Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "Excellent friction reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayer coating cutting tool

ActiveCN103537719AOvercoming poor friction performanceImprove wear resistanceVacuum evaporation coatingSputtering coatingOxidation resistantCoefficient of friction

The invention discloses a multilayer coating cutting tool which comprises a cutting tool substrate and composite coatings deposited on the cutting tool substrate. The composite coatings include a TiAlVN layer and a TiAlSiN layer, wherein the TiAlVN layer and the TiAlSiN layer are mutually, periodically and alternately deposited. The multilayer coating cutting tool has the advantages that friction coefficients are low, abrasion-resistant performance is high, shock-resistant performance is high, oxidation-resistant performance is good, and the combination between the coated coatings and the cutting tool substrate is good.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

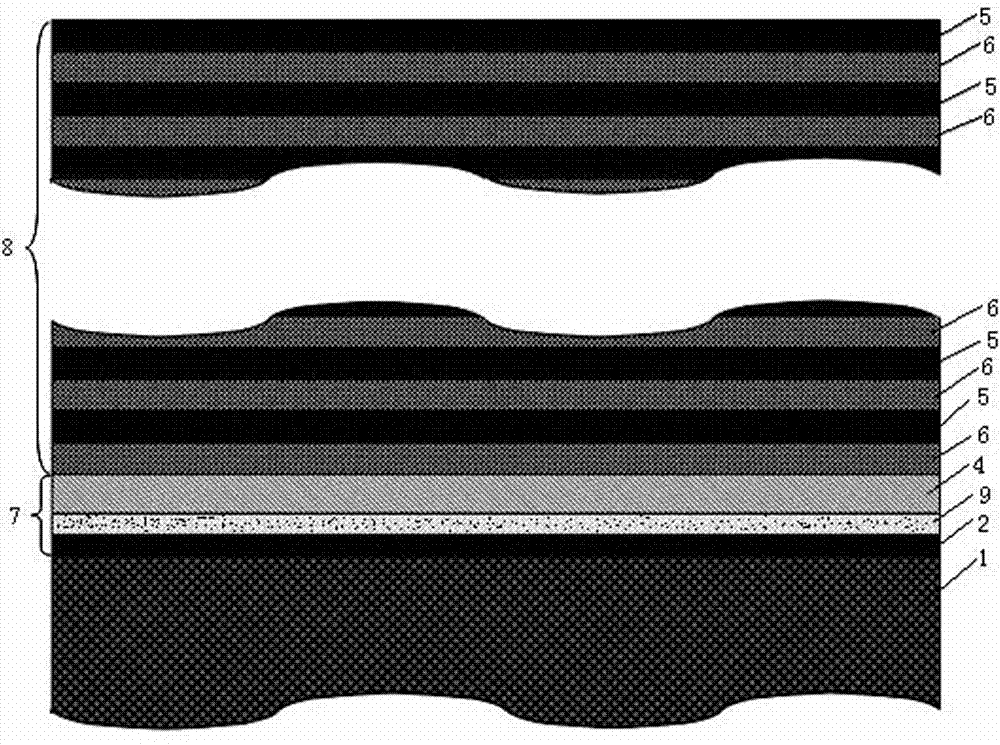

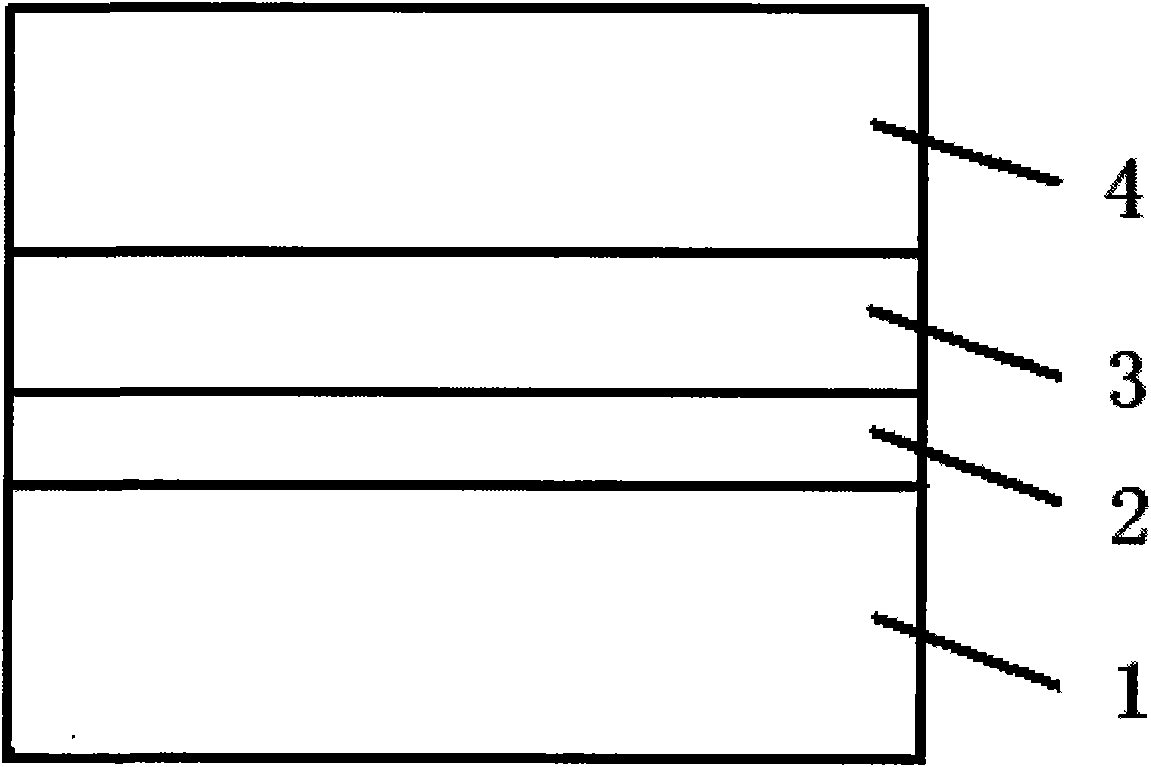

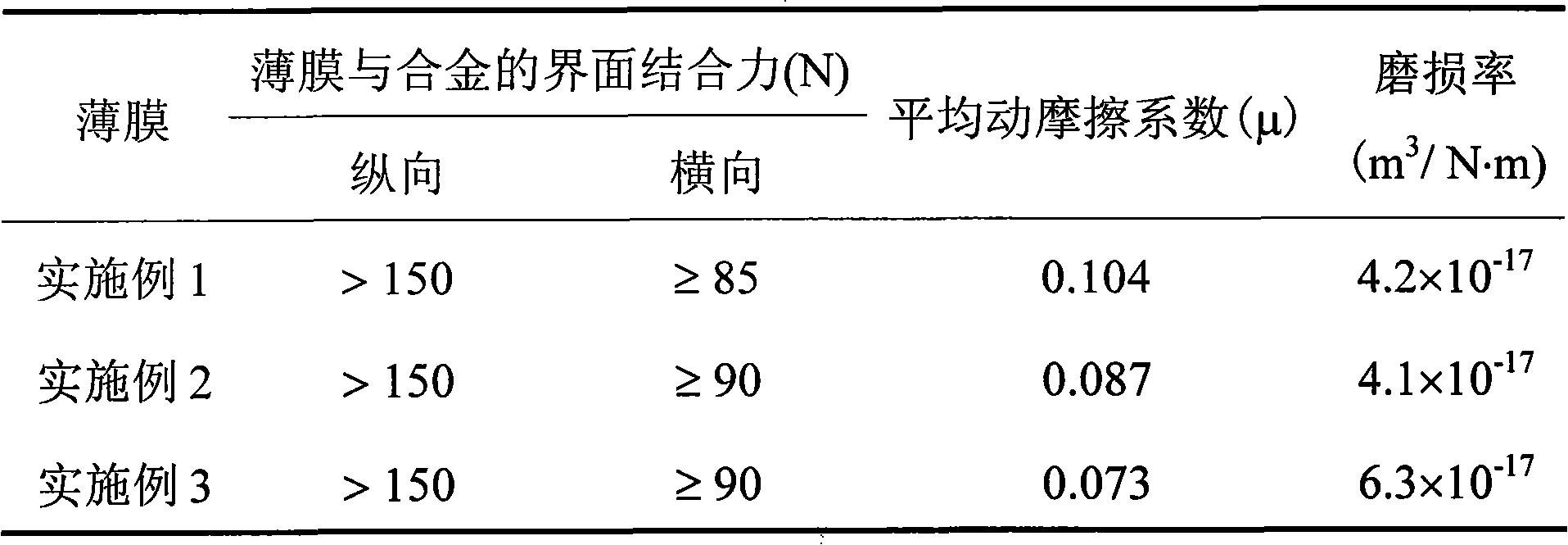

Ultra-hard carbon film and preparation method thereof

ActiveCN101554790AImprove bindingExtended service lifeVacuum evaporation coatingSputtering coatingCarbon filmHardness

The invention discloses an ultra-hard carbon film which is formed by a substrate, a pure Ti binding layer, a Ti plus C composite gradient transition layer and an amorphous pure carbon film layer mainly taking the sp structure, and prepared by adopting an unbalanced magnetron sputtering method. The binding force between the film and the substrate of the ultra-hard carbon film is significantly improved at the pure Ti binding layer and the Ti plus C composite gradient transition layer which are deposited on an alloy surface, the hardness of the amorphous pure carbon film layer mainly taking the sp structure can reach 41 to 53GPa, simultaneously, the carbon film contains lower internal stress, and the thickness of the ultra-hard carbon film is controllable. When dry friction experiment is implemented at atmospheric environment, the ultra-hard carbon film has extremely low friction coefficient and wear rate, presents excellent anti-frication and wear-resisting property, can be used for manufacturing protective films on the surface of spare parts of bearings and worm and gear and the like, and greatly prolongs the service life of the spare parts of machines.

