Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

269results about How to "Extend oil change intervals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

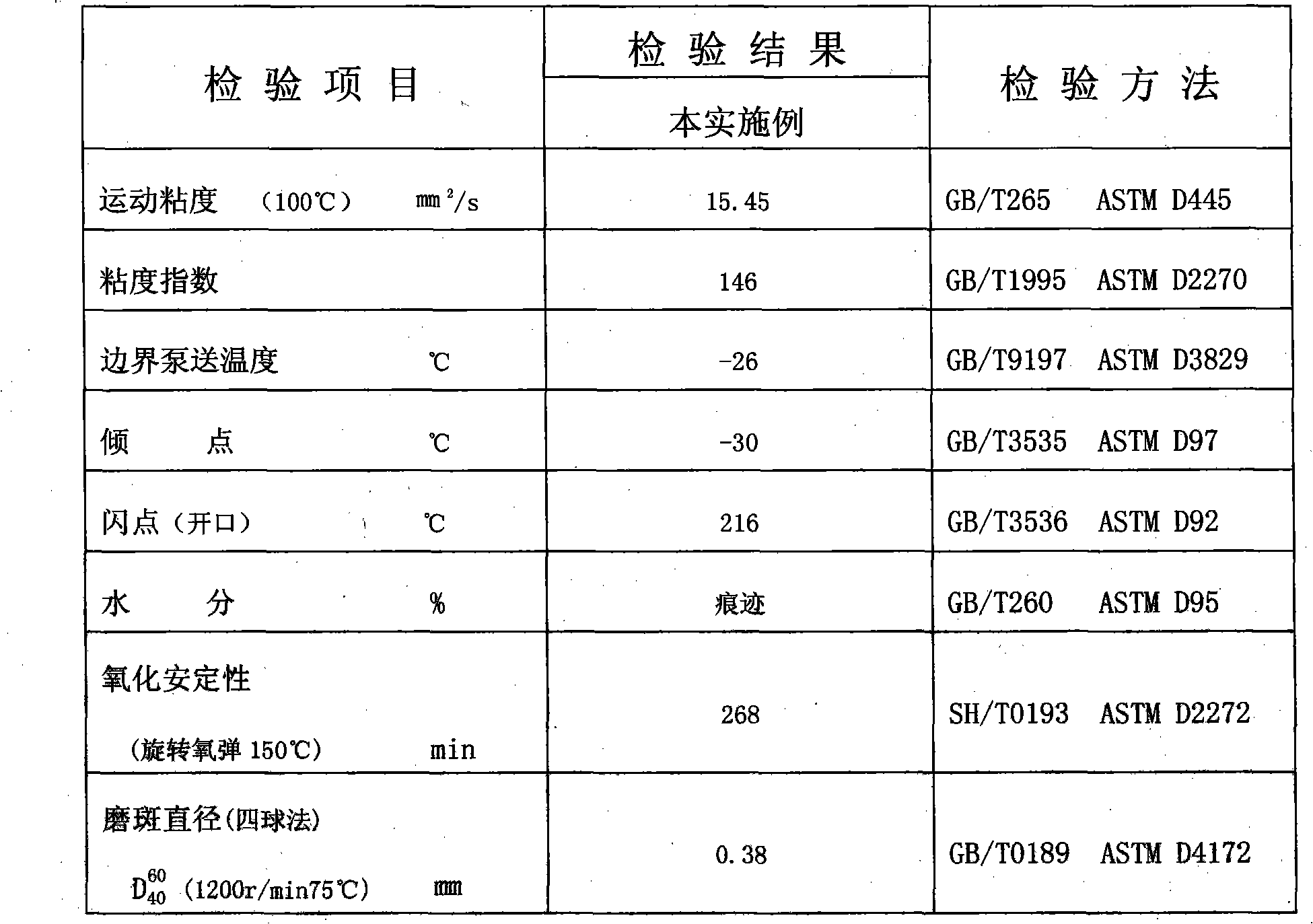

Energy-saving diesel engine oil with ultra-long oil change mileage and preparation method thereof

ActiveCN105542922AEasy to operateImprove solubilityAdditivesBase-materialsFriction reductionAntioxidant

The invention discloses energy-saving diesel engine oil with ultra-long oil change mileage and a preparation method thereof. The energy-saving diesel engine oil is prepared from, by mass, 10-18% of diesel engine oil complexing agent, 0.3-0.8% of anti-wear agent, 0.5-1.5% of antioxidant, 3-8% of viscosity index improver, 0.002-0.005% of anti-foaming agent and the balance synthesized basic oil. The energy-saving diesel engine oil has high wear resistance and friction reduction performance, high oxidation stability and high thermal stability, and the oil change cycle can be effectively prolonged; by means of the anti-wear agent without sulfur and phosphorus, the wear resistance and friction reduction performance are effectively improved, and the oxidation of an oil product can not be accelerated; alkyl multi-benzyl toluene is added to basic oil, and through the good complexing effect of alkyl multi-benzyl toluene and antioxidant, the antioxidant performance of the oil product is improved, the use cycle of the oil product is greatly prolonged, and the ultra-long oil change aim is achieved.

Owner:北京雅士科莱恩石油化工有限公司

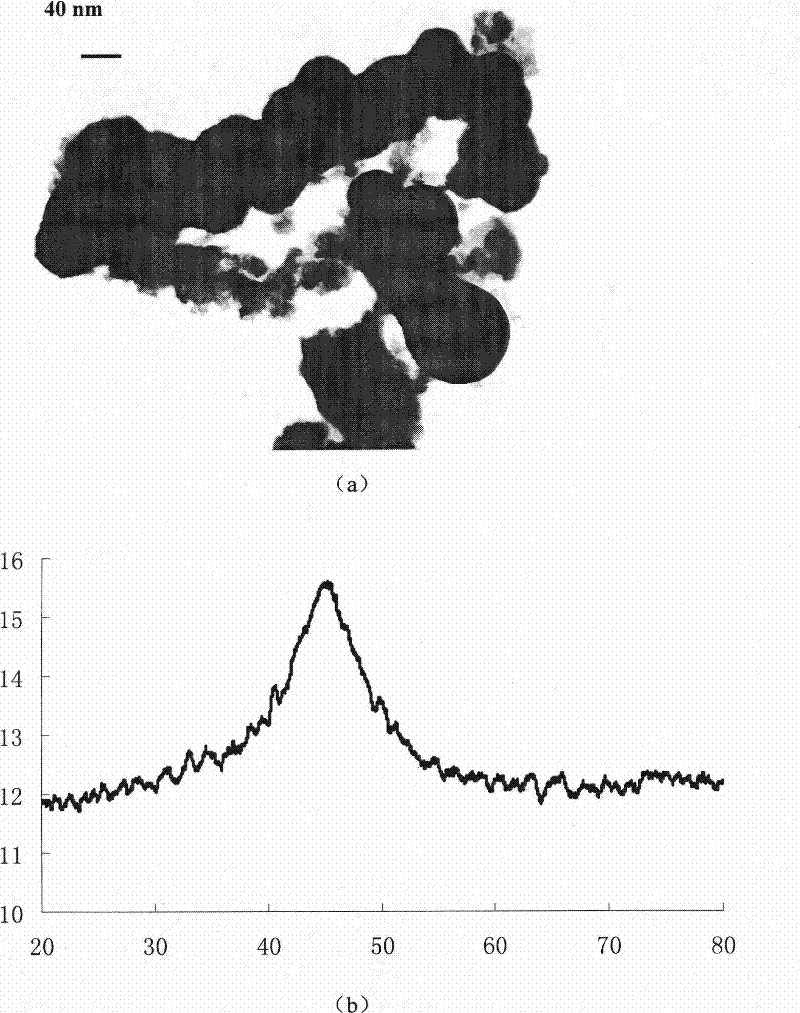

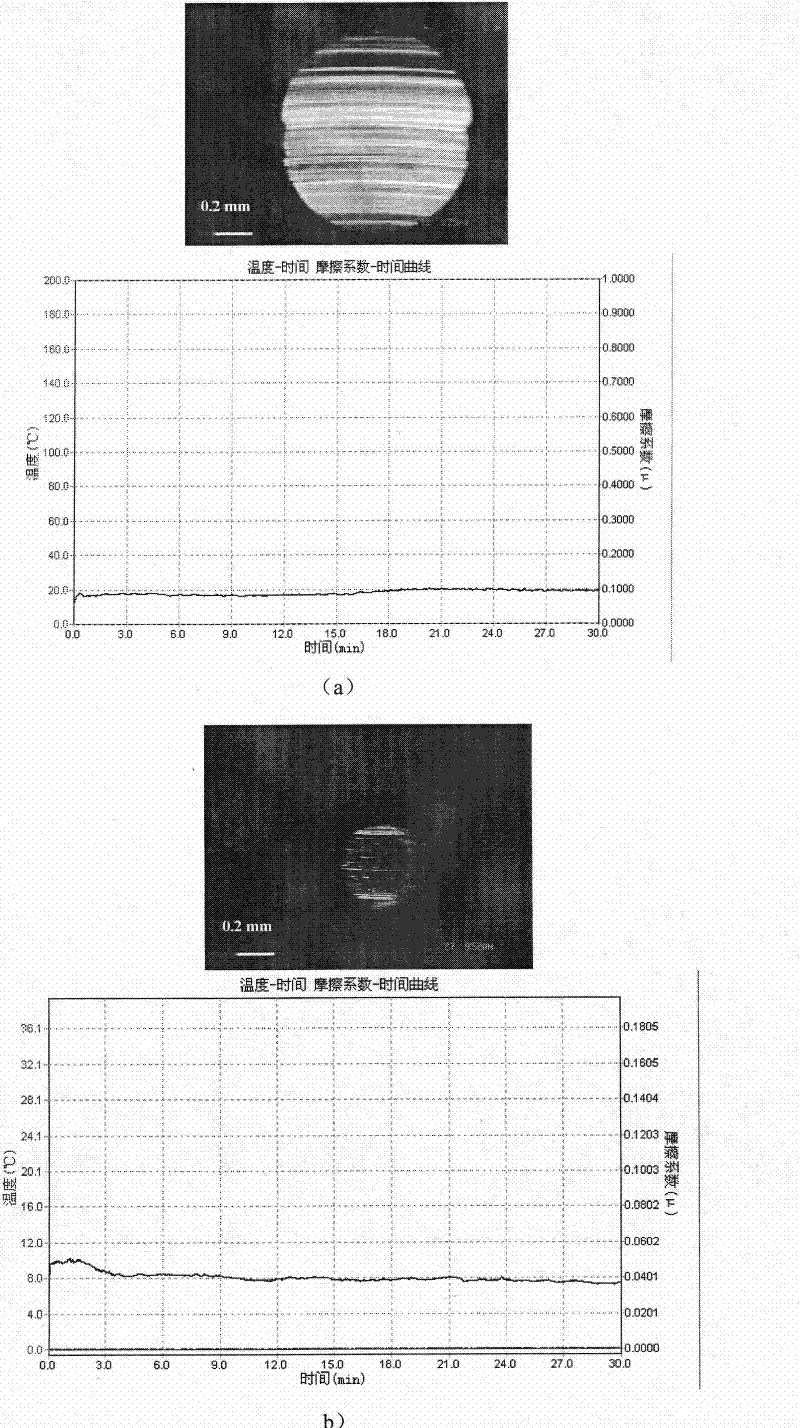

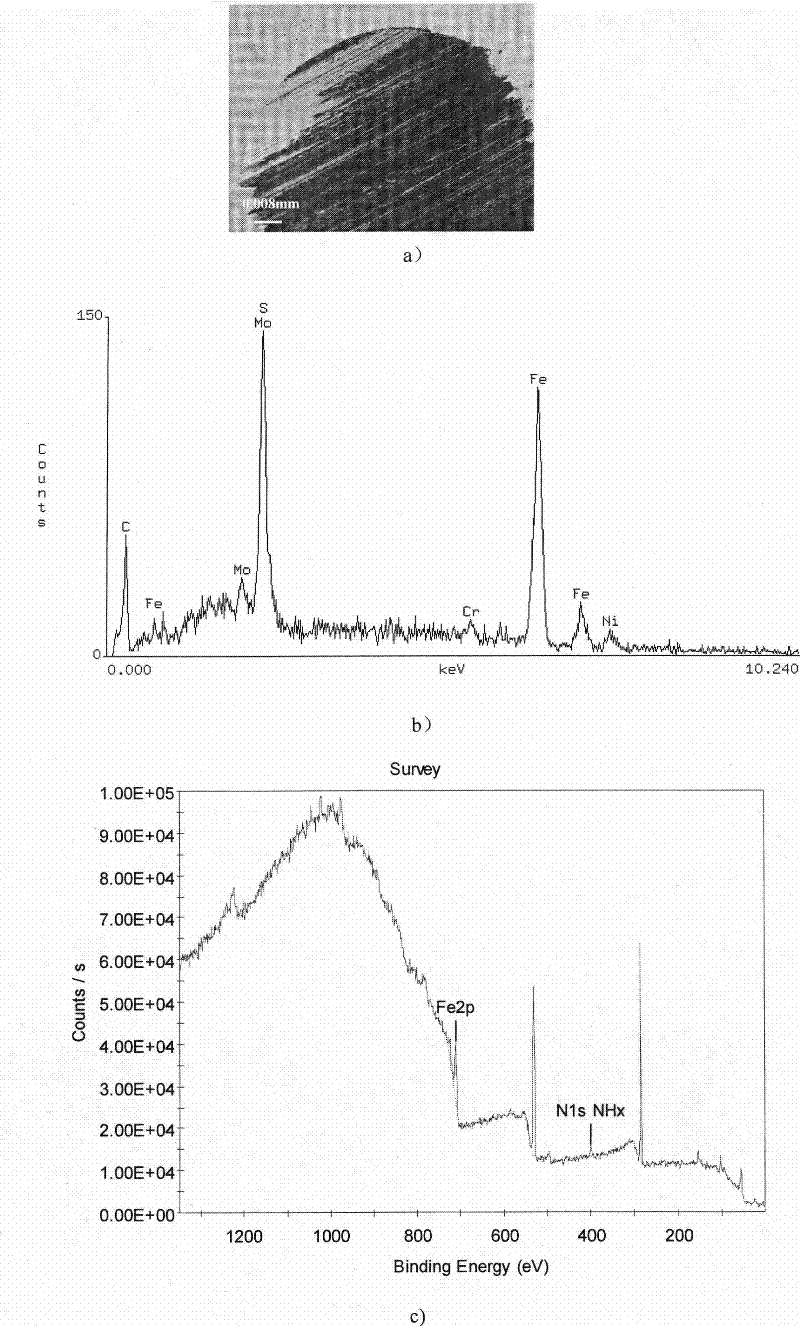

Vehicle engine oil additive and engine oil

The invention provides a vehicle engine oil additive and engine oil. The additive comprises the following components: 15 to 34 weight percent of nano WS2 powder, 0 to 24 weight percent of nano MoS2 powder, 20 to 20.5 weight percent of dispersant, 0 to 0.5 weight percent of antioxidant, 0 to 1 weight percent of metal passivant and the balance of base oil, wherein the kinematic viscosity of the base oil at 40 DEG C is 70 to 190mm2 / s, and the kinematic viscosity of the base oil at 100 DEG C is 12 to 20mm2 / s. The engine oil of the invention comprises 5 to 20 weight percent of additive and 80 to 95 weight percent of petrolic oil or comprises 15 to 25 weight percent of additive and 75 to 85 weight percent of diesel engine oil. The engine oil can improve the service life of engine, reduce oil consumption and has obvious energy-saving and emission-reducing effects and other effects.

