Ultra-hard carbon film and preparation method thereof

A carbon film and superhard technology, applied in the field of superhard carbon film and its preparation, can solve the problems of weak film bearing capacity, limited application, high reaction temperature, etc., achieve low friction coefficient and wear rate, excellent friction reduction and durability Grinding performance and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

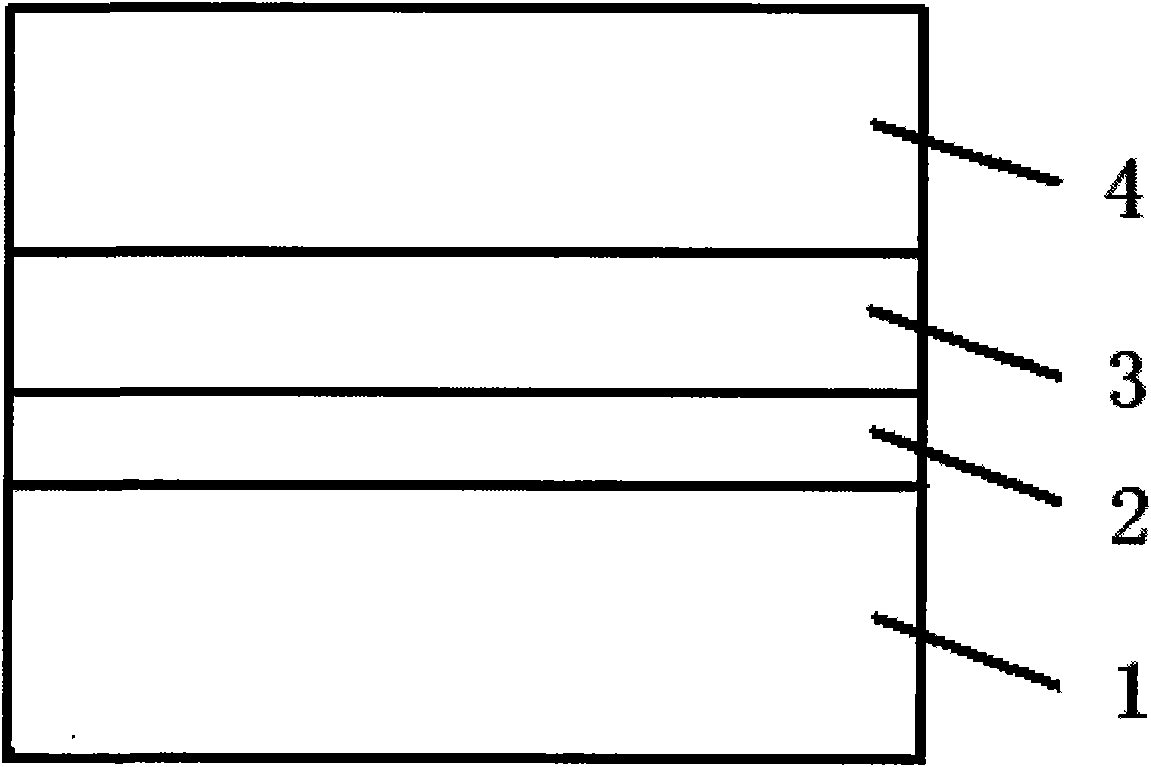

Image

Examples

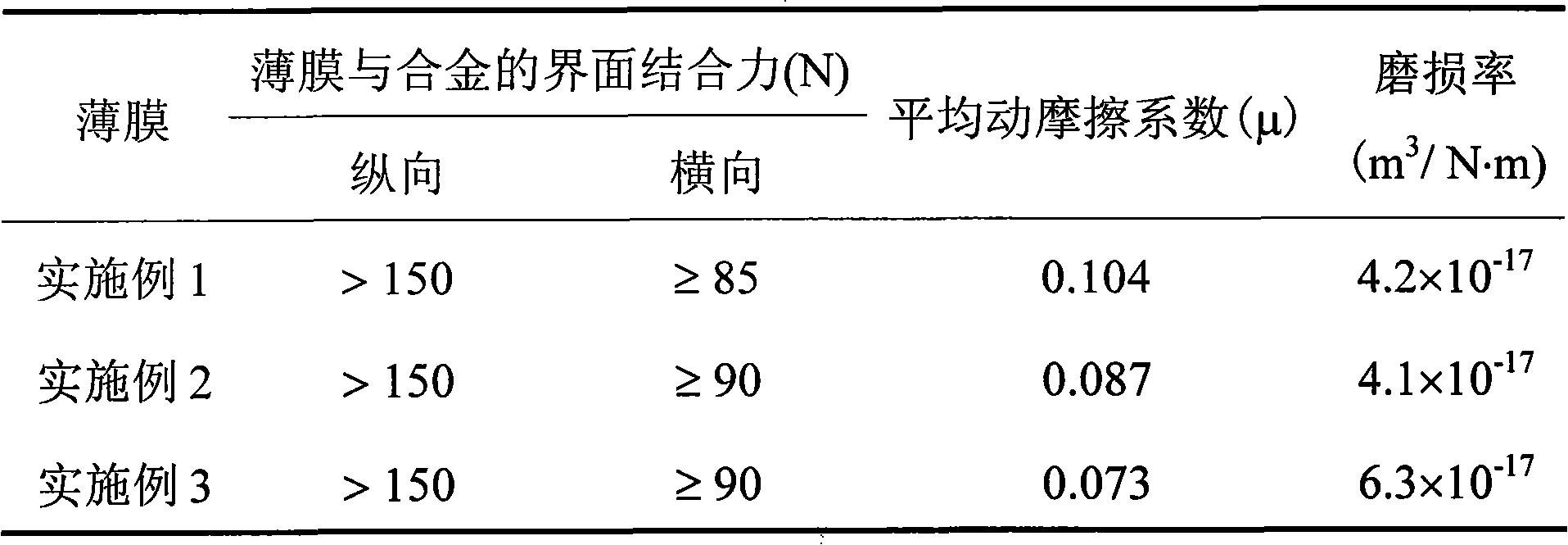

Embodiment 1

[0017] The superhard carbon film is prepared by unbalanced magnetron sputtering method, and the steps are as follows:

[0018] 1) Place pure graphite targets and metal Ti targets in four directions perpendicular to the horizontal plane and at 90 degrees to each other. The rotating speed of the turret is 4rpm, and the distance between the substrate and the target is adjusted to 12cm;

[0019] 2) Vacuumize the reaction chamber to 3.0×10 -4 Pa, argon gas with a purity of 99.99% is introduced, and the flow rate of the argon gas is controlled at 30 sccm. Clean the target and substrate by sputtering with a titanium target current of 0.3A and a bias voltage of 500V for 30 minutes;

[0020] 3) Control the pure argon gas flow rate to 40 sccm, deposit a pure Ti bonding layer on the substrate with a titanium target current of 5A and a bias voltage of 70V for 5min; then gradually reduce the current of the two titanium targets from 5A to 0, and simultaneously The current of each graphit...

Embodiment 2

[0023] The superhard carbon film is prepared by unbalanced magnetron sputtering method, and the steps are as follows:

[0024] 1) Place pure graphite targets and metal Ti targets in four directions perpendicular to the horizontal plane and at 90 degrees to each other, and arrange the graphite targets and metal Ti targets alternately; The rotating speed of the turret is 4rpm, and the distance between the substrate and the target is adjusted to 12cm;

[0025] 2) Vacuumize the reaction chamber to 3.0×10 -4 Pa, argon gas with a purity of 99.99% is introduced, and the flow rate of the argon gas is controlled at 30 sccm. Clean the target and substrate by sputtering with a titanium target current of 0.3A and a bias voltage of 500V for 30 minutes;

[0026] 3) Control the pure argon gas flow rate to 30 sccm, deposit a pure Ti bonding layer on the substrate with a titanium target current of 5A and a bias voltage of 60V for 5min; then gradually reduce the current of the two titanium ta...

Embodiment 3

[0029] The superhard carbon film is prepared by unbalanced magnetron sputtering method, and the steps are as follows:

[0030] 1) Place pure graphite targets and metal Ti targets in four directions perpendicular to the horizontal plane and at 90 degrees to each other. The rotating speed of the turret is 4rpm, and the distance between the substrate and the target is adjusted to 12cm;

[0031] 2) Vacuumize the reaction chamber to 3.0×10 -4 Pa, argon gas with a purity of 99.99% is introduced, and the flow rate of the argon gas is controlled at 30 sccm. Clean the target and substrate by sputtering with a titanium target current of 0.3A and a bias voltage of 500V for 30 minutes;

[0032] 3) Control the pure argon gas flow rate to 20 sccm, deposit a pure Ti bonding layer on the substrate with a titanium target current of 5A and a bias voltage of 55V for 5 minutes; then gradually reduce the current of the two titanium targets from 5A to 0 within 30 minutes, and then At the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com