Owner:ZHEJIANG UNIV

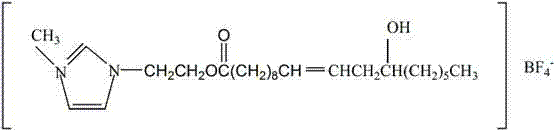

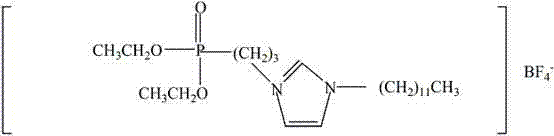

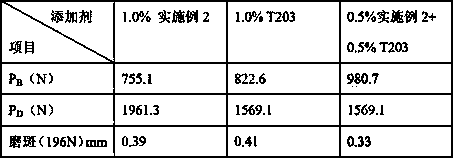

Composite extreme pressure anti-wear agent and total-synthesis anti-wear hydraulic oil containing same

ActiveCN102776053AExcellent friction reductionImprove wear resistanceAdditivesTetrafluoroborateBase oil

The invention discloses a composite extreme pressure anti-wear agent and total-synthesis anti-wear hydraulic oil containing the composite extreme pressure anti-wear agent, belonging to the field of production of lubricating oil. The hydraulic oil is mainly prepared by mixing aqueous base oil and the composite extreme pressure anti-wear agent, wherein the composite extreme pressure anti-wear agent is a compound of two kinds of imidazolyl tetrafluoroborate ion liquid. Compared with the prior art, the total-synthesis anti-wear hydraulic oil has the characteristics of excellent lubricating performance, energy saving, environment friendliness and the like and has high popularization and application values.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

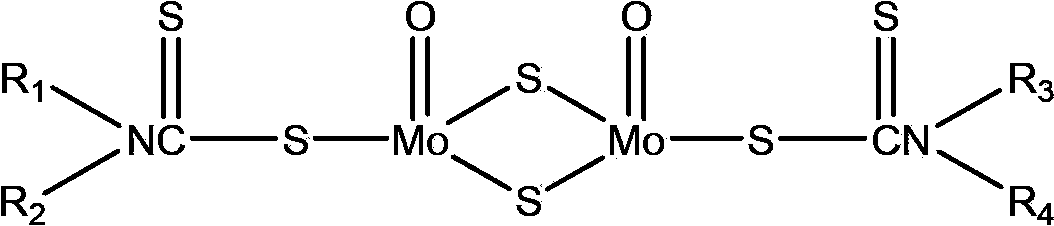

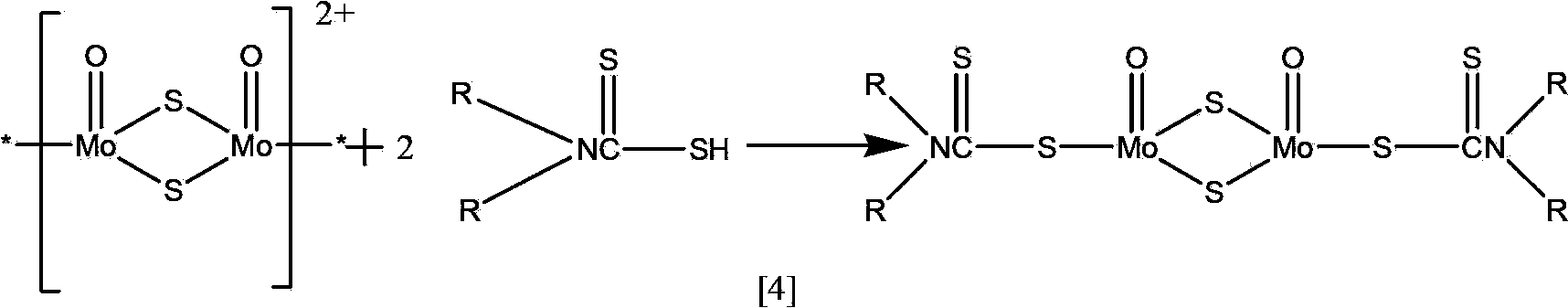

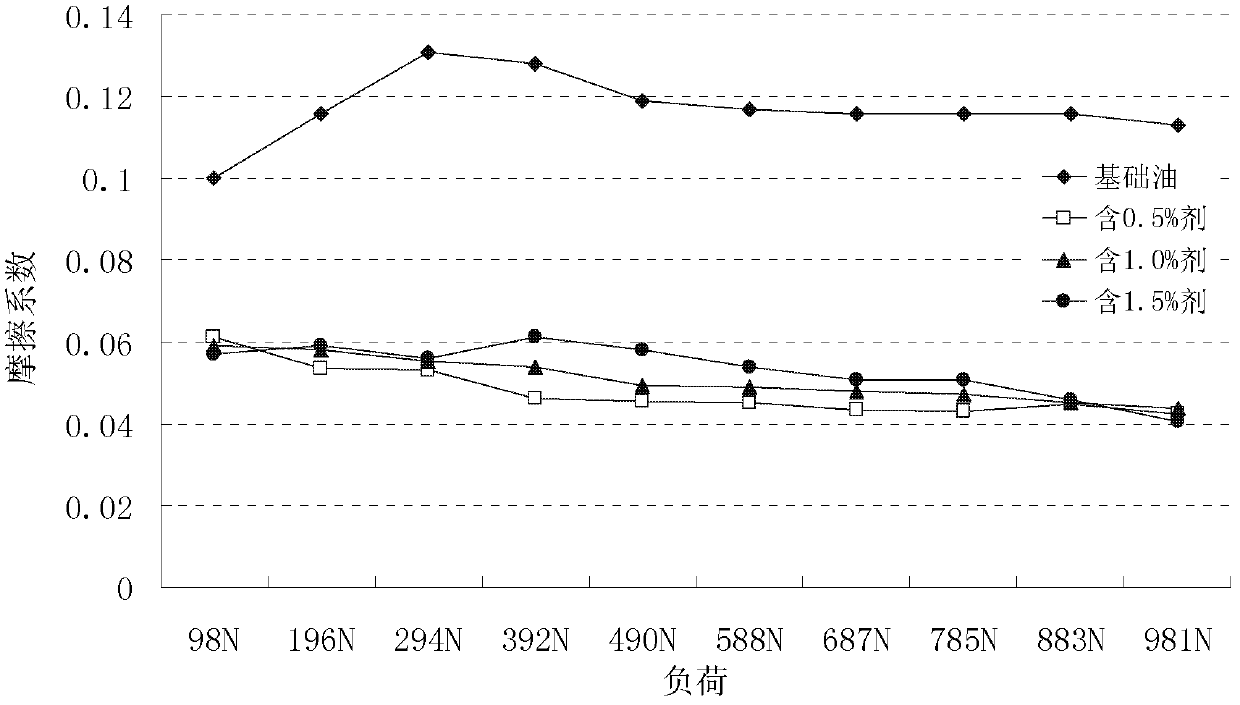

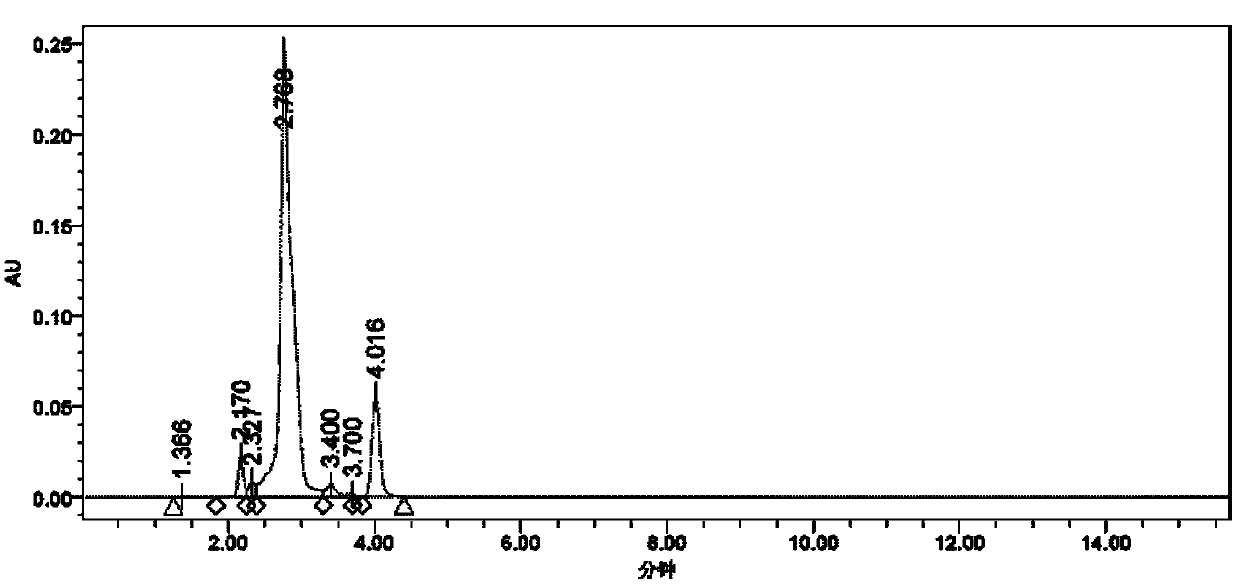

Oil-soluble molybdenum dialkyldithiocarbamate additive preparation method

ActiveCN103509057AExcellent friction reductionImprove wear resistanceAdditivesGroup 6/16 element organic compoundsFriction reductionVegetable oil

The present invention provides molybdenum dialkyldithiocarbamate, wherein alkyl groups are the same or different C1-C20 straight chain or branch chain alkyl groups. The present invention further relates to a preparation method for the compound, wherein a hexavalent molybdenum source compound reacts with an alkali metal sulfide or an alkali metal hydrosulfide, and then reacts with dithiocarbamic acid. The prepared compound has characteristics of good friction reduction, good wear resistance and anti-oxidation, and can be added to mineral oils, synthetic oils, vegetable oils, synthetic esters, polyether, hydrogenated oils, lithium base grease, calcium base grease and other lubricating oils (greases) so as to obtain lubricating systems with characteristics of good wear resistance and good friction reduction, wherein the addition amount is 0.1-4.0 wt% when being adopted as the additive.

Owner:PETROCHINA CO LTD

Preparation of metal doped diamond-like surface ion liquid lubricant self-assembled lubricating film

InactiveCN101463466AImprove tribological propertiesExcellent friction reductionVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention discloses a method for preparing a metallic contamination adamantine surface ionic liquid lubricant self-assembly lubricative film. The method takes ionic liquid lubricant as raw material, adopts magnetron sputtering equipment to prepare a metallic contamination adamantine carbon film and assembles the liquid lubricant film which is stable, uniform and ordered on the carbon film. The method is characterized in that the preparation process is operated at normal temperature, and the requirements for the material and the shape of a substrate are lower; the film is stable and uniform, and has lower surface roughness; the film also has good performances on antifriction, wear resistance and adhesion resistance. The test of friction and wear proves that the ionic liquid lubricant and adamantine has good combining performance and better performances on antifriction, wear resistance and adhesion resistance, so that the lubricative film is expected to become the effective means of solving the problems of protecting and lubricating materials I the technical fields such as space machinery, information technology, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

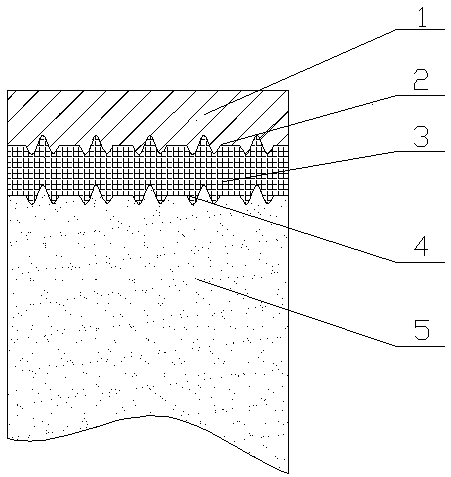

Matrix with enhanced bonding strength of surface coating and preparation method of matrix

InactiveCN107761072AHigh hardnessImprove surface wear resistanceVacuum evaporation coatingSputtering coatingCoated surfaceMetallurgy

The invention discloses a matrix with the enhanced bonding strength of a surface coating and a preparation method and belongs to the technical field of machine manufacturing. The preparation method comprises the following steps: carrying out main friction on a matrix material, microtexture composite morphology on the worn surface and active treatment of a coating; coating with a hard coating and then texturing the surface of the hard coating on the texture morphology in a vertical corresponding mode; and finally, coating with a soft coating. According to a composite coating disclosed by the invention, the antifriction and antiwear properties of the matrix surface are enhanced; and by correspondingly superposing a dual-layer texture, the bonding strength between the coating and the matrix as well as between the coatings are improved, and the service life of the matrix is prolonged.