Owner:CENT SOUTH UNIV

Lubricating oil containing surface modified carbon nanomaterials and preparation method thereof

The invention relates to lubricating oil containing surface modified carbon nanomaterials and a preparation method thereof, in particular to lubricating oil containing graphene, carbon nanotubes and nanocarbon fibers and a preparation method thereof. Graphene, carbon nanotubes and carbon nanofibers are coated with polydopamine and grafted with long-carbon-chain paraffins correspondingly on surfaceto obtain corresponding modified carbon nanomaterials. The modified carbon nanomaterials, base oil, and other lubricant functional additives are mixed in proportion to obtain the lubricating oil containing the surface modified carbon nanomaterials. The lubricating oil containing the surface modified carbon nanomaterials and the preparation method thereof solve problems of stability and dispersibility, produces ball effects and supporting effects, and further produce a solid-liquid dual-function lubrication mechanism and a stable porous structure, and remarkably improve performance of the lubricating oil.

Owner:HEILONGJIANG HUASHENG GRAPHITE CO LTD

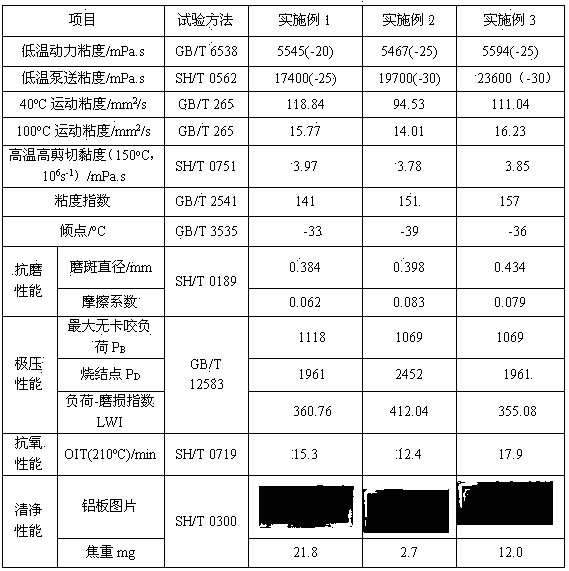

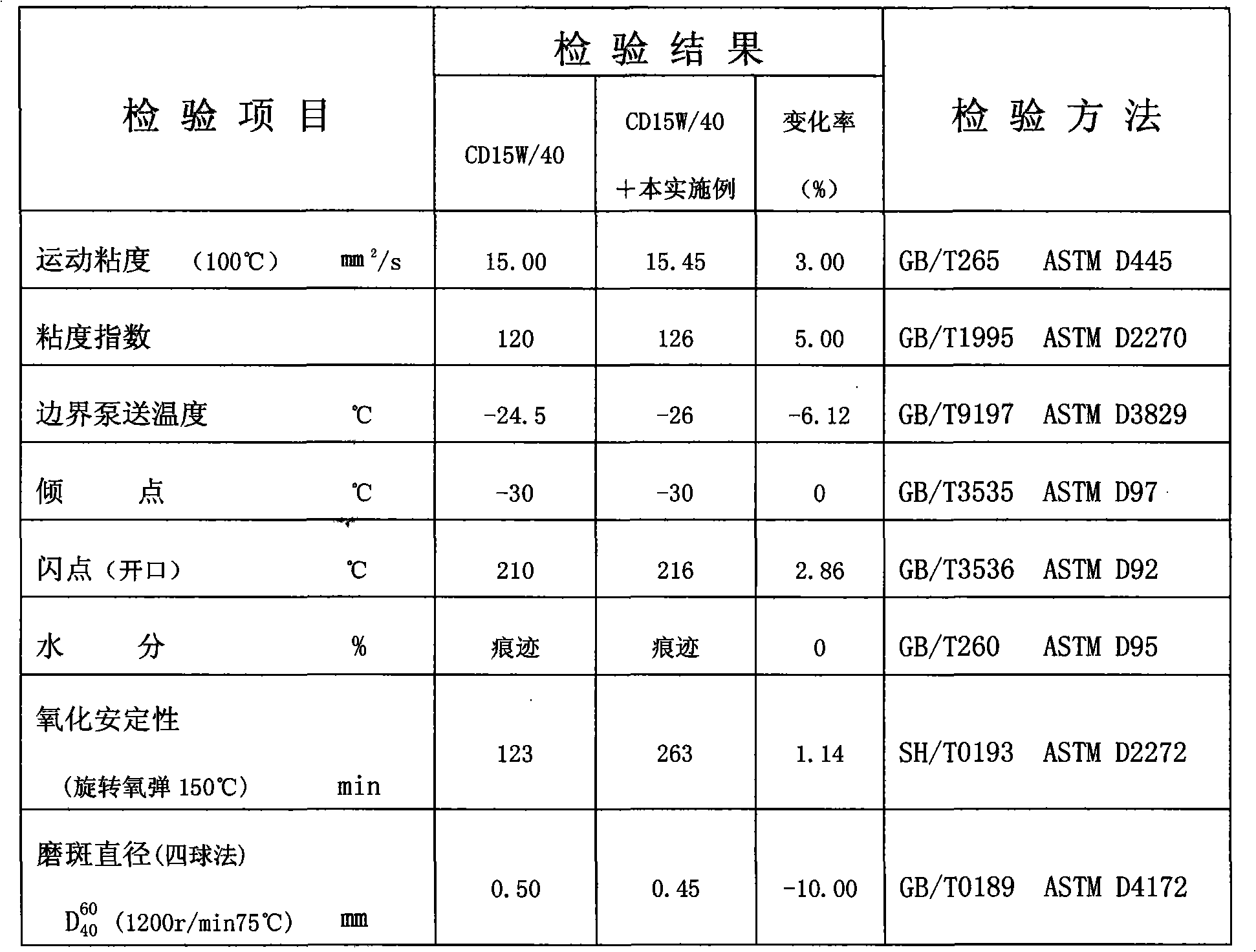

Gasoline engine lubricating coil composition and preparation method thereof

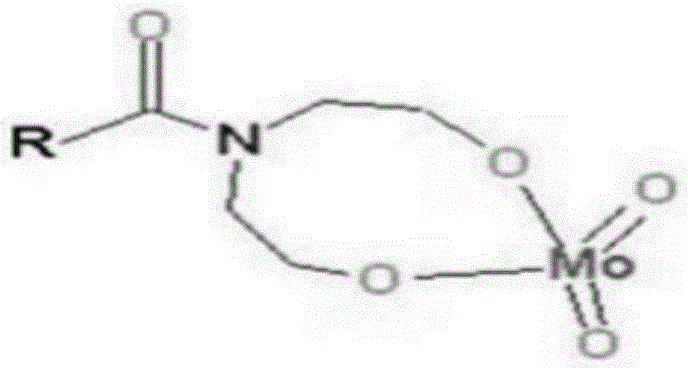

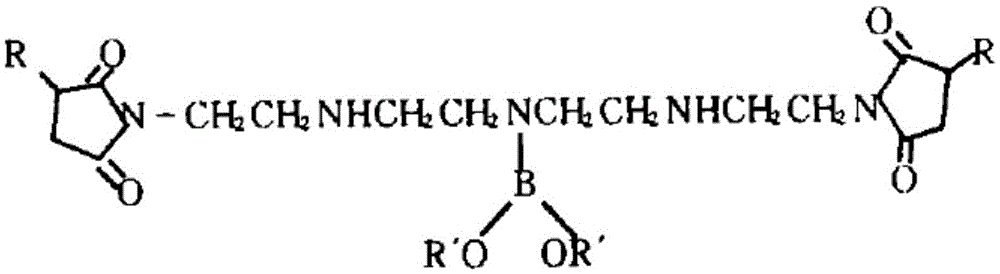

InactiveCN107760419AReduce usageGive full play to the synergistic effectLubricant compositionChemical compositionBoron containing

The invention discloses a gasoline engine lubricating coil composition and a preparation method thereof. The gasoline engine lubricating coil composition comprises the following components in percentby weight: (A) 0.1 to 6.0 percent of an ashless dispersing agent, (B) 0.1 to 8.0 percent of a clearing agent, (C) 0.01 to 1.5 percent of oil-soluble or dispersible oil stability boron-containing compound, (D) 0.003 to 0.5 percent of oil-soluble or dispersible oil stability molybdenum-containing compound, (E) 0.02 to 3.2 percent of zinc dialkyl dithiophosphate, (F) 0.01 to 3.0 percent of an antioxidant and (G) lubricating oil base oil with a main amount, wherein the boron molybdenum mass ratio of the component (C) to the component (D) ranges from 1:5 to 10:1. The blended gasoline engine oil composition contains all of the boron-containing compound, the molybdenum-containing compound and the zinc dialkyl dithiophosphate, completely exerts the synergistic effect between the additives, improves the anti-oxidation property, the anti-wear and friction-reducing properties and the extreme pressure property of the lubricating oil composition and reduces the ash content and the thionazin contentof the lubricating oil composition.

