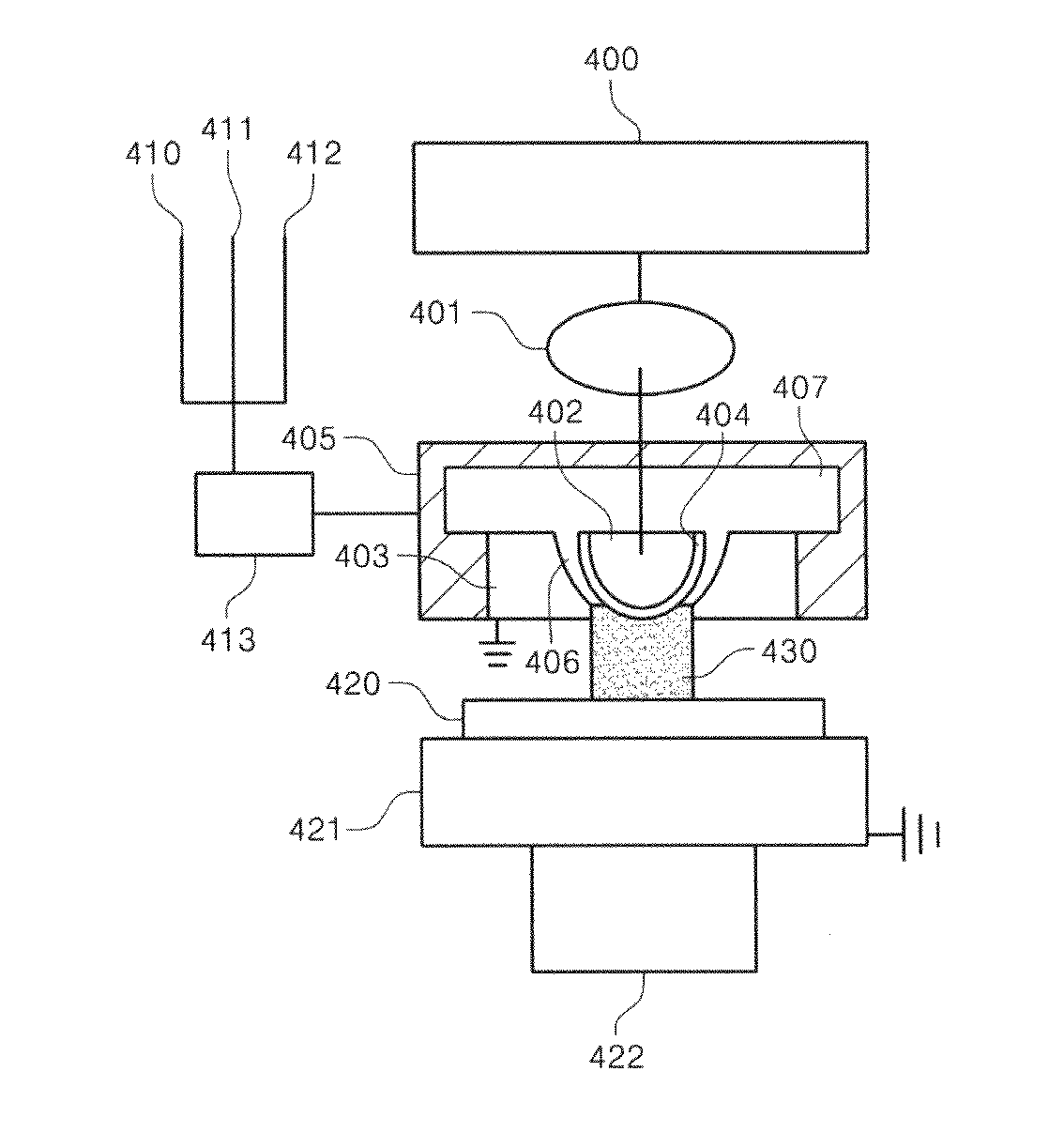

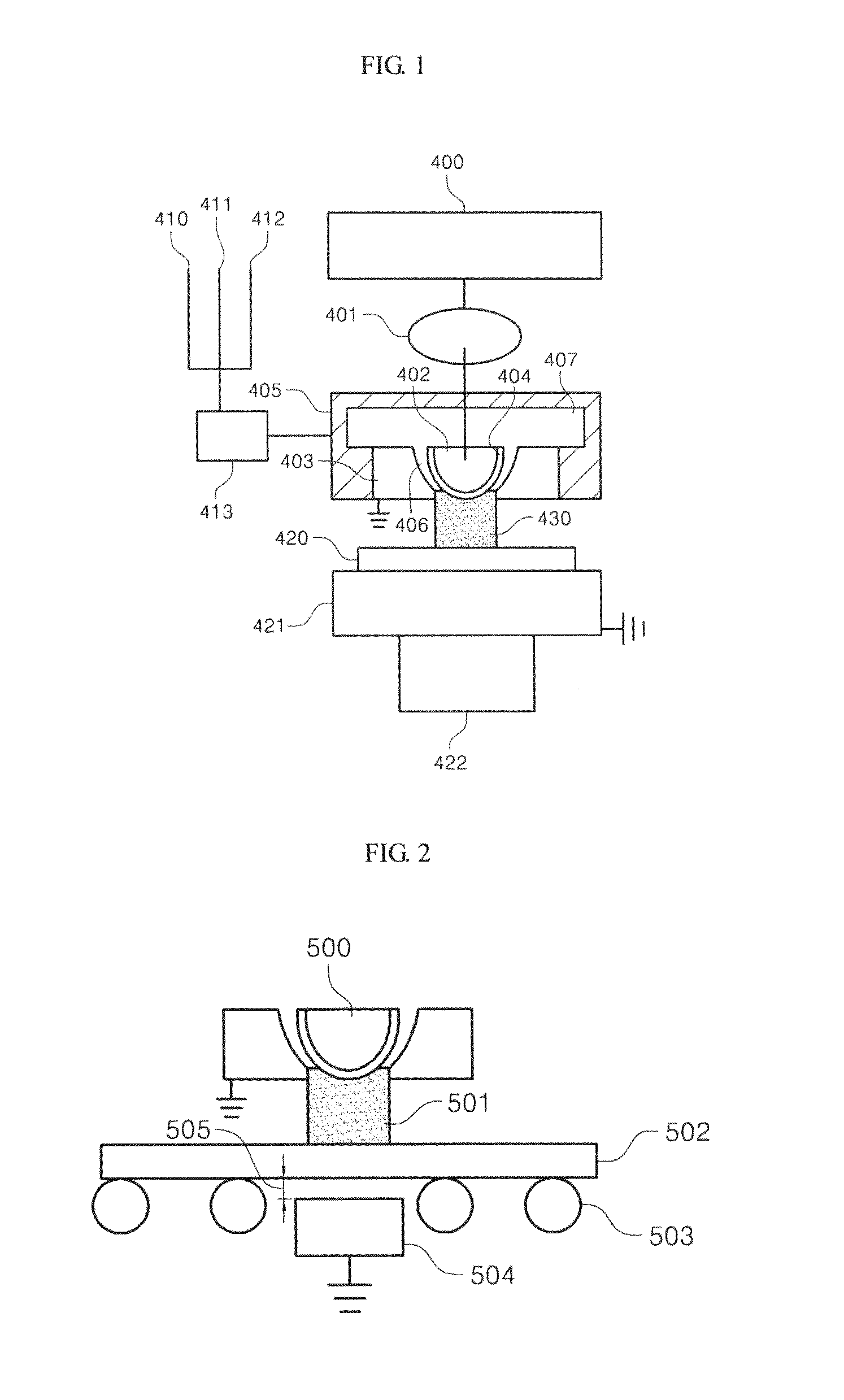

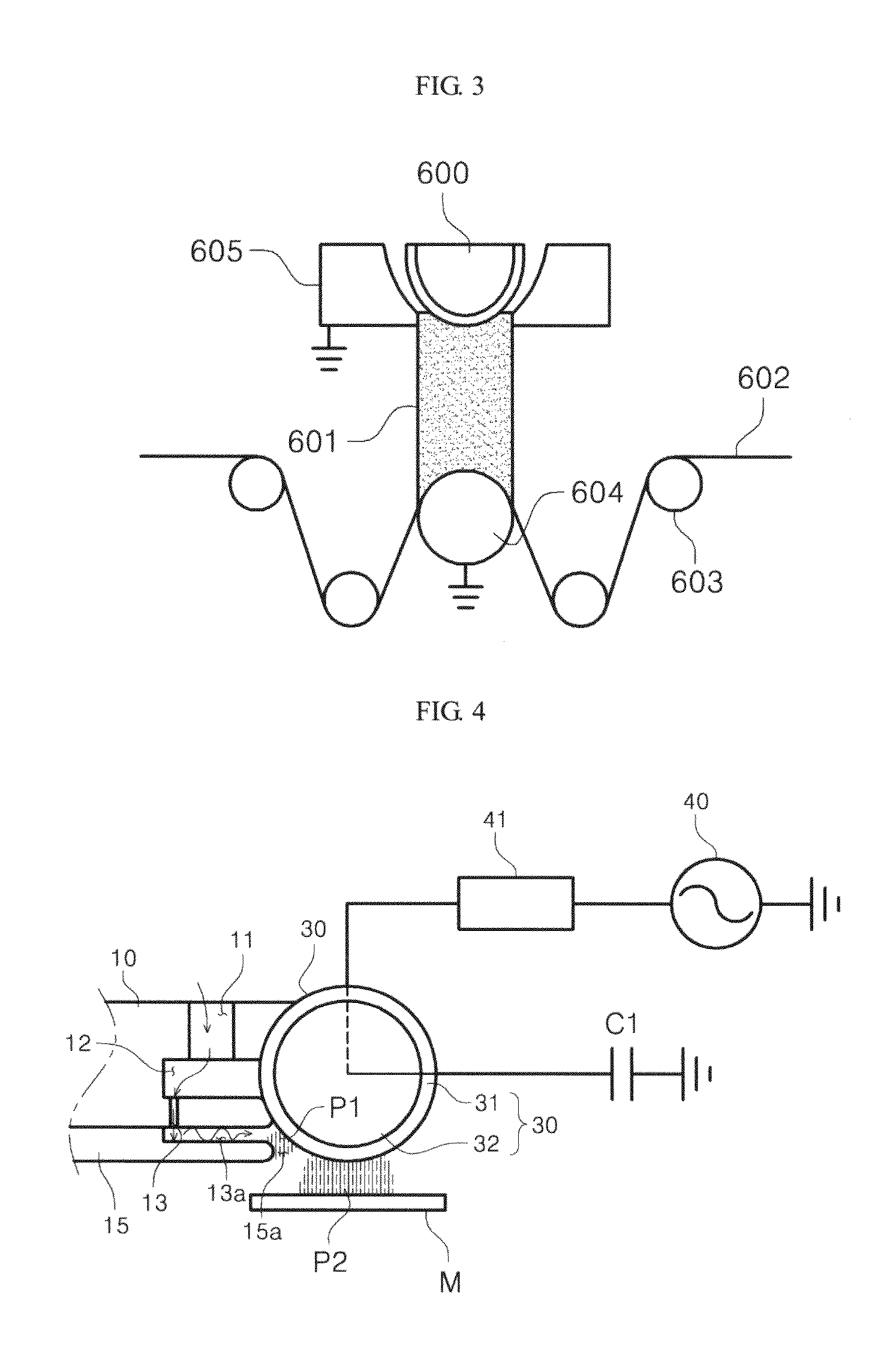

The present invention relates to a method of coating fluorocarbon or hydrocarbon on the surface of a workpiece using atmospheric pressure plasma. More particularly, the present invention relates to a method of coating hydrocarbon or fluorocarbon on the surface of a workpiece using plasma generated under atmospheric pressure such that the workpiece can have a hydrophobic or super-hydrophobic surface.The method of coating a surface of a workpiece with fluorocarbon to be hydrophobic or super-hydrophobic according to the present invention comprises the steps of generating first atmospheric pressure glow plasma by supplying a reaction gas into a discharge space formed between a first electrode and a second electrode, the reaction gas containing hydrogen gas, fluorocarbon gas and inert gas, the first and second electrodes being connected to an RF power supply of an atmospheric pressure plasma generator; and approaching the workpiece to the first electrode downstream of a reaction gas flow passing through the discharge space, such that the plasma created in the discharge space is transferred into a space between the first electrode and the workpiece to generate a second atmospheric pressure glow plasma therein, whereby a fluorocarbon coating layer can be formed on the surface of the workpiece.