Owner:JIANGSU UNIV

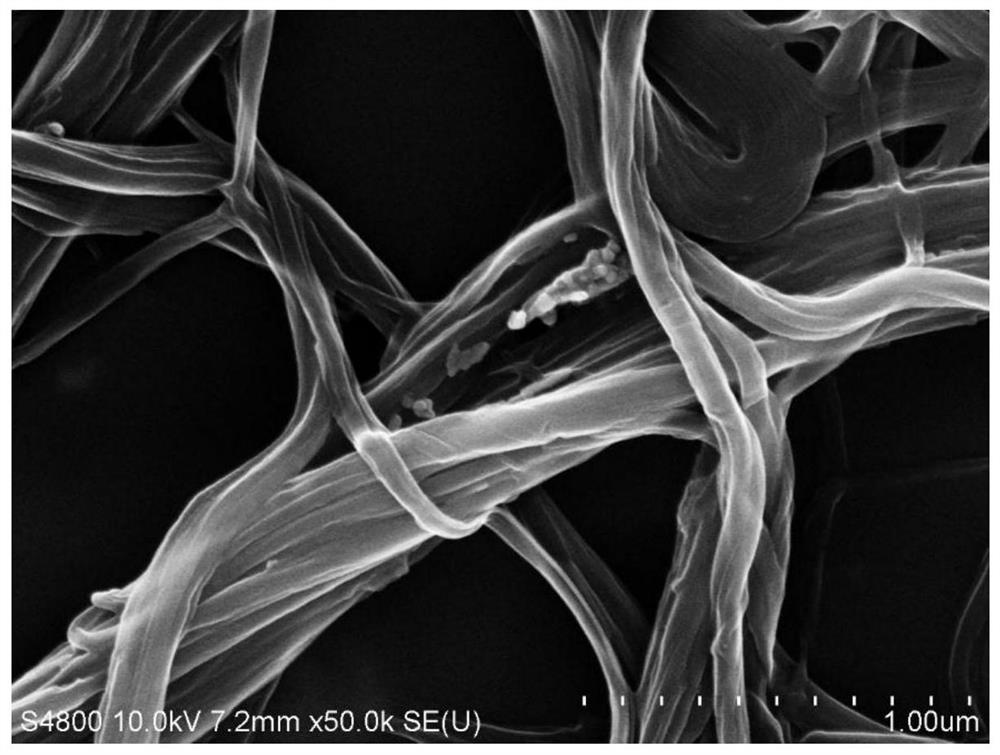

Nanometer hybrid material-modified epoxy resin self-lubricating composite coating layer and preparation method thereof

The invention provides a nanometer hybrid material-modified epoxy resin self-lubricating composite coating layer and a preparation method thereof. The preparation method comprises the following stepsof firstly, preparing a carbon nanotube / graphene oxide / molybdenum disulfide nanometer hybrid material by a hydrothermal method, and adding the carbon nanotube / graphene oxide / molybdenum disulfide nanometer hybrid material into epoxy resin, a curing agent and an organic solvent, so as to obtain a mixed solution; spraying the mixed solution onto a substrate, curing and forming, so as to obtain an epoxy resin self-lubricating composite coating layer with high abrasion-reduction property and abrasion-resistant property. The nanometer hybrid material-modified epoxy resin self-lubricating composite coating layer has the advantages that the preparation method is novel; the abrasion-reduction property and abrasion-resistant property of the epoxy resin coating layer are enhanced by preparing the carbon nanotube / graphene oxide / molybdenum disulfide nanometer hybrid material for the first time; the conditions are mild, the operation is simple, and the large-area abrasion-reduction and abrasion-resistant coating layer is easy to prepare, and is suitable for large-scale production; the obtained composite coating layer is dense and uniform, and the lower friction coefficient and higher abrasion-resistant property are realized.

Owner:名畔科技(镇江)有限公司

A polyimide-based self-lubricating wear-resistant coating material and its preparation method

InactiveCN102286248AGood anti-friction and anti-wear propertiesImprove carrying capacityPretreated surfacesCoatingsMuffle furnacePolytetrafluoroethylene

The invention discloses a polyimide-based self-lubricating abrasion-resistant coating material and a preparation method thereof. The coating material consists of the following raw materials in part by weight: 100 parts of polyimide bonded resin, 10 to 50 parts of irradiation polytetrafluoroethylene micro-powder solid lubricating agent and 200 to 400 parts of organic solvent. The preparation method comprises the following steps of: weighing and mixing the raw materials, and performing ultrasonic dispersion and magnetic stirring to form uniform resin solution; pouring the resin solution into a spray gun, and spraying the resin solution to the surface of a workpiece subjected to surface polishing and cleaning treatment under the pressure of 0.10 to 0.40Pa and under the action of oil-free compressed air, wherein the distance between the nozzle of the spray gun and the workpiece is not less than 20 centimeters, and the spray gun and the workpiece form an angle of 60 to 90 degrees; and putting the coated workpiece into a muffle furnace, performing section curing, cooling the workpiece to room temperature together with the furnace after curing, and thus obtaining the abrasion-resistant coating material on the surface of the workpiece. The coating material has the properties of low friction, high load resistance, abrasion resistance and high temperature resistance; and the preparationmethod is simple, easy in operation and low in cost.

Owner:SOUTH CHINA UNIV OF TECH

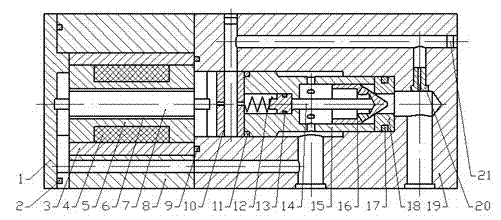

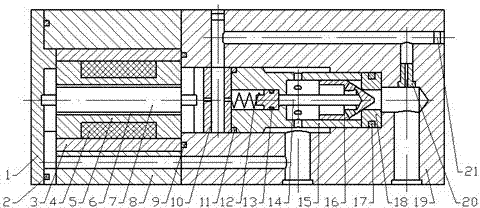

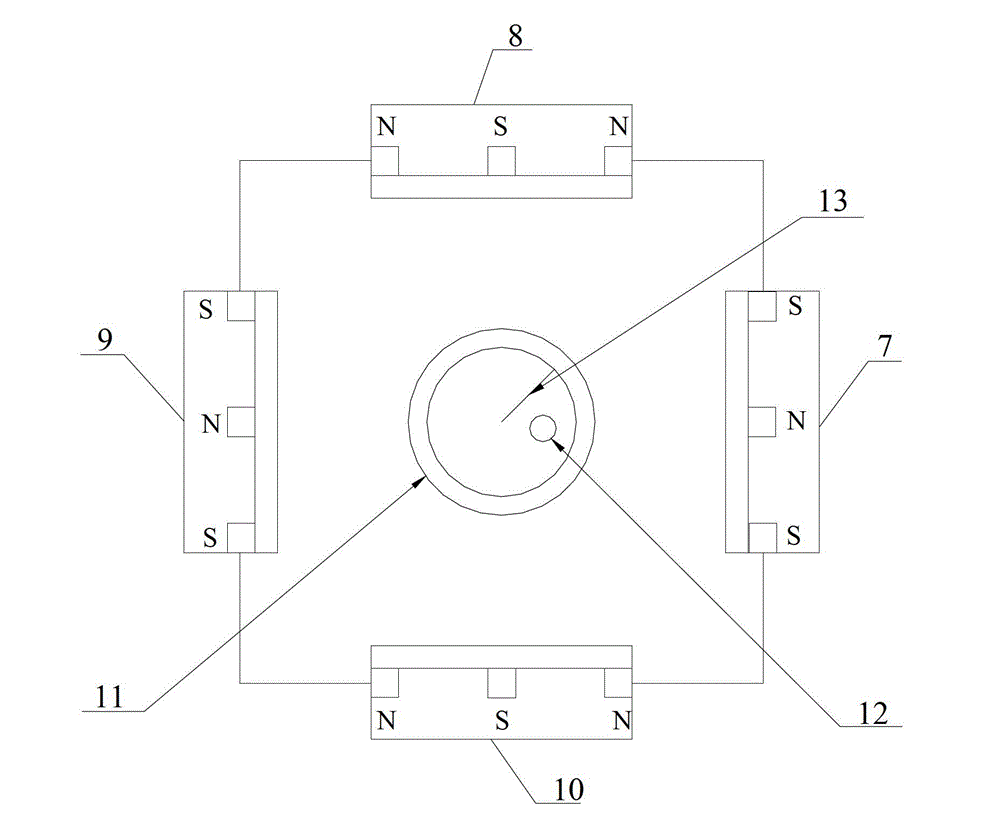

Magnetorheological pilot-operated overflow valve

InactiveCN102374204ALarge damping forceIncrease magnetic inductionServomotor componentsEngineeringPressure difference

The invention provides a magnetorheological pilot-operated overflow valve belonging to the technical field of hydraulic drive. The magnetorheological pilot-operated overflow valve comprises an end cover, an end cover seal ring, a magnetorheological valve housing, a coil, an iron core, a valve core, a pilot-operated valve body, a pilot-operated seal ring, a damp piece, a main valve housing seal ring, a spring, a guide rod seal ring, a guide rod, a main valve housing, a main valve core, a main valve seat insert, a main valve seat, a main valve body and a damper. The main valve core is in a parabolic ball shape, and the half cone angle of the valve core is larger than that of the valve seat, thus, the pressure difference between an inlet and an outlet of a cone valve can be effectively reduced; the minimum negative pressure moves backwards along a liquid flow direction, appears at the back of the valve core and is avoided appearing in the valve seat, thus, the possibility of gas etching is reduced, noise is reduced, key parts of the valve core and the valve seat are protected, and the service life of the magnetorheological pilot-operated overflow valve is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