Owner:江西福安路润滑材料有限公司 +1

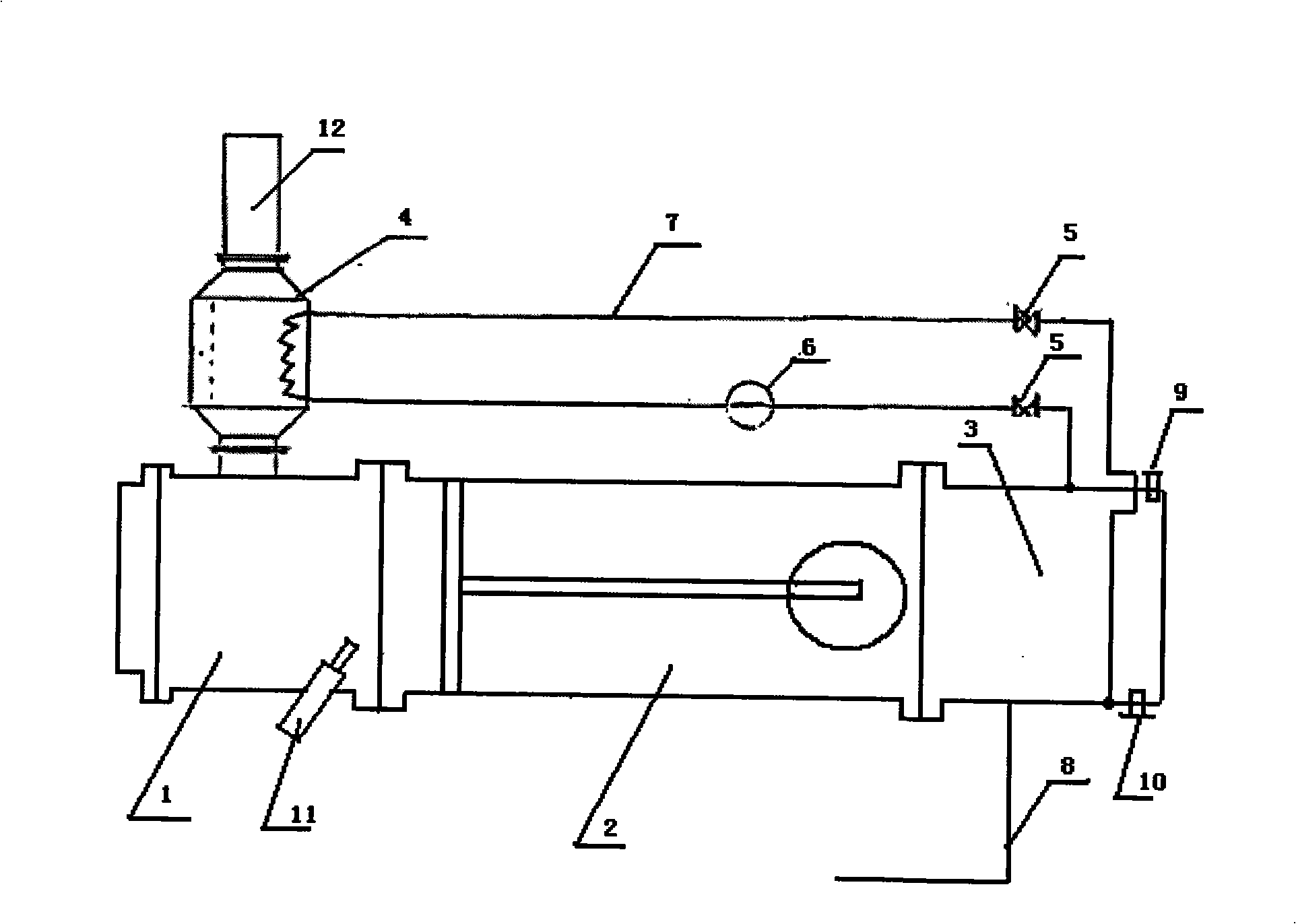

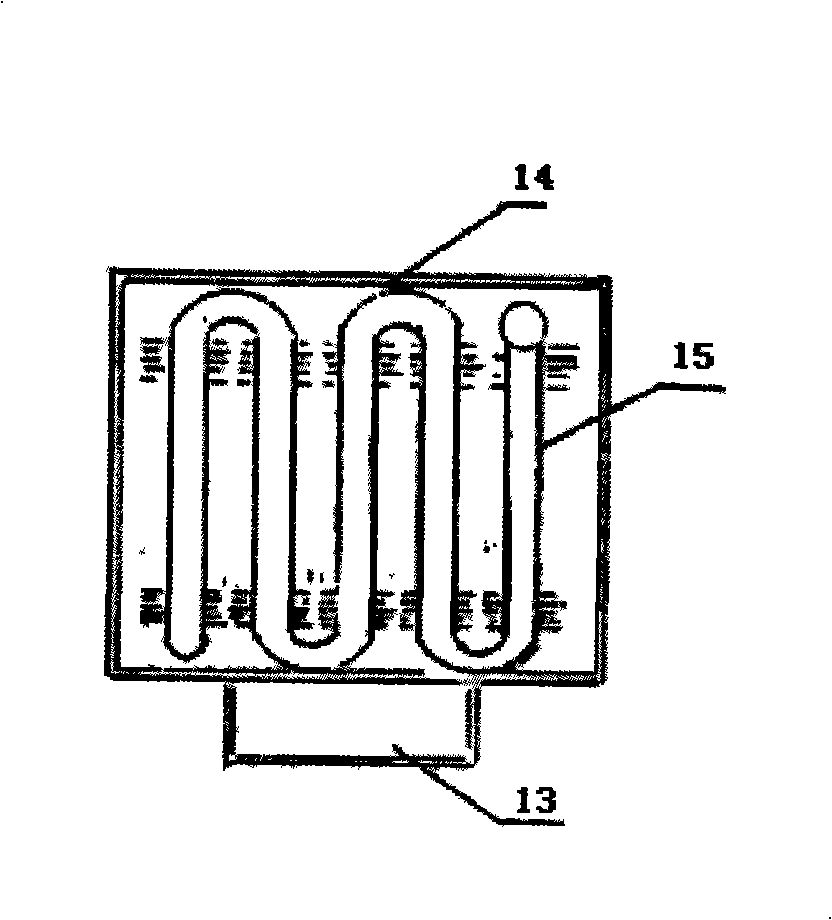

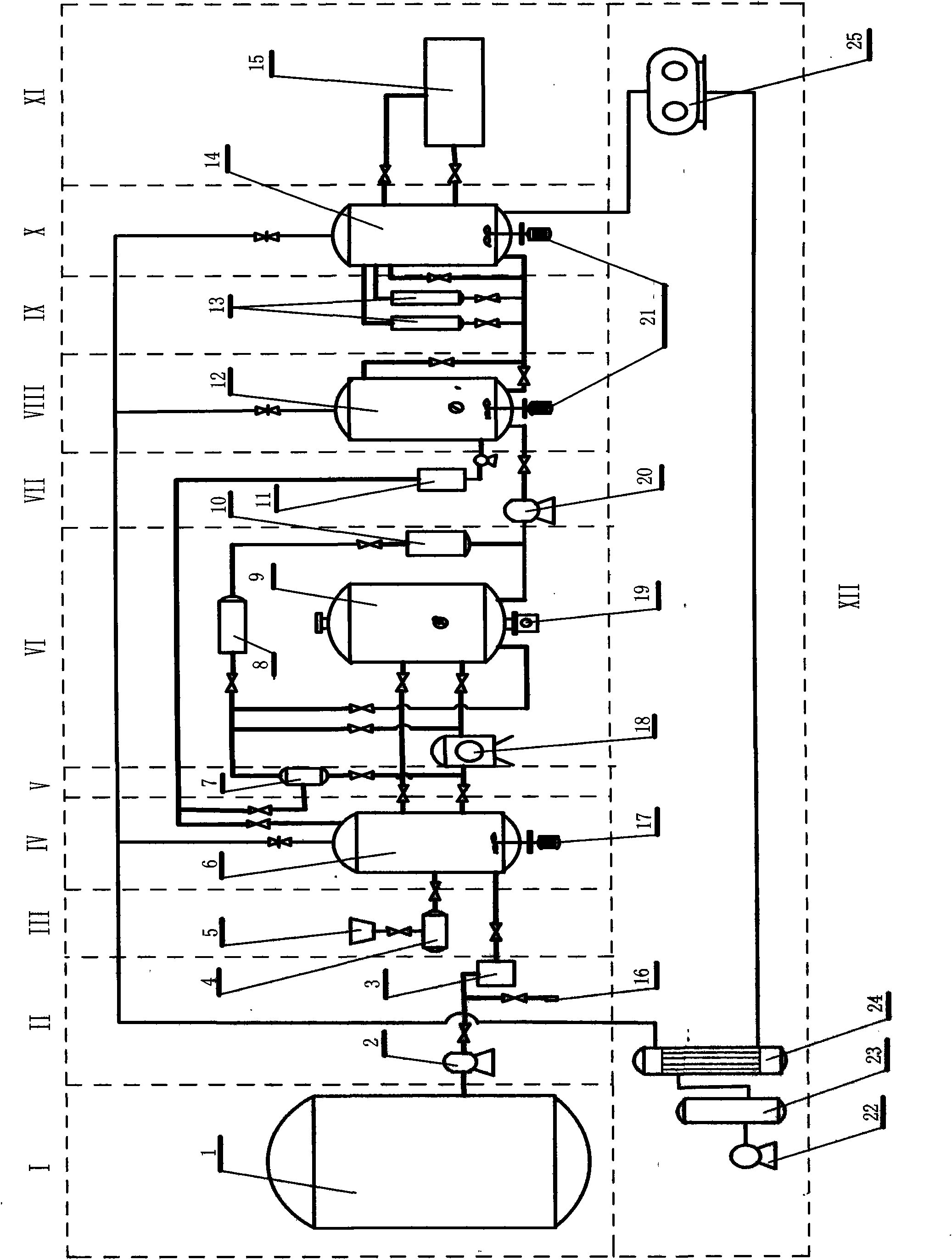

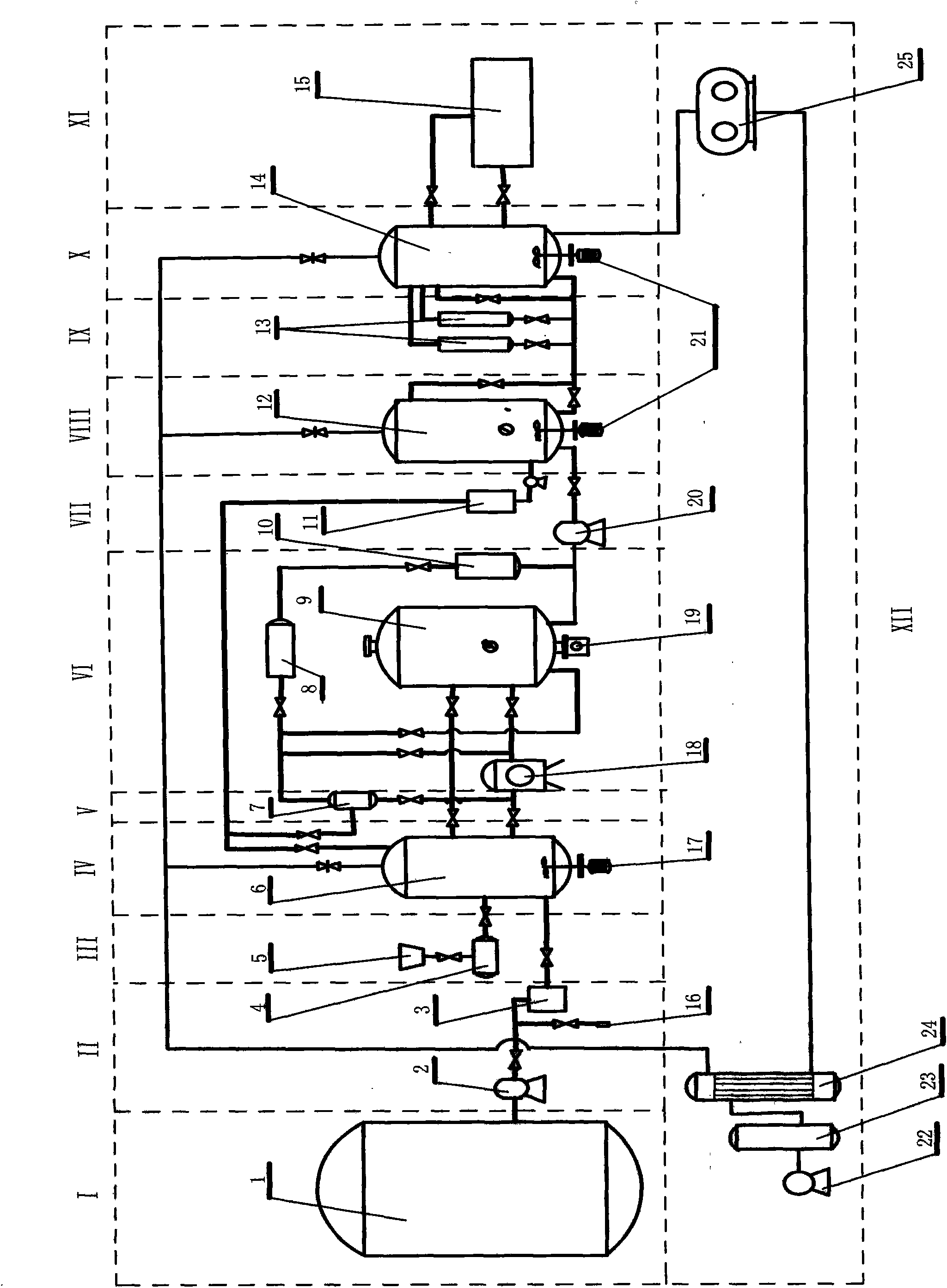

Engine oil processing system

ActiveCN101270682AExtend oil change intervalsExtend engine lifeMachines/enginesLubrication temperature controlAutomotive engineeringBoiling point

The invention relates to a processing system aiming at the dilution problem of engine oil. The processing system comprises a heat exchanger, the engine oil, an insulating tube, an oil pump, an oil pressure sensor, an oil temperature sensor, an oil way switch and a vent pipe used for recycling fuel. When the engine is in operation, if oil pressure valve is below limiting value, an exhaust manifold is used to heat the insulating tube. The engine oil of a control pipeline and the fuel in an oil sump are used to exchange heat to lead bulk temperature to the boiling point of the fuel, thus separating the fuel from lubricant. The separated fuel goes through ventilation system and enters burning system again.

Owner:CHERY AUTOMOBILE CO LTD

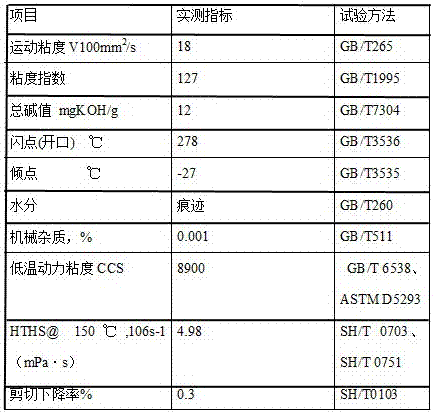

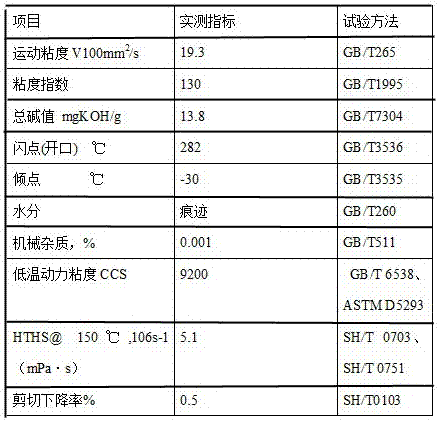

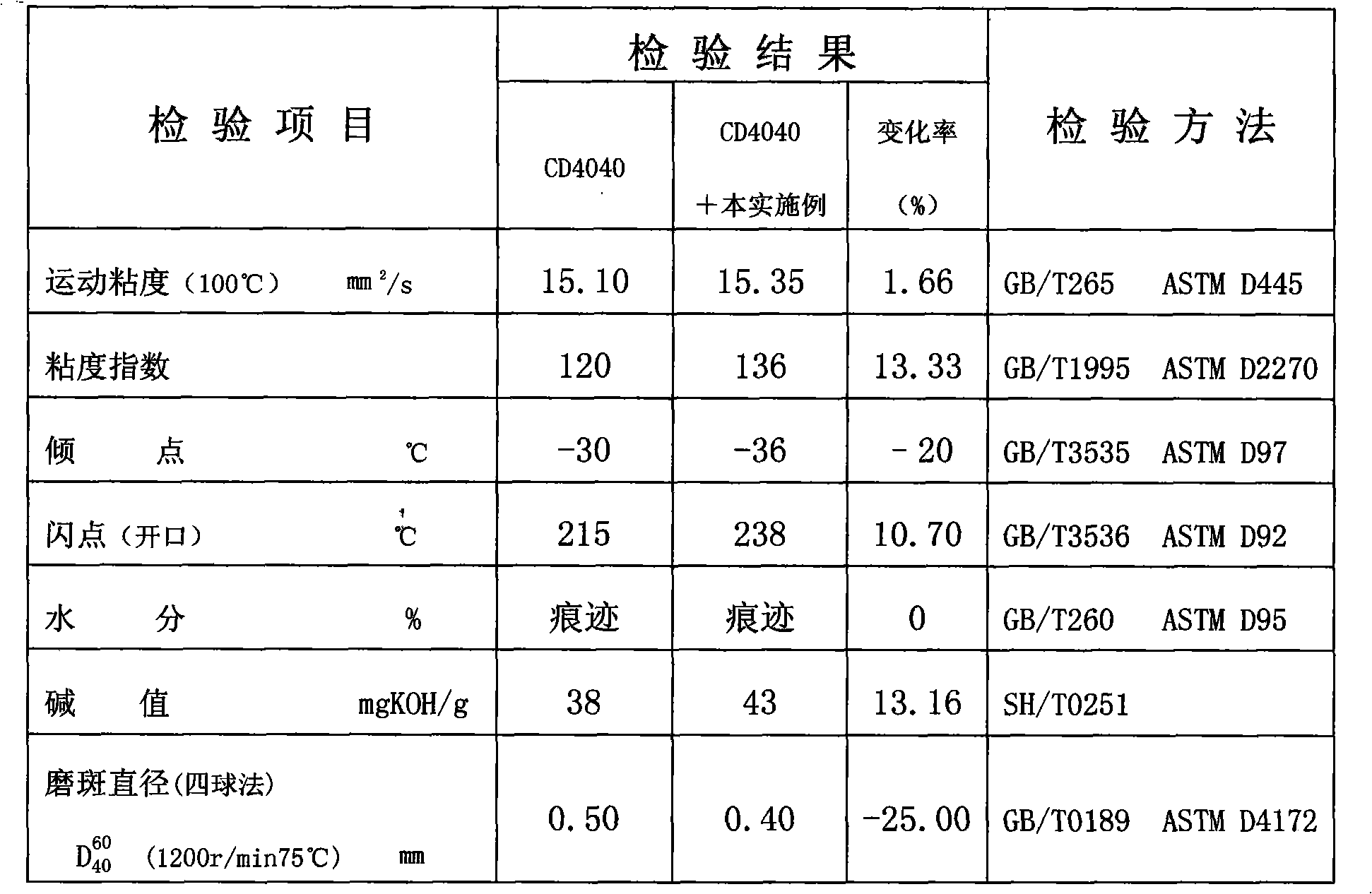

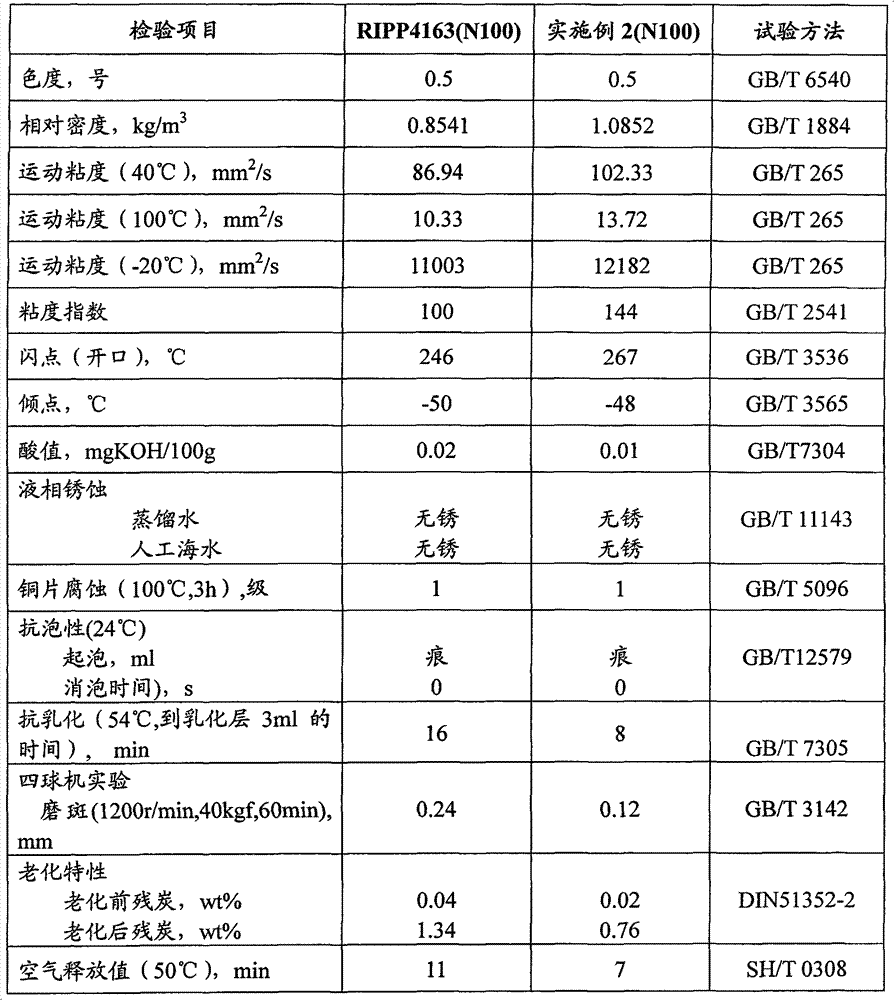

High-pressure-charging long-service-life diesel engine oil and manufacturing method thereof

The invention provides a high-pressure-charging long-service-life diesel engine oil which comprises the following components in percentage by weight: 80-90% of base oil and 10-20% of additive. The base oil comprises 72-80% of paraffin base Type II or Type III, 3-6% of high-viscosity poly-alpha-olefin of which the viscosity is 100-300 mm<2> / s at 100 DEG C and 1-3% of ester oil. The additive comprises 1-3% of hyperalkaline calcium sulfonate, 7-10% of polyisobutylene polysuccimide, 1-3% of sulfurized calcium alkyl phenate, 1-3% of sulfur / phosphorus bis octyl alkaline octyl salt, 0.001-0.005% of oil-soluble graphene, 0.3-1% of amine high-temperature antioxidant, 0.1-0.3% of pour-point depressant and 0.001-0.002% of composite defoaming agent. The diesel engine oil has the advantages of excellent high temperature detergency, excellent acid neutralizing capacity and rust resistance, is capable of effectively reducing high-temperature deposits on engine components and prolonging the oil change period, can inhibit the carbon deposits and paint film on the engine piston from generation, can form a complex micelle with a metallic detergent, has the characteristics of excellent consonance effect, excellent heat stability and outstanding abrasion resistance.

