Pre-prepared thickening agent containing nano-zinc oxide and lubricating grease composition obtained by same

A lubricating grease composition, nano-zinc oxide technology, applied in the field of lubricating grease, can solve problems such as uncontrollable nano-particle agglomeration, achieve the effects of prolonging the grease change cycle, excellent friction reduction, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

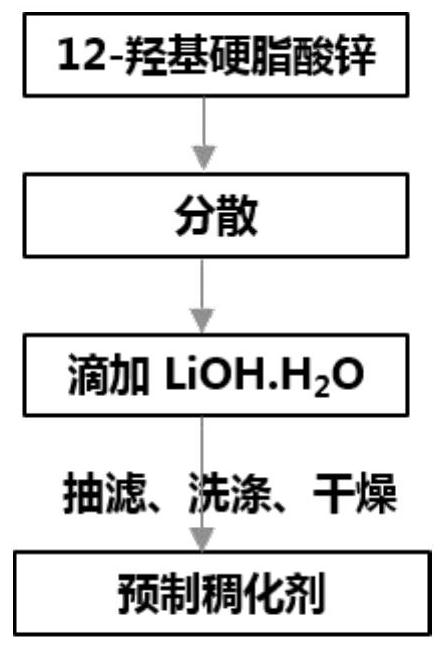

[0027] Embodiment 1: A kind of prefabricated thickener containing nanometer zinc oxide

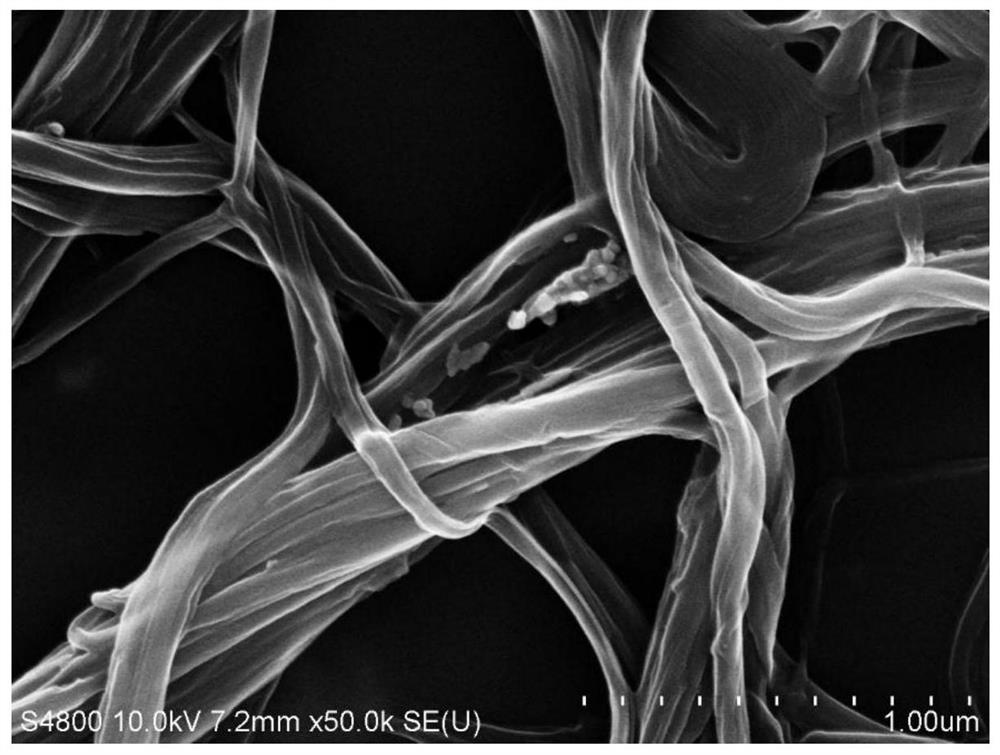

[0028] See attached figure 1 In the process flow shown, 10.00g 12-hydroxystearic acid zinc and 0.10g phenolphthalein were dissolved in 20-50mL ethanol as an acid-base indicator, and 1.27g LiOH.H 2 O is configured as a mixed solution of ethanol and water, and LiOH.H 2 The O solution was slowly and dropwise added to the upper 12-hydroxyzinc stearate system until reaching the end of the reaction. After the above system continued to react for 2 hours, the solid powder was separated by filtration, washed (5 times, using 20 mL of ethanol for each washing), and dried at 60° C. to obtain a solid powder, which is a prefabricated thickener powder containing nano-zinc oxide. The microscopic morphology and XRD data of the obtained prefabricated thickener are shown in the appendix image 3 And attached Figure 4 . attached by image 3 It can be seen that the nano-zinc oxide material is distribute...

Embodiment 2

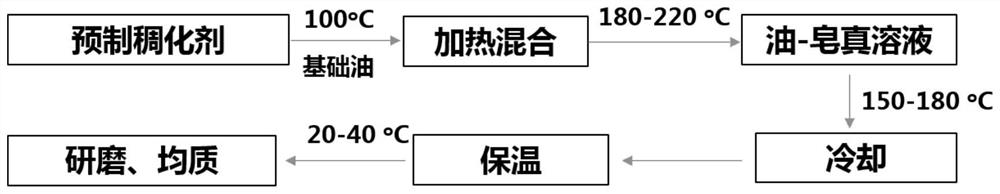

[0029] Embodiment 2: Preparation of blank comparative example grease composition

[0030] See attached figure 2 In the process flow shown, 10.0g of prefabricated thickener soap powder 12-hydroxystearate lithium not containing nano-zinc oxide is added to 80g of synthetic ester base oil diisooctyl sebacate at 100°C (Kinematic viscosity: 25mPa.s at 20°C). After stirring and mixing for 20-30 minutes, the system was heated up to 210°C. At this time, the system was in a slightly transparent state and kept for 10 minutes. Subsequently, the temperature was lowered to 180° C. and kept for 30 minutes, then slowly cooled to room temperature, and the grease composition was obtained after grinding and homogenizing.

Embodiment 3

[0031] Embodiment 3: preparation lubricating grease composition

[0032] See attached figure 2 Shown technological process, the thickening agent prefabricated soap powder in 10.0g embodiment 1 is added in the synthetic ester base oil diisooctyl sebacate of 80g in 100 ℃ (kinematic viscosity: 20 ℃ is 25mPa .s), after stirring and mixing for 20-30 minutes, the temperature of the system was raised to 210°C. At this time, the system was in a slightly transparent state and kept for 10 minutes. Subsequently, the temperature was lowered to 180° C. and kept for 30 minutes, then slowly cooled to room temperature, and the grease composition was obtained after grinding and homogenizing. attached by Figure 5 It can be seen that the lubricating grease composition containing nano zinc oxide has a smaller viscosity in the low temperature region, showing better low temperature fluidity. And it has better thixotropy and structural recoverability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com