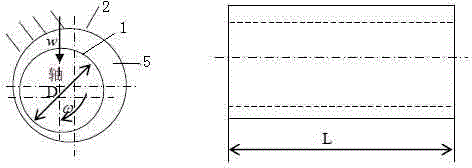

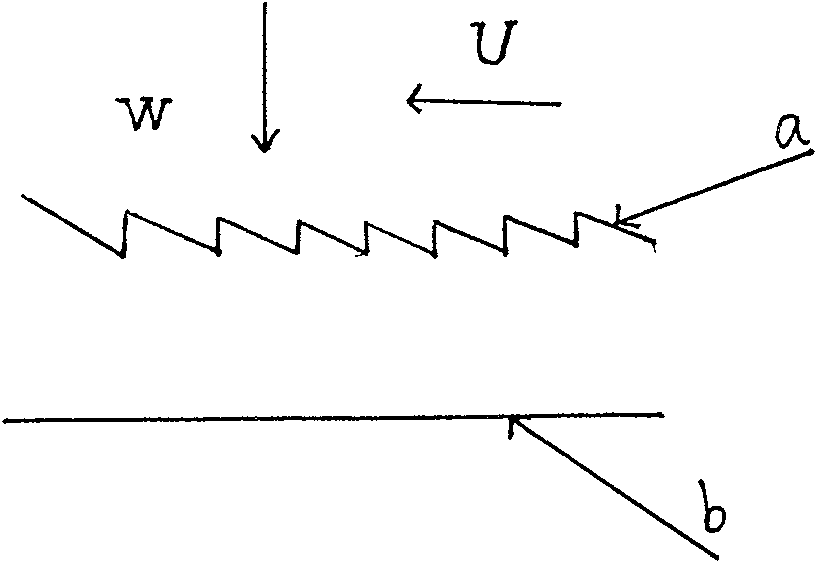

Novel energy-saving radial sliding bearing

ActiveCN104454980AImprove carrying capacityExcellent friction reductionBearing componentsSliding contact bearingsCarrying capacityThin layer

The invention provides a novel energy-saving radial sliding bearing, which is formed by matching a shaft and a bearing sleeve hole or bearing block hole. A bearing sleeve hole wall or bearing block hole wall at an inlet region of a convergent wedge-shaped pore of the bearing is coated by a thin layer material, and the surface-treated bearing sleeve hole wall or bearing block hole wall is paired with the shaft; a gap formed between the bearing sleeve hole wall or bearing block hole wall and the shaft is filled with lubricating oil. The novel energy-saving radial sliding bearing designed by adopting an interface slip technology and adopting a surface coating method has the advantages of great carrying capacity, low coefficient of friction and excellent energy-saving performance. Compared with the traditional interface-slip-free radial sliding bearing, the bearing provided by the invention has the advantages of obviously improved carrying capacity, and obviously improved antifriction and energy-saving performances, thus having an important application value.

Owner:怀宁吉利来精密机械科技有限公司

Method for preparing rare earth modified graphene ceramic composite film on glass substrate

InactiveCN102718500AImprove mechanical propertiesImprove tribological propertiesCeramic layered productsGlass/slag layered productsFriction reductionCeramic composite

The invention relates to a method for preparing a rare earth modified graphene ceramic composite film on a glass substrate. The method includes: (1) subjecting the surface of the glass substrate to hydroxylation pretreatment to obtain a treated glass substrate; (2) preparing rare earth sol solution and placing graphene into the obtained rare earth sol solution for treatment for 4-10h to obtain rare earth modified graphene sol; (3) immersing the treated glass substrate into the rare earth modified graphene sol, standing, upwardly lifting the glass substrate out of the sol, and drying; and (4) preserving the glass substrate obtained at the step (3) at 80-120 DEG C for 30-90min, heating to 600-800 DEG C, preserving heat for 1-5h and naturally cooling to the room temperature. The method is simple in preparation process, low in cost, free of environment pollution and fine in film forming. The composite ceramic film prepared by the method is uniform and compact and has excellent characteristics of friction reduction and abrasion resistance.

Owner:DONGHUA UNIV

Carbon-titanium composite coating and preparation method of coating

ActiveCN103147040AImprove wear resistanceHigh hardnessVacuum evaporation coatingSputtering coatingArtificial hip jointsHardness

The invention discloses a carbon-titanium composite coating consisting of a pure titanium bottom layer, a carbon-titanium transition layer and a nano-multilayer composite top layer, wherein the pure titanium bottom layer, the carbon-titanium transition layer and the nano-multilayer composite top layer are deposited on a matrix in sequence; the nano-multilayer composite top layer is formed by alternately depositing carbon-titanium composite nanolayers and carbon nanolayers; the carbon-titanium composite nanolayers are contacted with the carbon-titanium transition layer and consist of TiC grains and amorphous carbon; and the carbon nanolayers consist of amorphous carbon. The carbon-titanium composite coating has the advantages of high hardness, low stress, large thickness, low friction coefficient and excellent abrasive resistance, and can be applied to surfaces of bearings, gyroscopes, gears and metal cutting tools as well as biomedicines such as surfaces of artificial hip joints, so that the service lives of the materials are greatly prolonged. The invention further discloses a preparation method of the carbon-titanium composite coating; and through a closed field unbalanced magnetron sputtering method, the carbon-titanium composite coating is well combined with the matrix, and continuous industrial production is facilitated.

Owner:ZHEJIANG UNIV

Preparation method of environment-friendly water-based metal cutting fluid

The invention discloses a preparation method of an environment-friendly water-based metal cutting fluid. The preparation method comprises the steps that: (1) 1 / 3 of a total amount of water is heated to a temperature of 40-50 DEG C; triethanolamine, polyethylene glycol, isopropanol, sodium molybdate, ethylene disodium tetraacetate, sodium silicate, and methyl benzotriazole are sequentially added into the water; the mixture is mixed by stirring for 20-30min, such that a mixture is prepared; (2) sodium benzoate and monoethanolamine benzoate are added into the mixture, and the mixture is stirred for 20-30min; (2) 1 / 3 of a total amount of water is heated to a temperature of 70-80 DEG C; glycerin and water-soluble borate are added to the water, and the mixture is stirred for 10-20min; (4) the solution obtained in the step (3) is mixed with the mixture obtained in the step (2), and the mixture is mixed by stirring for 30-40min under a temperature of 50-60 DEG C; and (5) nano-grade silica is added into the mixed solution obtained in the step (4); and the mixture is stirred for 2-4h, such that the cutting fluid is obtained.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Method for growing abrasion-proof antifriction ceramic film on stannum, aluminum alloy surface in situ

InactiveCN101220494AImprove uniformityImprove wear resistanceAnodisationCeramic coatingNegative phase

A method for an in-situ grown wear resistance and anti-friction ceramic coating on the surface of tin-aluminium alloy relates to the method for preparing the ceramic coating on the surface of tin-aluminium alloy and solves the disadvantage of poor wear resistance of tin-aluminium alloy. The steps of the method are as follows: (1) Sodium silicate of 2 to 12g / L and sodium fluoride of 0 to 2g / L are dissolved in distilled water, forming electrolyte; (2) tin-aluminium alloy, the oxide film of which is removed, is arranged in the electrolyte as the anode, and a stainless steel plate is the cathode, and the temperature of the electrolyte is controlled to be 15 to 40 DEG C; power is switched on and the peak value voltage is adjusted between minus 200 volt and 600 volt, and the positive and negative phase current density is 8 to 30 ampere / dm<2>, and the frequency is 50 to 200 Hz, and the reaction time is 5 to 40 min while electrifying in constant current condition; (3) The surface is cleaned by water after being fetched out and is dried naturally or at the temperature of 80- 100 DEG C. The ceramic coating of the invention has the advantages of wear resistance, anti-friction, corrosion resistance, heat resistance, good electrical resistance property, good uniformity of the ceramic coating and high bonding strength with the matrix owning to the in-situ growth of the ceramic coating on the matrix.

Owner:HARBIN INST OF TECH

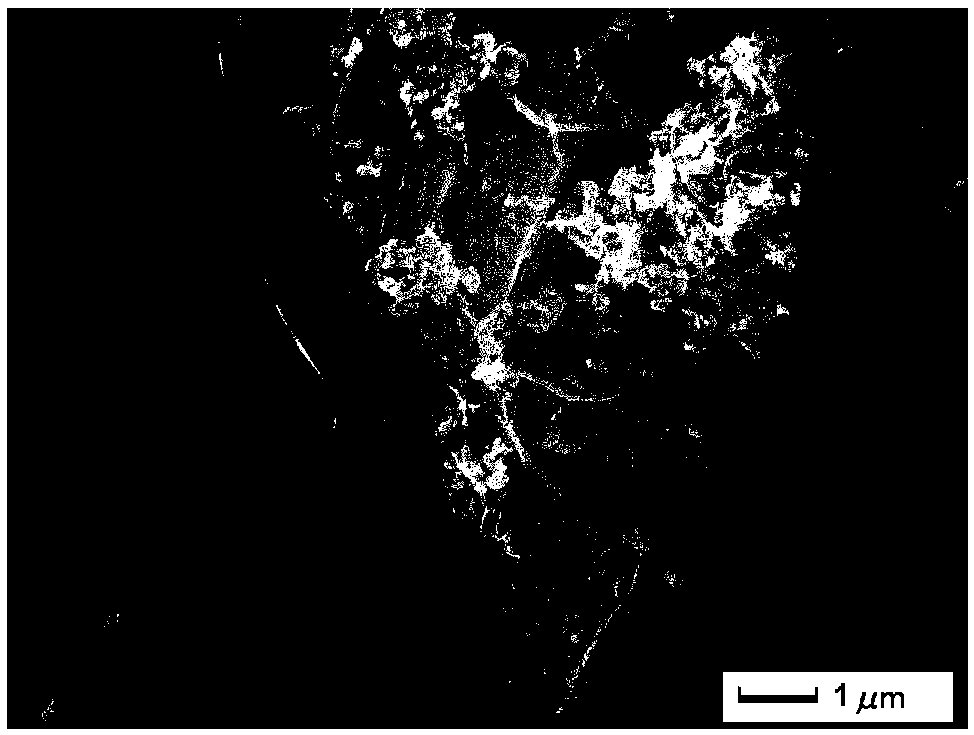

Quick in-situ preparation method of noctiluca-shaped graphene wrapped silicon carbide microsphere

The invention discloses a quick in-situ preparation method of a noctiluca-shaped graphene wrapped silicon carbide microsphere. The method comprises the following steps of dispersing silicon carbide particles in a liquid phase medium to form suspension with a certain concentration, aggregating irradiating pulse laser light with certain energy density to the suspension, allowing the silicon carbideparticles to achieve silicon carbide epitaxy graphene growth, partial multilayer graphene sheet stripping and irregular particle spheroidization in situ by the double action of light and heat of laserirradiation and quick cooling of a surrounding liquid environment, after irradiation, centrifuging, separating and pickling the suspension, and drying a precipitate to form the high-dispersity noctiluca-shaped graphene wrapped silicon carbide microsphere. The method is simple to operate; the preparation can be accomplished under a room temperature condition of normal temperature and pressure; thecost is low; a product is high in purity; and the graphene wrapped silicon carbide microsphere shows excellent dispersion stability and antiwear and friction-reducing performance in lubricating oil.