Owner:YANTAI HENGBANG CHEM

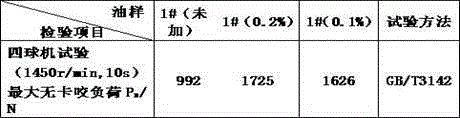

Solid-liquid phase composite internal combustion engine oil additive

InactiveCN101880574ASave fuelExtend oil change intervalsAdditivesLiquid mediumExternal combustion engine

The invention relates to a solid-liquid phase composite internal combustion engine oil additive and a preparation method thereof. The additive consists of a solid lubricating material, a liquid medium and other auxiliary materials. The auxiliary materials consist of a dispersant, an oxidation and corrosion inhibitor, a detergent and a stable dispersant, which are processed into the solid-liquid phase composite internal combustion engine oil additive with a stable dispersion system by high-speed shearing emulsification, ultrasonic oscillation and sanding dispersion. The additive is added into a finished product of the internal combustion engine oil according to a certain proportion. During usage, a liquid-solid composite lubricating film is formed on the surface of a friction pair of an internal combustion engine. The composite lubricating film can improve the lubrication status of the surface of the friction pair of the internal combustion engine so as to reduce the friction and relieve the abrasion. Meanwhile, the energy is saved and the air leakage quantity of the engine is reduced. The air tightness is improved and the power property is enhanced. The service life of the engine is prolonged.

Owner:北京德润同创科技有限公司

Biodegradable lubricating oil

InactiveCN103773555AEmission reductionExtend oil change intervalsAdditivesCopper oxideCleansing Agents

The invention discloses biodegradable lubricating oil. The biodegradable lubricating oil comprises base oil, an anti-oxidant, a rusting inhibitor, an anti-foaming agent, a metal deactivator, a demulsification agent, an antiwear agent, a cleaning agent, a viscosity index improver, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of diarylamine and dithiocarbamate. The rusting inhibitor is an alkylsuccinic acid derivative. The anti-foaming agent is a dimethyl siloxane polymer. The metal deactivator is triazole. The demulsification agent is polyalkoxypolyphenol. The antiwear agent comprises alkyl phosphate ester and salt. The cleaning agent is calcium petroleum sulfonate. The viscosity index improver is an ethylene-propylene copolymer. The biodegradable lubricating oil is prepared by a simple method, has high quality, a long use period, improved extreme pressure resistance, and completely improved oxidation resistance, corrosion resistance and foaming resistance, can be degraded biologically and completely exceeds environmental protection requirements on the same type of products.

Owner:TIANJIN ZEYA TECH

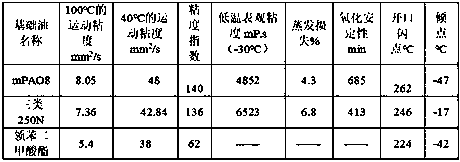

Environment-friendly fully-synthetic diesel engine oil and preparation method thereof

PendingCN111303970AImprove low temperature fluidityImprove liquidityLubricant compositionWaste oilDiesel engine

The invention relates to the technical field of lubricating oil, and particularly provides environment-friendly fully synthetic diesel engine oil which is composed of the following components in partsby weight: 77.2 parts of base oil, 5 parts of a detergent, 3 parts of an ashless dispersant, 1.2 parts of an antirust agent, 0.7 parts of an antioxidant, 4.4 parts of an extreme pressure agent, 0.5 parts of a friction modifier, 7.7 parts of a viscosity index improver, 0.3 parts of a pour point depressant, 0.3 parts of an anti-foaming agent, and 50 ppm of a demulsifying agent. The base oil is prepared by mixing mPAO8 which is catalytically synthesized by adopting metallocene, deeply hydrogenated and optimized straight-chain third-class mineral oil 250N and phthalate, and the mass ratio of mPAO8 to third-class mineral oil 250N to phthalate is 2: 2: 1. The low-viscosity diesel engine oil has the advantages that the base oil is blended according to a scientific proportion, the low-temperaturefluidity of the oil product is effectively improved, the oxidation resistance of the oil product is improved, the oil change period of the oil product is prolonged, the pollution degree of waste oilto the environment is reduced, the energy loss of the low-viscosity diesel engine oil is reduced, and the transmission efficiency of an engine is improved.

Owner:郑州市久润润滑油有限责任公司

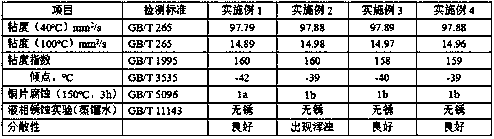

Synthetic compressor lubricating oil composition and production method thereof

InactiveCN102952615AReduce vibrationImprove the lubrication effectLubricant compositionSocial benefitsFoaming agent

The present invention relates to a synthetic compressor lubricating oil composition and a production method thereof. The synthetic compressor lubricating oil composition is prepared by mixing the following raw materials, by weight, 80-90 parts of a liquid A and 10-20 parts of a liquid B, wherein the liquid A is prepared by mixing one or a plurality of poly alpha-olefin synthetic base oil with different viscosities, and the liquid B is prepared by mixing the following additives, by weight, 5.0-15.0 parts of an ester, 0.05-2 parts of an antioxidant, 0.01-2 parts of a rust inhibitor, 0.01-0.5 part of a metal deactivator, 0.5-3 parts of an extreme pressure wear resistance agent, 0.005-0.05 part of anti-emulsification agent, and 0.003-0.01 part of an anti-foaming agent. According to the present invention, stability is high, an oil change period is long, compressor energy consumption can be substantially reduced, a service life of the compressor can be prolonged, significant economic and social benefits are provided, and environmental pollution can not be caused.

Owner:BEIJING ALLUBE PETROCHEM

Antiwear energy-saving environment-friendly diesel engine oil

The invention belongs to the technical field of lubricating oil. The antiwear energy-saving environment-friendly diesel engine oil comprises the following components in percentage by weight: 84.5-86% of base oil, 0.5% of antioxidation and anticorrosion agent, 14.0-15.5% of other additive and 0.05-0.2% of microfluorine solid lubricant powder. The preparation method comprises the following steps: adding base oil into a blending kettle, heating to 65 DEG C+ / -5 DEG C, sequentially adding the tackifier, pour-point depressant, antioxidation and anticorrosion agent and complexing agent while continuously stirring, stirring for 30-40 minutes, and standing to settle; and heating the oil to 65 DEG C+ / -5 DEG C, adding a certain amount of polyhexafluoroethylene superfine micropowder while continuously stirring, stirring for 4-5 hours, and standing to settle to obtain the finished product. Compared with the prior art, the wear-resistant lubricating oil with the polyhexafluoroethylene superfine micropowder has the advantages of reasonable component design, favorable antiwear and antifriction properties, favorable use effect and excellent high temperature resistance, and can prevent the machine from overheating in the high-speed operation process due to the favorable thermal conductivity.

Owner:天津市东宝润滑油脂有限公司

Multifunctional barium-free anti-rusting oil and preparation process thereof

InactiveCN103602492AConcentration is easy to monitor and adjustGuaranteed anti-rust performanceLubricant compositionSulfonateCresol

The invention discloses multifunctional barium-free anti-rusting oil. The multifunctional barium-free anti-rusting oil comprises the following components in percentage by weight: 8%-10% of petroleum calcium sulfonate, 4%-6% of petroleum sodium sulfonate, 2%-5% of S-80, 0.1%-0.5% of T501 / 2, 6 di-tert-butyl p-cresol, 0.3%-0.5% of T706 benzotriazole, 10%-20% of 32# base oil, and 60%-70% of a refined petroleum solvent. The preparation process of the multifunctional barium-free anti-rusting oil comprises the following steps of: adding the refined base oil, the petroleum calcium sulfonate, the S-80 and the petroleum sodium sulfonate into a reaction kettle; heating to 90 DEG C-95 DEG C, cooling to 70 DEG C-80 DEG C after dissolving uniformly, adding the T706 benzotriazole and the T501 / 2, 6 di-tert-butyl p-cresol for uniformly dissolving, preserving the heat for stirring for over half an hour; and finally, filtering and filling into a barrel after diluting by using the refined petroleum solvent. Compared with the prior art, the multifunctional barium-free anti-rusting oil disclosed by the invention has the advantages that anti-rusting requirements of various metals can be satisfied at the same time, an oil film is thin, easy to clean, and the multifunctional barium-free anti-rusting oil is compatible with automobile lubricating oil, can be used for oil assembling, and is barium-free and environment-friendly.