Owner:KANG BANG KWON

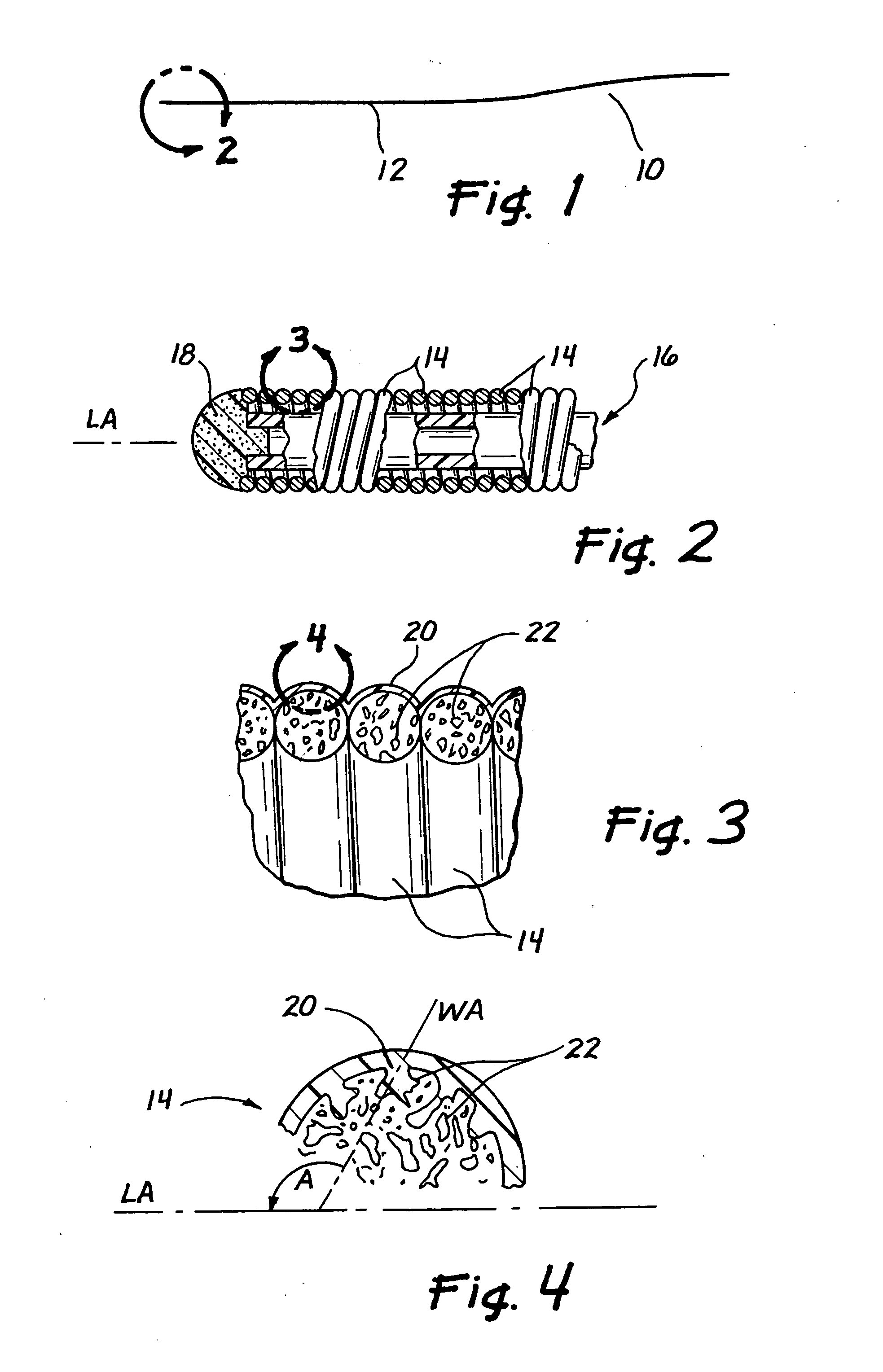

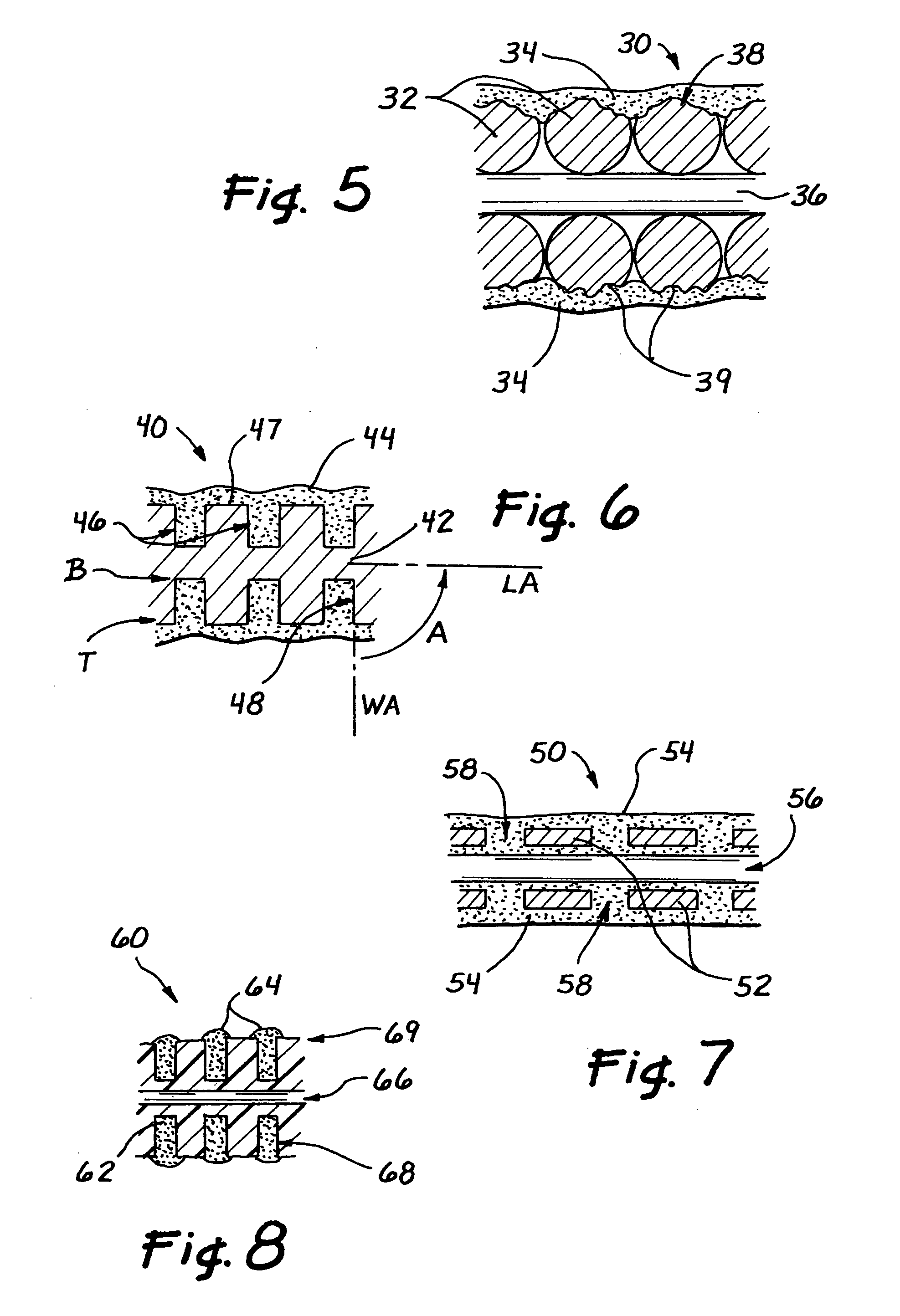

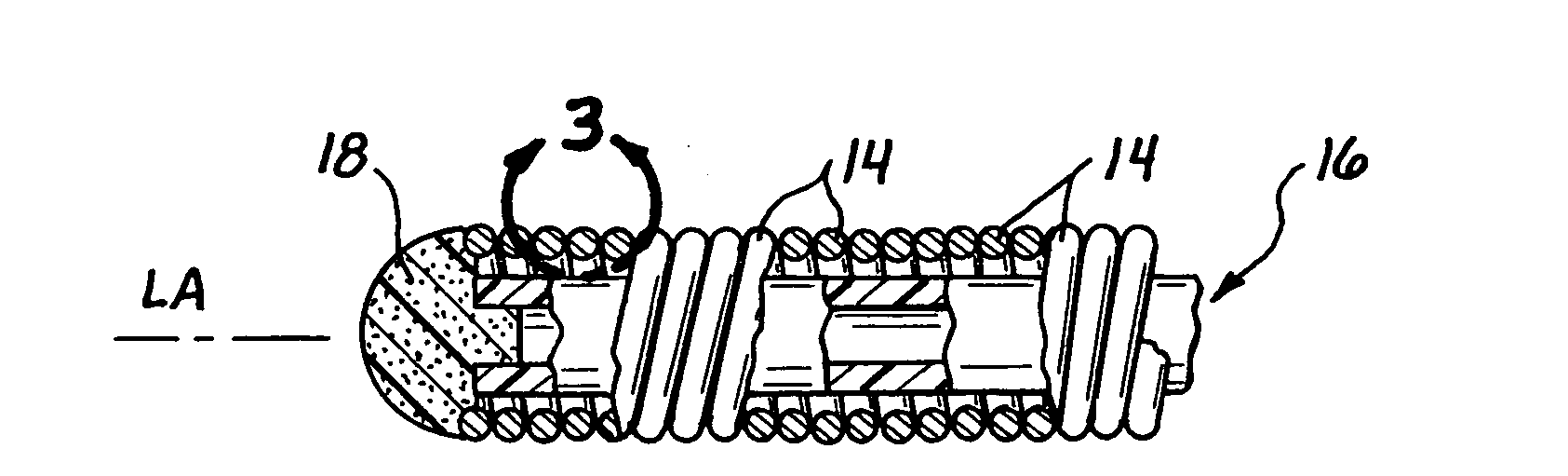

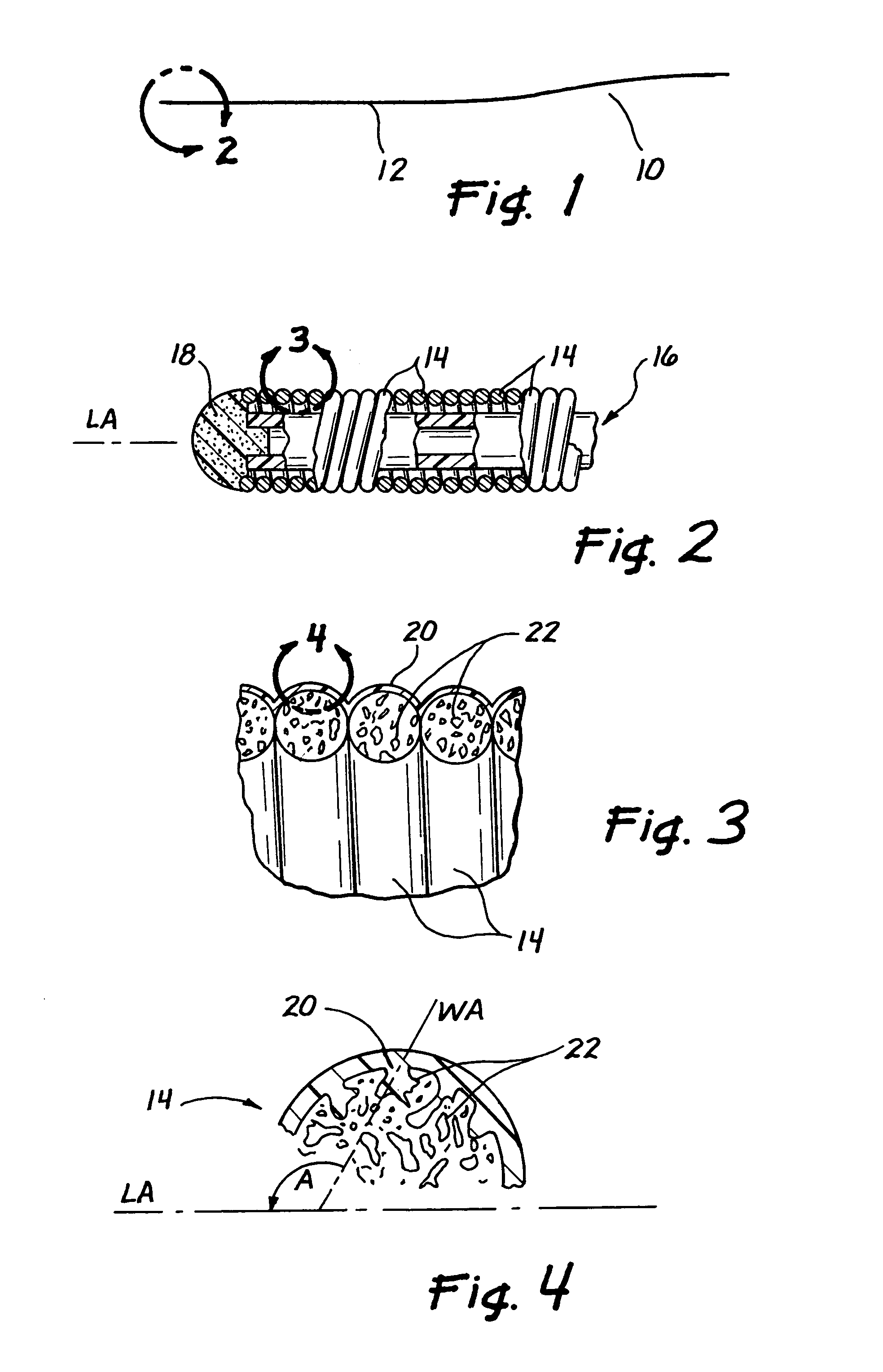

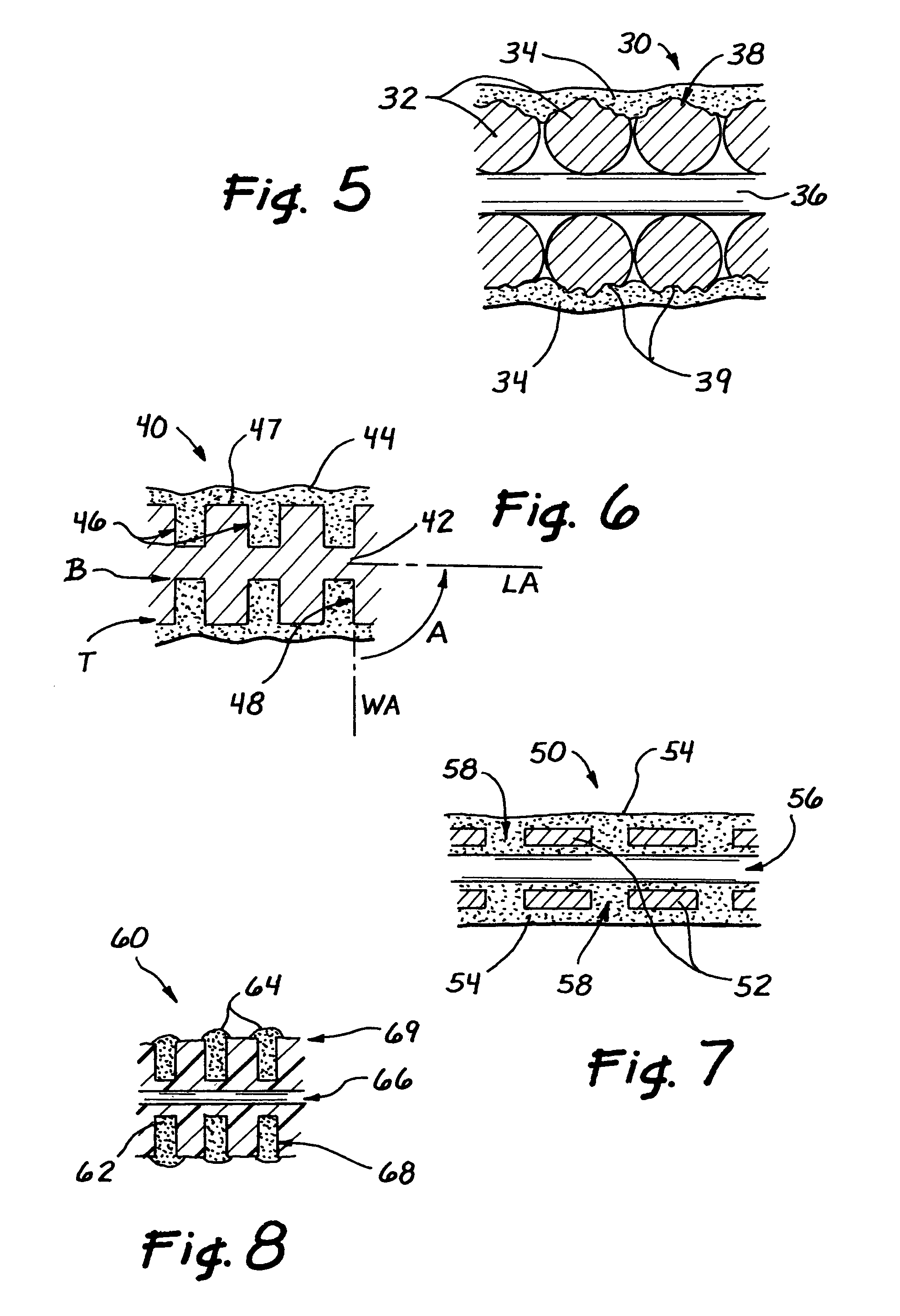

Medical devices having full or partial polymer coatings and their methods of manufacture

Medical devices for insertion into the body of human or veterinary patients, wherein the device comprises a) a working element (e.g. a wire, a guidewire, a tube, a catheter, a cannula, a scope (e.g., rigid or flexible endoscope, laparoscope, sigmoidoscope, cystoscope, etc.) a probe, an apparatus for collecting information from a location within the body (e.g., an electrode, sensor, camera, scope, sample withdrawal apparatus, biopsy or tissue sampling device, etc.) which has an outer surface and b) a continuous or non-continuous coating on the outer surface of the working element. The outer surface of the working element is prepared to create a surface topography which promotes mechanical or frictional engagement of the coating to the working element. In some embodiments the coating is a lubricious coating, such as a fluorocarbon coating or a hydrogel that becomes lubricious when contacted by a liquid. In some embodiments, the coating may expand as swell. Also disclosed as methods for manufacturing such devices.

Owner:MICROVENTION INC

Optical solidifying fluorine-carbon paint and its preparing method and use

InactiveCN101210145AHigh hardnessVariety of colorsLiquid surface applicatorsCoatingsScratchingPollution

Owner:ZHUHAI DONGCHENG UV MATERIALS

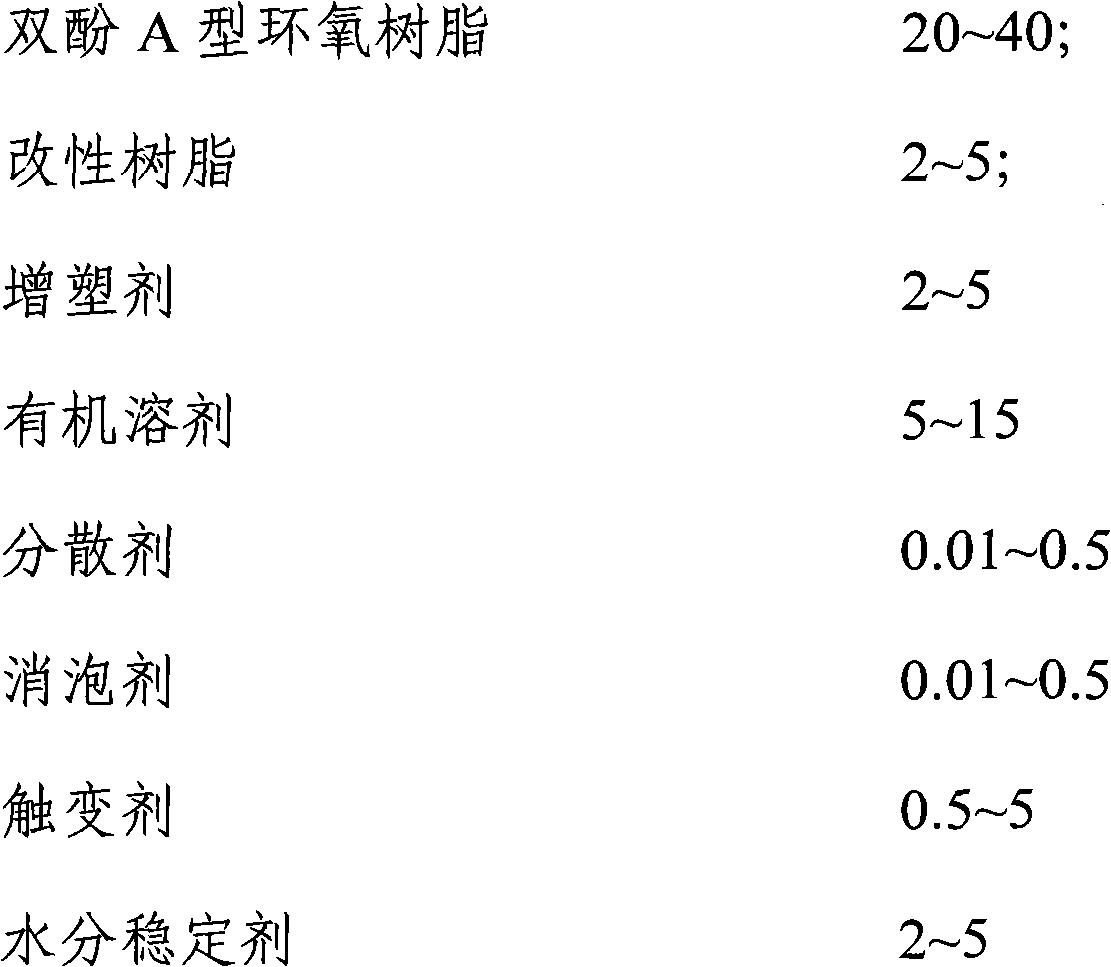

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

Medical devices having full or partial polymer coatings and their methods of manufacture

Medical devices for insertion into the body of human or veterinary patients, wherein the device comprises a) a working element (e.g. a wire, a guidewire, a tube, a catheter, a cannula, a scope (e.g., rigid or flexible endoscope, laparoscope, sigmoidoscope, cystoscope, etc.) a probe, an apparatus for collecting information from a location within the body (e.g., an electrode, sensor, camera, scope, sample withdrawal apparatus, biopsy or tissue sampling device, etc.) which has an outer surface and b) a continuous or non-continuous coating on the outer surface of the working element. The outer surface of the working element is prepared to create a surface topography which promotes mechanical or frictional engagement of the coating to the working element. In some embodiments the coating is a lubricious coating, such as a fluorocarbon coating or a hydrogel that becomes lubricious when contacted by a liquid. In some embodiments, the coating may expand as swell. Also disclosed as methods for manufacturing such devices.

Owner:MICROVENTION INC

Fluorocarbon coating and its preparing method

InactiveCN1580154AMeet the needs of assembly line operationsSimple processCoatingsChemical reactionPolymer science

The invention relates to a kind of fluo-carbo dope and the preparation method. It is mainly made up of fluororesin, bridging agent, dye, filling, compounding and component solvent. The weight ratio as follow, fluororesin : bridging agent : dye : filling : compounding : component solvent equal to 1:0.10-0.30:0-0.35:0-0.05:0.01-0.05:0.10-0.40. The mentioned fluororesin is composed by 3-fluororesin or 4-fluororesin or both. The book of words gives the preparation method. chemical reaction will take place when fluororesin gets along with bridging agent under the condition solidifying process of fluo-carbo dope. So, add no-close isocyanic ester, it can be executed into dry fluo-carbo dope as to be used to sectional repair in the roofing surface. The dope has low capability of the lacquer film surface, good dirt resistance, easy ablution and excellent mechanical property and excellent aging performance.