Owner:UNIV OF JINAN

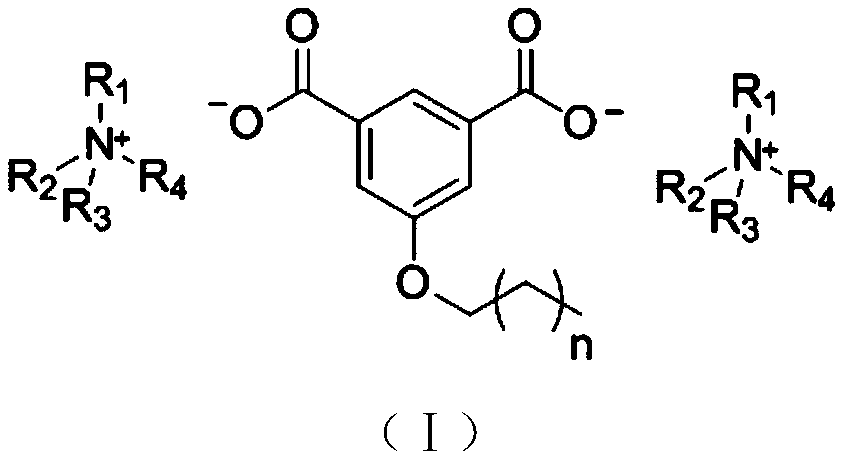

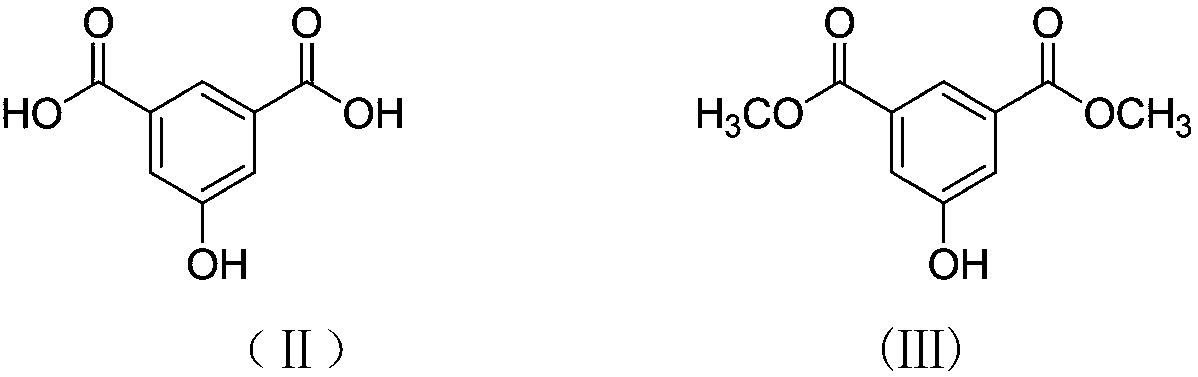

Aromatic dicarboxylic acid ionic liquid, as well as preparation method and application thereof

ActiveCN109485573AExcellent friction reductionImprove wear resistanceOrganic compound preparationAdditivesTectorial membraneFriction reduction

The invention provides an aromatic dicarboxylic acid ionic liquid, as well as a preparation method and application thereof. The ionic liquid has a structure as shown in a general formula (I), whereinR1, R2, R3 and R4 are independently and respectively selected from alkyl having carbon atom number of 1-18, and n is an arbitrary integer of 2-12. Due to the intense adsorption effect of two polar carboxyl (-COO-) and introduction of rigid benzene ring, the ionic liquid can form a firm and orderly physical adsorption protective film on the surface of a metal friction pair in the friction process and has excellent friction reduction and abrasion resistance. Furthermore, the aromatic dicarboxylic acid ionic liquid has relatively ideal thermal stability and the highest decomposition temperature of 205 DEG C.

Owner:BAOJI UNIV OF ARTS & SCI

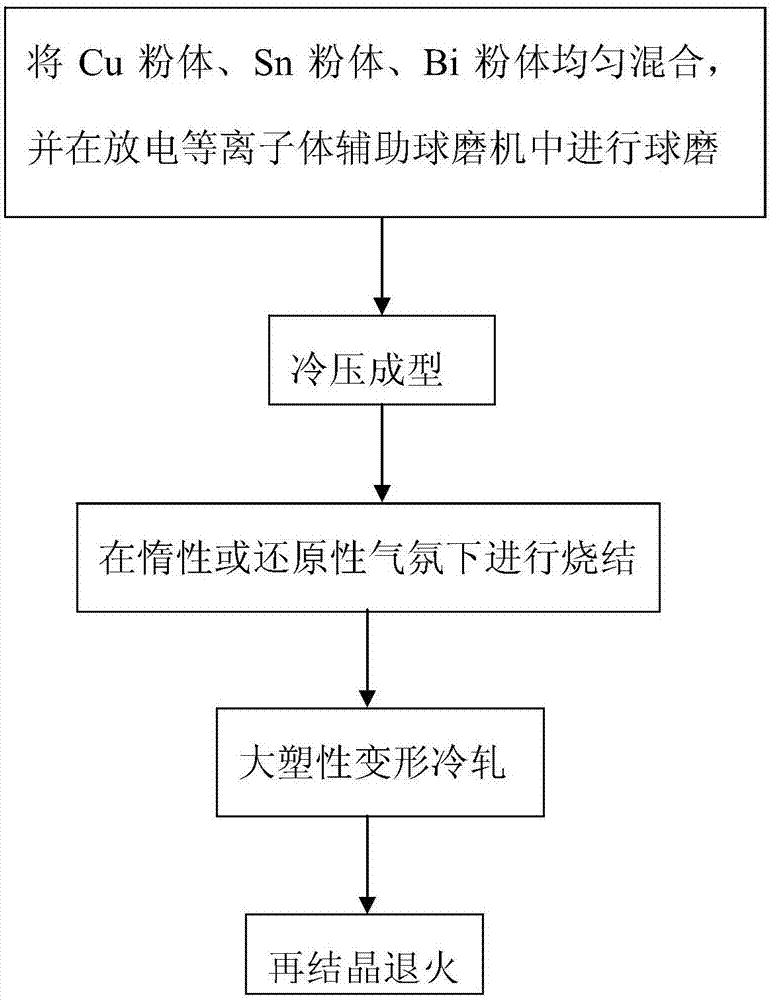

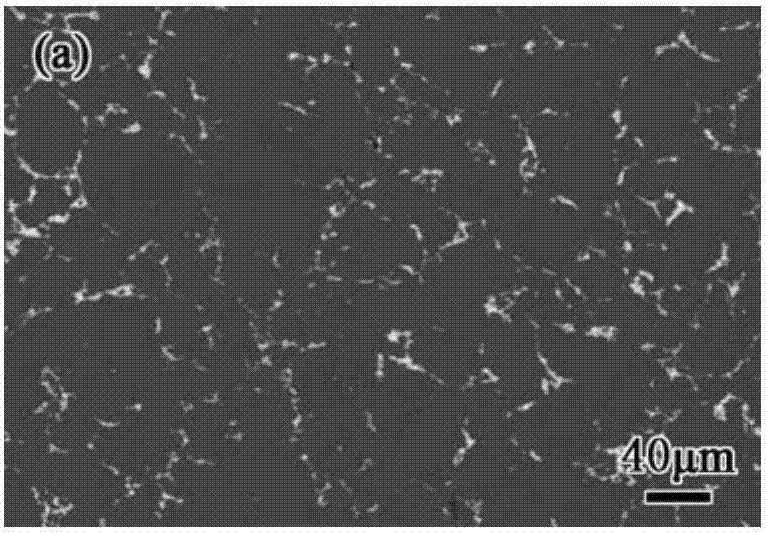

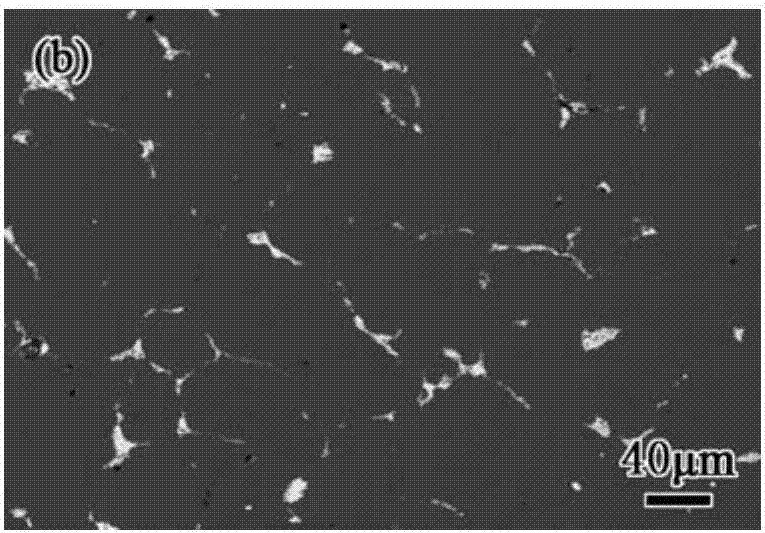

Method for preparing Cu-Sn-Bi bearing alloy by discharge plasma assisted ball-milling

The invention discloses a method for preparing a Cu-Sn-Bi bearing alloy by discharge plasma assisted ball-milling. The method comprises the following steps of: mixing Cu, Sn and Bi original powder in certain percentage by weight; then, obtaining Cu-Sn-Bi supersaturated solid solution alloy powder through discharge plasma assisted ball-milling; and performing pre-cold-pressing, sintering, cold-rolling and recrystallizing-annealing on the alloy powder, thereby preparing the Cu-Sn based bearing alloy which is approximately to be fully compact. The Cu-Sn-Bi alloy prepared by the method has relatively high compactness, tensile strength and plasticity, and has relatively good wear resistance and friction reduction. The method solves the key problems such as difficulty sintering and non-compactness generated in preparing the Cu-Sn based bearing alloy by powder sintering, and is beneficial for realizing industrial production.