Owner:SHANGHAI THRIVING SPECIAL OIL SCI & TECH

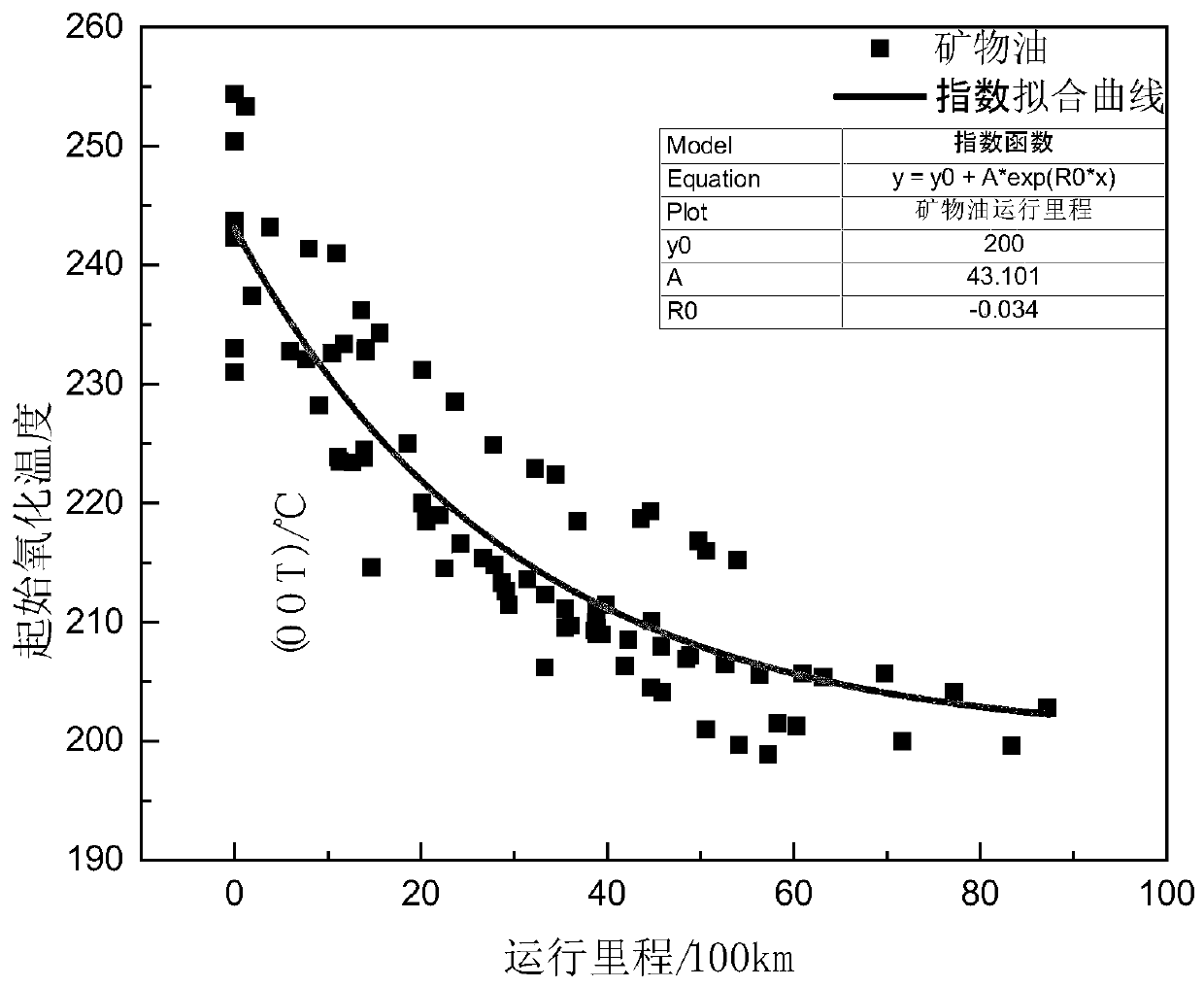

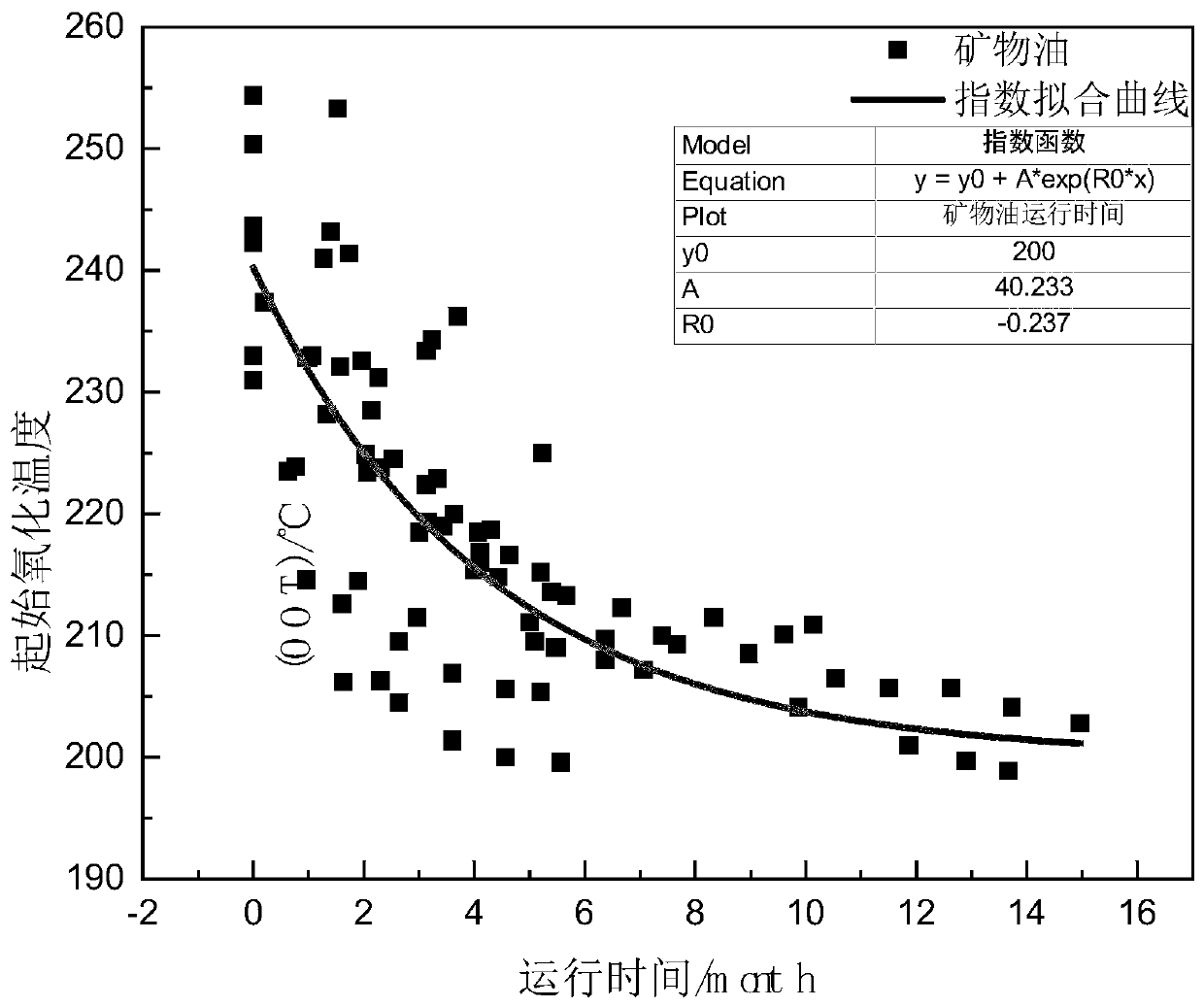

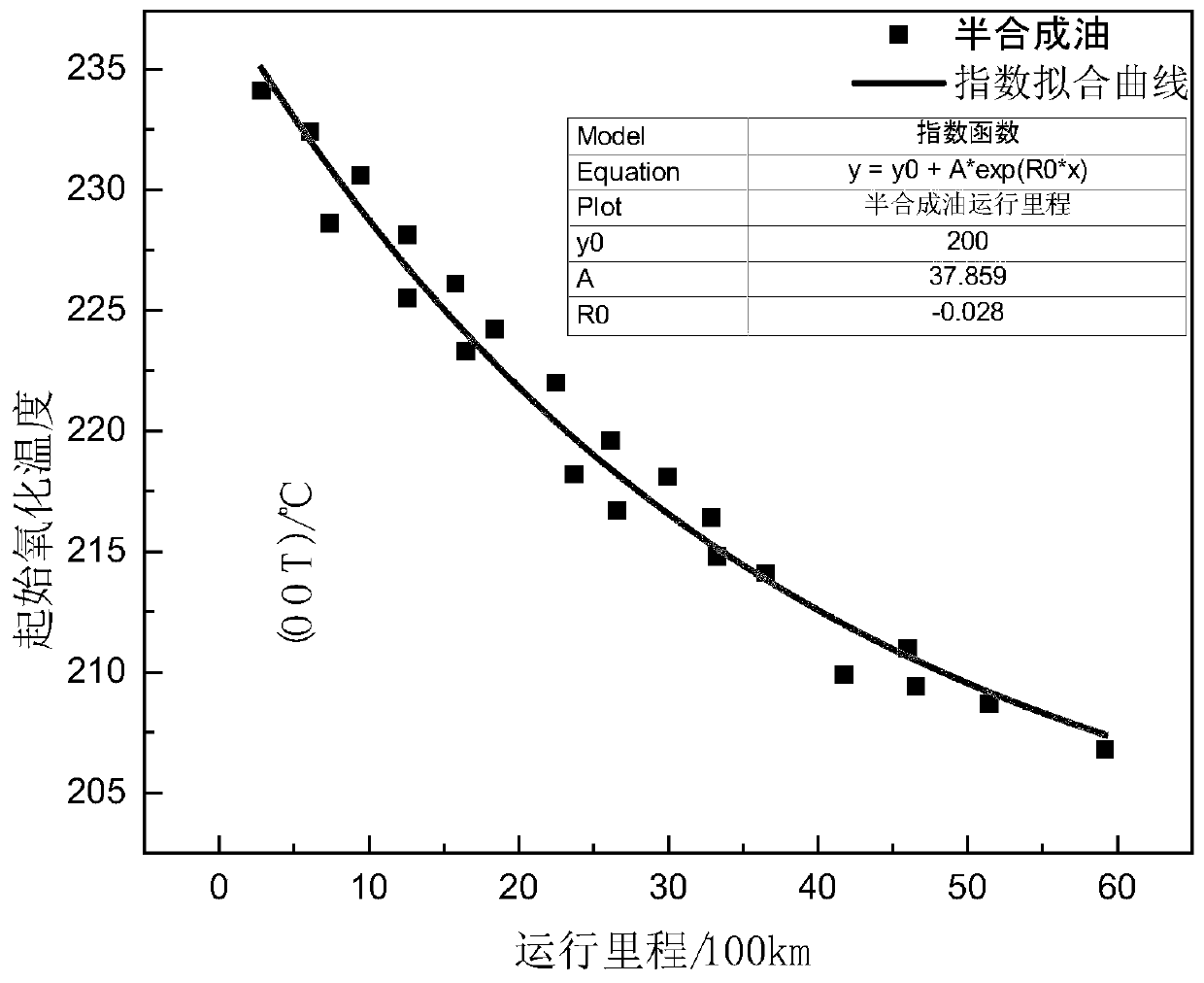

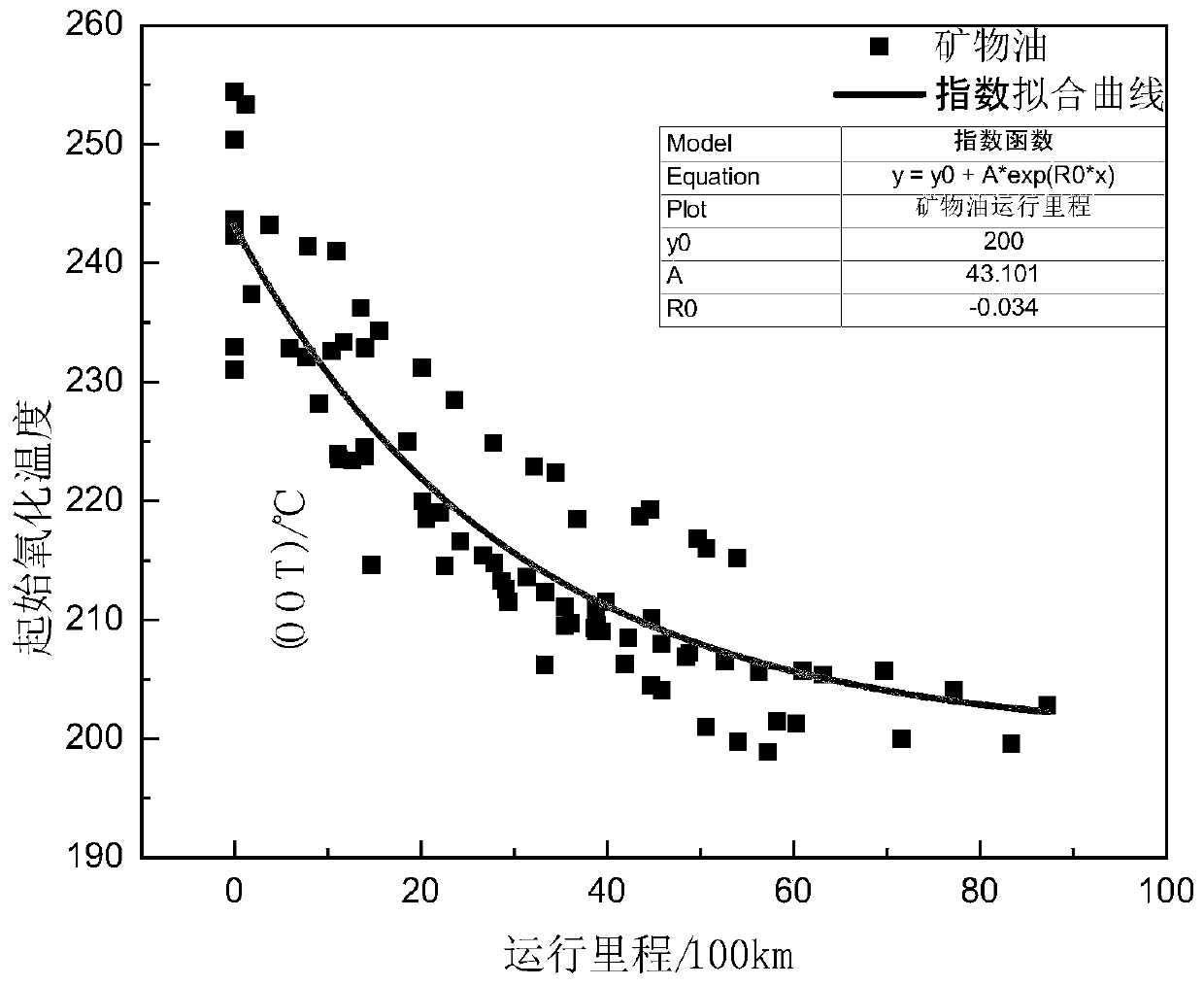

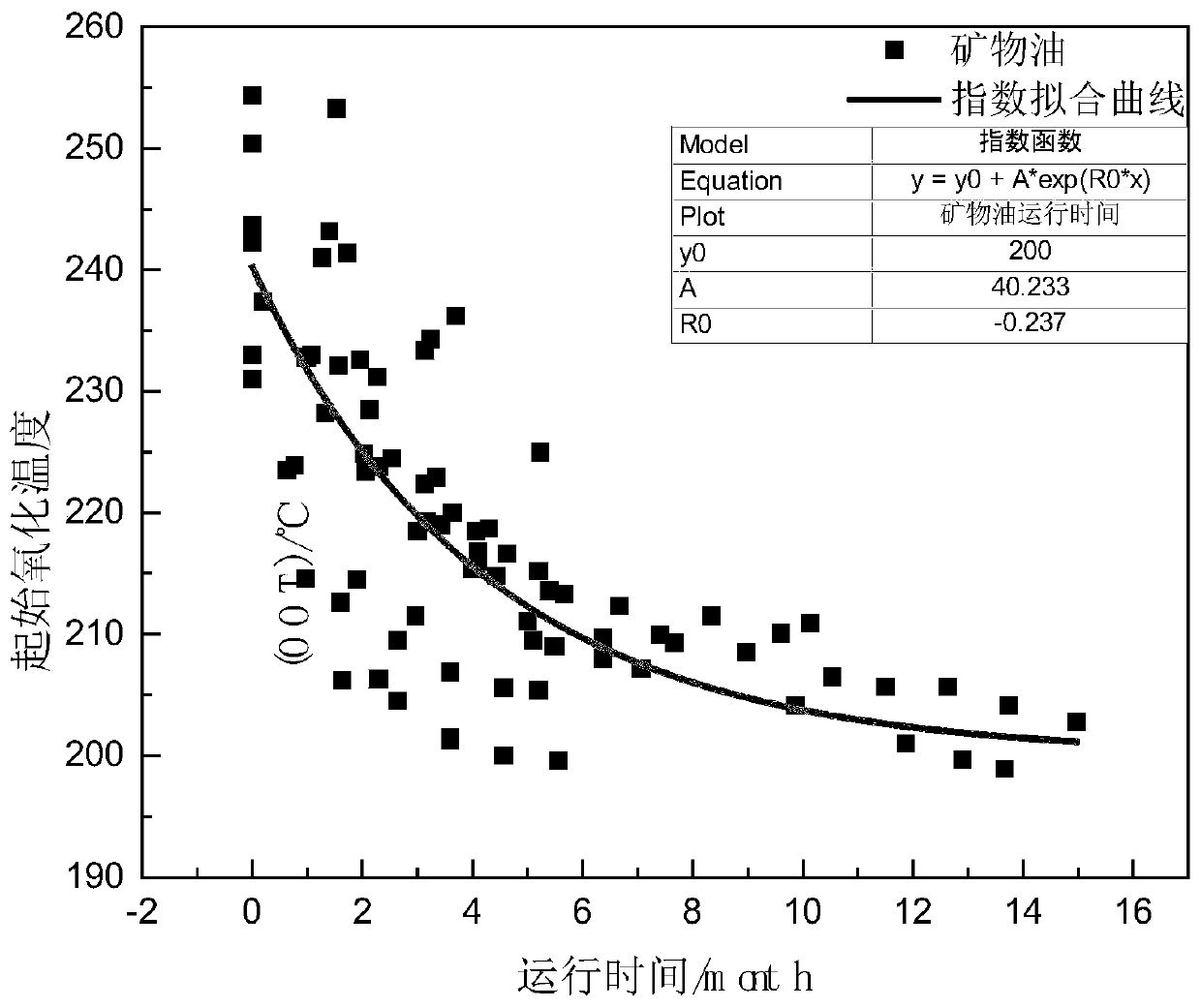

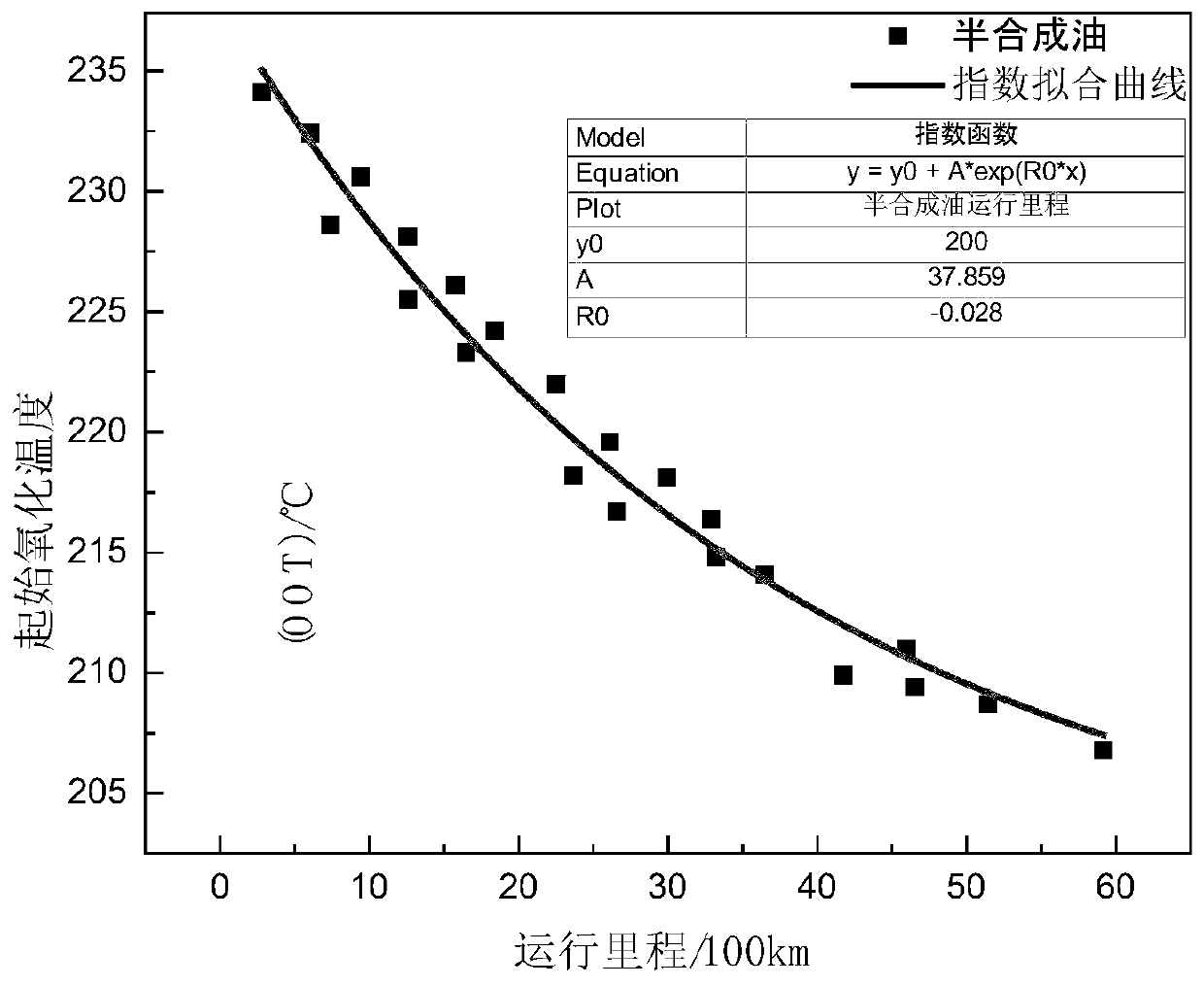

Method for establishing engine lubricating oil quality prediction model

ActiveCN111126685AHigh precisionSimple formulaForecastingComplex mathematical operationsMultiple linear regression analysisProcess engineering

The invention discloses a method for establishing an engine lubricating oil quality prediction model. The method comprises steps of selecting the initial oxidation temperature as a lubricating oil quality reference index; selecting N motor vehicles running under conventional urban working conditions as test objects, carrying out long-time running condition and lubricating oil performance trackingmonitoring, carrying out regular sampling, and at least recording the type of used lubricating oil, the total running mileage, the total running time and the initial oxidation temperature of an oil sample; selecting an exponential function to fit the independent variable and the dependent variable; performing linear transformation on the exponential function; introducing intermediate variables, carrying out multiple linear regression analysis on the intermediate variable, the running mileage and the running time, and completing establishment of the engine lubricating oil quality prediction model; by means of the engine lubricating oil quality prediction model established through the method, the relation between the lubricating oil initial oxidation temperature and the vehicle running mileage and running time can be established, the reasonable oil change period is predicted, lubricating oil waste is reduced, and resources are saved.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Graphene-containing vegetable lubricant and preparation method thereof

InactiveCN106350167AReduce friction lossGood friction and lubrication propertiesLubricant compositionSucrosePolymethyl methacrylate

The invention discloses a graphene-containing vegetable lubricant. The graphene-containing vegetable lubricant is prepared from the following raw materials: castor oil, modified castor oil, liquid graphene, trimethyl citrate, N,N-dimethylacetamide, modified nano cerium vanadium oxide, modified sodium carboxymethylcellulose, sucrose ester, an organic molybdenum compound, dodecyl selenium, 4-hydroxy-4-methyl-2-pentanone, benzotriazole, polymethyl methacrylate, 1-butyl-3-vinyl imidazole hexafluoroantimonate, polyurethane, cyclohexane and an organic anti-aging agent. The graphene-containing vegetable lubricant disclosed by the invention has the advantages that the castor oil and other additives are combined, an environment-friendly