Owner:大连振邦氟涂料股份有限公司

Long-acting water-soluble and environmentally-friendly steel structural protective coating

ActiveCN103450719AImprove adhesionHigh reactivityAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceAcrylic coating

The invention provides a long-acting water-soluble and environmentally-friendly steel structural protective coating. The long-acting water-soluble and environmentally-friendly steel structural protective coating is characterized in that a water-soluble inorganic zinc silicate coating is used as a primer of the protective coating; a water-soluble silicon-acrylic coating is used as an intermediate coating; a water-soluble fluorocarbon coating serves as a top coating; the water-soluble inorganic zinc silicate coating comprises the raw materials of high-modulus potassium silicate inorganic nanometer resin and synthesized organic polymer emulsion, wherein the high-modulus potassium silicate inorganic nanometer resin has the modulus of 5.3 to 6.2, and the particle diameter is 5 to 20nm; the synthesized organic polymer emulsion is composed of one or a plurality of water-soluble styrene-acrylic emulsion, water-soluble pure acrylic emulsion, water-soluble silicone acrylic emulsion, water-soluble fluorocarbon emulsion and water-soluble fluoro-silicon emulsion; and the water-soluble silicon-acrylic coating comprises the raw material of a silicon-acrylic matrix, wherein the silicon-acrylic matrix is one of a mixture of silicone acrylic emulsion and pure acrylic emulsion, the mixture of silicone acrylic emulsion and styrene-acrylic emulsion, and silicone acrylic emulsion. By adopting the long-acting water-soluble and environmentally-friendly steel structural protective coating, the corrosion resistance and weather resistance of the protective coating are obviously improved; the corrosion resisting effect can last for 20 years; and the weather resistance lasts for more than 20 years.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Thrust bearing applying interface sliding technology

InactiveCN101265942AWith carrying capacityExcellent friction reductionBearing componentsSliding contact bearingsCarrying capacityThrust bearing

The invention is a thrust bearing using the interface slippage technology, and is characterized in that the bearing comprises a static and a moving flat panels that are parallel to each other; the gap between the static and the moving flat panels is filled with fluid lubricating oil; a coating layer II is arranged on part of the static flat panel; a coating layer I is arranged on the rest partof the static flat panel; a coating layer III is arranged on the surface of the moving flat panel, Therefore, a thrust bearing is formed by the two flat panels through a certain relative moving between the static flat panel and the moving flat panel, the coating layer I is a fluorocarbon coating layer, and the coating layer II and III are coatings of mica powder modified by silane coupling agents. The thrust bearing is simple in the bearing forming and has a certain carrying capacity, good anti-friction and wear-resistance without the need of processing the matching surface into a geometric shape. With simple and compact structure and small size and low production cost, the thrust bearing can replace the traditional fluid motive power lubrication thrust bearing for bearing purpose.

Owner:HUAIHAI INST OF TECH

Lotus leaf effect self cleaning fluorocarbon paint

The present invention belongs to the field of self-cleaning coating technology. In the concrete, it relates to a self-cleaning fluorocarbon coating with lotus leaf effect. It is made up by using organic silicon modified fluorocarbon resin, solidifying agent, hydrophobic particles, pigment, filling material, adjuvant and solvent according to the mixing ratio of 1:0.1-0.3:0.03-0.1:0-0.36:0-0.1:0.01-0.05:0.1-0.3 through a certain preparation process.