Owner:SOUTH CHINA UNIV OF TECH

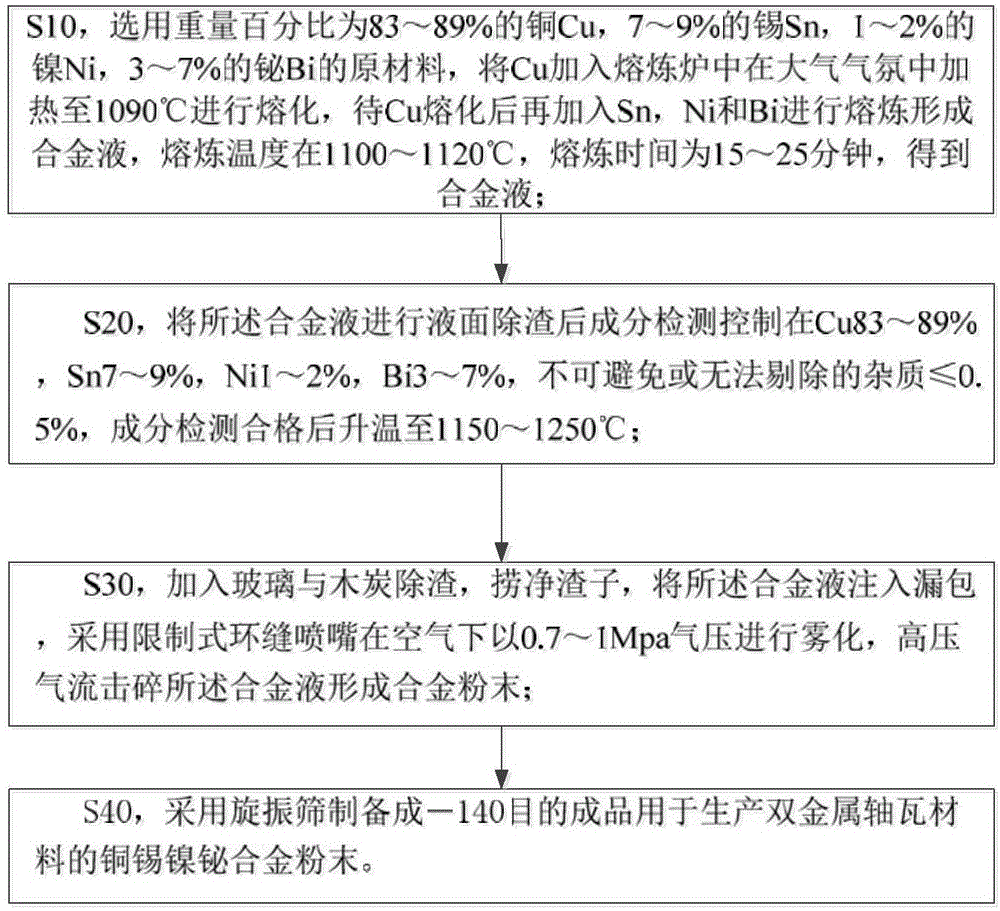

Preparation method for copper-tin-nickel-bismuth alloy powder used for producing thermometal bearing bush material

The invention belongs to the technical field of alloy power preparation and particularly relates to a preparation method for copper-tin-nickel-bismuth alloy powder used for producing a thermometal bearing bush material. The preparation method comprises the following steps that by weight, 83%-89% of copper, 7%-9% of tin, 1%-2% of nickel and 3%-7% of bismuth are selected and used, Cu is added into a smelting furnace and is heated to 1083-1090 DEG C in the air atmosphere; Sn is added after Cu is molten, Ni and Bi are smelted to form alloy liquid, the smelting temperature is 1100-1120 DEG C, and the smelting time is 15-25 minutes; the temperature is increased to 1150-1250 DG C; slag is fished out, atomization is conducted through a limited type circular seam nozzle under air at the air pressure being 0.7-1 Mpa, and the alloy liquid forms alloy powder; and the -140 meshes alloy powder is prepared through an eddy-vibrating screen. According to the preparation method, the alloy powder prepared through a melting-gas atomization method can meet the requirement of an antifriction coating material in an engine sliding bearing.

Owner:浙江旭德新材料有限公司

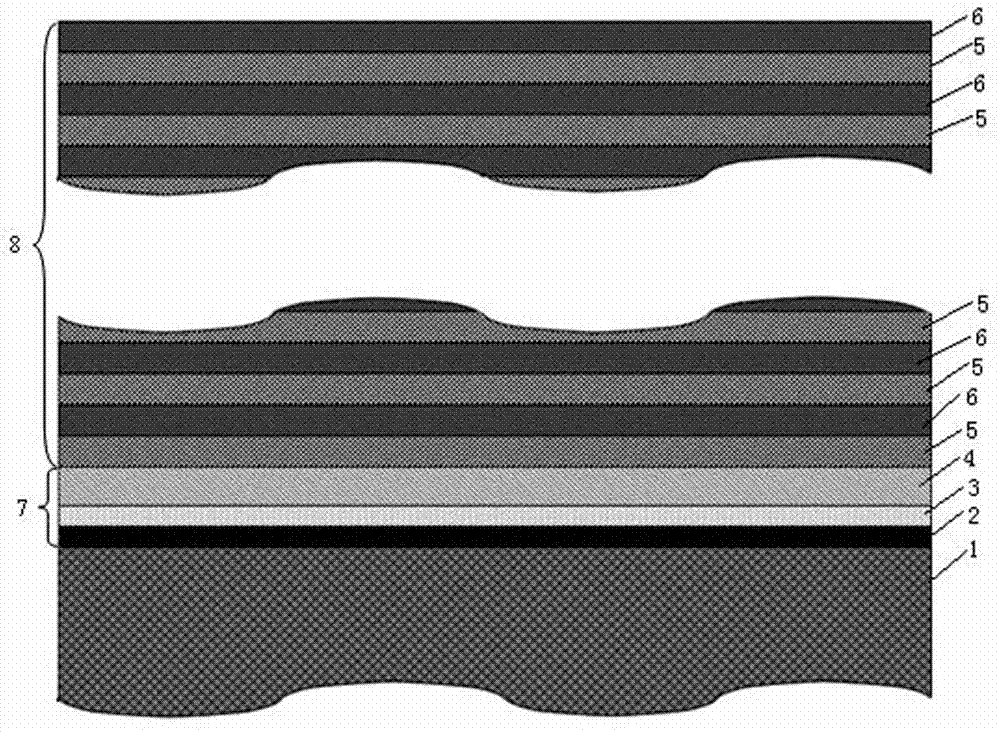

Amorphous carbon composite coating and preparation method and application thereof

ActiveCN105441872AImprove bindingHigh hardnessVacuum evaporation coatingSputtering coatingHigh energyHardness

The invention discloses an amorphous carbon composite coating and a preparation method and application thereof. The amorphous carbon composite coating is composed of a pure-carbon ultrathin bottom layer and an amorphous carbon top layer which are sequentially deposited on an ultrahigh molecular weight polyethylene (UHMWPE) substrate subjected to high-energy argon ion modification treatment. The binding force of the amorphous carbon composite coating and the substrate can be improved through the designs of high-energy argon ion modification and the pure-carbon ultrathin bottom layer. According to the amorphous carbon composite coating, the surface hardness of the UHMWPE substrate is greatly improved, and the amorphous carbon composite coating is low in friction coefficient and good in abrasion resistance, and can be used in biomedicine, such as a joint prosthesis socket cup surface. The service life of materials is greatly prolonged, and the amorphous carbon composite coating is broad in application prospect.

Owner:ZHONGAO HUICHENG TECH CO LTD

Method for preparing composite polytetrafluoroethene conductive material

A method for preparing a composite polytetrafluoroethene (PTFE) conductive material relates to the technical field of the manufacture of the composite PTFE conductive material. The crystallization behavior of PTFE is improved through the filling of graphene nanoplatelets; the interfacial adhesion between the graphene nanoplatelets and PTFE is regulated to endow PTFE with excellent wear-resisting property and conductivity, while maintaining certain mechanical properties of PTFE; the composite PTFE conductive material, which is prepared through the cold pressed sintering method, has comprehensive mechanical properties, wear-resisting property and conductivity.

Owner:YANGZHOU UNIV

Thrust bearing applying interface sliding technology

InactiveCN100545469CWith carrying capacityExcellent friction reductionBearing componentsSliding contact bearingsThrust bearingEngineering

The present invention is a kind of thrust bearing using interface sliding technology, which is characterized in that it includes a stationary flat plate and a moving flat plate parallel to each other, the gap between the stationary flat plate and the moving flat plate is filled with fluid lubricating oil, Part of the surface is provided with II coating, the remaining surface is provided with I coating, and the surface of the moving plate is provided with III coating, so that a certain relative motion between the stationary plate and the moving plate makes the two plates form Thrust bearing; the I coating is a fluorocarbon coating; the II coating and III coating are mica powder coatings modified by a silane coupling agent. The bearing of the present invention has a simple implementation method, has a certain load capacity and good anti-friction and wear-resistant properties, does not need to process the geometric shape of the mating surface, has a simple and compact structure, small size, and low manufacturing cost, and can replace traditional fluid dynamic pressure lubrication. Thrust plain bearings are used for load bearing.

Owner:HUAIHAI INST OF TECH

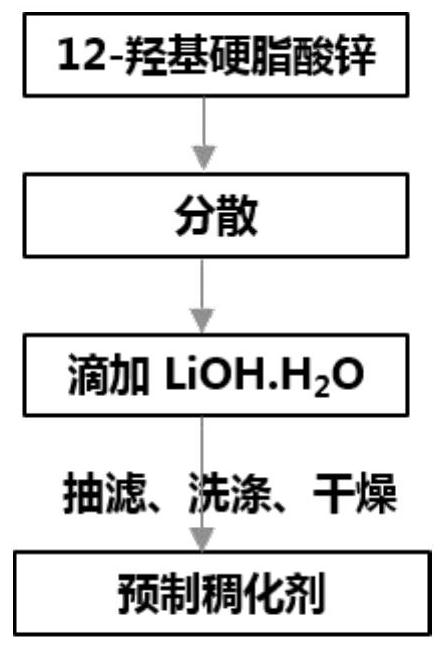

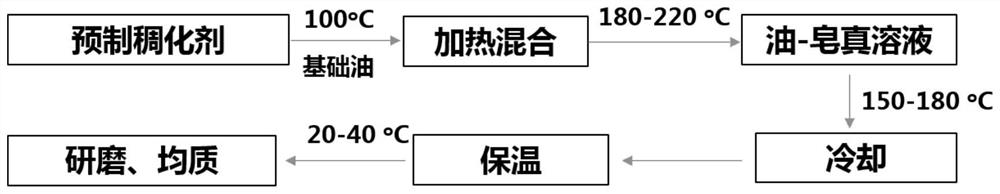

Pre-prepared thickening agent containing nano-zinc oxide and lubricating grease composition obtained by same

The invention relates to an in-situ preparation technology of an efficient anti-friction and anti-wear nano-material additive and a lubricating grease composition obtained by the same. The lubricating grease composition consists of lithium 12-hydroxystearate, base oil and a nano additive. The in-situ preparation method of an efficient anti-friction and anti-wear nano additive, which comprises the following step of: in a proper solvent environment, directly obtaining a prefabricated thickening agent system containing small-size nano zinc oxide and lithium 12-hydroxystearate by a one-step method through double decomposition reaction between zinc 12-hydroxystearate and lithium hydroxide monohydrate. The in-situ preparation technology of the efficient anti-friction and anti-wear agent provided by the invention has the beneficial effects of high efficiency, good controllability, good dispersibility, organic combination with the lubricating grease preparation process and the like, and the obtained lubricating grease composition shows excellent tribological properties, good low-temperature viscosity and longer service life.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