vegetable lubricant is prepared, the balance of properties is achieved by controlling the types and quantity of the additives, the vegetable lubricant has better oxidation resistance and self-cleaning capability and also has good lubricating property, viscosity-temperature characteristic, low temperature fluidity, low volatility, corrosion resistance, anti-foam property and anti-emulsifying property, and the overall performance is good.

Owner:梁海东

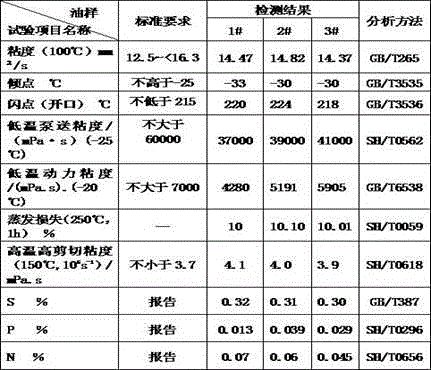

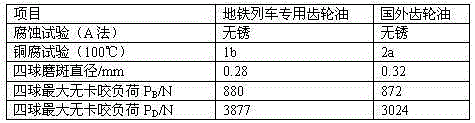

Subway train special gear oil and preparation method

InactiveCN105296115APrevent severe heatImprove high temperature stabilityAdditivesHigh torqueHeavy duty

A subway train special gear oil is particularly suitable for using in high temperature and extreme pressure work status of a subway train in frequent start, braking and high-speed operation, has excellent high temperature stability, resistance to extreme pressure and anti-wear properties and high temperature oxidation resistance, ensures subway train gearboxes maintain stable oil films under very heavy duty conditions, reduces noise, prevents gear wear, can effectively prevent and subway train low rotation speed / high torque wear and intense heat produced in high-speed operation, and is especially suitable for using in high temperature and extreme pressure work status of the subway train in frequent start, braking and high-speed operation. By use of the subway train special gear oil, the gear oil change period may be extended by more than 20%, and the subway operating cost is reduced.

Owner:JIANGXI KIRBY LUBRICANT PROD

Novel metal magnetic lubricating oil additive and preparation method thereof

InactiveCN103333729AEnergy saving, environmental protection and high efficiencySave fuelAdditivesSolubilityAntioxidant

A purpose of the present invention is to provide a novel environmental protection non-sulfur-phosphorus metal magnetic lubricating oil additive with characteristics of simple production method, low cost, good oil solubility and high yield, and a preparation method thereof. The novel metal magnetic lubricating oil additive is characterized in that the additive is prepared from mixed amide, molybdenum oxide, tungsten oxide, hydroxyethyl ethylene diamine and ammonia water according to a weight ratio of 100:8.5-10:8.5-10:10-15:10-15, wherein the mixed amide is prepared through carrying out a reaction of tall oil, diethanolamine and methyl oleate. The additive is an oil-soluble metal magnetic tungsten-molybdenum-nitrogen complex, is a friction modifier, an anti-wear agent and an antioxidant for internal combustion engine motor lubricating oil, has a significant oil saving effect, and does not contain sulfur and phosphorus so as to further provide advantages of energy saving and environmental protection.