Owner:鳄鱼制漆(上海)有限公司

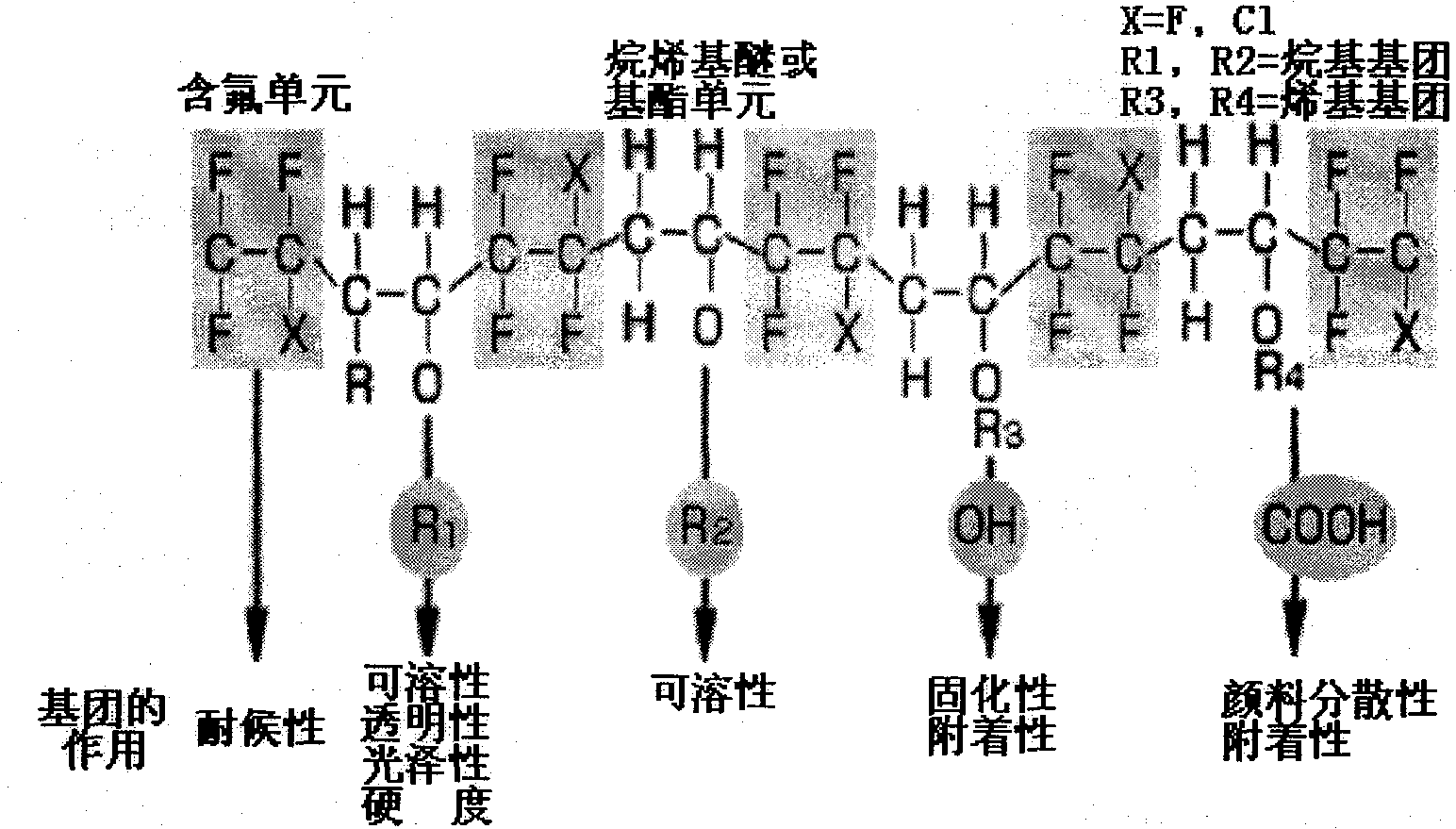

Thermosetting fluorine-carbon resin for metal coiled material and coating thereof

The invention relates to a thermosetting fluorocarbon resin and the coating thereof. The copolymerization chain segment of the resin comprises chlorotrifluoroethylene of 45.0-55.0mol percent, vinyl-acetic ester of 28.0-37.0mol percent, vinyl versatate of 4.0-10.0mol percent, hydroxyl vinyl ether of 10.0-14.0mol percent and aliphatic olefine acid of 0-0.6mol percent. The fluorocarbon coating mainly comprises the following components with certain weight percentage, thermosetting fluorocarbon resin of 20.0-40.0 percent, cross-linking agent of 0-15.0 percent, paint of 0-35.0 percent, promoter of 0.15-1.5 percent and mixed solvent of 30.0-60.0 percent. The fluorocarbon coating adopts no acid catalyst, has stable properties in storage, has excellent softness, methyl ethyl ketone wiping resistance and aging resistance, etc., and is applicable for rolling coating of metal rolling material.

Owner:万博新材料科技(南通)有限公司

Titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint and preparation method thereof

InactiveCN103242718ASolve the problem of pollution flashoverImprove hydrophobicityCoatingsPolymer sciencePolymer chemistry

The invention discloses titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint which comprises the following components in parts by weight: 30-50 parts of fluorocarbon resin, 10-30 parts of filler, 1-10 parts of pigment, 3.5-10 parts of curing agent, 2-10 parts of coupling agent, 0.03-3 parts of assistant, 35-45 parts of solvent and 0.001-0.1 part of drying agent. The invention also discloses a preparation method of the fluorocarbon resin paint. The static contact angle theta of the fluorocarbon resin paint can be up to 118 degrees; and the fluorocarbon resin paint has favorable hydrophobicity and hydrophobic migration performance and high pollution flashover preventing performance, thus ensuring that the physical / chemical properties and electric properties of a prepared coating can meet pollution flashover preventing conditions. The invention is used for insulator pollution flashover prevention, and solves the problem of insulator pollution flashover of a high-voltage transmission line.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Watersoluble fluorine-carbon modified elastic paint for exterior wall of construction

The invention discloses a water elastic coating used for the protection and decoration on the surface of an outer wall of a construction. The current elastic coating mainly aims at solving the stain resistance of the elastic coating, while relates less to the aspects of acid rain resistance and aging resistance. The mass percentage of each component in the coating is as follows: 10 to 20 percent of water, 2 to 4 percent of latent solvent, 0.5 to 1.0 percent of dispersant, 0.2 to 0.4 percent of multifunctional accessory ingredient, 0.2 to 0.5 percent of foam killer, 0.1 to 0.2 percent of preservative, 0.2 to 0.6 percent of mildew preventive and algaecide, 15 to 23 percent of acid resistant pigment, 5 to 18 percent of acid resistant filler, 10 to 15 percent of fluorocarbon latex, 30 to 40 percent of crylic acid elastic latex, 1 to 1.5 percent of film forming additive, 0.3 to 0.8 percent of rheological additive and 0.5 to 1.0 percent of thickening agent. The water elastic coating has the durability, the acid rain resistance and the stain resistance of fluorocarbon coating and simultaneously has the elastic crack resistance of acrylic acid elastic coating.

Owner:ZHEJIANG TRANSFER PAINT CO LTD

Preparation method of highly-hydrophobic fluorocarbon coating for photovoltaic component back plate

ActiveCN104530852AAvoid stickingReduce transmittancePolyurea/polyurethane coatingsCarbon coatingPtru catalyst

The invention provides a preparation method of a highly-hydrophobic fluorocarbon coating for a photovoltaic component back plate. The preparation method is suitable for outdoor coatings and in particular suitable for coated type photovoltaic back plates. The fluorocarbon coating consists of a component A and a component B in a mass ratio of (1-5):1, wherein the component A comprises fluorocarbon resin, hydrophobic modified nano-particles, a tin type catalyst and an anhydrous diluent A; and the component B comprises an isocyanate curing agent and an anhydrous diluent B. The nano-particles can be uniformly dispersed in main body resin after being subjected to coupling agent hydrophobic modification, is good in compatibility, and can form a micro-nano rough grain structure after being coated on a substrate; and by combining low surface energy of the fluorocarbon resin, the surface of the fluorocarbon coating has high hydrophobicity of a 'lotus leaf effect', has a good antifouling effect, and can greatly reduce influence of water drops on components. Meanwhile, the prepared fluorocarbon coating is excellent in weathering resistance, chemical resistance and salt spray resistance, so that the fluorocarbon coating is suitable for coated type photovoltaic component back plates and is good in performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Cross-linking type fluorine-containing acrylic resin

ActiveCN101113192AImprove performanceMaintain the cost-effective advantageCoatingsCross-linkPolymer science

The invention relates to a crosslinking type fluorine-containing acrylic resin, which is obtained by the heating and polymerization of more than one acrylic acid type monomer under initiator. The invention is characterized in that: the amount of each monomer applied in polymerization reaction is according to weight portions: methyl methacrylate 5-10 portions, alkyl acrylate monomer 10-20 portions, functional acrylic acid monomer 5-10 portions, fluorine-containing acrylic monomer 10-25 portions, organic solvent 40-60 portions; the fluorine-containing acrylic monomer is either or both of trifluoroethyl methacrylate and trifluoroethyl acrylate; the content of the fluorine-containing acrylic monomer takes 20-50 percent of the total weight of all monomer applied in the polymerization reaction. The resin can be crossingly cured at normal temperature and low medium temperature and has the wide application. Coating produced with the resin, comprehensive performance of which is close to fluorocarbon coatings maintains performance price ratio advantage of the acrylic resin.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