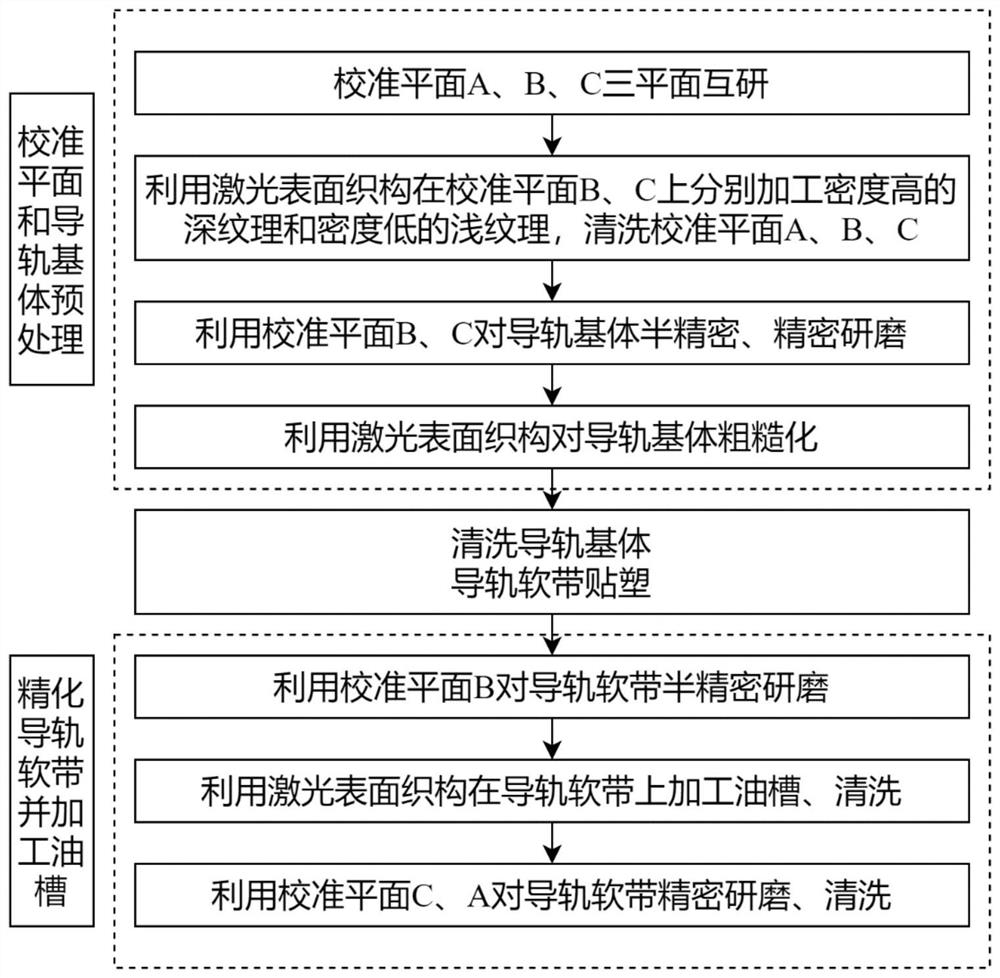

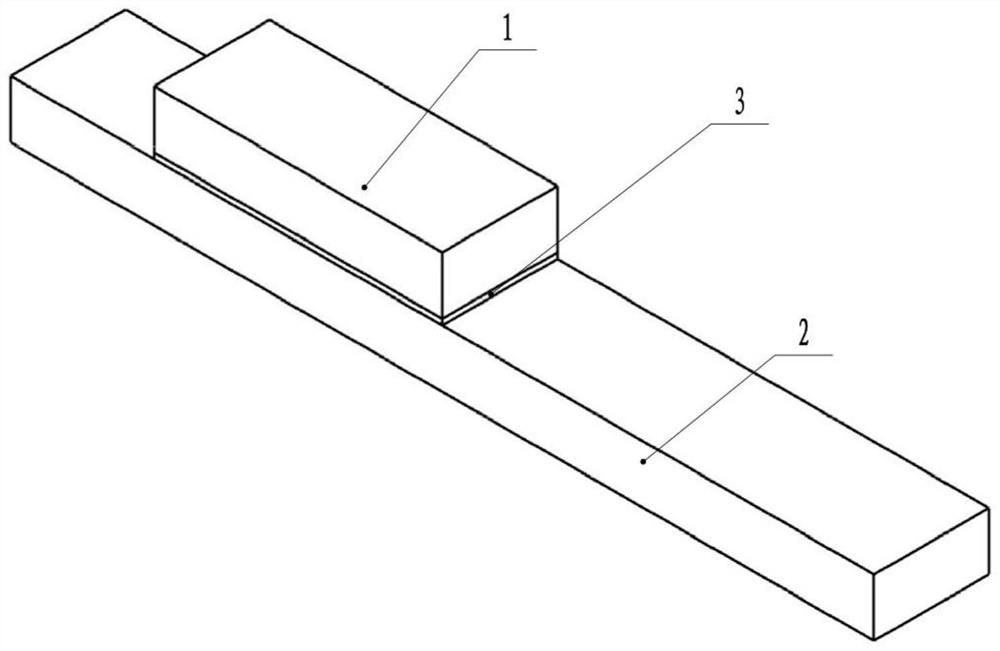

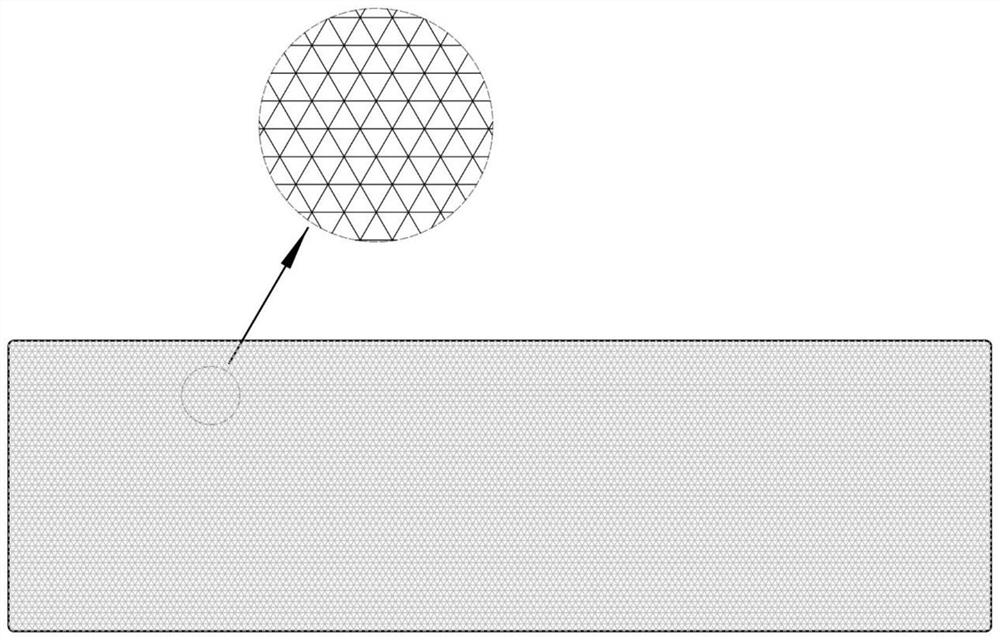

Sliding guide rail plastic-pasting process method

The invention belongs to the technical field of precision machining and testing, and relates to a sliding guide rail plastic-pasting process method, which comprises the following steps of: machining a high-flatness calibration plane by utilizing a three-plane mutual grinding method to grind and refine a guide rail base body, roughening the guide rail base body by utilizing a laser surface texture, and after the guide rail base body is subjected to plastic pasting, matching the laser surface texture with the calibration plane for grinding to refine a guide rail soft belt and machine an oil groove. The method can replace manual scraping to machine the guide rail base body and the guide rail soft belt, so that the machining efficiency is higher, the labor intensity is lower, and the precision consistency is better; the sliding guide rail can be subjected to high-precision plastic pasting machining without more scraping experience, so that the processing cost is lower; and complex oil grooves with different shapes and depths can be designed, so that flowing of lubricating oil and antifriction of the sliding guide rail are facilitated, the using performance of a sliding pair is improved, the service life of the sliding pair is prolonged, and the good market application prospect and popularization value are achieved.

Owner:DALIAN UNIV OF TECH

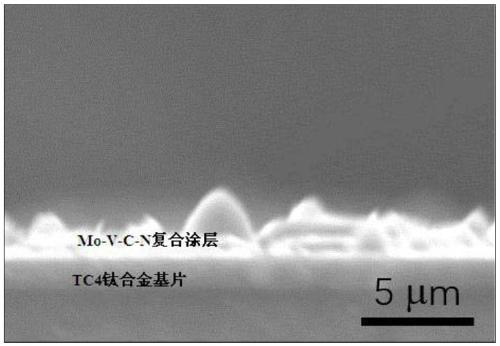

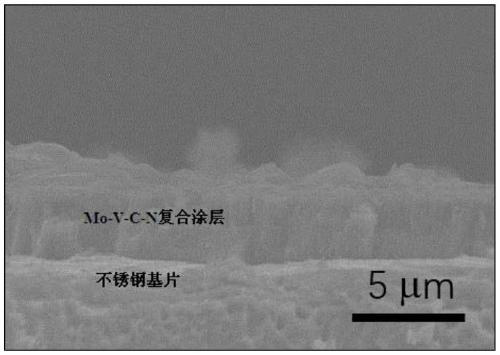

Preparation method of Mo-V-C-N composite coating

ActiveCN111534803AExcellent friction reductionImprove wear resistanceVacuum evaporation coatingSputtering coatingHardnessWear resistance

The invention discloses a preparation method of an Mo-V-C-N composite coating. The method comprises the steps that firstly, a substrate is treated; secondly, an Mo target, a V arc target and the substrate are placed, and a vacuum chamber is vacuumized and heated; thirdly, the substrate is etched; fourthly, an Mo priming layer is formed through deposition; fifthly, an Mo-V buffer layer is formed through deposition; sixthly, an Mo-V-N transition layer is formed through deposition; seventhly, an Mo-V-C-N body layer is formed through deposition; eighthly, vacuum annealing treatment is performed; and ninthly, the substrate provided with the Mo-V-C-N composite coating on the surface is obtained through cooling. According to the preparation method, through layered arrangement of the Mo-V-C-N composite coating, good component transition is formed, good combination with the substrate is ensured, and cracking and stripping of the Mo-V-C-N composite coating are avoided; and the prepared Mo-V-C-Ncomposite coating is uniform and dense in structure, high in hardness, good in toughness, low in friction coefficient and good in wear resistance, has a lubricating effect under both high temperatureand low temperature and is suitable for serving as a space self-lubricating layer.