Owner:LIAONING QIZHONG LUBRICATING OIL MFG

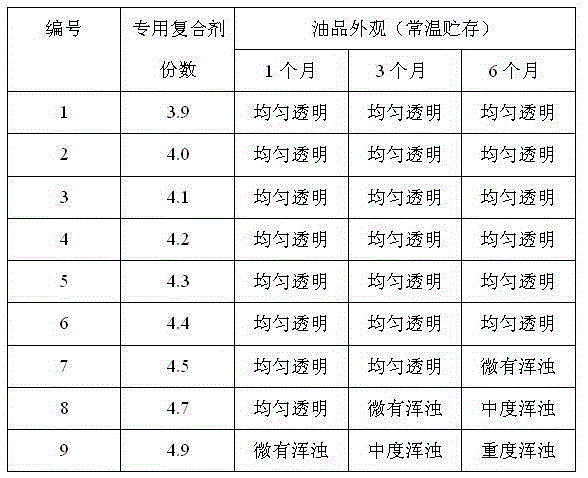

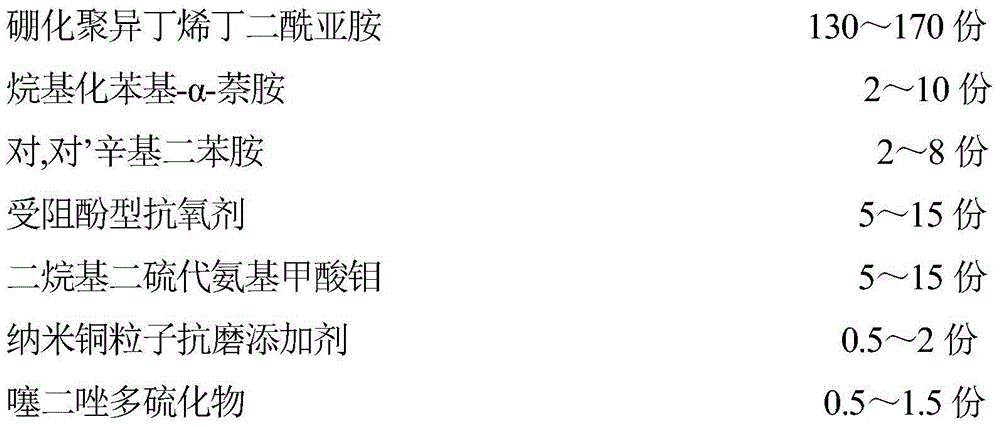

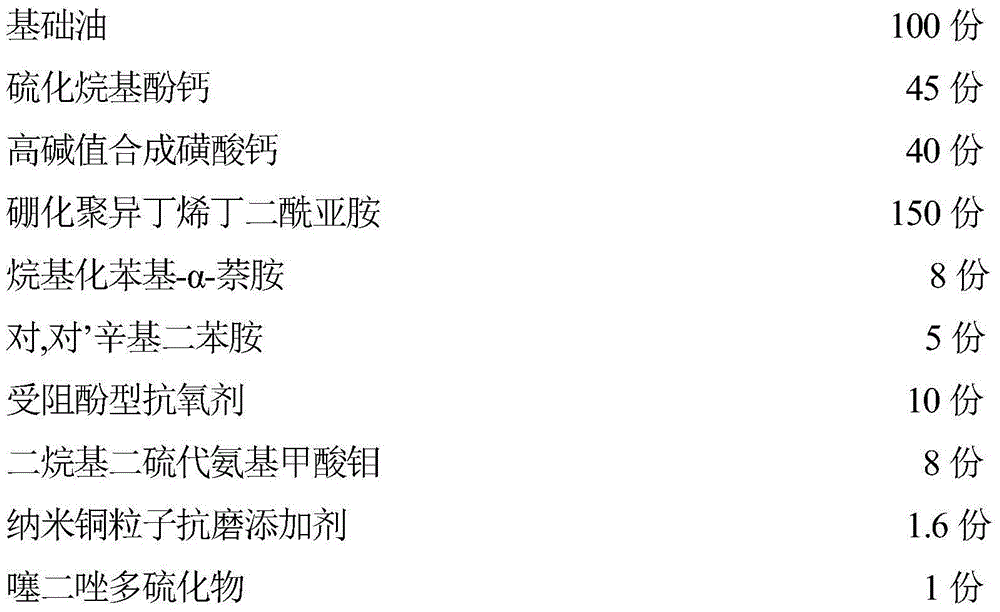

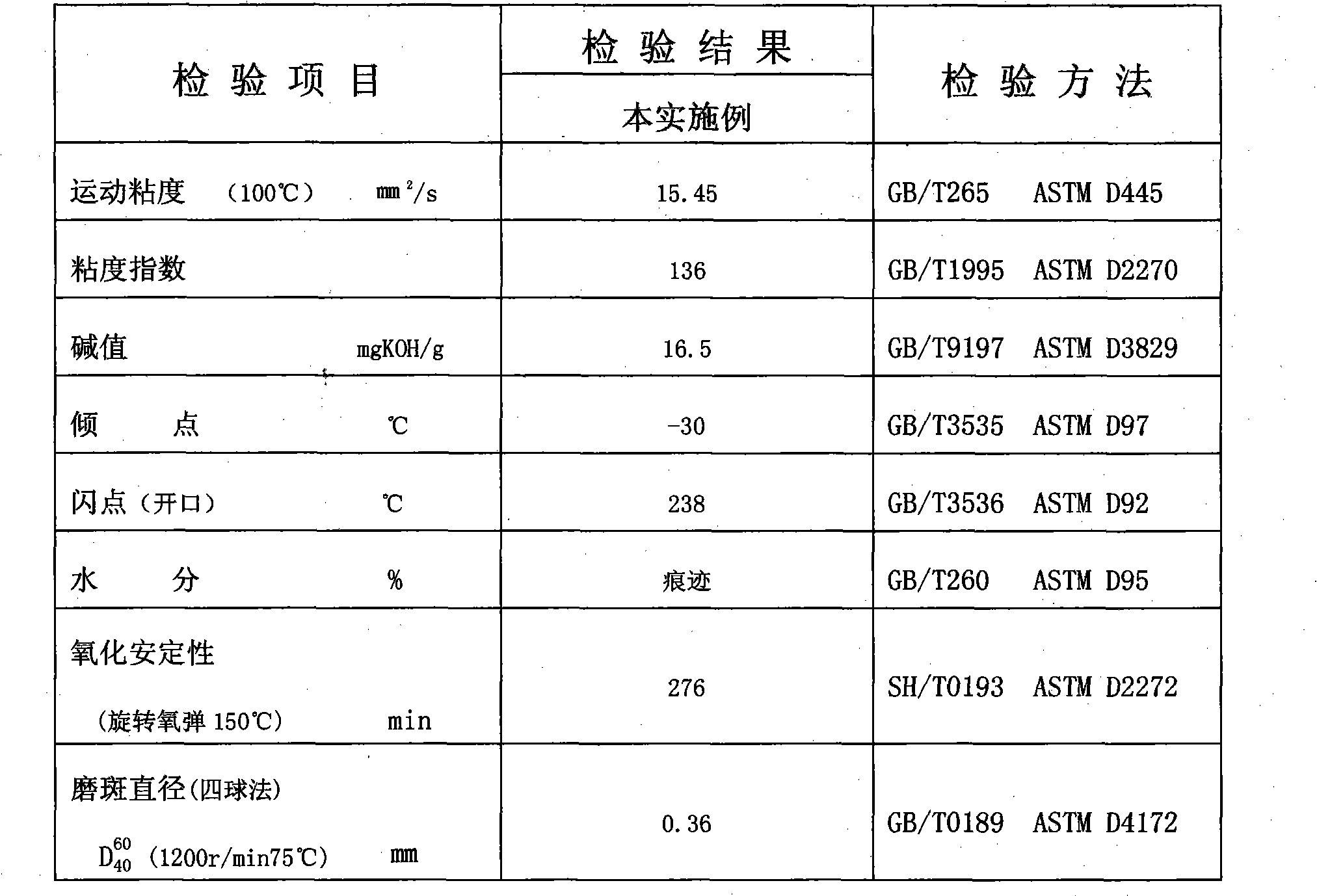

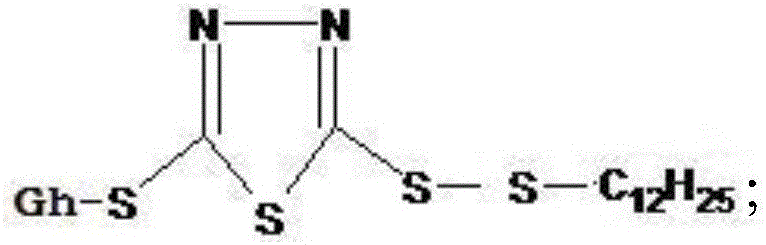

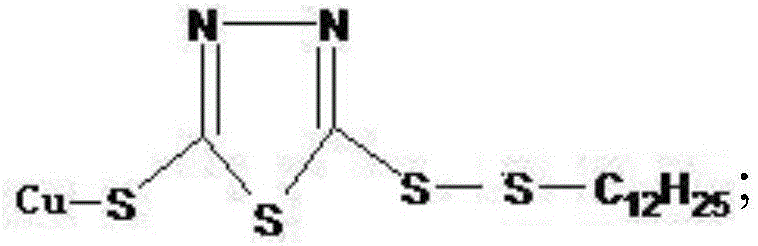

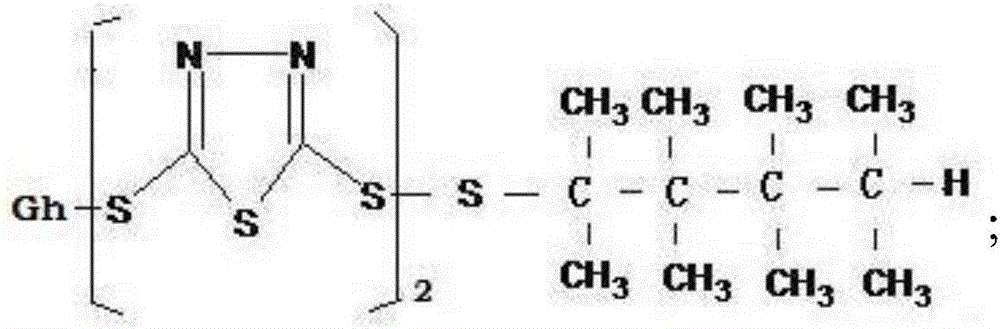

Lubricating oil compound additive for compressed natural gas engine

The invention discloses a lubricating oil compound additive for a compressed natural gas engine. The lubricating oil compound additive consists of the following components in parts by weight: 100 parts of base oil, 30-70 parts of sulfurized calcium alkyl phenate, 20-50 parts of high alkali value synthesized calcium sulfonate, 130-170 parts of borated polyisobutylene succinimide, 2-10 parts of alkylated phenyl-alpha-naphthylamine, 2-8 parts of p,p'-octyl diphenylamine, 5-15 parts of a hindered phenol-type antioxidant, 5-15 parts of molybdenum dialkyldithiocarbamate, 0.5-2 parts of a nano-copper particle antiwear additive, and 0.5-1.5 parts of thiadiazole polysulfide. The lubricating oil compound additive can be used for blending compressed natural gas engine oil of various quality grades, and can be particularly used for blending a special lubricating oil for a heavy-load compressed natural gas engine of a bus, the product blended by use of the lubricating oil compound additive is excellent in product performance, and has longer oil exchange period as well as relatively excellent lustration dispersivity, lubricating performance, abrasion resistance and oxidation resistance, and the additive dose is 6.0%-7.2%, and is lower than the average addition level of the industry.

Owner:陕西通用润滑科技有限公司

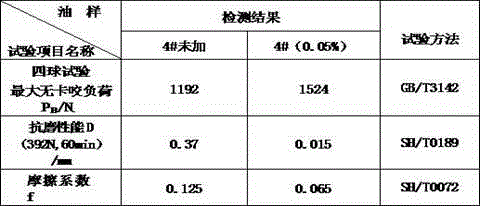

Solid-liquid phase composite internal combustion engine oil

The invention relates to a solid-liquid phase composite internal combustion engine oil. According to the theory of solid-liquid phase composite lubrication technology, and aimed at the requirements of the performance, characteristics, working conditions and the like of an internal combustion engine on a lubrication system, the invention provides a technical scheme for the solid-liquid phase composite internal combustion engine oil composition and a preparation method thereof. The components of the oil include solid lubricant material, liquid medium and other auxiliary materials-dispersing agent, oxidation and corrosion inhibitor, detergent additive, internal combustion engine oil complexing agent, defoaming agent and stabilizing and dispersing agent, which are processed into the solid-liquid phase composite internal combustion engine oil with a stable dispersion system by high-speed shearing emulsification, ultrasonic oscillation and sanding dispersion.

Owner:北京德润同创科技有限公司

Graphene-based high-molecular nanometer alloy anti-wear self-repairing material, and preparation method and application thereof

ActiveCN106085551AImprove bearing capacityImprove reliabilityOrganic chemistryAdditivesCombustionGraphene

The invention relates to an anti-wear self-repairing material, especially to a graphene-based high-molecular nanometer alloy anti-wear self-repairing material and a preparation method and application thereof, belonging to the field of high-molecular materials. A graphene-based high-molecular nanometer alloy anti-wear self-repairing agent prepared in the invention realizes the breakthrough that heavy-load anti-wear anti-attrition effect almost reaches the level of zero wearing and overcomes the two world-famous problems of proneness to agglomeration and precipitation and incapability of better performing extreme-pressure anti-wear effect of a metal nanometer anti-wear material in fluid lubrication products; the agent provides core technological guarantee for development fluid lubrication technology and mechanical equipment towards impact resistance, heavy load, high carrying capacity, miniaturization, low viscosity, low energy consumption and high reliability; and the agent provides superhigh engine performance and protection effect, guarantees economic performance of vehicle combustion and has superstrong anti-wear and lubrication performance, metal deactivation performance and the performance of self-repairing of metal wearing.

Owner:YANTAI HENGNUO CHEM TECH CO LTD

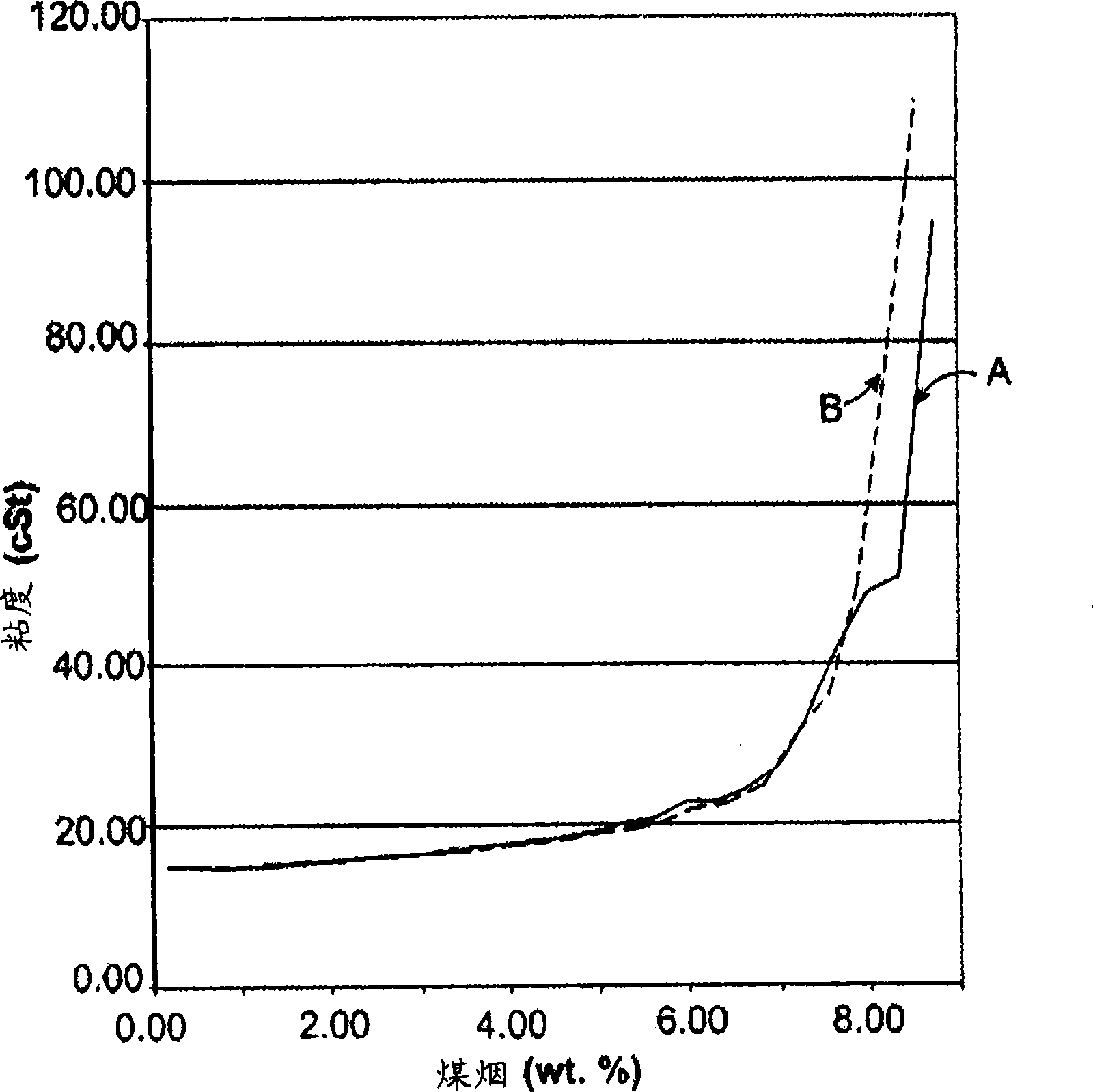

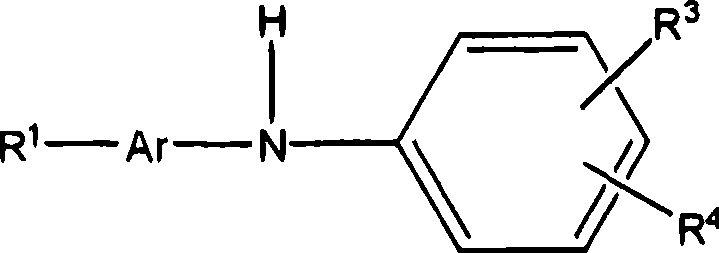

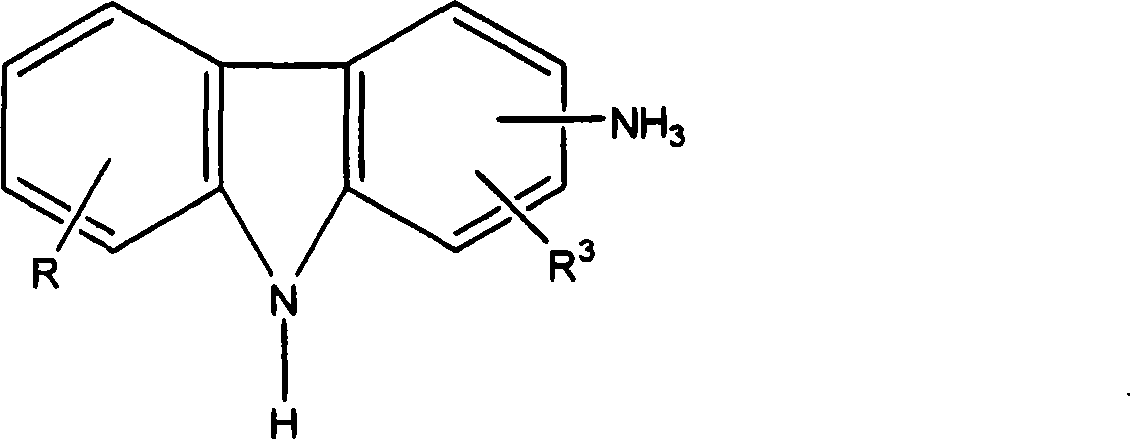

Lubricant composition for bio-diesel fuel engine applications

A diesel engine operating on a fuel containing from about 5 to about 100 wt. % biodiesel components is lubricated with a lubricating oil composition including a major amount of oil of lubricating viscosity, and a minor amount of at least one highly grafted, multi-functional olefin copolymer. The olefin copolymer is made by reacting an acylating agent with an olefin copolymer having a number average molecular weight greater than about 1,000 in the present of a free radical initiator to provide an acylated olefin copolymer having a degree of grafting (DOG) of the acylating agent on the olefin copolymer of at least 0.5 wt.%, and reacting the acylated olefin copolymer with an amine to provide the highly grafted, multi-functional olefin copolymer. As used, the highly grafted, multi-functional olefin copolymer is effective to reduce a viscosity increase in the lubricating oil composition for the engine.

Owner:AFTON CHEMICAL

Biodegradable lubricating oil

InactiveCN103194299AGood emissionExtend oil change intervalsLubricant compositionWorking temperatureCopper oxide

The invention relates to a biodegradable lubricating oil. The biodegradable lubricating oil is composed of base oil, an antioxidant, a corrosion inhibitor, an antifoaming agent, a metal deactivator, a demulsifier, an anti-wear agent and copper oxide powder, wherein the base oil is composed of synthetic base oil poly(alpha-olefin), synthetic base oil synthetic fat and synthetic base oil polyether; the antioxidant is anyone or a mixture of diarylamine and sterically hindered phenol, wherein the weight ratio of diarylamine to sterically hindered phenol in the mixture is 1:1; the corrosion inhibitor is a salt formed through using fatty acid and amine; the antifoaming agent is polydimethylsiloxane; the metal deactivator is a toluyltriazole derivative; the demulsifier is polyalkoxyphenol; the anti-wear agent is sulfurated triphenyl phosphate; and the copper oxide powder is nanometer powder, and the particle granularity of the powder is 25-35nm. The biodegradable lubricating oil has the advantages of simple preparation method, scientific and environmentally-friendly preparation scheme, degradability, high work temperature range, good lubricating characteristic, long service life, good protection to parts, high comprehensive performances, reasonable cost, realization of above 90% biodegradation of waste oil, extremely low gas discharge, and obvious energy saving effect.

Owner:陈冬梅

Wear-resisting energy-saving agent for lubricating oil, its preparation method and application

The present invention provides an antiwear energy-saving agent containing refined mineral oil, zinc dialkyl dithiophosphate and deactivator for lubricating oil, it possesses excellent functions of reducing friction, reducing wear, resisting rust, resisting corrosion and resisting oxidation, and has strong cleaning dispersing power and good extreme pressure resistance and long-acting lubricating property and excellent compatibility with lubricant. This invention also provides its preparation method and application to lubricating oil and soaking field.