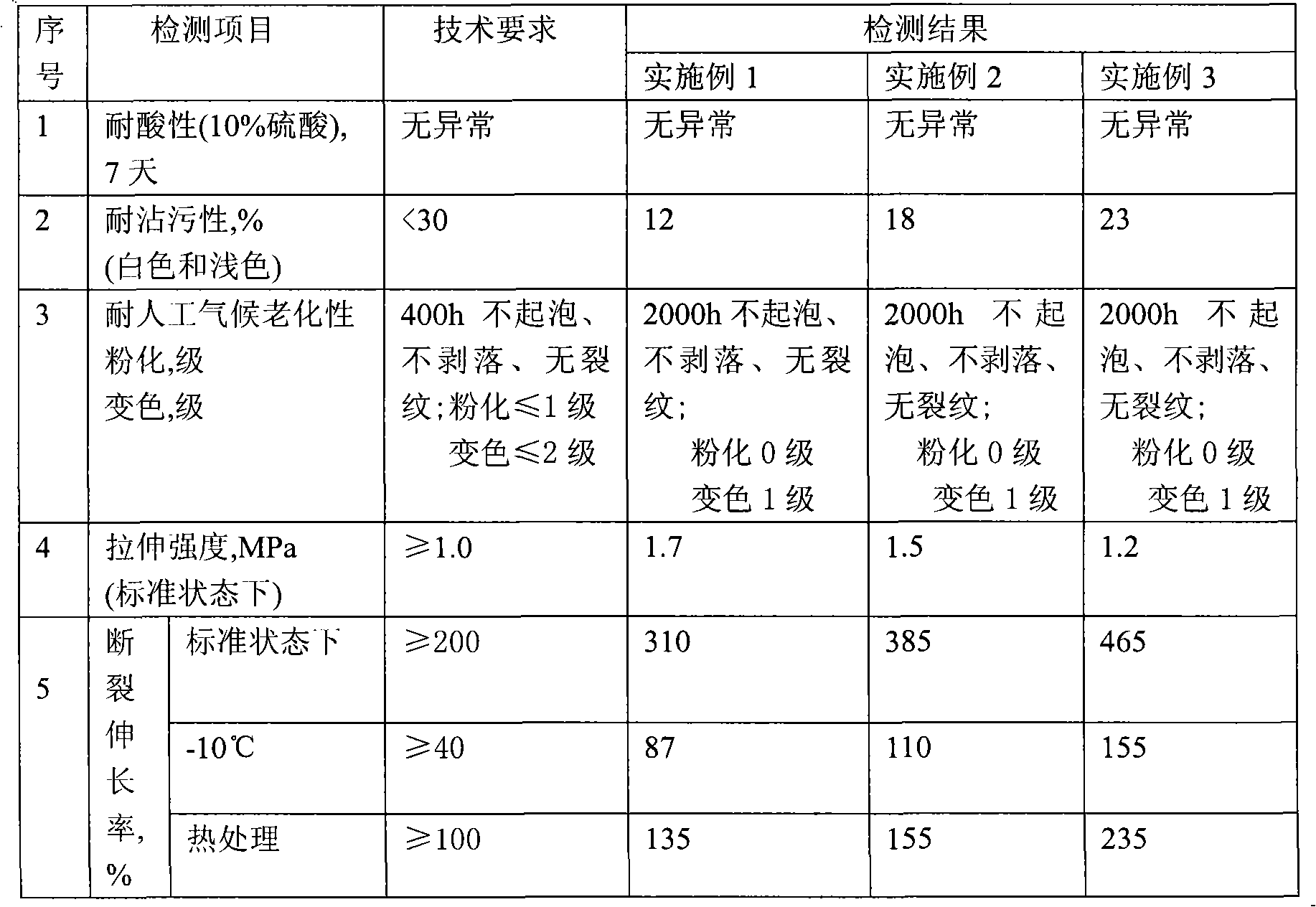

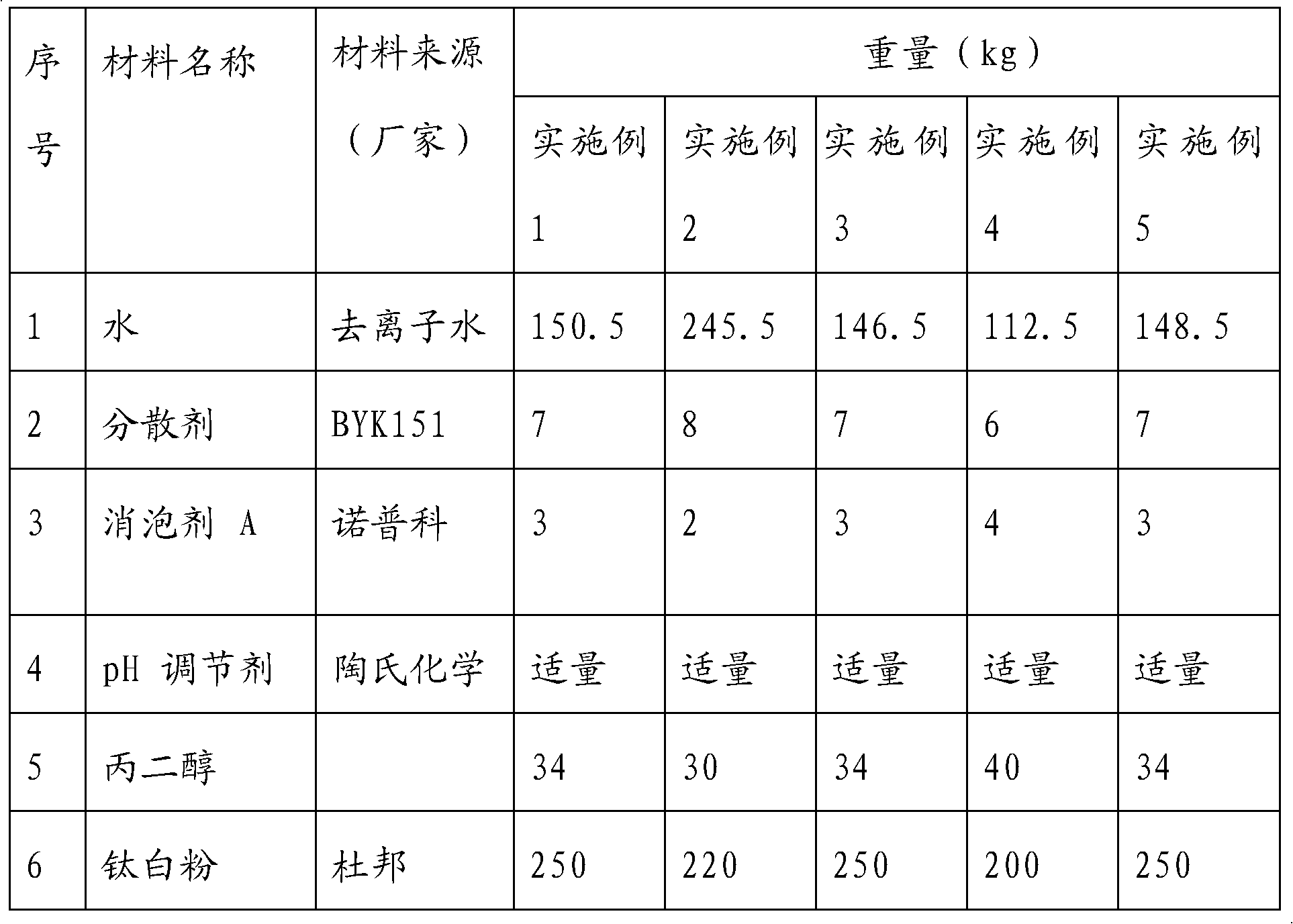

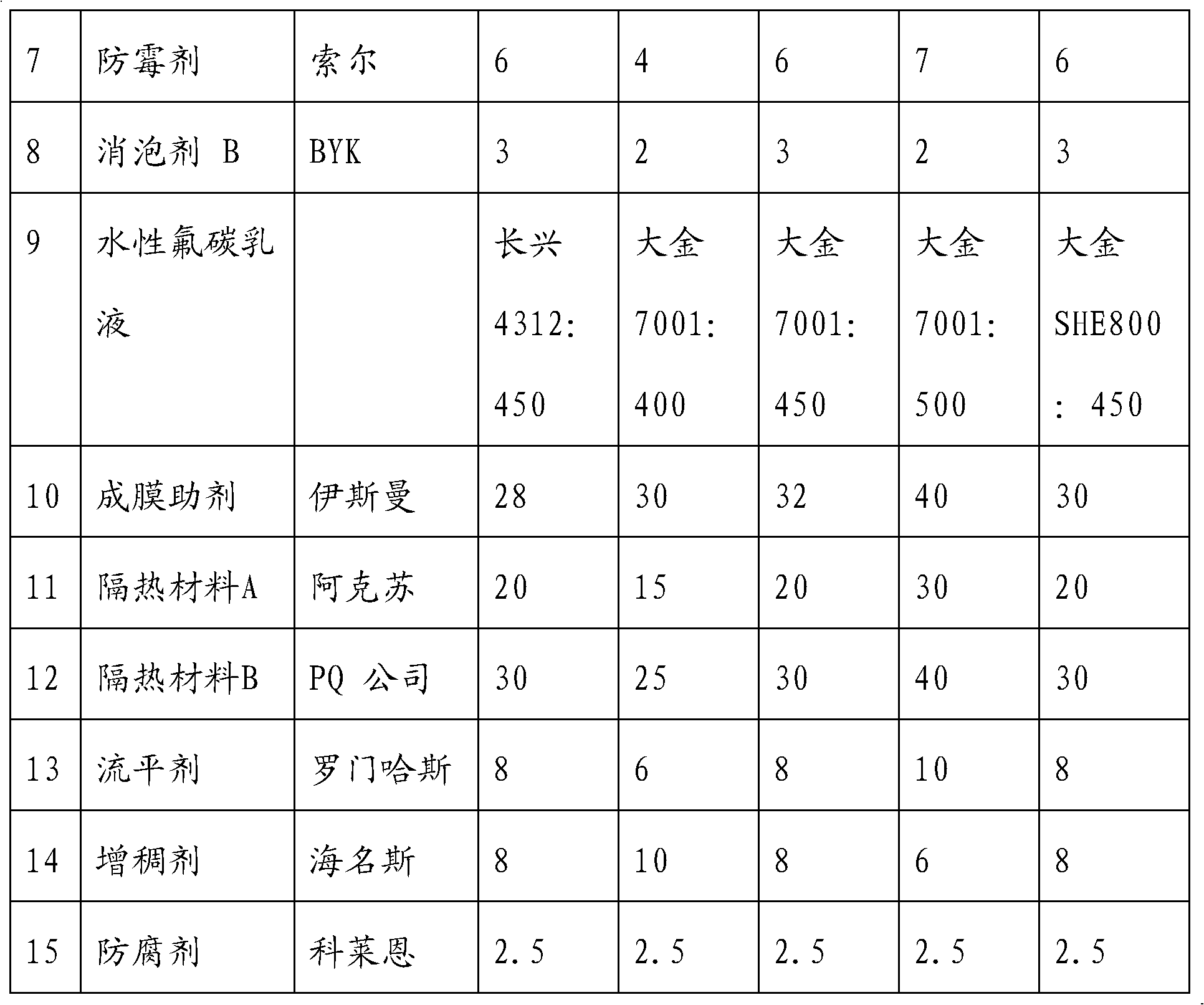

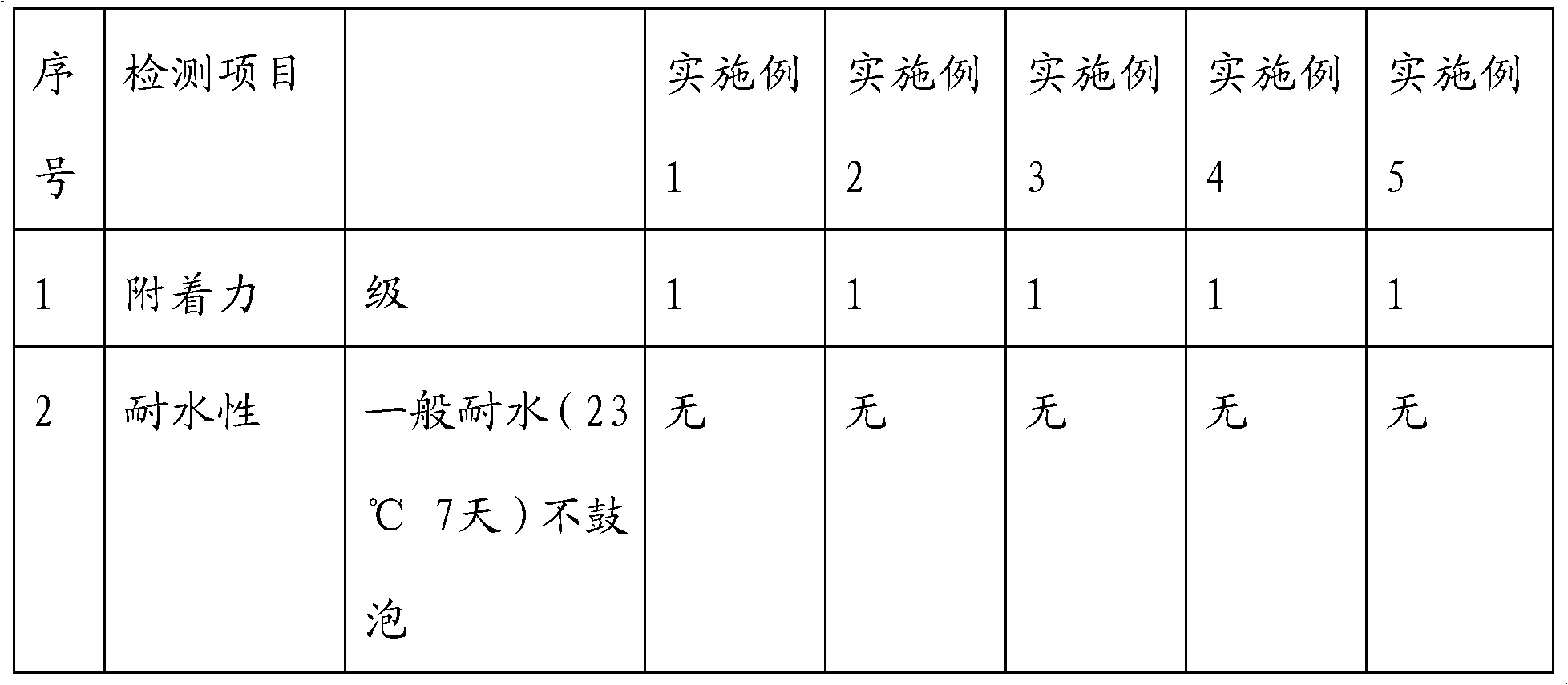

Water-based fluorocarbon heat insulation coating and preparation method

InactiveCN102585626AImprove reflectivityLow thermal conductivityReflecting/signal paintsWater basedInsulation system

A water-based fluorocarbon heat insulation coating is prepared by the following components by weight: 100 to 250 parts of water, 6 to 8 parts of dispersing agent, 2 to 4 parts of defoamer A, pH regulators of right amount, 30 to 40 parts of propylene glycol, 200 to 250 parts of titanium dioxide powder, 4 to 7 parts of mildew preventive, 2 to 4 parts of defoamer B, 400 to 500 parts of water-based fluorocarbon emulsion, 28 to 40 parts of film-forming assistant, 15 to 30 parts of heat insulation material A, 25 to 40 parts of heat insulation material B, 6 to 10 parts of flatting agent, 6 to 10 parts of thickening agent and 2.5 parts of preservative. A product of the water-based fluorocarbon heat insulation coating has various performances, can achieve the effect of oil-based fluorocarbon coating, can overcome the shortcomings of the oil-based fluorocarbon coating, and can meet requirements of an external wall heat insulation system in addition.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Weatherability fluorocarbon paint and preparation method thereof

The invention discloses a weatherability fluorocarbon paint and a preparation method thereof. The paint is composed of a component A and a component B, wherein the component A comprises an isocyanate curing agent and a waterless diluent A, and the component B comprises fluorocarbon resin, saturated polyester, low molecular compound containing special reactive groups, a catalyst, and a waterless diluent B. The component A and the component B are mixed according to a substance amount ratio of NCO / OH of 0.6-1.5:1.0 so as to obtain the fluorocarbon paint. Saturated polyester is added into the paint so as to soften the coating formed by the paint. At the same time, the added low molecular compound containing special reactive groups effectively increases the crosslinking density of coating, so that the coating is hard and flexible, has a strong weatherability and excellent wear resistant property, and can be used to prepare a solar battery backplane which can be used under severe climate conditions.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

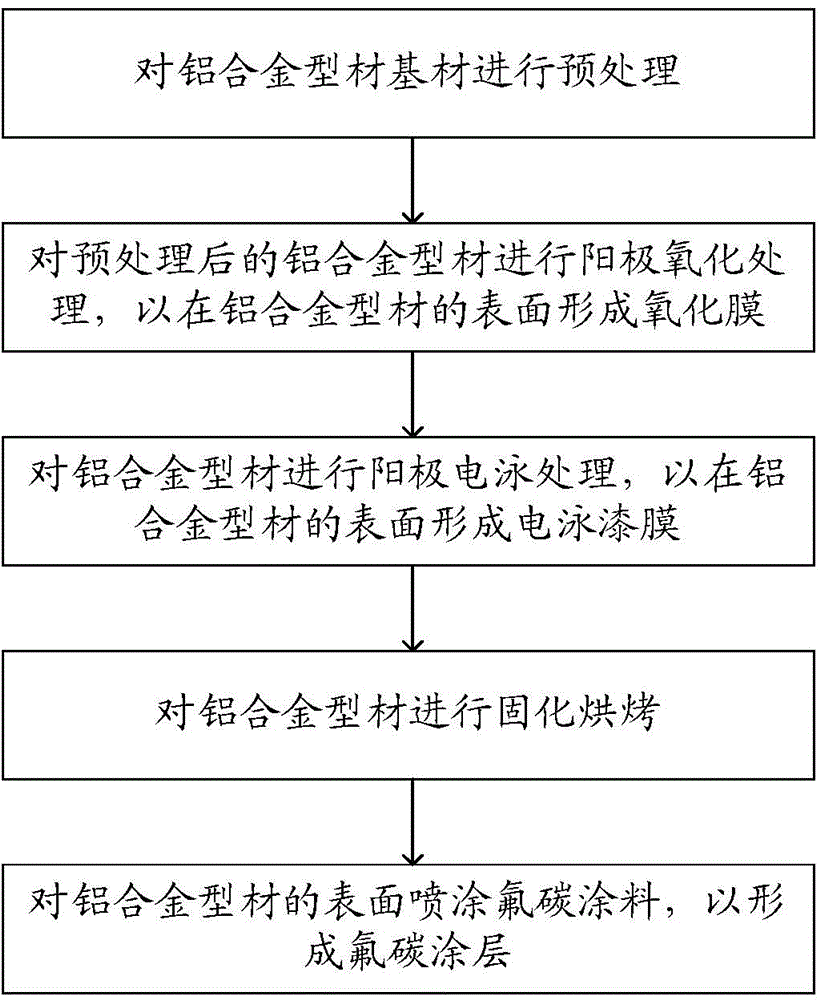

Aluminum alloy section and manufacturing method thereof

ActiveCN104589760AResistance to corrosion damageGuaranteed adhesion effectAnodisationLamination ancillary operationsComposite filmHigh humidity

The invention provides an aluminum alloy section and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) pre-treating an aluminum alloy section base material; (2) anodizing the pre-treated aluminum alloy section base material so as to form an oxidation film on the surface of the aluminum alloy section; (3) carrying out anodic electrophoresis treatment on the aluminum alloy section so as to form an electrophoresis film on the surface of the aluminum alloy section; (4) curing and roasting the aluminum alloy section; and (5) spraying a fluorocarbon coating to the surface of the aluminum alloy section so as to form a fluorocarbon coating. The manufacturing method is stable and feasible in production process. A special composite film protective coating is arranged on the surface of an aluminum alloy section product produced by the manufacturing method, has excellent performances such as corrosion resistance and weather resistance, and can effectively resist the corrosion destruction effect on the aluminum alloy section by ultraviolet light, high humidity and corrosive saline ions. Therefore, the aluminum alloy section is particularly suitable for buildings in island and seaside regions under marine climates.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