Owner:西安稀有金属材料研究院有限公司

Compression-resistant gear oil

InactiveCN103602435AGood anti-oxidation and corrosion resistanceExtend oil change intervalsLubricant compositionMaleic anhydrideBoundary lubrication

The invention discloses a compression-resistant gear oil, which is prepared from the following raw materials by weight: 15-22 parts of glycerin, 10-17 parts of mineral oil mixture, 2.5-7.3 parts of maleic anhydride, 2.3-6.5 parts of sodium carbonate, 2.3-4.6 parts of ten carbon diacid and 1.2-6.3 parts of potassium borate. Compared with the existing gear oil, the compression-resistant gear oil has the advantages of good antioxidant corrosion resistance, good corrosion, long oil change cycle, reduction in emission of waste oil, waste gas and particulates, good biodegradability and low price compared with a traditional lubricating oil. At the same time, the compression-resistant gear oil can rapidly form a wear-resistant, high temperature-resistant and extrusion-resistant boundary lubricating oil film on a heavy-load industrial gear under high speed, low speed, heavy load, high torque or impact load, so as to prevent the tooth surface from destroy phenomena such as wear, abrasion, gluing and pitting, and prolong the service life of the heavy load industrial gear.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Lubricating oil for gears

ActiveCN106221871AImprove resistance to decompositionImprove wear resistanceLubricant compositionParticulatesGear wheel

The invention discloses a lubricating oil for gears. The lubricating oil is prepared from modified base oil, succinate, diethylenetriamine penta(methylene phosphonic acid), octyl diphenylamine, sorbitol, nano copper powder, C12 dibasic acids, beta-sitosterol, cholesteryl nonanoate, ethanediol amide cocoate and auxiliary additives. The lubricating oil for gears has the characteristics of favorable oxidation resistance, favorable corrosion resistance, favorable rust resistance, favorable wear resistance, favorable anti-friction property, high torque, favorable high-temperature stability, favorable demulsibility, long oil change period, favorable biodegradability and lower price than the traditional lubricating oil, and reduces the emissions of waste oil, waste gas and particles. The lubricating oil has the advantages of favorable viscosity, favorable lubricating property, favorable cooling property, excellent viscosity-temperature characteristics, high viscosity index, low condensation point and high flash point, and well reduces the friction between gear pairs.

Owner:东营国安化工有限公司

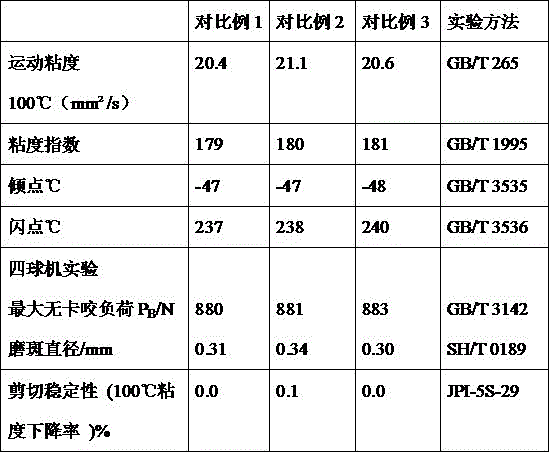

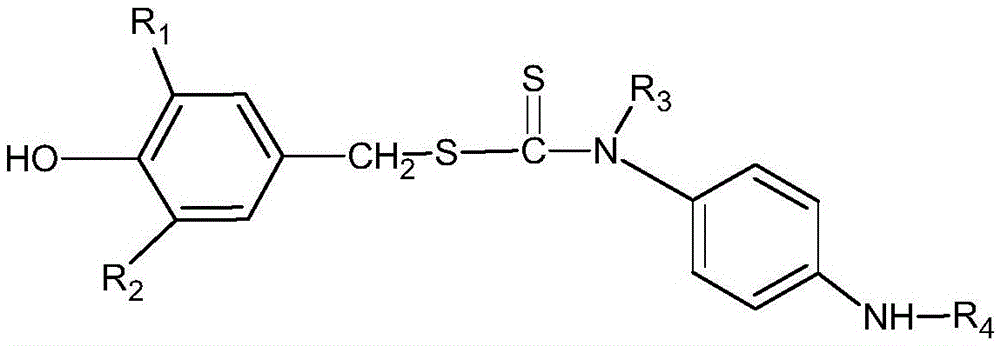

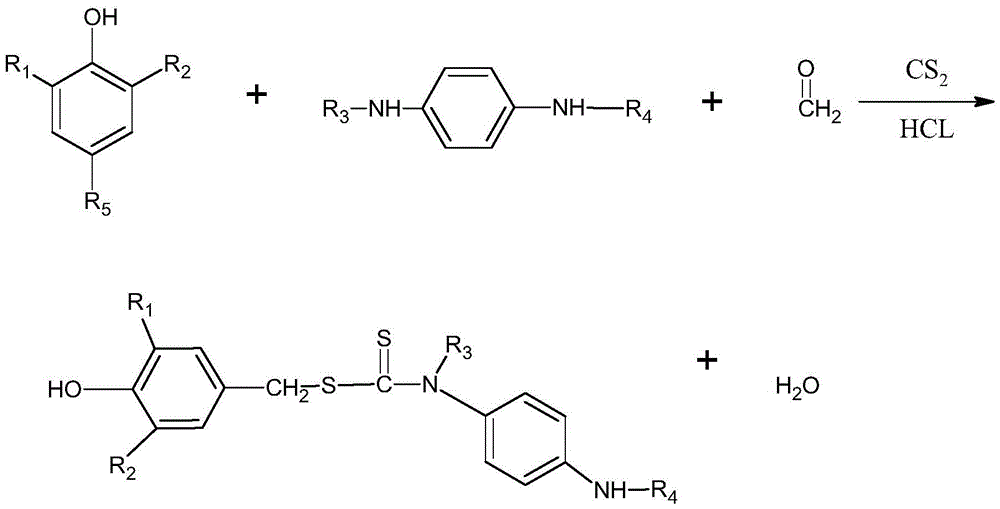

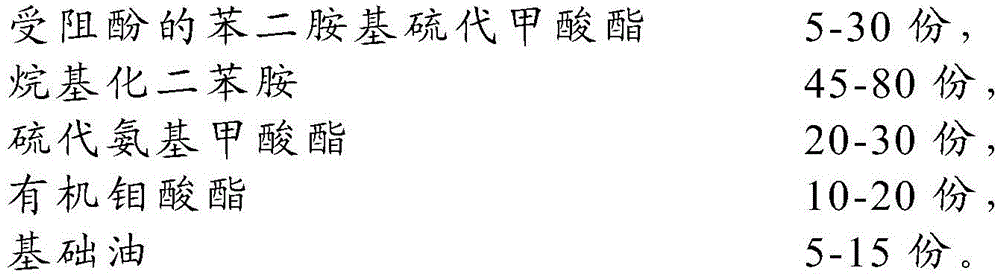

Hindered-phenol-containing phenylenediaminothioformate, antioxidant containing compound and application thereof in gas engine lubricating oil

PendingCN105481741AImprove antioxidant capacityGood extreme pressure and anti-wearOrganic chemistryAdditivesMannich reactionOxidation resistant

The invention provides a hindered-phenol-containing phenylenediaminothioformate, an antioxidant containing the compound and application thereof in gas engine lubricating oil. The preparation process comprises the following steps: (1) by using the Mannich reaction principle, carrying out condensation reaction on an alkali constituent N,N-dialkyl phenylenediamine, an acid constituent hindered phenol and formaldehyde to generate a Mannich intermediate a; and (2) adding carbon bisulfide into the Mannich intermediate a to carry out the nucleophilic addition reaction, thereby obtaining the hindered-phenol-containing phenylenediaminothioformate product. The new synthetic antioxidant has the advantages in the phenol-type and amine-type antioxidants, and has higher oxidation resistance. The antioxidant has favorable extreme pressure antiwear and anti-friction anti-friction properties. The gas engine lubricating oil has the advantages of high viscosity index, high flash point, low sulfur content, high oxidation resistance and excellent oxidation stability, and greatly prolongs the service time of the oil product.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Nanoscale compound wear-resisting brake pad

InactiveCN106402217AImprove wear resistanceImprove thermal stabilityFriction liningActuatorsEthylene-propylene-diene-monomerCarbon nanotube

The invention discloses a preparing method of a nanoscale compound wear-resisting brake pad. The nanoscale compound wear-resisting brake pad is prepared through heat-alkali treatment, ultrasonic vibrating, microwave ultraviolet treatment and other modification measures of carbon nanotubes, polyphenylene sulfide, zinc oxide, ethylene-propylene-diene monomer rubber and other raw materials.

Owner:GAOYOU SHUNDA POWER MACHINE

Double thiadiazole derivative and preparation method thereof

ActiveCN103319435AExcellent extreme pressureExcellent friction reductionOrganic chemistryAdditivesAlkaneAlkyl substitution

The invention discloses a double thiadiazole derivative lubricant additive and a preparation method thereof, wherein 2,5-dimercapto-1,3,4-thiadiazole is adopted as a raw material, the 2,5-dimercapto-1,3,4-thiadiazole and halogenated alkane are subjected to a nucleophilic substitution reaction under a catalyst effect to generate monoalkyl thiadiazole, and the monoalkyl thiadiazole is subjected to a coupled reaction under an oxidizing agent effect to obtain bis-5,5'-dithiodi-(1,3,4-thiadiazole-2-thioalkyl) additive, wherein the additive is characterized in that excellent extreme pressure property and antifriction property are provided for the lubricant with the additive, and the additive can be adopted as a lubricant additive to be separately used or is compounded with other additives to be used, and is applicable for industrial lubricating oils and lubricating greases.

Owner:PETROCHINA CO LTD

Water-based nano tungsten disulfide lubricating agent capable of protecting surface of aluminum profile and used for isothermal die forging and preparation method of water-based nano tungsten disulfide lubricating agent

InactiveCN105400584AGood suspensionNo agglomeration, turbidity and precipitationAdditivesFriction reductionWater based

The invention discloses a water-based nano tungsten disulfide lubricating agent capable of protecting the surface of an aluminum profile and used for isothermal die forging and a preparation method of the water-based nano tungsten disulfide lubricating agent. The water-based nano tungsten disulfide lubricating agent is prepared from raw materials in parts by weight as follows: 7.4-7.6 parts by weight of PAO6 (poly-alpha-olefin), 0.2-0.25 parts of a silane coupling agent kh 560, 8.2-8.4 parts of nano tungsten disulfide, 0.8-1 part of nano carbon balls, 0.8-1 part of nano bentonite, 1-1.2 parts of Span-80, 0.4-0.5 parts of butyl acrylate, 0.6-0.8 parts of methyl acrylate, 0.1-0.2 parts of ammonium persulfate, 0.8-0.9 parts of barium fluoride, 0.3-0.4 parts of nano TiO2, 0.5-0.6 parts of tetraethoxysilane, 0.5-0.6 parts of micron TiO2 and the balance of water. The lubricating agent has an excellent protection function on the surface of the aluminum profile through comprehensive use of barium fluoride, nano TiO2, tetraethoxysilane and micron TiO2 and has better friction reduction and abrasion resistance by comparison with ordinary water-based lubricating agents.

Owner:安徽创奇乐智能游乐设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com