Owner:臧玉蓉 +1

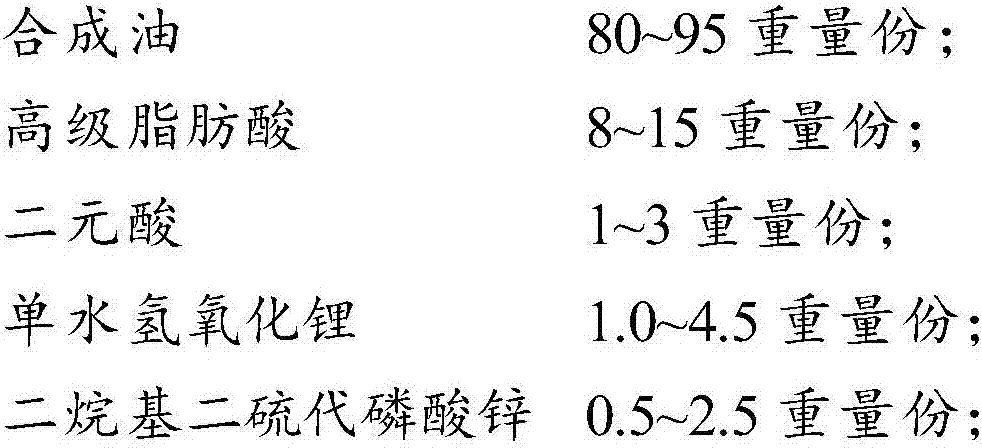

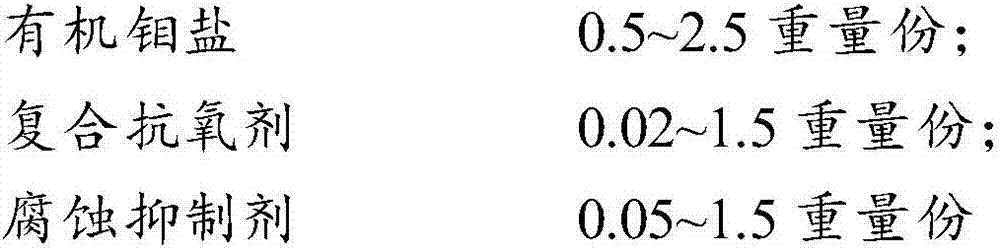

Hub bearing lubricating grease for electric automobile as well as preparation method thereof

InactiveCN107987940AImprove wear resistanceExtend oil change intervalsLubricant compositionPhenolic antioxidantEngineering

The invention provides hub bearing lubricating grease for an electric automobile. The hub bearing lubricating grease for the electric automobile is prepared from water and the following components inparts by weight: 80 to 95 parts of synthetic oil, 8 to 15 parts of higher fatty acid, 1 to 3 parts of binary acid, 1.0 to 4.5 parts of lithium hydroxide monohydrate, 0.5 to 2.5 parts of zinc dialkyl dithiophosphate, 0.5 to 2.5 parts of organic molybdenum salt, 0.02 to 1.5 parts of composite antioxidant and 0.05 to 1.5 parts of corrosion inhibitor, wherein the composite antioxidant comprises an amine antioxidant and a phenolic antioxidant. The lubricating grease prepared from the synthetic oil, the higher fatty acid, the binary acid, the lithium hydroxide monohydrate, the organic molybdenum salt, the composite antioxidant, the zinc dialkyl dithiophosphate and the corrosion inhibitor thiadiazole derivate through specific proportion can generate the synergistic effect; and the prepared lubricating grease has excellent high-temperature and low-temperature lubricating property, oxidation resistance and anti-wear extreme pressure property.

Owner:东莞太平洋博高润滑油有限公司

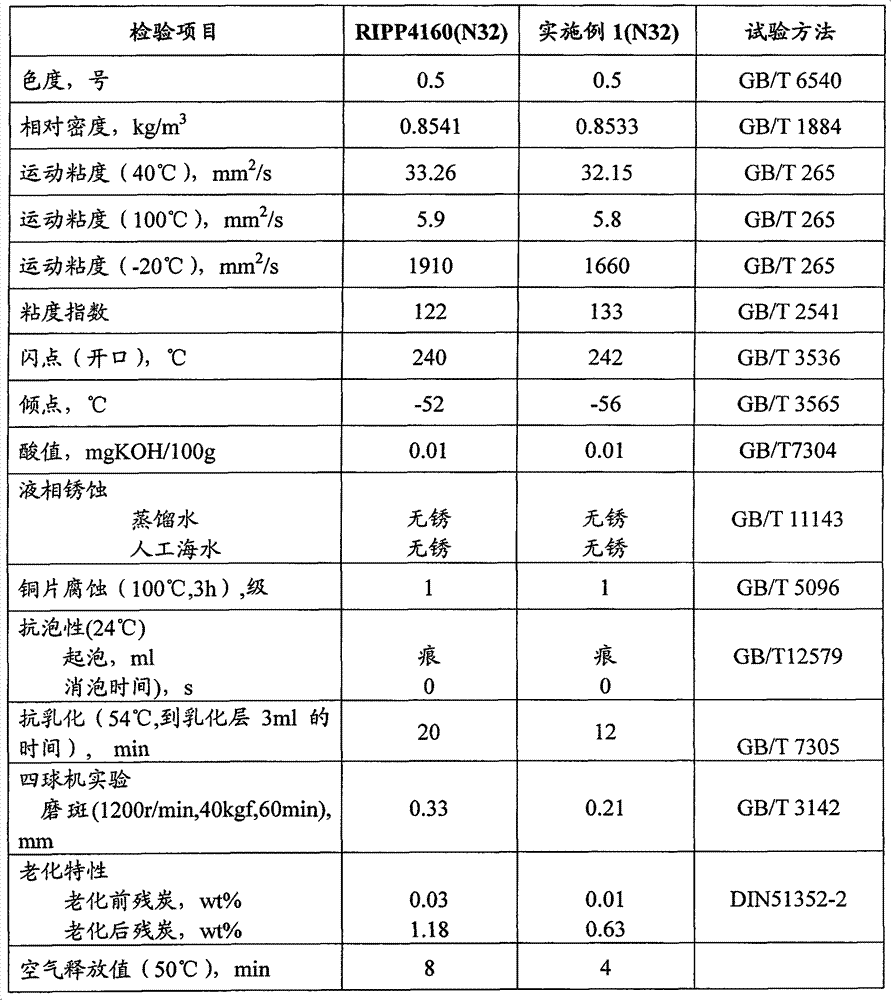

Lubricating oil composition for diesel engines

InactiveCN107353975AImprove high temperature performanceReduce frictionLubricant compositionLubricationChemical composition

The invention relates to a lubricating oil composition for diesel engines, belonging to the technical field of addition of lubricating oil. The invention aims to provide a long-oil-change-period low-emission lubricating oil composition for diesel engines. In order to solve the technical problem, the technical scheme is as follows: the lubricating oil composition for diesel engines comprises the following components in percentage by weight: 0.4-2.5% of hindered phenol antioxidant, 0.9-2.0% of amine antioxidant, 0.8-3.0% of antioxygen anti-friction multifunctional additive, 0.2-1.5% of metal anti-friction agent, 4.0-15.0% of complexing agent and the balance of base oil. The lubricating oil composition for diesel engines has the advantages of long oil change period, low volatility and excellent stability, and can be widely used in the field of diesel engine lubrication.

Owner:山西潞安太行润滑科技股份有限公司

Energy-saving environment-friendly gasoline engine lubricating oil

InactiveCN105695065APromote degradationExtended service lifeLubricant compositionGasolineViscosity index

The invention relates to an energy-saving environment-friendly gasoline engine lubricating oil which comprises base oil and additives. The base oil is completely-synthetic poly-alpha-olefin base oil. The additives are composed of the following components in percentage by mass: 75-87% of base oil, 3-6% of viscosity index improver, 5-9% of composite detergent, 3-6% of composite dispersing agent, 1.5-3% of composite antioxidation and anticorrosion additive, 0.06-0.1% of metal passivator, 0.05-0.3% of rust inhibitor and 0.02-0.05% of antifoaming agent. The lubricating oil is composed of the completely-synthetic poly-alpha-olefin base oil, composite antioxidation and anticorrosion additive, composite metal detergent, composite ashless dispersant, metal passivator, rust inhibitor, antifoaming agent and viscosity index improver. The lubricating oil implements energy saving and long oil change period, reduces the discharge of waste oil, waste gas and particles, has higher biodegradability than the traditional lubricating oil, prolongs the fuel economy and service life of the engine, and inhibits the oil sludge and carbon deposit in the engine from generation.

Owner:HEBEI XINDA LUBRICATING OIL TECH CO LTD

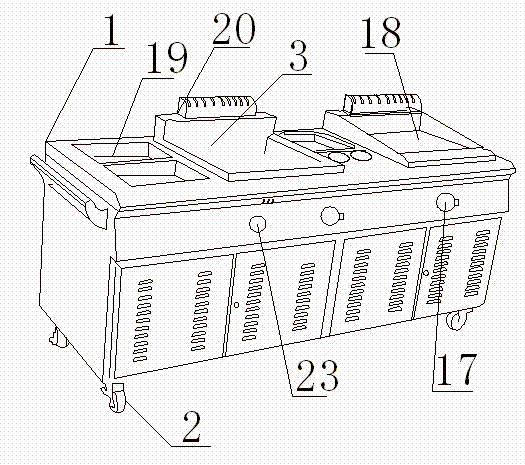

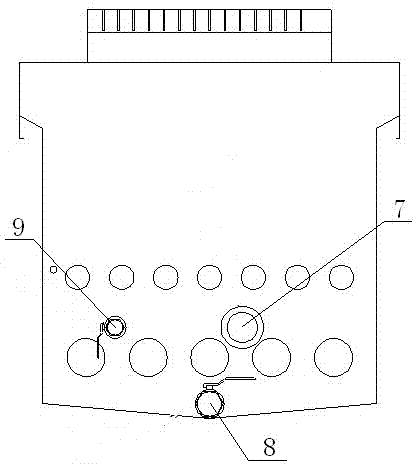

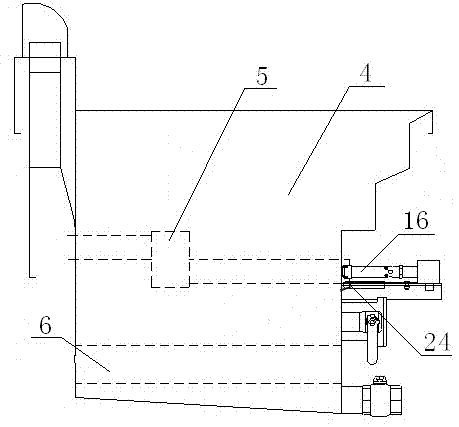

Multifunctional gas firing snack vehicle

The invention relates to commercial kitchen equipment, in particular to a multifunctional gas firing snack vehicle, which comprises a vehicle body, castors and a frying furnace, wherein the castors are arranged at the bottom of the vehicle body, and the frying furnace is arranged at the upper part of the vehicle body. The multifunctional gas firing snack vehicle is characterized in that the bottom of an inner liner of the frying furnace is a triangular pyramid body, a heated bag and a heat radiation pipe are welded inside the frying furnace, the front surface of the frying furnace is respectively provided with a liquid observation mirror, a water discharge valve and an oil discharge valve, the inner liner is divided into two parts by the horizontal middle line of the liquid observation mirror, the upper part is oil, the lower part is water, and the heated bag is respectively connected with a fire guiding pipe group and a smoke discharge pipe group. The multifunctional gas firing snack vehicle has the beneficial effects that the taste of the fried food is pure and fresh and is beneficial to the health of customers, the oil replacing period is prolonged, more oil can be saved, the combustion is more sufficient, the heating is more uniform, and the heat efficiency is higher.

Owner:山东汇泉厨业有限公司

Direct rapid kinetic oil having self-repairing function

InactiveCN101082011AWith self-healing functionReduce coefficient of frictionAdditivesBase oilPour point

The present invention is one kind of fast kinetic energy oil possessing self repairing function. The fast kinetic energy oil consists of base oil and additives, which includes catalyst, mineral matter, metallic detergent, antiwear agent, dispersant, antioxidant, pour point depressant and defoaming agent. The fast kinetic energy oil possesses self repairing function, energy saving effect, environment friendship and long oil replacing period.

Owner:孙国中 +1

Lubricant additive containing Ni-P powder recycled from electroless plating waste liquid, preparation and application thereof

InactiveCN101747985AExtend oil change intervalsIncrease pressureAdditivesElectroless nickelLiquid waste

The invention discloses a Ni-P alloy nano-powder lubricant additive prepared from nickel and phosphorus recycled from electroless nickel plating waste liquid, and a using method thereof in different friction occasions, wherein Ni-P powder is subjected to in-situ dispersion and recovered from electroless nickel plating waste liquid, dispersed again and then prepared into the lubricant additive through certain steps, together with metal chemical friction modifiers, detergent-dispersant, oxygen corrosion-resistant agents, auxiliary performance regulator, stabilizer and base oil. The lubricant additive has the advantages of good suspension stability, capability of greatly reducing equipment friction and wear, greatly reducing the frequency of equipment maintenance and parts replacement and prolonging equipment lifespan and overhaul time limit, as well as good effect of saving energy and protecting environment. The lubricant additive can be widely used in gasoline / diesel internal combustion engines, general fluid machinery, mechanical chemical sealing pieces, transmission gearboxes and other occasions, can realize the recycling of nickel and phosphorus in the electroless nickel plating waste liquid with high added value in order to change pollutants into useful things, and realizes the coordination and unification of economic, environmental and social benefits.

Owner:NANJING UNIV OF TECH

Engine lubricating oil change period prediction method

ActiveCN111091244AHigh precisionSimple formulaForecastingResourcesThermodynamicsMultiple linear regression analysis

The invention discloses an engine lubricating oil change period prediction method, which comprises the following steps of: selecting an initial oxidation temperature as a lubricating oil quality reference index, i.e., when the initial oxidation temperature of lubricating oil reaches a certain threshold value, replacing, and selecting running mileage and running time as visual reference indexes ofengine oil change; establishing a multiple linear regression model of the lubricating oil quality by taking the initial oxidation temperature as a dependent variable and taking the running mileage andthe running time of the motor vehicle as independent variables; and calculating the oil change period according to the multiple linear regression model, i.e., the maximum mileage that the motor vehicle can run or the longest running time within the given running mileage within the given time. According to a test data sample obtained by testing, the relation model between the initial oxidation temperature of the lubricating oil and the running mileage and running time of the vehicle is established by adopting a multiple linear regression analysis method, accurate calculation can be performed through the engine oil change period prediction model, a reasonable oil change period is provided, and resources are saved.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Preparation process of lubricating oil with high wear-resistant extreme pressure and wear-resistant antifriction property

The invention relates to a preparation process of lubricating oil with high wear-resistant extreme pressure and wear-resistant antifriction property. The preparation process comprises the following steps: mixing 35%-45% of hydroisomerization dewax type-III base oil with 35%-45% of poly-alpha olefin PAO, stirring at a uniform speed, heating the mixture to 48-58 DEG C within 10 minutes, and thermally insulating for 20 minutes, so as to obtain base oil; preparing a tungsten disulfide particle additive, adding the tungsten disulfide particle additive into the base oil, and stirring at a uniform speed for 15 minutes, wherein tungsten disulfide particles account for 1.5%-2.5% of the total components; preparing a nitrogen-containing boric acid ester additive, and stirring at a uniform speed for 15 minutes; adding a viscosity index improver, thermally insulating, stirring until the kinematic viscosity and the pour point meet standards, and continuing to thermally insulate; adding 2%-3% of a clean dispersing agent; adding 1.5%-2% of an oxidation and corrosion inhibitor; adding 0.3%-0.7% of a pour point depressant; adding 0.01% of an antifoaming agent; and continuing to stir at a uniform speed, heating to 62-66 DEG C within 10 minutes, and thermally insulate for 30 minutes, so as to obtain a finished product.

Owner:昆山中润信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com