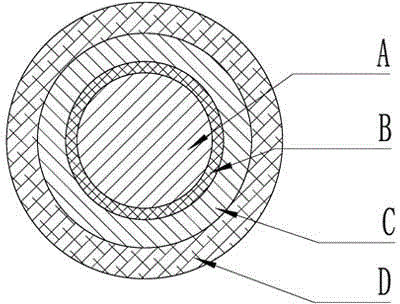

Multilayer compound eccentric-wear-preventing continuous sucker rod and manufacturing device and method thereof

ActiveCN104060944AAccelerated corrosionImprove partial wear resistanceDrilling rodsLayered productsEpoxyManufacturing technology

The invention relates to a multilayer compound eccentric-wear-preventing continuous sucker rod and a manufacturing device and a manufacturing method thereof. The sucker rod is characterized in that one section or several sections of the external surface of a fiber reinforced resin matrix composite rod body are respectively covered with a thermosetting wear layer; each thermosetting wear layer is made from one of polyurethane, a fluorocarbon coating, modified epoxide resin, vinylester resin, unsaturated polyester and phenolic resin; by adopting a manufacturing technology of multilayer composite winding and pultrusion or weaving and pultrusion, an internal layer of longitudinal fibers, an intertwining layer or a weaving layer and an external layer of longitudinal fibers are formed from interior to exterior in sequence; the manufactured rod body has a continuous length of 0-5000m. The sucker rod has the beneficial effects that the radial strength and the axial compressive strength are enhanced; the corrosion resistance and the eccentric wear resistance of the thermosetting wear layers are improved by 30%; the maximum temperature tolerance of the thermosetting wear layers is up to 190 DEG C; meanwhile, the bonding between an sucker rod body and each thermosetting wear layer is greater in length and quite high in strength, so that the slippage and the layering of an eccentric-wear-preventing layer from the surface of the sucker rod in the normal operation of an oil well are avoided.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

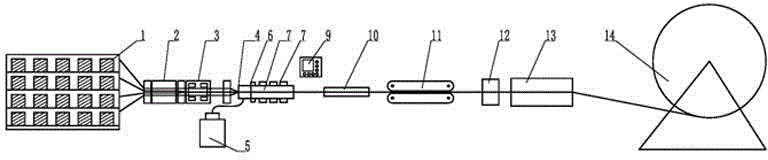

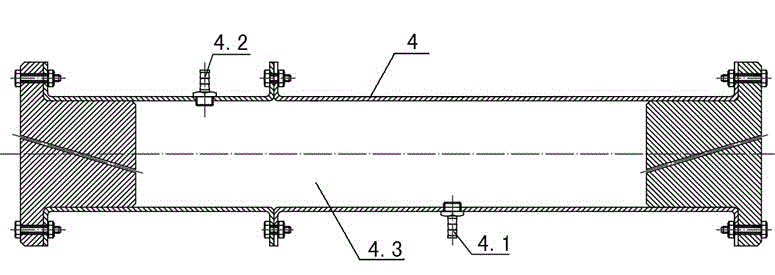

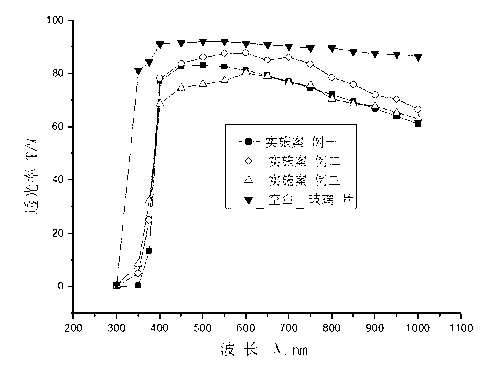

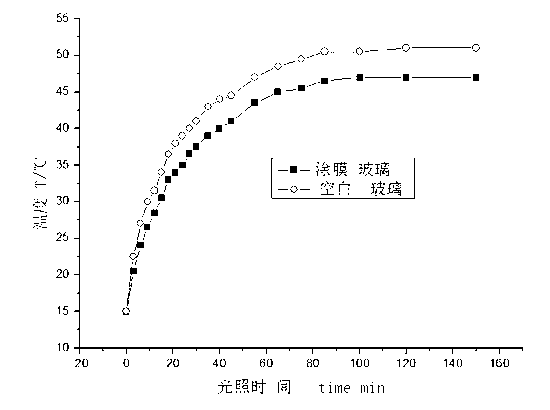

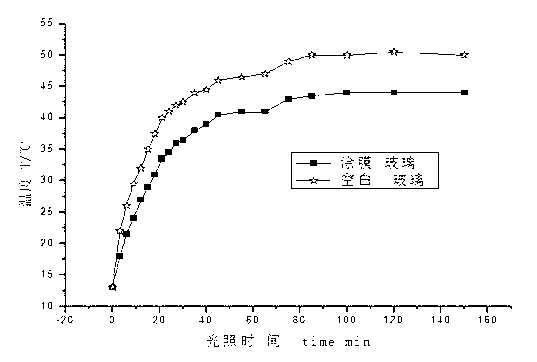

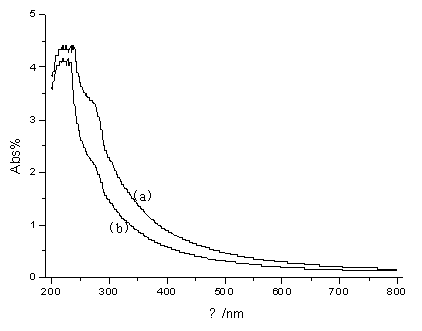

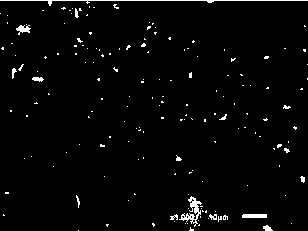

Preparation process of insulating, self-cleaning and transparent fluorocarbon coating

The invention discloses a preparation process of a functional fluorocarbon coating with insulating, self-cleaning, weather-resisting and transparent functions, wherein the preparation method comprises the steps that: a stable aqueous slurry is prepared by anatase nanometer TiO2 and nanometer tin-antimony oxide (ATO); the slurry is added to a fluorocarbon emulsion or a mixed emulsion of fluorocarbon emulsion and silicone acrylic emulsion (styrene-acrylic emulsion) under the action of various assistants; the assistants mainly comprise a film-forming assistant, a wetting agent, a dispersant, a thickener and an antifoaming agent; the rest part is de-ionized water. The invention also comprises a process for preparing the stable anatase nanometer TiO2 and nanometer tin-antimony oxide (ATO) slurry. After the transparent and insulating fluorocarbon coating is coated on the glass, the glass has good transparent and insulating effect (the light transmittance is 70-85% and the light transmittance of the sample glass is 91%), self-cleaning performance, washing resistance, good weather resistance and the like.

Owner:HUNAN UNIV +1

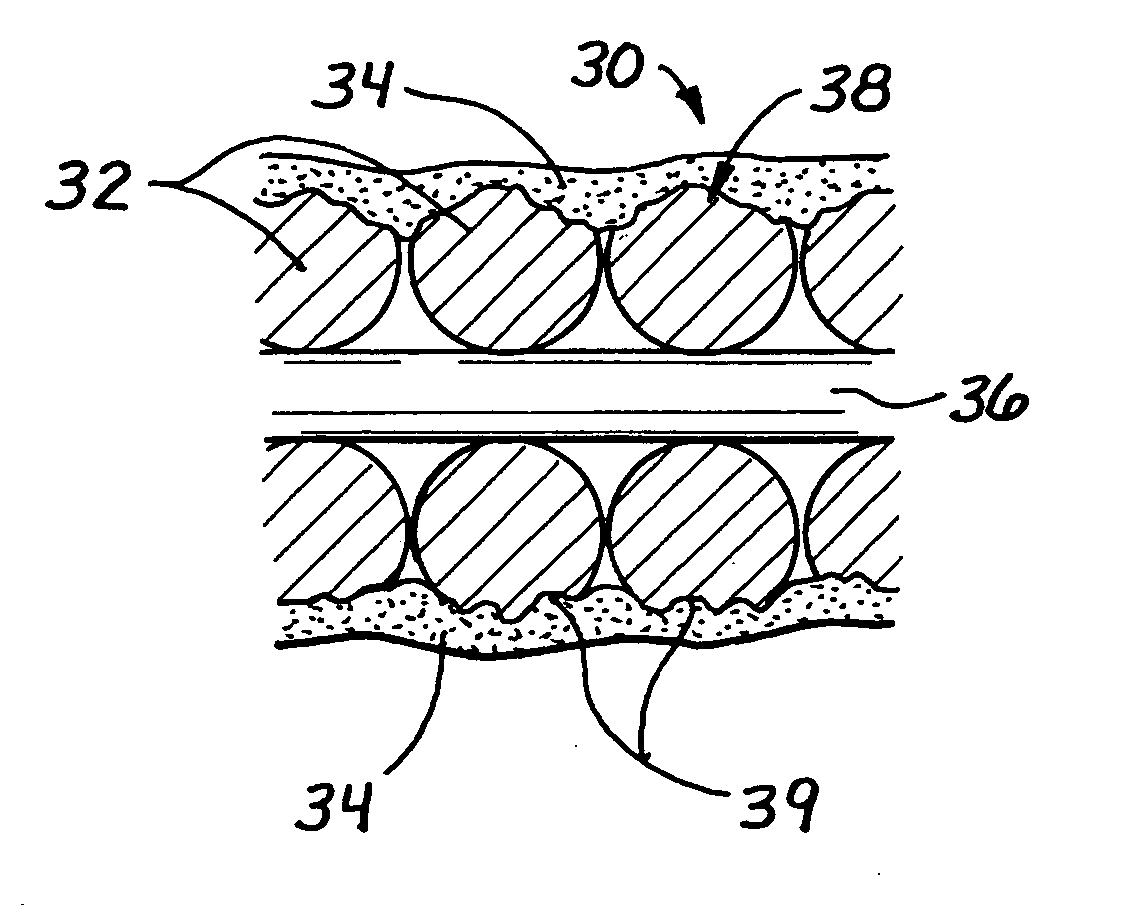

Method of treating razor blade cutting edges

ActiveUS20160001456A1Maintenance benefitsPretreated surfacesSpecial surfacesBoiling pointDissolution

The present invention relates to razor blade cutting edges and methods of producing edges exhibiting improved shave performance longevity and lower cutting forces. Conventional razor blades have increasing cutting forces with use due to the outer coating wear and adhesion loss. Blade edges produced according to the novel process exhibit significantly lower cutting forces when subjected to wool felt cutting shaving simulation, which correlates to more comfortable shaves initially and over the life of the blades. The present invention treats razor blade edges having a first adherent polyfluorocarbon coating with a first solvent to partially remove the polyfluorocarbon coating, adds a second polyfluorocarbon coating, heats, and treats the blade edge with a second solvent providing a final blade edge having a thin, uniform polyfluorocarbon coating. Preferred solvents include perfluoroalkanes, perfluorocycloalkanes, and perfluoroaromatic compounds having a critical temperature or boiling point above the dissolution temperature for the polyfluorocarbon in the solvent.

Owner:THE GILLETTE CO

Nano silicon dioxide (SiO2) improved fluorocarbon coating and preparation thereof

InactiveCN103131275AImprove stain resistanceGood anti-ultraviolet aging performanceCoatingsSilver pasteAcrylic resin

The invention relates to a preparation method of nano silicon dioxide (SiO2) improved fluorocarbon coating. The preparation method of the nano SiO2 improved fluorocarbon coating is characterized in that the nano SiO2 improved fluorocarbon coating comprises the following components, by mass, 1% to 5% of nano SiO2, 40% of acrylic resin with solid contents, 25% to 28% of polyvinylidene difluoride, 24% to 27% of fumed SiO2, 0.4% of silver paste, 6% of cellulose acetate, 4% of dispersing agent, 2% to 5% of mixed solvent, and allowance. nano SiO2 is added into the fluorocarbon coating, thus improving contamination corrosion resistance, ultraviolet aging resistance, corrosion resistance and the like of the fluorocarbon coating, and the preparation method of the nano SiO2 improved fluorocarbon coating belongs to the technical field of processing of coatings.

Owner:CHANGZHOU UNIV

High weatherability self-cleaning fluorocarbon coating

The invention discloses a tetrafluoroethylene-vinyl ether copolymer fluorocarbon coating which can be in curing under the normal temperature and contains an anti-aging composite additive and self-cleaning additive and a preparation method thereof.

Owner:北京航材百慕新材料技术工程股份公司

Surface insulation varnish paint for wind power generation and method for producing the same

The invention relates to surface insulating enamel pain used for the wind power generation. The invention takes fluorocarbon resin as the base material of the corrosion resistant coating of a wind power generating device, the fluorocarbon resin is solidified through diisocyanate trimer curing agent, to ensure fluorocarbon coating and the diisocyanate trimer curing agent to be respectively packaged independently to be component A and component B, when being used, the component A and the component B are mixed according to the proportion and are evenly agitated, and then construction is performed by using the spray painting method or the brush painting method after the component A and the component B are cured for 30 minutes. The component A includes fluorocarbon resin, pigment and filler, auxiliary agent and solvent; the component B is curing agent diisocyanate trimer; and the weight ratio of the mixing ratio of the component A and the component B is: the component A: the component B= 8 to 10:1.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

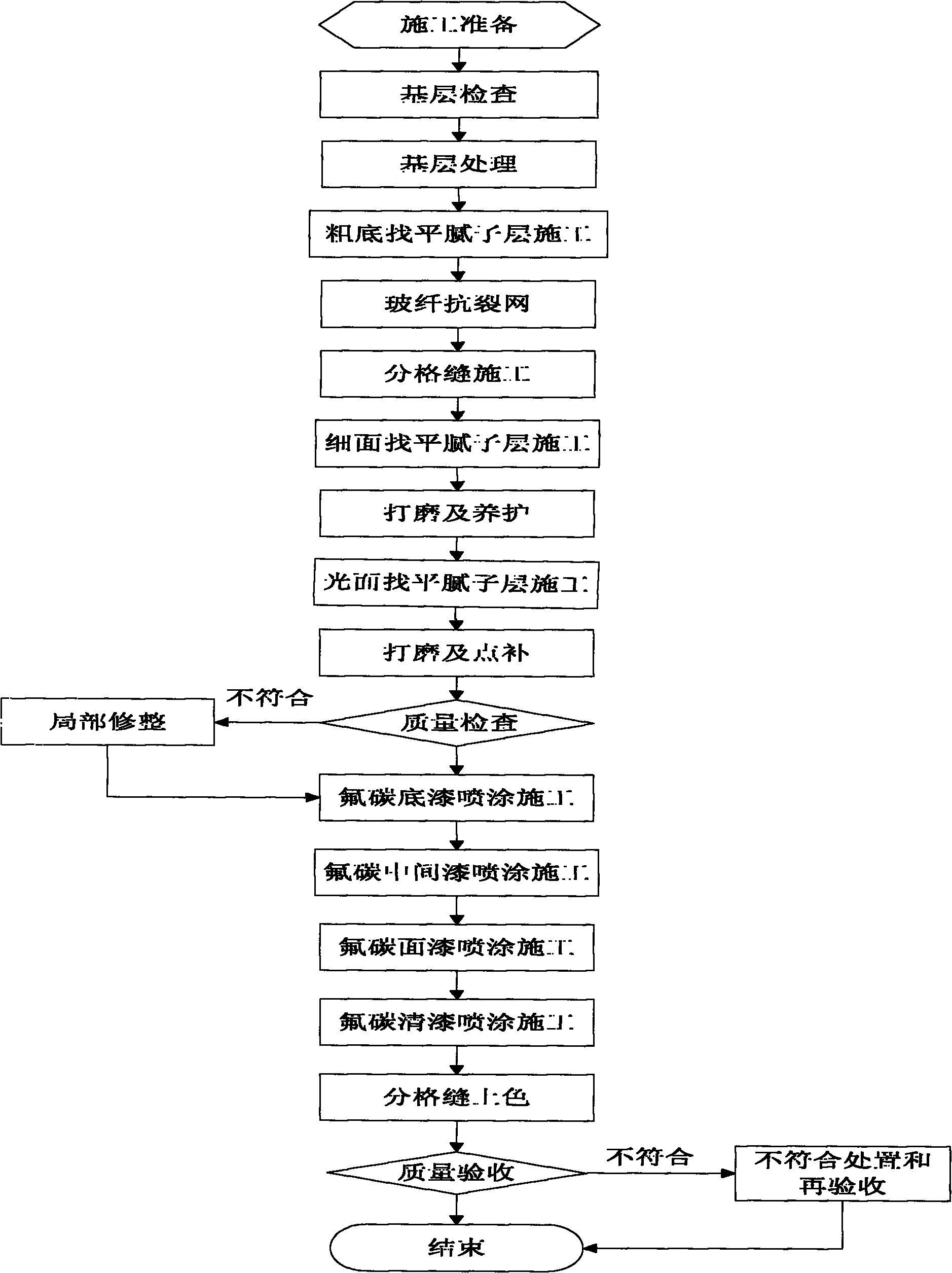

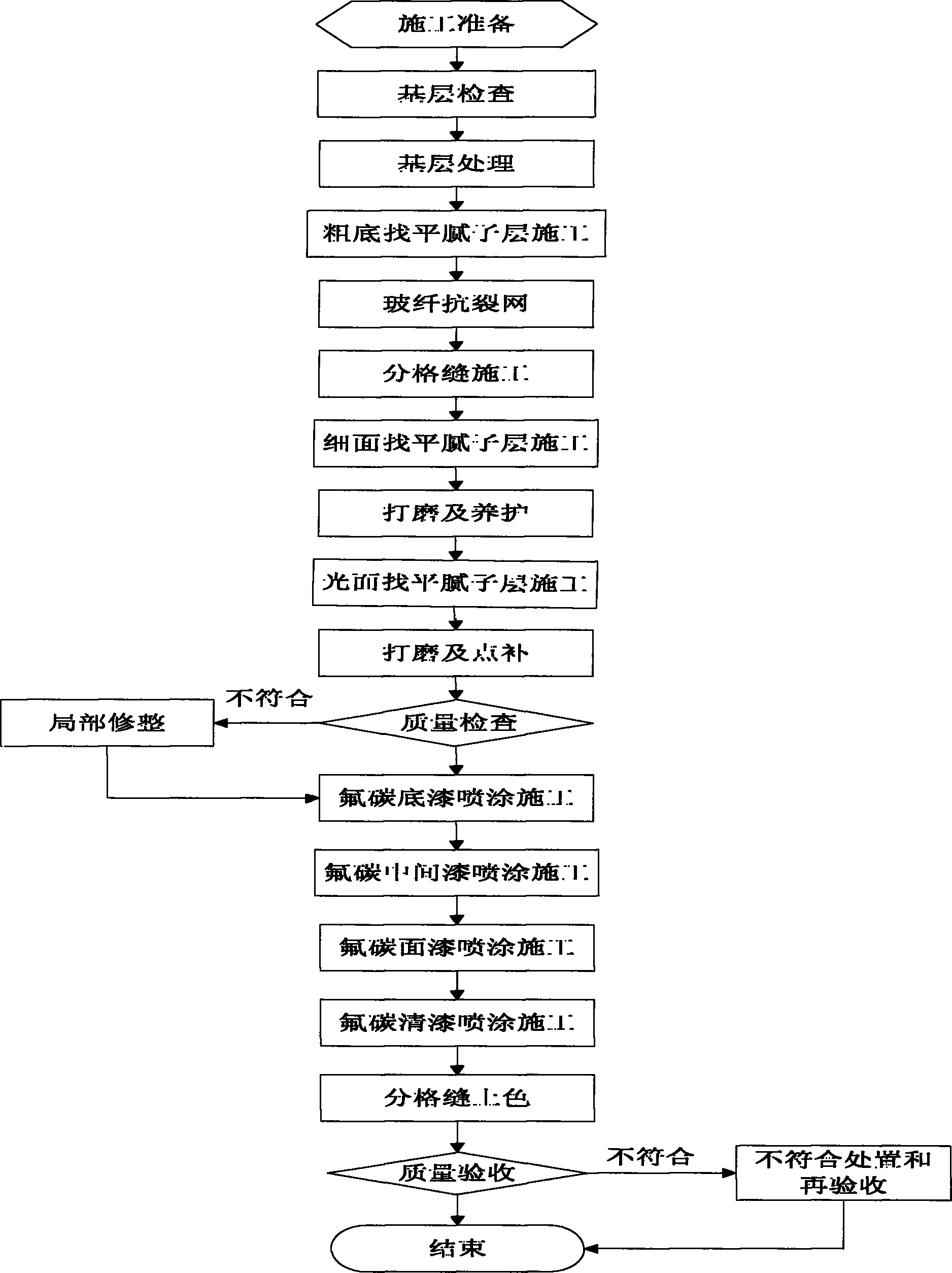

Construction process for outer wall metal fluorocarbon coating

InactiveCN101832015ASimplify construction stepsEasy to operateBuilding constructionsGlass fiberLacquer

The invention discloses a construction process for an outer wall metal fluorocarbon coating. The construction process comprises the following steps of: 1, checking a base layer; 2, treating the base layer; 3, performing coarse bottom leveling putty layer construction, wherein the used outer wall leveling coarse bottom putty is a finished putty special for the outer wall and a proper amount of quartz sand is added into the finished putty; 4, laying a glass fiber crack resistant net; 5, performing dividing joint construction; 6, performing fine surface leveling putty layer construction to ensure that the glass fiber crack resistant net is clamped between the coarse bottom leveling putty layer and the fine surface leveling putty layer; 7, polishing and maintaining; 8, performing polished side leveling putty layer construction; 9, performing fluorocarbon primer spraying construction; 10, performing fluorocarbon intermediate coating spraying construction; 11, performing fluorocarbon finish paint spraying construction; 12, performing fluorocarbon varnish spraying construction; and 13, coloring dividing joints. The construction process for the outer wall metal fluorocarbon coating has the advantages of simple construction steps, reasonable design, convenient operation, low construction cost, high construction quality, and excellent use efficiency, and can prevent the hollowness, delamination, crack and other quality defects on the surface of the outer wall metal fluorocarbon coating.

Owner:陕西建工第二建设集团有限公司

Environment friendly water-soluble metal fluorocarbon coatings

InactiveCN101397435AReduce pollutionReduce the risk of useEmulsion paintsThermal insulationRaw material

The invention relates to an environment-friendly aqueous fluorocarbon metallic paint, consisting of the following raw materials in the following percents by weight: 35-65 percent of fluorocarbon emulsion, 5-12 percent of aluminum paste, 0.1-0.5 percent of antifoam agent, 0.1-0.3 percent of wetting agent, 0.1-0.3 percent of leveling agent; 0.2-0.8 percent of dispersing agent, 2-8 percent of metal orienting agent, and 0.1-0.3 percent of thickener: organic modified montmorillonite, 1.0-5.0 percent of polyurethane associative thickening agent, 1-3 percent of film forming agent, 1-3 percent of anti-freezing agent, 6-10 percent of solvent, and deionized water as the rest. The environment-friendly aqueous fluorocarbon metallic paint can reduce environmental pollution and application risks in thermal-insulation decoration systems and the performance can equal to that of solvent-based fluorocarbon aluminum paste (pearl powder) coating.

Owner:上海三银制漆有限公司

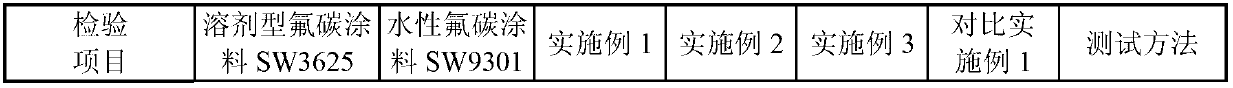

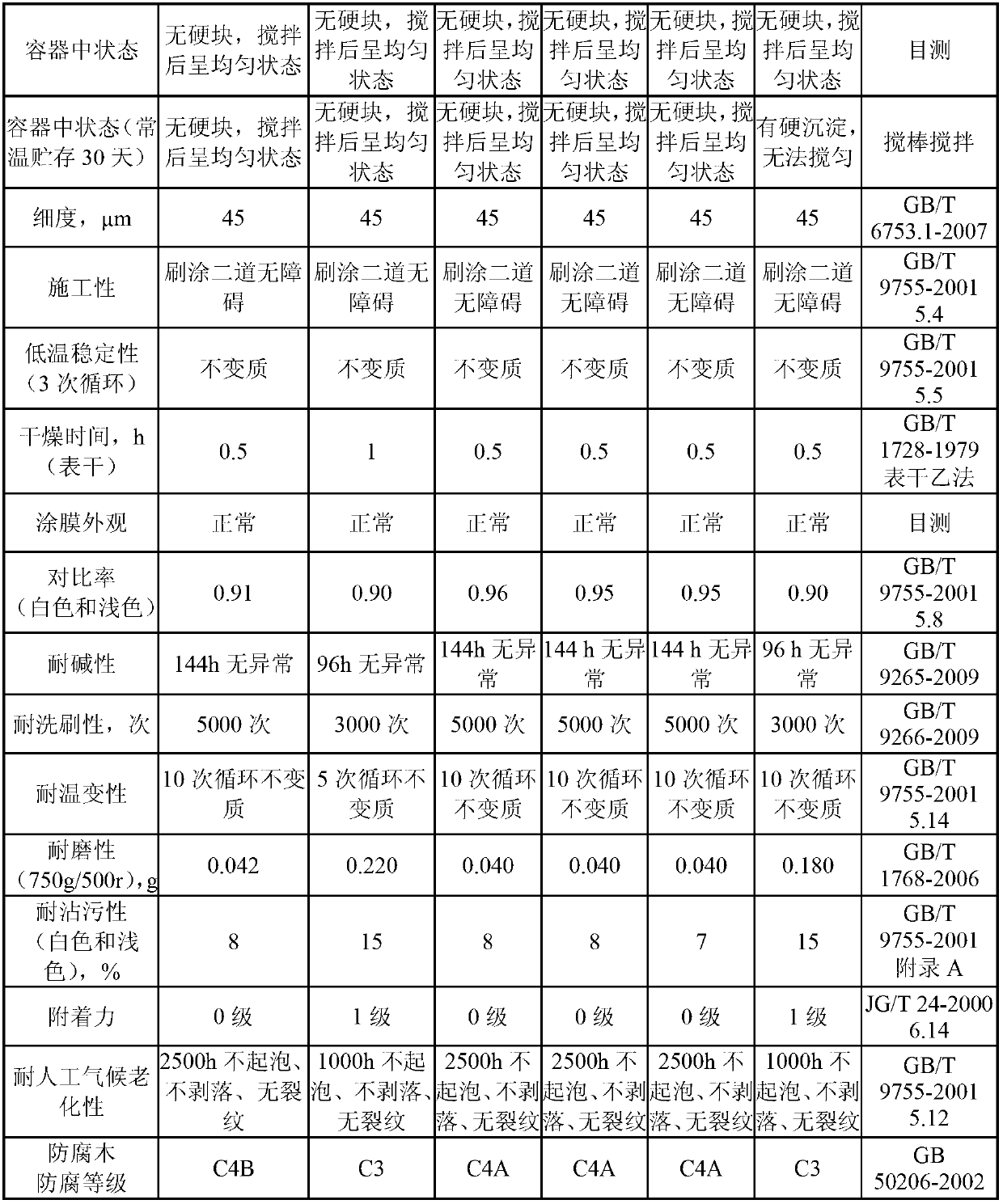

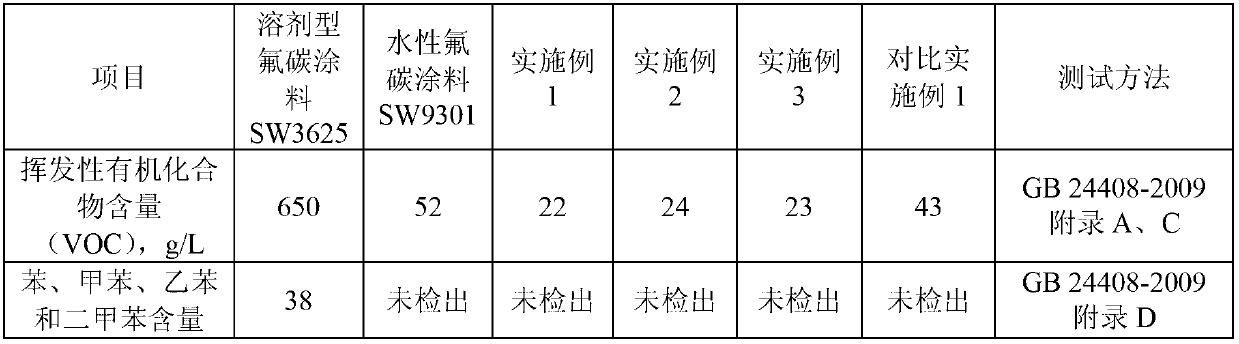

Waterborne fluorocarbon coating, and preparation method and application thereof

ActiveCN102898904AImprove wear resistanceGood alkali resistanceCoatingsMohs scale of mineral hardnessFoaming agent

The invention discloses a waterborne fluorocarbon coating, and a preparation method and application thereof. A formula for raw materials of the waterborne fluorocarbon coating comprises 13.0 to 48.0% of a waterborne fluorocarbon emulsion, 1.0 to 3.0% of hydroxyethyl cellulose, 10.5 to 18.8% of an inorganic pigment, 18.2 to 32.2% of a filling material, 5.0 to 7.0 % of wear-resistant powder, 0.6 to 2.3% of a wetting dispersant, 0.5 to 1.0% of a multifunctional auxiliary agent, 0.1 to 0.5% of a de-foaming agent, 0.4 to 4.0% of a bactericide, 0.1 to 3.2% of a thickening agent, 0.6 to 3.0% of a film forming auxiliary agent, 1.0 to 4.2% of an anti-freezing agent and 14.0 to 20.0% of water, wherein the pH value of the waterborne fluorocarbon coating is 8.0 to 9.5, and the Moh's hardness of the wear-resistant powder is more than 9.0. The waterborne fluorocarbon coating has no toxicity, no pollution and both functions of decoration and protection; a paint film formed by the coating has good wear resistance and weatherability and can improve anti-corrosive performance and wear resistance of a regenerated woodwork.

Owner:上海三银涂料科技股份有限公司

Preparation method of high-performance fluorocarbon coating

ActiveCN105505183ASimple preparation processGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterOligomer

The invention relates to a preparation method of a high-performance fluorocarbon coating. The fluorocarbon coating is composed of a component A and a component B. The component A is composed of an isocyanate-capped polyol oligomer and an anhydrous diluent A, and the component B consists of fluorocarbon resin, dispersant, inorganic filler, catalysts and anhydrous diluents. The component A and the component B are mixed in accordance with the molar ratio of isocyanate to hydroxyl value being (0.6-1.5): 1 to obtain the fluorocarbon coating. The polyol oligomer contains polyester polyol and polyether polyol, endows the coating with outstanding mechanical performance, good low-temperature flexibility and hydrolysis resistance and is capped by isocyanate to be reacted with fluorocarbon resin, and soft segments formed by the polyol oligomer and the fluorocarbon resin and isocyanate hard segments are distributed regularly in the coating to form a three-dimensional network interpenetration structure. The prepared fluorocarbon coating has the advantages of ageing resistant and wind and sand resistant performance and is applicable in preparation of coating type solar cell back plates used in areas with adverse environments.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Preparation method of fluorocarbon coating

ActiveCN104194599AImprove aging resistanceHigh hardnessPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method of a fluorocarbon coating. The fluorocarbon coating is composed of a component A and a component B. When in use, the component A and component B are mixed in a mass ratio of (1-2):1. The component A is composed of fluorocarbon polyurethane prepolymer, a nano inorganic filler, a hydrolysis stabilizer, a dispersing agent, a leveling agent, a tin catalyst, an initiator, hydroxy acrylate and an anhydrous diluter; and the component B is composed of a hydroxy acrylic resin, an isocyanate curing agent and an anhydrous diluter. The method can effectively enhance the crosslinking density of the polymers in the fluorocarbon coating, so that the fluorocarbon coating has more compact IPN (interpenetrating network) structure. The prepared fluorocarbon coating has the advantages of excellent weather resistance, excellent water resistance, excellent chemical resistance, excellent salt spray resistance, outstanding hardness and outstanding abrasion resistance, and is a high-performance fluorocarbon coating applicable to solar cell back panels.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Elastic heat-insulation fluorocarbon coating and preparation method and use method thereof

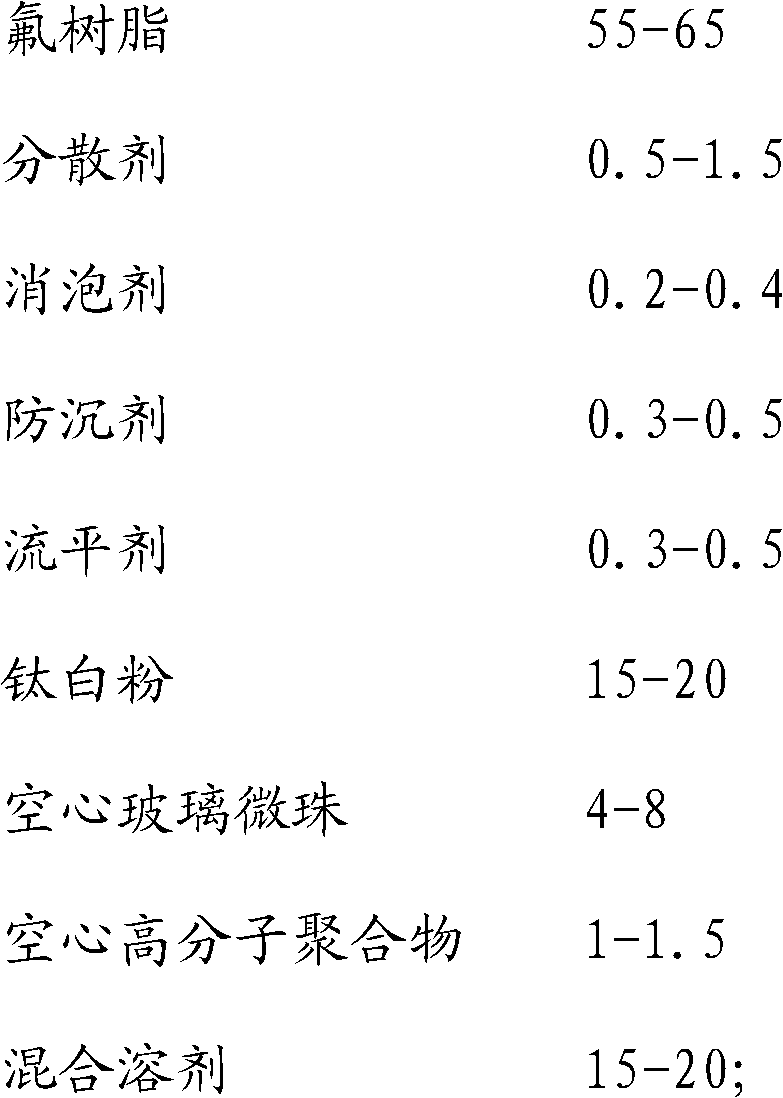

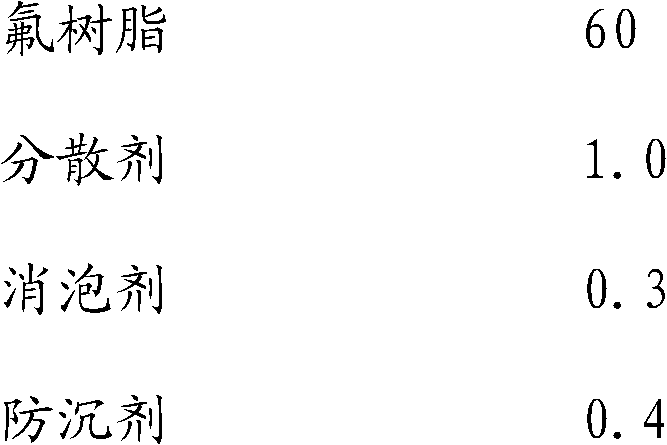

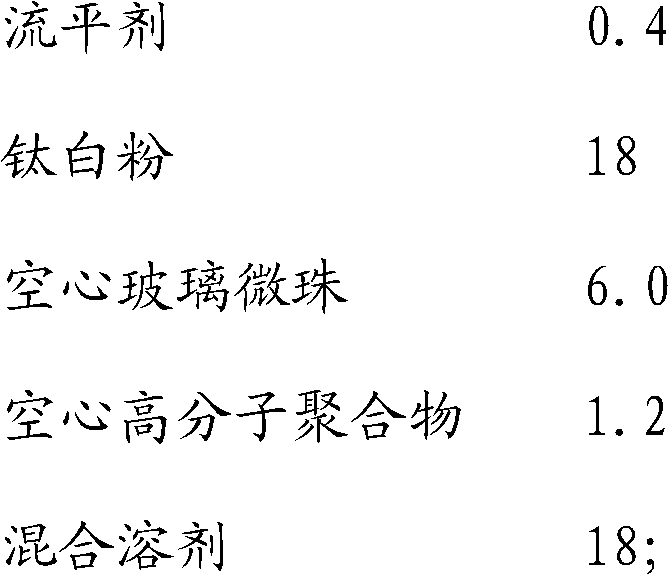

InactiveCN102492338AGood weather resistanceGood gloss and color retentionReflecting/signal paintsButyl acetateTitanium

An elastic heat-insulation fluorocarbon coating consists of a host and curing agent. The host is prepared by the following components, by weight, 55 to 65 parts of fluororesin, 0.5 to 1.5 parts of dispersant, 0.2 to 0.4 part of defoamer, 0.3 to 0.5 part of anti-settling agent, 0.3 to 0.5 part of flatting agent, 15 to 20 parts of titanium white, 4 to 8 parts of hollow glass microballs, 1 to 1.5 parts of hollow macromolecular polymer and 15 to 20 parts of mixed solvent. The curing agent is manufactured by the following components, by weight, 90 parts of E405 to 80T, 5 parts of butyl acetate and 5 parts of propylene glycol methyl ether acetate. The weight proportion of the host and the curing agent can be calculated according to the hydroxyl value of the fluororesin and the NCO (isocyanate) content of the curing agent, namely OH / NCO=1:(1.05 to 1.15). The elastic heat-insulation fluorocarbon coating has the advantages of excellent weatherability, stain resistance, washability, decoration performance, excellent normal-temperature and low-temperature elasticity, capability of resisting to fine fissures, improved heat insulation effect and benefits to transport and settlement.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

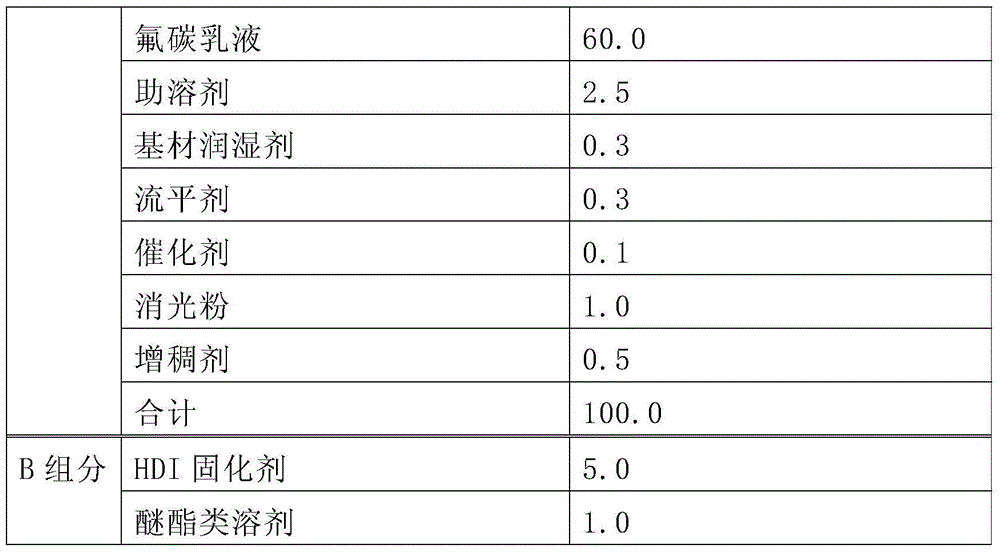

Coated water-based double-component fluorocarbon paint, and preparation and application thereof

ActiveCN104559617AIncrease the degree of cross-linkingStrong adhesionPolyurea/polyurethane coatingsPhotovoltaic energy generationWater basedPolyethylene terephthalate glycol

The invention discloses a coated water-based double-component fluorocarbon paint, and preparation and application thereof. Particularly, the paint comprises a component A and a component B in a mass ratio of (12-25):1. The component A is composed of deionized water, an anti-settling agent, a wetting and dispersing agent, a defoaming agent, a pigment, a water-based fluorocarbon resin, a substrate wetting agent, a leveling agent, a cosolvent, a catalyst, matting powder and a thickener; and the component B is composed of a polyisocyanate curing agent. The paint can be used for preparing a coated PET (polyethylene terephthalate) back panel film.

Owner:ETERNAL CHEM (CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com